Page 1

Operating Instructions

60 Years of Innovation60 Years of Innovation

Swiss Precision since 1954

Page 2

Table of Contents

1. Safety and Liability ....................................................4

1.1 General Information ............................................................. 4

1.2 Liability .................................................................................. 4

1.3 Safety Instructions ............................................................... 4

1.4 Correct Usage ...................................................................... 4

1.5 Optimizing Performance of the Battery System ............... 4

2. Getting Started ...........................................................5

2.1 Installation ............................................................................ 5

2.2 Main Menu ............................................................................ 6

3. Measurement .............................................................7

3.1 Performing Measurements ................................................. 7

3.2 Measurements Screen ...................................................... 10

3.3 Measuring Methods .......................................................... 12

3.4 Instrument Verification / Daily Performance Check ....... 24

4. Settings ....................................................................25

4.1 Measurements ................................................................... 25

4.2 Verification (Performance & Uncertainty Check) ............ 27

4.3 Conversions (Hardness Conversions) ............................. 28

4.4 Reporting ............................................................................ 28

5. Data (Explorer) .........................................................29

5.1 Measurements ................................................................... 29

5.2 Verifications ........................................................................ 31

6. Wizards .....................................................................31

6.1 Measurement Wizard ........................................................ 32

6.2 Device Verification ............................................................. 32

6.3 Impact Direction Calibration (Leeb only) ......................... 32

6.4 Conversion Curve Creation............................................... 32

6.5 Combined Method ............................................................. 34

6.6 Mapping Wizard (Coming Soon) ...................................... 34

7. Information ...............................................................35

7.1 Documents ......................................................................... 35

7.2 Upload PDF-Files from an USB-stick .............................. 35

8. System ......................................................................36

8.1 Features .............................................................................. 36

8.2 Probes................................................................................. 37

8.3 Hardware ............................................................................ 37

8.4 Date & Time ........................................................................ 37

8.5 Language ............................................................................ 37

8.6 Device information ............................................................. 37

9. Maintenance and Support .......................................38

9.1 Maintenance....................................................................... 38

9.2 Support Concept ............................................................... 39

9.3 Standard Warranty and Extended Warranty ................... 39

9.4 Disposal .............................................................................. 39

© 2016 Proceq SA 2

Page 3

10. Troubleshooting ......................................................... 40

10.1 Incorrect Measurements / Failed Performance Check ..... 40

10.2 No Reading Displayed ......................................................... 41

10.3 Battery ................................................................................... 42

10.4 Touchscreen Calibration ...................................................... 42

11. Equotip Link Software ............................................... 42

11.1 Starting Equotip Link ............................................................ 42

11.2 Application Settings ............................................................ 42

11.3 Connecting to an Equotip 550 Touchscreen Unit .............. 43

11.4 Connection to Portable Rockwell Probe ............................ 43

11.5 Adjusting the Settings .......................................................... 43

11.6 Exporting Data ...................................................................... 44

11.7 Exporting and Importing of Setting Profiles ....................... 45

11.8 Exporting and Importing of Conversion Curves ................ 45

12. Technical Specifications ............................................ 45

12.1 Instrument ............................................................................. 45

12.2 Power Supply ........................................................................ 46

12.3 Equotip Leeb Impact Devices ............................................. 46

12.4 Equotip Portable Rockwell Probe ....................................... 47

12.5 Equotip UCI Probe ................................................................ 47

13. Standards & Guidelines ............................................. 47

14. Ordering Information ...............................................48

14.1 Units .................................................................................... 48

14.2 Impact Devices & Probes ................................................. 48

14.3 Parts and Accessories ...................................................... 49

14.4 Test Blocks ..............................................................................

© 2016 Proceq SA 3

Page 4

1. Safety and Liability

Table of Contents

1.1 General Information

This manual contains important information on the safety, use and maintenance of the Equotip 550. Read through the manual carefully before the

first use of the instrument.

1.2 Liability

Our “General Terms and Conditions of Sales and Delivery” apply in all

cases. Warranty and liability claims arising from personal injury and damage to property cannot be upheld if they are due to one or more of the

following causes:

• Failure to use the instrument in accordance with its designated use as

described in this manual.

• Incorrect performance check for operation and maintenance of the instrument and its components.

• Failure to adhere to the sections of the manual dealing with the performance check, operation and maintenance of the instrument and its

components.

• Unauthorised modifications to the instrument and its components.

• Serious damage resulting from the effects of foreign bodies, accidents,

vandalism and force majeure.

All information contained in this documentation is presented in good faith

and believed to be correct. Proceq SA makes no warranties and excludes

all liability as to the completeness and/or accuracy of the information.

1.3 Safety Instructions

The equipment is not allowed to be operated by children or anyone under

the influence of alcohol, drugs or pharmaceutical preparations. Anyone

who is not familiar with this manual must be supervised when using the

equipment.

• Carry out the stipulated maintenance properly and at the correct time.

• Following completion of the maintenance tasks, perform a functional

check.

1.4 Correct Usage

The instrument is only to be used for its designated purpose as described

herein.

• Replace faulty components only with original replacement parts from

Proceq.

• Accessories should only be installed or connected to the instrument

if they are expressly authorized by Proceq. If other accessories are

installed or connected to the instrument then Proceq will accept no

liability and the product guarantee is forfeited.

1.5 Optimizing Performance of the Battery System

To increase the performance of the battery, it is recommended to first

completely discharge and then completely charge it.

4 © 2016 Proceq SA

Page 5

2. Getting Started

Table of Contents

The Equotip 550 is typically used for testing the hardness of metallic surfaces. The user has a choice to select either Leeb rebound, the Portable

Rockwell or UCI principle, see chapter “3.1 Performing Measurements”.

In combination with the Equotip Leeb Impact Device U the instrument is

used to test the roll hardness of paper, film or foil rolls.

2.1 Installation

To install the Battery into the Equotip 550 Touchscreen Unit, lift the stand

as shown, insert the battery and fasten it in place with the screw.

Buttons

On the upper right of the unit there are three buttons:

Power On/Off – Press to power on or to return to the home

screen. Press and hold to power off.

Soft Key – Switches in and out of full screen view or toggles

between the actual screen and the last viewed pdf document (eg.

Operating Instructions).

Back Button – Returns to previous screen.

Energy Saving

Energy saving may be programmed as desired under System/Power settings, see chapter “8.3 Hardware”.

Connections

Figure 1: Insert Battery

There are three status LEDs on the right side of the display. The middle

light is the power indicator which is red when charging and turns to green

when battery is fully charged. The lower LED is used for application specific notification.

• A complete charge requires < 9 h (Instrument not operating)

• Charging time is much longer if the instrument is in use.

• An optional Quick Charger (Part No. 327 01 053) can be used to

© 2016 Proceq SA 5

NOTE! Only use the battery charger provided for charging.

charge a spare battery or to charge the battery outside of the instrument. In this case it takes < 5.5 h for a complete charge.

1 2

Snap-in connectors

Figure 2: Connections

For Leeb Impact Devices

use the Snap-in connector 1.

For UCI Probe

use the Snap-in connectors 1 or 2.

For the Portable Rockwell Probe

use the USB Host connector.

USB Host

USB Device

Ethernet

Power Supply

USB Host:

Additionally connect a mouse,

keyboard or USB stick.

USB Device:

Connect to PC.

Ethernet:

Connection to network.

Power Supply:

Connect the power supply

through this connection.

Page 6

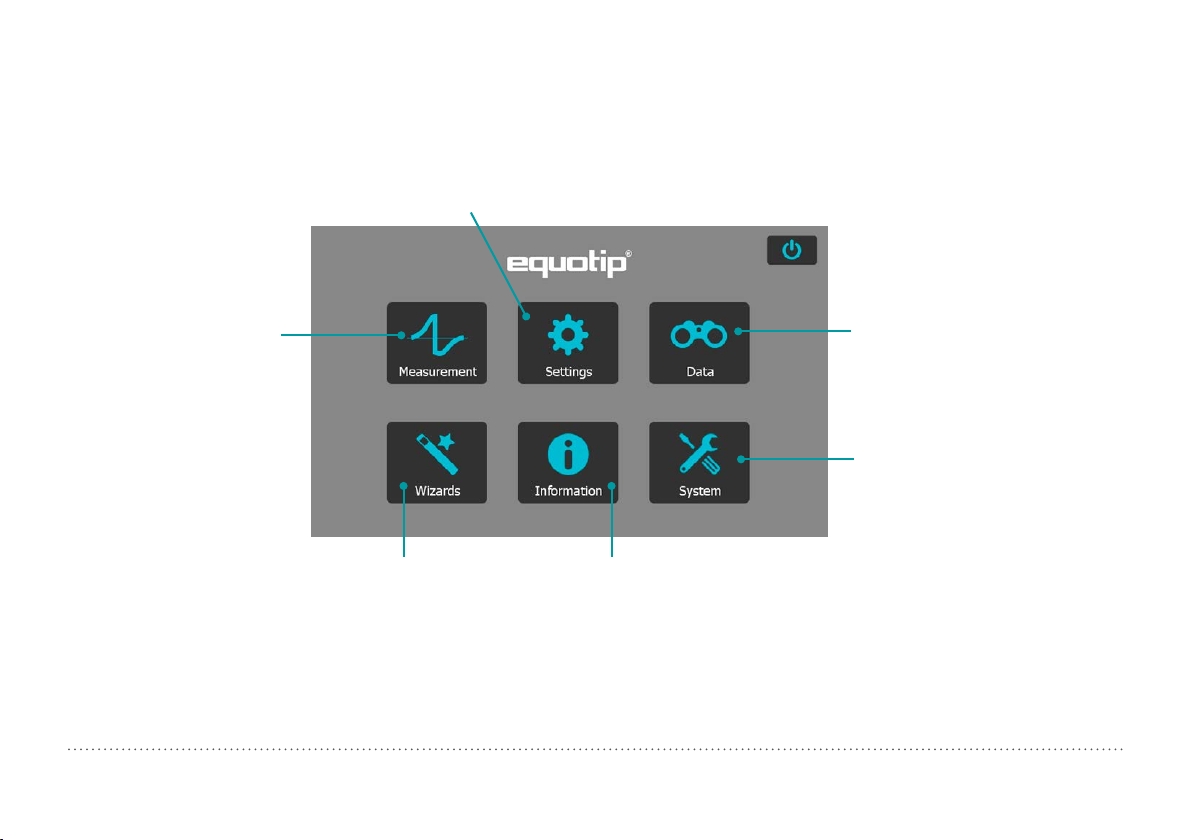

2.2 Main Menu

Table of Contents

On start up the main menu is displayed. All functions may be accessed directly via the Touchscreen. Return to the previous menu by pressing the

back button or the return icon (arrow) at the top left corner of the Touchscreen.

Settings: For application

specific settings, see chapter

“4. Settings”.

