Page 1

Swiss Solutions since 1954

Design Patent Pending

®

Operating Instructions

Page 2

© 2016 Proceq SA 2

Contents

1. Safety and Liability ..................................................... 3

1.1 General Information ...........................................................3

1.2 Liability ...............................................................................3

1.3 Safety Instructions ............................................................3

1.4 Correct Usage ...................................................................3

2. Technical Specifications .............................................. 4

3. Operation ...................................................................... 6

3.1 Getting Started ..................................................................6

3.2 Main Menu .........................................................................8

3.3 Pundit PL-200 ...................................................................8

3.4 Pundit PL-200PE .............................................................22

3.5 Pundit 250 Array ..............................................................31

4. Explorer Document Handling ..................................... 42

5. Ordering Information ................................................. 43

5.1 Units .................................................................................43

5.2 Transducers .....................................................................44

5.3 Pundit Array Transducer Parts and Accessories ...........44

5.5 Accessories .....................................................................44

6. Maintenance and Support ......................................... 45

6.1 Maintenance ....................................................................45

6.2 Support Concept .............................................................45

6.3 Warranty Information .......................................................45

6.4 Disposal ...........................................................................45

7. PL-Link Software ....................................................... 45

7.1 Starting PL-Link ...............................................................45

7.2 Viewing the Data ............................................................46

7.3 Adjusting the Settings .....................................................48

7.4 Analysis of B-scans .........................................................48

7.5 Exporting Data .................................................................49

7.6 Further Functions ............................................................49

7.7 Conversion Curves ..........................................................50

7.8 E-modulus Calculator .....................................................50

Page 3

3 © 2016 Proceq SA

1. Safety and Liability

1.1 General Information

This manual contains important information on the safety, use and maintenance of the Pundit Touchscreen. Read through the manual carefully

before the first use of the instrument. Keep the manual in a safe place for

future reference.

1.2 Liability

Our “General Terms and Conditions of Sales and Delivery” apply in all

cases. Warranty and liability claims arising from personal injury and damage to property cannot be upheld if they are due to one or more of the

following causes:

• Failure to use the instrument in accordance with its designated use as

described in this manual.

• Incorrect performance check for operation and maintenance of the instrument and its components.

• Failure to adhere to the sections of the manual dealing with the performance check, operation and maintenance of the instrument and its

components.

• Unauthorised modifications to the instrument and its components.

• Serious damage resulting from the effects of foreign bodies, accidents,

vandalism and force majeure.

All information contained in this documentation is presented in good faith

and believed to be correct. Proceq SA makes no warranties and excludes

all liability as to the completeness and/or accuracy of the information.

1.3 Safety Instructions

The equipment is not allowed to be operated by children or anyone under

the influence of alcohol, drugs or pharmaceutical preparations. Anyone

who is not familiar with this manual must be supervised when using the

equipment.

• Carry out the stipulated maintenance properly and at the correct time.

• Following completion of the maintenance tasks, perform a functional

check.

1.4 Correct Usage

• The instrument is only to be used for its designated purpose as describe herein.

• Replace faulty components only with original replacement parts from

Proceq.

• Accessories should only be installed or connected to the instrument

if they are expressly authorized by Proceq. If other accessories are

installed or connected to the instrument then Proceq will accept no

liability and the product guarantee is forfeit.

The following statement applies to the products covered in this manual,

unless otherwise specified herein. The statement for other products will

appear in the accompanying documentation.

Page 4

© 2016 Proceq SA 4

NOTE! This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to Part 15

of the FCC Rules and meets all requirements of the Canadian

Interference-Causing Equipment Standard ICES-003 for digital apparatus. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected

• Consult the dealer or an experienced radio/T.V. technician

for help

This device complies with part 15 of the FCC:

Operation is subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.”

This Class B digital apparatus complies with Canadian ICES-0003.

2. Technical Specifications

Pundit Touchscreen

Display 7” colour display 800x480 pixels

Memory Internal 8 GB flash memory

Regional settings Metric and imperial units and multi-lan-

guage and timezone supported

Power input 12 V +/-25 % / 1.5 A

Battery 3.6 V, 14 Ah

Battery lifetime > 8h (in standard operating mode)

Humidity < 95 % RH, non condensing

Operating temperature -10°C to +50°C

IP classification IP54

Dimensions 250 x 162 x 62 mm

Weight ~ 1.5 kg (incl. battery)

Standards and Directives CE certification

Pollution Degree 2

Installation Category 2

Page 5

5 © 2016 Proceq SA

Power Supply

Model HK-AH-120A500-DH

Input 100-240 V / 1.6 A / 50/60 Hz

Output 12 V DC / 5 A

Max. Altitude 2’500 m above sea level

Humidity < 95%

Operating Temperature 0°C - 40°C

Environment Indoor use only

Pollution Degree 2

Installation Category 2

Pundit PL-200 and PL-200PE

Range 0.1 – 7930 μs

Resolution 0.1 μs (< 793 μs), 1 μs (> 793 μs)

Display 7” colour display 800x480 pixels

Pulse Voltage UPV 100 Vpp – 450 Vpp

Pulse Voltage UPE 100 Vpp - 400 Vpp

Receiver Gain 1x – 10’000x (0 – 80dB) [11 steps]

Receiver Sensitivity 10 μV

Receiver Input Impedance 7 kΩ

Pulse Echo Range 0.1 – 1200 μs

Transducer Frequency 50 kHz

Aperture Size 2x25 cm

2

Bandwidth 20 – 500 kHz

Pundit 250 Array

Receiver

Gain 0 – 80 dB

Analog Bandwidth 15 kHz – 100 kHz

Nominal transducer

frequency

50 kHz shear wave

Range 0 – 1000μs

Resolution 1 μs

Transmitter

Pulse Voltage +/-150 V

Pulse Shape rectangle

Pulse Delay 8 ms – 200 ms

Power Supply

Batteries 6 x NiMH, Size AA, 2300 mAh (can be

replaced by the user)

Battery lifetime > 7 h

Mains 12 V – 15 V

Operating Time min. 7 h

Charging Time approx. 150 min

Page 6

© 2016 Proceq SA 6

Aperture

Number of Channels 8 (with upgrade option to 16)

Transducers per Channel 3

Wave Type shear wave, horizontally polarized

Center Frequency approx. 45 kHz

Transducer Bandwidth 80 % – 100 %

Channel distance 3 cm

Aperture Size 21 cm x 5 cm

Miscellaneous

Weight ~ 3 kg

Operating Temperature -10° – 50°

Humidity < 95 % RH, non condensing

Dimensions 240 x 273 x 153 mm

Laser used for positioning support

Camera 240 x 320 Pixel

3. Operation

The information provided in this manual covers all applications supported

by the Pundit Touchscreen.

3.1 Getting Started

Battery Installation Pundit Touchscreen

To install the Battery into the Pundit Touchscreen Unit, lift the stand as shown. Insert the

battery and fasten in place with the screw.

There are two status LEDs

1

(see page 11) and above them a light

sensor. The upper LED is red while charging and turns to green when it is

fully charged. The other LED is application specific.

NOTE! Only use the power supply provided.

• A complete charge requires approx. 9h (Instrument not operating).

• Charging time is much longer if the instrument is in use.

• An optional quick charger (Part No. 327 01 053) can be used to charge

a spare battery or to charge the battery outside of the instrument. In

this case it takes approx. 4h for a complete charge.

Page 7

7 © 2016 Proceq SA

Energy Saving

Energy saving may be programmed as desired under System/Power settings.

Connecting the Transducers

(G)

Connect the Transducers to the Pundit Touchscreen Unit using the BNC Adapter Cable

and the BNC Cables. Ensure that the screws

are fastened on the BNC adapter cable.

USB Host:

Connect a mouse, keyboard or USB stick.

USB Host

USB Device

Ethernet

Power Supply

USB Device:

Connect to a PC.

Ethernet:

Connection for firmware upgrades.

Power Supply:

Connect the power supply through this connection.

Buttons

Lift the protective visor.

At the upper right of the screen there are three buttons

2

(see page 11).

Power On/Off – Press to power on. Press and hold to power off.

Soft Key – Open a pdf document (e.g. Operating instructions) or

toggle full screen view.

Back Button – returns to previous screen.

Battery Installation Pundit Array Transducer

Remove the battery pack from the Pundit Array Transducer by loosening

the two screws and pulling out the battery pack. On the underside there

is a plate which has to be removed by unscrewing two screws to access

the battery compartment.

NOTE! Insert the six AA NiMH rechargeable batteries into the

battery pack being sure to observe the correct polarity and

replace into the Pundit Array Transducer. Before first use, fully charge the batteries using the charger provided. While the

battery is charging the status LED is green. It will extinguish

when fully charged. A full charge takes about 2.5 hours.

By pressing and holding the fuel gauge button, the actual

charge statues can be seen. Each LED represents 20%

charge, so all 5 LEDs lit indicates a charge of more than 80%.

Page 8

© 2016 Proceq SA 8

Any AA batteries may be used with the instrument, but the fuel gauge is

only accurate when the recommended NiMH batteries are used.

WARNING!

If standard alkaline batteries (non-rechargeable) are used, it is

very important not to connect the charger as this will result in

damage to the instrument.

3.2 Main Menu

On start up the main menu containing 6 icons is displayed.

Measurement:

Application specific measurement screen.

Settings:

For application specific settings.

Explorer:

File manager functionality for reviewing measurements saved on the instrument.

System:

For system settings, e.g. language, display options, power settings.

Information:

For device information and operating instructions.

