Page 1

... more than 50 years of know-how you can measure!

Made in Switzerland

Operating Instructions

Moisture Meter

Page 2

2© by Proceq SA

Contents

1. Safety and Liability 3

1.1 Safety and usage precautions 3

1.2 Liability and warranty 3

1.3 Safety instructions 3

1.4 Correct Usage 3

2. Tutorial 4

3. Getting started 4

3.1 Insert Battery 4

3.2 Contact In-Situ and/or Ambient Probe 4

3.3 Overview Keypad 5

3.4 Standard Display 5

3.5 Overview Screens & Menu Structure 6

3.6 Detailed Menu Structure & Settings 7

4. HygroLink 10

5. Step by Step Guide “Relative Humidity Testing according to ASTM F2170” 11

6. Example of Test Report 12

7. Technical Specifications 13

8. Part Numbers and accessories 14

8.1 Units 14

8.2 Parts and Accessories 14

9. Maintenance and Support 14

9.1 Support Concept 14

9.2 Standard Warranty and Extended Warranty 14

Page 3

3© by Proceq SA

1. Safety and Liability

1.1 Safety and usage precautions

This manual contains important information on the safety, use and maintenance of the Hygropin.

Read through the manual carefully before the first use of the instrument. Keep the manual in a safe

place for future reference.

1.2 Liability and warranty

Proceq’s “General Terms and Conditions of Sale and Delivery” apply in all cases. Warranty and liability claims arising from personal injury and damage to property cannot be upheld if they are due

to one or more of the following causes:

Failure to use the instrument in accordance with its designated use as described in this •

manual.

Incorrect performance check for operation and maintenance of the instrument and its •

components.

Failure to adhere to the sections of the manual dealing with the performance check, •

operation and maintenance of the instrument and its components.

Unauthorized structural modifications to the instrument and its components.•

Serious damage resulting from the effects of foreign bodies, accidents, vandalism and •

force majeure.

All information contained in this documentation is presented in good faith and believed to be

correct. Proceq SA makes no warranties and excludes all liability as to the completeness and/or

accuracy of the information.

1.3 Safety instructions

The instrument is not allowed to be operated by children or anyone under the influence of alcohol,

drugs or pharmaceutical preparations. Anyone who is not familiar with this manual must be

supervised when using the instrument.

1.4 Correct Usage

The instrument is only to be used for its designated purpose as describe herein.•

Replace faulty components only with original replacement parts from Proceq.•

Accessories should only be installed or connected to the instrument if they are expressly •

authorized by Proceq. If other accessories are installed or connected to the instrument then

Proceq will accept no liability and the product guarantee is forfeit.

Page 4

4© by Proceq SA

2. Tutorial

The Hygropin is a multifunction hand-held indicator with data logging capability that can be used

for identifying, diagnosing and monitoring potential moisture problems. Each of the two probe

inputs can be configured independently. The integrated real time clock keeps track of date and

time while recording data.

Practical advice for measuring humidity

The most common source of error when measuring relative humidity is a difference between the

temperature of the probe and the temperature of the environment. At a humidity condition of 50

% RH, a temperature difference of 1°C (1.8 °F) typically results in an error of 3 %RH on relative

humidity.

When using Hygropin, it is good practice to monitor the display for temperature stability. The probe

should be given sufficient time to come to equilibrium with the environment to be measured. The

larger the initial temperature difference between the probe and the environment, the more time is

required for temperature equilibrium.

In extreme situations, condensation may occur on the sensors when the probe is colder than the

environment. As long as the humidity / temperature limits of the humidity sensor are not exceeded,

condensation does not alter the calibration of the sensor. However, the sensor has to dry out before it can provide a valid measurement.

3. Getting started

3.1 Insert Battery

3.2 Contact In-Situ and/or Ambient Probe

Page 5

5© by Proceq SA

3.3 Overview Keypad

ON / OFF Turns the instrument “on” or “off”.

MENU Activates the internal menu. Press this key again to go back.

UP Change data displayed, navigate through menu, make a

DOWN selection or change values.

ENTER Confirm a selection and data capture.

