Page 1

PROFOMETER® PM-6

OPERATING INSTRUCTIONS

60 Years of Innovation

60 Years of Innovation

Made in Switzerland

Made in Switzerland

Page 2

Scope of Delivery

A

C D

A

Profometer Touchscreen Unit

B

Battery complete

B

E

C

Universal Probe with Cart

D

Profometer PM-6 probe

Cable 1.5 m

E

Power Supply with cable

(USA, UK or EU)

F

USB Cable 1.8 m (6 ft)

G

DVD with Software

H

Documentation

I

Carrying Strap complete

F

G

© 2014 Proceq SA 2

H

I

Page 3

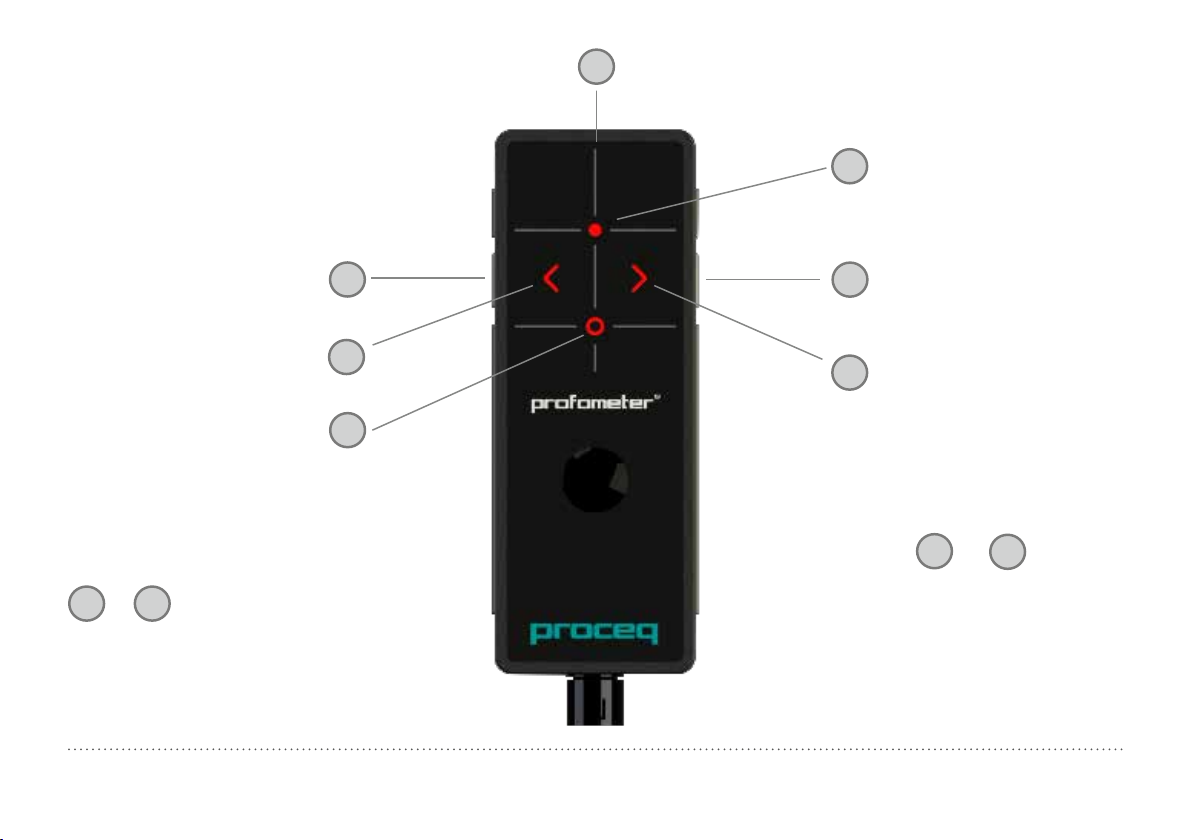

Overview

5

12

4

12

1

1

11

10

11

1212

3 © 2014 Proceq SA

9

12

2

11

12

8

12

3

11

7

6

12

Press to power on. To power off

press again and tap “X Off” on

the screen.

Soft Key – Switches in and out

of full screen view.

Back Button – Returns to

previous screen.

Page 4

Center Line (CL)

16

Measurement Center when

15

Spot range is set (MC Sp)

Short: Start / Stop

Long: Set marker

Arrow LED indicates proximity of rebar*

Measurement Center when Standard,

Large or Auto range is set (MC SLA)

*When an Arrow LED lights up move the

probe along the rebar axis until MC LED

or 15 lights up. Then the MC is

14

precisely above a rebar axis.

© 2014 Proceq SA 4

12

17

14

Short: Measure diameter

13

Long: Zeroing

Arrow LED indicates proximity of rebar*

17

By pushing

ously the cursor jumps to the next line

(in Multi-Line, Area-Scan and Cross-Line

Mode only)

12

and 13 simultane-

Page 5

Table of Contents

1. Safety and Liability ...................................................6

1.1 General Information ...........................................................6

1.2 Liability ...............................................................................6

1.3 Safety Instructions ............................................................6

1.4 Correct Usage ...................................................................6

2. Measuring Principle ..................................................... 7

2.1 Measuring Principle ..........................................................7

2.2 Calibrated Measuring with Profometer PM-6 ..................7

2.3 The

2.4 Resolution ..........................................................................8

2.5 Sphere of influence by Ferromagnetic Material ...............8

Measuring

Range................................................ 7

3. Operation ...................................................................... 8

3.1 Getting Started ..................................................................8

3.2 Main Menu .........................................................................9

3.3 Settings ..............................................................................9

3.4 Measurement Screen ......................................................11

3.5 Measurement Modes and Storage of Data ....................12

3.6 Review of Data ................................................................18

3.7 Practical Hints .................................................................24

4. Explorer Document Handling ..................................... 27

5. Ordering Information ................................................. 28

5.1 Units .................................................................................28

5.2 Upgrades .........................................................................28

5.3 Parts and Accessories ....................................................28

6. Technical Specifications ............................................ 29

7. Maintenance and Support ......................................... 30

7.1 Maintenance and Cleaning .............................................30

7.2 Support Concept .............................................................30

7.3 Standard Warranty and Extended Warranty ..................30

7.4 Disposal ...........................................................................30

8. PM-Link Software ...................................................... 30

8.1 Starting PM-Link .............................................................30

8.2 Adjusting Settings ...........................................................32

8.3 Exporting Data .................................................................33

8.4 Deleting Data ...................................................................35

8.5 Further Functions ............................................................35

9. Appendices ................................................................. 35

9.1 Appendix A1: Rebar Diameters ......................................35

9.2 Appendix A2: Neighboring Bar Correction .....................36

9.3 Appendix A3: Minimum / Maximum Cover ....................36

© 2014 Proceq SA 5

Page 6

1. Safety and Liability

1.1 General Information

This manual contains important information on the safety, use and maintenance of the Profometer PM-6. Read through the manual carefully before the first use of the instrument. Keep the manual in a safe place for

future reference.

1.2 Liability

Our “General Terms and Conditions of Sales and Delivery” apply in all

cases. Warranty and liability claims arising from personal injury and damage to property cannot be upheld if they are due to one or more of the

following causes:

• Failure to use the instrument in accordance with its designated use as

described in this manual.

• Incorrect performance check for operation and maintenance of the instrument and its components.

• Failure to adhere to the sections of the manual dealing with the performance check, operation and maintenance of the instrument and its

components.

• Unauthorised modifications to the instrument and its components.

• Serious damage resulting from the effects of foreign bodies, accidents,

vandalism and force majeure

All information contained in this documentation is presented in good faith

and believed to be correct. Proceq SA makes no warranties and excludes

all liability as to the completeness and/or accuracy of the information.

1.3 Safety Instructions

The equipment is not allowed to be operated by children or anyone under

the influence of alcohol, drugs or pharmaceutical preparations. Anyone

who is not familiar with this manual must be supervised when using the

equipment.

• Carry out the stipulated maintenance properly and at the correct time.

• Following completion of the maintenance tasks, perform a functional

check.

1.4 Correct Usage

• The instrument is only to be used for its designated purpose as describe herein.

• Replace faulty components only with original replacement parts from

Proceq.

• Accessories should only be installed or connected to the instrument

if they are expressly authorized by Proceq. If other accessories are

installed or connected to the instrument then Proceq will accept no

liability and the product guarantee is forfeit.

