Page 1

Made in Switzerland

Operating Instructions

Concrete Durability Testing

family

Page 2

2

© 2017 Proceq SA

Contents

1 Safety and Liability .......................................... 3

2 Getting started ............................................. 3

2.1 Resipod Basics ............................................ 3

2.2 The Resipod Measurement Principle ............................ 4

2.3 The Resipod Display ........................................ 5

3 Measuring Resistivity with Resipod ............................. 7

3.1 Making a Measurement ...................................... 7

3.2 Memory Function ........................................... 8

4 Resistivity Measurements on Site ............................. 10

4.1 Influences ................................................ 10

4.2 Applications .............................................. 11

5 Quality Control Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Resipod Bulk Resistivity ..................................... 13

5.2 Resipod Geometric ........................................ 16

6 Units, Parts and Accessories ................................. 17

7 Technical Specifications ..................................... 17

8 Maintenance and Support ................................... 18

9 ResipodLink Software ...................................... 20

Page 3

3

© 2017 Proceq SA

1 Safety and Liability

Safety and Usage Precautions

This manual contains important information on the safety, use and maintenance of the Resipod.

Read through the manual carefully before the first use of the instrument. Keep the manual in a safe

place for future reference.

Liability

Our “General Terms and Conditions of Sale and Delivery” apply in all cases. Warranty and liability

claims arising from personal injury and damage to property cannot be upheld if they are due to one

or more of the following causes:

- Failure to use the instrument in accordance with its designated use as described in this

manual.

- Incorrect performance check for operation and maintenance of the instrument and its

components.

- Failure to adhere to the sections of the manual dealing with the performance check,

operation and maintenance of the instrument and its components.

- Unauthorized structural modifications to the instrument and its components.

- Serious damage resulting from the effects of foreign bodies, accidents, vandalism and force

majeure.

All information contained in this documentation is presented in good faith and believed to be

correct. Proceq SA makes no warranties and excludes all liability as to the completeness and/or

accuracy of the information.

Safety Instructions

The instrument is not allowed to be operated by children or anyone under the influence of alcohol,

drugs or pharmaceutical preparations. Anyone who is not familiar with this manual must be

supervised when using the instrument.

2 Getting started

Note: When shipped, battery packs are not fully charged. Prior to use, please

charge the battery completely. To prevent the battery from damage, avoid deepdischarging or storing it long-term when empty. Store the instrument at room temperature and charge the battery fully at least once a year.

2.1 Resipod Basics

Charging the Resipod

The battery status symbol will be displayed when the accumulator is at 10% of its capacity. In this

case it is still possible to make a large number of measurements, but it is advisable to recharge

the battery by connecting the unit to a wall adaptor or a PC via the USB port. A complete charging

cycle will last approximately 6 hours. Autonomy is > 50 hours.

Operation - Power ON / OFF

Press the “Hold” button on the side of the Resipod to power on.

Press and hold the button for >2 s to shut the unit off (auto shutdown after 10 min. of stand-by)

Page 4

4

© 2017 Proceq SA

Functional Check

Perform a functional check as described in chapter 8.

Performing a reset

A small reset button is located beneath the watertight cover for

the USB port. If the instrument has locked up or does not respond,

pressing this button with a paper clip will perform a reset.