3.4 Standard Display

Depending on the settings the Hygropin is able to display:

relative humidity and temperature measured by two probes•

calculate psychrometric parameters like dew / frost point etc. for both probes•

difference between the values measured by the two probes•

Press slightly button to turn the Hygropin on:

Trend Indicator

increasing value

decreasing value

stable value

Humidity and

Temperature

Data Logging

Logging for Probe 1

is active.

Probe selected

Date and Time

Battery charge indicator

Change probe that is displayed or scroll through the measuring values using the or

button.

By pressing the temperature and humidity values of the selected probe are stored. More

information can be found in the Data Capture chapter.

Enter the Menus and Settings screens by pressing the key:

Page 6

6© by Proceq SA

3.5 Overview Screens & Menu Structure

Standard

H+T+Calc

Large

Page 7

7© by Proceq SA

3.6 Detailed Menu Structure & Settings

Device Info

Serial Number

Software Version

Device Type

Device Name

Battery Charge Status

Device Settings

Submenu Display Settings

Submenu Local Settings

Submenu Input 1 / Input 2 Settings

Barometric pressure for calculations

see “Calculated Parameters”

Display refresh interval 1 s / 10 s / 1 min / 10 min

Battery charge via USB ON / OFF

Manual date setting

Manual time setting

Submenu Display Settings

Trend indicator on display ON / OFF

Decimal display resolution 0.x / 0.xx

Display contrast adjustment 0..50

Back light mode ON / OFF / Key pressed

Display Mode Standard / H+T+Calc / Large

Show difference for each parameter between Probe 1 and

Probe 2

ON / OFF

Submenu Local Settings

Date format dd mm yyyy

mm dd yyyy

yyyy mm dd

Date separator “.” or ”/”

Time format 24 h / 12 h

Unit system Metric / English

Real time clock does not auto adjust for daylight saving time.

Page 8

8© by Proceq SA

Submenu Probe Settings

Probe Type HygroClip / Analog / Pressure

Calculation (digital probe

only)

See “Calculated Parameters”

Output Voltage (analog probe)

…

Measuring Range (analog

probe)

…

Calculated Parameters

The Hygropin can calculate any of the following psychrometric parameters based on humidity and

temperature:

Dew point (Dp) above and below freezing•

Frost point (Fp) below freezing and dew point above freezing•

Wet bulb temperature (Tw)•

Enthalpy (H)•

Vapor concentration (Dv)•

Specific humidity (Q)•

Mixing ratio by weight (R)•

Vapor concentration at saturation (Dvs)•

Vapor partial pressure (E)•

Vapor saturation pressure (Ew)•

Any of the above parameters can be set in the submenu “Probe Setting”.

Calculating some of these parameters requires barometric pressure as an input parameter. A fix

barometric pressure value can be specified in the “Device Settings” Menu.

Probe Menu

Submenu detail information digital probe

Submenu Humidity Adjustment

Submenu Temperature Adjustment

These functions are for service and calibration purpose only.

