Proceq Pprofometer 600, 39210001, 39220001, 39230001, Profometer 630 AI. Profometer 650 AI Operating Instructions Manual

Page 1

Made in Switzerland

Design Patent Pending

Made in Switzerland

®

Operating Instructions

Page 2

© 2017 Proceq SA 2

Scope of Delivery

D

K

T

C

B

E

F G

I

A

O

N

P

L M

U

Q S

R

H J

Page 3

3 © 2017 Proceq SA

Scope of Delivery

Profometer 600 (39210001)

Profometer 630 AI / 650 AI (39220001 / 39230001)

Profometer Corrosion (39250001)

Upgrade kit to Profometer Corrosion (39250002)

Upgrade kit to Profometer 600 Cover Meter (39250003)

Profometer Corrosion rod electrode (39250010)

Profometer Corrosion wheel electrode (33001001)

Profometer Corrosion four wheel electrode (33001004)

A

Carrying case

•

•

•

•

•

B

Profometer touchscreen

•

•

•

C

Battery complete

•

•

•

D

Power supply incl. cables

•

•

•

E

USB cable

•

•

•

F

DVD with software and documentation • •

•

•

•

G

Documentation • •

•

•

•

H

Activation key •

•

I

Carrying strap complete

•

•

•

J

Probe cable 1.5 m (5 ft) •

•

•

K

Universal probe with ruggedized scan cart •

•

•

L

Chalk • • •

M

Interface box • •

N

Cable coil l=25 m (82 ft) with clamp • •

O

Rod electrode with spare parts •

P

Copper sulphate, 250g • • •

Q

Citric acid, 250g • •

R

Rod electrode cable, 1 lead, l=1.5 m (5 ft) •

S

Tool kit • •

T

Wheel electrode with cables and spare parts •

U

Four wheel electrode with cables and spare parts •

Page 4

© 2017 Proceq SA 4

Table of Contents

1. Safety and Liability ...................................................5

1.1 General Information ...........................................................5

1.2 Liability ...............................................................................5

1.3 Safety Instructions ............................................................5

1.4 Correct Usage ...................................................................5

2. General Operation ........................................................ 6

2.1 Getting Started ..................................................................6

2.2 Main Menu .........................................................................7

2.3 Upgrade procedure ...........................................................7

2.4 Cover Meter and Corrosion functionalities ......................8

3. Profometer 6 Cover Meter............................................ 9

3.1 Measuring Principle ..........................................................9

3.2 Cover Meter Operation ...................................................10

4. Profometer Corrosion ................................................. 30

4.1 Measuring Principle ........................................................30

4.2 Profometer Corrosion Operation ....................................33

5. Explorer Document Handling ..................................... 43

6. Ordering Information ................................................. 44

6.1 Units .................................................................................44

6.2 Upgrades .........................................................................44

6.3 Parts and Accessories ....................................................44

7. Technical Specifications ............................................ 45

8. Maintenance and Support ......................................... 46

8.1 Maintenance and Cleaning .............................................46

8.2 Support Concept .............................................................47

8.3 Standard Warranty and Extended Warranty ..................47

8.4 Disposal ...........................................................................47

9. Profometer Link Software .......................................... 47

9.1 Starting Profometer Link .................................................47

9.2 Connecting to a Profometer Touchscreen Unit ..............48

9.3 Viewing Cover Meter Data ..............................................48

9.4 Viewing Corrosion Data ..................................................49

9.5 Editing and moving data files .........................................49

9.6 Exporting Data .................................................................50

9.7 Merging Corrosion Scans ...............................................51

9.8 Further Functions ............................................................51

10. Appendices ................................................................. 52

10.1 Appendix A1: Rebar Diameters ......................................52

10.2 Appendix A2: Neighboring Bar Correction .....................52

10.3 Appendix A3: Minimum / Maximum Cover ....................52

Page 5

5 © 2017 Proceq SA

1. Safety and Liability

1.1 General Information

This manual contains important information on the safety, use and maintenance of the Profometer 6. Read through the manual carefully before

the first use of the instrument. Keep the manual in a safe place for future

reference.

1.2 Liability

Our “General Terms and Conditions of Sales and Delivery” apply in all

cases. Warranty and liability claims arising from personal injury and damage to property cannot be upheld if they are due to one or more of the

following causes:

• Failure to use the instrument in accordance with its designated use as

described in this manual.

• Incorrect performance check for operation and maintenance of the instrument and its components.

• Failure to adhere to the sections of the manual dealing with the performance check, operation and maintenance of the instrument and its

components.

• Unauthorised modifications to the instrument and its components.

• Serious damage resulting from the effects of foreign bodies, accidents,

vandalism and force majeure

All information contained in this documentation is presented in good faith

and believed to be correct. Proceq SA makes no warranties and excludes

all liability as to the completeness and/or accuracy of the information.

1.3 Safety Instructions

The equipment is not allowed to be operated by children or anyone under

the influence of alcohol, drugs or pharmaceutical preparations. Anyone

who is not familiar with this manual must be supervised when using the

equipment.

• Carry out the stipulated maintenance properly and at the correct time.

• Following completion of the maintenance tasks, perform a functional

check.

1.4 Correct Usage

• The instrument is only to be used for its designated purpose as describe herein.

• Replace faulty components only with original replacement parts from

Proceq.

• Accessories should only be installed or connected to the instrument

if they are expressly authorized by Proceq. If other accessories are

installed or connected to the instrument then Proceq will accept no

liability and the product guarantee is forfeit.

Page 6

© 2017 Proceq SA 6

2. General Operation

2.1 Getting Started

Battery installation

To install the battery, remove the protection foil and lift the stand as

shown. Insert the battery and fasten in place with the screw.

There are two status LEDs (Figure 1,

1

) and above them a light sensor.

The upper LED is red while charging and turns to green when it is fully

charged. The other LED is application specific.

NOTE! Only use the power supply provided.

• A complete charge requires < 9h (Instrument not operating).

• Charging time is much longer if the instrument is in use.

• An optional quick charger (Part No. 327 01 053) can be used to charge

a spare battery or to charge the battery outside of the instrument. In

this case it takes < 4h for a complete charge.

Energy Saving

Energy saving may be programmed as desired under System/Power settings.

Figure 1: Main menu, leds, buttons

Buttons

Lift the protective visor.

On the upper right of the screen there are three buttons (Figure 1,

2

).

Power On/Off – Press to power on. Press and hold to power off.

Fullscreen / PDF viewer / Hard Keys Mode.

Back Button – returns to previous screen.

1

2

Page 7

7 © 2017 Proceq SA

Probes connection Profometer 6

Connect the universal probe to either of the two sockets or on the

upper side of the Profometer touchscreen using the probe cable.

Profometer Corrosion

Mount the interface box on the right side of the Profometer touchscreen

using the attached screws and and connect the cable to either of

the two sockets or on the upper side of the Profometer touchscreen.

Connect the electrode signal cable to socket and the ground cable to

the socket of the interface box. Wheel electrodes: connect the path

measurement cable to socket of the interface box.

USB Host:

Connect a mouse, keyboard or USB stick.

USB Device:

Connect application specific probes and PC.

Ethernet:

Connection for firmware upgrades.

Power Supply:

Connect the power supply through this connection.