Exit:

Power Off.

All functions may be accessed directly via the touch screen. Return to the

previous menu by pressing the back button or the return icon (arrow) at

the top left of the touch screen.

3.3 Pundit PL-200

Scroll up and down the screen by dragging your finger up or down the

screen. The current setting is displayed on the right hand side. Tap on an

item to adjust it.

Transducer

Connected transducer

Select the frequency of the transducer to be used. The custom transducer setting allows non-standard transducers up to 500 kHz to be used.

If this option is selected, the transducer frequency must also be entered.

NOTE! When a transducer frequency is selected, the factory

settings are automatically loaded for that transducer, based

on 1.5m cables being used. Generally, the accuracy this provides is sufficient for most applications, so zeroing is not required with this configuration.

Zeroing Transducer

For increased accuracy or when working with different cable lengths, the

Pundit PL-200 should be zeroed.

Enter the expected calibration value as it is

marked on the Calibration Rod.

Page 9

9 © 2016 Proceq SA

Couple the transducers to the Calibration Rod using the ultrasound Couplant

and press firmly together.

Tap on the start icon to carry out the zeroing.

On completion “Zeroing succeeded” will be displayed.

Tap to return to the settings menu.

Tap to return to the zeroing start screen.

Tap to reload the factory calibration values for the

transducer. This setting provides sufficient accuracy for

most measurements, but for exact zeroing, perform the

procedure described above.

Measurement Settings

Measurement Range

Short range (default). For measurements up to approximately 800 μs.

This corresponds to a path length of approximately 3 m for normal concrete. This provides the maximum measurement resolution of 0.1 μs.

For larger objects select the long range. In this case the measurement

resolution is 1 μs.

The measurement screen indicates (--- μs) if a measurement is out of

range.

Pulse Repetition Frequency

Pulse Repetition Frequencies (PRF) of 5 Hz to 40 Hz (measurements per

second) may be selected. High values should be selected only when the

instrument is used on large objects with high receiver amplification settings. In such cases, it helps to increase the update rate on the display.

For general concrete or ceramic materials testing a PRF of between 1030 Hz is normally used.

The transducers supplied with the instrument are not damped and, therefore, on being excited by the transmitter they have a long ring-down time.

The ring-down time may exceed the pulse interval when the PRF is set

to high values, i. e. the previous pulse may still be ringing as the next

pulse arrives. This effect may cause errors when testing short path length

specimens having low internal damping. If this occurs reduce the PRF.

Line Scan

Line Scan provides the capability to measure along a linear grid at equal

spacing. The distance between the transducers may be varied for each

measurement to accommodate irregular shaped objects (see “3.4.2

Measurement Modes” – Line Scan).

Series Length

Set the number of measurements to be made or leave it open ended.

Distance between Measurements

Set the spacing.

Unit

Choose between pulse velocity or transmission time as the unit for the

graphical display of the results.

Page 10

© 2016 Proceq SA 10

Units

Unit

Choose between metric and imperial units.

Amplitude Unit

Choose to display the receive signal amplitude either as a percentage or

in decibels.

Compressive Strength Unit

Choose the unit for compressive strength correlations.

E-modulus Unit

Choose the unit for E-modulus calculations.

E-modulus Density Unit

Choose the unit for entering density for E-modulus calculations.

Trigger

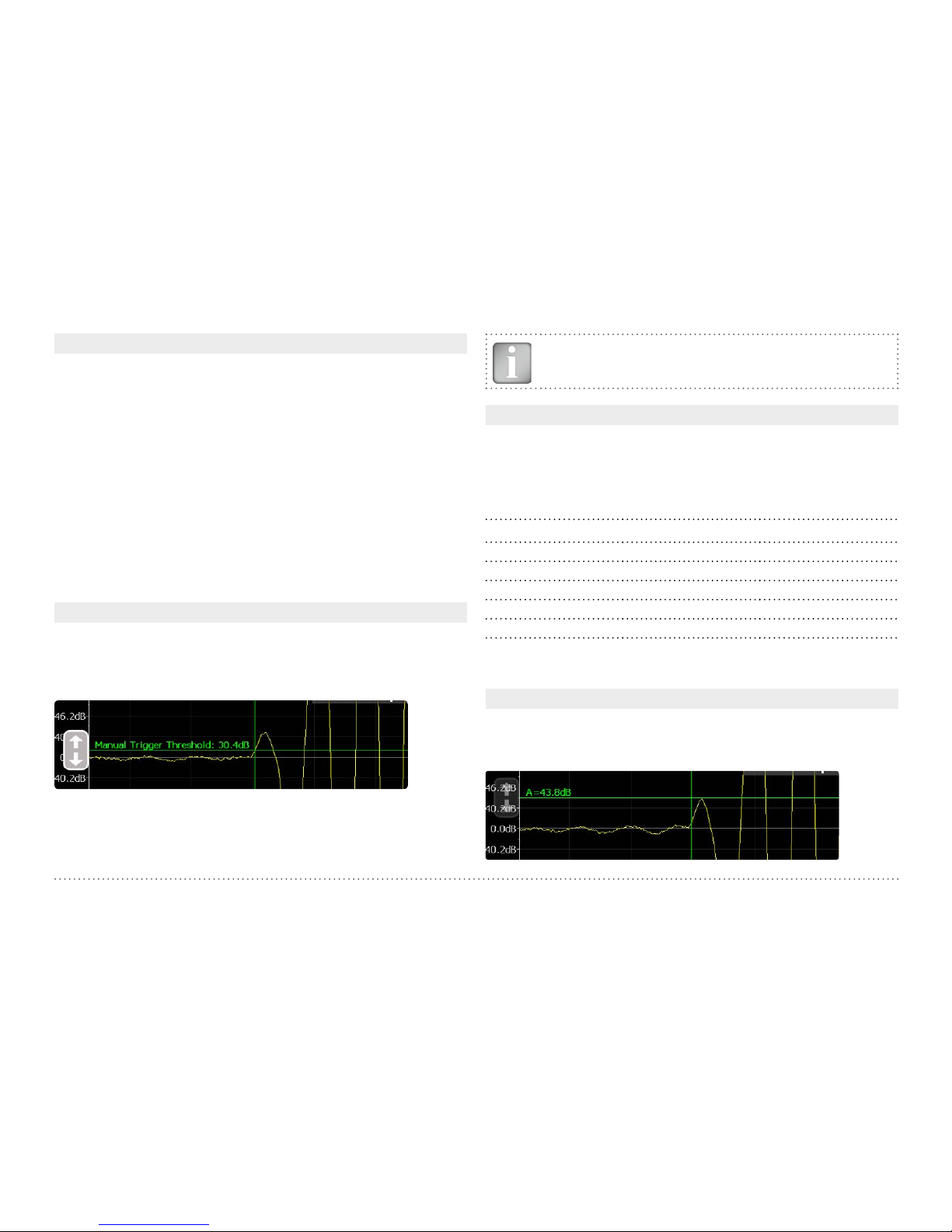

Amplitude Trigger

When selected, allows a user defined amplitude threshold for triggering.

Drag the horizontal cursor to the desired trigger level. The zoom function

is useful to set a specific trigger threshold.

Follow Trigger

When selected, the point at which the trigger occurs is always displayed

in the centre of the screen, irrespective of the measured transmission

time. This does not apply if manual triggering or dual cursor triggering is

being used (see “3.3.1 Measurement Screen”).

NOTE! Both triggering options can be selected at the same

time. If none are selected then the triggering is carried out

automatically as normal.

Corrections

Temperature correction UPV

Pulse velocity measurements are affected by several factors. Two key

factors are the moisture content of the concrete and the temperature.

The table below shows the correction factor that should be entered

based on the recommendations made in BS 1881: Part 203.

Temperature Dry concrete Wet concrete

10 °C – 30 °C 1.0 (No correction) 1.0 (No correction)

60 °C 1.05 1.04

40 °C 1.02 1.02

0 °C 0.99 0.99

-4 °C 0.98 0.92

The correction factor is applied to pulse velocity calculations. The measured transmission time is unaffected.

Amplitude Analysis

Marker

When selected a marker is activated that can be used to record the amplitude of the received signal (see”3.3.5 Measuring with Pundit PL-200”).

Page 11

11 © 2016 Proceq SA

Area Scan

Raster X: set the grid spacing for the X-axis.

Raster Y: set the grid spacing for the Y-axis.

Measurement count X: Set the number of measurements to be made

in the X-direction.

Measurement count Y: Set the number of measurements to be made in

the Y-direction.

Colour Scheme: Select the colour scheme (can be adjusted later in the

explorer).

Result: Select the measurement parameter you wish to display.

Auto Color Range: On or off. If not selected then the user may define

minimum and maximum settings for the colour range and these may also

be adjusted later in the explorer. The color scheme may also be inverted

by setting the maximum value lower than the minimum.

Data Logging Mode

Interval: Select the interval between measurements. (Minimum interval

is 1 minute).

Number of events: Until the test is completed. (Maximum number of

events is 3000).

Averaging: Determines the number of readings to be taken and averaged at each interval measurement.

Result: select transmission time or pulse velocity.

Distance between transducers: This must be set if pulse velocity is

selected as the test result unit.

3.3.1 Measurement Screen

The standard measurement screen is shown. All settings are directly accessible from the measurement screen.

Zoom

Zoom in by placing thumb and index finger together on the

screen and spreading them apart. This can be used in both the

horizontal and vertical directions when making a measurement.

Zoom out by placing thumb and index finger apart on the

screen and pinching them together.

