Page 1

Page 2

Bedienungsanleitung

Operating Instructions

Mode d’emploi

Bewehrungs-Suchsystem

Rebar Detection System

Système de détection d’armatures

Modell S / SCANLOG

Page 3

Proceq SA

Ringstrasse 2

CH-8603 Schwerzenbach

Switzerland

Tel. +41-43-355-38-00

Fax +41-43-355-38-12

info-europe@proceq.com

Proceq USA, Inc.

117 Corporation Drive

Aliquippa, PA 15001

USA

Phone +1-724-512-0330

Fax +1-724-512-0331

info-usa@proceq.com

Proceq Asia Pte Ltd

12 New Industrial Road #02-02A

Singapore 536202

Republic of Singapore

Phone +65-6382-3966

Fax +65-6382-3307

info-asia@proceq.com

www.proceq.com

Subject to change without notice

.

Copyright © 2007 Proceq SA Switzerland 820 390 01 ver 05 2007

Page 4

Page 5

English

Page 6

Page 7

English

© 2007 Proceq SA Contents 1

Contents

1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Information . . . . . . . . . . . . . . . . . . . . . . . 2

Liability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Regulations. . . . . . . . . . . . . . . . . . . . . . . . 2

Standards and Regulations Applied. . . . . . . . . . . 2

2 Product Description

. . . . . . . . . . . . . . . . . . . . . . 3

Model S (Basic Unit) . . . . . . . . . . . . . . . . . . . . . . 3

Model SCANLOG. . . . . . . . . . . . . . . . . . . . . . . . . 3

Universal Probe . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ScanCar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Startup

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connecting the Components . . . . . . . . . . . . . . . . 6

Putting the Indicating device into Operation . . . . 6

4 Settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bar Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Object Number. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Limit Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Corrections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Basic Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Measure with Statistics

. . . . . . . . . . . . . . . . . . . . 9

Scanning Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Measure with Grid . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Measuring Process

. . . . . . . . . . . . . . . . . . . . . . 9

Measure with Statistics . . . . . . . . . . . . . . . . . . . . 9

Detecting Insufficient Concrete Cover . . . . . . . . . 12

Determining the Bar Diameter . . . . . . . . . . . . . . . 13

Making Reinforcement Visible with CyberScan . . 14

Measure with Grid . . . . . . . . . . . . . . . . . . . . . . . . 17

Data Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Maintenance and Storage

. . . . . . . . . . . . . . . . . 22

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Performance Check . . . . . . . . . . . . . . . . . . . . . . . 22

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 Data

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Form of Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . 23

Accessories / Spare Parts . . . . . . . . . . . . . . . . . . 24

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page 8

2 Safety © 2007 Proceq SA

1 Safety

1.1 General Information

1.1.1 Basic Information

The rebar locator complies with state-of-the-art technology and the recognized safety regulations.

Please read through these operating instructions carefully before initial startup.

1.1.2 Designated Use

The rebar locator is used for the non-destructive location

of rebars and for the measurement of concrete cover

and bar diameters.

1.2 Liability

Our «General Terms and Conditions of Sale and Delivery» apply in all cases. Warranty and liability claims

arising from personal injury and damage to property cannot be upheld if they are due to one or more of the following causes:

- Failure to use the rebar locator in accordance with its

designated use

- Incorrect startup and operation of the rebar locator

- Unauthorized structural modifications to the rebar

locator

- Serious damage resulting from the effects of foreign

bodies, accidents, vandalism and force majeure

1.3 Safety Regulations

1.3.1 Unauthorized Operators

Anyone who is not familiar with the operating instructions

must not use the rebar locator or must be supervised

when using it.

1.3.2 Safety Icons

The following icons are used in conjunction with all

important safety notes in these operating instructions.

Warning!

This note warns you about the risk of material

damage, financial loss and legal penalties

(e.g. loss of warranty rights, liability cases, etc.).

This denotes important information.