Page 9

9© by Proceq SA

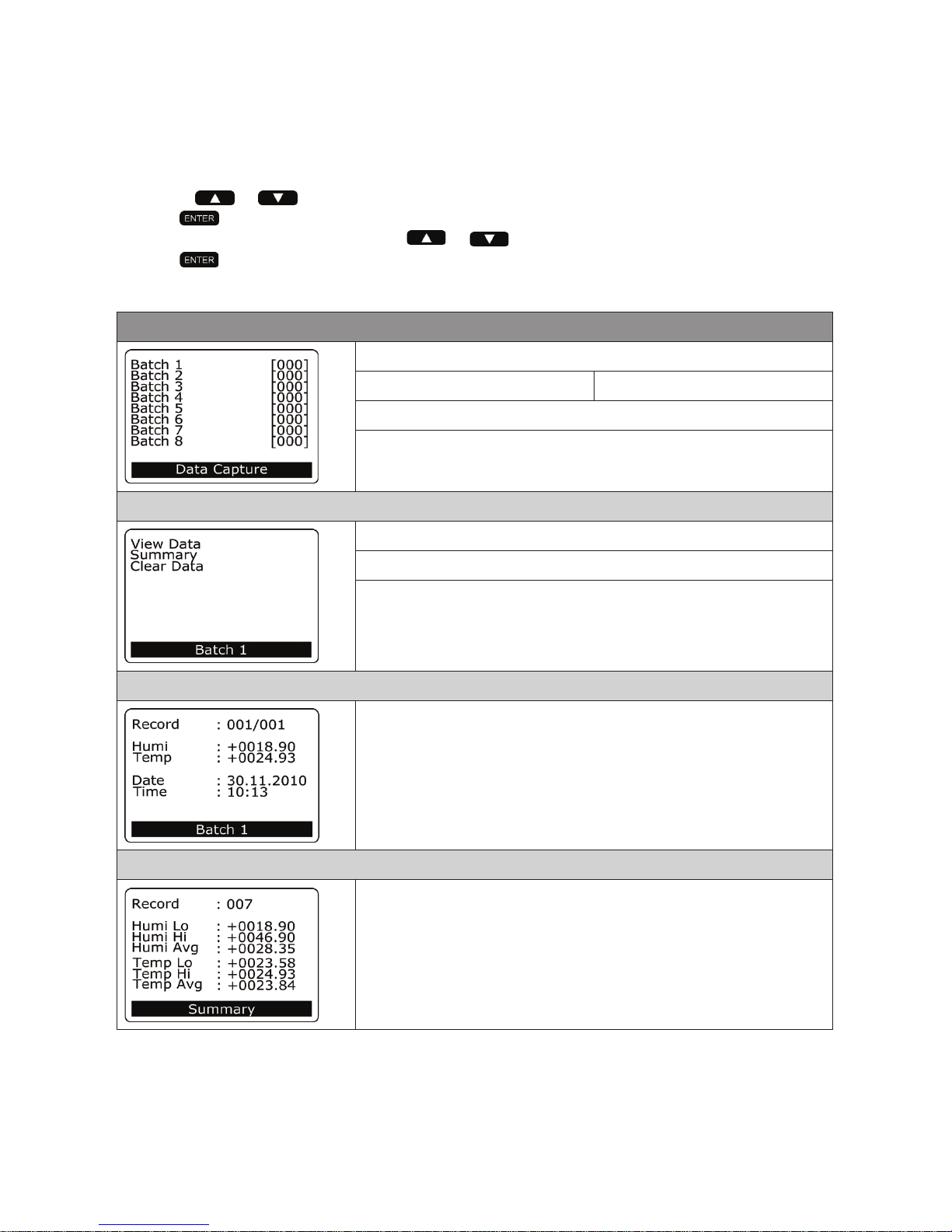

Data Capture

Up to 250 relative humidity and temperature records can be manually captured and organized in

each of the 8 data batches (non-volatile memory). The captured data is automatically date and time

stamped. The calculated parameter cannot be captured.

Capturing Data:

Use the • or key to select the probe

Press •

Select the target data batch with the • or key

Press • to trigger the Data Capture function

Data capture is confirmed on the Hygropin display•

Data Capture

Data Batch 1 [Numbers of Records]

…

Data Batch 8 [Numbers of Records]

Select data batch to be viewed

Submenu Batch 1..8

Submenu View Data

Submenu View Summary Batch

Clear Data Batch

Submenu View Data

View individual data records inclusive date and time stamp.

Submenu Summary

View the maximum, minimum and average values of each

batch.

Page 10

10© by Proceq SA

Data Logging

The Hygropin can automatically record up to 10,000 humidity-temperature values measured by a

single probe. Each record is stamped for date and time. The calculated parameter cannot be recorded. When recording data from two probes at the same time, the recording capacity per probe

is cut in half.

The Hygropin features two data logging mode: start-stop (recording ends when the memory is full)

and loop (when the memory is full, the oldest record is dumped to make room for a new record)

Data logging can be started and stopped from the keypad. The HygroLink software allows the

downloading of the recorded data for further analysis.

Data Logging

Status Data logging ON / OFF

No. of sample taken max. 10’000 H+T

Status Logging Interval 5s…1h

Status Logging Mode StartStop / Loop

Start / Stop Recording

Submenu Settings

Submenu Settings

Interval setting 5s..1h

Logging Mode setting StartStop / Loop

Logging Probe 1 ON / OFF

Logging Probe 2 ON / OFF

Cannot be changed while the Hygropin is recording data.

