Page 1

PROFOSCOPE

OPERATING INSTRUCTIONS

Swiss Precision since 1954

Design Patent Pending

Page 2

Page 3

© 2015 Proceq SA 3

Contents

1. Safety and Liability ....................................................................5

1.1 Safety and Usage Precautions .............................................................. 5

1.2 Liability ................................................................................................... 5

1.3 Safety Instructions ................................................................................. 5

1.4 Designated Use ..................................................................................... 5

1.5 Labeling used in the Manual .................................................................. 5

2. Overview of the Profoscope .......................................................6

3. Tutorial ....................................................................................... 7

3.1 The Measurement Principle ................................................................... 7

3.2 Calibrated Measuring with Profoscope ................................................. 7

3.3 The Measuring Range ............................................................................ 8

3.4 Factors

Affecting

the

Measur

ement ............................................. 8

4. Getting Started ...........................................................................11

5. Performing a Real Test ............................................................... 12

5.1 Preparations .......................................................................................... 12

5.2 Locate a Rebar ...................................................................................... 13

5.3 Measure Cover Depth ............................................................................ 18

5.4 Measure Rebar Diameter ....................................................................... 22

6. Settings ...................................................................................... 24

6.1 Navigating through the Settings Menu .................................................. 24

6.2 Regional

Setting ............................................................................ 25

6.3 Rebar

Diameter ...........................................................................25

6.4 Measuring

Range

Selection .........................................................26

6.5 Audio

Setting ................................................................................ 26

6.6 Minimum

Cover ..............................................................................26

6.7 Neighboring

Bar

Compensation ....................................................27

6.8 Memory Function (for Profoscope+ only) .............................................. 27

7. Technical Specifications ............................................................ 29

Page 4

4 © 2015 Proceq SA

8. Standards and Guidelines .......................................................... 30

8.1 Standards .............................................................................................. 30

8.2 Guidelines .............................................................................................. 30

9. Part Numbers and Accessories .................................................. 30

10. Maintenance and Support .......................................................... 31

10.1 Protective Cover and Batteries .............................................................. 31

10.2 Support Concept ................................................................................... 31

10.3 Standard Warranty and Extended Warranty .......................................... 31

11. Quick Reference Guide for ProfoLink (for Profoscope+ only) .... 31

11.1 Installation.............................................................................................. 31

11.2 Data Management and File structure: ................................................... 32

Page 5

© 2015 Proceq SA 5

1. Safety and Liability

1.1 Safety and Usage Precautions

This manual contains important information on the safety, use and maintenance of the Profoscope.

Read through the manual carefully before the first use of the instrument. Keep the manual in a safe

place for future reference.

1.2 Liability

Our “General Terms and Conditions of Sale and Delivery” apply in all cases. Warranty and liability

claims arising from personal injury and damage to property cannot be upheld if they are due to one

or more of the following causes:

• Failure to use the instrument in accordance with its designated use as described in this manual.

• Incorrect performance check for operation and maintenance of the instrument and its components.

• Failure to adhere to the sections of the manual dealing with the performance check, operation

maintenance of the instrument and its components.

• Unauthorized structural modifications to the instrument and its components.

• Serious damage resulting from the effects of foreign bodies, accidents, vandalism and force

majeure.

All information contained in this documentation is presented in good faith and believed to be correct. Proceq SA makes no warranties and excludes all liability as to the completeness and/or accuracy of the information.

1.3 Safety Instructions

The instrument is not allowed to be operated by children or anyone under the influence of alcohol,

drugs or pharmaceutical preparations. Anyone who is not familiar with this manual must be supervised when using the instrument.

1.4 Designated Use

• The instrument is only to be used for its designated purpose as described in these operating

instructions.

• Replace faulty components only with original replacement parts from Proceq.

• Accessories should only be installed or connected to the instrument if they are expressly

authorized by Proceq. If other accessories are installed or connected to the instrument then

Proceq will accept no liability and the product guarantee is forfeit.

1.5 Labeling used in the Manual

NOTE! This symbol indicates important information.

Page 6

6 © 2015 Proceq SA

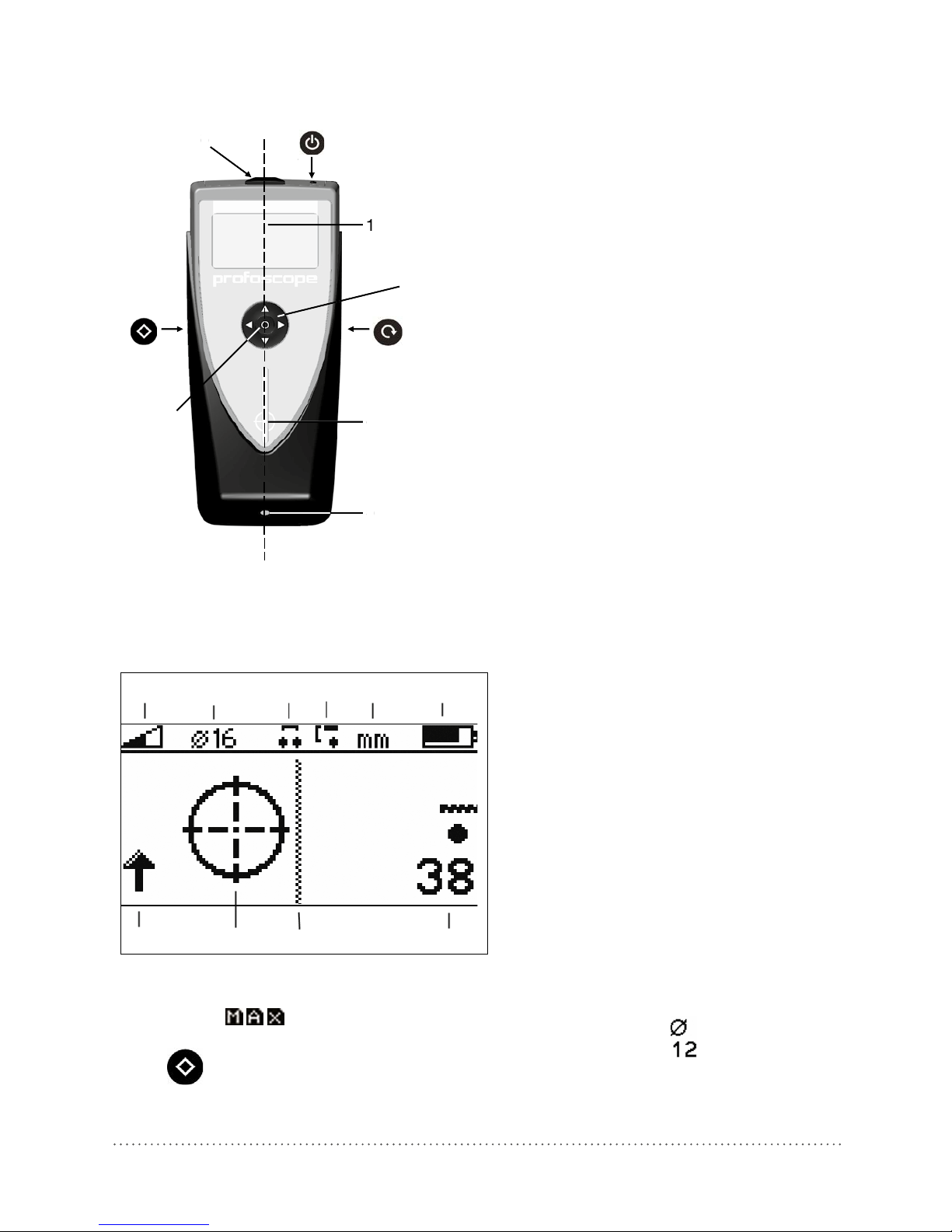

2. Overview of the Profoscope

2

8

5

4

7

1

3

6

10

9

8

5

4

7

1 Display

2 Navigation

3 Reset Key

4 Measurement Center (MC)

5 LED Indicator

6 Function Key

7 On/Off Button

8 Battery Compartment

9 Center Line (CL)

10 Select Button

Fig 1: Profoscope set up

The Profoscope Display

11 12 13 14

15 16

17 18 19 20

11 Measuring Range (Standard, Auto)

12 Reference Rebar Diameter

13 Neighboring Rebar Correction Active

14 Minimum Cover Alert

1]

Active

15 Measuring Unit

16 Battery Status

17 Signal Strength (Increasing / Decreasing)

2]

18 Rifle Scope

19 Center Line

20 Measured Cover Depth

Fig 2: Profoscope display

1]

The minimum cover alert is automatically deactivated, when the memory function is set. One of

the three icons appears instead, see 6.8.