1.4 Standards and Regulations Applied

SIA 162 / DIN 1045 / DGZfP B2 / BS 1881: Part 204

Page 9

English

© 2007 Proceq SA Product Description 3

2 Product Description

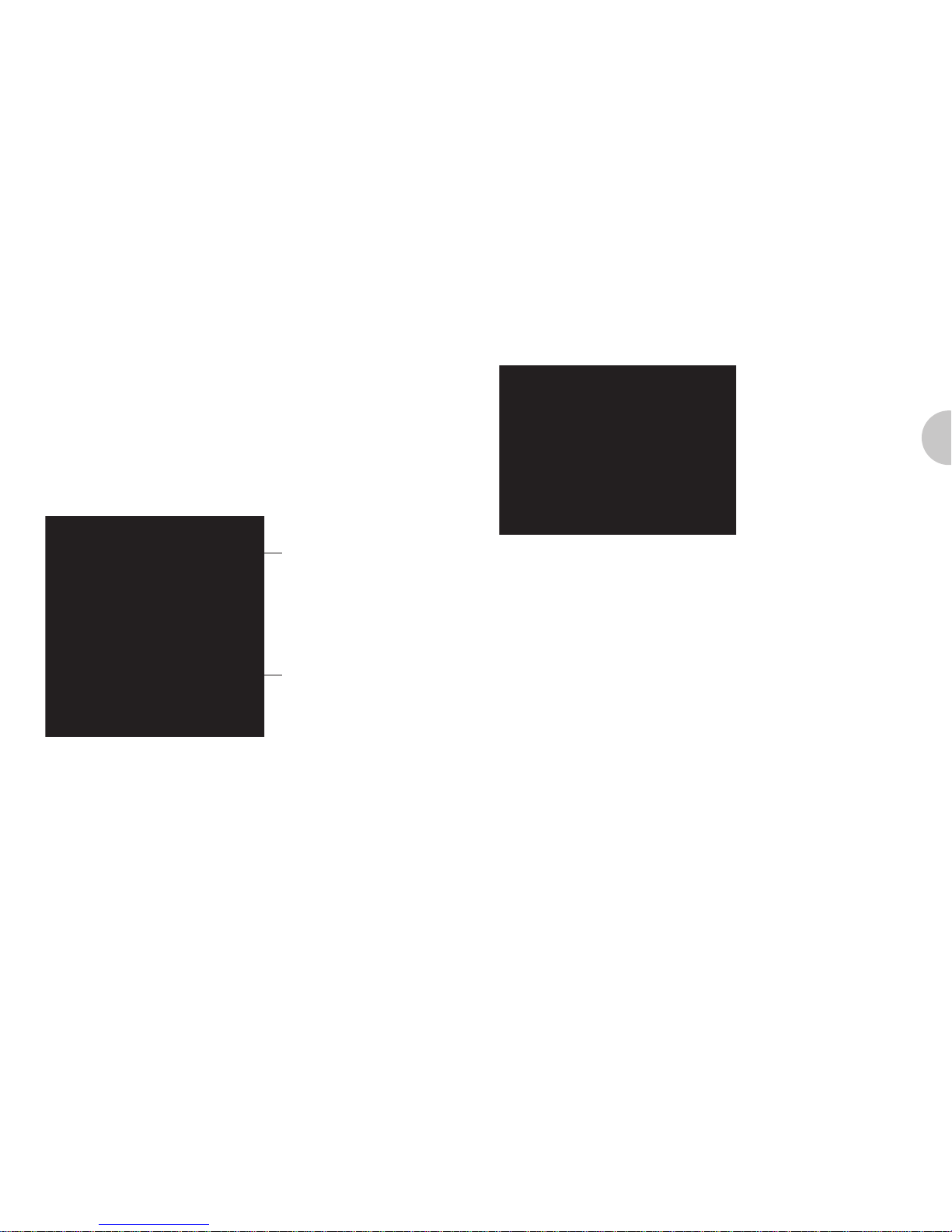

2.1 Model S (Basic Unit)

The PROFOMETER 5+ rebar locator is a lightweight,

compact device for the non-destructive location of rebars

and for the measurement of concrete cover and bar

diameters.

The measuring method is based on the eddy-current

principle with pulse-induction.

Indicating device

Universal probe

Fig. 2.1 Model S

The basic unit can perform the following functions:

- Locating rebars

- Measuring concrete covers

- Storing individual cover values and statistical

evaluation

- Determining the bar diameters

2.2 Model SCANLOG

Indicating device

ScanCar

Universal probe

Fig. 2.2 Model SCANLOG

The SCANLOG rebar locator is identical to model S and

comprises the following additional functions:

- «CyberScan» function for displaying the concrete cover

- «Measure with Grid» function for grey-scale display of

the concrete cover

- ScanCar probe carriage with integral path measuring

device for scanning the rebars

- Storage areas for «CyberScan» and «Measure with

Grid» objects

In the case of both models, the data can be printed

directly on a printer connected to the indicating device or

transferred to a PC.

Page 10

4 Product Description © 2007 Proceq SA

2.3 Universal Probe

2.3.1 Functioning

The universal probe is designed to function in relation to

the direction. This means it reacts most sensitively to the

rebars parallel to its longitudinal axis, and least sensitively to the ones at right angles to its longitudinal axis.

For this reason the probe should be positioned parallel to

the bars to be tested and moved over them sideways for

scanning.

The probe has both a small and a large measuring

range. Use the ← and → keys to switch over between

the two measuring ranges. The active measuring range

is displayed in the measuring display (see Fig. 5.1).

The large measuring range should only be used if the

concrete cover is larger than is shown in the intersection

point of the curves in Fig. 2.4. If the bar diameter is 16

mm, this applies for a cover of approx. 60 mm.