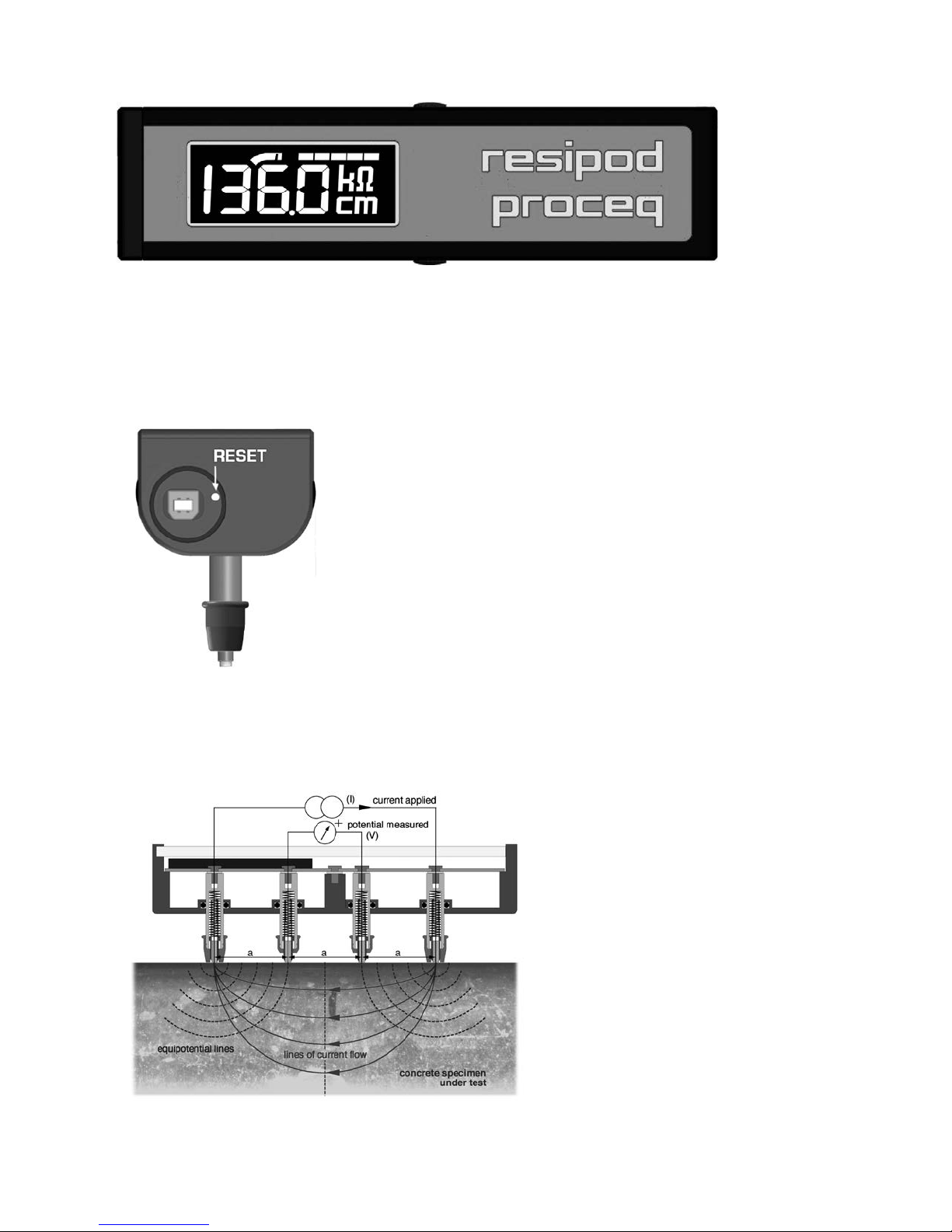

2.2 The Resipod Measurement Principle

The Resipod is an evolution of the industry standard CNS Farnell RM MKII resistivity meter,

operating on the principle of the Wenner probe.

The Resipod is designed to

measure the electrical resistivity of

concrete. A current is applied to the

two outer probes and the potential

difference is measured between

the two inner probes. The current

is carried by ions in the pore liquid.

The calculated resistivity depends

on the spacing of the probes.

Resistivity ρ= 2πaV/l [kΩcm]

Hold

Save

Page 5

5

© 2017 Proceq SA

Resipod models

Two versions of Resipod are available:

- The 50 mm probe spacing model

conforms to the accepted industry

standard.

- The 38 mm (1.5”) probe spacing model

conforms to the specification of the

AASHTO T 358 surface resistivity test

method.

Due to the inhomogeneous nature of concrete, a wider probe spacing is preferred as it allows a

more homogeneous flow of the measuring current. However, this usually has to be offset against

the need to avoid the influence of reinforcing steel (see chapter 3). 50 mm spacing is typically

considered a good compromise.

Both units operate with a digitally generated 40 Hz alternating current at 38 V max.