6 © 2014 Proceq SA

Page 7

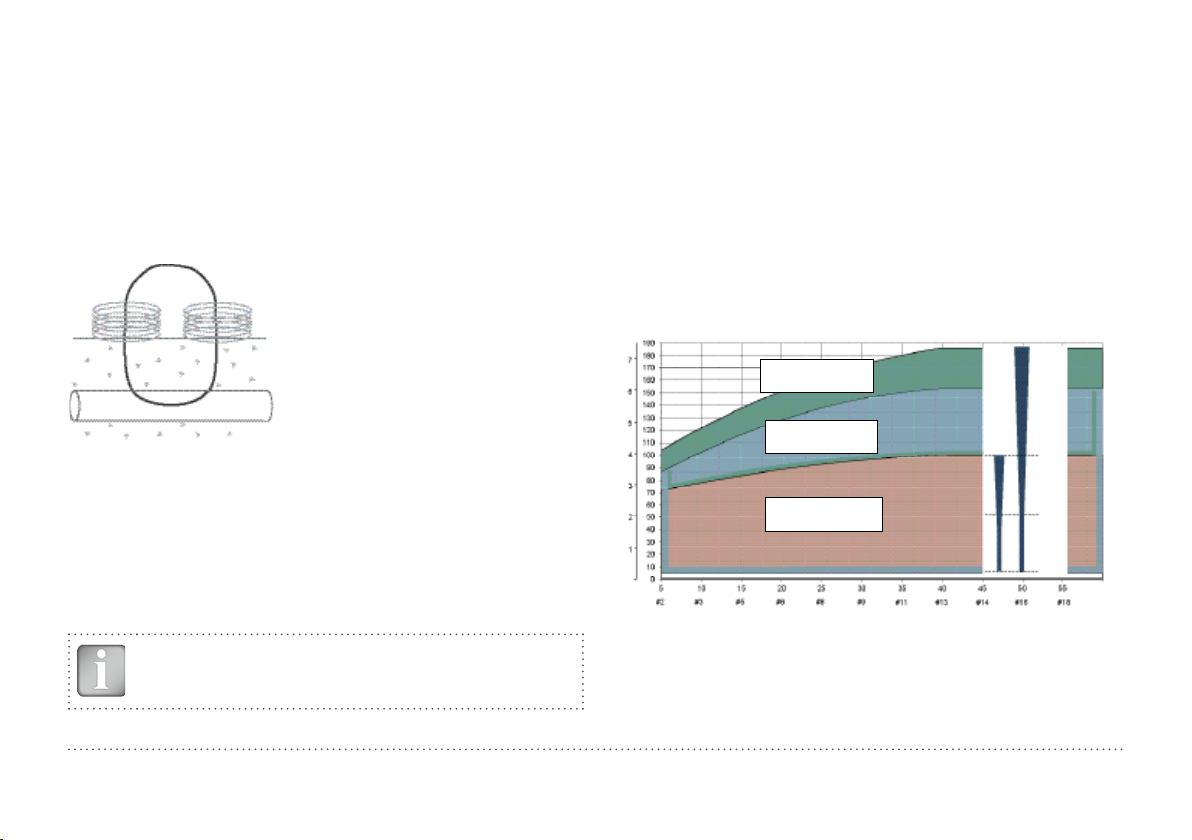

2. Measuring Principle

2.1 Measuring Principle

The Profometer PM-6 uses electromagnetic pulse induction technology

to detect rebars. Coils in the probe are periodically charged by current

pulses and thus generate a magnetic field. On the surface of any electrically conductive material which is in the magnetic field, eddy currents are

produced. They induce a magnetic field in the opposite direction. The

resulting change in voltage can be utilized for the measurement.

Coils

Magnetic Field

Concrete

Rebar

Figure 1: Measurement principle

The Profometer PM-6 uses different coil arrangements to generate several magnetic fields. Advanced signal processing allows locating a rebar

as well as measuring of cover and rebar diameter.

This method is unaffected by all non conductive materials such as concrete, wood, plastics, bricks etc. However any kind of conductive materials within the magnetic field (sphere of approx. 200 mm / 8 inch radius)

will have an influence on the measurement.

NOTE! Remove all metallic objects such as rings and watches before you start measuring.

2.2 Calibrated Measuring with Profometer PM-6

The Profometer PM-6 is calibrated to measure on a normal rebar arrangement; which is an arrangement of non-stainless steel rebars fastened with binding wires only e. g. when measuring on welded mesh

wires the cover and diameter readings must be corrected (see “3.7 Practical Hints”). The following information on accuracy, measuring ranges

and resolutions refer to measurements on normal rebar arrangements.

2.3 The

The measuring range is dependent on the bar size. The expected accuracy of the cover measurement is indicated in the graphic below. It

complies with BS1881 part 204, for a single rebar with sufficient spacing.

[inch] [mm]

Cover depth

Up to the indicated limits the cover is measured and displayed.

In the Locating Mode a rebar is shown. In the Single-Line Mode the cover curve is shown but a

rebar is only set up to 90 % of the maximum cover.

Figure 2: Measuring ranges and accuracy

Measuring

Range

Large

measuring range

Spot probe

measuring range

Standard

measuring range

Rebar size

185 mm

153 mm

100 mm

50 mm

±3 mm

measuring

±2 mm

±1 mm

±1 mm

accuray

[mm]

1

/16 inch]

[

© 2014 Proceq SA 7

Page 8

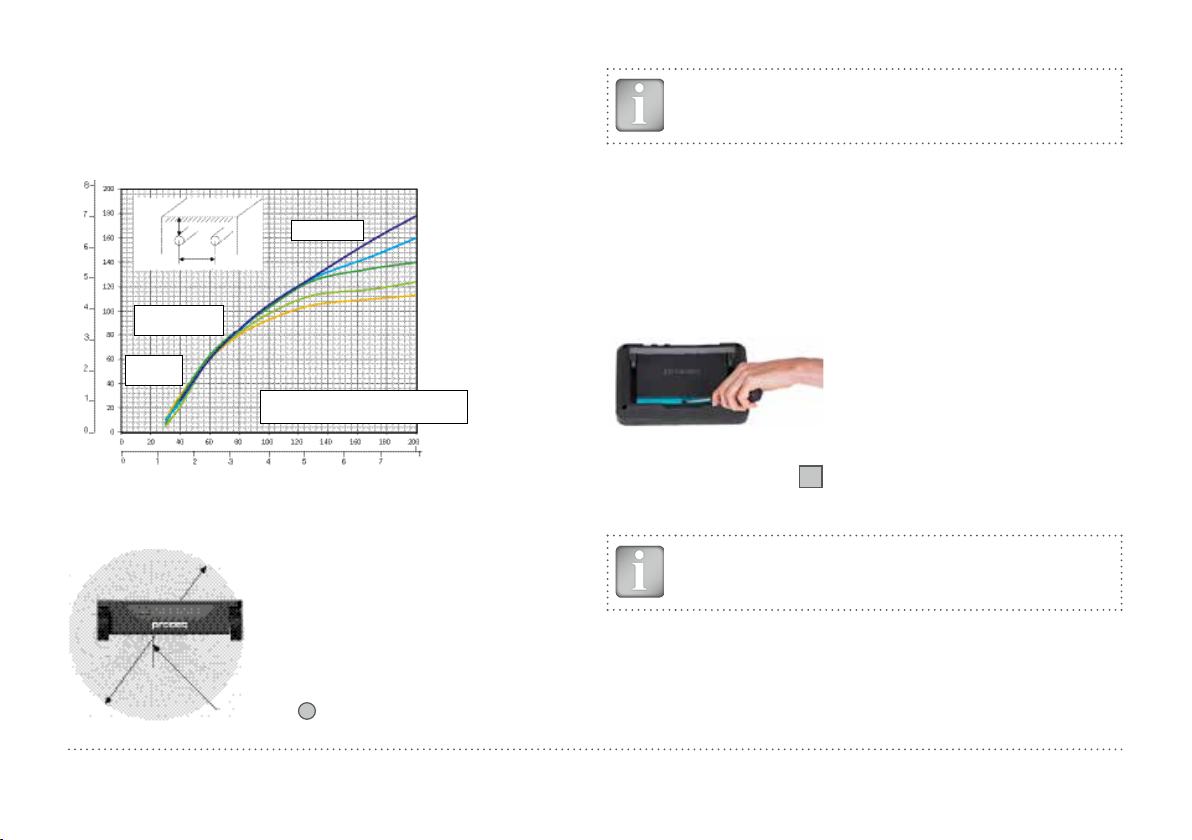

2.4 Resolution

There is a limit to the minimum spacing of bars

depth and rebar diameter. It is impossible to distinguish between individual bars above these

C

[inch]

[mm]

C

Spot probe

range

Cover depth

Standard

range

S

limits.

Large range

Below the curve:

Individual rebar can be detected

Rebar spacing

Figure 3: Resolution

depend

Ø 40 mm

Ø 26 mm

Ø 16 mm

Ø 12 mm

Ø 8 mm

[mm]

S

[inch]

ing on the cover

# 13

# 12

# 8

# 5

# 4

# 3

# 2

2.5 Sphere of influence by Ferromagnetic Material

Sphere of influence: Diameter 400 mm / 16 inch

NOTE! This effect can be reduced by the neighboring bar

corretion implemented in the Profometer PM-6.

3. Operation

3.1 Getting Started

Battery Installation

To install the Battery (B) into the Profometer Touchscreen Unit (A), lift the

stand as shown. Insert the battery and fasten in place with the screw.

Figure 5: Insert Battery

There are two status LEDs

LED is red while charging and turns to green when it is fully charged. The

other LED is application specific.

NOTE! Only use the power supply provided.

and above them a light sensor. The upper

1

Any ferromagnetic material within the

sphere may have an influence on the

signal value (e. g. during a reset)

• A complete charge requires <9h (Instrument not operating)

• Charging time is much longer if the instrument is in use.

• An optional quick charger (Part No. 327 01 053) can be used to charge

MC (SLA)

14

a spare battery or to charge the battery outside of the instrument. In

this case it takes <5.5 h for a complete charge.

Figure 4: Influence sphere

8 © 2014 Proceq SA

Page 9

Connect the Universal Probe (C) to one of the

sockets on the upper side of Profometer Touchscreen Unit (A) using the Probe Cable (D).