USB Host

USB Device

Ethernet

Power Supply

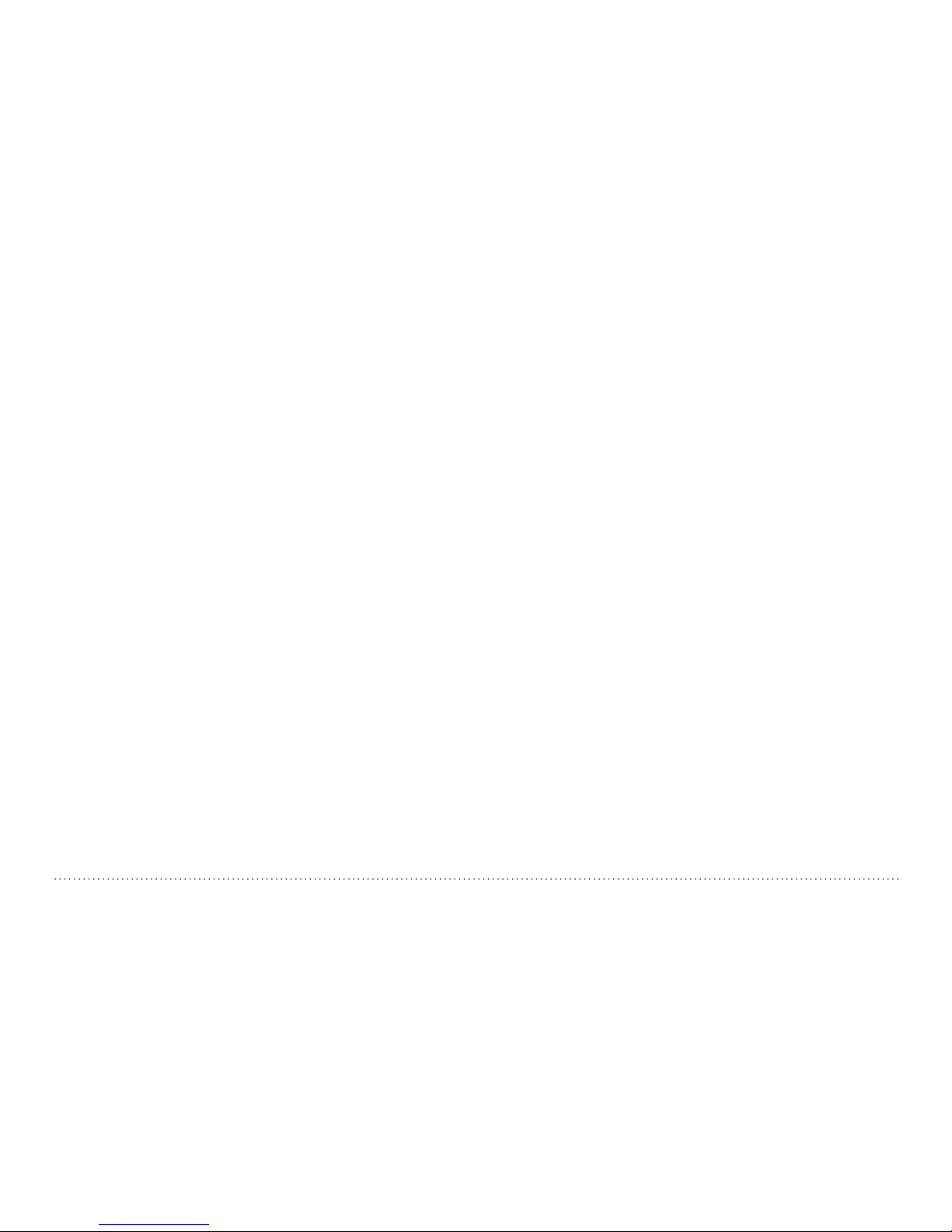

2.2 Main Menu

On start up, the main menu is displayed. All functions are accessible

directly via the touchscreen.

Return to the previous menu by pressing the back button or the return

icon (arrow) at the top left of the touchscreen.

Measurement

Select to access either Cover Meter or Corrosion measuring

modes.

Settings

Application specific settings.

Explorer

File manager application for reviewing saved measurements.

System

Select your preferred interface language, date and time settings and power saving options.

Information

Open documentation (Operating Instructions and additional

PDF files) and device info.

Power off

Switch off the device.

2.3 Upgrade procedure

The following procedure has to be performed in order to upgrade to Profometer 630 AI / 650 AI functionalities from a Profometer 600 unit or to

unlock Profometer 600 / 630 AI / 650 AI Cover Meter functionalities on a

Profometer Corrosion unit.

The Activation Key can be provided together with the initial purchase

(when a Profometer 630 AI or 650 AI unit is supplied) or can be ordered

anytime after the initial purchase in order to upgrade / unlock to further

functionalities.

Page 8

© 2017 Proceq SA 8

1. Press the Power On/Off button to power on the touchscreen

2. Access the System menu, then go to Features and Enter activation

key

3. Enter the activation key

2.4 Cover Meter and Corrosion functionalities

A Profometer unit can have both the features of Cover Meter and Corrosion Analysis Instrument in the following cases

• Profometer 6 Cover Meter with the upgrade kit to Profometer Corro-

sion (392 50 002)

• Profometer Corrosion with the upgrade kit to Profometer 600 Cover

Meter (392 50 003) plus any possible upgrade to Profometer 630 AI

or 650 AI

In either case the corresponding functionality (Cover Meter and/or Corrosion) will be available on the Platform depending on whether the universal

probe or the interface box respectively is initially connected to the unit.

An image on the top of the measuring screen will indicate whether the

universal probe

and/or the interface box are connected to the unit.

When going into the Settings or Explorer menus the user will be prompted whether to access the Cover Meter or Corrosion corresponding submenus.

The user can disable at any time either feature by going into the System

/ Features menu and unchecking the corresponding box.