Measurement:

Measurement display screen,

see chapter “3. Measurement”.

Figure 3: Main Menu

6 © 2016 Proceq SA

Wizards: Task

related workflows, see

chapter “6. Wizards”.

Data (Explorer): File manager for

reviewing measurement data on the

instrument, see chapter “5. Data

(Explorer)”.

System: System settings,

e. g. language, display

options etc, see chapter

“8. System”.

Information: Operating

instructions and other

reference documents, see chapter

“7. Information”.

Page 7

3. Measurement

Table of Contents

3.1 Performing Measurements

3.1.1 Leeb Testing Procedure (except Leeb U)

Select automatic compensation for impact direction “Automatic”, see

chapter “3.2.1 Controls”. If “Automatic” is not allowed, set the impact

direction ( ). The Equotip Leeb Impact Devices DL doesn’t support automatic mode. The impact direction must be selected manually.

Select the appropriate material group, hardness scales and number of

impacts per measurement series. For more information see chapter “4.

Settings”. Conduct impacts by cycling through “load, position and trigger” mechanism:

1. Load the impact device – while not in

contact with the test piece – by holding it firmly with one hand and sliding

the loading tube with the other hand

until contact is grabbed by the clutch.

2. Position the support ring on the test

piece. Take particular care to fully

position the support ring on the test

piece, but not coinciding with a previous test indentation.

3. To trigger an impact, press the

trigger button to release the impact

body. To perform another impact,

repeat this cycle.

Figure 4: Leeb Testing Procedure

After the last of the impacts is performed, the hardness average and further statistics of the measurement series are displayed.

NOTE! Make sure the loading tube is allowed to slowly return

back to the starting position. Do take care so the loading

tube does not spring back uncontrolled, which may result in

permanent device damage.

NOTE! If possible, follow the standard practice of Leeb rebound hardness testing as described in the standards DIN

50156-1 (metallic materials), ASTM A956 (steel, cast steel and

cast iron only), or other applicable standards. If these are not

available, the user is recommended to average a minimum of

n = 3 impacts at an indentation distance of 3 to 5 mm (0.12

to 0.20”) for each location of the sample that shall be tested.

NOTE! Do not carry out an impact in an area that has already

been deformed by another impact. Also, do not load the device

when it is already positioned in the new test location, since the

material under the device may be affected through prior stress,

and the catch chuck of the device may get damaged.

© 2016 Proceq SA 7

Page 8

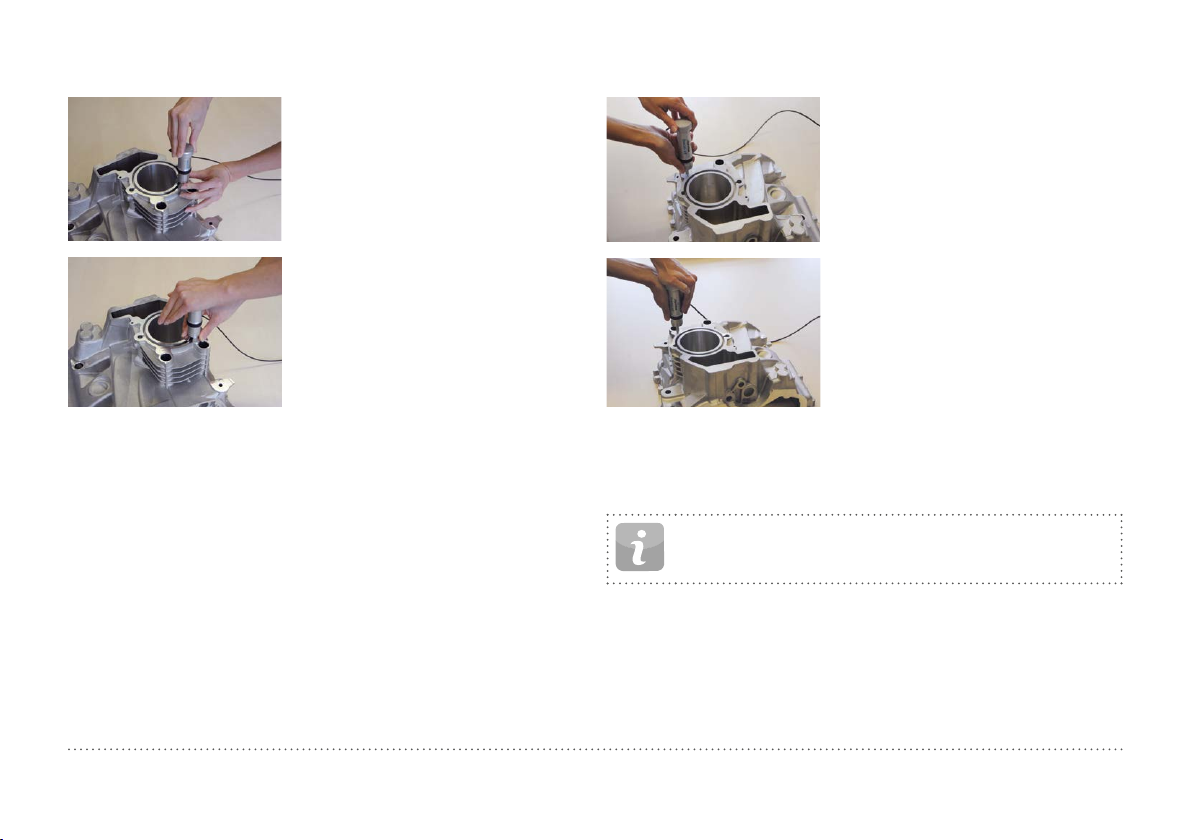

3.1.2 Portable Rockwell Testing Procedure

Table of Contents

1. Place the probe on the sample to

test. For flat surfaces the standard

foot is most suitable. For cylindrical

objects it is recommended to use

one of the special feet. For locations

difficult to access a tripod foot can

be used. See chapter “14. Ordering

Information” for more details.

2. Press the probe slowly but firmly

against the surface to perform the

measurement. Suppress vibrations

as much as possible, and follow the

instructions on the screen.

3. Release the probe when the instrument says so. Again, this movement

has to be done in a controlled manner. If the probe is released too fast,

a warning will be shown and the

measurement should be repeated.

Figure 5: Portable Rockwell Testing Procedure

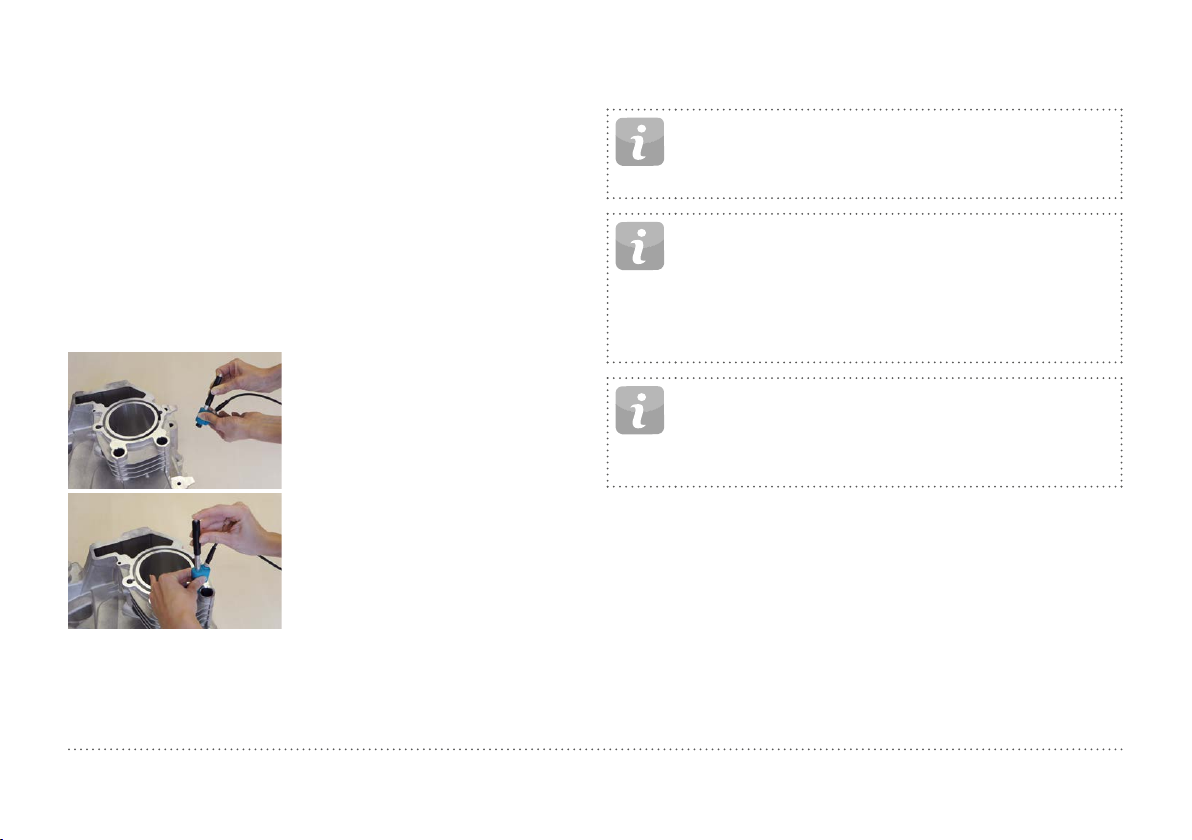

3.1.3 UCI Testing Procedure

1. Place the probe on the sample to

test. The probe must be perpendicular to the surface (± 5°). The

special foot can be used to increase

repeatability and reduce distortion of the results, see chapter “14.

Ordering Information”.

2. Press the probe slowly but firmly

against the surface until the selected measuring force is reached.

The instrument will indicate when to

release the probe with an on-screen

prompt and audible sound.

3. Release the probe from the material. It is important to remove the

probe completely from the test

object. Otherwise the results can be

biased.

Figure 6: UCI Testing Procedure

NOTE! A warning will be shown if the user applied too much

load when pressing the probe against the surface. Please avoid

frequent overloading, as this could seriously damage the probe.

8 © 2016 Proceq SA

Page 9

3.1.4 Leeb U Testing Procedure

Table of Contents

The Equotip 550 Leeb U enables the user to quickly and precisely diagnose roll imperfections, hardness inconsistencies and uneven winding,

thereby preventing problems for printing and converting operations.

With Equotip Impact Device Leeb U automatic impact direction mode is

not supported and the user must select the appropriate impact direction

manually (90° down, 45° down, 0°).

As for roll hardness testing no conversion curves are used, no material

group has to be selected.

Conduct impacts by cycling through “position and trigger”.

1. Position the probe on the roll to be

tested. Make sure to fully position the support ring on the roll to

ensure an impact perpendicular to

the test surface.