Probe Connections

3.3 Settings

NOTE! The settings must be checked prior to each measurement.

USB Host:

Connect a mouse, keyboard or USB stick.

USB Device:

Connect application specific probes and PC.

Ethernet:

Connection for firmware upgrades.

USB Host

USB Device

Ethernet

Power Supply

Power Supply:

Connect the power supply through this

connection.

Figure 6: Top and left

views

3.2 Main Menu

On start up the main menu is displayed. All functions may be accessed

directly via the Touchscreen. Return to the previous menu by pressing the

back button or the return icon (arrow) at the top left of the Touchscreen.

Measurement: Application specific measurement screen.

Settings: For application specific settings.

Explorer: File manager functionality for reviewing measurements

saved on the instrument.

System: For system settings, e. g. language, display options.

Information: For device information and remaining storage capacity.

Off: Power off.

Scroll up and down the screen by dragging your finger up or down the

screen. The current setting is displayed on the right hand side. Tap on an

item to adjust it.

1)

For the scanning in Y-direction in the Cross-Line Mode the diameter, respectively spacing for rebars running in X-direction can be set in addition.

2)

Settings can be changed in files already stored.

Measuring Range

Select between Standard, Large or Auto ranges (see Figure 2).

NOTE! The range cannot be changed during the measurement. To change the range, store the data first and open a

new file.

Standard is the default setting, because it is the most accurate one.

Auto switches automatically between Standard and Large. Spot should

be selected for measurements on small areas, in corners and on rebar

arrangements with small spacing.

Rebar Diameter Scan-X / Rebar Diameter Scan-Y

Select the Rebar Diameter (6 to 40 mm / #2 to #12, see Appendix A1),

either determined from the drawing or as measured.

Neighboring Rebar Correction Spacing for Scan-X / Scan-Y

It mitigates the influence of neighboring rebars. By setting the spacing

to the rebars running parallel to the rebar on which the measurement

1) 2)

1) 2)

© 2014 Proceq SA 9

Page 10

is taking place, the diameter and the cover are automatically corrected.

This is possible for rebar spacing from 50 to 130 mm / 2.00 to 5.20 inch

(see Appendix A2).

2)

Unit

Select Metric, Metric Japanese, Imperial or Imperial Diameter, Metric

Cover and Distance.

Minimum Cover

2)

A Minimum Cover value from 10 to 142 mm / 0.40 to 5.56 inch can be

set in 1 mm / 0.04 inch steps (see Appendix 3). In the Single-Line, MultiLine and Cross-Line Mode/View rebars with less cover than minimum

cover will be shown in red color. In the Single-Line View and Statistical

View a horizontal, respectively vertical dotted line in red indicates the

Minimum Cover value set.

Cover Offset

2)

When a Cover Offset value is set the measured cover will be reduced by

this value; e. g. when a wooden or plastic plate is used to measure with

the probe cart on rough surfaces (see “3.7 Practical Hints”). In this case

the plate thickness must be set as Cover Offset value). A value from 1 to

50 mm / 0.04 to 1.92 inch can be set.

Display Inclined Rebar

By setting this feature the inclined rebar is displayed in the Locating Mode

when all four wheels of the cart have passed over the inclined rebar. In

the Single-Line and Multi-Line Modes it is only shown in the cart symbol.

NOTE! In areas with small rebar spacing this feature may not

work properly.

NOTE! To get smooth color intervals the Minimum and Maximum Cover should be set in 5 mm / 0.20 inch steps.

Sharpen

2)

With this setting the signal strength color spectrum of the Multi-Line and

Maximum Cover

2)

A Maximum Cover value from 20 to 190 mm / 0.80 to 7.48 inch can be

set in steps of 1 mm / 0.04 inch (see Appendix A3). In the Single-Line,

Multi-Line and Cross-Line Mode/View rebars with cover more than Maximum Cover will be shown in grey color.

NOTE! The Maximum Cover must be at least 10 mm / 0.40

inch higher than the Minimum Cover. If not, the instrument

will correct it automatically.

The Maximum Cover should also be set for different files measured on

the same surface to get the same color range for comparison purpose.

Cross-Line Views can be sharpened.

Display Curve

2)

Select Cover Value, Signal Strength or None. The respective curve or

no curve is displayed in Single-Line View.

Align Rebar Positions

2)

When measuring in the Multi-Line or Cross-Line Mode along at least two

lines of at least 55 cm / 22.00 inch length, the rebar positions of the last

line are aligned to the rebar positions of the two previous lines.

NOTE! This feature should only be set, if the rebars are running

parallel to the Start line (X- or Y-line). It is not activated during

the measurements (activated only when storing the data).

10 © 2014 Proceq SA

Page 11

Return to start on new line

3

With this feature set, the cursor jumps back to the start line when changing line in the Multi-Line and Cross-Line Modes.

Line Height (in Y-direction)

The line height must be set in the Multi-Line, Area-Scan and Cross-Line

Modes. It determines the spacing between the measuring rows. A height

5 to 203 cm / 2.00 to 80.00 inch can be set.

Grid Width (in X-direction)

The grid width must be set in the Area-Scan and Cross-Line Modes. A

width from 5 to 203 cm / 2.00 to 80.00 inch can be set.

3.4 Measurement Screen

The standard measurement screen is shown on page 3. All settings are

directly accessible from the measurement screen.

Zoom in by placing thumb and index finger together on the

screen and spreading them apart. This can be used in both the

horizontal and vertical directions when making a measurement.

Zoom out by placing thumb and index finger apart on the

screen and pinching them together.

Pan the image from left to right by dragging.

Measuring screen controls (see page 3)

File name: Enter the file name and tap return. Saved measure-

1

ments will be stored with this file name. If several measurements

are made under the same filename, a suffix increments after each

measurement and follows the file name.

Measurement Mode: Select the type of measurement to be carried

2

3

out (see “3.5 Measurement Modes and Storage of Data”).

The top right hand corner of the display shows the current time, the

3

3

battery status and a warning triangle for zeroing the probe: after 5

minutes in orange, after 10 minutes in red.

NOTE! Tap on the triangle to perform zeroing.

Display of selected Settings and Screen Mode:

4

3

3

3

3

3

3

3

3

5

6

7

8

9

10

11

– Measuring Range

– Rebar Diameter

– Neighboring Rebar Correction

– Cover Offset

– Lin e Heigh t (for Multi-Line, Area-Scan & Cross-Line Mode only)

– Grid Width (for Area-Scan and Cross-Line Mode only)

– Probe Direction X: Undefined direction

^, v, <, >: On vertical wall, probe head

towards up, down, left, right

_, ˉ: On horizontal surface, on soffit

Settings: Switches to the settings menu (see “3.3 Settings”).

Rebar Diameter: Measuring or change setting of rebar diameter

Start:

Restart with measurements and reposition cursor to the start line.

(All data of current measurements are deleted)

File Info or delete, Cursor to Start line in Multi-Line and Area-Scan

Modes

Zoom in to cursor position (for Single-Line Mode only)

Set cursor to line below or above (for Multi-Line Mode only)

Zoom to fit During measurement: Goes back to standard view

Stored file: Complete measuring area is displayed.

In the Modes/Views “Zoom to fit” does not show all the details

for scanning distance > 10/30 meters (> 32.8/98.4 feet).

Measurements or store measured data

© 2014 Proceq SA 11

Page 12

3.5 Measurement Modes and Storage of Data

When Measurement Mode is selected for the first time after switching

on the instrument, zeroing of the probe is performed. Confirm it and wait

for the button assessment window. Wait or tap anywhere on the screen.

The Measurement Modes available are shown at

screen.

Locating Single-Line Multi-Line Area-Scan Cross-Line

PM-600

PM-630

PM-650

•

• • • •

• • • • •

NOTE! Valid for all Measuring Modes: In case measuring data

shall be stored create a folder in the Explorer (see “4. Explorer

Document Handling”) and check if the correct folder is active.

Stored files can be reopened to continue with the measurements.