Page 9

9 © 2017 Proceq SA

3. Profometer 6 Cover Meter

3.1 Measuring Principle

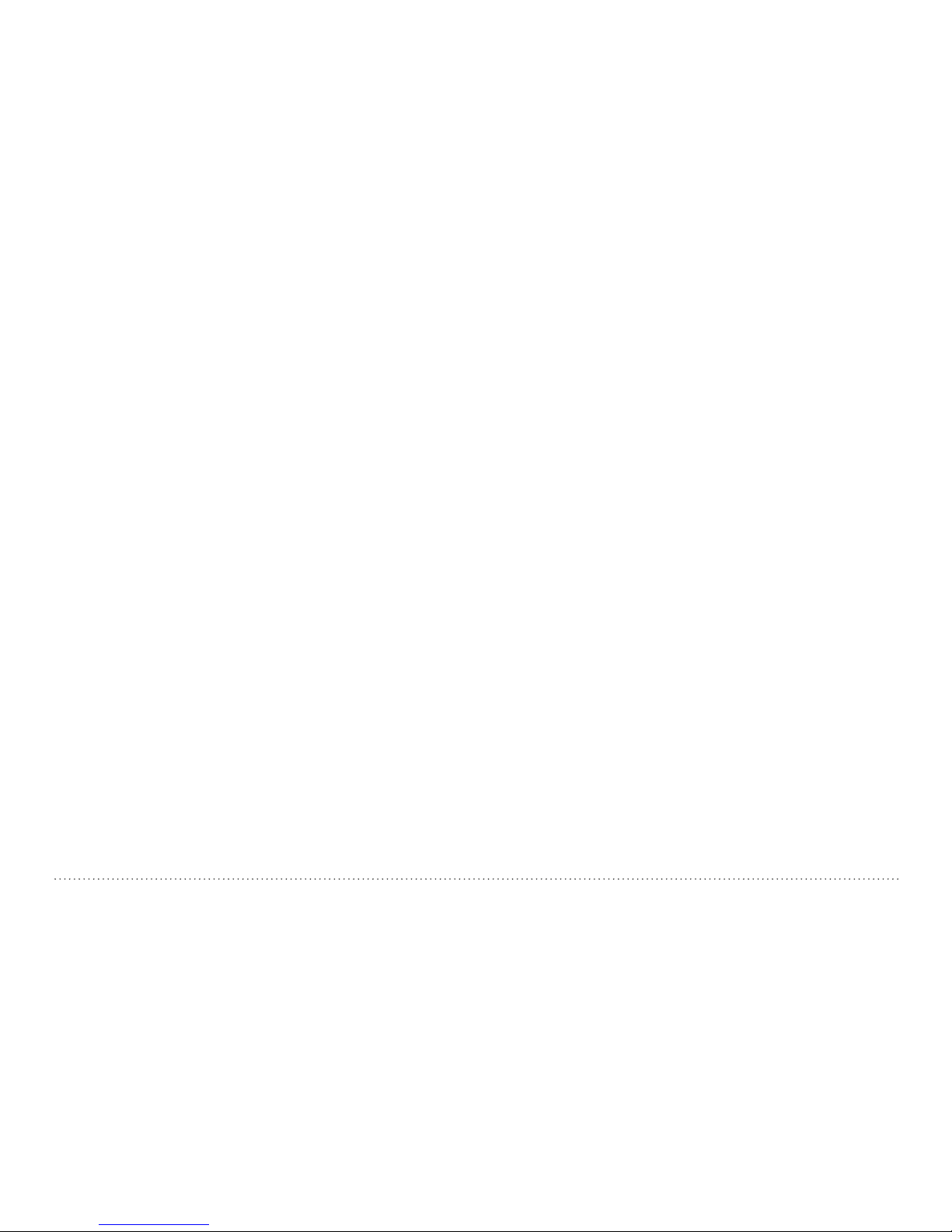

3.1.1. Pulse induction

The Profometer 6 uses electromagnetic pulse induction technology to

detect rebars. Coils in the probe are periodically charged by current

pulses and thus generate a magnetic field. On the surface of any electrically conductive material which is in the magnetic field, eddy currents are

produced. They induce a magnetic field in the opposite direction. The

resulting change in voltage can be utilized for the measurement.

Coils

Concrete

Rebar

Magnetic Field

Figure 2: Measurement principle

The Profometer 6 uses different coil arrangements to generate several

magnetic fields. Advanced signal processing allows locating a rebar as

well as measuring of cover and rebar diameter.

This method is unaffected by all non conductive materials such as concrete, wood, plastics, bricks etc. However any kind of conductive materials within the magnetic field (sphere of approx. 200 mm / 8 inch radius)

will have an influence on the measurement.

NOTE! Remove all metallic objects such as rings and watches before you start measuring.

3.1.2. Calibrated Measuring with Profometer 6

The Profometer 6 is calibrated to measure on a normal rebar arrangement; which is an arrangement of non-stainless steel rebars fastened

with binding wires only e. g. when measuring on welded mesh wires the

cover and diameter readings must be corrected (see “3.2.4. Practical

Hints”). The following information on accuracy, measuring ranges and

resolutions refer to measurements on normal rebar arrangements.