2. While holding the impact device

firmly with two hands, slide the

loading tube smoothly down to

load and trigger an impact.

Move the impact device to the next

point on the roll and repeat.

Figure 7: Leeb U Testing Procedure

NOTE! Some features mentioned in this Operating Instructions are specifically addressing metal hardness testing applications and therefore not available for Equotip Leeb U.

© 2016 Proceq SA 9

Page 10

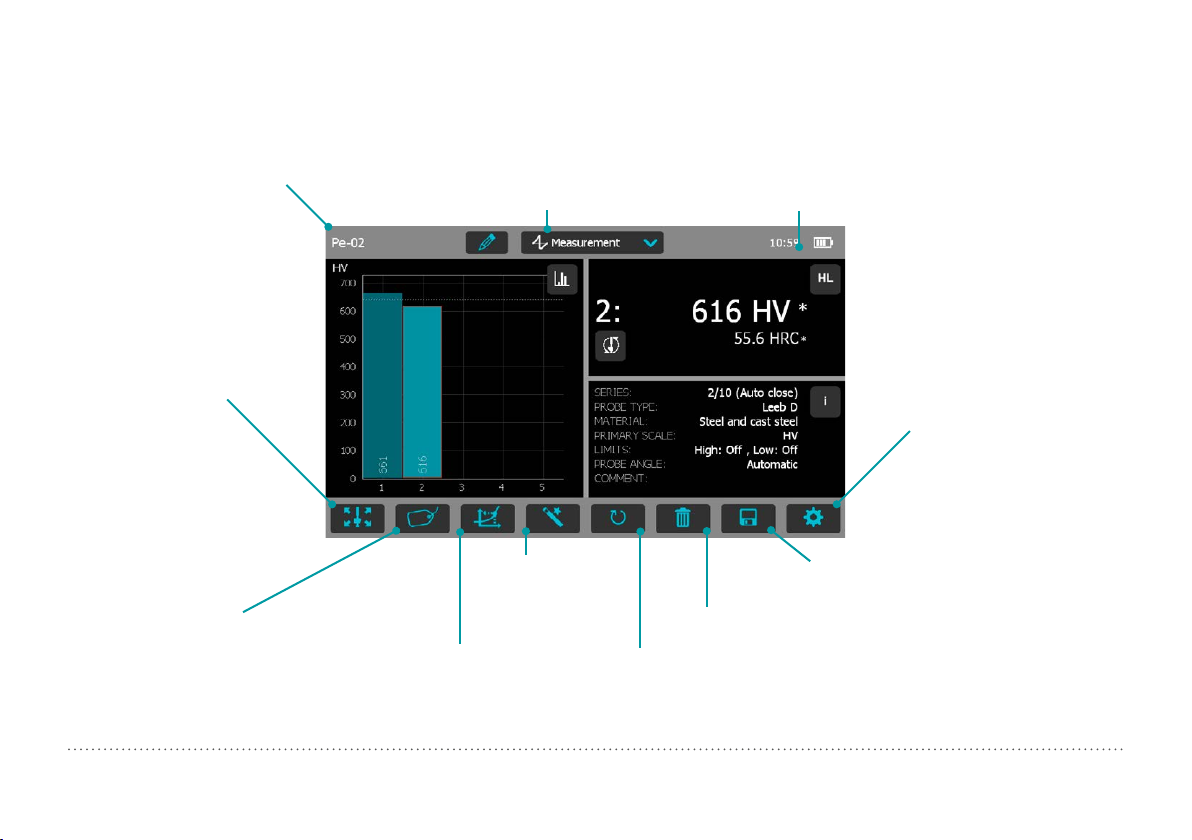

3.2 Measurements Screen

Table of Contents

3.2.1 Controls

File Name: Enter the file name

and tap return. Saved measurements will be stored automatically. If filename management

is activated, this function is

locked.

Impact Direction: To

manually set the impact

direction if required

(Leeb only, by default

this is automatic).

Material: Select the

material group to use

for conversions (not

available for Leeb U).

Figure 8: Measurement Screen

10 © 2016 Proceq SA

Measurement Scale: Select the hardness

scale (primary and secondary) to be displayed

(not available for Leeb U).

Measurement Mode:

Switch between

measurement and conversion.

Wizards: Direct

access to wizards.

Redo: Restart the measurement series

or a single measurement.

Time and battery status

Settings: direct shortcut to

settings menu.

(only applicable to the

actual measurement series)

Save: Store measurement data.

Delete: Delete the last measurement.

Page 11

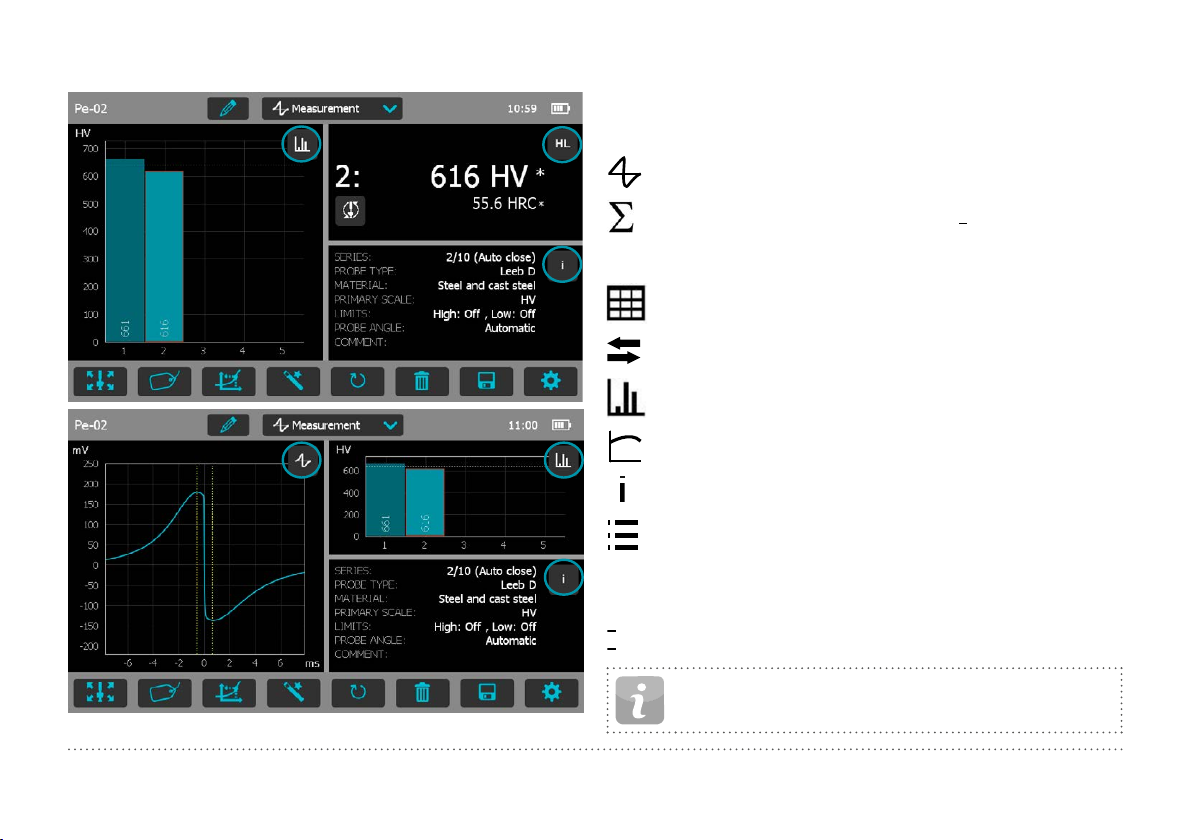

3.2.2 Measurement Views

HL

ID

+

Table of Contents

Equotip 550 is fully customizable as a device and can display three different measurement views simultaneously. Each view can be switched to

meet the user’s requirements by simply clicking on the icon related to the

particular display at the top right corner of each screen.

Signal View: Display the probe signal from the last active

measurement. This may be useful for advanced evaluations.

Statistic View: View statistics for the active measurement series. Number of impacts (n), Average (x), Standard deviation

(σ), Minimum/Maximum () and Range () are displayed in the

primary scale.

Table View: Display the measurements for the active series in

a table format.

Conversion View: Display the actual value on the conversion

curve.

Bar View: Display the measurements of the series as a histogram.

Profile View: Display the measurement results as a profile.

Info: Display the measurement settings e.g. series length,

probe type, material group etc.

User’s View: The user can choose between probe angle, mini-

mum, maximum, range and probe type for the field contents. To

change, tap on each individual box.

Single Record View: Display the last or selected measurement

result in both the primary and secondary hardness scales.

Sample ID’s: Defines the custom field.

Figure 9: Measurement Views

© 2016 Proceq SA 11

NOTE! Screen views cannot be duplicated.

Page 12

3.3 Measuring Methods

Table of Contents

Equotip 550 family of instruments is capable of accepting three diffrent

test methods using a single indicating unit.