4. HygroLink

Installation

To start the installation wizzard of the software & driver package execute HygroLink_Setup.exe on

the included CD ROM.

Remove the red cover cap and connect the USB cable to the connector.

1. Establish connection to Hygropin

2. Download all data from the Hygropin in Excel-Files

3. Delete all data on the Hygropin

4. Disconnect Hygropin

5. Check for updates HygroLink

Page 11

11

© by Proceq SA

5. Step by Step Guide

“Relative Humidity Testing according to ASTM F2170”

For details please check the ASTM F2170-09 standard.

Step 1: Check the correct functionality of the instrument (Chapter 8, ASTM F2170-9)

Recalibrate probes annually•

Check periodically the correct functionality of instrument and probe with the humidity •

standard tube (780 10 470)

Step 2: Conditioning (Chapter 9, ASTM F2170-9)

Concrete floor slab and air space surrounding slab shall be at service temperature /

humidity for at least 48 hours.

Step 3: Define number of test holes (Chapter 10.1, ASTM F2170-9)

3 test holes for the first 1000 ft•

2

/ 100 m2

at least 1 additional test hole for each additional 1000 ft•

2

/ 100 m

2

Step 4: Define depth of test holes (Chapter 10.2, ASTM F2170-9)

40% of slab thickness if slab is drying from top only•

20% of slab thickness if slab is drying from top and bottom•

Step 5: Drill and prepare test holes (Chapter 10.3, ASTM F2170-9)

Drill hole using a 8mm /

5/16in drill bit

Clean test hole

Cut sleeve according to

measuring depth

Insert sleeve in test hole

and close cap

Cast holes (Chapter 10.4, ASTM F2170-9)

Use “Add-on for wet

concrete” (780 10 370)

Cut sleeve and rod

according to measuring

depth

Remove rod after concrete hardens

Close cap

Step 6: Wait 72 hours for moisture equilibrium (Chapter 10.3.4, ASTM F2170-9)

Step 7: Measurements (Chapter 10.5, ASTM F2170-9)

Insert In-Situ probe into

sleeve

Wait for temperature

equilibrium

Check for stable value

(trend indicator) before

record data

Measure ambient

condition

Step 8: Report (Chapter 11, ASTM F2170-9)

Use the Test Report template (chapter 6) to record and report all necessary information.

Page 12

12© by Proceq SA

6. Example of Test Report

Name and address of structure: Identify floor:

Area: .................... m2 ft

2

No. Holes ....................

Slab thickness: .................... mm inch

Test Location

(use room number or building

grid)

Depth from top of

slab

mm inch

Relative Humidity in concrete, %

Temperature in

concrete,

°C °F

Ambient

Temperature,

°C °F

Ambient

Relative Humidity %

Notes:

Instrument used: Make, Model, Serial number Instrument used: Last calibration date of probe

Test performed: Name Test performed: Date

Test performed: Company name Test performed: Company address

Location Map

Instructions: Indicate sensor locations with symbol and number of test hole. Show doors, rooms,

columns or other location indicators.

Page 13

13© by Proceq SA

7. Technical Specifications

Display Unit

Power Supply

Battery 9 V alkaline (standard)

Ni-MH 8.4V, 170…250mAh (rechargeable via USB)

Mains Via USB charger

General

Probe input Two separate digital probe inputs

Real time Clock Yes

Psychrometric Calculations Yes

Start-up time 3 s

Data refresh rate 1 s

Interface type USB

Data Logging

Memory Max. 10’000 readings

Interval 5 s to 1 h

Display

Display Pixel graphic LCD

Backlight

Display modes % RH and temperature, date and time

% RH, temperature and calculated parameter

Mechanical

Dimension 270 x 70 x 30 mm (10.63 x 2.76 x 1.17”)

Weight Ca. 198 g (7.0 oz)

IP classification IP 40

Environmental conditions

Operating temperature -10 °C to 60 °C (14 °F to 140 °F)

Humidity 0 to 100% RH, no condensing

In-Situ Probe

Measuring range 0 to 100% RH

- 40 °C to 85 °C (-40 °F to 185 °F)

Accuracy ± 1.5 % RH / ± 0.3 K

Response time < 15 s

Dimension Ø 5 mm (Ø 0.2 in.)