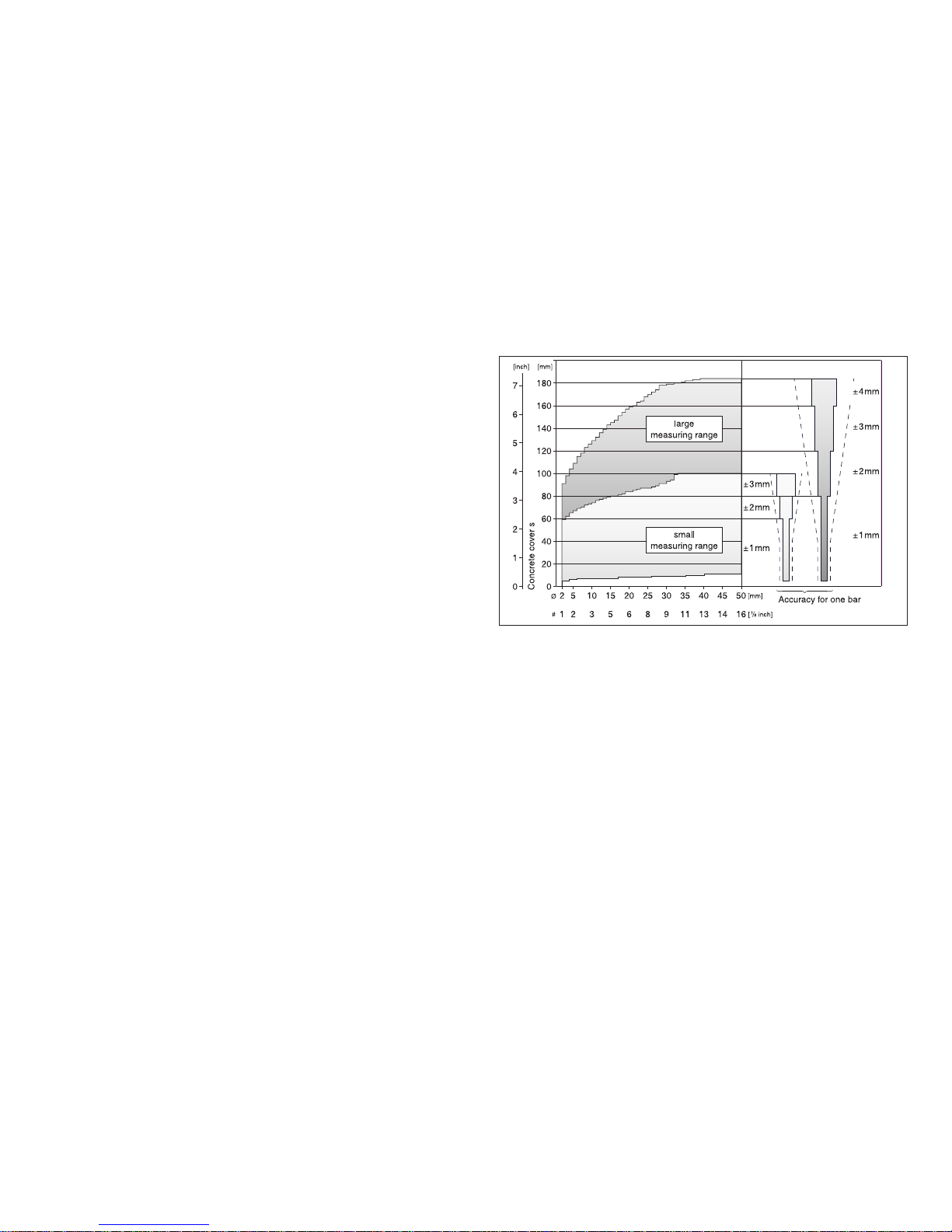

2.3.2 Measuring Ranges and Accuracy

Fig. 2.3 Measuring ranges and accuracy of the universal

probe

Key:

Ø : Bar diameter in mm

#: Bar diameter in «Bar size #»

---: Lowest accuracy limit required by the standard

BS 1881: Part 204: ±2 mm or ±5 %

PROFOMETER 5+ measures up to 50 % more accurately than required by this standard.

The size of the two measuring ranges of the universal

probe depends on the bar diameters. The accuracy of

the concrete cover indication refers to individual bars.

See also Fig. 2.4.

Page 11

English

© 2007 Proceq SA Product Description 5

2.3.3 Resolution

Fig. 2.4 Resolution

On concrete elements, measurements are often influenced by neighboring bars. For parallel bars in the same

layer, the diagram in Fig. 2.4 shows the smallest bar

spacings a at which rebars are still identifiable individually in relation to concrete cover s. For intersection points

of the bar spacing a and concrete cover s above the corresponding curve the current value indicates the approximate depth of the reinforcement level. For possibility for

correction, see «Corrections», page 7.

Example of bars in a position which can still be located:

Bar diameter d = 16 mm, concrete cover s = 55 mm and

smallest bar spacing a = 70 mm.

2.4 ScanCar

Fig. 2.5 ScanCar with integrated universal probe

For the SCANLOG model, the ScanCar is required to

perform the «CyberScan» and «Measure with Grid»

functions. For model S, it can be used as a carriage

without any other functions.

If the path measuring cable is connected, the

air gap of 4 mm between the probe and the

concrete surface is automatically corrected

when the concrete cover is displayed.

0 20

00

1

2

3

4

5

6

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

40 60 80 100 120 140 160 180 200

80 1 2

Bar diameter d

small

measuring range

large

measuring range

Ø 26

Ø 16

Ø 10

Ø 26

Ø 16

Ø 10

3 4 5 6 7

Bar spacing a

Concrete Cover s

[mm][inch]

[mm]

[inch]

Bar

diameter d

a

s

ScanCar, carriage with

integrated path measuring

device

Integrated universal probe

becomes mobile probe

Page 12

6 Startup © 2007 Proceq SA

3 Startup

3.1 Connecting the Components

• Connect the universal probe to input A.

• If you want to use the ScanCar probe carriage,

connect it to input B.

• If you use a headset, connect it to the socket marked

with the headset symbol.

3.2 Putting the Indicating device into

Operation

• Press the ON/OFF key.

The following data is briefly displayed:

- Instrument model (model S or SCANLOG)

- Instrument serial no.

- Installed software version

- Whether automatic self-test is O.K.

- The more or less black battery symbol indicates the

battery status

Then the measuring display of the previously measured

object appears (Fig. 5.1, Fig. 5. 7 and Fig. 5.13)

When the measuring display is visible the backlight of

the LCD can be turned on and off by pressing the ↑ key

for more than 2s.

If no display appears, replace the batteries.

4 Settings

The indicating device has a user menu navigation.

Please follow the instructions in the display fields.

• Press the MENU key to display the main menu:

Modell SCANLOG only

Select menu option

Call selected option

Call measuring display of

the selected function

Fig. 4.1 Main menu

4.1 Bar Diameter

Setting the bar size that exists on the structure makes a

good basic accuracy of the cover readings possible. The

suggested default size is 16mm or #5. The bar diameter

setting can be done in metric units and US bar size

numbers.

Metric System

The bar size can be increased in mm. This makes it

possible to set bar diameters according to different

Page 13

English

© 2007 Proceq SA Settings 7

standards. The instrument indicates concrete cover

depth and distances in [mm] and [m] respectively.