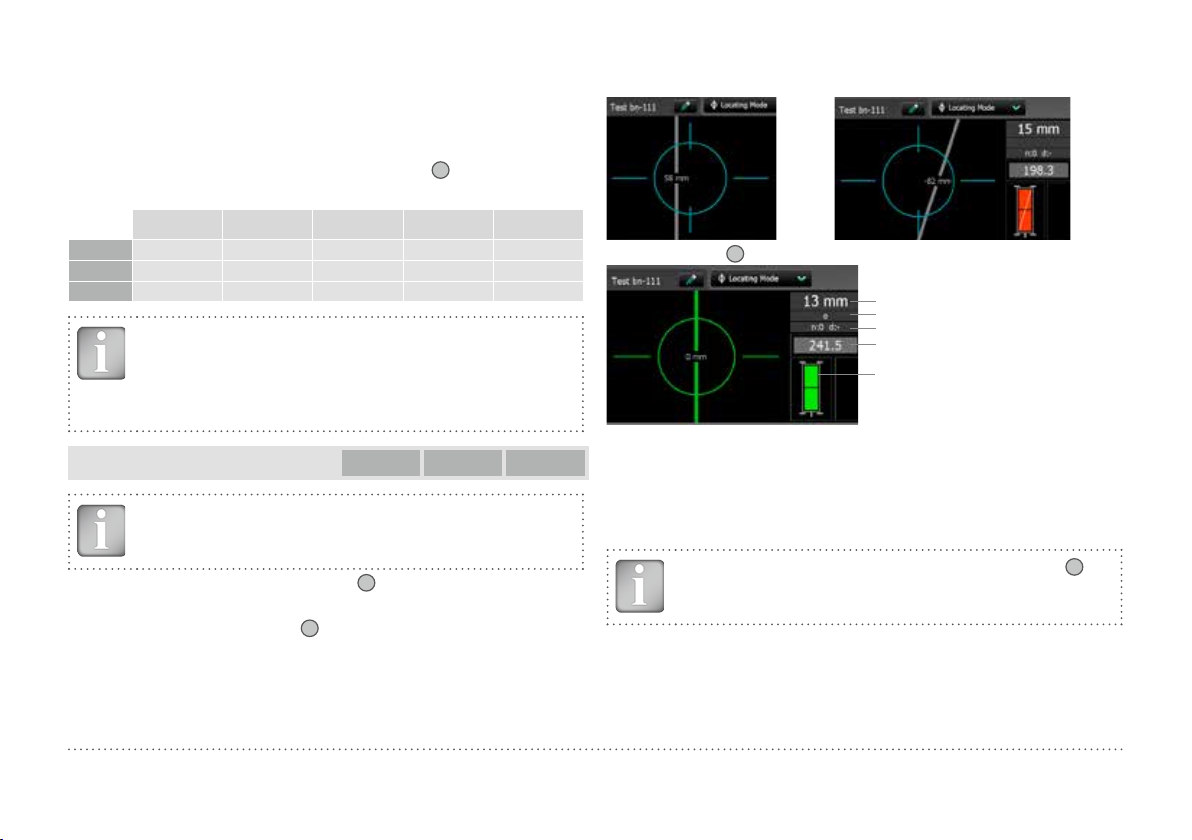

Locating Mode

PM-600 PM-630 PM-650

NOTE! The Locating Mode is the default mode because all

measurements should start with this mode.

2

on the measuring

Approaching a rebar Rebar is inclined to the CL

When the Center Line

is precisely over the rebar (red LED of probe center is lit) it shows:

16

(minimum inclination for a display is 6 degrees).

Actual Cover

Distance to next rebar

Nos./Meas. diameter

Signal strength

Both rectangles Green:

Ideal probe position:

Both coils maximum signal strength and

green

Bad probe position:

Coil rectangles of different size and red

A rebar is shown only within the cover

ranges indicated in Figure 2.

Figure 7: Screens of Locating Mode

• Enter the setting menu by tapping on

5

. Set the correct settings, es-

pecially Measuring Range and Display Inclined Rebar (on or off)

• Hold the probe cart with the CL

16

parallel to the assumed direction of the

rebar to be scanned. Then scan perpendicular to the CL until the probe

cart crosses a rebar. The display shows (only if probe is fixed on the cart):

NOTE! The prope position indication refers always to

(SLA), even the Spot Range is set.

In most cases the rebars of the first and second layers are fixed in a rectangular mesh (e. g. vertical and horizontal rebars in a wall).

14

MC

12 © 2014 Proceq SA

Page 13

In case an inclined rebar is displayed,

one has to find out the exact rebar direction.

14

15

MC

• For this purpose locate the rebar as

/

described below, but first remove the

probe from the cart.

14

• Once the MC

15

/

is above the re-

Center point

bar axis mark the position of the MC

on the surface at CL

edge of the probe and on either side

of the MC.

16

at the upper

Direction of rebar

L

• Position the CL point at the lower

edge of the probe precisely at the

marked center point.

• Turn the probe around this center

point until the maximum signal is

displayed. (Placing a set square with

one corner at the center point facilitates the turning of the probe).

The CL

16

runs parallel to and above

the rebar axis, when the signal strength

reaches the maximum and the MC

15

lights up.

14

/

Figure 8: Finding the rebar

direction

Center point

above rebar

Set square

R

Whenever possible start with locating the rebars of the first layer, e. g. on

a column the horizontal stirrups.

16

• Holding the CL

horizontally, move vertically up or down until the

the probe cart vertically until both rectangles in the probe symbol are

green and of equal, minimum size.

• Now move the probe cart horizontally until one of the Arrow LEDs

14

lights up and then move back until MC LED

or

15

lights up.

• At this position you may also measure the diameter either by pushing

13

on the right side of the probe or 6 on the Touchscreen (e. g. when

the probe is fixed to the telescopic extension rod).

• If the spacing of parallel rebars is between 5 and 13 cm (2.00 to 5.20

inch), set the respective Neighboring Rebar Correction value first.

If the cover is too small for diameter measurement “too close” is displayed.

• In this case place a wooden or plastic board on the surface and set the

board thickness as Cover Offset to measure the diameter.

Finally the measured diameter must be set. The cover reading will be corrected according to the diameter set.

NOTE! For more details about diameter measurement see

“3.7 Practical Hints”.

7

• Tap

to store the diameter and cover measurement.

• Repeat this procedure at each rebar.

The saved data can be seen in the Snapshot and Normal Statistics View

(see “3.6 Review of Data”).

NOTE! Cover values are only saved for later viewing, if the

diameter was measured and saved.

Arrow LED lights up and then move back until the MC LED lights up.

After having located the first layer rebars continue with locating the second layer rebars.

14

• Position the MC

15

/

at the mid line of the first layer rebars, e. g.

on a column hold the probe with the CL running vertically and move

© 2014 Proceq SA 13

17

Page 14

Single-Line Mode

PM-630 PM-650

NOTE! It is advisable to locate the first and second layer rebars with the Locating Mode to find the optimum line position prior to measuring with the Single-Line Mode.

The Single-Line Mode is mainly used if cover must be shown along one

line on a rather long distance (e. g. in a tunnel). Therefore the measurements are made across the first layer rebars.

The maximum scan length is 999 m / 3’280 feet in each direction (to the

right and to the left from the zero line).

• Enter the setting menu by tapping on

5

. Set the correct settings, es-

pecially Rebar Diameter, Unit, Minimum Cover and Display Curve.

In case Single-Line scanning is done over rebars of different diameters

and/or of different spacing measure each diameter.

• Position the probe cart at the start line in an optimum position (the MC

15

14

/

at the mid line of the rebars running parallel to the moving direc-

tion, both rectangles in the probe symbol are of equal minimum size).

• In case

is shown at 7 tap on it and will be shown.

• Start with the measurement if the cursor is at the start line. If not perform a reset

8

.

• Move the probe cart with constant speed crosswise over the rebars,

not exceeding the maximum speed (speed bar half filled in green).

• Above each rebar, when the red LED of MC

/

lights up, you may

14

15

measure the rebar diameter and on completion, it will be displayed

in blue. The measured diameter may be deleted within 5 seconds by

tapping on 6.

• In case the spacing between the rebars is in the range of 5 to 13 cm

(2.00 to 5.20 inch), set the respective Neighboring Rebar Correction

value first (see Figure 26).

The cursor position can be adapted in two ways to changed cart position:

• Tap on the cursor and wait until it becomes white and orange. Move

the cursor to the desired position (even left to the zero line is possible). Be aware: Scanning is not anymore possible between the new

cursor position and the zero-line. Already scanned rebars cannot be

removed by a new scanning but you may scan again on the left of

the first rebar or on the right of the last rebar. To delete the already

scanned rebars tap

• Tap on

and set the required displacement distance. In case you

and .

must jump due to an obstacle like a column, move the cart until the

right wheels touch the column, set the displacement distance (column

width + 107 mm / 4.20 inch for the cart width) and reposition the cart

with the left wheels touching the column. Tap on / .

At the end when stopped scanning a marker (dotted blue line) is set.

Probe position

To see the actual cursor position short tap on the cursor and the position is shown in white on

the X-axis.

The rebars are displayed to scale depending on the diameter

The cover curve is shown (if selected) within the cover ranges indicated in Figure 2 but a rebar

will only be shown up to 90 % of those limits.

The actual position is shown in a resolution of ± 3 mm / 0.12 inch.

Red indicates rebars with insufficient cover, others with sufficient

cover.

Red dotted is the minimum

required cover. Blue number

indicates measured diameter.

Either the Cover, Signal Strength

or None curve can be displayed

by tapping on

ing “Display Curve”.

and chang-

14 © 2014 Proceq SA

Page 15

To display a rebar as a

circle zoom the horizontal

and vertical axis to the

same scale.

The spacings of the rebars

are shown in blue.

The distances from the

start line to the first rebar

and from the end line to

the last rebar are shown in

white color. If the figures

are not shown, zoom in.

In the Single-Line Mode one can also change from cover curve to signal

strength curve or no curve (see also “3.6 Review of Data”).

The path length measurement accuracy depends on the test surface. The

accuracy of measurements done on a smooth concrete surface (concrete

poured in metallic shuttering) is shown in the specifications, see “6. Technical Specifications”. On rougher surfaces the measured length may be

reduced or checked at certain intervals by setting markings on the test

surface and comparing with marks set on the display (long push on

After storage (tap

7

), the data can be seen in the Statistics View, the

12

).

Single-Line View and also in the Snapshot View if at least one diameter

was measured (see “3.6 Review of Data”).

PM-630 PM-650

Spacing between rebars (in blue)

Figure 9: Screen of Single-Line Mode with cover curve

• To change a diameter tap on the rebar.

A window opens.

• Tap on the window and change diameter.

To erase set diameter to zero.

The new diameter is set and shown in orange.