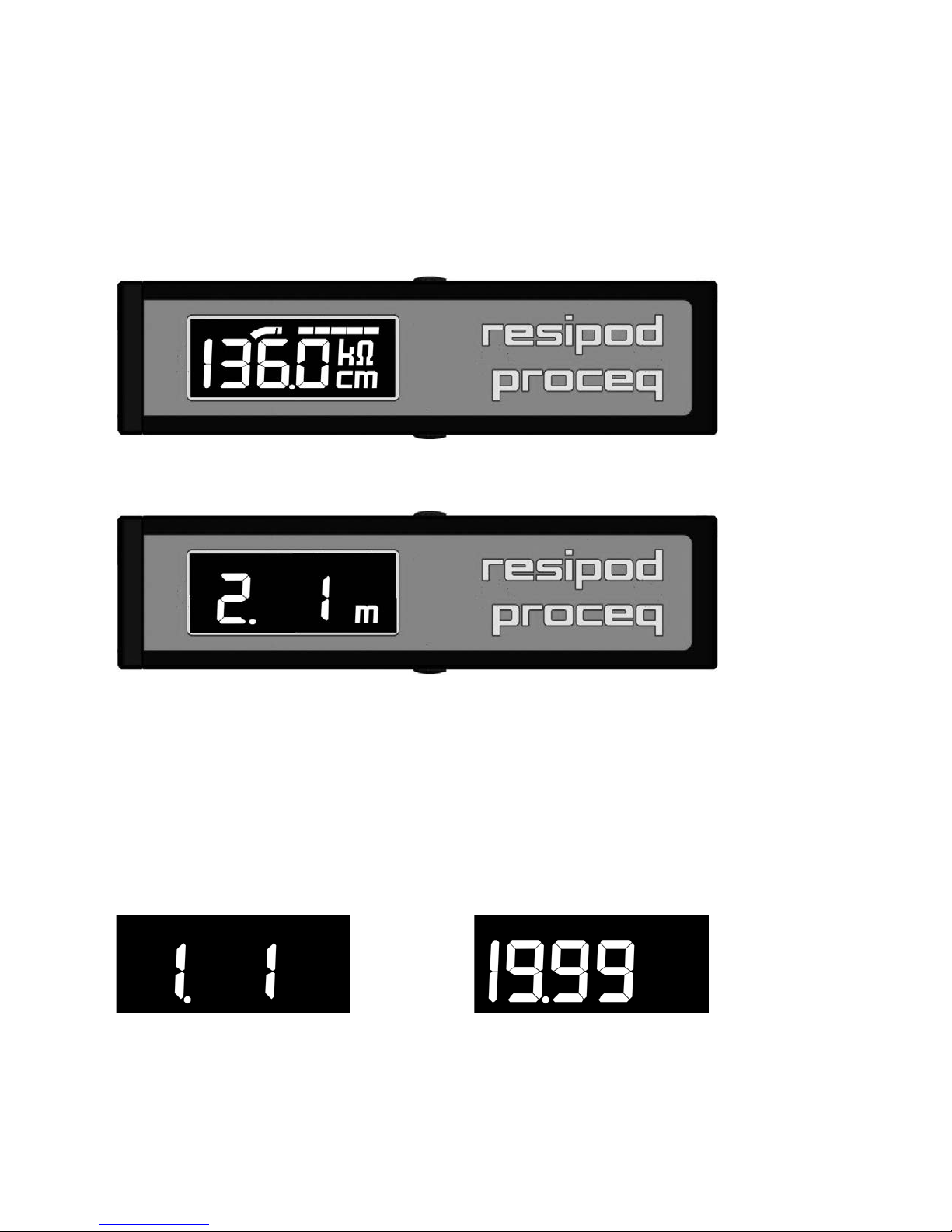

2.3 The Resipod Display

1. Measured resistivity

2. Battery status

3. Range indication

4. Current indication

20%, 40%, 60%, 80%, 100%

5. Indication of scaled reading

Measured resistivity

Display resolution depends on the measured resistivity and the nominal current flowing. See

technical data.

Battery status

The battery status symbol will be displayed when the accumulator is at 10% of its capacity.

Otherwise it is blanked out.

Page 6

6

© 2017 Proceq SA

Range indication

Resipod has two current ranges.

Range indicator to the right: 200 µA range

Provided the external resistance (contact resistance of the

two outer probes plus resistance of the specimen) is not too

high, Resipod will drive the maximum current (200 µA) through

the specimen.

Range indicator to the left: 10 - 50 µA range

When the external resistance is too high, Resipod

automatically switches to supply 50 µA.

For even higher resistances, the unit applies the maximum voltage across the outer electrodes

and senses the resulting current through the specimen. In this case, the displayed resistivity is a

calculated value (voltage across inner probes divided by current sensed in outer probes), and the

reading is rounded to the nearest kΩcm. This mode works down to a current of 10µA (1 segment

lit). Below this range “OL” is indicated. (See “Indication of poor connection” below).

Current indication

All five segments lit indicate that the full 200 µA or 50 µA are

being driven into the test object. When this is not possible,

(see above), The display indicates this current to the nearest

multiple of 10 µA.

Indication of scaled reading

The ResipodLink software allows the user to introduce a correction to the displayed reading. This

is typically used together with a non-standard probe spacing, in which case the probe spacing

value used to calculate the resistivity must be changed. It may also be used to introduce a correction based on a form factor if desired.

Whenever the apostrophe to the right of the kΩ symbol is lit,

it indicates that a correction factor has been applied.

Page 7

7

© 2017 Proceq SA

3 Measuring Resistivity with Resipod

Preparing the concrete surface

The concrete surface must not be coated with any electrically insulating coating, and it should be

clean. The rebar grid beneath the surface should be marked out with the help of a rebar locator

(e.g. Profoscope). If the concrete is completely dry it will not be possible to make a measurement

as the current is carried by ions in the pore liquid, (See 2.2). Therefore it may be necessary to wet

the surface.

3.1 Making a Measurement

A good connection between the

instrument and the concrete surface is

the most important factor for obtaining a

reliable measurement. Dip the contacts

in water several times before making a

measurement – use a shallow container

so you can press against its bottom

– this will fill the reservoirs. Press the

Resipod firmly down until the outer two

rubber caps rest on the surface to be

tested.