US System of Units

In this system the bar sizes must be set in numbers 01

to 16. The «bar size #» specifies the diameter in eights

of an inch. In this mode the instrument indicates cover

depth and distances in inches and feet.

Example: Bar size #5 corresponds to a diameter of 5/8”

(15.9mm).

• To switch from mm to inches press the MENU key and

subsequently select «Basic Setups» and «Unit»

4.2 Object Number

The measured values can be stored under object numbers.

The following number is set automatically as the first

digit of the six-figure object number according to the

measuring function:

- 1 for «Measure w. Statistics»

- 2 for «Scanning Bars»

- 3 for «Measure with Grid»

4.3 Limit Value

For description, please see under «Measure with

Statistics», page 9 and «Detecting Insufficient Concrete

Cover», page 12.

4.4 Corrections

Neighboring bar corrections

This mode is mainly used for determination of the bar

diameter in close spaced parallel bar arrangements.

There are structures where the bar spacing is smaller

than indicated in Tab. 5.2. When measuring these bars,

the displayed value of the concrete cover is too low and

the diameter value too high. In such instances, corrections can be made. This however only applies to the

parallel bars on both sides. The bars that are arranged

crosswise must have the minimum spacing shown in

Tab. 5.2.

• Enter the previously determined bar spacing. See

«Measure with Statistics», page 9, «Detecting Insufficient

Concrete Cover», page 12, «B. Determining diameters

with correction», page 14, «Making Reinforcement

Visible with CyberScan», page 14 and «Measure with

Grid», page 17.

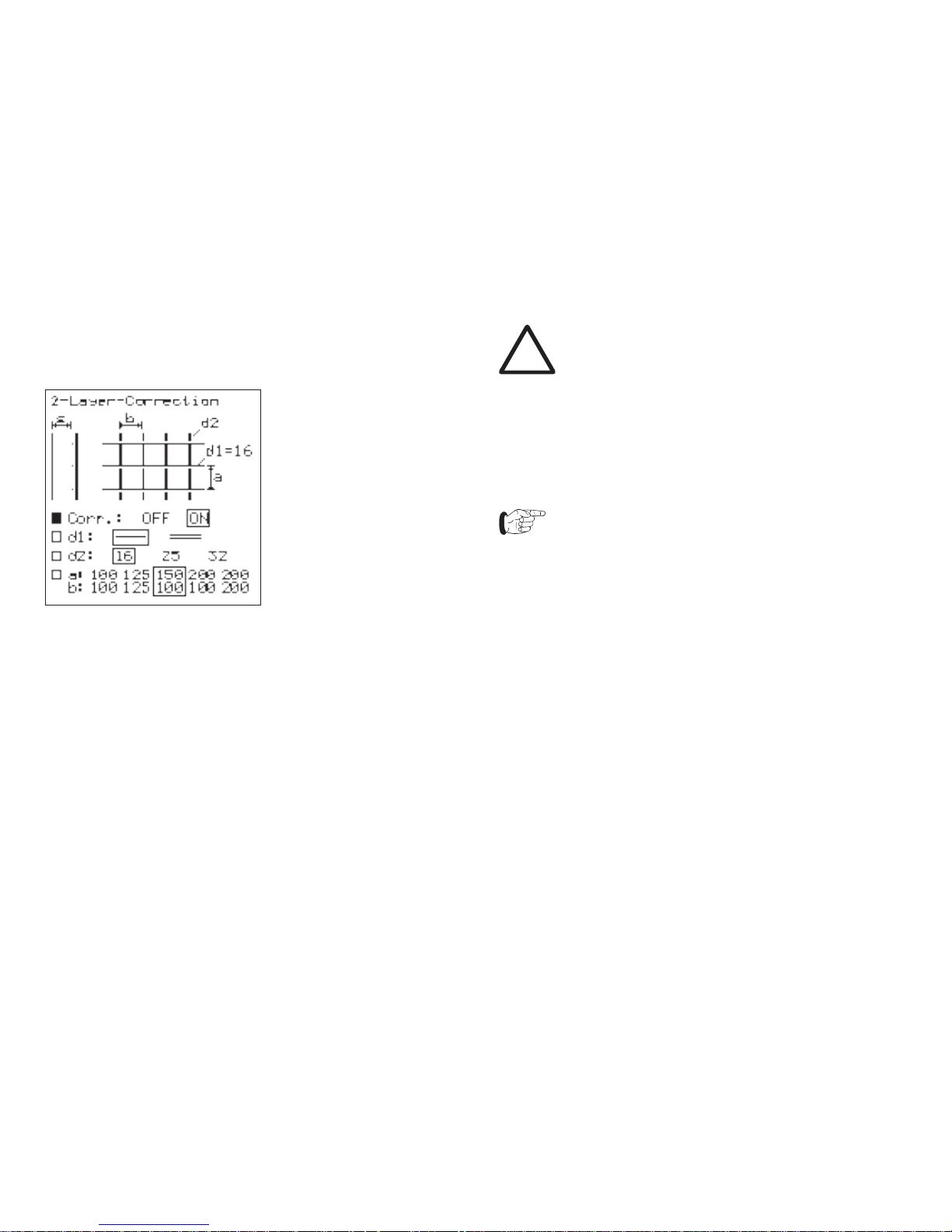

2-Layer-Correction

This mode is used for cover measurement in congested

standard orthogonal bar arrangements. A more accurate

cover reading can be reached by use of this correction.

The congested bars induce a too strong measuring

signal which can be corrected this way.

• Select the spacings a and b which you determined by

locating the bars. In some cases the bar diameters

cannot be measured by the PROFOMETER 5+ and

must be determined by removing the concrete. The

diameter setting is automatically selected as 16mm.

Page 14

8 Settings © 2007 Proceq SA

This mode can only be activated in measuring function

«Measurement with Statistics».