2]

The signal strength arrow is replaced by the measured bar diameter: e. g. when the Function

Key (6) for bar diameter is pressed.

Page 7

© 2015 Proceq SA 7

3. Tutorial

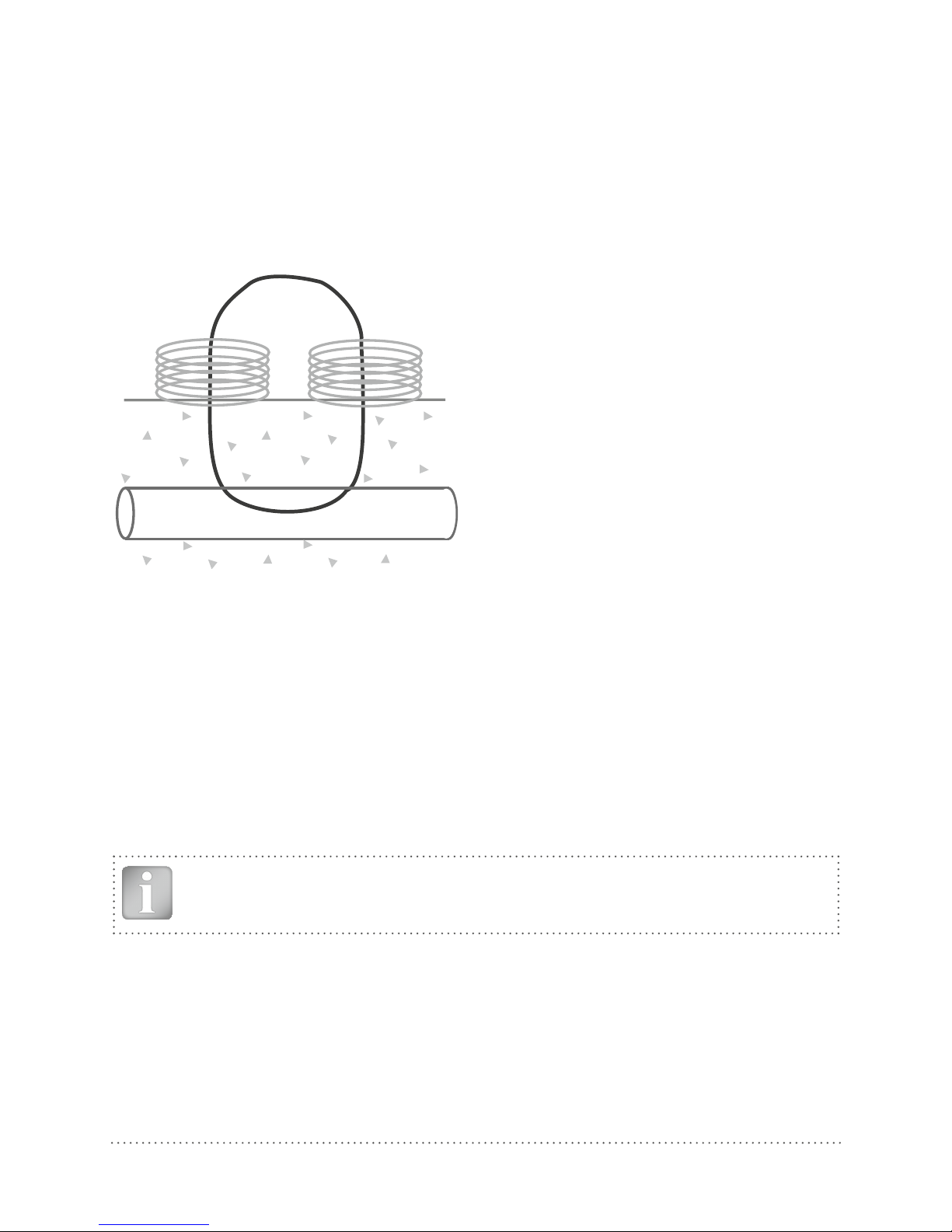

3.1 The Measurement Principle

The Profoscope uses electromagnetic pulse induction technology to detect rebars.

Coils in the probe are periodically charged by current pulses and thus generate a magnetic field.

On the surface of any electrically conductive material which is in the magnetic field eddy currents

are produced. They induce a magnetic field in the opposite direction. The resulting change in voltage can be utilized for the measurement.

Coils

Concrete

Rebar

Magnetic Field

Fig 3: Measurement principle

The Profoscope uses different coil arrangements to generate several magnetic fields. Advanced

signal processing allows

1. Localization of a rebar

2. Localization of the mid-point between rebars.

3. Determination of the

cover

4. Estimation of the bar diameter

This method is unaffected by all non conductive materials such as concrete*, wood, plastics,

bricks etc. However any kind of conductive materials within the magnetic

field

(approx. 400 mm /

16” sphere) will have an influence

on

the measurement.

* Some concrete types and other structural materials may have metallic content.

NOTE! Remove all metallic objects such as rings and watches before you start measuring.

3.2 Calibrated Measuring with Profoscope

The Profoscope is calibrated to measure on a normal rebar arrangement; which is an arrangement

of non-stainless steel rebars fastened with binding wires only. E. g. when measuring on welded

mesh wires the cover and diameter readings must be corrected (see 5.3.3 and 5.4.5). The following

information on accuracy, measuring ranges and resolutions refer to measurements on such normal

rebar arrangements.