Cable length 200 cm (79 in.)

Maximum air velocity at probe 20 m/s (3,935 ft /min)

Page 14

14© by Proceq SA

Standards and Regulations applied

CE / EMC immunity

EMC Directive 2004/108/EG:•

EN 61000-6-1: 2001•

EN 61000-6-2: 2005•

EN 61000-6-3: 2005 •

EN 61000-6-4: 2001 + A11•

Technical Standard

ASTM F 2170-09•

Special note NIST traceability:

All probes for the Hygropin are factory calibrated referring to the Swiss Calibration Service (SCS).

An individual calibration certificate is included with each probe. SCS is accredited with the Swiss

Federal Office of Metrology which is a signatory of the BIPM (http://www.bipm.org/) Under the

Mutual Recognition Agreement NIST recognizes all registered in the BIPM database.

8. Part Numbers and accessories

8.1 Units

Part No. Description

780 10 000 Hygropin Unit consisting of: Instrument incl. In-situ probe, carrying case and ac-

cessories (10pcs measuring sleeves, CD incl. HygroLink, documentation)

8.2 Parts and Accessories

780 10 400 In-Situ Probe

780 10 450 Ambient Probe

780 10 470 Humidity Standard 75%RH

780 10 350 Set of Measuring Sleeves 20pcs

780 10 360 Set of Measuring Sleeves 100pcs

780 10 370 Add-on for Wet Concrete 10pcs

9. Maintenance and Support

9.1 Support Concept

Proceq is committed to providing a complete support service for this instrument. It is recommended that the user registers the product on the www.proceq.com to obtain valuable information

on available updates and other useful information.

9.2 Standard Warranty and Extended Warranty

The standard warranty covers the electronic portion of the instrument for 24 month and the mechanical portion of the instrument for 6 month. An extended warranty for one, two or three years for

the electronic portion of the instrument may be purchased up to 90 days of purchase.

Page 15

15© by Proceq SA

Page 16

... more than 50 years of know-how you can measure!

Made in Switzerland

Proceq Europe

Ringstrasse 2

CH-8603 Schwerzenbach

Phone +41-43-355 38 00

Fax +41-43-355 38 12

info-europe@proceq.com

Proceq UK Ltd.

Bedford i-lab, Priory Business Park

Stannard Way

Bedford MK44 3RZ

United Kingdom

Phone +44-12-3483-4515

info-uk@proceq.com

Proceq USA, Inc.

117 Corporation Drive

Aliquippa, PA 15001

Phone +1-724-512-0330

Fax +1-724-512-0331

info-usa@proceq.com

Proceq Asia Pte Ltd

12 New Industrial Road

#02-02A Morningstar Centre

Singapore 536202

Phone +65-6382-3966

Fax +65-6382-3307

info-asia@proceq.com

Proceq Rus LLC

Ul.Optikov 4

korp.2, lit. A, Office 321

197374 St. Petersburg

Russia

Phone/Fax + 7 812 448 35 00

info-russia@proceq.com

Proceq Middle East

P.O. Box: 262419

Jebel Ali Free Zone

Dubai, United Arab Emirates

Phone +971 50 482 9510

info-middleeast@proceq.com

Proceq SAO Ltd.

South American Operations

Rua Haddock Lobo, 746 - 5 andar

Cerqueira Cesar, São Paulo

Brasil Cep. 01414-000

Phone +55 11 3083 38 89

info-southamerica@proceq.com

Proceq China

UnitG,10thFloor,Huamin•EmpirePlaza

No. 728, Yan An Road(W)

Shanghai, 200050

Phone +86 21-63177479

Fax +86 21 63175015

info-china@proceq.com

www.proceq.com

Subject to change without notice.

Copyright © 2010 by Proceq SA, Schwerzenbach

Part number: 820 780 01 E

Loading...

Loading...