2-Layer-Correction

4.5 Language

The language of the display texts can be selected.

4.6 Basic Setups

The following settings are possible:

- Unit

If you choose «mm» the bar diameter setting can be

selected in mm and the results will be indicated in the

metric system. If you chose «inch» the bar diameter

setting can be made in bar size numbers and the

results are indicated in imperial units. Please refer also

to «Bar Diameter» on page 6.

Warning!

By changing the unit from mm to inch or vice

versa existing measured and stored values are

falsified. In order to avoid confusing results the

user must clear the memory after changing the

units.

The mode «2-Layer-Correction» can only be used for

metric units.

- Probe

When starting up the device for the first time,

the code no. engraved on the probe must be

entered in the submenu «Probe».

- Audible locating aid

(Short) beep tone selectable in two frequencies or

Variotone can be selected.

The remaining settings are described under the respective functions.

4.7 Data Output

For description, please see under «Data Output»,

page 20.

4.8 Measure with Statistics

For description, please see under «Measure with

Statistics», page 9.

Page 15

English

© 2007 Proceq SA Measuring Process 9

4.9 Scanning Bars

Model SCANLOG only

For description, please see under «Making Reinforcement Visible with CyberScan», page 14.

4.10 Measure with Grid

Model SCANLOG only

For description, please see under «Measure with Grid»,

page 17.

5 Measuring Process

5.1 Measure with Statistics

This function can be used to locate rebars, measure

concrete covers and determine bar diameters. The cover

values can be stored under object numbers.

5.1.1 Rebars Connected with Binding Wires

Settings

See also under «Settings», page 6.

• Enter the bar diameter.

If the bar diameter is unknown,

enter 16 mm.

• Enter the object number.

Limit value: To avoid confusions, set the limit value

to «0» during the measuring process. Enter the value

required for the building after completion of the series of

measurement. The percentage of the covers that are too

small will be displayed in the statistical evaluation. See

also «Detecting Insufficient Concrete Cover», page 12.

• Enter the desired audible locating aid («MENU» →

«Basic setups» → «Audible locating aid»): (Short) beep

tone or variotone.

• Enter the requested values under the menu option

«Corrections» → «Neighbouring Bar Correction» or «2 Layer-Correction» if the correction is required.

• Select the «Measure w. Statistics» function.

• Press the START/RESET key.

Page 16

10 Measuring Process © 2007 Proceq SA

The measuring display appears:

Preselected bar diameter

Bar spacing or limit value if set

Object number

Symbol for measuring range

Flow bar shows proximity of

probe to bar

Diameter if measured

Signal value

Intermediate storage of

concrete cover

Backlight switched on

Current cover, continously updated

Fig. 5.1 Measuring display «Statistics»

If required the backlight of the LCD can be switched on.

This can be done by pressing key ↑ for more than 2s.

RESET process

• Hold the probe in the air and press the START/RESET

key. A bar appears in the display that informs you on the

progress of the procedure. The probe shall not be moved

before the bar has disappeared and «0» is displayed.

• Please repeat this check procedure from time to time.

Locating the rebars and measuring the concrete cover

For locating the rebars, the diameter setting is not as

important as for measuring the cover.

In the case of double layer arrangements of

rebars, always start the location with the first

layer.

If the rebars of the first layer are too close to

each other, it is likely to be impossible to lo cate the bars of the second layer. See also

«Universal Probe», page 4.

• Move the probe from a starting position in one direc tion. Observe the locating aids: current concrete cover,

flow bar, (short) beep, variotone, signal value. As long

as the flow bar moves to the right, the probe is approa ching a rebar. If the flow bar stops moving, the probe is

directly over the rebar axis. If the centerline of the

probe has overshot the rebar axis somewhat, acoustic

and visual indication is given in the «beep» setting by a

short beep and by «—» in the «Current cover» display

field. At the same time, the flow bar moves to the left

and the cover is temporarily stored in the field Memo».

• When having activated the audible locating aid «Vario tone» («MENU» → «Basic Setups» → «Audible locating

aid»), the audio frequency increases as the probe

approaches a rebar. In this operation mode the cover

of the scanned rebar is also temporarily stored in the

field «Memo».

• In the case of loud noises from the surroundings, use

the headset to hear the acoustic signals.

Page 17

English

© 2007 Proceq SA Measuring Process 11

Irrespective of the settings, the signal value is

a yardstick for the distance between the probe

and a metallic object.

• The bar direction can be detected by moving the probe

in the direction of its longitudinal axis along the rebar.

Make sure that the signal value and the current cover

remain as constant as possible.

Storing the measured values

To store the measured values, select an object number

in the menu.

• Press the PRINT/STORE key to store the measured

value shown in the field «Memo».

• Use the ↓ key to delete the measured value, or in the

case of several values, the last of the remaining mea sured values.

Warning!

You cannot undo the deletion of a value!

• To receive a statistical evaluation of the stored measu red values, press the END key.

• If you then enter a limit value («MENU» → «Limit Value»),

the percentage of the measured values which are

below the entered limit value is displayed.

• Pressing END again completes the measurement

series and starts a new one with an object number that

is incremented by 1.

Measuring the diameter

See «Rebars Connected with Binding Wires», page 13.

5.1.2 Welded Reinforcing Meshes

The unit cannot detect whether the rebars are welded to

one another or connected with binding wires. The two

reinforcement types with the same dimensions however

create different signals.

Settings

• Proceed as described under «Rebars Connected with

Binding Wires», page 13.

• Observe the following exception:

The setting of the bar diameter must be slightly higher

than the actual diameter (see Tab. 5.1, page 12). The

input depends on the bar diameter and on the mesh

width. With special constructions, this value should be

determined by means of a test on an open system.