Page 8

8 © 2015 Proceq SA

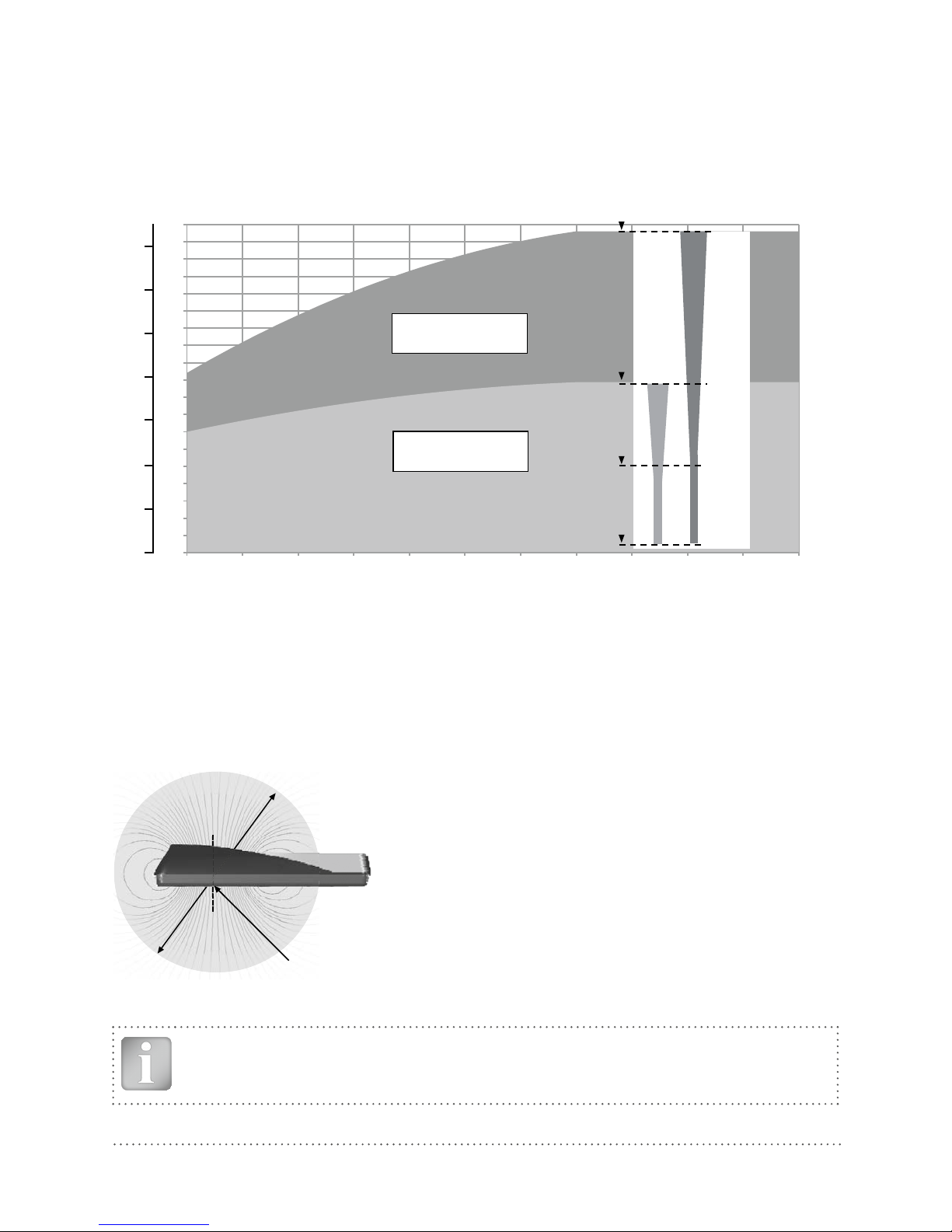

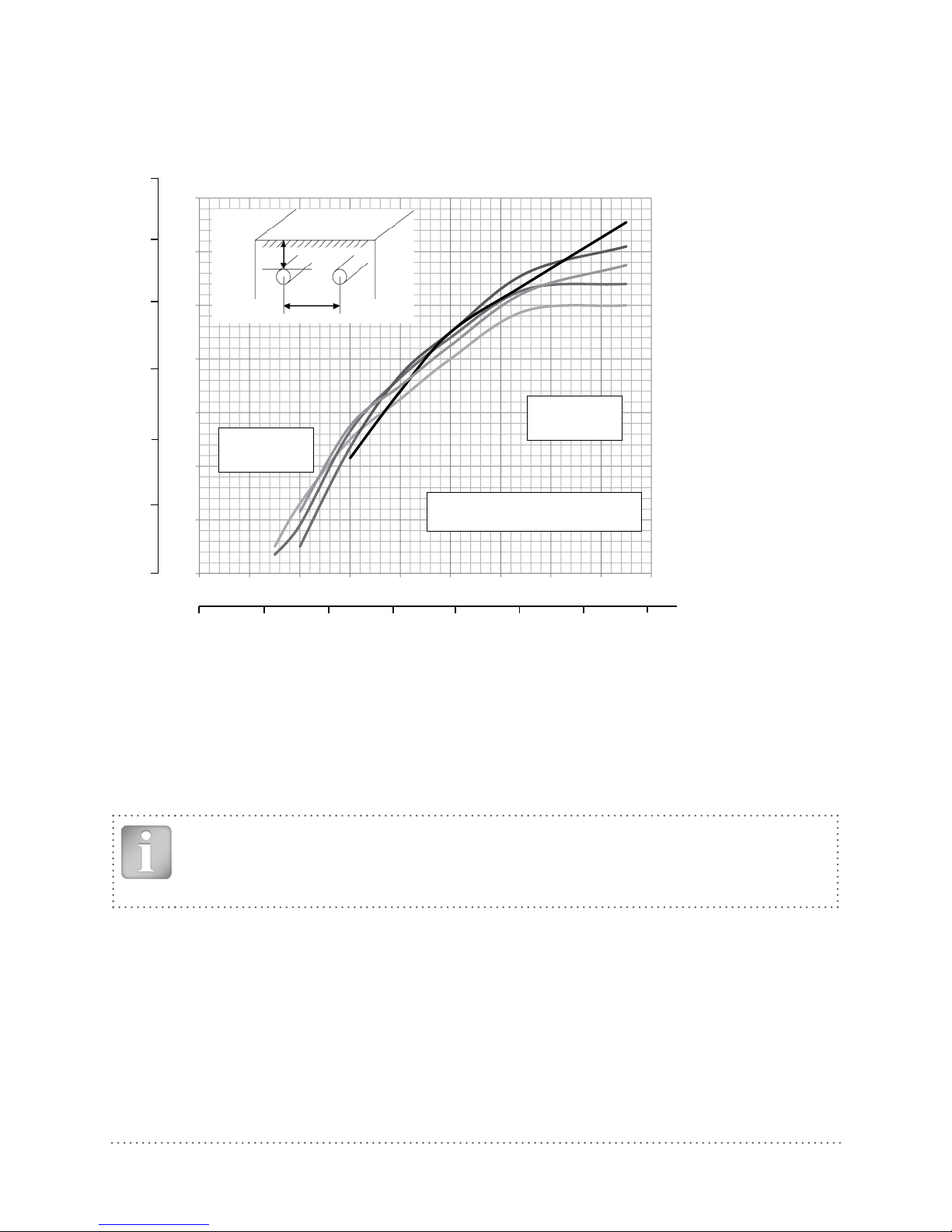

3.3 The Measuring Range

The pulse induction principle used by Profoscope has defined operating ranges and accuracies.

The measuring range is dependent on the bar size. The expected accuracy of the cover measurement is indicated in the graphic below. (Complies with BS1881 part 204, for a single rebar with

sufficient spacing and known diameter).

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

5 10 15 20 25 30 35 40 45 50

55

7

6

5

4

3

2

1

#2 #3 #5

#6 #8 #9

#11 #13 #14 #16 #18

[inch] [mm]

Rebar size

Cover depth

Large

range

Standard

range

±4 mm / 0.16”

±3 mm / 0.12

”

±1 mm / 0.04”

±1 mm / 0.04”

measuring accuracy

[mm]

[1/16 inch]

7.5 / 185

4 / 100

2 / 50

[inch] / [mm]

0 / 0

Fig 4: Measuring ranges

3.4 Factors

Affecting

the

Measur

ement

3.4.1 Errors due to Neighboring Bars

All rebars within the sphere of influence affect the reading.

MC (4)

Sphere of influence diameter 400 mm / 16”

Any ferromagnetic material within the

sphere may have an influence on the

signal value (e.g. during a reset)

Fig 5: Influence area

NOTE! This effect can be reduced by the neighboring bar correction implemented in the

Profoscope.