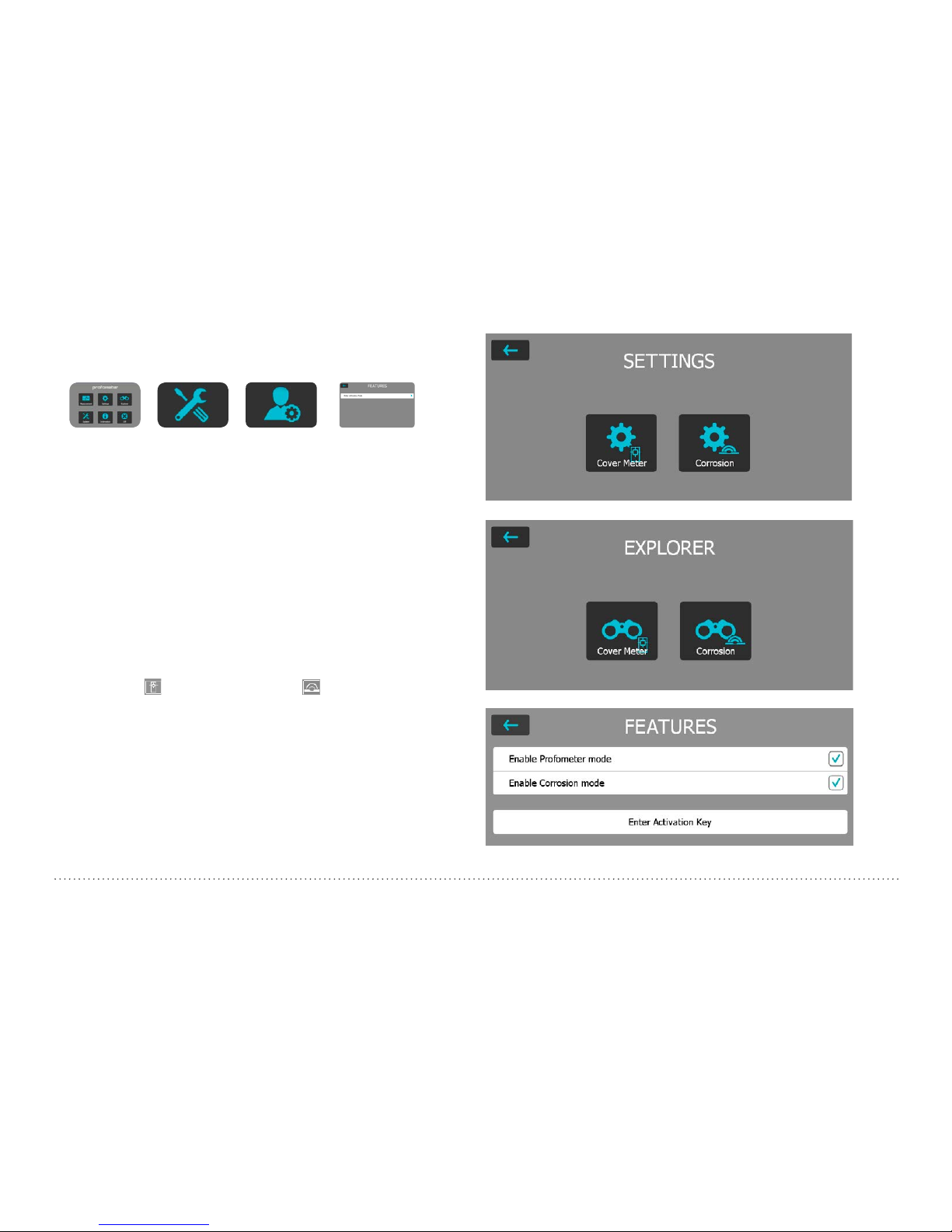

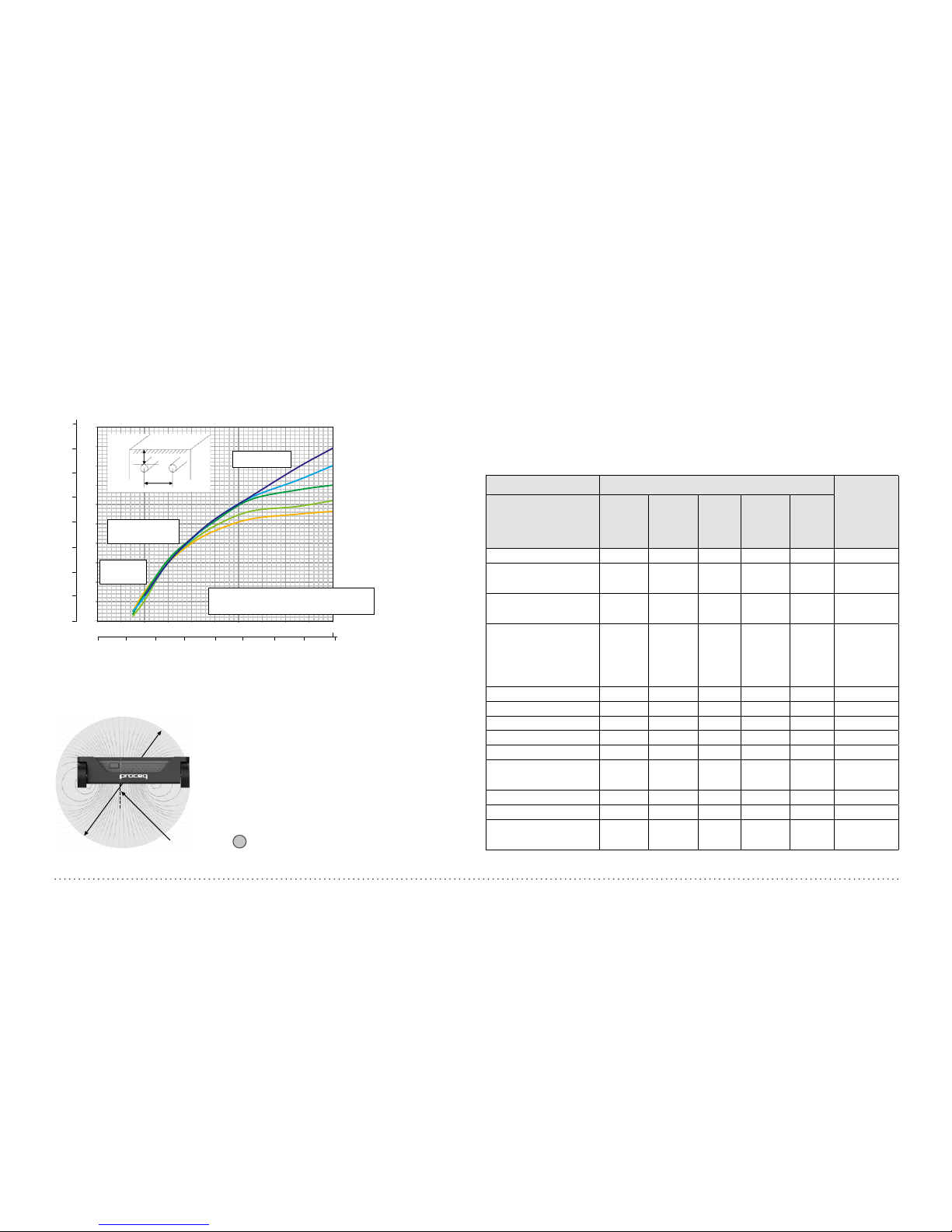

3.1.3. The

Measuring

Range

The measuring range is dependent on the bar size. The expected accuracy of the cover measurement is indicated in the graphic below. It

complies with BS1881 part 204, for a single rebar with sufficient spacing.

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

5 10 15 20 25 30 35 40 45 50 55

7

6

5

4

3

2

1

#2 #3 #5

#6 #8 #9

#11 #13 #14 #16 #18

[inch] [mm]

Rebar size

Cover depth

Spot probe

measuring range

Standard

measuring range

±4 mm

±2 mm

±1 mm

±1 mm

[mm]

[

1

/8 inch]

153 mm

50 mm

Large

measuring range

measuring

accuray

185 mm

100 mm

Figure 3: Measuring ranges and accuracy: up to the indicated limits the

cover is measured and displayed. In the Locating Mode a rebar

is shown. In the Single-Line Mode the cover curve is shown but

a rebar is only set up to 90 % of the maximum cover.

Page 10

© 2017 Proceq SA 10

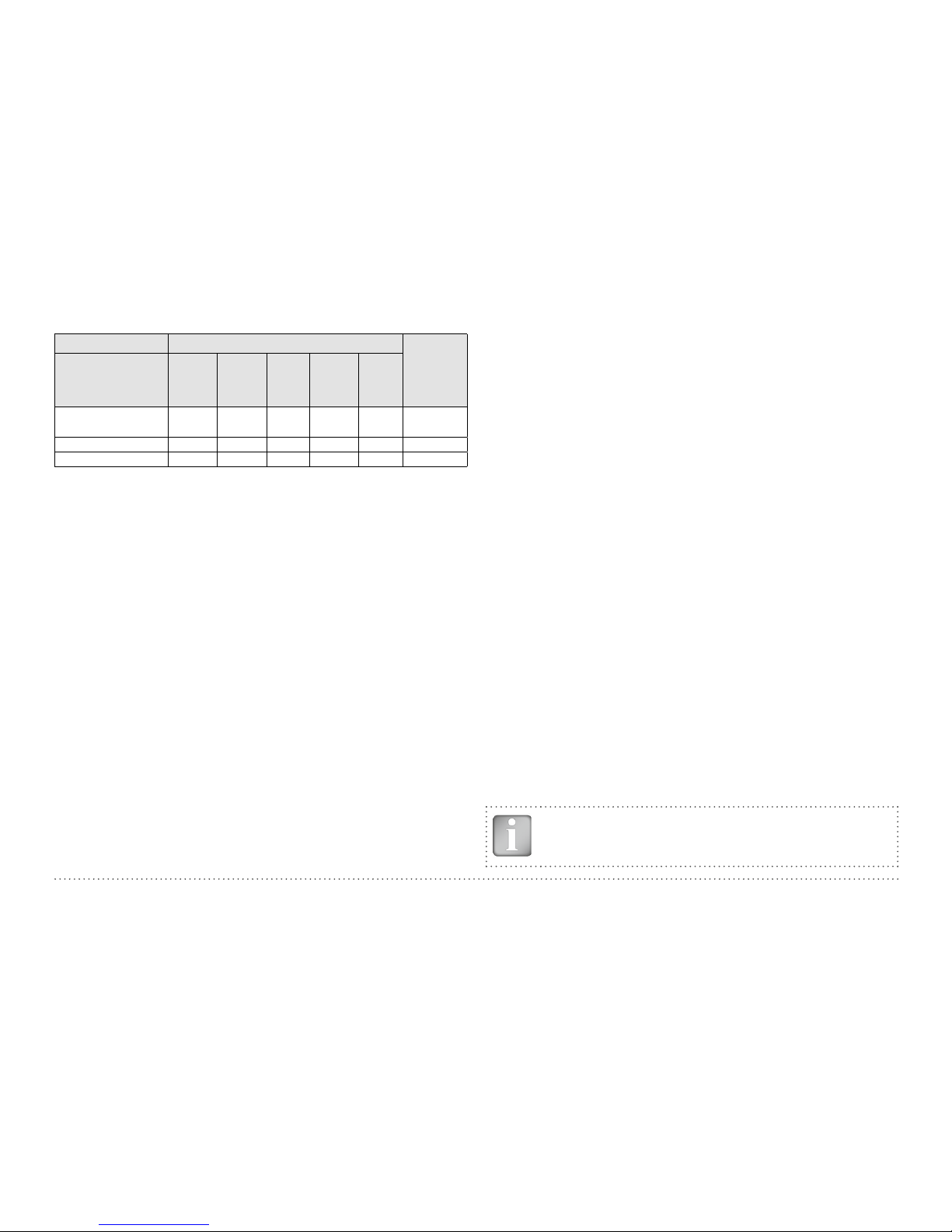

3.1.4. Resolution

There is a limit to the minimum spacing of bars

depend

ing on the cover

depth and rebar diameter. It is impossible to distinguish between individual bars above these

limits.