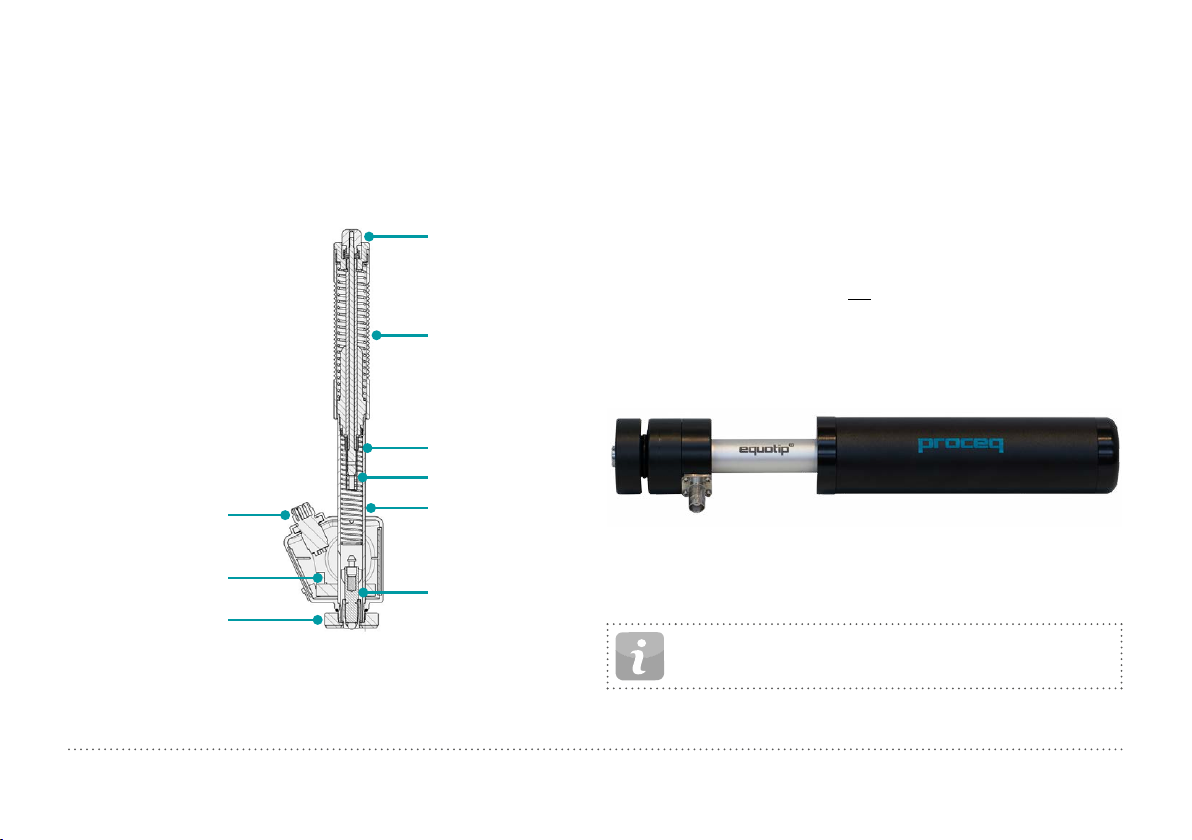

3.3.1 Equotip Leeb

3.3.1.1 Test Principle

Release button

Loading tube

Impact Spring

Catch chuck

Connection cable – 4 pole

Sensor of impact device with

ID ROM

Support ring

Figure 10: Schematic View of a Leeb Impact Device

Guide tube

Impact Body

During measurement with Equotip 550 impact devices (D, DL, DC, C,

G, S, and E); an impact body with a ball indenter is launched by spring

energy against the sample to be measured, and then rebounds. Before

and after the impact, a permanent magnet inside the impact body passes

through a coil in which a voltage signal is induced by the forwards and

backwards movement. This induction signal behaves proportionally to

the velocities. The ratio of the rebound velocity vr to the impact velocity vi

multiplied by 1000 yields the hardness value HL (Leeb hardness). HL is a

direct measure of the hardness. The third resp. fourth letter of the HL unit

refers to the impact device HLD D impact device.

v

r

HL =

·1000

v

i

Equotip Leeb U

Although the Equotip Leeb Impact Device U is constructed differently to

simplify the measurement process, the underlying principle is the same.

Figure 11: Equotip Leeb U Impact Device

Existing Parotester impact devices type U are fully supported by the

Equotip 550. Typ P and PG impact devices can be still used, but the unit

is shown as HLU although it would be actually LP resp. LPG.

NOTE! HLU values can be directly compared to LU on existing Parotester instruments.

12 © 2016 Proceq SA

Page 13

3.3.1.2 Sample Preparations

Table of Contents

Keep the sample free of vibrations during the test. Light and thin parts

must be specially fastened, see chapter “3.3.1.6 Testing Light Samples”.

Ensure that the surface of the work piece is clean, smooth and dry. If required, use appropriate cleaning agents for cleaning, such as acetone or

isopropanol. Do not use water or any other detergent fluids.

NOTE! Please use the surface roughness comparator plate

provided to estimate the average roughness of the test piece

prior to testing.

Figure 12: Surface Roughness Comparator Plate

3.3.1.3 Standards

Brief descriptions of referenced standards:

DIN 50156

ASTM A956

ASTM A370

ASTM E140

ISO 18265

ISO 16859

Leeb hardness testing of metallic materials

Standard test method for Leeb hardness testing of steel

products

Test methods and definitions for mechanical testing of

steel products

Standard hardness conversion tables for metals rela-

tionship among Brinell, Vickers, Rockwell, Superficial,

Knoop, Scleroscope and Leeb hardness

Metallic materials – Conversion of hardness values

Leeb hardness testing of metallic materials

© 2016 Proceq SA 13

Page 14

3.3.1.4 Test Conditions

Table of Contents

To ensure proper hardness readings, the following conditions must be fulfilled. If one or more conditions are not met, the measurement result may be

significantly false.

Impact device type D/DC/DL/S/E G C

Surface

preparation

Roughness grade class ISO 1302

Max. roughness depth R

Average roughness R

Minimum sample

mass

Of compact shape (kg / lbs)

On solid support (kg / lbs)

Coupled on plate (kg / lbs)

Minimum sample

thickness

Uncoupled (mm / inch)

Coupled (mm / inch)

Surface layer thickness (mm / inch)

Minimum space

Between indentation and sample edge

(mm/inch)

Between indentations (mm/inch) 3 / 0.12 4 / 0.16 2 / 0.08

Indentation size on

test surface

With 300 HV,

30 HRC

With 600 HV,

55 HRC

With 800 HV,

63 HRC

Table 1: Leeb Test Piece Requirements

(μm / μinch)

t

(μm / μinch)

a

Diameter (mm / inch)

Depth (μm / μinch)

Diameter (mm / inch)

Depth (μm / μinch)

Diameter (mm / inch)

Depth (μm / μinch)

N7 N9 N5

10 / 400 30 / 1200 2.5 / 100

2 / 80 7 / 275 0.4 / 16

5 / 11 15 / 33 1.5 / 3.3

2 / 4.5 5 / 11 0.5 / 1.1

0.05 / 0.2 0.5 / 1.1 0.02 / 0.045

25 / 0.98 70 / 2.73 15 / 0.59

3 / 0.12 10 / 0.4 1 / 0.04

0.8 / 0.03 0.2 / 0.008

5 / 0.2 8 / 0.3 4 / 0.16

0.54 / 0.021 1.03 / 0.04 0.38 / 0.015

24 / 960 53 / 2120 12 / 480

0.45 / 0.017 0.9 / 0.035 0.32 / 0.012

17 / 680 41 / 1640 8 / 2560

0.35 / 0.013 0.30 / 0.011

10 / 400 7 / 280

14 © 2016 Proceq SA

Page 15

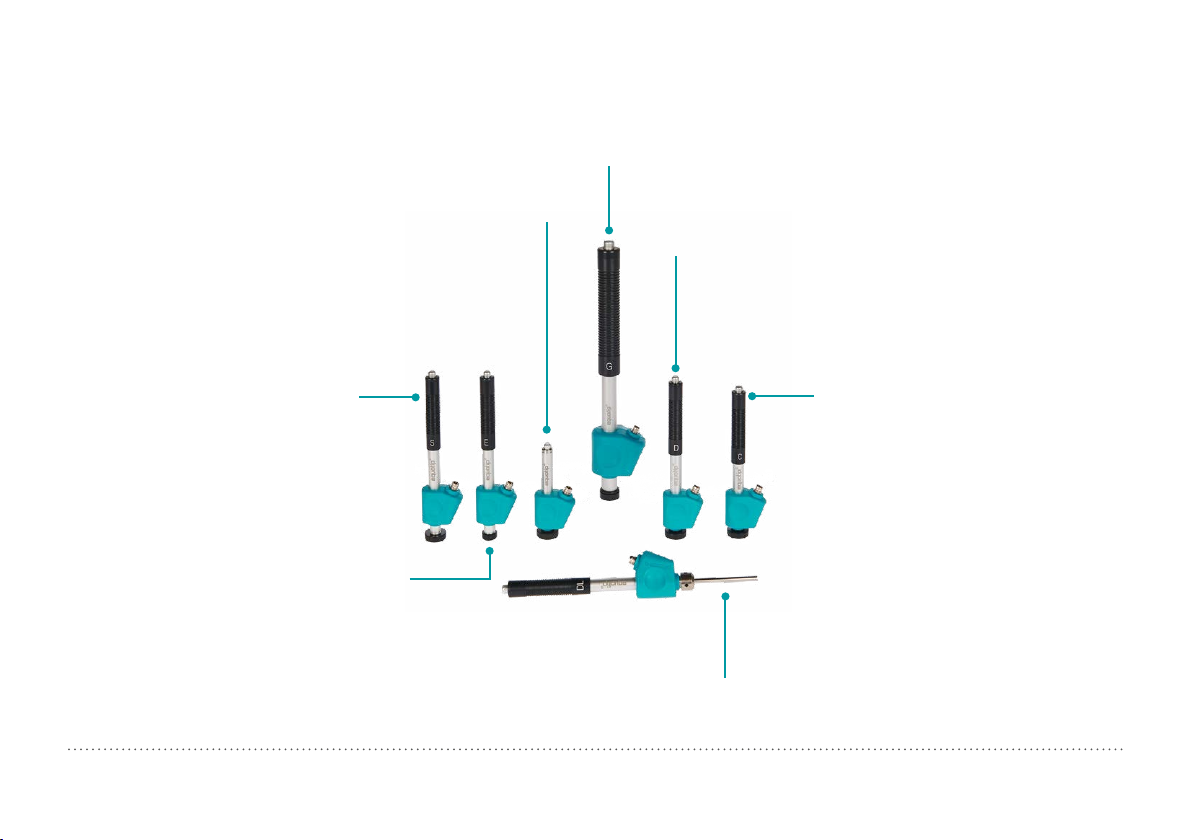

3.3.1.5 Selecting the Equotip Leeb Impact Device

Table of Contents

For optimized testing of diverse metallic materials and sample geometries, a range of impact devices are available as per “Table 1: Leeb Test Piece

Requirements”.

Type G: Increased impact energy. For solid and inhomogenous

components, e.g. heavy castings and forgings.

Impact energy: 90 Nmm

Type DC: Short device. For use in very

confined spaces, e.g. in holes, cylinders or

for internal measurements on assembled

machines. Impact energy: 11 Nmm

Type D: Universal unit. For the majority of

your hardness testing requirements.

Impact energy: 11 Nmm

Type S: Si3N4 ball indenter. For testing

especially in the very high hardness range

(in excess of 50 HRC / 650 HV): Tool steels

with high carbide content inclusions.

Impact energy: 11 Nmm

Figure 13: Equotip Leeb Impact Devices

© 2016 Proceq SA 15

Type E: Diamond ball indenter.

For testing in the very high hardness

range (in excess of 50 HRC / 650 HV):

Tool steels with high carbide content

inclusions. More durable than type S.

Impact energy: 11 Nmm

Type C: Reduced impact energy. Surface

hardened components, coatings, thin

walled or impact sensitive components

(small measuring indentation).

Impact energy: 3 Nmm

Type DL: Slim front section.

For measurements in confined spaces, at the

base of grooves or on recessed surfaces.

Impact energy: 11 Nmm

Page 16

3.3.1.6 Testing Light Samples

Table of Contents

If the samples are lighter than specified in chapter “3.3.1.4 Test Conditions” or sample sections have unfavorable mass distribution they can

vibrate as the impact body hits the test point. This results in unwanted

energy absorption. Such samples shall be supported by solid worktops.

If the mass falls below the specific requirements but still exceeds the

coupling amount then coupling it to a larger mass can help prevent vibrations.