Page 9

© 2015 Proceq SA 9

3.4.2 Resolution

There is a limit to the minimum spacing of bars depending on the cover depth and rebar diameter.

It is impossible to distinguish between individual bars above these limits.

1

2

3

4

5

6

1

2

3

4

5

6

7

60

80

100

120

140

0

20

40

020406080100 120 140160 180

0

[inch]

[mm]

Cover depth

Large

range

Standard

range

Ø 40 mm

Ø 26 mm

Ø 16 mm # 5

Ø 12 mm

Below the curve:

Individual rebar can be detected

Rebar spacing

[inch]

[mm]

C

S

# 12

# 13

# 8

# 4

# 3

Fig 6: Resolution

3.4.3 Effect of Setting Incorrect Bar Diameter

The accuracy of the cover measurement is also dependent on setting the correct bar diameter.

The following chart gives an estimation of the error of the cover reading for different rebar sizes if a

default size of 16 mm / #5 is set.

NOTE! In case the diameter is not known and cannot be measured the rebars should

be exposed in one area to set the correct diameter in the Profoscope. With the correct

diameter set the cover over a single rebar can be measured with the accuracy shown in

chapter 3.3.

Ø 8 mm

# 2

Page 10

10 © 2015 Proceq SA

-1

-½

0

½

1

1½

-10

0

10

20

30

40

020406080100 120140 160180

-50

-40

-30

-20

0 20

40

60

80

100

120

140

160

180

-1½

-2

[inch]

[mm]

Ø 6 mm

Ø 8 mm

Ø 16 mm

Ø 12 mm

Ø 20 mm

Ø 34 mm

Ø 40 mm

[inch]

Standard range

Large range

# 2

# 3

# 4

# 5

# 8

# 13

Real Cover

[mm]

Error of cover

Fig 7: Error values for covers measured with default diameter of 16 mm / # 5 set

3.4.4 Factors Affecting Diameter Determination

Two factors affect the determination of the rebar diameter. One is the cover depth. Diameter can be

determined for rebars with cover not exceeding 80% of the Standard range. 64 mm / 2.5”.

The second is the spacing between neighboring bars. For accurate determination of the diameter,

the spacing between the rebars must be greater than the limits shown in the drawing below with

reference to the MC (4).

S

2

S

1

S

1

>150 mm

>6

”

S

1

: 130 mm / 5.2” without Neighboring rebar correction

50 mm / 2.0” with Neighboring rebar correction (see 5.4.2)

S

2

: min. 150 mm / 6”

depending on the rebar diameter

Fig 8: Minimum rebar spacing for correct readings

# 6

# 11

Ø 26 mm

Page 11

© 2015 Proceq SA 11

3.4.5 Orientation

The strongest signal results when the Center Line (9) of the probe is parallel to a bar. The Center Line

(9) in the Profoscope is the long axis of the instrument. This property is used to help determine the

orientation of the rebars (see 5.2.3).

4. Getting Started

A start-up test kit (two 16 mm / #5 diameter rebars) is provided with the packaging to help you

familiarize yourself with the instrument.

NOTE: Complete the tutorial or see a demo by a qualified Proceq representative.

1. Verify that there are no metal items on hands, fingers, or in the vicinity of the test area,

(e. g. steel frame of the table, metal trolleys etc.)

2. Power on: Press the On/Off Button (7)

on the

top

panel.

3. Reset the instrument with the Reset Key (3)

4. Check the location of the Measurement Center (MC) which indicates the center of the probe.

MC (4)

Fig 9: Measurement Center (MC)

5. Check the operation with the start-up test kit and confirm:

• The location and orientation of the rebars

• The position between two rebars

• Cover depths approximately 15 mm / 0.59 and 60 mm / 2.36”

• Diameter 16 mm / #5, see 3.4.1

Congratulations! Your new Profoscope is fully operational and you can now continue with your

measurements.

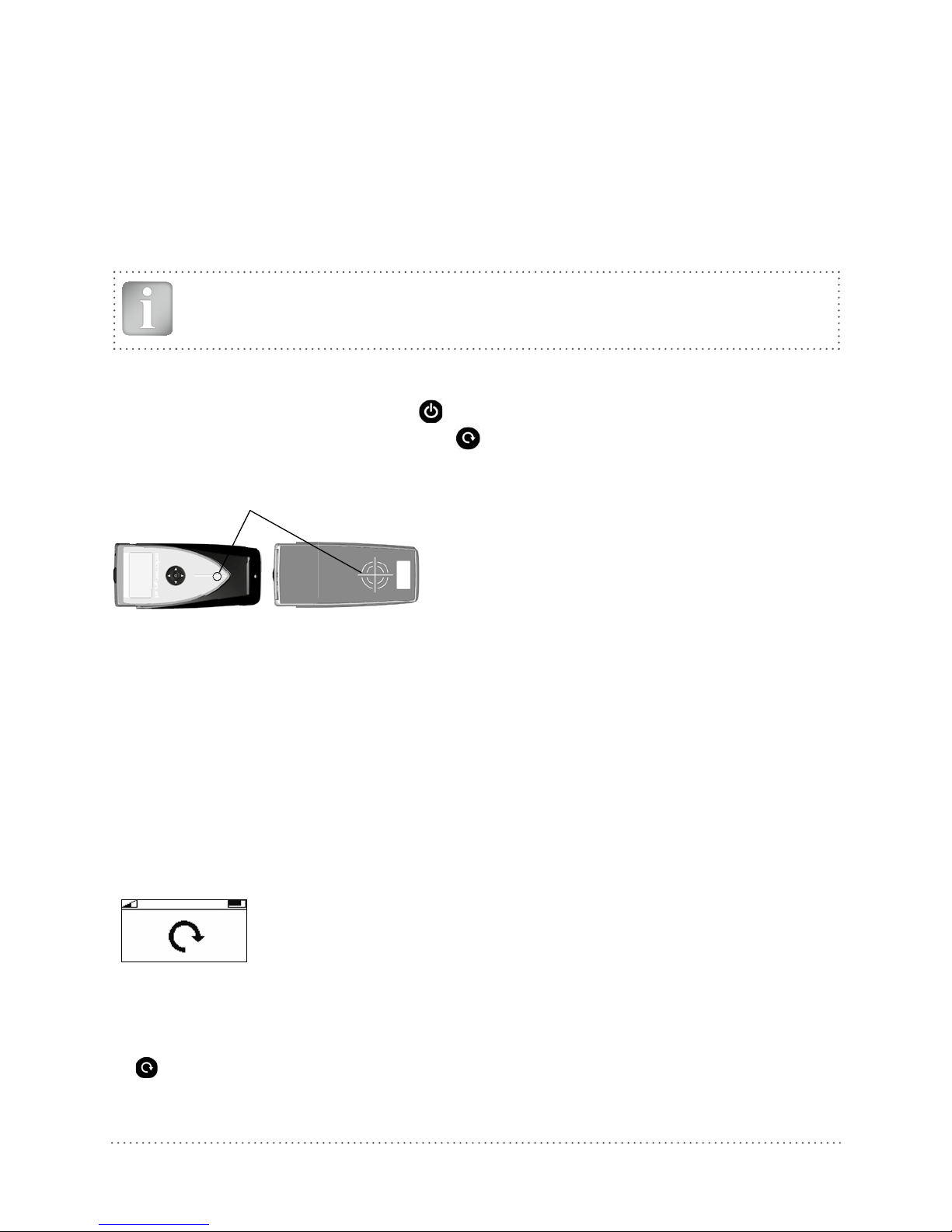

Performing a Reset

The pulse induction measuring principle is prone to drift with temperature and other external influences. Performing a reset corrects for any

drift and ensures accurate measurements. We recommend a reset every

5 minutes or so.