0

20

40

60

80

100

120

140

160

180

200

0 20 40 60 80 100 120 140 160 180 200

1

2

3

4

5

7

6

8

0

1

2

3

45

6

7

0

[inch]

[mm]

Cover depth

Spot probe

range

Standard

range

Ø 40 mm

Ø 26 mm

Ø 16 mm

Ø 12 mm

Ø 8 mm

Below the curve:

Individual rebar can be detected

Rebar spacing

[inch]

[mm]

C

S

# 12

# 13

# 8

# 4

# 3

# 2

S

C

# 5

Large range

Figure 4: Resolution

3.1.5. Sphere of influence by Ferromagnetic Material

MC (SLA) C

Sphere of influence: Diameter 400 mm / 16 inch

Figure 5: Influence sphere

Any ferromagnetic material within the sphere may have an influence on

on the signal value (e. g. during a reset).

3.2 Cover Meter Operation

3.2.1. Cover Meter Operation

Scroll up and down the screen by dragging your finger up or down the

screen. The current setting is displayed on the right hand side. Tap on an

item to adjust it.

Measuring Mode Adjust-

able after

data storage

Settings Locate Single-

Line

MultiLine

CrossLine

AreScan

Measuring Range

• • • • •

No

Rebar Diameter

Scan X

• • • • •

Yes

Rebar Diameter

Scan Y

1]

•

Yes

Artificial Intelligence

2]

/ Neighboring Rebar

Correction

• • • • •

Yes

Cover Calibration

2]

• • • • •

Yes

Unit

• • • • •

No

Minimum Cover

• • • • •

Yes

Maximum Cover

• • •

Yes

Cover Offset

• • • • •

No

Display Inclined

Rebar

•

Yes

Sharpen

• •

Yes

Display Curve

•

Yes

Align Rebar

Positions

• •

No

Page 11

11 © 2017 Proceq SA

Measuring Mode Adjust-

able after

data storage

Settings Locate Single-

Line

MultiLine

CrossLine

AreScan

Return to start on

new line

• •

Yes

Line Height

• • •

Yes

Grid Width

• •

Yes

1]

This parameter affects all measurement modes (in addition to Cross-Line) when-

ever Artificial Intelligence Correction is selected

2]

Only available on Profometer 630 AI / 650 AI

Meauring Range

Select between Standard, Large or Auto ranges (see Figure 3).

The Standard range setting is the default setting and the most accurate.

Auto range setting automatically switches between Standard and Large

range; it is only available when in the Locating Mode. Spot range setting should be selected for measurements of small areas, in corners

and where the distance between reinforcing bars is small. The Large

range setting should be selected when the concrete cover is deeper, to

provide more accurate results.

Rebar Diameter Scan X / Rebar Diameter Scan Y

Select the Rebar Diameter (6 to 40 mm / #2 to #12, see “10.1 Appendix A1:

Rebar Diameters”), either determined from the drawing or as measured.

Tap on the info button on top of the Settings page to view a graphical

overview of the above mentioned parameters.

Artificial Intelligence / Neighboring Rebar Correction

It compensates the influence of 1

st

and 2

nd

layer neighbor rebars (AI) or 1st

layer neighbor rebars only (NRC) on cover measurement of 1st layer rebars.

If both a1 and a2 spacings are entered, Φ1 ≤ Φ2 and Standard Range is set,

then the Artificial Intelligence is automatically applied.

If only a1 spacing is entered or Φ1 > Φ2 or Large/Spot Range is set, then the

Neighboring Rebar Correction (only taking into account 1st layer) is automatically applied.

The user can enter the spacing value manually or choose the Auto function,

which redirects to a Single-Line scan where the spacing is automatically

measured and averaged.

The rebar size measurement is anyway only corrected with NRC.

Tap on the info button on top of the Settings page to view a graphical overview of the above mentioned parameters.

Cover Calibration

This correction is used for calibrating the cover measured by the instrument (Measured Cover) to the actual value directly measured on a open

location (Reference Cover). The corresponding Rebar Diameter Setting is

also to be specified.

This correction can be used regardless of rebar geometry and Measuring

Range selected

Unit

Select Metric, Metric Japanese, Imperial or Imperial Diameter, Metric

Cover and Distance.

Minimum Cover

A Minimum Cover value from 10 to 142 mm / 0.40 to 5.56 inch can be set

in 1 mm / 0.04 inch steps (see “10.3 Appendix A3: Minimum / Maximum

Cover”). In the Single-Line, Multi-Line and Cross-Line Mode/View rebars

with less than minimum cover will be shown in red color. In the SingleLine View and Statistical View a horizontal, respectively vertical dotted

line in red indicates the Minimum Cover value set.

Maximum Cover

A Maximum Cover value from 20 to 190 mm / 0.80 to 7.48 inch can be set

in steps of 1 mm / 0.04 inch (see “10.3 Appendix A3: Minimum / Maximum

Cover”). In the Single-Line, Multi-Line and Cross-Line Mode/View rebars

with cover exceeding the Maximum cover will be shown in grey color.

NOTE! The Maximum Cover must be at least 10 mm / 0.40

inch higher than the Minimum Cover. If not, the instrument

will correct it automatically.

Page 12

© 2017 Proceq SA 12

Return to start on new line

With this feature set, the cursor jumps back to the start line when changing line in the Multi-Line and Cross-Line Modes.

Line Height (in Y-direction)

The line height of must be set in the Multi-Line, Area-Scan and CrossLine Modes. It determines the spacing between the measuring rows. A

height of 5 to 203 cm / 2.00 to 80.00 inch can be set.

Grid Width (in X-direction)

The grid width must be set in the Area-Scan and Cross-Line Modes. A

width from 5 to 203 cm / 2.00 to 80.00 inch can be set.

3.2.2. Cover Meter Measurement Modes

When Measurement Mode is selected for the first time after switching on

the instrument, zeroing of the probe is performed. Confirm it and wait for the

button assessment window. Wait or tap anywhere on the screen. The Measurement Modes available are shown in the menu on the top of the screen.

Locating Single-Line Multi-Line Area-Scan Cross-Line

Profometer 600

•

Profometer 630 AI

• • • •

Profometer 650 AI

• • • • •

NOTE! Valid for all Measuring Modes: In case measuring data

shall be stored create a folder in the Explorer (see “5. Explorer

Document Handling”) and check if the correct folder is active.

The Maximum Cover should also be set for different files measured on

the same surface to get the same color range for comparison purposes.