The following requirements must be met for coupling:

• The contact surface of the sample and the surface of the solid support

must be level, flat and ground smooth.

• The sample must exceed the minimum sample thickness for coupling.

Follow the coupling procedure.

• Apply a thin layer of coupling paste to the contact surface of the sample.

• Press the sample firmly against the support.

• Push the sample in a circular motion and carry out the impact as usual,

perpendicular to the coupled surface.

NOTE! Clamping may strain the sample, which can affect the

hardness readings.

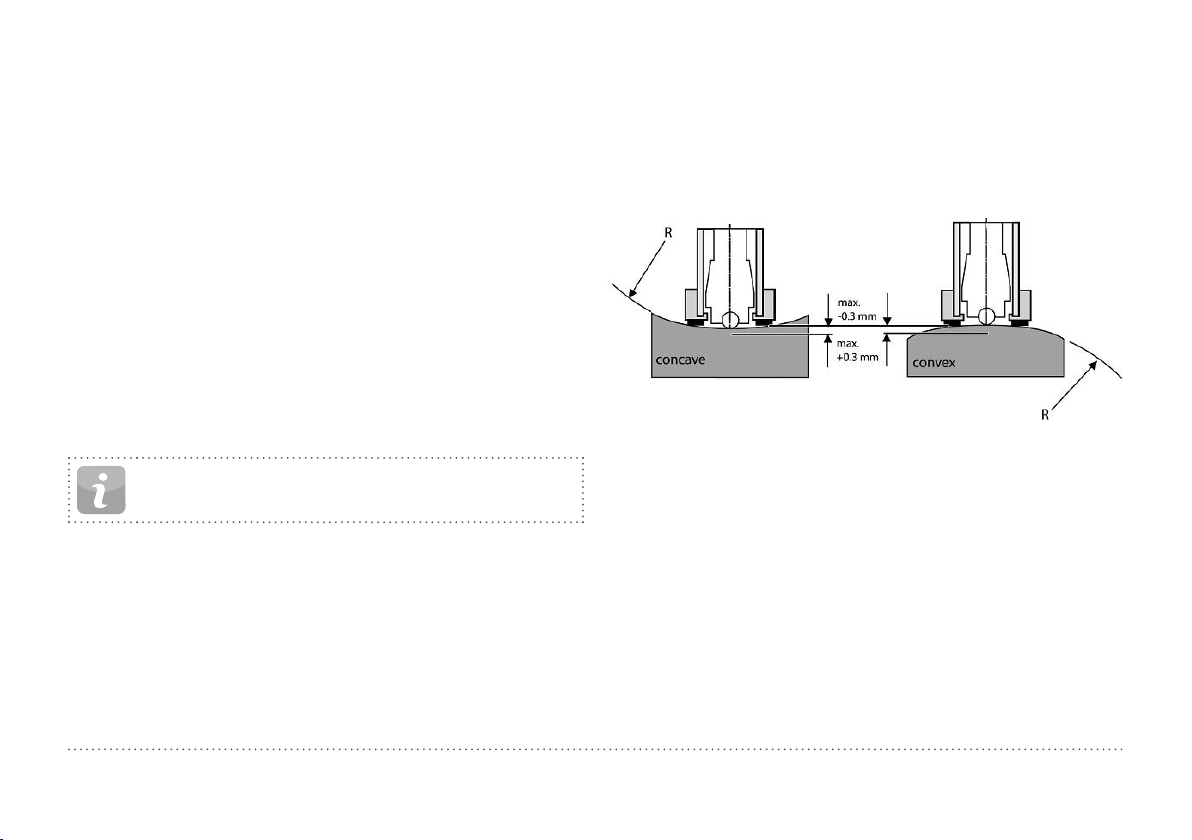

3.3.1.7 Testing Curved Surfaces

The instrument works properly only when the ball indenter at the front of

the impact body is precisely at the end of the tube at the time of the impact. When concave or convex surfaces are tested, the ball indenter either

does not entirely leave the test tube or comes out too far. In such cases,

replace the standard support ring by a specially suited ring, see chapter

“14. Ordering Information” or contact your local Proceq representative.

Figure 14: Leeb Testing on Curved Surfaces

16 © 2016 Proceq SA

Page 17

3.3.1.8 Testing Thin Samples

Table of Contents

Pipes and tubes sometimes have mass distributions that can affect the

result of the Leeb hardness test due to vibration. During on-site testing

of pipelines, for example the test locations cannot be supported by solid

worktops or clamped.

To benefit from the convenience and speed of the Leeb test, the user can

make use of a custom conversion after conducting the following calibration procedure, for example:

• Data pairs are measured on reference samples. For the Leeb HLDL reference measurements, it is crucial that they are done on parts that are

installed in the same way as those to be tested on-site. For example, two

pipe samples “Pipe type 5 mm Duplex soft” (730 HLDL / 255 HB) and

“Pipe type 5 mm Duplex hard” (770 HLDL / 310 HB) are measured using

the Equotip Leeb impact device DL and a Brinell tester, respectively.

• The original HLDL-HB conversion curve for “1 Steel and cast steel”

is now adapted using the two data points. The detailed procedure on

how to create custom conversion curves in the Equotip 550 is given in

chapter “6.4 Conversion Curve Creation”.

• To measure “Pipe type 5 mm Duplex” in future, it can be selected via

“Material” – “Pipe type 5 mm Duplex”, using the hardness scale “HB

Brinell” also see chapter “6.4.3 Example of a Custom Conversion (TwoPoint Method)”.

NOTE! The user needs to determine and qualify the adaptation of conversion curves for each tube diameter and wall

thickness. Guides to the procedure are provided in Nordtest

Technical Report Series 424, Reports 99.12/13 and ASME

Final Report CRTD-91.

3.3.1.9 Material Groups

No need to select any material when measuring in the native Leeb rebound scale HL as no conversion is applied. In contrast, hardness scale

conversions are correct only when the appropriate material group is selected. Free online material databases and the Equotip 550 on-board reference documents can be useful to assign your materials to one of the

default material groups. Suitability of conversions should be qualified on

calibrated samples before use. For further information, please consult a

Proceq representative.

NOTE! For a given test principle (native scale), the dropdown

menu only lists the material groups for which conversions

are available.

NOTE! If there is no conversion curve available, the user has

the possibility to create its their own, see chapter “6.4 Conversion Curve Creation”.

© 2016 Proceq SA 17

NOTE! It is important to include all the critical information

about the geometry of the test sample.

Page 18

D/DC DL S E G C

Table of Contents

Steel and cast steel

Cold work tool steel

Stainless steel

Cast iron lamellar graphite GG

Cast iron, nodular graphite GGG

Cast aluminium alloys

Copper/zinc alloys (brass)

CuAI/CuSn-alloys (bronze)

Wrought copper alloys, low alloyed

Table 2: Overview of Available Conversions

Vickers

Brinell

Rockwell

HV

HB

HRB

HRC

HRA

Shore

Rm N/mm²

HS

σ1

σ2

σ3

Vickers

RockwellHVHRC

Vickers

Brinell

Rockwell

HV

HB

HRB

HRC

Brinell

Vickers

Rockwell

Brinell

Vickers

Rockwell

Brinell

Vickers

Rockwell

Brinell

Rockwell

HB

HV

HRC

HB

HV

HRC

HB

HV

HRB

HB

HRB

81-955

81-654

38-100

20-68

30-99

275-2194

616-1480

449-847

80-900

21-67

85-802

85-655

46-102

20-62

90-664

90-698

21-59

95-686

96-724

21-60

19-164

22-193

24-85

40-173

14-95

80-950

81-646

101-964

101-640

37-100

21-68

22-70

61-88

31-97

275-2297

614-1485

449-849

80-905

21-67

28-104

340-2194

615-1480

450-846

104-924

22-68

* 119-934

105-656

70-104

21-64

* * * 92-326 *

* * * 127-364

20-187

21-191

20-184

22-196

* * * * *

84-1211

83-686

20-72

61-88

29-103

283-2195

616-1479

448-849

82-1009

23-70

88-668

87-661

49-102

20-64

23-176

22-198

90-646

48-100

305-2194

618-1478

450-847

* 98-942

* *

19-37

19-168

24-86

Brinell HB 60-290 * * * * *

Brinell HB 45-315 * * * * *

*Custom conversion curve / correlation

81-1012

81-694

20-70

30-102

275-2194

615-1479

450-846

20-67

*

21-167

23-85

18 © 2016 Proceq SA

Page 19

3.3.2 Equotip Portable Rockwell

Table of Contents

3.3.2.1 Test Principle

During measurement with Equotip 550 Portable Rockwell probe, a diamond

indenter is forced into the test piece, and then released back out of the material. The indentation depth is measured continuously during this process.

Indentation depth is calculated after decreasing the total load to preload.

10N

Figure 15: Portable Rockwell Test Principle

50N

10N

3.3.2.2 Sample Preparations

Ensure that the surface of the work piece is clean, smooth and dry. If

required, use appropriate cleaning agents for cleaning, such as acetone

or isopropanol. Do not use water or any other detergent fluids.

3.3.2.3 Measurement on Basis of DIN 50157

Both depth measurements d1 and d2 are taken at preload, first during

application (d1) then after release of the total load (d2). The difference between d1 and d2 originates from the deformation response of the material

to penetration.

NOTE! By calculating the penetration depth between the

preload and total load, surface roughness discrepancies are

significantly disregarded.

NOTE! The hardness testing principle in Portable Rockwell

follows the Rockwell stationary test. As for the Rockwell

test, no adjustment for the test direction is required. However, there are three main differences to traditional stationary

Rockwell tests:

• The test loads are lower.

• The Portable Rockwell indenter is sharper.

• The dwell times during the test are shorter.

NOTE! “MM” stands for “mobile mechanical” measurement,

an ancillary that is required by the German standard DIN

50157 to explicitly denote the lower applied loads, sharper

indenter shape and shorter loading times during a measurement. The different denomination is formal, i.e. the HMMRC

results should be very close if not equal to stationary HRC

readings.

© 2016 Proceq SA 19

Page 20

3.3.2.4 Test Conditions

Table of Contents

To ensure proper hardness readings, the following conditions must be

fulfilled. If one or more conditions are not met, the result may be significantly false.

3.3.2.5 Installing the Measuring Clamp

The clamp is designed to facilitate the hardness testing of very thin or

small samples.