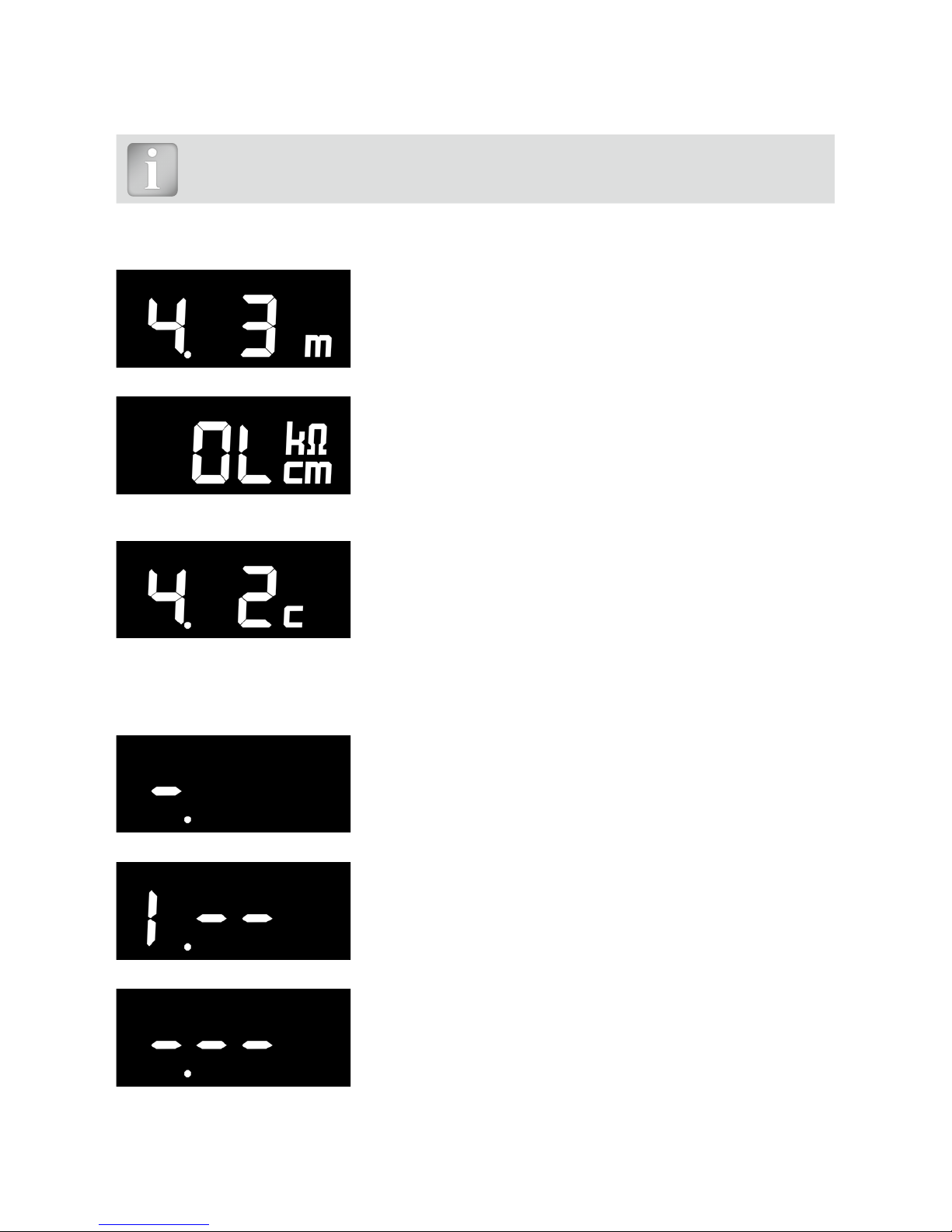

Indication of poor connection

In the case of a poor connection, the Resipod will display one of the following alerts.

“Open Line” indication

Bad connection of the two outer probes to the concrete

surface. No measurement possible.

Inner two probes are not making contact.

(check for holes or dry spots on the specimen)

Or Sample resistivity <1kΩcm

Material resistivity is extremely low.

Overflow

The measured resistivity is out of range. This limit is

dependent on the spacing, but it is typically a resistivity of

>1000 kΩcm.

Contact selection

The steel probe tips are rugged and may be used to scratch away a thin layer of plaque on the

surface in order to make a better connection. The size of the contact however, means it is not

always possible to drive the full 200µA into the concrete to obtain the maximum measurement

resolution.

Page 8

8

© 2017 Proceq SA

In order to enable this, the Resipod is also supplied with large surface area foam contact pads.

Simply snap out the steel contacts and replace with the foam pads. They should likewise be moistened before measurements.

Hold and Save function

Once a stable reading has been achieved, click the hold button on the side of the Resipod to freeze

the actual measurement on the screen.

Hold

• The display flashes to indicate the “hold” status.

• Click the hold button again to return to “live” mode or:

Save

• Click the save button to record the measurement. An “m” appears to indicate that a new

reading has been stored in this memory location. (In the example, the reading is the first reading

stored in memory object 2.)

3.2 Memory function

The Resipod can store up to 512 measurements. The memory is arranged so that the readings are

stored in objects from 1 to 19. Each object can contain up to 99 readings.

Object 1 - Reading 1 Object 19 – Reading 99

You may check the last entry “Object – Reading” number simply by pressing the “Save” button

when the instrument is not in hold modus.

Page 9

9

© 2017 Proceq SA

Moving to the next Object

To move to the next object simply switch the Resipod off and then on again.

Note: The Resipod will always move to the next object when you switch it on and off.

If you wish to carry on measuring in the previous object, simply delete the current

reading as described below and you will be returned to the previous object.

Deleting a reading

The last reading has been stored in Object 4 – Reading 3.

To delete this reading, press the hold button to set the display

blinking.

(If the Resipod is held in the air for this the “open line” screen

will be displayed and will blink.)

Press the “Save” button for 2 seconds to delete the reading.

Object 4 – Reading 3 has been deleted. The display shows a

small “c” to indicate the last reading has been cancelled. Subsequent readings can be cancelled this way, but only sequentially.

It is not possible to scroll back and delete an earlier reading.

Memory status indications

A number of special screens provide information about the status of the memory.

Object number is >19.

All 19 objects have been used. It is necessary to delete readings

before using the memory further (see above).

Reading number is >99

The current object is full. Move to the next object to store further

readings (see above).

Memory is empty.

Page 10

10

© 2017 Proceq SA

4 Resistivity Measurements on Site

4.1 Influences

Influence of rebars on electrical resistivity measurements

The presence of rebars disturbs electrical resistivity measurements as they conduct current much

better than the surrounding concrete. This is particularly the case when the cover depth is less than

30 mm.

As far as possible, reinforcement bars should not be directly beneath the probe and should not

run parallel to the probe. The recommended measurement orientation is determined by the spacing of the

rebars compared with the probe spacing.

The optimum orientation is to measure diagonally to the

rebars as shown. This is possible if the probe span is

less than the rebar grid spacing.

For the Resipod 38 mm, the probe span is

38x3 = 114 mm (4.5”)

For the Resipod 50 mm, the probe span is

50x3 = 150 mm (5.9”)

If the rebar spacing is so close that it cannot be

avoided, the influence of the steel can be minimized by

measuring perpendicular to the rebars as shown.

RILEM TC154-EMC: ELECTROCHEMICAL TECHNIQUES FOR MEASURING METALLIC CORROSION

recommends making 5 readings from the same location

moving the probe a few mm between each measurement and taking a median from the 5 values.

Influence of aggregate size

As explained in 2.2, the current flows in the pore liquid of concrete. Ideally the probe spacing

should be larger than the maximum aggregate size as aggregate material is typically non-conducting. The variable spacing probe supplied with Resipod Geometric should be used for aggregate

sizes larger than the standard probe spacing.