On power on, the Profoscope reminds the user to perform a reset.

Fig 10: Reset

Hold the Profoscope in free space (no metal within a 200 mm / 8” sphere) and press the Reset Key

(3)

. A circular arrow rotates on the display for approximately 2.5 seconds while the reset is car-

ried out.

Page 12

12 © 2015 Proceq SA

5. Performing a Real Test

Read the

Tutorial

Understanding the limits of the pulse induction principle

Complete

Getting Started

Check the operation of your Profoscope with the

start-up test kit

Regional Settings Change default settings to your regional standard

What do you

want to do?

5.2

Locate a Rebar

No further

Settings necessary

Locate the Rebar

Check the

Orientation

• Place center line directly over the

rebar

5.3

Measure

Cover Depth

Key-in Rebar

Diameter

Place Center Line

Directly over the

Rebar

Read off Cover Depth

• An accurate rebar diameter setting

will give an accurate cover depth

result

• Activate neighboring bar correction

if necessary

Create Rebar Grid

• Check minimum bar spacing

5.4

Measure Rebar

Diameter

Determining

Unknown Rebar

Diameter

Work with Default

• Known error tolerances given in

the Tutorial section

Drill Inspection Hole

• Remove all doubt

6.8

Memory

Function

6.8.1

Manual Storage

Mode

or

6.8.2

Automatic Storage

Mode

Prior to storage:

• Locate the rebars (see 5.2)

• Create rebar grid

(for Profoscope+

only)

5.1 Preparations

5.1.1 Measuring Screen Short Cuts

UP

Navigation (2)

LEFT

RIGHT

DOWN

Select Button (10)

Pressing the up arrow will switch the back-light on/

off.

Pressing the right arrow toggles between measuring

ranges.

Fig 11: Short cuts

Page 13

© 2015 Proceq SA 13

5.1.2 Settings in the Main Menu

Prior to the measurements, check if the correct settings are selected (see 4.).

• Regional Setting

Choose between Metric, ASTM inch, ASTM mm or Japanese Bar Diameter

Keep the default diameter of 16 mm / #5

• Bar Diameter

Keep the default diameter of 16 mm / #5

• Measuring Range

Choose the “Auto” mode (see also short cuts in chapter 5.1.1)

• Audio Setting

Set it according to your preference

• Minimum Cover Alert

Must be turned off by setting (-)

• Neighboring Bar Correction

Must be turned off by setting (-)

• Memory function

(for Profoscope+ only)

Must be turned off by setting (-)

5.2 Locate a Rebar

Switch on the Profoscope and perform a reset as explained in “Getting Started”. The Profoscope

can immediately be used to locate a rebar.

NOTE! The Profoscope is able to locate a rebar and also the mid-point between two

rebars. It is important to be able to distinguish between the two situations.

5.2.1 Finding a Rebar

Place the Profoscope on the test surface and move it slowly in a chosen direction. The Profoscope

reacts differently depending on its orientation relative to the rebars. There are three scenarios.

Scenario A: Sweeping Perpendicular to the Rebars

Center Line (9)

The Center Line (9) is in parallel to the rebars

This is the correct scenario to detect the rebars.

Try it out on the start up test kit.

Arrows on screen indicate of the rebar.

Fig 12: Sweeping perpendicular and display of rebar proximity

Page 14

14 © 2015 Proceq SA

Continue sweeping in the chosen direction.

As you get closer, the Rifle Scope indicates either:

• The presence of a rebar beneath the instrument or,

• The mid-point between two rebars beneath the instrument.

It is very simple to differentiate between the two.

Approaching a Rebar

MC (4)

Center Line (9)

Riftle Scope (18)

Fig 13: Approaching a rebar

Rifle Scope moves in opposite direction to the Profoscope.

The signal strength is increasing as the Rifle Scope moves towards the Center Line (9).

Continue sweeping until the Rifle Scope is exactly at the Center Line (9). The LED Indicator will

light. (If the acoustic signal is activated it will sound as long as the LED is lit). The rebar is directly

beneath the MC (4).

Center Line (9)

Riftle Scope (18)

Fig 14: Rebar centered

Approaching a Midpoint

The Rifle Scope moves in the same direction as the Profoscope.

The signal strength is decreasing as the Rifle Scope moves towards the Center Line (9).

MC (4)

Fig 15: Approaching a mid point

Continue sweeping until the Rifle Scope is exactly at the Center Line (9). The midpoint is directly

beneath the MC (4). The LED Indicator will not light.

Page 15

© 2015 Proceq SA 15

Distinguishing between a Rebar and a mid point

Fig 16: Distinguishing between a Rebar and a mid point

Scenario B: Sweeping Parallel to the Rebars

The Center Line (9) is perpendicular to the rebars.

MC (4)

Center Line (9)

Try it out on the start up test kit.

Fig 17: Sweeping parallel

If there are rebars within the range, the Rifle Scope will remain close to the Center Line (9) of the

screen and moves very

little.

Little or no movement of the Rifle Scope.

Fig 18: Rifle close to the Center Line (9)

In this case turn the Profoscope by 90° and continue sweeping as described under Scenario A)

above.

Page 16

16 © 2015 Proceq SA

Scenario C: Sweeping at an Angle to the Rebars

Markings for MC (4)

Center point

Try it out on the start up test kit.

Fig 19: Sweeping at an angle

The response on the screen will be similar to the case when you are sweeping perpendicular (Scenario A), but the movement of the Rifle Scope will be slower.

Move the Profoscope until the LED lights. The MC (4) is precisely above the rebar. Mark the position

of the MC (4) on all four sides of the Profoscope, thus the center point for checking the orientation

(see 5.2.2) is defined on the test surface.

5.2.2 Check the Rebar Direction

Once you have defined the center point, you need to check the direction of the rebar by rotating

around the center point.

Center point

above rebar

Direction of rebar

R

L

Try it out on the start up test kit.

LED-Light up when Center Line (9) over the

rebar

Fig 20: Checking the rebar direction

Position the Profoscope with the lower edge (LED output) of the Center Line (9) at the center point

of the rebar. Rotate the Profoscope around this center point either from left (L) or right (R). It will light

up once the Center Line (9) is precisely over and parallel to the rebar. Mark the position of the Center

Line (9) at the display side of the Profoscope. A line drawn through this point and the marked center

point will give the orientation of the rebar.

NOTE! The signal strength arrow can be used as an aid here. The signal strength

will increase as you rotate towards the correct orientation and decrease as rotate away.

Page 17

© 2015 Proceq SA 17

5.2.3 Verification of the Cover along one Rebar

Verify by moving the Profoscope with the Center Line (9) parallel to the rebar direction and with the

MC (4) directly above the rebar. Observe that the cover depth reading displays a constant value. You

may also start directly with the mapping of the rebar grid, see 5.2.4.

5.2.4 Map out the Rebar Grid

“Reset Key (3)” the Profoscope and proceed with Scenario A to locate further rebars.

Sweep in one direction first and then at 90° to build up the grid.

Please consider the following advice when measuring with the Profoscope:

• Whenever possible begin by locating the first rebar layer. (e. g. in a column the horizontal stirrups are the first layer), i. e. hold the Profoscope with the Center Line (9) horizontal and move

the Profoscope in the vertical direction. Mark the locations of the first layer on the surface.