Pan

Pan the image from left to right by dragging.

1

1

2

3

4

5

6

7

8

9

10

11

2

Page 12

© 2016 Proceq SA 12

Measuring screen controls

1

Filename: Enter the file name and press return. Saved measure-

ments will be stored with this file name. If several measurements are

made under the same file name, a suffix increments after each measurement.

2

Measurement mode: Select the type of measurement to be carried

out (see section “3.4.2 Measurement Modes”).

3

The top right hand corner of the display shows the current trans-

ducer selected, current time and the battery status.

4

Gain: Adjust the receiver gain, from 1x up to a maximum of 10 000x.

5

Voltage: Adjust the transmitter voltage. For best results, it is best to

begin with low transmitter voltage and a low gain setting. Then increase

until a stable signal level is achieved. Signal clipping should be avoided.

6

Continuous/Burst Transmission:

Continues transmitting until the stop icon is pressed.

Records a measurement as soon as a stable signal is

detected.

7

Settings: Enter the settings menu.

8

Stop/Save:

Stop the current measurement.

Save the current measurement.

Save the current series and continue the measurement.

9

Start/Snapshot:

Begin the measurement.

Save the current measurement as displayed on the

screen and continue measuring.

10

Cursor Selection:

Automatic triggering.

Note: In data logging mode triggering is always

automatic, but may be adjusted manually in PL-Link.

Manual triggering. Set the cursor position manually, by

dragging it to the left or right. The trigger position may also

be adjusted later on the saved waveform in the Explorer.

Dual cursor. Transmission time mode only. Both cursors

have to be set manually. The second cursor is particularly useful when measuring with shear wave transducers.

Dual cursor is selected automatically when measuring in

E-modulus mode.

11

Zoom:

Zoom in and out of the current measurement.

Page 13

13 © 2016 Proceq SA

3.3.2 Basic Measurement Modes

Transmission Time

The measured transmission time between the transducers.

Distance

Enter the pulse velocity of the material

under test.

Result is the transmission time and the

distance between the transducers.

Pulse Velocity

Enter the distance between the transducers.

Result is the transmission time and

the pulse velocity of the material under

test.

Compressive Strength

Prior to carrying out this measurement, a conversion curve valid for the

concrete under test must be created in PL-Link and downloaded to the

instrument.

Select the correlation curve.

Enter the distance between the transducers.

If a SONREB curve is selected, enter the

rebound value determined at the same location as the pulse velocity measurement.

SONREB is a method of combining an ultrasonic pulse velocity measurement with a rebound hammer measurement to improve the accuracy of

compressive strength estimation.

Result is the transmission time and the

compressive strength of the material

under test.

3.3.3 Special Measurement Modes

Crack Depth

The crack depth measurement implemented in Pundit PL-200 is in accordance with the method described in BS 1881:Part 203.

Enter the distance ‘b’ as indicated in

the diagram shown on the screen.

Position the transducers as shown in ‘Step 1’ on the screen.

Measure t1.

Page 14

© 2016 Proceq SA 14

Position the transducers as shown in ‘Step 2’ on the screen.

Measure t2.

Result shows the transmission times

t1 and t2 and the crack depth ‘d’.

An incorrect measurement of t1 or t2

may be deleted and repeated before

continuing.

An error message is displayed for an

invalid measurement

(t2 < t1 or t2 > 2 x t1).

NOTE! For this method to give good results, the crack must

be perpendicular to the surface. It must also be free of water

or debris which would allow the wave to propagate through

the crack. The crack must be sufficiently wide to prevent the

wave from simply propagating around it. There must also be no

rebars within the vicinity of the crack. If any of these conditions

occur, the result will be severely affected and it may appear that

the crack depth is much shallower than is actually the case.

Surface Velocity

The surface velocity measurement implemented in Pundit PL-200 is in

accordance with the method described in BS 1881:Part 203.

The transmitter remains in a fixed position. The receiver is moved at a

fixed interval.

Enter the distance ‘b’ as indicated in the

diagram shown on the screen.

Enter the number of measurements to

be made.

Measure the transmission time at distance ‘b’.

Record the first measurement at distance ‘b’.

Move the receiver a further distance ‘b’ and measure again. Continue

until you have completed the series.

The pulse velocity is calculated from the slope of the curve.

NOTE! If the points recorded show a discontinuity, it is likely

that a surface crack or surface layer of inferior quality is present. In this case the measured velocity is unreliable.

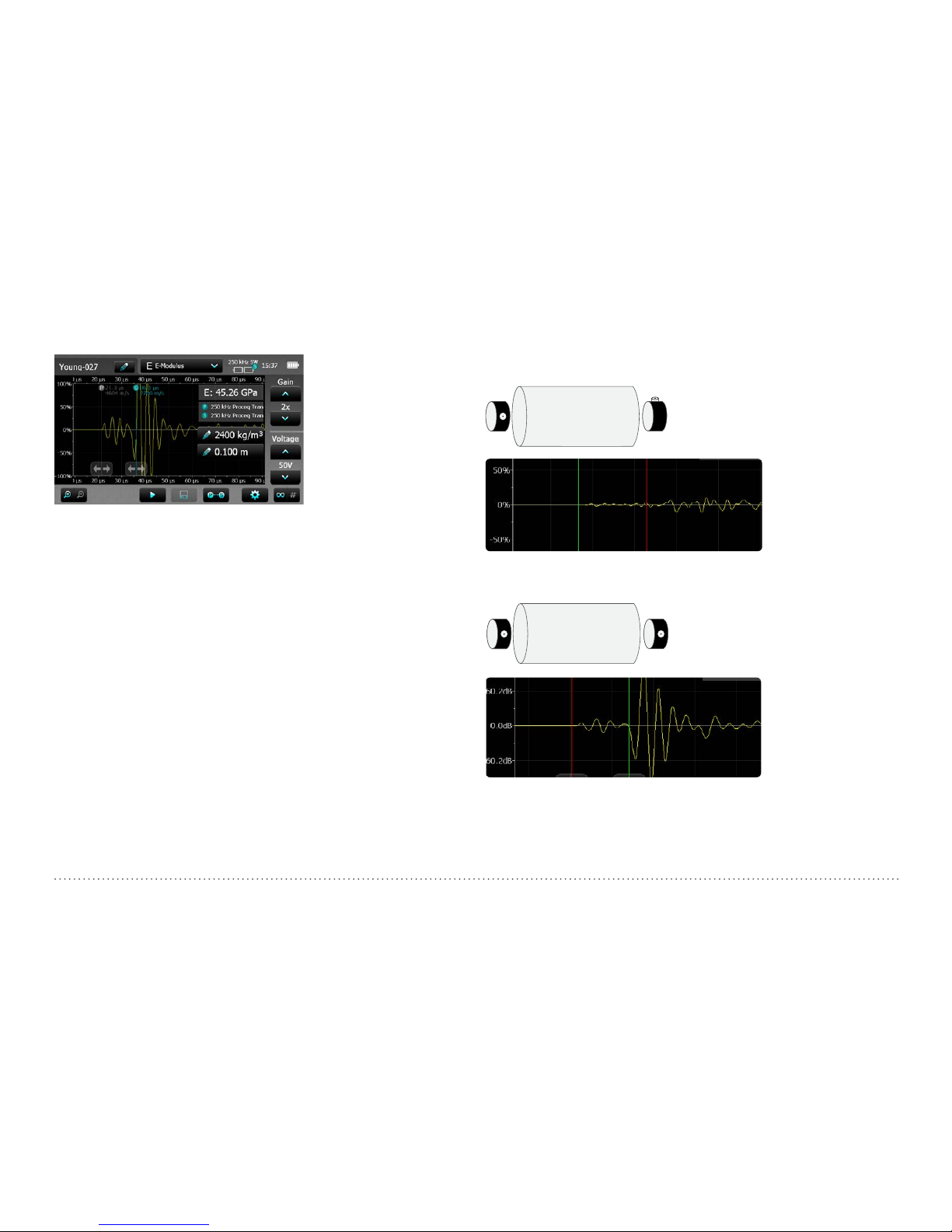

E-Modulus

The dynamic E-modulus and the Poisson’s Ratio of a material (e.g. concrete or rock) may be determined by measuring the P- and S-wave pulse

velocities. The method is described in the following two standards and is

equally applicable to concrete or other solids:

ASTM D 2845 – Standard Test Method for Laboratory Determination of

Pulse Velocities and Ultrasonic Elastic Constants of Rock.

ISRM – Aydin A., Upgraded ISRM Suggested Method for Determining

Sound Velocity by Ultrasonic Pulse Transmission Technique: Rock Mech

Page 15

15 © 2016 Proceq SA

Rock Eng (2014) 47:255-259, DOI: 10.1997/s00603-013-0454-z).

The dual cursor mode is

automatically activated.

Use the first cursor to mark

the onset of the P-wave

component.

Use the second cursor to

mark the onset of the Swave component.

In order to calculate the

E-modulus it is necessary

to enter the density of the

material.

When downloaded to

PL-Link, the Poisson’s

Ratio of the material is also

calculated.

P-waves vs. S-waves

In a P-wave (longitudinal wave) the particle displacement is parallel to

the direction of wave propagation. The particles oscillate back and forth

about their individual equilibrium positions. In an S-wave (shear wave) the

particle displacement is perpendicular to the direction of wave propagation. The particles oscillate up and down about their individual equilibrium positions as the wave passes by.

Measuring with S-wave Transducers

Detection of the shear wave (S-wave) requires the use of the waveform

display in order to manually locate the onset of the shear wave echo as

it is always preceded by a weak P-wave component that is detected by

the automatic triggering.