Influence of temperature

The temperature of the concrete should be measured and recorded with resistivity measurements.

Resistivity decreases as the temperature increases. Reference values for resistivity measurements

are typically quoted for 20°C (68°F). Empirical studies have shown that a one degree increase in

temperature can reduce the resistivity by 3% for saturated concrete and 5% for dry concrete.

Influence of moisture content

A higher moisture content lowers the resistivity. This can be due to saturation or due to a change

in the water/cement ratio.

Page 11

11

© 2017 Proceq SA

Influence of carbonation

Carbonated concrete has a higher resistivity than concrete without carbonation, however provided the depth of the carbonated layer is significantly smaller than the probe spacing, the effect

of this layer is small. Consequently if the carbonated layer is thick, it may be necessary to increase

the probe spacing to obtain good results.

4.2 Applications

Empirical tests and theory have shown that resistivity is directly linked to both the likelihood of

corrosion due to chloride diffusion and to the corrosion rate once depassivation of the steel has

taken place.

Estimation of the likelihood of corrosion

Resistivity measurements can be used to estimate the likelihood of corrosion. When the electrical

resistivity (ρ) of the concrete is low, the likelihood of corrosion increases. When the electrical resistivity is high (e.g. in case of dry and carbonated concrete), the likelihood of corrosion decreases.

Empirical tests have arrived at the following typical values for the measured resistivity which can

be used to determine the likelihood of corrosion. These figures are for Ordinary Portland Cement

at 20°C.

When ≥ 100 kΩcm Negligible risk of corrosion

When = 50 to 100 kΩcm Low risk of corrosion

When = 10 to 50 kΩcm Moderate risk of corrosion

When ≤ 10 kΩcm High risk of corrosion

Indication of corrosion rate

The following interpretation of resistivity measurements from the Wenner four-probe system has

been cited when referring to depassivated steel (Langford and Broomfield, 1987).

> 20 kΩ cm Low corrosion rate

10-20 kΩ cm Low to moderate corrosion rate

5-10 kΩ cm High corrosion rate

< 5 kΩ cm Very high corrosion rate

Empirical reference values

A large body of empirical resistivity data has been collected by many studies over a number of

years. The data presented here is taken from “Test methods for on-site measurement of resistivity of concrete – a RILEM TC-154 technical recommendation” by Rob B. Polder. The values have

been converted to kΩcm to match the display of the Resipod. More details on the interpretation

of results may be found in that document.

Page 12

12

© 2017 Proceq SA

Global reference values at 20°C for the electrical resistivity of concrete of mature

structures (age > 10 years).

Environment Concrete resistivity ρ kΩcm

Ordinary Portland Cement

(CEM I)

Blast furnace slag cement

(>65% slag) or fly ash (>25%)

or silica fume (5%)

Very wet, submerged, splash

zone, fog room

5-20 30-100

Outside, exposed 10-40 50-200

Outside, sheltered, coated,

hydrophobised (not carbonated) (20°C / 80% RH)

20-50 100-400

Outside sheltered as above

(Carbonated)

100 and higher 200-600 and higher

Indoor climate (carbonated)

20°C / 50%RH

300 and higher 400-1000 and higher

Resistivity mapping

Mapping out the resistivity of a structure enables useful interpretations to be made by comparing

the values against those in the above table. Please note that the temperature correction described

earlier should be taken into consideration. If exposure conditions are the same, varying resistivity

values may indicate local variations of the water/cement ratio. If it is known that the concrete is

homogenous throughout the structure, then the resistivity measurements can be used to determine

how relatively wet and dry the various areas are.

Correlation to permeability

Studies have shown that resistivity can be directly correlated to chloride diffusion rate. On site

mapping of the resistivity of a concrete structure will identify the most permeable areas. Such

areas are more likely to be susceptible to chloride penetration. The Resipod model with 38 mm

spacing conforms to the AASHTO T 358 Surface Resistivity Test Method which uses surface

resistivity as an indication of the permeability of concrete. Details of the test can be found on the

official AASHTO website http://tig.transportation.org/Pages/SurfaceResistivityTest.aspx.

On site assessment of curing efficiency

Resistivity measurements may be used on site to determine premature drying of concrete. This

is a particularly important application in hot countries where premature drying out can lead to

structural weakening due to non-completion of the hydration reaction. The method uses the strong

dependence of resistivity on the humidity of the concrete. Site measurements are compared with

measurements made on a saturated reference cylinder to define a relative resistivity which can be

used to isolate the effects of humidity and thereby determine premature drying. Please refer to

“Electrical resistivity as a tool to on site assessment of curing efficiency – by L. Fernandez Luco,

C. Andrade and M.A. Climent (June 2009)”.

Resistivity measurements and cathodic protection systems

The effectiveness of a cathodic protection system depends very much on the resistivity of the

concrete. Mapping out the resistivity prior to installation allows the structure to be divided into

separate zones requiring different levels of current flow.