• When locating the second layer (e. g. in a column the vertical rebars are the second layer) hold

the Profoscope with the Center Line (9) perpendicular to the rebars of the first layer (e. g. in a

column hold it vertical). Now move the instrument with the MC (4) along the midpoint line of two

first layer rebars parallel to direction of the first layer (e. g. in a column move it horizontally) to

detect the rebars of the second layer.

Vertical rebars

(Second Layer)

Midpoint line of Stirrups

Stirrups (first layer)

E. g. Reinforce-

ment arrangement

in a Column

MC (4)

Fig 21: Creation of a rebar map

You will soon see the rebar configuration to help you begin drilling or to conduct further measurements of cover depth (see 5.3) and rebar diameter (see 5.4), with storage of values (see 6.1, only

with Profoscope+ possible) and so forth.

Page 18

18 © 2015 Proceq SA

5.3 Measure Cover Depth

Once the rebar grid has been located the cover can be measured.

NOTE! In all cases mentioned under 5.3.2 and 5.3.3 (especially when the measured cover is close to a minimum required one), it is advisable to expose at least one first layer

rebar of each rebar arrangement to determine the real cover. The measured covers can

then be compared and if necessary corrected with the real cover.

5.3.1 Cover Measurement on areas with sufficient Spacing of the Rebars

A sufficient spacing is equal to or larger than the minimum spacing defined in 3.4.4.

Set the Rebar Diameter

An accurate knowledge of the rebar diameter will also give best cover depth results.

The default Reference Rebar Diameter set in the instrument is 16 mm or #5. This can be seen in the

status row at the top of the display screen.

If you already know the actual rebar

dia

meter, select the icon in the menu to set this as the reference.

NOTE! If you DO NOT know the rebar diameter, then proceed to 5.4. to measure the

diameter first. But this is only possible to a maximum cover of 60 mm to 65 mm / 2.5”

to 2.6”.

Now you can set the measured diameter.

Read the Cover Depth

Place the centre line of the Profoscope directly over the rebar and read off the cover depth.

e. g.

Cover depth = 15 mm

Midpoint line

MC (4)

Fig 22: Display of cover depth Fig 23: Cover depth measurements

NOTE! Ensure that the Centre Line (9) is directly over and in line with the rebar and that

the MC (4) is ideally at the midpoint between two rebars of the second layer.

Page 19

© 2015 Proceq SA 19

5.3.2 Cover Measurement on Areas with insufficient Spacing of the Rebars

An insufficient spacing is smaller than the minimum spacing defined in 3.4.4.

Special case of Rebars without spacing

In overlapping areas the rebars are normally tied together: e. g. this is the case in a cut and cover

tunnel section on the lower part of the side walls, where rebars from the bottom slab are tied together with the vertical rebars of the wall.

D

s ~

1.4 D

r

C

D

s

Ds= Set Diameter

Real Diameter D

r

Fig 24: Measured diameter Ds at overlapping areas

In such areas you will measure a larger diameter and a smaller cover than it is actually the case.

However, the accuracy of the cover measurement can drastically be increased by setting the measured diameter in the Profoscope prior to the measurements. In case the diameter can not be measured the rebars should be exposed in one area. The diameter to be set is in general 1.4 times the

real diameter of a single bar.

Covers 12 18 26 34 40

Real Diameter D

r

16 25 40 40 40

Set Diameter D

s

19 1 0 0 0 1

Accuracy in mm

when measured with the

diameter D

s

set

38 2 0 0 2 3

58 3 0 1 4 4

88 4 0 0 8 10

98 4 0 0 9 12

108 0 0 10 14

128 0 -1 12 17

158 -3 12 21

163 12 22

168 13 23

178 24

Tab. 1 Accuracy of cover measurements at overlapping rebars

Page 20

20 © 2015 Proceq SA

+4

+1

-3

-5

0

5

10

15

20

25

0

20

4

0

60

100

12

140

0

¼

½

¾

-¼

1

12

3

4

5

6

7

80

160

40/40

34/40

12/16

18/25

26/40

[inch]

[inch]

Accuracy

Dr: Real Diameter

Ds: Set Diameter

D

r/Ds

Real Cover

[mm]

4 mm

[mm]

Fig 25: Accuracy of cover measurements and overlapping rebars

Table 1 and Figure 25: Accuracy for cover measurements when setting the measured diameter

• For smaller rebars with a diameter up to 16 mm / # 5 the accuracy of cover measurement is

within 1 mm to 4 mm / 0.04” to 0.16”

• For rebars with a diameter from about 18 mm to 30 mm / # 6 to # 9 the accuracy of cover

measurement is within 0 to 3 mm / 0.00” to 0.12”

NOTE! Without setting the measured diameter the error can be up to 44 mm / 1.73”

• For larger rebars with a diameter > 30 mm / > # 9 the accuracy of cover measurement is within

1% to 15% of the actual cover.

The accuracy is decreasing with larger cover.

Special case of measuring cover at stirrups

You will find typical arrangement of rebars with stirrups in concrete beams, columns, piles and girders.

For some common arrangements you may refer to the Excel-Macro “Cover Measurement at Stirrups” on our website www.proceq.com under Profoscope.

NOTE! In all other cases the first layer rebar must be exposed on some spots to determine the real cover and compare it with the Profoscope readings.

Page 21

© 2015 Proceq SA 21

5.3.3 Measurements over Welded Reinforcement Meshes

The instrument cannot detect whether the rebars are welded to one another or connected with binding wires. The two reinforcement types with the same dimensions however create different signals.

The setting of the bar diameter must be slightly higher than the actual diameter of the mesh rebar.

The input depends on the bar diameter and on the mesh spacings. This input value should be

determined by means of a test on an open system with specific rebar mesh wire arrangements.

Measure on each arrangement with different covers to find out the diameter setting at which the

correct cover is indicated.

Welded reinforing mesh

a

1

[mm]

a2

[mm]

current d

[mm]

d to be set

[mm]

100

150

100

150

5

6

8

7

Fig 26: Examples for diameter settings at welded mesh

Select the “Standard” measuring range. The “Large” measuring range cannot be used with welded

reinforcing meshes. Locate and measure the cover as explained in the previous chapters.

5.3.4 Minimum Cover Alert

This is particularly useful for detecting insufficient concrete cover depth when conducting

large scale checks on structures after removing the formwork or large scale building inspec-

tions and so forth.

Enter the settings menu, select the icon and set the required cover depth limit. Verify that minimum

cover alert symbol is active in the status line at the top of the display.

Move the Profoscope over the test surface. Whenever the cover depth is less than the programmed

minimum the LED Indicator will light and if it is enabled, an acoustic alarm will be given.

NOTE! In this mode the LED will not light to indicate that a rebar has been located.

Page 22

22 © 2015 Proceq SA

5.4 Measure Rebar Diameter

In case the real rebar diameter is not known, the Profoscope can accurately determine the diameter

of a rebar under certain conditions.

NOTE! The determination of the rebar diameter with Profoscope is limited to a maximum

cover of 64 mm / 2.5”.

The tutorial chapter on the pulse induction principle describes the limitations of the technology and

clearly outlines the conditions whereby accurate readings of rebar diameter CANNOT be made if

there is too much interference from neighboring rebars or other metallic objects within the sphere

of influence.

We present four working methods which are recommended to obtain the best results.

NOTE! In all cases mentioned under 5.4.2 and 5.4.3, it is advisable to expose at least one

first layer rebar of each rebar arrangement to measure the real diameter. The obtained

diameter values can then be compared and if necessary corrected with the measured

real diameter.

5.4.1 Diameter Measurement on Areas with sufficient Spacing of the Rebars

A sufficient spacing is equal or larger as the minimum spacing defined in 3.4.4.