S-waves travel in a one-dimensional plane. The strongest signal appears

when the transducers are correctly aligned. This property can be used

to correctly detect the S-wave component of the received signal. When

measurements with the 250 kHz shear wave transducers are performed,

it is crucial to use the special shear wave coupling paste, otherwise shear

waves cannot be properly transmitted into the object under test.

Misaligned by 90°

Weak S-wave component

Weak S-wave

component with

the transducers

misaligned.

Rotate one transducer into and out of alignment and watch the S-wave

component increase and decrease.

Correctly aligned

Strong S-wave component

Much stronger

S-wave component

when the

transducers are

correctly aligned.

Page 16

© 2016 Proceq SA 16

3.3.4 Multi-Measurement Modes

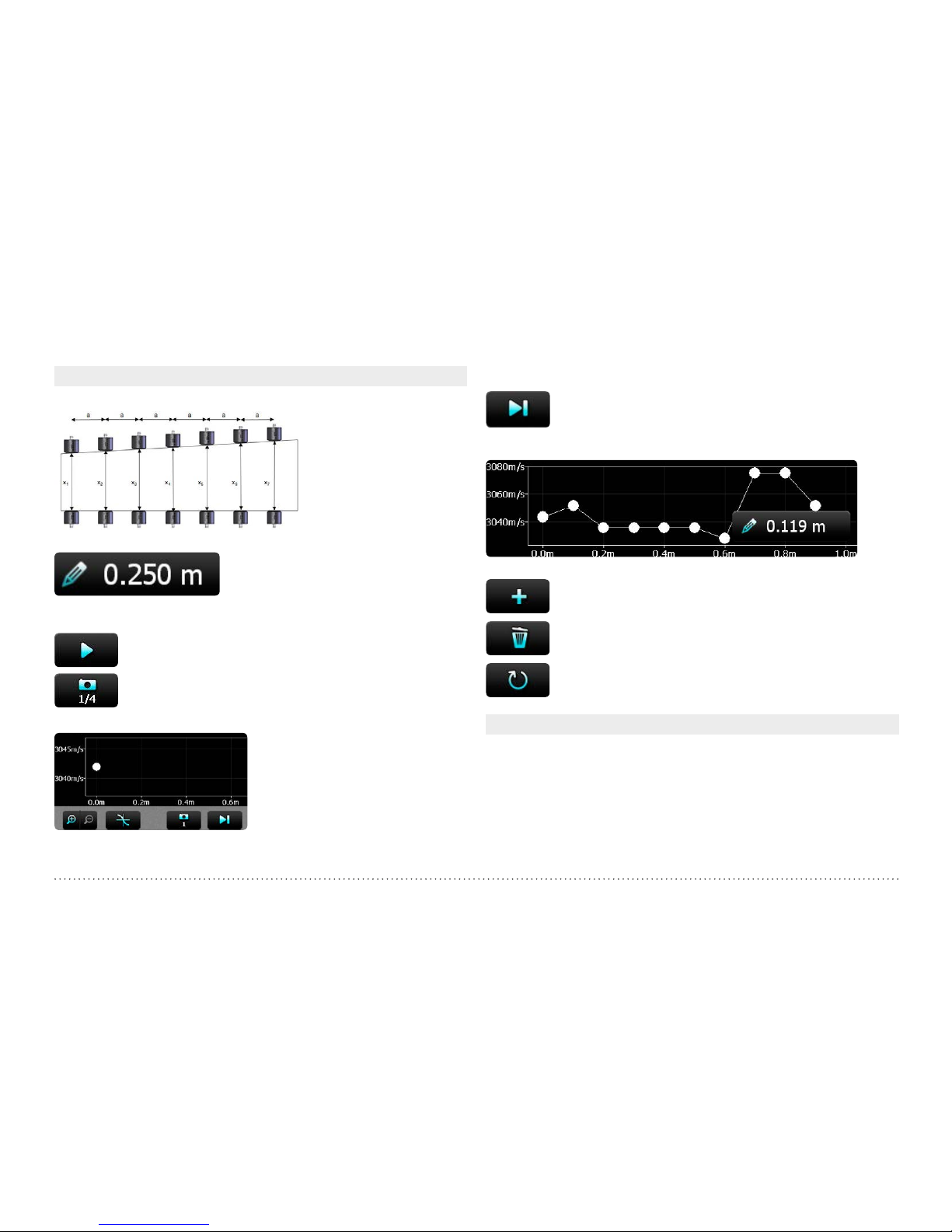

Line Scan

The distance ‘a’ is entered in the ‘Settings’ menu.

Position the transducers at the starting position and enter the distance x1.

(Not required if transmission time only is

being measured.)

Press the start icon to begin.

Press the snapshot icon and record the first measurement. If burst mode is selected this will be recorded

automatically.

Move the transducers the distance ‘a’ to the next point on the grid.

If the distance ‘x’ does not change press the snapshot icon again to

make the second measurement and so on.

Press this icon to save the current series. If the distance ‘x’ is different at the new position a new value

may be entered before proceeding with the scan.

Enter the new distance ‘x’.

Press to continue the scan.

Use this icon to delete the last measurement made.

Press the to save the current series and reset the instrument for a new series.

Area Scan

Area scan allows a 2D visualization of an element based on pulse velocity, transmission time or distance measurements. The measurement

grid is defined in ‘Settings.’ If the expected variation of the measured

parameter is not known then select ‘Auto color range.’ This may be subsequently adjusted in the explorer. If the expected range is known, the

color range may be defined by setting a maximum value and a minimum

value. E.g. The Indian standard IS 13311 defines pulse velocity bands for

concrete quality classification.

Page 17

17 © 2016 Proceq SA

> 4’500 m/s: Excellent

3’500 – 4’500 m/s: Good

3’000 – 3’500 m/s: Medium

< 3’000 m/s: Doubtful

Setting the maximum speed to 4’500 m/s and the minimum speed to

3’000 m/s provides a simple visualization of areas of the structure that

require attention.

The cursor position indicates the position of the next measurement. Ensure that this aligns with a grid drawn out on the test structure.

You may drag the cursor to the position

on the grid where you wish to start measuring. Arrows indicated the direction of

proceeding with the measurement.

It is possible to drag the cursor to another location on the grid in order to

avoid obstacles etc. It is also possible to

drag the cursor back to previous measurement and either delete it, or measure

it again. In the example below measurement #71 is indicated and may be deleted or repeated. If the measurement

is repeated by pressing the snapshot

button, the previous value is overwritten.

The black areas were excluded by dragging the cursor to the next position to be

measured.

Data Logging

The data logging mode allows the user to program a test sequence. A

typical application for this would be to track the pulse velocity change

as concrete sets. The parameters must be set in Settings. Initially the

information box shows the current settings. During the test a countdown

timer indicates the remaining time to the next measurement, the number

of measurements already made and the time at which the test will be

concluded.

The test may be stopped at any time by pressing on the icon.

The information screen may be switched in and out by pressing on the

‘i’ button. The waveforms are saved with each measurement and may

be viewed by tapping on the marker. The trigger points may be adjusted

manually if necessary once the data has been exported to PL-Link.

Page 18

© 2016 Proceq SA 18

3.3.5 Measuring with Pundit PL-200

Three transducer arrangements are commonly used.

Direct Transmission: The optimum

configuration with maximum signal

amplitude. The most accurate method of pulse velocity determination.

Path length is measured from centre

to centre of the transducers.

Indirect Transmission: Signal amplitude is approximately 3 % of signal amplitude when compared to

direct transmission. Path length may

be uncertain. Use the surface velocity mode to eliminate this uncertainity.

The pulse velocity will be influenced

by the concrete surface zone. Where

possible, carry out a comparison

with a direct transmission measurement to eliminite any uncertainly.

Semi-direct Transmission: Sensitivity is somewhere between the

other two methods. Path length is

measured from centre to centre of

the transducers.

Preparation

Basic preparations are common to each application. The distance (path

length) between the transducers should be measured as accurately as

possible (unless you are measuring in transmission time mode).

It is essential in all ultrasonic pulse tests to use some form of couplant

between the faces of the transducers and the material under test. Failure

to do so will result in a loss of signal due to inadequate acoustic coupling.

The ultrasound couplant provided provides good coupling when used

on concrete or other materials having smooth surfaces. Silicone grease,

medium bearing grease or liquid soap may also be used to good effect.

For rougher surfaces, a thick grease or petroleum jelly is recommended.

In some cases it may be necessary to prepare the surface by smoothing

it. If this is not possible the exponential transducers (Part No. 325 40 170)

should be considered.

For line scans a test grid should be drawn out on the surface.

Amplitude Analysis

Amplitude analysis is a method developed at Tonji University in Shanghai

and is widely used throughout China for comparison testing of concrete

in structures.

In order to record the amplitude the Amplitude Analysis Marker must be

set in the settings menu . When this is set, the amplitude is recorded

along with the transmission time as part of the test result.

Page 19

19 © 2016 Proceq SA

A reference measurement is made on a section of concrete of known quality.

t

0

: Reference transmission time

A

0

: Reference receive level

Subsequent measurements on the structure are compared with these

two values and an inference is made about the concrete quality based

on this.

Six different cases are identified which allow the user to make a statement about the concrete quality.

Good quality – High strength.

High fine aggregate content. Low coarse aggregate content.

High coarse aggregate content. Low fine aggregate content.

Defect on surface. Poor coupling.

Measuring through rebar.