Page 13

13

© 2017 Proceq SA

5 Quality Control Applications

The Resipod model with 38 mm spacing conforms to the AASHTO T 358 Surface Resistivity Test Method which uses surface resistivity as an indication of the permeability of concrete. Details of the test can be found on the official AASHTO website:

http://tig.transportation.org/Pages/SurfaceResistivityTest.aspx

The Resipod family is completed by two further instruments differentiated by application as can

be seen in the table:

Application

Resipod

Resipod

Geometric

Resipod Bulk

Resistivity

Surface resistivity test on standard cylinders (4” x 8”, 100 x

200mm) or (6” x 12”, 150 x 300mm) with a maximum aggregate size (1.5”, 38mm). Fixed probe spacing (1.5”, 38mm)

Bulk resistivity test on cylinders up to 100mm (4”) diameter

Surface resistivity test on non-standard cylinders with aggregate sizes that may exceed > 1.5”, 38mm

Correction factor for probe spacing

Correction factor for sample geometry

User definable correction factor

Variable probe spacing

Surface resistivity mapping on site for: estimation of likelihood of corrosion, corrosion rate and implementation of

cathodic protection systems

5.1 Resipod Bulk Resistivity

The accessory comprises of a stand that allows the instrument to be conveniently mounted, cables

that are easily inserted into the rear connectors and the measurement plates with conductive foam

inserts suitable for 4”x8” cylinders.

The stand accommodates both Resipod versions (38 mm and 50 mm).

Page 14

14

© 2017 Proceq SA

38 mm Resipod in stand 50 mm Resipod in stand

Cable Connection

The cables are simply attached as shown here.

Measuring the offset

The foam inserts provide the electrical contact to the cylinder, but they also have a resistance

which must be measured and compensated for to determine the true bulk resistivity of the cylinder

under test.

The resistance of the foam inserts varies with the pressure applied.

The resistances of the top and bottom inserts can be measured as follows:

Test set-up to measure the resistance of the upper foam insert (R

upper

):

Upper plate

Upper foam insert

Lower plate

Page 15

15

© 2017 Proceq SA

Test set-up to measure the resistance of the lower foam insert (R

lower

):

Cylinder under test

Upper plate

Lower foam insert

Lower plate

Test set-up to measure the bulk resistivity of the cylinder (R

measured

):

Upper plate

Upper foam insert

Cylinder under test

Lower foam insert

Lower plate

The measured resistance is the sum of the resistance of the cylinder plus the two inserts, therefore:

R

cylinder

= R

measured

– R

upper

- R

lower

Page 16

16

© 2017 Proceq SA

Calculation of the Bulk Resistivity

Resipod displays a number in kΩcm. The number obtained from the Resipod display should be

divided by 2πa (where “a” is the probe spacing, i.e. either 3.8 cm or 5.0 cm). For a Resipod with

38mm probe spacing:

Cylinder size 2πa A (cm2) L (cm) A/L (cm)

4x8 23.88 81.07 20.32 3.99

The bulk resistivity ρ = K

x R

cylinder

, where K = A/L

Example

R

cylinder

= 52 kΩcm

R

cylinder

(corrected) = 52 / 23.88 = 2.18 kΩ

Bulk resistivity ρ = K x R

cylinder

= 2.18 x 3.99 = 8.69 kΩcm

Bulk Resistivity in ResipodLink

ResipodLink offers the possibility to calculate K automatically and download it onto the Resipod

instrument, so that the display shows directly the correct value in kΩcm. See Chapter 9.

5.2 Resipod Geometric

Resipod Geometric is supplied with a stand for mounting the Resipod and a variable spacing

probe that allows probe spacing to be varied between 40mm and 70mm. This allows it to accommodate larger aggregate sizes.

The ResipodLink software (Chapter 9) allows the user to enter the correct probe spacing and also

a geometric correction factor to give the correct resistivity reading directly on the instrument.

The geometric correction factor for cylinders is designed to comply with the latest research intended to extend the current AASHTO surface resistivity method to other sample geometries.

In addition to this the user also has the possibility to enter a self-determined correction factor.

Page 17

17

© 2017 Proceq SA

6 Units, Parts and Accessories

Part No. Description

381 10 000 Resipod, 50mm probe spacing, test strip, foam contact pads, charger with USB-

cable, software, carrying strap, documentation and case.

381 20 000 Resipod, 38mm (1.5”) probe spacing, test strip, foam contact pads, charger with

USB-cable, software, carrying strap, documentation and case.

381 30 000 Resipod Bulk Resistivity, 50mm probe spacing, test strip, foam contact pads,

charger with USB-cable, software, carrying strap, documentation and case,

Bulk Resistivity Accessory.

381 40 000 Resipod Bulk Resistivity, 38mm (1.5”) probe spacing, test strip, foam contact

pads, charger with USB-cable, software, carrying strap, documentation and

case, Bulk Resistivity Accessory.

381 50 000 Resipod Geometric, 50mm probe spacing, test strip, foam contact pads, char-

ger with USB-cable, software, carrying strap, documentation and case, Resipod

Geometric Accessory.

381 60 000 Resipod Geometric, 38mm probe spacing, test strip, foam contact pads,

charger with USB-cable, software, carrying strap, documentation and case,

Resipod Geometric Accessory.

Parts and Accessories Description

381 01 088 Bulk Resistivity Accessory

381 01 098 Resipod Geometric Accessory

381 01 094 Variable Spacing Probe

381 01 089 Resipod Stand

381 01 043 S Set of replacement foam contact pads (5x4)

381 01 092 S Bulk resistivity contact pads. Set of 10 pieces

381 01 038 Test strip

381 01 031 Inner contact cap (See note below)

381 01 041 Outer contact cap (See note below)

381 01 033 Contact complete (See note below)

381 01 036 Contact spring

381 01 014 USB cover

381 01 070 Key for USB port

391 80 110 Carrying strap

To replace one of the inner contacts requires parts 381 01 031, 381 01 033 and 381 01 036.

To replace one of the outer contacts requires parts 381 01 041, 381 01 033 and 381 01 036.