Probe setup 50 N

probe

with

clamp

50 N probe

with round

standard

foot (ø =

42 mm)

Minimum test

piece thickness

Maximum test

piece thickness

Test piece surface

condition

40 mm N/A

recommended mean surface roughness

< 2 μm to minimize data scatter

R

a

1 mm at ~20 HB

130 μm at ~70 HRC

foot to be

Surface

curvature

used for

plane

surfaces

Maximum test

piece hardness

Minimum spacing

Table 3: Portable Rockwell Test Piece Requirements

three times the diameter of a test indentation

70 HRC

50 N

probe

with

tripod

very

small curvatures

acceptable

50 N probe

with special feet

18 – 70 mm

radius of

curvature or

70 mm – ∞

Cantilever

Cantilever screw

Knurled screw

Probe holder

Figure 16: Portable Rockwell Clamp

• Use the 3 mm Allen key setup tool to release the cantilever. Turn it by 90°.

• Take the probe and remove the foot. The diamond indenter remains

mounted.

• Screw the probe into the probe holder of the clamp clockwise (hand-tight).

• Turn the cantilever so its tip is centred over the probe; tighten the cantilever screw securely using the 3 mm Allen key setup tool.

• The recommended clearance between the bottom of the probe holder

and the sample surface should be between 2 and 5 mm. Adjust the

height with the two knurled screws.

20 © 2016 Proceq SA

Page 21

NOTE! In case the probe connector is in an inconvenient

Table of Contents

position, release the set screw. Ensure that the springs in

the mechanism do not get lost. Turn the mechanism into a

convenient position, aligning the set screw with the guide

channel. Lock the set screw so that the probe holder will still

slide up and down without rubbing on the set screw.

3.3.2.6 Considerations

• When measuring cylindrical samples with adapters Z4 or Z4+28, make

sure, the sample is not twisted on the clamp support. This is best

ensured when the back part of the clamp rests on a table and only the

sample support of the clamp sticks out over the table’s edge.

• When applying the load, slowly squeeze the leavers and allow the

sample to adjust to the support. During the measurement, do not

touch the sample, if possible. When releasing, grab the sample again.

• Whenever the sample geometry (i.e. the wall thickness) allows it, freehand measurements usually offer better measuring performance. This

applies particularly to measurements on cylinders.

• For small diameter rods (or stiff enough pipes), the V-notch clamp

adapter Z2 has been designed. When installing the Z2 support ensure

that the centre of the V-notch is centred underneath the probe holder.

3.3.2.7 Installation of Standard Foot or Tripod

The round standard foot permits measurements on test objects that are only

accessible from one side, such as large

metal sheets. The tripod is used when

the flat foot cannot be placed on the test

piece without wiggling.

1. The diamond indenter remains

mounted.

2. Install the foot on the probe.

Figure 17: Portable Rockwell

with Tripod

3.3.2.8 Installing the Special Foot

Two special feet extend the Portable Rockwell application range to cylindrical test pieces.

1. The diamond indenter remains

mounted.

2. Install the foot on the probe.

3. Place the foot on the test piece and

release the set screw on the foot.

Then press down the probe onto the

test piece and lock the set screw.

Figure 18: Portable Rockwell

Special Feet

© 2016 Proceq SA 21

Page 22

3.3.2.9 Conversion Standard

Table of Contents

Measurements in HV and HRC are direct correlations therefore no conversion is required. The user has the option of either ASTM E140 or ISO

18265 for conversion to any other scales.

3.3.3.2 Sample Preparations

Ensure that the surface of the work piece is clean, smooth and dry. If

required, use appropriate cleaning agents for cleaning, such as acetone

or isopropanol. Do not use water or any other detergent fluids.

3.3.2.10 Material Groups

Since Portable Rockwell is based on static indentation principle, the

hardness conversions are less dependent on material specific properties for the majority of times.

The user still has the possibility to apply customer conversion curves if

required, see chapter “6.4 Conversion Curve Creation”.

3.3.3 Equotip Ultrasonic Contact Impedance (UCI)

3.3.3.1 Test Principle

The UCI method uses the same pyramid-shaped diamond as a conventional Vickers hardness tester. Unlike Vickers testing, no optical evaluation of the indentation is required, enabling fast and portable measurements. The UCI method excites a rod into an ultrasonic oscillation. The

test load is applied by a spring and typically ranges from 1 to 5 kg of force

(HV1 – HV5). As the diamond is forced into the material, the frequency of

the rod oscillation changes in response to the contact area between the

diamond and the material under test. The instrument detects the shift in

frequency, converts it to a hardness value which is immediately displayed

on the screen.

3.3.3.3 Standards for UCI measurements

There are two standards which describe the UCI measurements, resp.

the instrument:

DIN 50159 Hardness testing with the UCI method

ASTM A1038 Standard test method for portable hardness testing by

the Ultrasonic Contact Impedance method

For conversions from one hardness unit to another, the user can chose

between the following standards:

ASTM E140 Standard hardness conversion tables for metals rela-

tionship among Brinell, Vickers, Rockwell, Superficial,

Knoop, Scleroscope and Leeb hardness

ISO 18265 Conversion of hardness values

22 © 2016 Proceq SA

Page 23

3.3.3.4 Test Conditions

Table of Contents

To ensure proper hardness readings, the following conditions must be fulfilled. If one or more conditions are not met, the result may be misleading.

Probe setup HV1 (~10 N) HV5 (~50 N)

Minimal required thickness

Minimal required weight

Required surface roughness

Acceptable surface curvature

Minimum space

Indentation size on test surface

300 HV, 30 HRC

600 HV, 55 HRC

800 HV, 63 HRC

Table 4: UCI Test Piece Requirements

Grade class N8 N10

Maximum roughness 15 μm / 600 μinch 60 μm / 2400 μinch

Average roughness 3.2 μm / 125 μinch 12.5 μm / 500 μinch

Indentation to edge 5 mm / 0.2 inch

Between indentations 3 mm / 0.12 inch

Depth 11.3 μm / 445 μinch 25.3 μm / 996 μinch

Diagonal 79.1 μm / 3114 μinch 177.1 μm / 6972 μinch

Depth 8 μm / 315 μinch 17.9 μm / 705 μinch

Diagonal 56 μm / 2205 μinch 125.3 μm / 4933 μinch

Depth 6.9 μm / 272 μinch 15.5 μm / 610 μinch

Diagonal 48.3 μm / 1900 μinch 108.5 μm / 4272 μinch

5 mm / 0.2 inch

0.3 kg / 0.66 lbs

Radius > 3 mm

© 2016 Proceq SA 23

Page 24

3.3.3.5 Installation of the Special Foot

Table of Contents

5 º

5º

The default foot allows the measurement to be performed on

every surface. The probe must be perpendicular to the surface (± 5°). The special foot can be used to increase the repeatability and avoid the distortion of the results, see chapter

“14. Ordering Information”.

1. Unscrew the standard foot and remove it

2. Screw the special foot to the probe tightly

NOTE! To measure in places with limited accessibility, the

probe can be used without any foot. If doing so, the side of

the rod of the probe must not touch any surface or be handled, as this leads to biased readings.

3.3.3.6 Conversions into Other Units

The frequency shift measured by the UCI probe is not only influenced by

the hardness, but also by its elastic properties. The default conversion curve

from the frequency shift to Vickers is valid for low-alloyed steel with an emodulus of 210 ± 10 GPa. As soon as a material has to be tested with a

different e-modulus, this existing conversion curve must be adapted. The

best way to do so is to calibrate the instrument on the material to be tested.

The Equotip 550 offers for this a fast and easy way. Once the hardness value

is converted to Vickers, it can be further converted to any other available

hardness unit according to either the ASTM E140 or the ISO 18265. Another

option is to adjust the default conversion based on the measurement of

Portable Rockwell or Leeb. To do so, see chapter “6.5 Combined Method”.

3.4 Instrument Verification / Daily Performance Check

See chapter “6.2 Device Verification” and follow the on-screen procedure. After the verification process your instrument is fully operational

and you can now continue with your measurements.

NOTE! The performance check should be done regularly before using the instrument to verify the mechanical and electronic functions of the probe and the indicating device. This

requirement is also included in the relevant hardness standards, see chapter “13. Standards & Guidelines”.

24 © 2016 Proceq SA

Page 25

4. Settings

Table of Contents

Figure 19: Settings Menu

4.1 Measurements

If changes are made here, they are set for all the upcoming measurement series. If the settings menu is accessed through the measurement

screen, changes are only valid for the actual measurement series.

4.1.1 Probe Type

Probe types are automatically recognised by the device. Default settings

can be set and will be used for each measurement device. If the measurement settings are accessed from the measurement screen, the active

probe can be selected.

4.1.2 Test piece management (Coming Soon)

Complete sets of settings can be managed in this menu. It allows the user to

save, edit, recall or delete these sets. This can be used to have a quick access

to different measurement settings, i.e. for different test pieces or applications.

4.1.3 Measurement Parameters

Material

The desired material group can be selected from the default list, in addition

you may predefine custom material groups which will be displayed here. For

custom material/curves please refer to chapter “6.4 Conversion Curve Creation”. For more information on material groups related to Leeb please refer to

chapter “3.3.1.9 Material Groups”, for Portable Rockwell chapter “3.3.2.10

Material Groups” and for UCI “3.3.3.6 Conversions into Other Units”.

Primary and Secondary scales

The user has the possibility to select two different scales in which the

measurement results are displayed.

NOTE! Conversion for HLD to HV, HB and HRC are standardized as per ASTM E140. Conversion for Portable Rockwell

(μm) and UCI can be switched between ASTM E140 and ISO

18265).

NOTE! Equotip Leeb Impact Device U does not support conversion curves, therefore these settings are not available.

Conversion Standards – Leeb

The conversion standard for Shore hardness HS switched between the

default conversion according to ASTM E448 or the Japanese conversion

according to JIS B7731.

NOTE! Measurements for certain types of Steel can be converted to tensile strength according to DIN EN ISO 18265.

Conversion Standards – Portable Rockwell

The default measuring method DIN 50157, is applicable for testing all

metallic material, and it generally yields more consistency. For conversions, user has the choice to select either ISO or ASTM.

© 2016 Proceq SA 25

Page 26

Conversion Standards – UCI

Table of Contents

The default measuring method is according to ASTM A1038 and DIN 50159.

For conversions, the user has the choice to select either ISO or ASTM.

Use Advanced Algorithm (Portable Rockwell only)

Advanced Algorithm provides faster measurements. This is especially

useful when testing softer material.

Impact direction (Leeb only)

With exception to DL and U devices all Leeb impact devices have automatic direction compensation. You may override this and set the impact

direction manually. For more information on impact direction please refer

to chapter “3.1.1 Leeb Testing Procedure (except Leeb U)”. Impact direction is not relevant to the Portable Rockwell and the UCI devices.

Trigger Load (UCI only)

For the Equotip UCI probe the load where the measurement will be triggered can be chosen in the range from HV1 to HV5 (10 – 50 N). The trigger load cannot be changed once the measurment series was started.

Units (Portable Rockwell only)

For Portable Rockwell probe, choose to display the indentation depth in

metric or imperial units.

4.1.4 Sample IDs

After Measurement

Use this setting to define if the current sample ID’s should be kept for the

next measurement series or deleted.