Cover Offset

When a Cover Offset value is set the measured cover will be reduced by

this value; e. g. when a wooden or plastic plate is used to measure with

the probe cart on rough surfaces (see “3.2.4. Practical Hints”). In this

case the plate thickness must be set as Cover Offset value). A value from

1 to 50 mm / 0.04 to 1.92 inch can be set.

Display Inclined Rebar

By setting this feature the inclined rebar is displayed in the Locating Mode

when all four wheels of the cart have passed over the inclined rebar. In

the Single-Line and Multi-Line Modes it is only shown in the cart symbol.

NOTE! In areas with small rebar spacing this feature may not

work properly.

Sharpen

With this setting the signal strength color spectrum of the Multi-Line and

Cross-Line Views can be sharpened.

Display Curve

Select Cover Value, Signal Strength or None. The respective curve or

no curve is displayed in Single-Line View.

Align Rebar Positions

When measuring in the Multi-Line or Cross-Line Mode along at least two

lines of at least 55 cm / 22.00 inch length, the rebar positions of subsequent lines are aligned to the rebar positions of the previous lines.

NOTE! This feature should only be set if the rebars are running

parallel to the start line (X- or Y-line). It is not activated during

the measurements (activated only when storing the data).

Page 13

13 © 2017 Proceq SA

E

Center Line (CL)

*When an Arrow LED lights up move the

probe along the rebar axis until MC LED

C

or D lights up. Then the MC is

precisely above a rebar axis.

By pushing

A

and B simultane-

ously the cursor jumps to the next line

(in Multi-Line, Area-Scan and Cross-Line

Mode only)

B

Short: Measure diameter

Long: Zeroing

D

Measurement Center when

Spot range is set (MC Sp)

Measurement Center when Standard,

Large or Auto range is set (MC SLA)

Short: Start / Stop

Long: Set marker

A

C

F

Arrow LED indicates proximity of rebar*

Arrow LED indicates proximity of rebar*

F

Figure 6: Universal Probe overview

Page 14

© 2017 Proceq SA 14

Locating Mode

Profometer

600

Profometer

630 AI

Profometer

650 AI

1

2

3

4567

12

11

10

9

8

Figure 7: Locating Mode

1

File name: enter the file name and tap return. Saved measurements

will be stored with this file name. If several measurements are made

under the same filename, a suffix increments after each measurement and follows the file name.

2

Probe connected, current time, battery status and warning triangle

for zeroing the probe when needed: after 5 minutes in orange, after

10 minutes in red.

NOTE! Tap on the triangle to perform zeroing.

3

Display of selected Settings:

• Measuring Range

• Type of correction (None, AI, NRC, CAL)

• 1

st

and 2nd layer rebar size and spacing

• Cover Offset (if set)

• Probe Direction X: Undefined direction

^, v, <, >: On vertical wall, probe head towards

up, down, left, right

_, ˉ: On horizontal surface, on soffit

4

Settings: switches to the settings menu

5

Rebar Diameter: measuring of rebar diameter

6 Store measured data

7 Restart: all data of current measurement are deleted

8 Actual Cover

9 Distance to the nearest rebar

10 Nos. / Measured diameter

11 Signal strength

12 Coils indicator

Whenever possible start with locating the rebars of the first layer, E.g on

a column this would be the horizontal stirrups.

Holding the CL E horizontally, move vertically up or down until the Arrow

LED lights up and then move back until the MC LED lights up.

After having located the first layer rebars continue with locating the second layer rebars.

• Position the MC (C or D depending on the set Measuring Range) at the

mid line of the first layer rebars, e. g. on a column hold the probe with

the CL running vertically and move the probe cart vertically until both

rectangles in the probe symbol 12 are green and of equal size. Whenever the coils rectangles 12 are of different size and red, the probe po-

Page 15

15 © 2017 Proceq SA

sition is not optimal and the cover / diameter measurement becomes

not reliable

• Now move the probe cart horizontally until one of the Arrow LEDs F

lights up and then move back until MC LED C or D lights up.

• At this position you may also measure the diameter either by pushing

B on the right side of the probe or 5 (see Figure 7) on the Touchscreen

unit (e. g. when the probe is fixed to the telescopic extension rod).

• If the spacing of parallel or orthogonal rebars is between 5 and 30 cm

(2.00 to 12.00 inch), activate AI or NRC correction. If the cover is too

small for diameter measurement “too close” is displayed.

• In this case place a wooden or plastic board on the surface and set the

board thickness as Cover Offset to measure the diameter.

Finally the measured diameter must be set. The cover reading will be corrected according to the diameter set.

NOTE! A rebar is shown only within the cover ranges indicated in Figure 3; for more details about diameter measurement

see “3.2.4. Practical Hints”.

• Tap

6

to store the diameter and cover measurement.

• Repeat this procedure at each rebar.

The saved data can be seen in the Snapshot and Normal Statistics View

(see “3.2.3. Cover Meter Display Views”).

Whenever a rebar is inclined to the Cover of the probe, if Display Inclined

Rebars is set, the angle will be shown on the display (minimum detected

inclination is 6 degrees).

NOTE! Cover values are only saved for later viewing, if the

diameter was measured and saved.