7 Technical Specifications

Measurement range: 1kΩcm - ca. 1000 kΩcm (dependent on probe spacing)

Resistance measurement accuracy:

Nominal current 200µA ±0.2 kΩcm or ±1% (whichever is greater)

Nominal current 50µA ±0.3 kΩcm or ±2% (whichever is greater)

Nominal current <50µA ±2 kΩcm or ±5% (whichever is greater)

Frequency 40 Hz

Memory Non volatile, ca. 500 measured values

Power Supply >50 hours autonomy

Charger connection USB type B, (5V, 100mA)

Dimensions 197 x 53 x 69.7 mm (7.8 x 2.1 x 2.7 inch)

Weight 318 g (11.2 oz)

Operating temperature 0° to 50°C (32° to 122°F)

Storage temperature -10° to 70°C (14° to 158°F)

Page 18

18

© 2017 Proceq SA

8 Maintenance and Support

Functional Check

Correct functioning of the Resipod can be checked with the test strip provided. The test strip is

intended to be used by both Resipod models (38 mm,1.5” and 50 mm spacing).

The upper row allows the functional check using the full 200 µA range. The lower row allows the

functional check using the reduced 50 µA range. Resistors to the outer pads limit the maximum

current to approx. 20 µA, (only two segments in the current indicator strip are active).

The expected test results are summarized in the table below:

Current range

Expected test result

38 mm (1.5”) spacing

Expected test result

50 mm spacing

200µA (upper row) 12 (±0.2) kΩcm 16 (±0.2) kΩcm

50 µA (lower row) 90 (±1.8) kΩcm 120 (±2.4) kΩcm

Page 19

19

© 2017 Proceq SA

Cleaning of the probes and the body

The probes can be removed for cleaning, replacement or

for fitting test accessories, such as the variable spacing

probe. They’re snap fit, so simply pull them off. Be careful

not to lose the spring.

After cleaning, replace the probes by inserting them into

the shafts and snapping them firmly into place. Ensure the

fit by pressing on the rubber cap as shown in the figure.

Long caps go on outer probes.

Probes need not be kept moist when the unit is not in use.

The unit can be rinsed with water (make sure USB cover is

firmly in place). Since the instrument has an extremely high

input impedance, check that the underside of the case is

clean (dirt or salt deposits might create leakage currents

and yield faulty readings).

Note! The springs are intentionally long to ensure a constant pressure on all four probes, while allowing a ± 4 mm

displacement on the inner tips to accommodate uneven or

curved surfaces.

Support Concept

Proceq is committed to providing a complete support service for this instrument by means of our

global service and support facilities. It is recommended that the user register the product on www.

proceq.com to obtain the latest on available updates and other valuable information.

Standard Warranty and Extended Warranty

The standard warranty covers the electronic portion of the instrument for 24 months and the mechanical portion of the instrument for 6 months. An extended warranty for one, two or three years

for the electronic portion of the instrument may be purchased up to 90 days of date of purchase.

Page 20

20

© 2017 Proceq SA

9 ResipodLink Software

Installing ResipodLink

Locate the file “ResipodLink Setup.exe” on your computer or on the CD and click on

it. Follow the instructions you see on the screen.

Make sure that the “Launch USB Driver install” tick is selected.

Starting ResipodLink and viewing data stored on Resipod

Double click on the ResipodLink icon on your desktop or start the ResipodLink via

the start menu. The Resipodlink starts with a blank list.

Application settings

The menu item “File – Application settings” allows the user to select the language and the date

and time format to be used.

Connect the Resipod to a USB port, then click on this icon to download all data

from the Resipod.

An “Id” number identifies the measurement object.

The “Name” column allows the user to assign a name for the measurement object.

The “Date and time” when the data is downloaded onto the PC.

The “Mean Value”.

The “Total” number of measurements in this series.

The “Standard Deviation” of the measurements in this series.

Page 21

21

© 2017 Proceq SA

Click on the double arrow icon in the “Id” column to see more details:

Note: Click on “Add” to attach a comment to the object.

Summary window

In addition to the “Series” view described above, ResipodLink also provides the user with a

“Summary” window. This is useful for uniformity testing to quickly identify areas or objects of

inferior quality. Click on the respective tab to switch between views.

To include or exclude a series from the summary, click on the summary symbol

in the impact counter column. This symbol is either “black” or “greyed out”,

which shows whether or not the series is included in the summary.

Adjusting the date and time

Right click in the “Date & Time” column.

The time will be adjusted for the selected

series only.

Please note, the Resipod does not have

an internal clock, so the date and time displayed for downloaded data, is the time at

which it was downloaded.

Exporting data

ResipodLink allows you to export selected objects or the entire project for use in third party programs. Click on the measurement object(s) you wish to export.

Page 22

22

© 2017 Proceq SA

Click on the “Export as CSV file(s)” icon. The data for this measurement object(s) is

exported as a Microsoft Office Excel comma separated file or files. The export options may be chosen in the following window.

Click on the “Export as graphic” icon to open the window which allows the various

export options to be chosen.

In both cases, a preview window shows the effects of the current output selection.

Finish by clicking on export to select the file location, name the file and in the case of a graphical

output to set the output graphic format: .png, .bmp or .jpg

Deleting and restoring data

The menu item “Edit – Delete” allows you to delete one or more selected series from the downloaded data.

Note: This does not delete data from the Resipod, only data in the current project.

Restoring original downloaded data

Select the menu item “File – Restore all original data” to restore the data to the original format as

it was downloaded. This is a useful feature if you have been manipulating the data, but wish to go

back to the raw data once again. A warning will be given to say that the original data is about to

be restored. Confirm to restore.