The cover changes accordingly but the cover

curve remains except above the rebar axis.

Multi-Line Mode

NOTE! It is advisable to locate the first and second layer rebars with the Locating Mode to find the optimum line position prior to measuring in the Multi-Line Mode.

The Multi-Line Mode is often used if cover, rebar location and rebar diameters of mainly rectangular areas of different sizes must be shown (see

“3.6 Review of Data”), thus mainly for the first layer rebars.

In one measuring sequence a maximum of 62 lines can be scanned and

stored in one file.

5

• Enter the settings menu by tapping

.

• Set the correct settings as for the Single-Line Mode. Additionally set

the Line Height. If desired, set also “Align Rebar Position” and “Return

to start on new line”.

NOTE! “Align Rebar Position” should only be set, if all rebars

are running parallel to the start line (Y-axis).

Figure 10: Single-Line View zoomed, showing change of rebar diameter

New set diameter shown in orange

© 2014 Proceq SA 15

Page 16

NOTE! For larger areas it is advisable not to set “Return to

start on new line” and to measure the lines alternatively start

to end, back from end to start.

• Position the probe cart at the first start line in a optimum position (the

15

14

MC

/

at the mid line of the rebars running parallel to the moving

direction, both rectangles in the probe symbol are green and of equal,

minimum size) and tap on reset 8 followed by tapping on .

• Move the probe cart crosswise over the rebars. Above each rebar,

14

when the red LED of MC

15

/

lights up, you may measure the rebar

diameter and on completion, it will be displayed. If the spacing between the rebars is in the range of 5 to 13 cm (2.00 to 5.20 inch), set

the respective Neighboring Rebar Correction value first.

At the end of the first line a marker (dotted blue line) is set.

To proceed with the next line tap

10

or push

12

13

and

simultaneously on

the probe. The cursor jumps to the next measuring row, either to the start

line or remains at the end line, depending on whether “Return to start on

new line” is set or not.

Changing the cursor position works like in the Single-Line Mode. Additionally one can change to another line within the displayed area (which

also can be changed as described in ”3.4 Measurement Screen”). However, to delete the already scanned rebars of one line set the cursor to

the zero line and tap

. By tapping on and all measured

data of all lines would be deleted.

At the start of each line you may change the probe direction (e. g. when

measuring on a wall along the bottom line close to the slab).

• Tap on

.The arrow in the probe cart symbol changes from to .

For the next line you may change back to .

NOTE! By changing the setting “Line Height” during the

measurements the height of all lines including the ones already measured will change and hence, also the line positions. Change the line height only if it was previously wrongly

set.

At each rebar you may measure the rebar diameter. At the end, set one

common diameter, normally the smallest one (see “3.7 Practical Hints”).

Figure 11 shows the rebars in a plan view in different colors depending on

the measured cover. Red means the cover is smaller than the minimum

set.

Rebars with insufficient cover in red, others have sufficient cover

Actual cover

Distance from MC to rebar

no. of snapshots/no. of rebars

/ last measured diameter

A rebar will only be shown up to 90 % of

the cover ranges indicated in Figure 2.

Accurate probe

position if

rectangles green

and of same size

cover ranges,

< xx in red

if minimum

cover set

Alternatively

diameter ranges

Figure 11: Screen of Multi-Line Mode

Alternatively the diameter can be displayed in different colors by tapping

on the cover spectrum. Rebars of which the diameter was not measured

or set are shown in white. Diameters measured are shown in the respective color. Diameters set in the Single-Line View are shown additionally

with an orange cross bar in the middle of the rebar (see Figure 20).

16 © 2014 Proceq SA

Page 17

After storage (tap 7 ), the data can be seen in the Statistics View, the

Single-Line View, the Multi-Line View and also in the Snapshot View if at

least one diameter was measured (see “3.6 Review of Data”).

In the Multi-Line View the signal strength spectrum can be seen in addition to the cover and diameter, see “3.6 Review of Data”.

Area-Scan Mode

PM-630 PM-650

NOTE! It is advisable to locate the first and second layer rebars with the Locating Mode to find the optimum line position prior to measuring in the Area-Scan Mode.

The Area-Scan Mode is mainly used to show the first layer rebar covers

on large areas, e.g. of concrete slabs in car parks. The measuring procedure is the same as for the Single-Line, respectively Multi-Line Mode.

The Area-Scan Mode is best suited for a combination with potential field

measurements; e. g. combined with Canin+ measurements. But in this

case the line height and grid width must be the same for both measurements (square grid required by Canin ProVista).

5

• Enter the settings menu by tapping

.

• Set the correct settings as for the Single-Line and Multi-Line Mode.

Additionally the grid width must be set. It must be about 1.1 times

larger than the maximum rebar spacing of the first layer rebars. This

guaranties at least one rebar located within one grid.

A cover will only be shown up to 90 % of the cover ranges indicated in Figure 2.

Figure 12: Screen of Area-Scan Mode

7

After storage (tap

), the data can be seen in the Statistics View, the

Multi-Line View and also in the Snapshot View if at least one diameter

was measured (see “3.6 Review of Data”).

Cross-Line Mode

PM-650

NOTE! It is advisable to locate the first and second layer rebars with the Locating Mode to find the optimum line position prior to measuring in the Cross-Line Mode.

The Cross-Line Mode is mainly to display the rebars of the first and sec-

NOTE! Since the Area-Mode is used on rather large areas,

“Return to start on new line” should not be set.

ond layer arranged in a rectangular mesh. The measuring procedure including turning the probe cart and changing cursor position is the same

as for Multi-Line Mode. In fact it is a Multi-Line scanning in X- and Y-

The measuring procedure including turning the probe cart and changing

cursor position is the same as for Multi-Line Mode.

Figure 12 is a plan view, where the cover values are shown as rectangles

direction. In addition to the Multi-Line settings the grid width to define the

space among the Y-lines must be set. If “Align Rebar Positions” is set,

it will affect the Cross-Line views Cover and Diameter only. The view of

Signal Strength remains unchanged.

of different colors. Red means the cover is smaller than the minimum set.

© 2014 Proceq SA 17

Page 18

3.6 Review of Data

NOTE! Each View can be changed in a measuring mode in

order to add data. Tap on . Set the cursor to the new

starting position and continue with the measurements (see

“3.5 Measurement Modes and Storage of Data”). All data will

be stored in the reopened file.

Measured data can be displayed in six different views: Snapshot,

Statistics, Single-Line, Multi-Line, Area-Scan and Cross-Line View. All

the settings stored with the measurements can be changed afterwards.

The views will change accordingly. To store the measuring series with the

changes tap

To change from SX- to SY-scanning tap on ,vice versa tap on

Figure 13: Screen of Cross-Line Mode

NOTE! By changing the setting “Line Height” or Grid

Width”during the measurements the height or width of all

lines including the ones already measured will change and

hence, also the line positions. Change the line height or

Snapshot View

The Snapshot View can be displayed if at least one diameter was measured and stored in one of the measurement Modes.

The cover values are shown as vertical bars to scale and the diameter as

a figure, both in the unit set. The Minimum Cover is not displayed in the

Snapshot View.

width only if it was previously wrongly set.

To show the rebars of the first layer above the ones of the second layer,

scan first the second layer in X-direction.

Alternatively the diameter or the cover of the rebars can be displayed like

for the Multi-Line Mode, thus for rebars running in X- and Y direction.

In the Cross-Line View the signal strength spectrum can be seen in addition to the cover and diameter, thus for both (SX- and SY) scanning

directions, see ”3.6 Review of Data”.

In the Snapshot View the data are shown in a chronological sequence

from left to right. Therefore in the Cross-Line Mode you should collect the

complete data of one layer prior to change the scanning direction from

SX to SY or vice versa.

Figure 14: Snapshot View

18 © 2014 Proceq SA

7

. To return to the initial settings tap 8 .

PM-600 PM-630 PM-650

Page 19

Statistics View

PM-600 PM-630 PM-650

The Statistics View can be displayed for measurements done and stored

in one of the measurement Modes. It shows the statistical calculation of

the cover values measured.

For measurements with the Cross-Line Mode the statistical evaluation of

the cover readings is done for each layer independently. Hence there is a

Statistical View each for the scanning in the X- and Y-direction.

NOTE! In practice only the cover values and statistical evaluation of the 1st layer rebars (closer to the surface) is of interest.

On the horizontal axis the cover values in the unit set are displayed. The

vertical bars show the percentage of the respective cover values measured and stored. The vertical cursor bar can be moved to any cover value.

The figure on the left of the cursor bar shows the percentage of measured

cover values smaller than the cursor position. The value on the right shows

percentage of measured cover values larger than the cursor position. The

cover value is displayed at the bottom of the cursor bar and at the top the

percentage of measured covers for that cover is shown. Minimum required

cover is shown as a vertical dotted line in red (if set). Covers below the minimum are shown as red bars, covers above the minimum as yellow bars.

There are two different Statistics Views, the Normal (see Figure 15) and

the DBV-Evaluation (see Figure 16). Tap on the statistical values windows to switch from Normal to DBV.

Statistics values box “Normal” showing Median, Mean, Number of covers measured, lowest/

highest, Standard Deviation.

Change from X- to Y-direction view (for Cross-Line Mode data only) by tapping on / .

The actual window is shown on top right (either of scan direction SX or SY)

Figure 15: Statistics View Normal

The DBV-Evaluation is an evaluation of the cover readings according

to the German Concrete and Construction Association DBV (Deutscher

Beton- und Bautechnik Verein). It is also recommended by RILEM.