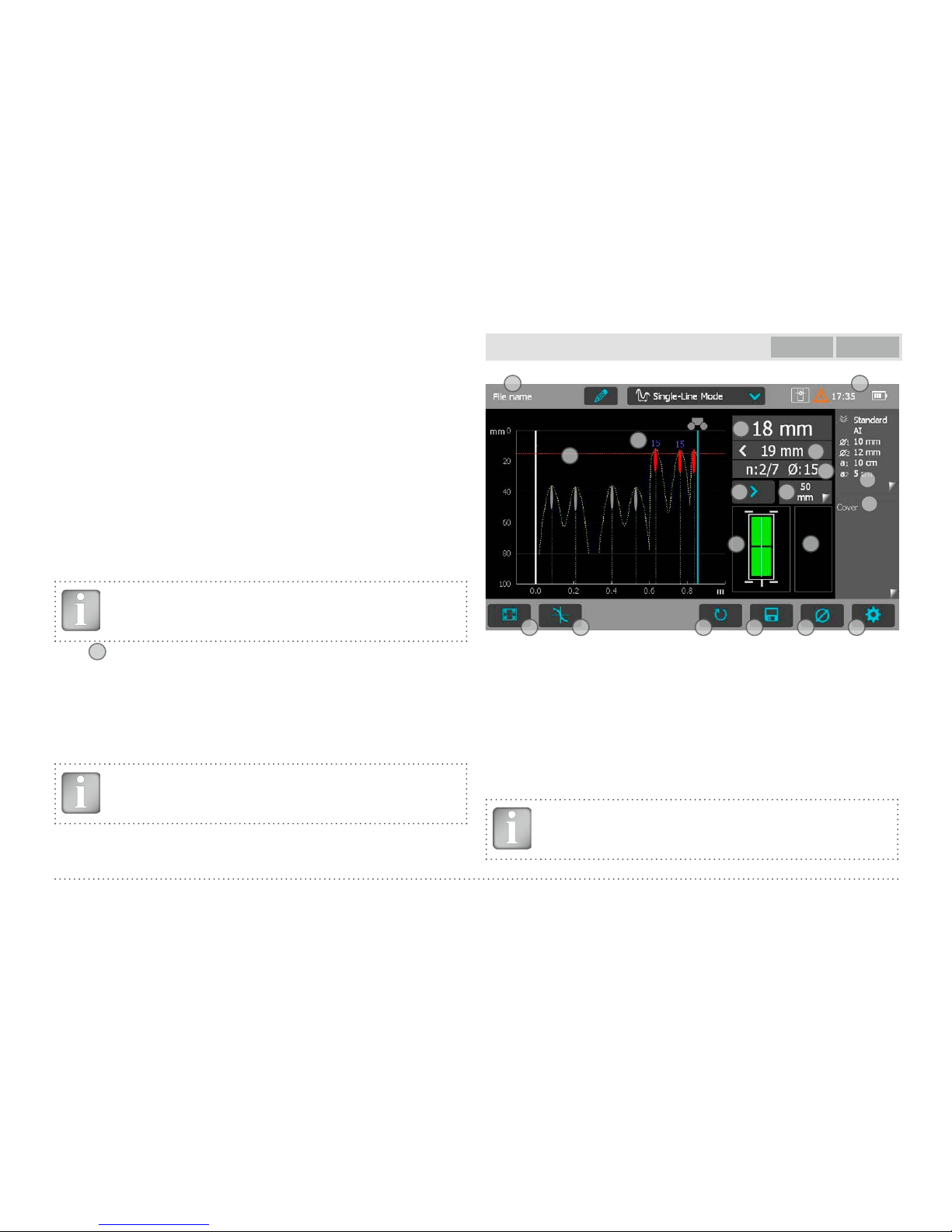

Single-Line View

Profometer

630 AI

Profometer

650 AI

1 2

3

4

5678910

16

17

1415

13

12

11

19

18

Figure 8: Single-Line Mode

1

File name: enter the file name and tap return. Saved measurements

will be stored with this file name. If several measurements are made

under the same filename, a suffix increments after each measurement and follows the file name.

2

Probe connected, current time, battery status and warning triangle

for zeroing the probe when needed: after 5 minutes in orange, after

10 minutes in red..

NOTE! Tap on the triangle to perform zeroing.

Page 16

© 2017 Proceq SA 16

3

Display of selected Settings:

• Measuring Range

• Type of correction (None, AI, NRC, CAL)

• 1

st

and 2nd layer rebar size and spacing

• Cover Offset (if set)

• Probe Direction

X: Undefined direction

^, v, <, >: On vertical wall, probe head towards up,

down, left, right

_, ˉ: On horizontal surface, on soffit

Zoom in by placing thumb and index finger together on

the screen and spreading them apart. This can be used in

both the horizontal and vertical directions when making a

measurement.

Zoom out by placing thumb and index finger apart on the

screen and pinching them together.

Pan the image from left to right by dragging.

4

Curve displayed: Cover / Signal strength / None

5

Settings: switches to the settings menu

6

Rebar Diameter: measuring of rebar diameter

7 Store measured data

8 Restart: all data of current measurement are deleted

9 Zoom in to cursor position

10 Zoom to fit the whole scan

11 Actual Cover

12 Distance to the nearest rebar

13 Nos. / Measured diameter

14 Skip distance

15 Skip button

16 Coils indicator

17 Speed bar

18 Minimum set cover value (if set)

19 Measured diameter

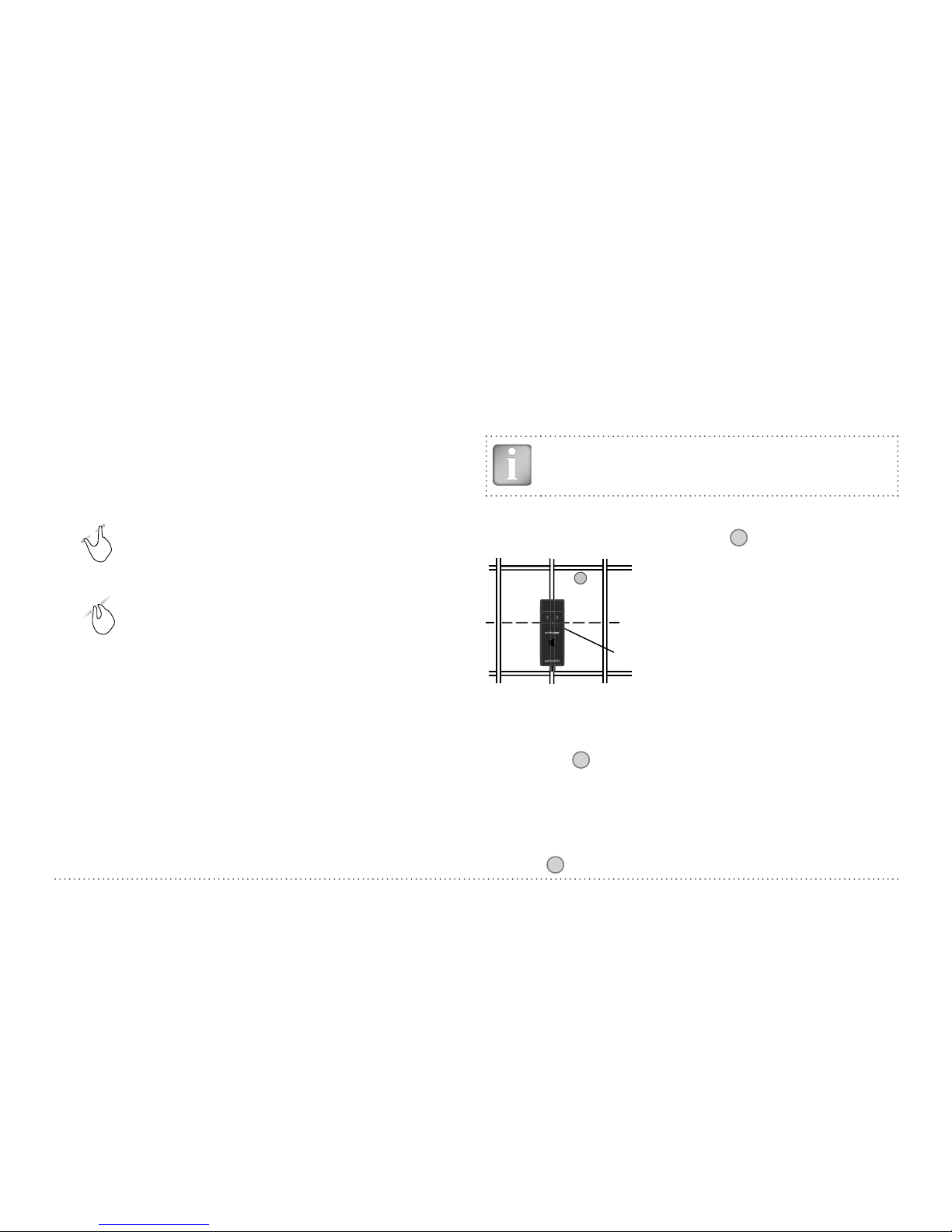

NOTE! It is advisable to locate the first and second layer rebars with the Locating Mode to find the optimum line position prior to measuring with the Single-Line Mode.

• Position the probe cart at the start line in an optimum position (see

Figure 9, the MC C / D at the mid line of the rebars running parallel to

the moving direction, both rectangles in

16

are of equal size).

Midpoint line

CL

16

MC C / D

Figure 9: Optimal probe position

• Start with the measurement if the cursor is at the start line. If not perform a reset

8

.

• Move the probe cart with constant speed crosswise over the rebars,

not exceeding the maximum speed (speed bar 17 half filled in green).