Use different distance pieces to find out the diameter

setting at which the correct cover is indicated.

Examples for diameter settings:

Fig. 5.2 Welded reinforcing mesh

Page 18

12 Measuring Process © 2007 Proceq SA

Tab. 5.1

• Select the small measuring range in the measuring

display. The large measuring range cannot be used

with welded reinforcing meshes.

Locating and measuring concrete covers

Here, the spacings between the bars of the other layers

of the mesh can also be located more easily. This particularly applies to the bars of the second layer.

The value displayed for the cover of a bar of the first

layer can vary by a few millimeters depending on whether the measurement is made over the point at which two

bars cross, or between the bars of the second layer.

If the rebars of the first layer are too close to

each other, it is likely to be impossible to loca te the bars of the second layer. See also

«Universal Probe», page 4.

Storing the measured values

• Proceed as described under «Storing the measured

values», page 11.

Measuring the diameter

«Welded Reinforcing Meshes», page 14.

5.2 Detecting Insufficient Concrete Cover

This function can be used for the following tasks:

- Check after removing formwork

- Building inspection

- Evaluation basis for modernisation

Settings

See also under «Settings», page 6

• Enter the bar diameter.

• Enter the limit value of the cover.

• Enter the bar spacing under the menu option «Neighb.

Bar Corr.» if the correction is required. The set limit va lue is not displayed in this case (see Fig. 5.1).

The setting of the audible locating aid is not of importance.

Measuring the concrete cover

With a preselected limit value, the probe can be moved

at a maximum search speed of 0.25 m/s without having

to watch the display. If the current cover displayed is less

than the limit value, an acoustic alarm sounds. When the

probe is over the bar, «—» is indicated in the «Current

concrete cover» display field.

Switching off the unit deletes the set limit

value.

Page 19

English

© 2007 Proceq SA Measuring Process 13

5.3 Determining the Bar Diameter

5.3.1 Rebars Connected with Binding Wires

A. Determining diameters without correction

For precise determination of the bar diameter, it is important that there are no unnoticed influences that could falsify the result. Therefore select a place on the structure

where there is sufficient spacing between the rebars.

If the spacings are too small, the resulting value will be

too high.

To measure the bar diameter in the first and second

layer, the minimum spacings a and b as shown in Tab.

5.2, page 13 are required.

• Select the «Measure w. Statistics» function.

• Carry out the RESET procedure. See also under

«RESET process», page 10.

• Place the probe parallel over the bar and press the ↑ key.

• The result of the bar diameter determination is

displayed in mm or inch.

Fig. 5.3 Rebar of 1st Fig. 5.4 Rebar of 2nd

layer layer

Tab. 5.2 Minimum spacings of the rebars in the 1st and 2nd

layer

Provided that the minimum spacings are observed, the

rebars can be measured with an accuracy shown in

Fig. 5.5.

mm

mm

Fig. 5.5 Determining diameters

Page 20

14 Measuring Process © 2007 Proceq SA

The result of diameter determination cannot be

stored.

B. Determining diameters with correction

There are structures where the rebar spacing is smaller

than indicated in Tab. 5.2. Corrections are possible for

these structures. However, this only applies to the parallel bars on both sides. The bars that run crosswise must

have the minimum spacings shown in Tab. 5.2.

Procedure:

• Locate the parallel rebars carefully and mark them on

the surface of the concrete.

• Measure the rebar spacings using a measuring rod

and enter the data in the «Corrections» → «Neighb.

Bar Corr.»

• Select the «Measure w. Statistics» function.

• Hold the probe in the air and carry out the «RESET

process» as described on page 10.

• Place the probe parallel over a bar and press the ↑ key.

As bar diameter (d=...), the display shows the value corrected by the influence of the neighboring bars.

• In addition to the bar spacing, the measured bar dia meter can now be entered in the menu.

With these settings, the concrete cover of those rebars

found to be situated close to one another can be determined precisely.

Only concrete covers can be stored under the

selected object number, not the measured bar

diameter!

5.3.2 Welded Reinforcing Meshes

If diameters are determined on welded rebar systems,

results are displayed most of the time. These values are,

however, always too high and cannot be used.

5.4 Making Reinforcement Visible with

CyberScan

Model SCANLOG only (with mobile probe)

The rebars arranged below a defined measuring area

are displayed. Using the x/y scales, rebars which have

to be exposed, or points where holes have to be drilled,

can be transferred immediately from the display to the

measuring area and marked.

The measuring area must be scanned with the mobile

probe once in direction x and once in direction y (see

«ScanCar», page 5). The rebars are located and displayed extended to the full size of the measuring area.

Measuring areas of 0.5 x 0.5 m, 1 x 1 m or 2 x 2 m can

be selected.

If the area that must be measured is smaller than the

size of the selected area the bars are only shown in the

length they were measured.

Page 21

English

© 2007 Proceq SA Measuring Process 15

x meter scale

Cursor

1st layer

2nd layer

Direction of travel of the

probe

Concrete covers of the 1st and 2nd layer

Preselected bar diameter

y meter scale

Fig. 5.6 Example of a measured object

Settings

See also «Settings», page 6.

• Enter the bar diameter of the first layer.

• Enter the object number.

• Enter the bar spacing under the menu option «Neighb.

Bar Corr.» if the correction is required. The «2-Layer correction» cannot be used by this function.

• Enter the size of the measuring area («MENU» →

«Basic setups» → «Scan Area»).

• Select the measuring function «Scanning Bars».

• Press the START key.

The following measuring display appears:

Fig. 5.7 Measuring display «CyberScan»

• Locate a rebar of the first layer in the measuring area

and mark it precisely. Then mark the left or top limit of

the measuring area parallel to the previously marked

bar on the concrete element.