The DBV-Evaluation requires at least 20 cover readings. The distribution

function F(c

calculated. The c(x%)–values are displayed in green when the measuring

) as well as the threshold values c(5 %) and c(10 %) are

min

series is accepted, respectively in red if not.

19 © 2014 Proceq SA

Page 20

Statistics values box DBV:

Above the measuring series is accepted, below not.

Cover values above the calculated upper

boundary are not considered and shown as

bars with a yellow frame only (see on the right

side bars at cover values 17 mm, 18 mm and

19 mm).

Figure 16: Statistics Views DBV-Evaluation

For more details of the DBV-Evaluation please refer to the Info sheet

“Statistics according to DBV-Evaluation” available as pdf-file on the Profometer Touchscreen under Information/Documents and in the download

section of www.proceq.com.

Single-Line View

PM-630 PM-650

The Single-Line View can be displayed if measurements have been

done and stored in the Single-Line, Multi-Line or Cross-Line Mode (not

from Area-Scan Mode). It shows the rebar positions in a cross section.

The rebars are shown to scale depending on the diameter set. To show

them as a circle zoom the horizontal and vertical axis to the same scale.

However, for measurements over a long distance, like in a tunnel the

scale of the horizontal axis will be much smaller and the rebars shown

as vertical bars.

Figure 17: Single-Line View with cover curve

Figure 17 shows a Single-Line View with Metric Unit, Minimum Cover

(dotted horizontal line in red) and Cover Curve (dotted curve in yellow).

In case a diameter was measured its value is shown in blue above the

rebar in the unit set. In case the diameter was manually set it is shown

in orange.

Figure 18 shows a Single-Line with the Signal Strength Curve (dotted

curve in yellow) set. The vertical axis shows the signal strength; hence

the Minimum Cover line is not shown.

© 2014 Proceq SA 20

Page 21

It is a Single-Line View from measurements done in the Multi-Line View,

because at position

10

on

to display the Single-Line View of the next row.

10

the 1 refers to the measuring row displayed. Tap

Tap to switch among

different views.

Multi-Line View

PM-630 PM-650

The Multi-Lline View can be displayed only if measurements have been

done and stored in the Multi-Line or Area-Scan Mode. It is a plan view, in

most cases of the first layer rebars. A Multi-Line View of the second layer

– main layer in columns and girders – may also be of interest.

Figure 18: Single-Line View with Signal Strength Curve

Tap to switch among

different views.

The spacing among the rebars as well as the distance from the start line

to the first rebar and from the last rebar to the end line are displayed

as figures in the unit set, but only if the spacing on the screen is large

enough. If not shown zoom in until the figures appear.

Figure 19: Multi-Line View with cover values displayed

For more details like changing a diameter refer to Single-Line Mode in

chapter “3.5 Measurement Modes and Storage of Data”. To set a new

diameter you may have to measure it first at the particular location of the

structure in the Locating Mode and set it manually.

Tap to switch among

different views.

Figure 20: Multi-Line View with diameter values displayed (if measured)

21 © 2014 Proceq SA

Page 22

To sharpen the

color spectrum set

“Sharpen”

By changing the

O- and G-slider

positions the color

spectrum can be

changed (see CrossLine View).

Tap to switch among

different views.

Figure 21: Multi-Line View with Signal Strength color spectrum

Area-Scan View

PM-630 PM-650

The Area-Scan View is in fact a simplified Multi-Line View which only

shows the lowest cover values in a predefined grid. It is mainly used in

combination with potential field measurements; e. g. combined with Canin+ measurements.

Figure 23: Area-Scan View (zoomed to show X- and Y-axis in the same

scale)

Cross-Line View

PM-650

The Cross-Line View can be displayed only if measurements have been

done and stored in the Cross-Line Mode. It is a plan view of the first and

second layer rebars.

Tap to switch among

different views.

Figure 22: Area-Scan View (X- and Y-axis with different scale)

© 2014 Proceq SA 22

Page 23

Tap to switch among

different views.

Two diameters and two NRCspacings (if set) are shown.

Left of / it’s the value of the

SX (scanning in X-direction

of the rebars running in

Y-direction), right of / it’s the

value of the SY (scanning

in Y-direction of the rebars

running in X-direction).

Either cover, diameter or

signal strength spectrum is

displayed.

Tap to switch among

different views.

Three demo files are stored on the Profometer PM-6 Touchscreen in the

explorer under Demo Files and the document “Profometer PM-650 Demo

Files Tutorial.pdf” under Information\Documents.

Try out different slider positions to get familiarized with the display of the

signal strength color spectrum, e. g. the extreme positions:

O- and G-slider lowest position:

Full color spectrum, full Signal

Strength range (of actual measurements)

O- and G-slider highest position:

Full color spectrum, highest

Signal Strength (shallower rebars) only

O- highest, G-slider lowest position:

Blue/violet only, highest Signal

Strength (shallower rebars) only

O- lowest, G-slider highest position:

Only grey color displayed, Signal Strength beyond actual one

To sharpen the color spectrum set “Sharpen”.

Tap on

to change the global diameter of the active layer (SX or SY)

Figure 24: Cross-Line Views: Cover, Diameter, Signal Strength

In the signal strength spectrum view two sliders are shown on the right.

• With the O-slider (Offset) the signal strength range is set (from full

actual signal strength range to higher strength only).

• With the G-slider (Gain) the signal strength resolution is set. The

signal strength is accordingly displayed in colors from full color

spectrum to part of it only, e. g. blue to violet only.

23 © 2014 Proceq SA

Page 24

3.7 Practical Hints

Effect of Setting Incorrect Bar Diameter

The accuracy of the cover measurement is also

the correct bar diameter.

The following chart gives an estimation of the error of the cover reading

for different rebar sizes

if

a default size of 16mm

depend

/ #5

ent on setting

is

set.

NOTE! Diameter can be determined for rebars with cover not

exceeding 80 % of the standard range (63 mm, 2.50 inch).

NOTE! The correct diameter can be set any time prior to

and after storage of data, see “3.5 Measurement Modes and

Storage of Data”.

[mm]

[inch]

Ø 6 mm

# 2

Ø 8 mm

# 3

Ø 12 mm

# 4

# 5

Ø 16 mm

# 6

Ø 20 mm

range

Large range

Ø 26 mm

Ø 34 mm

# 8

Ø 40 mm

[mm]

[inch]

# 11

# 12

#5 set.

Error of Cover values

Standard range

Spot probe

Real Cover

Figure 25: Error of cover measurement with diameter 16mm /

Factors Affecting the Diameter Measurement

Two factors affect the determination of the rebar diameter. One is the

cover depth. The second is the spacing between neighboring bars. For

accurate determination of the diameter

must be greater than

ence to

the

MC

the

14

limits shown in the drawing below with refer-

15

/

.

, the

spacing between the rebars

MC

14/15

S

>75 mm

>1.5 ”

S

1

1

S

min. 150 mm / 6 inch

2

: 130 mm / 5.20 inch without Neighboring rebar correction

S

1

50 mm / 2.00 inch with Neighboring rebar correction

(see “3.3 Settings”)

Figure 26: Minimum rebar spacings for correct readings

Rebar Orientation

The strongest signal results when the Center Line (CL) of the probe is parallel to a bar. The CL

axis of the probe. This property is used to help determine the orientation of

the rebars (see Locating Mode in “3.5 Measurement Modes and Storage

of Data”).

16

of the Profometer PM-6 probe is the longitudinal

Welded Meshes

The instrument cannot detect whether the rebars are welded to one another or connected with binding wires. The two reinforcement types with

the same dimensions however create different signals.

The setting of the bar diameter must be slightly higher than the actual

© 2014 Proceq SA 24

Page 25

diameter of the mesh rebar. The input depends on the bar diameter and

on the mesh width. This input value should be determined by means of a

test measurement on an open system with specific rebar mesh wire arrangements. Measure on each arrangement with different covers to find

out the diameter setting at which the correct cover is indicated.

Welded reinforing mesh

a

1

[mm]

100

150

a2

[mm]

100

150

current d

[mm]

5

6

d to be set

[mm]

8

7

Figure 27: Examples for diameter settings at welded meshes to measure

correct cover values

NOTE! The “Standard Range” must be selected. With the

“Large Range” or “Spot Range” selected, locating of the

rebars may be completely wrong.

Diameter Measurements on welded Reinforcement Meshes

In most cases a diameter can be measured but the displayed value is far

too large and cannot be used. The only way to determine the diameter is

by an inspection hole.

Measure Rebar Diameter

In case the rebar diameter is not known, the Profometer PM-6 can accurately determine the diameter of a rebar under certain conditions.

NOTE! The Determination of the rebar diameter with Profometer PM-6 is limited to a maximum cover of about 63 mm

(2.50 inch).

The tutorial chapter on the pulse induction principle describes the limitations of the technology and clearly outlines the conditions whereby accurate readings of rebar diameter CANNOT be made if there is too much

interference from neighboring rebars or other metallic objects within the

sphere of influence.

NOTE! In any case, it is advisable to expose at least one first

layer rebar of each rebar arrangement to measure the real diameter. The obtained diameter values can then be compared

and if necessary corrected with the measured real diameter.