Method 1

Map out a rebar grid on a test surface and then select one rebar from the grid that has sufficient

spacing from other rebars.

Step 1 Create a rebar grid as described in 5.2.4.

Step 2 Select one rebar that has the largest spacing from neighboring rebars.

Step 3 Use a ruler and confirm that the spacing is at least as indicated in 3.4.4. If not, redo

Steps 1 and 2 until a rebar is located with the required spacing to a neighboring rebar.

Step 4 Place the MC (4) of the Profoscope over the rebar at the midpoint line of the rebars run-

ning crosswise to the rebar under test and click the Function Key (6)

on the left side.

Midpoint line

CL (9)

MC (4)

Fig 27: Diameter measurement

Page 23

© 2015 Proceq SA 23

The measured rebar diameter appears for a few seconds instead of the signal strength arrow on the

bottom left corner of the display.

Fig 28: Display of measured diameter

Note down the rebar diameter. With the Profoscope+ you may also store the measured diameter

(see 6.8.1).

5.4.2 Diameter Measurement on Areas with insufficient Spacing of the Rebars

(Neighboring Rebar Correction)

Method 2

As described in the tutorial neighboring rebars that are within the sphere of influence will also

be detected by the Profoscope and will affect cover depth and diameter estimation results.

A insufficient spacing is smaller as the minimum spacing defined in 3.4.4.

The effects of neighboring rebars can be mitigated by keying-in a correction value.

NOTE! This works only for rebars of the same layer running in parallel to the rebar under

test.

Step 1 Create a rebar as described in 5.2.4.

Step 2 Select one rebar that has the largest spacing from neighboring rebars.

Step 3 Use a ruler to measure the spacing. In case the spacing from the rebar under test to a

neighboring rebar is equal or less than 130 mm / 5.2” go to the main menu, select the icon

and input the measured spacing. Verify that neighboring rebar correction symbol is

active in the status line at the top of the display.

Step 4 Place the MC (4) of the Profoscope over the rebar at the midpoint line of the rebars run-

ning crosswise to the rebar under test and click the Function Key (6)

on the left side.

The measured rebar diameter appears for a few seconds instead of the signal strength arrow on the

bottom left corner of the display.

Fig 29: Display of measured diameter with neighboring rebar correction set

Note down the rebar diameter. With the Profoscope+ you may also store the measured diameter

(see 6.8.1).

Try it out on the start-up test kit.

Page 24

24 © 2015 Proceq SA

5.4.3 Work with a Default Value

Method 3

The purpose of this approach is to work with a default value with known error tolerances.

From the menu item “Bar diameter” select the default value 16 mm or #5 for the diameter.

Use the chart in section 3.4.3 of the tutorial to understand the errors that can be expected in the cover readings when the actual rebar diameters differ from the reference value.

You may correct the measured cover with the error value.

5.4.4 Drill an Inspection Hole

Method 4

The purpose of this approach is to accurately determine the rebar diameter through destructive

means.

If neither of the methods 1, 2 and 3 are feasible for whatever reason and you are still in doubt (this

could be the case when rebars are bunched too close together or are too small in diameter), then

drill an inspection hole wide enough to allow the use of a caliper to measure the rebar diameter. Set

this value into the Profoscope and proceed.

5.4.5 Diameter Measurements on Welded Reinforcement Meshes

In most cases a diameter can be measured but the displayed value is far too high and cannot be used.

The only way to determine the diameter is by an inspection hole as described under 5.4.4 above.

6. Settings

6.1 Navigating through the Settings Menu

UP

Navigation (2)

LEFT

RIGHT

DOWN

Select Button (10)

The settings menu can be entered by pressing the

Select Button (10). Use the Navigation (2) to select

the desired menu icon and press the Select Button

(10) again.

Fig 30: Navigation with the keys (2) and (10)

Scroll within the menus to the setting you wish to make and press the Select Button (10) to implement it. To go back to the main menu press the Select Button (10) In case all settings are done or

to exit from the main menu press either the Reset Key (3) or Function Key (6). In either case the

measuring field appears on the display. You are ready for the measurements.

Each menu item is described in detail below.

*

*Icon only in Profoscope

+

Fig 31: Main menu icons

Page 25

© 2015 Proceq SA 25

6.2 Regional

Setting

The Profoscope supports four regional settings. This setting affects all other displays and

should be done prior to making other selections.

Metric

Cover and bar diameters in mm

according to table in 6.3

ASTM inch

Cover in inch, bar diameters

according

to table in 6.3

ASTM mm

Cover in mm, bar diameters

according

to table in 6.3

Japanese

Cover in mm, bar diameters

according

to table in 6.3

6.3 Rebar

Diameter

Based on the regional setting, the bar diameter menu supports following bar

dimensions.

Metric ASTM Japanese

Bar size Diam.

(mm)

Bar size Diam.

(inch)

Diam.

(mm)

Bar size Diam.

(mm)

5 5 #2 0.250 6 6 6

6 6 #3 0.375 10 9 9

7 7 #4 0.500 13 10 10

8 8 #5 0.625 16 13 13

9 9 #6 0.750 19 16 16

10 10 #7 0.875 22 19 19

11 11 #8 1.000 25 22 22

12 12 #9 1.125 29 25 25

14 14 #10 1.250 32 29 29

16 16 #11 1.375 35 32 32

18 18 #12 1.500 38 35 35

20 20 #13 1.625 41 38 38

22 22 #14 1.750 44 41 41

25 25 #15 1.875 48 44 44

28 28 #16 2.000 51 48 48

32 32 #18 2.250 57 51 51

36 36

57 57

40 40

44 44

50 50

Tab. 2 Rebar diameters

Page 26

26 © 2015 Proceq SA

6.4 Measuring

Range

Selection

Auto Standard*

< 80 mm < 3 inch

Auto Large*

< 180 mm < 7 inch

Standard

< 80 mm < 3 inch

*The Profoscope measures first in the “Auto Standard” range. It switches automatically from “Auto

Standard” to “Auto Large” if the signal becomes too weak.

The range “Standard” must be set, when measuring over welded wire meshes.

6.5 Audio

Setting

The device can give an audible tone to assist in location or to give an

alarm when minimum cover alert is activated.

- No audio signals, silent

Centre Key pressed. Tone when rebar is centered.

Minimum

cover alert.

6.6 Minimum

Cover

If a minimum cover is selected, the LED is lit when the cover is below this limit. If audio is on,

an audio signal is given.

The minimum cover setting is possible with a cover up to 180 mm / 7.08”.

Metric, ASTM mm,

Japanese

ASTM

inch

- mm - inch

5 mm 0.20 inch

6 mm 0.24 inch

7 mm 0.28 inch

... ...

179 mm 7.04 inch

180 mm 7.08 inch

Tab. 3 Minimum covers

Page 27

© 2015 Proceq SA 27

6.7 Neighboring

Bar

Compensation

Cover and bar diameter measurements are influenced by neighboring bars. This can be compensated by selecting the bar spacing.

Metric, ASTM mm,

Japanese

ASTM

inch

- mm - inch

50 mm 2.0 inch

60 mm 2.4 inch

70 mm 2.8 inch

80 mm 3.2 inch

90 mm 3.6 inch

100 mm 4.0 inch

110 mm 4.4 inch

120 mm 4.8 inch

130 mm 5.2 inch

Tab. 4 Spacings for neighbor bar corrections

The space setting is possible with a spacing from 50 mm to 130 mm / 2.0” to 5.2”.

For larger spacing the compensation is not necessary and the space value must be set to zero (-).