Defects, honeycombing, voids.

3.3.6 Transducer Selection Guideline

Physical Influences on Transducer Selection

The selection of the correct transducer for the application is largely dependent on the aggregate (grain) size and the dimensions of the test

object.

Page 20

© 2016 Proceq SA 20

Effect of particle size

Inhomogeneities (e. g. aggregate particles, voids) in concrete influence

the propagation of an ultrasound pulse. They will scatter the signal. The

effect is very large if the size of the aggregate is equal to or larger than

the wavelength of the ultrasonic signal. This influence can be significantly

reduced by choosing the pulse frequency, such that the wavelength is at

least twice as large as the aggregate size.

It also follows that it is very difficult to detect an anomaly if it is smaller

than half the wavelength.

For rocks and other fine grained materials such as ceramics and wood,

the grain size is less significant. For such materials, the size of the object

to be tested is the most significant factor.

Best results have been obtained on wood with 54 kHz.

For ceramics, the small sample size and fine grain means that 250 kHz or

500 kHz is most widely used.

Effect of sample size

The pulse velocity is reduced significantly if the lateral dimensions (perpendicular to the direction of transmission)

is less than the wavelength.

Higher frequency signals, have a better defined edge and therefore make

it easier to identify the onset of the received pulse. However they are

more influenced by scattering. A 500 kHz signal has a wavelength of

around 7 mm (assuming the speed of sound to be 3500 m/s) and is heavily scattered by the coarse aggregate in concrete, limiting the transmission to a few decimeters at most. A 24 kHz signal has a wavelength of

around 150 mm and is largely unaffected by scattering. The maximum

transmission range may be several meters.

Transducer Wavelength

The wavelength may be easily calculated:

Wavelength = ultrasonic pulse velocity / frequency

For concrete, the ultrasonic pulse velocity ranges from 3000 m/s (poor

quality) to 5000 m/s (high quality). An average value for ordinary concrete

of 3700 m/s (longitudinal wave) and 2500 m/s (shear wave) have been

used for the computation of the wavelengths, the maximum aggregate

size and the minimum lateral dimension of the test object.

NOTE! For ultrasonic measurements made on rock,

ASTM D2845 recommends a minimum lateral dimension of 5x the wavelength. It also recommends using a wavelength at least 3x the average grain size.

e. g. An NX core specimen has a diameter of 54.7 mm

A transducer frequency of 250 kHz or 500 kHz would be recommended for this size of specimen based on this recommendation, (depending on pulse velocity of the rock types to

be tested). Maximum grain size would be 5 mm or 2.33 mm

respectively.

Page 21

21 © 2016 Proceq SA

P-wave Transducers

Test Object Limitations Application

Wavelength Maximum

grain size

Minimum lateral

dimension

24 kHz

Part No. 325 40 026

154 mm ≈ 77 mm 154mm Concrete:

Very coarse, aggregate, Large objects (several meters)

54 kHz

Part No. 325 40 131

68.5 mm ≈ 34 mm 69 mm Concrete, Wood, Rock

150 kHz

Part No. 325 40 141

24.7 mm ≈ 12 mm 25 mm Fine grained material, Refractory bricks

Rock (NX cores)

250 kHz

Part No. 325 40 177

14.8 mm ≈ 7 mm 15 mm Fine grained material, Refractory bricks,

Rock, Small samples

500 kHz

Part No. 325 40 175

7.4 mm ≈ 3 mm 7 mm Fine grained material, Refractory bricks

Rock, Use on small samples limited by size of transducer

Exponential Transducer

54 kHz

Part No. 325 40 170

68.5 mm ≈ 34 mm 69 mm Concrete: rough surfaces, rounded surfaces. (No couplant required.)

Wood, Rock (heritage sites)

The signal strength is not as strong as the standard transducer and

therefore it is recommended to use this transducer with a high receiver

gain and also to verify the trigger point using the waveform display.

S-wave Transducer

250 kHz

Part No. 325 40 049

≈ 5 mm Greater than the thickness of

the object.

Used for determination of elastic modulus, Concrete, wood, rock (small

samples only), Requires special shear wave couplant

Page 22

© 2016 Proceq SA 22

3.4 Pundit PL-200PE

Connected Transducer

If a Pulse Echo Transducer is connected this will be recognized automatically.

Test Transducer

Each individual dry contact transducer can be tested for correct functionality.

The graphic on the right hand side of the screen indicates which transducer pair is to be tested (blue highlight). Press the Pulse Echo Contact

Tester onto the transducer pair as shown.

A successful test is indicated by the

transducer pair being highlighted green.

The next pair to be tested is then highlighted blue.

Continue until each transducer pair has

been tested.

If one contact pair fails the test, it may

be repeated before continuing.

A-scan Analysis

Echo Tracking

This is particularly useful if a quick read-out of slab thickness is desired.

For complex objects containing internal defects, pipes and rebars it is

recommended to perform a complete B-scan for analysis of the object.

Enable Gate

The gate function is used to search for the correct echo in a specific section of the A-scan. It is used in the measurement modes Distance, Pulse

Velocity and Area Scan. See chapter “3.4.2 Measurement Modes”.

Filter

Filters are used to filter out unwanted noise, to make it easier to identify

the correct echo.

• OFF – No filter is applied. The raw signal is displayed.

• Normal – Applies a medium band filter to the received signal.

The received signal is saved post-filtering, so it is not possible to alter the

filter afterwards. Switching the filter off allows the raw data to be viewed.

Time Gain Compensation

When switched on amplifies signals that are further away from the transducer.

Area Scan

Raster X: set the grid spacing for the X-axis.

Raster Y: set the grid spacing for the Y-axis.

Measurement count X: Set the number of measurements to be made

in the X-direction.

Measurement count Y: Set the number of measurements to be made

in the Y-direction.

Colour Scheme: Select the colour scheme (can be adjusted later in the

explorer).

Result: Select the measurement parameter you wish to display.

Auto Color Range: On or off. If not selected then the user may define

minimum and maximum settings for the colour range and these may also

be adjusted later in the explorer. The color scheme may also be inverted

by setting the maximum value lower than the minimum.

Page 23

23 © 2016 Proceq SA

B-scan

Distance between measurements

Set the spacing between measurements. For good resolution images,

a spacing of 1 cm is recommended. For a quicker initial scan a coarser

spacing may be used, e. g. 2.5 cm corresponding to the spacing markers

on the Pulse Echo Transducer. When searching for larger objects such as

delaminations or thickness variations, much coarser grid spacings may

be used, e. g. 10 cm and upwards.

2.5 cm

SAFT

When activated, applies a Synthetic Aperture Focusing Technique to the

raw data to produce a sharper image.

SAFT uses path length and positioning information to correct the image. The quality of the final image is dependent on the spacing of the

measurements.

Envelope

When this setting is activated it uses an envelope of the A-scan to generate the B-scan image. This can also help to generate a clearer B-scan

image.

Color Range and Color Scheme

Color range may be automatic or manual. When set to manual, the color

gain icon

9

appears on the measurement screen.

Four different color schemes may be chosen according to preference.

Original – Original signal is used to generate the B-scan.

Envelope – Envelope signals is used to generate the B-scan.

Units

Choose between metric and imperial units

3.4.1 Measurement Screen

The standard measurement screen is shown on page 24. All settings

are directly accessible from the measurement screen.

Page 24

© 2016 Proceq SA 24

Zoom

Zoom in by placing thumb and index finger together on the

screen and spreading them apart. This can be used in both the

horizontal and vertical directions when making a measurement.

Zoom out by placing thumb and index finger apart on the

screen and pinching them together.

Pan

Pan the image from left to right by dragging.

25

25

25

25

25

25

25

25

25

1

1

2

3

4

5

6

7

8

9

10

2

Measuring screen controls

1

Filename: Enter the file name and press return. Saved measure-

ments will be stored with this file name. If several measurements are made

under the same file name, a suffix increments after each measurement.

2

Measurement mode: Select the type of measurement to be carried

out (see section “3.4.2 Measurement Modes”).

3

The top right hand corner of the display shows the current trans-

ducer selected, current time and the battery status.

4

Gain: Adjust the receiver gain, from 1x up to a maximum of 10 000x.

5

Voltage: Adjust the transmitter voltage. For best results, it is best to

begin with low transmitter voltage and a low gain setting. Then increase

until a stable signal level is achieved. Signal clipping should be avoided.

6

Settings: Enter the settings menu.

7

Stop/Save (Right Button on Transducer):

Stop the current measurement.

Save the current measurement.

Save the current series and continue the measurement.

8

Start/Snapshot (Left Button on Transducer):

Begin the measurement.

Save the current measurement as displayed on the

screen and continue measuring.

Page 25

25 © 2016 Proceq SA

L

R

9

Cursor Selection

Automatic triggering.

Manual triggering. Set the cursor position manually, by

dragging it to the left or right. The trigger position may

also be adjusted later on the saved waveform in the

Explorer or in PL-Link.

Available in transmission time mode only. Allows a

marker to be set on a second echo and the difference

between thet two echos is displayed.

Manually adjust the colour intensity.

10

Automatic Estimation of Pulse Velocity

This setting is available in the Distance and B-scan

modes. The pulse velocity may be entered manually after having made a control measurement on an

object of known thickness. Alternatively, it is possible

to estimate the pulse velocity directly on surface of the

test object. Tap on this button and press the transducer

against the surface to make a measurement. A number

of measurements can be made and an average value

is calculated. Tap to apply the pulse velocity setting. Pulse velocity may be subsequently adjusted on

saved files in the Explorer or in PL-Link.