Step 1

Step 2

Step 3

Step 4

Locate and mark a rebar grid of the first and second layer

rebars as described under Locating Mode in “3.5 Measurement Modes and Storage of Data”.

Select one rebar that has the largest spacing from neighboring rebars.

Use a ruler and confirm that the spacing is at least as indicated in Figure 26. If not, redo Steps 1 and 2 until a rebar

is located with the required spacing to a neighboring rebar.

15

Place the MC

14

or

of the Profometer PM-6 over the

rebar at the centerline of the rebars running crosswise to the

rebar under test and measure the diameter.

25 © 2014 Proceq SA

Page 26

CL

16

Midpoint line

MC (SLA)

Correct probe position

indication on display

Line-Scanning on Different Rebar Arrangements

Single-Line, Multi-Line and Area-Scanning are mainly done to measure

and show the cover values along a long line, respectively on a large area.

Ideal: Both

rectangles

14

full and

green

However, for accurate cover readings the diameter must be measured

first, thus on each different rebar arrangement. The measured diameter is

to be set prior to scanning the cover. Therefore it is advisable to open for

each area of different rebar arrangement a separate test file and to scan

over rebars only with the same measured rebar diameter.

Figure 28: Correct Probe positioning for diameter measurements

The diameter displayed for the settings “Metric”, “Imperial” and “Japanese” are shown in Appendix A1.

NOTE! When measuring a diameter on rather old structures

set the unit “Metric” and convert the displayed diameter from

Millimeter to the “Imperial” or “Japanese” bar size if neces-

upper part single rebars

lower part overlapping rebars

For example: To scan a wall of a cut and

cover tunnel section at least two test files

must be opened. One for the lower part

with overlapping vertical rebars with a

larger diameter measured, one on the upper part with single vertical rebars, (see

Figure 31).

sary.

Rebar diameter determination in rather thin slabs:

In thin slabs the rebar mesh of the opposite side may be too close and

will affect the rebar diameter measurements. In those cases the measured diameter is too high.

Figure 30: Line scanning on different rebar arrangements

In case the diameter cannot be measured the re-

Real Diameter D

r

D

Ds= Set Diameter

s

Figure 31: Measured diameter D

C

Ds ~ 1.4 D

at overlapping areas

s

bars should be exposed

in one area. The diameter

r

to be set is in general 1.4

times the real diameter of

a single bar.

Figure 29: Rebar diameter measurements on thin slab

© 2014 Proceq SA 26

Page 27

Scanning on Small Surfaces and Near to Edges

On small areas and near edges you may have to place a cover sheet for

scanning with the probe cart.

The cut and insert functions are useful in case a file is/files are stored in

the wrong folder or a specific folder was only created after the files have

been stored in the main level.

Below the subfolder “Inclined Rebar” is open

For correct cover measurements the sheet

thickness must be set as Cover Offset value.

Figure 32: Scanning near to the edge

In this case no Cover Offset value must be set

• Tap on the first with the name “..” to go back to the upper folder

Download measuring files to an USB stick:

4. Explorer Document Handling

From the main menu select Explorer to review saved files.

• Connect the USB-stick to the USB Device plug on the left side of

the Profometer Touchscreen

If folders have been created as suggested in the first note of “3.5 Measurement Modes and Storage of Data” the folders are shown in the first

lines from top (see following figure).

Name of folder (in the main level only \ is shown)

• Tap on

to access the files stored in it.

• To create a new folder tap on

• To cut/copy a file/files tap on

and tap on /

• To insert/copy a file tap on

• Tap on a saved file to open it.

• Return to the Explorer list by

pressing the back button.

• To delete a file tap in the

check box to the left of the

file and delete it.

, write the name and tap on

to the left of the file(s) to become

to open the folder and tap on

• Click on the checkbox of each file to be downloaded and click on

• The name of the downloaded file is “PM-Product version_Year_

Month_Day_Time”

Upload pdf-files from an USB-stick:

• Create the folder “PQ-Import” in the main directory of the USB-stick

(not as a subfolder in another folder) and fill it with all the pdf-files to be

uploaded to the Profometer Touchscreen

• Go to Information/Documents

• Connect the USB-stick to the USB Device plug on the left side of the

Profometer Touchscreen

• Click on

and confirm with click on

The uploaded pdf-files appear on the bottom of the document list.

27 © 2014 Proceq SA

Page 28

5. Ordering Information

5.1 Units

Part No. Description

392 10 001 Profometer PM-600 consisting of Profometer

Touchscreen, universal probe with probe cart, probe

cable 1.5 m (5 ft), power supply, USB cable, chalk,

DVD with software, documentation, carrying strap and

carrying case

392 20 001 Profometer PM-630 consisting of Profometer

Touchscreen, universal probe with probe cart, probe

cable 1.5 m (5 ft), power supply, USB cable, chalk,

DVD with software, documentation, carrying strap and

carrying case

392 30 001 Profometer PM-650 consisting of Profometer

Touchscreen, universal probe with probe cart, probe

cable 1.5 m (5 ft), power supply, USB cable, chalk,

DVD with software, documentation, carrying strap and

carrying case

5.2 Upgrades

Part No. Description

392 00 115 Software Upgrade from Profometer PM-600 to PM-630

392 00 116 Software Upgrade from Profometer PM-630 to PM-650

5.3 Parts and Accessories

Part No. Description

392 40 010 Profometer Touchscreen

392 40 020 Profometer PM-6 Universal probe

392 40 030 Profometer PM-6 Scan cart complete

327 01 050 Profometer PM-6 Probe cable 1.5 m (5 ft)

392 40 040 Profometer PM-6 Telescopic extension rod 1.6 m (5.3 ft)

with probe cable 3 m (10 ft)

327 01 063 Profometer PM-6 Probe cable 3 m (10 ft)

327 01 068 Profometer PM-6 Probe cable 10 m (33 ft)

392 00 004S Profometer PM-6 Self-adhesive protective film for

probe (set of 3)

325 34 018S Chalk (set of 10)

327 01 045 Carrying strap complete

327 01 033 Battery complete

327 01 053 Quick charger

351 90 018 USB-cable 1.8 m (6 ft)

327 01 061 Power supply

711 10 013 Power supply cable USA 0.5 m (1.7 ft)

711 10 014 Power supply cable UK 0.5 m (1.7 ft)

711 10 015 Power supply cable EU 0.5 m (1.7 ft)

© 2014 Proceq SA 28

Page 29

6. Technical Specifications

Instrument

Cover Measuring Range Up to 185 mm (7.3 inch), see Figure 2

Cover Measuring Accuracy ± 1 to ± 4 mm (0.04 to 0.16 inch),

Measuring Resolution Depending on diameter and cover,

Path Measuring Accuracy

on smooth Surface

Diameter Measuring Range Cover up to 63 mm (2.50 inch), Diame-

Dia. Measuring Accuracy ± 1 mm (± # 1)

Display 7” colour display 800x480 pixels

Memory Internal 8 GB Flash memory

Regional Settings Metric and imperial units and multi-

Power Input 12 V +/-25 % / 1.5 A

Dimensions 250 x 162 x 62 mm

Weight (of display device) About 1525 g (incl. Battery)

Battery Lithium Polymer, 3.6 V, 14.0 Ah

Battery Lifetime > 8h (in standard operating mode)

Max. Altitude 3000 m above sea level

Humidity < 95 % RH, non condensing

Operating Temperature 0°C – 30°C (Charging*, instrument on)

Environment Suitable for indoor & outdoor use

see Figure 2

see Figure 3

± 3 mm (0.12 inch) + 0.5 % to 1.0 % of

measured length

ter up to 40 mm (# 12)

language supported

0°C – 40°C (Charging*, instrument off)

-10°C – 50°C (Non-charging)

IP Classification Touchscreen IP54, Probe IP67

Pollution Degree 2

Installation Category 2

Standards and Guidelines BS 1881 part 204, Din 1045,

SN 505262, DGZfP-guideline B2,

CE certification

*charging equipment is for indoor use only (no IP classification)

Power Supply

Model HK-AH-120A500-DH

Input 100-240 V / 1.6 A / 50/60 Hz

Output 12 V DC / 5 A

Max. Altitude 3000 m above sea level

Humidity < 95%

Operating Temperature 0°C - 40°C

Environment Indoor use only

Pollution Degree 2

Installation Category 2

29 © 2014 Proceq SA

Page 30

7. Maintenance and Support

8. PM-Link Software

7.1 Maintenance and Cleaning

To guarantee consistent, reliable and accurate measurements, the instru

ment should be calibrated on a yearly basis. The customer may however,

determine the service interval based on his or her own experience and

usage.

Do not immerse the instrument in water or other fluids. Keep the housing

clean at all times. Wipe off contamination using a moist and soft cloth.

Do not use any cleaning agents or solvents. Do not open the housing of

the instrument yourself.

7.2 Support Concept

Proceq is committed to providing a complete support service for this

instrument by means of our global service and support facilities. It is

recommended that the user register the product on www.proceq.com

to obtain the latest on available updates and other valuable information.

7.3 Standard Warranty and Extended Warranty

The standard warranty covers the electronic portion of the instrument for

24 months and the me chanical portion of the instrument for 6 months. An

extended warranty for one, two or three years for the electronic portion

of the instrument may be purchased up to 90 days of date of purchase.