Edit Entries

The entries of the different sample ID fields can be deleted or edited here.

For easy increasing or decreasing, use the up- and down- arrows. For adding or removing entry fields, please see chapter “8.1.2 General Features”.

4.1.5 Workflow

Activate User Guidance

Select to display on screen instructions and messages when taking a

measurement.

Auto Close Series

Automatically end a series after a set number of measurements. The user

can set the series from 1 to 1000 measurements.

Measurement Comment Handling

Use this setting to allow or disallow the user to enter a comment at the

completion of a measurement series. When set to “free” this enables the

user inputing a comment.

Measurement Series Filename

Enter the file name for the measurement series will be stored. This possibility is disabled, if filename management is activated.

Save to Folder

Set the folder location where the measurement series file to be stored.

This option is disabled, if folder management is activated.

Store Signal Data (Leeb only)

Select to store the raw waveform for Leeb measurements. For Portable

Rockwell the signal form will be stored for each measurement automatically,

for UCI this option is not available..

NOTE! Storing signal data will cause measurement files to

take up more memory.

Enable Warnings

Choose to enable warning display signals and sounds to indicate false

measurements.

26 © 2016 Proceq SA

Page 27

Use report templates

Table of Contents

Here a template for the report can be selected. By default, the default

template will be used. This default template can be selected in the template manager.

Operator

Here the test operator can be edited. This operator name is stored for the

following measurements, but not for the verifications.

4.1.6 Limits

Enable Upper and Lower Limits

Select to enable the display of the upper and lower tolerance limits for the

measurements. Specific color coding is adopted to differentiate between

upper and lower limits.

4.2 Verification (Performance & Uncertainty Check)

To see how a verification can be performed please refer to chapter “6.2

Device Verification”.

4.2.1 Test Block Management

It is important to verify the correct functionality of the instrument on a

testblock calibrated in the genuine native scale of the probe being used.

In the test block management section, different test blocks information

can be stored. Test blocks that are listed here can then be used during

the verification process.

4.2.2 Workflow

Standard

Select the standard according to which the verification should be performed.

It can be selected between ISO, ASTM or a customer defined standard.

Minimum series count

The minimum required number of measurements can be selected here. If

a standard was selected before, this setting is fixed.

Maximum series count

The maximum allowed number of measurements can be selected here. If

a standard was selected before, this setting is fixed.

Operator reference

Here the reference operator name can be entered if required. This name

will be used for the verification processes. If no name is entered here, the

user can still enter it during the verification process.

NOTE! First time user: It is recommend to complete a “Tutorial on Leeb and Portable Rockwell Hardness Testing” as

appropriate or watch a demonstration by a qualified Proceq

representative.

NOTE! The performance check should be done regularly before each use of the instrument to verify the mechanical and

electronic functions of the impact device and the indicating device. This requirement is also included in the DIN and

ASTM Leeb hardness standards, see chapter “8.1 Features”.

4.2.3 Verification Standards and Extended Uncertainty

It is recommended for the instrument to be verified prior to testing. This

gives the user the extra assurance that the device is working correctly

and the measurement data are accurate. Although the verification process is similar on all Leeb, Portable Rockwell (mechanical penetration

depth) and UCI standards, user has the option to comply with the preferred standard/verification procedure.

© 2016 Proceq SA 27

Page 28

DIN 50156

Table of Contents

DIN 50157

DIN 50159

ASTM A956

ASTM A1038

ISO 16859

Extended

Uncertainty

(Combined

Uncertainty)

Leeb hardness testing of metallic materials. Will be replaced by ISO 16859.

Hardness testing of metallic materials with portable

measuring instruments operating with mechanical penetration depth.

Hardness testing with the UCI method.

Standard test method for Leeb hardness testing of steel

products.

Standard test method for portable hardness testing by

the Ultrasonic Contact Impedance method

Hardness testing of metalic materials by Leeb.

Measurement uncertainty analysis is applied to understand the differences in test results and to determine

sources of error. The uncertainty of an Equotip Leeb,

Equotip Portable Rockwell or Equotip UCI hardness

testing system consists of a statistical component, a

component inherent to the measurement device and a

component arising from the metrological chain between

national standard and the user device (traceability).

Although uncertainty could be a complicated topic,

Equotip 550 automatically calculates the combined uncertainty of the system. All the required information is already available in the calibration certificates provided by

Proceq. Therefore the device only requires adding these

values in the specified fields and following the simple

steps on the display in order to complete the process.

4.3 Conversions (Hardness Conversions)

There is no direct correlation between any two hardness scales. Therefore conversions must be determined by comparison testing for any

given alloy.

4.3.1 Standard Conversions

Proceq has developed correlations to convert the Leeb hardness measurements to other commonly used hardness scales based on groups

of alloys that have a close relationship. The conversions for HLD and

Material Group 1 (Carbon Steels) are standardized according to ASTM

E140-12b.

4.3.2 Custom Conversion Curves

See chapter “6.4 Conversion Curve Creation”.

4.3.2.1 Custom Compensation

In some cases a user must measure hardness on many samples with identical size and shape that is below the ideal limits for accuracy. Studies have

been published by ASME and Nordtest that have identified and confirmed

the validity of the strategy to apply a compensation factor to correct for the

inaccuracies induced by the non-ideal geometry. The methods outlined in

chapters “6.4 Conversion Curve Creation” can be applied to create this

compensation factor to be applied automatically to the Equotip test result.

4.4 Reporting

The content of the measurement reports can be adjusted here.

4.4.1 Images Explorer

Images, i.e. company logos can be loaded from an USB stick on the device, for use in reports. Pictures must be in the *.png or *.jpg format, ideally

come with 72dpi and a maximum resolution of 496x652 pixel.

Upload Images from an USB-stick

To do so follow the steps below.

• Create the folder “PQ-Import” in the main directory of the USB-stick

(not as a subfolder in another folder) and fill it with all the picture-files

to be uploaded to the Equotip Touchscreen

28 © 2016 Proceq SA

Page 29

• Connect the USB-stick to the USB Device plug on the left side of the

Table of Contents

Equotip Touchscreen

• Click on

• The uploaded images appear in the Images Explorer

and confirm with click on

NOTE! The USB stick must be either formatted in FAT or

FAT32. NTFS is not supported.

4.4.2 Report template explorer

The report templates can be managed here. Either the default template

can be used, or a fully customized template can be created and edited.

Templates can also be copied or exported to an USB stick.

4.4.3 Reporting via PDF

It’s possible to create reports directly on the instrument as PDF and store

them on USB stick. Choose the measurement files in the data explorer of

which a report should be created, mark them by ticking the box. Tap the

button to create the reports. The report will be created with the selected report template. Repeat this for each file. For each measurement

series there will be a separate PDF created.

NOTE! The report option is only visible if an USB stick is connected to the instrument. The USB stick must be either formatted in FAT or FAT32. NTFS is not supported.

Optionally, also the project file can be exported to the USB stick. Here all

files will be included in one file.

4.4.4 Reporting via Equotip Link

Alternatively to create reports the PC-Software Equotip Link can be used.

For more details please refer to chapter “11. Equotip Link Software”.

5. Data (Explorer)

Figure 20: Data Explorer Menu

5.1 Measurements

5.1.1 Storing Measurements

If the auto close option is disabled or chosen number of impacts is not

reached, the series can be closed and saved manually by tapping the

store button .

If the auto close option is enabled, the measurement series will be automatically stored as soon as the chosen number of impacts is reached.

The name under which the series will be stored can be edited in the upper left corner.

© 2016 Proceq SA 29

Page 30

NOTE! If the file name already exists, the name will be ex-

Table of Contents

tended by a number and increased with every additional file.

Tap on a saved file to open it and return to the Data Explorer list by pressing the back button.

The stored measurements can be organized in folders, by tapping the

Data Explorer button on the new folder option

Enter the name of the new folder and confirm by tapping on the back

button in the upper left corner.

The folder in which new measurements are stored can be selected under

Settings Measurement Save to Folder.

.

5.1.2 Data Explorer

From the main menu select Data Measurements to review and manage

saved measurements data.

Each folder and measurement series is shown as one line in the explorer

view.

For each series the probe used, mean value of the series, series name,

date & time of the measurement can be seen.

The list can be sorted by tapping on the corresponding header. The small

arrow indicates which list is sorted.

Figure 21: Measurement View in Data Explorer

5.1.3 Review of Data

In the detailed view of a measurement series, all information can be seen

and the settings are editable.

All the different views can be switched according to the users needs.

For more details about the different views, please refer to chapter “3.2.2

Measurement Views”.

5.1.4 Delete Files

From stored measurement files, single impacts can be eliminated afterwards. To do so, open the measurement series, tap the value to eliminate

and tap delete button .

Whole measurement files can be deleted in the Data Explorer. To do so,

tap on the box of the appropriate files to select and all selected files can

be deleted by tapping the delete button

To erase all data stored on the instrument, in the root folder tap on the

box on the left end of the header row then tap the delete button

.

.

30 © 2016 Proceq SA

Page 31

5.1.5 Copy Files

Table of Contents

To copy measurement series, select the file and click on the icon. Go

to the folder where the copy should be created and tap the icon to

paste the file. When copying a file all attributes will be duplicated

NOTE! The file cannot be added in the same folder!

5.1.6 Cut & Paste Files

To move existing measurement series from one place to another, set the

tick of the corresponding file and tap on the icon. Go to the folder

where the file should be moved in and tap the icon to paste the file

5.2 Verifications

From the main menu select “Data”, and then “Verifications” to review and

manage saved verification data “6.2 Device Verification”.

The verification data is stored and managed in the same manner as the

measurement data. Except no deletion is allowed.

Each folder and measurement series is shown as one line in the explorer

view.

Additionally the result for each verification data series, either a “passed”

or a “failed” is displayed.

6. Wizards

Figure 22: Wizards Menu

Wizards are a unique feature of Equotip 550. These simple step-by-step

instructions are for the majority of users, no matter how experienced they

are. Interactive wizards help speed up the workflow and improve the

measurement’s reliability.

All settings concerning wizards can be edited in the System User Settings. Also see chapter “8.1 Features”.

NOTE! For Equotip Leeb Impact Device U only the “Device

Verification” wizard is available.

© 2016 Proceq SA 31

Page 32

6.1 Measurement Wizard

Table of Contents

This particular wizard helps define the best measurement principle e.g.

impact device to fit the application, simply based on sample geometries

and surface conditions. To start, some basic information must be provided to define the test piece. When information is evaluated by the device

a series of recommendations are displayed in order of their relevance to

the application in question.

After the initial process is complete, the device recommends the appropriate probe, scope of application and preparation information. Settings

will then be adopted and the intelligent measurement process begins.

NOTE! Please verify that correct series number, impact direction, material group, scales and limits are defined as well as

sub file and folder name.