Direction of travel:

The front of the mobile probe is where the

single wheel is.

Page 22

• Use the ↑, ↓, ←, →

keys to end the mea-

suring process of the

1st layer:

Fig. 5.10 Instructions

4 Smallest measured

cover of the 1st layer

• Place the cursor bet ween 2 rebars that are

as far apart as possible.

• Mark the position on

the measuring area.

• Start measuring the

bars in the 2nd layer

from this position.

• After the measuring

area has been scan ned, the following

display appears:

Fig. 5.11 Rebars of 2nd

layer

• Use the ↑, ↓, ←, →

keys to end the mea suring process of the

2nd layer. The smallest

concrete cover is indi cated.

• Press the PRINT/

STORE key to store

the measuring display.

• Press the END key if

the result must be

deleted.

16 Measuring Process © 2007 Proceq SA

Measuring procedure

• Start with the END key.

The following display

appears:

Fig. 5.8 Scanning

display

• Determine the direction

of travel using the ↓,

→ keys.

• Position the travel path

where the concrete ele ment is to be examined.

• Please note that loca ting and measuring is

in relation to the center

of the probe.

• After the measuring

area has been scan ned, the following is

displayed:

Fig. 5.9 Rebars of 1st

layer

• Travelling backwards

with the probe deletes

the displayed rebars.

1 Speed display. The

flow bar must be within

the scale.

2 Current concrete cover

3 Symbol for travelling

and scanning

The layer measured first

is displayed in thicker

lines.

1 2 3 4

Page 23

English

© 2007 Proceq SA Measuring Process 17

5.5 Measure with Grid

Model SCANLOG only

This function displays concrete covers over a large area

in grey scale or colour shades. The smallest concrete

cover measured in a grid field is displayed.

Settings

See also «Settings», page 6.

• Enter the bar diameter of the first layer.

• Enter the object number.

• Enter the bar spacing under the menu option

«Corrections»

→ «Neighb. Bar Corr.» if the correction is required.

The «2-Layer Correction» can not be used by this

function.

• Select the size of the grid field («MENU» → «Basic

setups» → «xy-grid»).

The grid should usually be greater than the division of

the first layer (e.g. +50 %) to ensure that at least one

rebar is within a grid field.

• Set the range in which the concrete covers are to be

displayed in grey scale («MENU» → «Basic setups»

→ «Display»).

Change the grey scale range to improve the contrast of

the displayed object (see Fig. 5.12).

Fig. 5.12 Adjusting grey scale range

The range can be adjusted as desired even after

measuring.

• Select the «Measure with Grid» function.

• Pressing the START key calls the measuring display:

Fig. 5.13 «Measure with Grid» measuring display

Page 24

5.5.1 Measuring with the Mobile Probe

• Scan the area to be measured with the mobile probe

(see «ScanCar», page 5) while observing the selected

grid.

Upper limit of object

Marking the travel paths acc.

to x/y-grid

Rebar of 1st layer

Left limit of object

Fig. 5.14 Measuring with the mobile probe

Direction of travel:

The front of the mobile probe is where the

single wheel is.

The front must always be opposite the x or y

axis. The direction of travel can be forward or

backward.

• Pressing the END key calls the top left corner of the

measuring area:

The x/y-coordinates are indicated in meters or feet.

One page contains 16 x 15

measured values that are

displayed in grey scale and

stored. The memory has a storage capacity of 500 pages.

The number of the remaining

free pages is indicated in the

measuring display (see Fig.

5.13).

5 4 3 2

1

Fig. 5.15 Measuring area before measuring

Key:

1 Cursor:

Press the ↑, ↓, ←, → keys briefly to move the cursor

step by step.

Keep the ↑, ↓, ←, → keys permanently pressed to go

to the next pages.

2 The arrow indicates the measuring direction. With the

↑, ↓, ←, → keys the measuring direction can be

changed.

3 Current concrete cover

4 Grey scale symbol of the current concrete cover

5 From 10 m in direction x, 10 a.s.o. is displayed.

• Follow the instructions in the display of Fig. 5.15 before

starting measuring.

18 Measuring Process © 2007 Proceq SA

Page 25

English

© 2007 Proceq SA Measuring Process 19

Scanning the measuring area with display of the

concrete covers

Key:

6 Speed display. The flow

bar must be within the

scale.

7 Smallest measured

concrete cover

8 Current concrete cover

9 Symbol for travelling and

scanning

6 7 8 9

Fig. 5.16 Measuring area after measuring

• If the rebars of the first layer run in a vertical direction

as shown in Fig. 5.14, the travel paths must

be positioned horizontally with the selected grid spa cing in direction y. Move the mobile probe along these

paths. In Fig. 5.16, pos. 7, the smallest concrete cover

measured in a grid field is displayed and stored auto matically as grey scale.

• After having finished one row, press the ↓ key. The

cursor jumps to below the last field and the arrow

direction changes automatically.

After every manual or automatic change of the

arrow direction, RESET must be pressed. See

also «RESET process», page 10.

• Once the second row at the edge of the measuring

area (y-axis) is completed, the cursor jumps to below

the last field and the arrow direction changes automa tically.

The indicating device operates in the same way if the

travel paths are positioned vertically, i.e. if measuring is

performed in direction y.

• If a hindrance prevents the measurements, you can

shift the cursor by the size of the obstacle.

• Individual values can be deleted by positioning the

cursor on the respective value and pressing the

PRINT/STORE key for two seconds.

• You can subsequently expand the object opened last in

the x and y-direction on new pages comprising 240

measured values.

• For all previous objects, measured values can only be

entered in pages that are not yet full.