NOTE! Typical shear wave pulse velocities for concrete are in

the region 2000 - 2500 m/s

3.4.2 Measurement Modes

Transmission time

The measured transmission time between the transmitter and receiver.

Distance

Enter the pulse velocity of the material under test or perform an “Automatic Estimation of Pulse Velocity” as described in the previous chapter.

The result is the thickness of the slab or distance to the internal object

(e. g. void, delamination) that is the source of the echo.

Pulse Velocity

Enter the thickness of the object under test.

The result is the transmission time and pulse velocity of the material under test.

Page 26

© 2016 Proceq SA 26

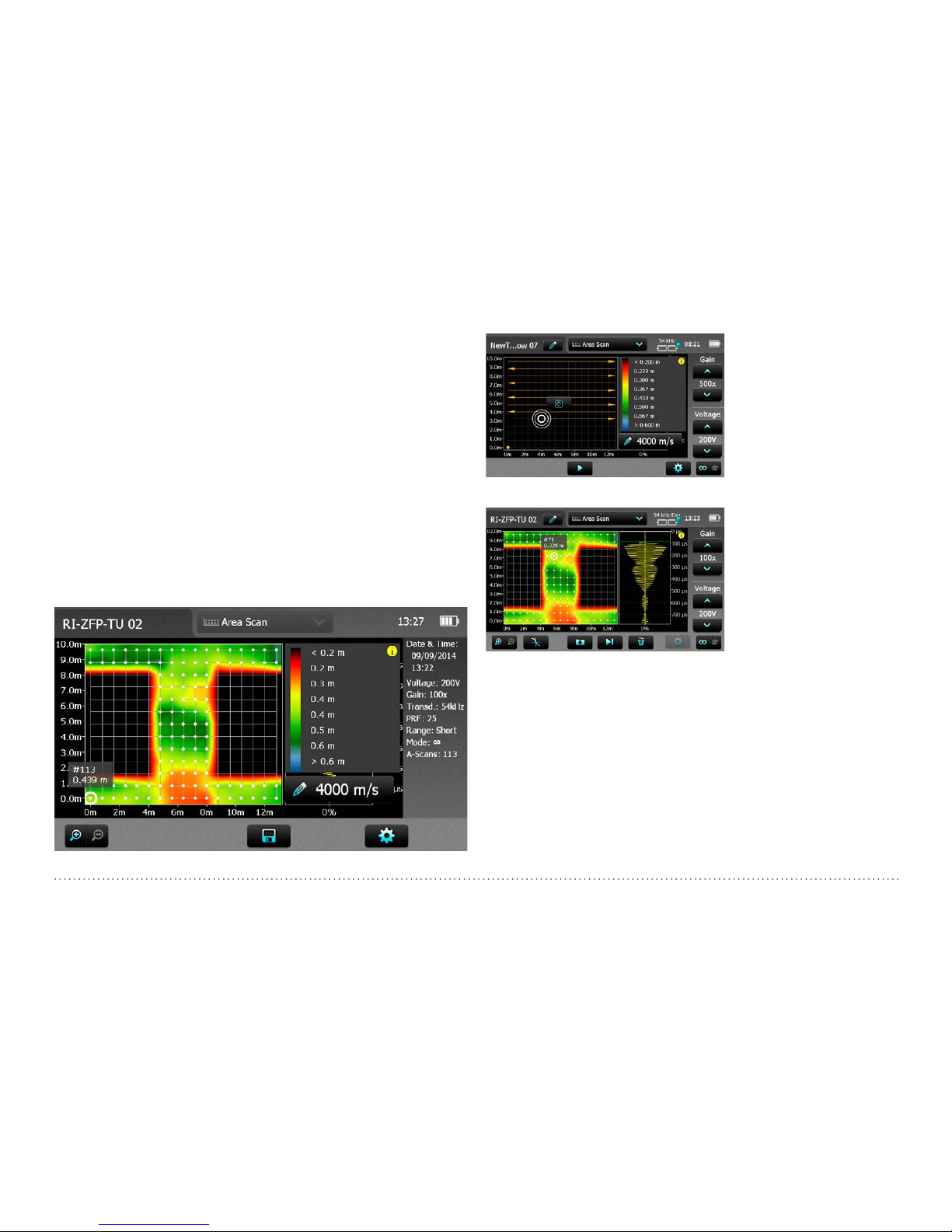

Area Scan

Area scan allows a 2D visualization of an element based on pulse velocity, transmission time or distance measurements.

The measurement grid is defined in ‘Settings.’ If the expected variation of

the measured parameter is not known then select ‘Auto color range.’ This

may be subsequently adjusted in the explorer.

If the expected range is known, the color range may be defined by setting

a maximum value and a minimum value.

e.g. The German guideline RI-ZFP-TU for Non-Destructive Assessment

of Tunnel Inner Shell Thickness specifies a measurement grid of 80 cm.

The purpose of the test is to determine areas of reduced thickness in

tunnel shells and also to locate possible voids between the tunnel shell

and the rock surface.

Setting the result to distance allows areas of reduced thickness to be

easily identified.

The cursor position indicates the position of the next

measurement. Ensure that

this aligns with a grid drawn

out on the test structure. You

may drag the cursor to the

position on the grid where

you wish to start measuring.

Arrows indicated the direction of proceeding with the

measurement.

It is possible to drag the cursor to another location on the

grid in order to avoid obstacles etc. It is also possible to

drag the cursor back to previous measurement and either

delete it, or measure it again.

In the example below measurement #71 is indicated and

may be deleted or repeated.

If the measurement is repeated by pressing the snapshot

button, the previous value is

overwritten. The black areas

were excluded by dragging

the cursor to the next position to be measured.

Page 27

27 © 2016 Proceq SA

B-scan

Provides a cross sectional image of the test object perpendicular to the

scanning surface in the plane through which the individual A-scans have

been collected.

The spacing between A-scans is entered in the “Settings” menu.

Position the transducer at the starting position.

Press the start icon to begin or the left button on the

transducer.

Record the first measurement. The measurement may

also be recorded by pressing the left button on the

transducer.

• The LED’s on the transducer provide a visual feedback when a measurement has taken place successfully. This is accompanied by an

acoustic tone on the display device. The volume of the tone may be

adjusted in system settings.

• Move the transducers to the next point of the scan. Make the second

measurement and continue.

• The current A-scan is shown on the right hand side of the screen.

• The current status of the B-scan is shown on the main part of the

screen.

Press this icon or the right button on the transducer to

save the current B-scan.

Press this icon or the right button on the transducer to

continue the current B-scan.

Use this icon to delete the last measurement made.

Press the to save the current series and reset the instrument for a new series.

The green cursor (cross-hairs) may be moved to any point on the B-scan

simply by dragging. The actually cursor position is displayed on the axes.

The current A-scan selected changes with the cursor position. This is

indicated by the A-scan number at the top of the chart and also on the

A-scan display at the right side of the measurement screen. This feature

is also available on saved B-scans in the Explorer or in PL-Link.

Gate Function

The gate function is used to search for the correct echo in a specific section of the A-scan. It is used in the measurement modes Distance, Pulse

Velocity and Area Scan. Without the gate function, it can occur that the

echo detected by the echo tracking function is not the one received from

the back wall of the test object. When the gate function is enabled, the

“gate” will be visible as a green band in measurement screen and the echo

tracking function will only look in the region defined for the correct echo.

Page 28

© 2016 Proceq SA 28

In the Distance and Pulse Velocity modes it is at the top of the measurement screen. In the Area Scan mode it is located in the A-scan window at

the right side of the screen.

Press and drag on either end of the gate to adjust the range.

Page 29

29 © 2016 Proceq SA

In order to find a suitable range, it is advisable to first carry out an automatic pulse velocity estimation and then to do a quick B-scan to determine the range of the back wall.

In this example the back wall is at 0.3m with a transmission time of 255

μs. If the aim were to look for variation in thickness it would be reasonable to set the gate between 200 μs and 300 μs.

In the distance mode, the gate can also be set using the distance scale

at the top of the screen as an aid.

Page 30

© 2016 Proceq SA 30

3.4.3 Measuring with Pundit PL-200PE

NOTE! Testing with Pulse Echo Technology requires in-depth

knowledge of the test object and application characteristics.

Proceq offers comprehensive ultrasonic training seminars

imparting this knowledge as well as all functionalities and

features of the Pundit instruments. Pundit PL-200PE users

are recommended by Proceq to register for the Advanced

Ultrasonic Tomography Applications training. Details can be

found on the Proceq website.

Preparation

• Very few preparations are necessary when measuring with the Pulse

Echo Transducer.

• The dry-contact transducer means that acoustic coupling is ensured

without the use of any couplant.

• The contacts are sprung and can accommodate surface irregularities

to a depth of 7 mm, so smoothing of the surface is also unnecessary.

• For Area Scans and B-scans a test grid should be drawn out on the

surface. Alternatively Proceq provide a calibrated tape (Part No. 327

010 71) that can be stuck on the surface for the test and then removed

afterwards.

• For best results with Distance, Pulse Velocity and Area Scan measurements make sure that Echo Tracking and Enable Gate are activated

in Settings.

Calibration

The most accurate results can be obtained if the instrument is calibrated

for the material under test.

• This is done by performing a pulse velocity measurement on a section

of the structure of known thickness.

• Alternatively, perform the automatic estimation of pulse velocity as described in chapter 3.4.1.