Note: Any names or comments that have been added to series will be lost.

Deleting data stored on the Resipod

Select the menu item “Device – Delete all measurements object on Resipod” to delete all data

stored on the Resipod. A warning will be given to say that all of the data is about to be deleted.

Confirm to delete. It is not possible to delete individual series.

Further Functions

The following menu items are available via the icons at the top of the screen:

“PQUpgrade” icon - Allows you to upgrade your firmware via the internet or from

local files.

Page 23

23

© 2017 Proceq SA

“Open project” icon – Allows you to open a previously saved .pqr project.

“Save project” icon – Allows you to save the current project.

“Print” icon – Allows you to print out the project. You may select in the printer dialog,

if you want to print out all of the data or selected readings only.

Setting a correction factor

See Chapter 2.2. The standard reading on the Resipod display indicates: Resistivityρ= 2πaV/l

[kΩcm], where “a” is the default probe spacing of the instrument, (either 38mm or 50mm).

The menu item “Device – Set measurement settings” allows a correction factor to be downloaded

onto the instrument, so that it gives a direct readout of the resistivity when being used with:

• The Variable Spacing Probe (381 01 094)

• The Bulk Resistivity Accessory (381 01 088)

• A different sample geometry

Note: When working with the AASHTO TP95-11 standard using the 38mm version of the Resipod, no correction is required as this is already considered in the

figures given in the standard.

Note: Whenever a non-standard contact spacing, or a geometric correction factor is set, then all measurements on the Resipod are deleted. Therefore it is important to save any measurements stored on the Resipod before commencing.

Page 24

24

© 2017 Proceq SA

Measurement mode

• Surface measurement for the 4-point Wenner probe measurement.

• Bulk measurement for working with the bulk resistivity accessory.

Contact Spacing

• Default spacing – either 38mm or 50mm depending on Resipod model.

• Custom spacing – with the variable spacing probe accessory this may be anywhere between

40mm and 70mm. It is also possible to set a spacing beyond this range, for use with customized

extension cables.

Geometric Correction Factor

• Flat – Default setting, used for measuring on site and also for use with the AASHTO T 358 standard.

• Cylinder – Set the length and diameter of the cylinder under test.

The surface measurement correction factor (k) is calculated according to the latest research for

surface resistivity of hardened cylinders.

k

2

�

~

=

1.09 - +

0.527 7.34

d/a (d/a)²

d = diameter of the cylinder (mm), a = probe spacing (mm), L = length of the cylinder (mm)

Formula valid for: d/a ≤ 4 and L/a ≥ 5 (e.g. for a 200mm cylinder, the maximum probe spacing

allowed is 40mm)

The bulk measurement correction factor is calculated according to the method described in

chapter 5.1.:

e.g. k = A/L = (π x 52) / 20 = 3.927

• Prism – Used for cubes and prisms. No correction factor is implemented to date for the surface

measurement. The bulk measurement is calculated according to the method described in chapter 5.1.

• Custom Correction Factor – For user defined correction factors, select this option and enter the

correction value directly. If not selected, the value shown here shows the calculated correction

factor (k) based on the options selected above.

Downloading loading the Correction Factor to Resipod

• Complete the action by pressing OK. A warning will be shown to indicate that all measurements

currently saved on the Resipod will be deleted.

Page 25

25

© 2017 Proceq SA

An apostrophe will appear to the right of the kΩ symbol to

indicate that a correction factor has been set.

Applied correction = 2πa/k (“a” in cm).

Display of corrected resistivity values in ResipodLink

The correction settings are recorded with the measurement data and displayed in ResipodLink as

this example of a bulk resistivity measurement shows

Page 26

26

© 2017 Proceq SA

Notes

Page 27

27

© 2017 Proceq SA

Notes

Page 28

Made in Switzerland

Proceq Europe

Ringstrasse 2

CH-8603 Schwerzenbach

Phone +41-43-355 38 00

Fax +41-43-355 38 12

info-europe@proceq.com

Proceq UK Ltd.

Bedford i-lab, Priory Business Park

Stannard Way

Bedford MK44 3RZ

United Kingdom

Phone +44-12-3483-4515

info-uk@proceq.com

Proceq USA, Inc.

117 Corporation Drive

Aliquippa, PA 15001

Phone +1-724-512-0330

Fax +1-724-512-0331

info-usa@proceq.com

Proceq Asia Pte Ltd

12 New Industrial Road

#02-02A Morningstar Centre

Singapore 536202

Phone +65-6382-3966

Fax +65-6382-3307

info-asia@proceq.com

Proceq Rus LLC

Ul. Optikov 4

korp. 2, lit. A, Office 410

197374 St. Petersburg

Russia

Phone/Fax + 7 812 448 35 00

info-russia@proceq.com

Proceq Middle East

P. O. Box 8365, SAIF Zone,

Sharjah, United Arab Emirates

Phone +971-6-557-8505

Fax +971-6-557-8606

info-middleeast@proceq.com

Proceq SAO Ltd.

Rua Paes Leme, 136, cj 610

Pinheiros, São Paulo

Brasil Cep. 05424-010

Phone +55 11 3083 38 89

info-southamerica@proceq.com

Proceq China

Unit B, 19th Floor

Five Continent International Mansion, No. 807

Zhao Jia Bang Road

Shanghai 200032

Phone +86 21-63177479

Fax +86 21 63175015

info-china@proceq.com

www.proceq.com

Subject to change without notice.

Copyright © 2017 by Proceq SA, Schwerzenbach

Part number: 82038104E

Loading...

Loading...