• If the measurement cannot be started in the top left

corner (x and y = 0) you can move the cursor to the

starting position using the corresponding arrow keys.

• If you want to reserve pages that will be needed later,

each page has to be selected separately. To confirm

the reservation you can set a grey scale symbol in the

second row using the PRINT/STORE key. The grey

scale symbol can be overwritten or deleted at any time.

Page 26

5.5.2 Measuring with the Universal Probe

Measuring with grid can also be performed with the

probe only, i.e. without path measuring (ScanCar). To do

this, the x/y-grid has to be drawn on the concrete surface

to be measured.

• Carry out the same settings as for «Measuring with the

Mobile Probe», page 18.

• During measuring, the grid fields must be scanned with

the universal probe.

• Please note that the smallest concrete cover measured

in a grid field is always displayed (see Fig. 5.16,

Pos. 7). Store this value using the PRINT/STORE key.

5.6 Data Output

Characteristics of the menu items:

5.6.1 Object Select

All object numbers used are listed.

5.6.2 Object Display

An object which has been selected from the list is called

from the memory and displayed.

5.6.3 Object Print

The object can be printed with the printers listed below.

They can be connected directly to the indicating device.

• Hewlett Packard Deskjet printers for graphic and

numerical printout.

• EPSON printers for numerical printout.

Printers with a parallel interface require the serial/parallel

interface converter, Art. No. 390 00 188. For printers with

a serial interface, use the printer cable Art. No. 330 00 460.

• Select the corresponding function in the «Printer select»

submenu.

Below, you will find examples of printouts of various

objects.

Fig. 5.17 Printout of a «Measure w. Statistics» object

20 Measuring Process © 2007 Proceq SA

Page 27

English

© 2007 Proceq SA Measuring Process 21

Fig. 5.18 Printout of a Fig. 5.19 Printout of

CyberScan object «Measure with

Grid» object

5.6.4 Object to PC

Data can be transferred to PC and edited by use of

the programme ProVista supplied on a data carrier.

Instructions on the installation of the software and the

operation can be found on the data carrier. For data

transfer to the RS232 interface use the transfer cable,

Art. No. 330 00 456. If only a USB interface is available an additional RS232/USB adapter, Art. No. 390 00

540 must be used. Information on the installation of the

adapter can be found on the included CD.

Fig. 5.20 Fig. 5.21

Object «Measuring with statistics» «Cyberscan» object

Fig. 5.22 Object «Measuring with grid»

5.6.5 Clear memory

Objects cannot be deleted individually

You can only delete the entire memory con-

tents. This action cannot be undone after it

has been confirmed.

Page 28

22 Maintenance and Storage © 2007 Proceq SA

6 Maintenance and Storage

6.1 Cleaning

Warning!

Never immerse the indicating device or

measuring equipment in water or wash it under

a running tap! Use neither abrasives nor

solvents for cleaning!

• Clean the indicating device and measuring equipment

with a clean, dry cloth after use.

• Clean dirty input sockets and connectors with a clean,

dry brush.

6.2 Performance Check

• Check the cables for damage.

• All measuring functions can be checked with the test

block, Art. no. 390 00 270.

• If the battery life symbol is only ¼ black a set of new

batteries should be taken on site.

6.3 Storage

• Store the indicating device and measuring equipment

in the original case and in a clean, dust-free room.

• If the unit is not used for a long period of time, remove

the batteries.

Page 29

English

© 2007 Proceq SA Data 23

7 Data

7.1 Form of Delivery

Model S Model

SCANLOG

Article no. 390 00 050 390 00 054

Indicating device

Carrying strap

Universal probe incl. protec-

tive film

Probe cable 1.5 m

ScanCar probe carriage with Option

path measuring cable 1.55 m

Interface converter serial/ Option

parallel incl. 2.0 m cable

Transfer cable 1.5 m

USB-memory stick for data

transfer

Headset

Protection sleeve for display

unit

Operating instructions

Carrying case

415 x 500 x 125 mm

Total weight 4.2 kg 4.5 kg

Model S

Model SCANLOG

Page 30

24 Data © 2007 Proceq SA

7.2 Accessories / Spare Parts

Designation Article no.

Extension rod for universal probe and 390 00 076

ScanCar

Test block 390 00 270

Marking pen 390 00 280

Protective film for universal probe 390 00 084

Headset 390 00 085

Protection sleeve for indicating device 330 00 470

Transfer cable 9/9-poles 330 00 456

Printer cable 9/9+25-poles for printer with 330 00 460

serial interface

Interface converter serial/parallel for printer 390 00 188

with parallel interface

RS232/USB adapter 390 00 540

Upgrading from model S to model SCANLOG 390 00 090

7.3 Technical Data

7.3.1 Indicating Device Model S

- Non-volatile data memory for 40 000 measured values,

can be divided into 60 objects

-

Graphics LCD, 128x128 pixels with backlight

- Interface RS 232

- Software for direct printing. ProVista software for data

transfer to PC and editing

- Power supply with 6 batteries, 1,5V, LR6 for an

operating time of approx. 45h, or 30h with switched on

backlight. We suggest to use alkaline batteries

- Permissible ambient temperature for the whole device:

-10 °C to +60 °C

7.3.2 Indicating Device Model SCANLOG

Model SCANLOG is identical to model S but additionally

includes:

- «CyberScan» function for displaying the concrete cover

on the indicating device

- «Measure with Grid» function for grey scale display of

the concrete cover

- Extended data memory:

- Storage areas for «CyberScan»

- Storage areas for «Measure with Grid»:

500 pages with 16 x 15 = 240 measured values

each

- The maximum number of objects, however, remains

60; #200 000 and 300 000 are demo objects

Loading...

Loading...