Physical influences on the Measurement

Inhomogeneities (e. g. aggregate particles, voids) in concrete influence

the propagation of an ultrasound pulse. They will scatter the signal. The

effect is very large if the size of the aggregate is equal to or larger than the

wavelength of the ultrasonic signal. This influence is significantly reduced

when the wavelength is at least twice as large as the aggregate size. It

also follows that it is very difficult to detect an anomaly if it is smaller than

half the wavelength.

The Pulse Echo Transducer is a shear wave transducer with a frequency

of 50 kHz.

Assuming a typical pulse velocity of 2500 m/s, the wavelength is 50 mm.

This means that anomalies smaller than 25 mm will be invisible.

Effect of sample size

The geometry of the object is very important for obtaining good results.

• The maximum penetration depth depends on the quality of the concrete and also on the amount of rebars present. Typically the maximum

transmission depth lies between 50 cm (19.7”) and 1m (39.4”).

• Generally, the minimum lateral dimension should be two times the

thickness of the object, or the depth of the anomaly you are trying to

detect. The reason for this is that if the object is too narrow, reflections

from the side walls will interfere with the echo from the rear wall.

Page 31

31 © 2016 Proceq SA

3.4.4 Analysis of B-scans

Please refer to the

separate booklet Pundit PL-200PE B-scan

Measurement Examples.

Explorer provides a number of tools that assist in the analysis of B-scans.

• Drag the cross hairs to a point of interest. (e. g. back wall of sample

as shown here)

• The object thickness (e. g. 0.3m) is displayed on the y-axis.

• The object position from the beginning of the scan is displayed on the

x-axis.

• The current A-scan (e. g. #22) is indicated above the B-scan and also

in the the A-scan window.

• The current transmission time is displayed at the right hand side of the

of the screen.

• The cursor position may also be adjusted by dragging on the position

display boxes.

• SAFT and Envelope may be switched ON/OFF in Settings.

• Pulse velocity may be corrected.

• Spacing between measurements may be corrected.

• The color scheme may be adjusted.

• Any modifications made to the scan may be saved.

• All of these items may be adjusted later in PL-Link once the files have

been downloaded to a PC.

3.5 Pundit 250 Array

Press the power button for ca. 1 second to turn the transducer on.

It takes about 20 – 25s to boot up.

When it is ready the start up screen will be displayed

which also displays information about the transducer

serial number and the hardware and firmware versions.

By entering the Settings menu, a screen showing various settings/actions appears:

Connecting Transducer

Connect the Pundit Array Transducer to the 12 pin connector of the

Pundit Touchscreen Unit using the cable provided. The Pundit Array

Transducer will be recognized automatically.

NOTE! If you have purchased the upgrade kit Part No. 327

30 130) you will need to enter the activation key provided,

before the Pundit Touchscreen recognizes the Array Transducer. To do this enter the menu System/Features/Enter Activation Key.

Page 32

© 2016 Proceq SA 32

Test Transducer

Each individual dry contact transducer can be tested for correct functionality. After having started the test procedure the graphic on the Pundit

Touchscreen Unit indicates which transducer row is to be tested (blue

highlight).

Press the Pundit Array Contact Tester onto the transducer row as shown.

A successful test is indicated by the transducer row being highlighted

green. The next row to be tested is then highlighted blue. Continue until

each transducer row has been tested.

If one row fails the test, it may be repeated before continuing. If it continues to fail the test, contact a Proceq service centre.

A-scan Analysis

A-scan Presentation

Determines how the A-scan is displayed. Choose between: Signal, Envelope or Signal and Envelope. The A-scan is shown on the right hand

side of the measurement screen as seen below. The signal is shown in

yellow and the envelope (if selected) is shown in red.

B-scan

All of these settings can be applied or removed from saved scans.

Surface Wave Cancellation

Removes the surface wave component from the displayed B-scan.

B-scan Stabilizer

Normalizes the signal strength to compensate for variations in the pressure applied to individual transducer elements. This allows a B-scan image to be obtained without having to press hard against the test object.

Color Scheme

Four different colour schemes are available.

Panorama B-scan

Two settings are used to create the image and to align it to the structural

element being tested.

Overlap of B-scans

Set the amount by which individual scans overlap when creating a panorama B-scan. The overlap range is from 0.21m corresponding to an overlap of one complete transducer (only relevant for the 16-channel con-

Page 33

33 © 2016 Proceq SA

figuration) to a negative overlap of -5m. The overlap is explained in the

chapter “Measurement Modes”.

Horizontal Panorama Offset

This setting enables the user to align a panorama B-scan to the structural drawings.

In this example the scan can be aligned to:

• point A, in which case the horizontal panorama offset would be set

to 1.5 m

• point B, in which case the horizontal panorama offset would be set

to -8.5 m

Corrections

Signal Zero Offset

This feature allows the user to work with the envelope peak for depth

measurements. This is much easier than trying to locate the beginning

of a pulse. The default value is zero. In order to use this feature, enter

the offset in microseconds determined when estimating the pulse velocity using an echo. (See “3.5.2 Measurement Modes” Estimate by Echo).

Time Gain Compensation

This feature amplifies echoes that are further away from the transducer to

provide a more balanced B-scan. The amount of amplification can be adjusted by the user either here in the settings or directly on the transducer

while carrying out a B-scan. (See Transducer Controls.)

Data Acquisition

Pulse Delay

The default value is 8ms. This will give the fastest screen refresh when

carrying out a real time B-scan.

For narrow objects and objects with very little attenuation the delay between pulse cycles can be increased. This reduces the noise effect of

reflections from side walls etc.

Units

Choose between metric and imperial units.

Transducer Energy Settings

Transducer Backlight

Turn the backlight of the auxiliary display on and off.

3.5.1 Measurement Screen

1

2

3

4

5

6

7

8

9

10

11

12

Page 34

© 2016 Proceq SA 34

Measuring screen controls

1

Filename: Enter the file name and press return. Saved measure-

ments will be stored with this file name. If several measurements are

made under the same file name, a suffix increments after each measurement.

2

Measurement mode: Select the type of measurement to be carried

out (see section “3.5.2 Measurement Modes”).

3

The top right hand corner of the display shows the current trans-

ducer selected, current time and the battery status.

4

Gain: Adjust the receiver gain from 0 – 62 dB

5

Settings: Enter the settings menu.

6

Delete last measurement

7

Stop/Save (Right Button on Transducer):

Stop the current measurement.

Save the current measurement.

Save the current series and continue the measurement.

8

Start/Snapshot:

Begin the measurement.

Save the current measurement as displayed on the

screen and continue measuring.

9

Cursor Selection

Manually adjust the colour intensity.

10

Automatic Estimation of Pulse Velocity

See section “3.5.2 Measurement Modes”

11

B-scan (real time) Cursor shows depth and horizontal position

12

A-scan (with envelope)

Keypad Controls

The gain can be adjusted directly on the transducer. Also the alignment

laser can be turned on and off at any time.

Handle Controls

There are three buttons on the handle. The centre button corresponds to

the control buttons 7 and 8 on the Pundit Touchscreen.

The outer buttons are used to adjust the gain. The functionality is summarized in the following table.

Page 35

35 © 2016 Proceq SA

Function Keypad Single

Handle

Dual

Handle

Left

Dual

Handle

Right

8

Start /

Snapshot

Press once

Press once

7

Stop / Save

Press and

hold

Press once

Adjust gain

Adjust end

gain (TGC)

Toggle

Alignment

Laser

NOTE! Gain adjustment is blocked once a panorama B-scan

has been started.

3.5.2 Measurement Modes

Pulse Velocity Estimation

Pundit 250 Array has two different methods available for estimating pulse

velocity.

Pressing the

key brings up the pulse velocity estimation screen.

Estimate by surface wave

This option should be used when the thickness of the test object is not

known. The pulse velocity of signals travelling near the surface of the

concrete is determined. Press the transducer against the surface to make

a measurement. A number of measurements can be made using the

snapshot key at different locations and an average value is calculated.

Tap

to apply the pulse velocity setting.

Page 36

© 2016 Proceq SA 36

Estimate by echo

The second and more accurate option should be used if the thickness of

the test object is known.

The thickness of the object must be entered manually.

Then press the transducer against the surface and begin a measurement.

The ideal situation is when multiple back wall echoes are visible.

Use the cursors to mark the position of the first and second back wall

echo, using the A-scan envelope to identify the peaks.

The transit time is calculated from peak to peak as seen in the screen

shot below. The offset is shown in the very top right of the measurement

screen (23us in this example). This value can be entered in Signal Zero

Offset setting, allowing the user to work with the envelope peak for depth

measurements.

For thicker objects a second back wall echo is not always visible. In this

case it is still possible to estimate the pulse velocity by echo but the procedure is slightly different.

The first cursor remains at the ‘0’ position and the second cursor is

moved to the position of the back wall echo. In this case however it is

necessary to identify the beginning of the pulse using the A-scan rather

than work with the peaks. The diagram below shows the form of the

transmission pulse which is a square wave. The received format is shown

on the left hand side. This is important to understand when trying to locate the depth of objects in the scan.

Page 37

37 © 2016 Proceq SA

The scan below shows the correct identification of the back wall echo using the beginning of a pulse. If the Signal Zero Offset has been correctly

determined, the peak of the envelope may be used instead.

During the pulse velocity estimation procedure “Estimate by surface

wave” the auxiliary display on the transducer shows the number of

measurements made, the last three measurements made and the average pulse velocity.

When using the procedure “Estimate by echo”, it simply shows the pulse

velocity calculated from the echo and the object thickness input by the

user.