6.3 Impact Direction Calibration (Leeb only)

Each Leeb impact device requires a calibration in order to automatically

compensate for impact direction. This is easily achieved using this wizard.

NOTE! All impact devices are already factory calibrated when

shipped, however based on the usage and application it is

recommended to recalibrate the impact direction prior to

verification process chapter “6.2 Device Verification”. If this

process is not completed currently inaccurate data may be

obtained.

NOTE! This wizard can also be started from the menu System Probes.

6.2 Device Verification

During the verification process, the user will be guided through the entire procedure. At the end of the procedure the instrument is considered

verified and the data is stored in the device memory. Verification data is

also stored as the verification is performed, therefore any discrepancies

occurring over time will be noticeable.

32 © 2016 Proceq SA

NOTE! This wizard can also be started from the menu System Probes.

NOTE! A Proceq reference test block is required to complete

this wizard successfully.

6.4 Conversion Curve Creation

When default conversions are not suitable for the material being tested,

it is recommended to create a customized conversion/correlation. This

wizard guides the user through the complete process in a simple manner and provides all the necessary information on comparative measurements.

This creates a brand new conversion curve which is used for any future

measurements on the material in question.

6.4.1 Minimizing Conversion Errors

Conversion errors will not normally exceed ±2 HR for Rockwell scales

and ±10 % for Brinell and Vickers provided the material group is selected correctly. In most cases, the conversion error is significantly lower.

If higher accuracy is required or if the alloy under test is not covered by

one of the standard conversions, the Equotip 550 provides a variety of

methods to define material-specific conversions.

Page 33

6.4.2 Methods for Setting Up Custom Conversions

Table of Contents

The Equotip 550 provides three techniques to accomplish custom conversions, each can be used for all of the three different measuring principles (example HLD HRC):

One-point method: The Leeb hardness HLD and the hardness in the

desired scale (i.e. HRC) are determined for a reference work piece. A

standard conversion function HLD-HRC is then adapted through vertical

offset until the measured reference data pair lies on the shifted curve.

Two-point method: Two reference samples are tested, one as soft and

one as hard as possible to find two data pairs (i.e. HLD / HRC). A standard

conversion function HLD-HRC is then adapted through adding a straight

line until both of the measured reference data pairs lie on the tilted curve.

Conversion polynomial: If a custom conversion needs to be applied

throughout a wide hardness range, several reference samples shall be

tested to find a stable basis for interpolation. Up to 5th order polynomials

can be programmed into the Equotip 550 indicating device by defining

the polynomial coefficients A

HRC(HLD) = A

+ A1· HLD + A2· HLD2 + A

0

see Equotip Technical Guide under Information Documents or in the

download section of the Proceq website.

NOTE! When using a polynomial conversion of a higher order, please make sure to have the coefficients with sufficient

digits to avoid inaccuracies in calculations.

i

in

· HLD3 + A4· HLD4 + A5· HLD

3

5

6.4.3 Example of a Custom Conversion (Two-Point Method)

The data pairs (640 HLD / 41.5 HRC) and (770 HLD / 54.5 HRC) were

measured on two reference samples made from “special steel”.

To measure “special steel” in the future using an adapted HLD-HRC conversion, the original HLD-HRC conversion curve for “1 Steel and cast

steel” is tilted using the two data points. In this example, the special

conversion is defined as valid for the range 41 to 55 HRC.

Once this curve has been created, it can be selected via material group

“Customer defined” – “Special steel”, using the hardness scale “HRC

Rockwell C” also see chapter “3.3.1.8 Testing Thin Samples”.

Figure 23: Two-Point Conversion

© 2016 Proceq SA 33

Page 34

Figure 24: Custom Conversion Menu

Table of Contents

6.4.4 Measuring Reference Samples

Sample surfaces must be prepared very carefully and if possible, sample

shall met the specific geometries to avoid coupling method.

The functioning of the Equotip 550 shall be verified against the Leeb test

block prior to each measurement series.

The functioning of the static hardness testing machine (HMMRC, HV, HB,

HRC etc.) shall be verified against respective test blocks of the corresponding measuring scale and range.

To obtain a pair of comparative values, the mean value from at least 10

HL measurements and at least 3 values from the static test shall be calculated. These values shall be obtained from proximate positions in a

small measuring area depending on application.

6.5 Combined Method

The existing default hardness conversions in Equotip Leeb devices are

based on specific sample geometries. A Portable Rockwell probe has

almost no restriction with regard to thickness and mass. For samples that

don’t meet the Leeb specification, a simple custom correlation based on

the Portable Rockwell measurements enables the user to apply a correction factor and create a new hardness conversion. This is one example where the combined method is used to fit one measuring method

with the help of another one, for an application which is not covered by

the default setup. But there are several other occasions where this helpful tool offers great help. This can be achieved following the combined

method wizard on the Equotip 550. This wizard allows the combination of

the Leeb and Portable Rockwell, the UCI and Portable Rockwell and also

the combination of UCI with Leeb method. In each combination the later

mentioned method is the reference method.

This wizard guides the user in five simple steps through the whole process, and finally creates the conversion curve. For other applications it

can be used accordingly. For more information please see the “Equotip

Application Guide” on the Proceq homepage.

6.6 Mapping Wizard (Coming Soon)

The mapping wizard allows the user to create a 2-dimensional map with

readings. This is used to ‘scan’ a whole area. This wizard guides the user

in the whole process from defining the area, through the measurements

up to the final measuring report.

34 © 2016 Proceq SA

Page 35

7. Information

Table of Contents

Figure 25: Information Menu

7.1 Documents

All documentation files are stored in this section of the instrument and

can be viewed directly when required.

• Quick Start Guide: Gives an overview on the instrument including

scope of delivery.

• Operating Instructions: This document.

• Certificates: Certificates applicable to this product.

• Application Booklet: In-depth technical information on the different

measurement principles, its standards, influence of elevated temperatures, heavy use instructions and more.

• Platform Remote Control Package: Instructions are given on how

the instrument can be used with the remote control, i.e. for automation etc.

• More documents may be added at a later date.

NOTE! The last viewed document can be quickly accessed

by pressing the “Soft Key”. For more information see chapter

“2.1 Installation”.

7.2 Upload PDF-Files from an USB-stick

Additional documents in the PDF format can be stored on the instrument.

To do so follow the steps below.

• Create the folder “PQ-Import” in the main directory of the USB-stick

(not as a subfolder in another folder) and fill it with all the pdf-files to be

uploaded to the Equotip Touchscreen

• Go to Information/Documents

• Connect the USB-stick to the USB Device plug on the left side of the

Equotip Touchscreen

• Click on

• The uploaded PDF-files appear on the bottom of the document list

and confirm with click on

NOTE! The USB stick must be either formatted in FAT or

FAT32. NTFS is not supported.

© 2016 Proceq SA 35

Page 36

8. System

Table of Contents

Figure 26: System Menu

Verification Notification: Verification of the instrument can be set to

forced, optional or disabled. When set to disabled the user will not be

forced to perform an indirect verification. The setting “optional” is just a

reminder. If “forced” or “optional” is selected, an entry appears where the

verification interval may be chosen.

Custom Fields: The custom entry fields can be edited here. Beside the

five default fields which cannot be deleted, additional 20 fields can be

added.

8.1.3 Data Management

Use Folder Manager

Activate this option to use automatic folder management as configured

in the Folder Manager.

Folder Manager

Here the desired path can be edited. A maximum of four subfolders can

be created with selectable information. As soon as one of this information

changes, a new folder will be created automatically.

8.1 Features

8.1.1 Device Lock Settings

Lock/Unlock: Select this to lock the instrument and protect it from unintentional changes.

Password: A password can be set for the lock/unlock function. If this

field is left empty, no password is required to unlock the user settings.

8.1.2 General Features

Measurement Wizard: There are three options available on how the

measurements wizards are enforced.

36 © 2016 Proceq SA

Use File Manager

Activate this option to use automatic file naming as configured in the File

Manager.

File Manager

An automatic name can be configured here consisting of four different

information fields.

Long Filename Viewing

Choose here between a full view of the filename, or if only a selected

range should be displayed in the measurement screen. This setting influences only the name on the measurement screen, but not in the explorer

or reports.

Page 37

8.1.4 Probe Features

Table of Contents

For each probe type there is an option to protect its settings. Furthermore, for each probe type the different features to protect can be selected.

Factory reset: Select the options to delete all relevant data from the

device.

NOTE! This step cannot be undone, deleted items are permanently destroyed!

8.2 Probes

Information about the connected probe can be viewed here.

Angle calibration (Leeb only): The angle calibration for this particular

probe can be redone. This calibration can be done only for Equotip

Leeb Impact Devices.

Verification: Verification measurement series can be started here.

To see information about other used probes, tap on the

Probe Serial Number (only for Leeb U): As the serial number can not be

recognized automatically, the user has to enter it manually here.

button.

8.3 Hardware

General settings about the user interface and power options can be edited here.

Sound: The volume of the audio notifications of the instrument can be

adjusted respectively switched off.

Display: The user can adjust the brightness of the display backlight.

Power: The time after when the instrument dims the display, or shuts

down can be adjusted, for both battery and AC powered operation.

8.4 Date & Time

Date and time is set in this submenu. The format of these settings and the

time zone can also be modified.

8.5 Language

The language setting of the instrument can be selected. Eleven different

languages are available. The language of the help file is the same as for

the rest of the menu.

8.6 Device information

Tap the info button in the upper right corner to view all the information related to the device e.g. name, version and serial number can be

found in this section as well as battery status. On this information page

the IP address (if ethernet is connected and a DHCP server is available)

and the instruments MAC address will also be shown.

© 2016 Proceq SA 37

Page 38

9. Maintenance and Support

Table of Contents

9.1 Maintenance

The instrument should be calibrated annually to ensure consistent, reliable and accurate measurements. However, the service interval may be

based on actual experience and usage. Consult the applicable standards

for more guidance.

9.1.1 Regular Device Check

Performance checks, see chapter “4.2 Verification (Performance & Uncertainty Check)” of the instrument should be carried out at least once a day or

at the latest after 1000 impacts. In the case of infrequent use, carry out the

check before the beginning and at the end of a test series. In addition, have

the device calibrated by an authorized Proceq Service Center once a year.

NOTE! The unit is working properly when the average is

within the target range. Otherwise, please see chapter “10.

Troubleshooting”.

9.1.2 Cleaning

Leeb Impact device: Unscrew the support ring. Remove the impact

body from the guide tube. Clean the guide tube with the cleaning brush.

Reassemble.

Leeb Indenters: Clean the ball of the Leeb impact bodies and Portable

Rockwell diamond indenter with acetone or similar solvent. (Do not use

water or water based detergents!)

Portable Rockwell and UCI probes: Clean the probes and the diamond indenters with a clean, dry cloth.