6.8 Memory Function (for Profoscope+ only)

Fig 32: Main menu icons of Profoscope+

Select memory card symbol to activate the data storage mode. Minimum cover function is automatically deactivated if the memory function is turned on.

Two different memory functions are supported:

Fig 33: Sub menu “Memory”

After selecting the memory function, the status line on the measuring screen is modified:

Page 28

28 © 2015 Proceq SA

Manual Storage Mode

Automatic Storage Mode

Memory card missing or defect

Object number (max.500)

Measurement number (max.99)

Fig 34: Display of memory functions

It is recommended to set up a separate object for each structural element (e. g. column, wall). Every

measuring position on this object can then be assigned to a measurement number.

6.8.1 Manual Storage Mode:

After locating a rebar (the Rifle Scope is on the Center Line (9) and the LED Indicator (5) is lit), the

cover value and the rebar diameter can be stored by pressing the Function Key (6). This procedure

must be repeated for each rebar.

Estimate diameter and store values

Delete last measurement

Open next object

Fig 35: Display of manual storage

6.8.2 Automatic Storage Mode:

This mode is used for surface scans.

Position the Profoscope with the Center Line (9) parallel to the rebars of which the cover will be

stored. Press the Function Key (6) and start moving sidewise over the rebars.

(6)

MC (4)

Rebars

Covers above the rebars are stored

CL (9)

Fig 36: Automatic storage of covers

Page 29

© 2015 Proceq SA 29

Every time a rebar is detected, the cover value is stored automatically.

Start / automatic storage

(Blinking while recording)

Delete last object

Open next object

Fig 37: Display of automatic storage

The rebar diameter is not stored in automatic mode

7. Technical Specifications

Power supply

Power source 2 x 1.5 V AA (LR6) batteries

Voltage range 3.6 V to 1.8 V

Current Consumption

Power on, backlight off ~ 50 mA

Power on, backlight on ~ 200 mA

Sleep mode ~ 10 mA

Power off < 1 μA

Battery Lifetime

Backlight off > 50 h

Backlight on > 15 h

Time Outs

Sleep mode 90 s

Auto shut down 120 s

Environmental Conditions

Temperature range -10º to 60º C / 14º to 140º F

Humidity range 0 to 100% rH

IP classification IP54

Conformity CE, RoHS and WEEE

Memory (for Profoscope+ only)

Memory Capacity 49’500 Measurements

Page 30

30 © 2015 Proceq SA

8. Standards and Guidelines

8.1 Standards

The Profoscope is designed according to the following standards:

British: BS 1881 part 204,

German: DIN1045

Swiss: SN 505 262

8.2 Guidelines

The non-destructive rebar detection method is described in the German guide line B2 of the DGZfP

(Deutsche Gesellschaft zum zerstörungsfreien Prüfen, German society of non destructive testing).

9. Part Numbers and Accessories

Part Number Item

391 10 000 Profoscope incl. standard accessories (Packaging with integrated start-up test

kit, batteries, canvas bag, carrying strap, chalk and product documentation).

391 20 000 Profoscope+ incl. standard accessories (Packaging with integrated start-up

test kit, batteries, canvas bag, carrying strap, chalk, product documentation

and ProfoLink software).

Standard Accessories

Delivered

391 80 100 Canvas bag

350 74 025 Battery type AA

391 80 110 Carrying strap

Optional

Accessories

391 10 121S Self-adhesive protection covers (Set of 3)

390 00 270 Calibration test block

325 34 018S Chalk (Set of 10)

Extended Warranty

391 88 001 Additional 1-year warranty *

391 88 002 Additional 2-year warranty *

391 88 003 Additional 3-year warranty *

* See 10.3

Page 31

© 2015 Proceq SA 31

10. Maintenance and Support

10.1 Protective Cover and Batteries

In order to prevent abrasion the instrument is protected by a self-adhesive protective cover. It is

recommended to check and replace this cover periodically.

Remove the two AA-batteries when the Profoscope is not used for longer periods to prevent damages due to battery leakage.

10.2 Support Concept

Proceq is committed to providing a complete support service for this instrument. It is recommended

that the user register the product on the www.proceq.com to ob- tain valuable information on available updates and other useful information.

10.3 Standard Warranty and Extended Warranty

The standard warranty covers the electronic portion of the instrument for 24 months and the mechanical portion of the instrument for 6 months. An extended warranty for one, two or three years

for the electronic portion of the instrument may be purchased up to 90 days of date of purchase.

11. Quick Reference Guide for ProfoLink (for Profoscope+ only)

11.1 Installation

Locate the file „Profolink_Setup“ on your computer or the CD and follow the installation wizard.

Open the Battery Compartment and connect the Profoscope+ to the USB port. If the icon appears on the Profoscope+ screen, the connection is established properly.

2

5

1

3

6

4

7

8

Fig 38: Profolink PC-Windows

1 Download objects from the Profoscope+

2 Expand object to see details

3 Measurement number

4 Cover value

5 Rebar diameter

6 Add object name

7 Switch between regional settings or units

8 Add comments

Page 32

32 © 2015 Proceq SA

Fig 39: Profolinke Menu “Device”

Select the menu “delete all objects” to delete all data stored on Profoscope+. This will delete all

objects and cannot be undone.

Fig 40: Profolink Menu “File”

“Add” function synchronizes data between PC and

Profoscope+. In addition, locally stored data files can be added to an existing project.

11.2 Data Management and File structure:

Profoscope

Measurements

(max.99)

Objects

(*.csv) (max.500)

PC / ProfoLink

Objects

(*.csv)

Projects

(*.pqs)

Fig 41: Data Management

Page 33

© 2015 Proceq SA 33

Notes

Page 34

34 © 2015 Proceq SA

Notes

Page 35

© 2015 Proceq SA 35

Notes

Page 36

36 © 2015 Proceq SA

Proceq Europa

Ringstrasse 2

CH-8603 Schwerzenbach

Phone +41-43-355 38 00

Fax +41-43-355 38 12

info-europe@proceq.com

Proceq UK Ltd.

Bedford i-lab, Priory Business Park

Stannard Way

Bedford MK44 3RZ

United Kingdom

Phone +44-12-3483-4515

info-uk@proceq.com

Proceq USA, Inc.

117 Corporation Drive

Aliquippa, PA 15001

Phone +1-724-512-0330

Fax +1-724-512-0331

info-usa@proceq.com

Proceq Asia Pte Ltd

12 New Industrial Road

#02-02A Morningstar Centre

Singapore 536202

Phone +65-6382-3966

Fax +65-6382-3307

info-asia@proceq.com

Proceq Rus LLC

Ul. Optikov 4

korp. 2, lit. A, Office 410

197374 St. Petersburg

Russia

Phone/Fax + 7 812 448 35 00

info-russia@proceq.com

Proceq Middle East

P. O. Box 8365, SAIF Zone,

Sharjah, United Arab Emirates

Phone +971-6-557-8505

Fax +971-6-557-8606

info-middleeast@proceq.com

Proceq SAO Ltd.

Rua Paes Leme, 136, cj 610

Pinheiros, São Paulo

Brasil Cep. 05424-010

Phone +55 11 3083 38 89

info-southamerica@proceq.com

Proceq China

Unit B, 19th Floor

Five Continent International Mansion, No. 807

Zhao Jia Bang Road

Shanghai 200032

Phone +86 21-63177479

Fax +86 21 63175015

info-china@proceq.com

Subject to change. Copyright © 2015 by Proceq SA, Schwerzenbach. All rights reserved.

Part Number: 82039101E ver 10 2015, Firmware Version 3.0.1, Profolink Version 1.0.1

Loading...

Loading...