Page 38

© 2016 Proceq SA 38

Estimate by surface wave Estimate by echo

B-scan

Provides a cross sectional image of the test object perpendicular to the

scanning surface in the plane through which the individual A-scans have

been collected. The width of the B-scan corresponds to the width of the

aperture, i.e., width = (number of channels-1) x 3 cm.

The Pundit Array Transducer is an 8 channel transducer. One channel

transmits and the echoes are received by the other seven channels. Each

channel transmits in turn.

A complete cycle consists of 56 individual A-scans. These are used to

Page 39

39 © 2016 Proceq SA

create a B-scan which is displayed in real time on the measurement

screen. This is extremely useful for carrying out quick spot checks at any

point of the structure without the need to save any data. Once areas of

interest have been located, more extensive scans can be made as described in the next chapter.

The cursor can be dragged to any point on the B-scan and the corresponding A-scan will be displayed in the right hand window.

As the cursor is moved around the B-scan, the left hand scale shows the

depth at which the cursor is located. The bottom scale shows the cursor

position relative to the left hand side of the transducer and the right hand

scale shows the transmission time.

Correct depth indication depends on the accuracy of the pulse velocity

setting. The pulse velocity (e.g. 2357 m/s in this example) can be entered

manually if known, or it can be estimated automatically as described in

the previous chapter.

Correct identification of the back wall echo is assisted by the A-scan

analysis as described previously.

The B-scan can be optimized in real time also by adjusting the gain and

the end gain (for time gain compensation) using the controls on the transducer as described under “Settings”.

B-scan Auxiliary Display

When carrying out a B-scan the auxiliary display provides useful information about the current settings.

Panorama B-scan

A panorama B-scan is created by stitching individual B-scans together

to make a larger image. A scan is always carried out from left to right.

Zero Overlap means that the transducer is moved by a complete transducer length to create the next B-scan. When carrying out a panorama

B-scan the auxiliary display shows the overlap, the number of scans

made and the distance from the origin.

Page 40

© 2016 Proceq SA 40

Due to the edge effects caused by the SAFT algorithm an image created

with zero overlap can be disjointed at the borders. For this reason it is

often better to use an overlap. For best results and ease of alignment

when carrying out the scan it is best to set the overlap as a whole number

of channels.

In this example the overlap is set to 3 cm which corresponds to a single

channel overlap.

When carrying out a typical application like trying to determine the extent

of a delamination on a large structure, it may be preferable to leave a gap

between B-scans in order to reduce the effort. This can be achieved by

setting a negative overlap as seen in the diagram below.

Page 41

41 © 2016 Proceq SA

Here the overlap is set to -10 cm, so when carrying out the scan a gap

of 10 cm is left from the end of one B-scan to the beginning of the next.

The image is constructed sequentially on the measurement screen as the

scans are saved.

This image is created from 8 individual B-scans with an overlap of 6 cm

(corresponding to two channels.)

The A-scan is blended out of the screen in order to provide more space

for the image. In order to see the A-scan, tap on the double arrow symbol

“<<” in the upper right hand corner of the screen.

Page 42

© 2016 Proceq SA 42

3.5.3 Pundit 250 Array Modularity

Pundit 250 Array Transducer with single handle.

Supplied as standard (Part No. 327 30 110).

Pundit 250 Array Transducer with

dual handle. Requires dual handle

kit accessory (Part No. 327 30 370).

Pundit 250 Array Transducer – 16 channels. Requires the following accessories:

• Pundit Array Transducer (Part No. 327 30 100)

• Pundit Array Transducer Extension Kit (Part No. 376 30 377)

• Dual Handle Kit (Part No. 327 30 370)

Changing from one model to another can be carried out simply on site.

The instructions on how to do this are provided with the extension kits.

4. Explorer Document Handling

From the main menu select Explorer to review saved files.

If folders have been created they are shown in the first lines from the top

(see following figure).

• Tap on a saved file to open it.

• Return to the Explorer list by

pressing the back button.

• To delete a file tap in the

check box to the left of the

file and delete it.

• Tap on

to access the files stored in it.

• To create a new folder tap on

, write the name and tap on

• To cut/copy a file/files tap on

to the left of the file(s) to become

and tap on /

• To insert/copy a file tap on

to open the folder and tap on

The cut and insert functions are useful in case a file is/files are stored in

the wrong folder or a specific folder was only created after the files have

been stored in the main level.

Below the subfolder “Inclined Rebar” is open

Name of folder (in the main level only \ is shown)

Page 43

43 © 2016 Proceq SA

• Tap on the first with the name “..” to go back to the upper folder

Download measuring files to an USB stick:

• Connect the USB-stick to the USB Device plug on the left side of

the Profometer Touchscreen

• Click on the checkbox of each file to be downloaded and click on

• The name of the downloaded file is “PM-Product version_Year_

Month_Day_Time”

Upload pdf-files from an USB-stick:

• Create the folder “PQ-Import” in the main directory of the USB-stick

(not as a subfolder in another folder) and fill it with all the pdf-files to

be uploaded to the Profometer Touchscreen

• Go to Information/Documents

• Connect the USB-stick to the USB Device plug on the left side of the

Profometer Touchscreen

• Click on

and confirm with click on

The uploaded pdf-files appear on the bottom of the document list.

5. Ordering Information

5.1 Units

PART NO. DESCRIPTION

327 10 002 Pundit Touchscreen without transducers consisting

of Pundit Touchscreen, BNC adapter cable, power

supply, USB cable, DVD with software, documentation,

carrying strap and carrying case

327 10 001

Pundit PL-200

consisting of Pundit Touchscreen, 2

Transducers 54 kHz, 2 BNC cables 1.5 m, couplant,

calibration rod, BNC adapter cable, power supply,

USB cable, DVD with software, documentation, carrying strap and carrying case

327 20 001 Pundit PL-200PE consisting of Pundit Touchscreen,

Pundit Pulse Echo Transducer incl. cable, contact

tester, power supply, USB cable, calibrated tape, DVD

with software, documentation, carrying straps and

carrying case

327 30 110 Pundit 250 Array consisting of Pundit Touchscreen,

Pundit array transducer, Pundit 250 Array software,

Pundit Array Cable 12-pin 1.5m, Pundit Array contact

tester, 6x Rechargeable AA NiMH batteries, battery

charger, USB cable, calibrated tape, DVD with

software, documentation, carrying strap and carrying

case Pundit Array

327 30 130

Upgrade Kit to Pundit 250 Array consisting of

Pundit Array Transducer, Pundit 250 Array software,

Pundit Array Cable 12-pin 1.5m, Pundit Array contact

tester, 6x Rechargeable AA NiMH batteries, DVD with

software, documentation, carrying case Pundit Array

Page 44

© 2016 Proceq SA 44

5.2 Transducers

PART NO. DESCRIPTION

325 40 026S 2 Transducers 24 kHz

325 40 131S 2 Transducers 54 kHz

325 40 141S 2 Transducers 150 kHz

325 40 177S 2 Transducers 250 kHz

325 40 175S 2 Transducers 500 kHz

325 40 176 2 Exponential Transducers 54 kHz, incl. calibration rod

325 40 049 2 S-Wave Transducers 250 kHz, incl. couplant

327 40 130 Pulse Echo Transducer, incl. cable, contact tester and

documentation

5.3 Pundit Array Transducer Parts and Accessories

PART NO. DESCRIPTION

327 30 370 Dual Handle Kit

327 30 100 Pundit Array Transducer

376 30 377 Pundit Array Transducer Extension Kit

327 30 337 Pundit Array Transducer Battery Pack Complete

327 01 085

Pundit Array Cable 12-pin 1.5m

327 30 381

Pundit Array contact tester

5.5 Accessories

PART NO. DESCRIPTION

327 01 043 Carrying strap complete

325 40 150 Transducer holder complete

327 01 049 BNC adapter cable for Pundit PL-200

325 40 021 Cable with BNC-plug, 1.5 m (5 ft)

325 40 022 Cable with BNC-plug, 10 m (33 ft)

710 10 031 Ultrasound couplant, 250 ml

325 40 048 Shear wave couplant, 100 g

327 01 033 Battery complete

327 01 053 Quick charger

710 10 028 Calibration rod 25 μs for Pundit PL-200

710 10 029 Calibration rod 100 μs for Pundit PL-200

327 01 070 Snap Ferrite for BNC Adapter cable*

327 01 051

Pundit Pulse Echo Cable

327 00 027

Pundit Pulse Echo Contact Tester complete

327 20 002

Pundit PL-200PE UPV Kit including BNC adapter cable, 2x cable with BNC-plug, L=1.5m (5ft), Ultrasound

couplant, 250ml bottle, 2 transducers 54 kHz, calibration rod

327 01 071S Calibrated Tape (Set of 5)

* In the case that receiving equipment within a radius of 10m suffers from interference, it is possible to order a ferrite to fit onto the BNC adapter cable. This serve

to further reduce the electromagnetic radiation produced by the instrument.

Page 45

45 © 2016 Proceq SA

6. Maintenance and Support

6.1 Maintenance

To guarantee consistent, reliable and accurate measurements, the instrument should be calibrated on a yearly basis. The customer may however,

determine the service interval based on his or her own experience and

usage.

Do not immerse the instrument in water or other fluids. Keep the housing

clean at all times. Wipe off contamination using a moist and soft cloth. Do

not use any cleaning agents or solvents. Do not open the housing ofthe

instrument yourself.

6.2 Support Concept

Proceq is committed to providing a complete support service for

this instrument by means of our global service and support facilities. It is recommended that the user register the product on