7.4 Disposal

Disposal of electric appliances together with household waste is not

permissible. In observance of European Directives 2002/96/EC,

2006/66/EC and 2012/19/EC on waste, electrical and electronic

equipment and its implementation, in accordance with national law,

electric tools and batteries that have reached the end of their life

must be collected separately and returned to an environmentally

compatible recycling facility.

8.1 Starting PM-Link

Locate the file “PM-Link Setup.exe” on your computer or

on the DVD and click on it. Follow the instructions on the

screen.

Make sure that the “Launch USB Driver install”

tick is selected.

The USB driver installs a virtual com port which

is needed to communicate with the Profometer

Touchscreen Unit.

Double click on the PM-Link Icon on your desktop or

start the Link via the start menu.

The Link starts with a blank list.

Application Settings

The menu item “File – Application settings” allows the user to select the

language and the date and time format to be used.

© 2014 Proceq SA 30

Page 31

Connecting to a Profometer Touchscreen Unit

Connect the Profometer Touchscreen Unit to a USB port, then select

to download data from the Profometer Touchscreen Unit.

The following window will be displayed: Select “USB” as the communication type. Click on “Next >”.

When a Profometer Unit has been found its details will be displayed on

screen. Click on the “Finish” button to establish the connection

Click on “Next >”. When a Profometer

Touchscreen Unit has been found its details will be displayed on screen. Click

on the “Finish” button to establish the

connection.

Measurement files stored on the device will be displayed as shown on the left.

Select one or more measurements and click

“Download”.

Viewing Data

The selected measurements on your Profometer Touchscreen Unit will be

displayed on the screen:

• Click on a folder

to access the files

stored in it or to

paste-in other

files.

• Click on the double arrow icon in the first column to see more details.

By clicking on the respective colored words one can switch:

• Among Views Snapshot, Statistics, Single-Line, Multi-Line, Area-

Scan and Cross-Line View.

• In Statistics View between Scan-X and Scan-Y (when measurements

done in the Cross-Line Mode)

• In Single-Line View between Scan-X and Scan-Y (when measured in

Cross-Line Mode) as well as among lines x and between Cover Curve

on/off. By setting the cursor on a rebar, the rebar number, cover, distance

and diameter appear.

• In Multi-Line and Cross-Line Views among Display Measurement Cover,

Diameter and Signal Strength. When Signal Strength is set, you may

click on Sharpen and adjust the color spectrum with the O- and G- sliders.

• Between Statistics Normal and DBV.

Settings can be changed except the ones used for measurements like

Measuring Ranges, Display Inclined Rebars, Return to start on new Line,

Line Height and Grid Width.

31 © 2014 Proceq SA

Page 32

By right click with the cursor in a

marked cell of the column “unit”

the unit can be changed for the

marked measurements.

Sample of View with very large numbers of measurements

By holding the cursor on

software and probe is displayed.

NOTE! Click on “Add” to attach a comment to the object.

Sample of Cross-Line View, Cover

the information about, hardware,

To see more data,

drag the slider to the

right.

Adjusting Settings

The settings including Diameter can only be adjusted in the Profometer

Touchscreen. To change settings you may store the objects with another name on the PC. Then open the relevant objects again on the Touchscreen to change settings and transfer the objects with the changed

settings to the PC.

To paste or delete measurements select one or more rows then right

click the mouse and choose one of these options: “Cut/ Copy” or “Delete”. To paste in another folder click on it and right click paste.

© 2014 Proceq SA 32

Adjusting date and time

Right click in the “Date & Time”

column.

Page 33

The time will be adjusted for the selected series only.

In “Data Logging” mode it is the date and time at which the measurement

was made.

8.2 Exporting Data

PM-Link allows you to export selected objects or the entire project for

use in third party programs. Click on the measurement object you wish to

export. It will be highlighted as shown.

Click on the “Export as CSV file(s)” icon. The data are

exported as a Microsoft Office Excel comma separated

file or files. The export options may be chosen in the following window:

Set the detailed Cover data to export, if you wish so (data may be huge!)

Click on the “Export as graphic” icon to open the following

window which allows the various export options to be chosen.

In both cases, the preview window shows the effects of the current output selection.

Prior to export data set the appropriate

• View: “Snapshot”, Statistics”, Single-Line”, Multi-Line”, “AreaScan” or “Cross-Line”

• Unit: “Metric”, “Metric Japanese”, “Imperial” or “Imperial Diameter,

Metric Cover and Distance”

• Curve: either “None” or “Cover Curve”

NOTE! In Multi-Line View one can switch between Cover and

Diameter, in Statitstics between Normal and DBV.

NOTE! In normal cases the Curve should be set to “None”,

especially when exporting huge files to an Excel-sheet because the cover and distance of the curve are copied each in

one cell, thus in distance intervals of 2.7 mm only.

33 © 2014 Proceq SA

Page 34

• Set the appropriate View, Display Measurements, Display Curve.

• Finish by clicking on export to select the file location, name the file

and in the case of a graphical output to set the output graphic format: .png, .bmp or .jpg.

Sample of an exported CVS-file

All Data (starting with PM-Link Version to Statistic Data up to Cover Data)

are written in the first columns starting with column A.

The Cover data of X- and Y-scan measured in the Cross-Line Mode are

shown in different blocks.

The diameters set in the Single-Line Mode are not shown.

Sample of an exported Graphics-file

Cross-Line View Signal Strength Sharpen On

© 2014 Proceq SA 34

Page 35

8.3 Deleting Data

The menu item “Edit – Delete” allows you to delete one or more selected

series from the downloaded data.

NOTE! This does not delete data from the Profometer Touchscreen Unit, only data in the current project.

The menu item “Edit – Select all”, allows the user to select all series in the

project for deletion, exporting etc.

8.4 Further Functions

The following menu items are available via the icons at the top of the

screen:

“PQUpgrade” icon - Allows you to upgrade your firmware via

the internet or from local files.

“Open project” icon – Allows you to open a previously saved

.pqm project.

“Save project” icon – Allows you to save the current project.

“Print” icon – Allows you to print out the project. You may

select in the printer dialog, if you want to print out all of the

data or selected readings only.

9. Appendices

9.1 Appendix A1: Rebar Diameters

Following rebar diameters can be selected:

Metric Imperial Japanese

Bar

size

Diam.

(mm)

6 6 #2 0.250 6 6 6

7 7 #3 0.375 10 9 9

8 8 #4 0.500 13 10 10

9 9 #5 0.625 16 13 13

10 10 #6 0.750 19 16 16

11 11 #7 0.875 22 19 19

12 12 #8 1.000 25 22 22

13 13 #9 1.125 29 25 25

14 14 #10 1.250 32 29 29

... ... #11 1.375 35 32 32

35 35 #12 1.500 38 35 35

36 36 38 38

37 37

38 38

39 39

40 40

Bar size Diam.

(inch)

Diam

(mm)

Bar

size

Diam.

(mm)

35 © 2014 Proceq SA

Page 36

9.2 Appendix A2: Neighboring Bar Correction

Following rebar spacings can be selected:

Metric, Imperial cm,

Japanese

5 cm 2.0

6 cm 2.4

7 cm 2.8

8 cm 3.2

9 cm 3.6

10 cm 4.0

11 cm 4.4

12 cm 4.8

13 cm 5.2

Imperial

inch

inch

inch

inch

inch

inch

inch

inch

inch

inch

9.3 Appendix A3: Minimum / Maximum Cover

Following covers can be selected:

Metric,

mm,

up to 190 mm up to 7.48 inch

Imperial

Japanese

10 mm 0.40 inch

11 mm 0.44 inch

... mm ... inch

141 mm 5.52 inch

142 mm 5.56 inch

Imperial

inch

© 2014 Proceq SA 36

Page 37

Proceq Europe

Ringstrasse 2

CH-8603 Schwerzenbach

Phone +41-43-355 38 00

Fax +41-43-355 38 12

info-europe@proceq.com

Proceq UK Ltd.

Bedford i-lab, Priory Business Park

Stannard Way

Bedford MK44 3RZ

United Kingdom

Phone +44-12-3483-4515

info-uk@proceq.com

Proceq USA, Inc.

117 Corporation Drive

Aliquippa, PA 15001

Phone +1-724-512-0330

Fax +1-724-512-0331

info-usa@proceq.com

Proceq Asia Pte Ltd

12 New Industrial Road

#02-02A Morningstar Centre

Singapore 536202

Phone +65-6382-3966

Fax +65-6382-3307

info-asia@proceq.com

Proceq Rus LLC

Ul. Optikov 4

korp. 2, lit. A, Office 410

197374 St. Petersburg

Russia

Phone/Fax + 7 812 448 35 00

info-russia@proceq.com

Proceq Middle East

P. O. Box 8365, SAIF Zone,

Sharjah, United Arab Emirates

Phone +971-6-557-8505

Fax +971-6-557-8606

info-middleeast@proceq.com

Proceq SAO Ltd.

South American Operations

Alameda Jaú, 1905, cj 54

Jardim Paulista, São Paulo

Brasil Cep. 01420-007

Phone +55 11 3083 38 89

info-southamerica@proceq.com

Proceq China

Unit B, 19th Floor

Five Continent International Mansion, No. 807

Zhao Jia Bang Road

Shanghai 200032

Phone +86 21-63177479

Fax +86 21 63175015

info-china@proceq.com

Subject to change. Copyright © 2014 by Proceq SA, Schwerzenbach. All rights reserved.

820 392 01E ver 02 2015

Made in Switzerland

Loading...

Loading...