• Above each rebar, when the red LED of MC C / D lights up, you may

measure the rebar diameter and on completion, it will be displayed in

blue. The measured diameter may be deleted within 5 seconds by tapping on

6

.

Page 17

17 © 2017 Proceq SA

• In case the spacing between parallel or orthogonal rebars is in the

range of 5 to 30 cm (2.00 to 12.00 inch), activate AI or NRC correction.

The cursor position can be adapted in two ways to a changed cart position:

• Tap on the cursor and wait until it becomes white and orange. Move

the cursor to the desired position (even left to the zero line is possible).

Be aware: Scanning is no longer possible between the cursor and the

zero-line. Rebars that have already been scanned cannot be removed

by a new scan, but you may scan to the left of the first rebar or to the

right of the last rebar. To delete rebars already scanned, tap

8

and

confirm with Yes.

• Tap on

14

and set the skip distance. For example, if you have to make

a break in the scan due to an obstacle such as a column, move the cart

until the right wheels touch the column, then set the skip distance to

the width of the column plus 107mm / 4.2 inches for the cart and reposition the cart at the other side of the column with the left wheels

touching the column. Tap on 15. A blue dotted line is set at the beginning of the skipped interval.

NOTE! The cover curve is shown (if selected) within the cover

ranges indicated in Figure 3 but a rebar will only be shown up

to 90 % of those limits.

To display a rebar as a

circle zoom the horizontal

and vertical axis to the

same scale.

The spacings of the rebars

are shown in blue.

The distances from the

start line to the first rebar

and from the end line to

the last rebar are shown in

white color. If the figures

are not shown, zoom in.

Spacing between rebars (in blue)

Figure 10: Screen of Single-Line Mode with cover curve

• To change a diameter tap on the rebar.

A window opens.

• Tap on the window and change diameter.

To erase set diameter to zero.

The new diameter is set and shown in orange.

The cover changes accordingly but the cover

curve remains except above the rebar axis.

New set diameter shown in orange

Figure 11: Single-Line View zoomed, showing change of rebar diameter

Page 18

© 2017 Proceq SA 18

Figure 12: Single-Line option to mask a rebar by double-tapping on it

When utilizing the Single-Line Mode, the user has the option to display

the Cover curve, Signal Strength curve or no curve. The Signal Strength

curve is used to confirm the presence of reinforcing bars. Local effects

such as metallic elements present below the surface (metallic wire, anchorage, etc.) or changes in testing speed when obtaining the data can result

in an “apparent” reinforcing bar appearing on the screen. It is possible to

hide the “apparent” reinforcing bar by double tapping on the corresponding dot when in Single-Line Cover or Signal Strength View and selecting

the “Mask” option. The corresponding cover values will not be taken into

account in the Statistical View (refer to Section “3.2.3. Cover Meter Display

Views”).

The path length measurement accuracy depends on the test surface. The

accuracy of measurements done on a smooth concrete surface (concrete

poured in metallic shuttering) is shown in the specifications, see “7. Technical Specifications”. On rougher surfaces the measured length may be

reduced or checked at certain intervals by setting markings on the test

surface and comparing with marks set on the display (long push on

A

).

After storage (tap

7

), the data can be seen in the Statistics View, the

Single-Line View and also in the Snapshot View if at least one diameter was measured (see “3.2.3. Cover Meter Display Views”).

The maximum scan length is 999 m / 3’280 feet in each direction (to the

right and to the left from the zero line).

Multi-Line Mode

Profometer

630 AI

Profometer

650 AI

1 2

3

4

56781011

17

18

1516

14

13

12

9

Figure 13: Multi-Line Mode

1

File name: enter the file name and tap return. Saved measurements

will be stored with this file name. If several measurements are made

under the same filename, a suffix increments after each measurement and follows the file name.

Page 19

19 © 2017 Proceq SA

2

Probe connected, current time, battery status and warning triangle

for zeroing the probe when needed: after 5 minutes in orange, after

10 minutes in red..

NOTE! Tap on the triangle to perform zeroing.

3

Display of selected Settings:

• Measuring Range

• Type of correction (None, AI, NRC, CAL)

• 1

st

and 2nd layer rebar size and spacing

• Cover Offset (if set)

• Probe Direction X: Undefined direction

^, v, <, >: On vertical wall, probe head towards

up, down, left, right

_, ˉ: On horizontal surface, on soffit

Zoom in by placing thumb and index finger together on

the screen and spreading them apart. This can be used in

both the horizontal and vertical directions when making a

measurement.

Zoom out by placing thumb and index finger apart on the

screen and pinching them together.

Pan the image from left to right by dragging.

4

Measured values displayed: Cover / Diameter

5

Settings: switches to the settings menu

6

Rebar Diameter: measuring of rebar diameter

7 Store measured data

8 Restart: all data of current measurement are deleted

9 Delete current line

10 Move to next line / Rotate probe

11 Zoom to fit the whole scan

12 Actual Cover

13 Distance to the nearest rebar

14 Nos. / Measured diameter

15 Skip distance

16 Skip button

17 Coils indicator

18 Speed bar

NOTE! It is advisable to locate the first and second layer rebars

with the Locating Mode to find the optimum line position prior

to measuring with the Multi-Line Mode (see Figure 9). “Align

Rebar Position” should only be set, if all rebars are running

parallel to the start line (Y-axis). For large areas it is advisable

not to set “Return to start on new line” and to measure the

lines alternatively start to end, back from end to start.

• Position the probe cart at the start line in an optimum position (see

Figure 9, the MC C / D at the mid line of the rebars running parallel to

the moving direction, both rectangles in 16 are of equal size).

• Start with the measurement if the cursor is at the start line. If not per-

form a reset 8.

• Move the probe cart crosswise over the rebars. Above each rebar,

when the red LED of MC C / D lights up, you may measure the rebar

diameter and on completion, it will be displayed. If the spacing between parallel or orthogonal rebars is in the range of 5 to 30 cm (2.00

to 12.00 inch), activate AI or NRC correction. At the end of the first line

a marker (dotted blue line) is set. To proceed with the next line tap 10

Page 20

© 2017 Proceq SA 20

or push A and B simultaneously on the probe. The cursor jumps to

the next measuring row, either to the start line or remains at the end

line, depending on whether “Return to start on new line” is set or not.

Changing the cursor position works like in the Single-Line Mode (tap

and drag the cursor or use the Skip button). At the start of each line

you may change the probe direction (e. g. when measuring on a wall

along the bottom line close to the slab).

• Tap on 10.The arrow in the probe cart symbol changes from

to .

For the next line you may change back to .

NOTE! By changing the setting “Line Height” during the

measurements the height of all lines including the ones already measured will change and hence, also the line positions. Change the line height only if it was previously wrongly

At each rebar you may measure the rebar diameter. At the end, set

one common diameter, normally the smallest one (see “3.2.4. Practical

Hints”).

When displaying the Cover values in the color palette the range is defined

by the Minimum and Maximum Cover values used in Settings.

When displaying the Diameter values in the color palette all rebars will

be shown in the respective color. Rebars for which the diameter was

not measured or set are shown in white; diameters set in the Single-Line

View (Figure 11) are shown additionally with an orange cross bar in the

middle of the rebar.

After storage (tap 7 ), the data can be seen in the Statistics View, the

Single-Line View, the Multi-Line View and also in the Snapshot View if

at least one diameter was measured. In the Multi-Line View the signal

strength spectrum can be seen in addition to the cover and diameter, see

“3.2.3 Cover Meter Display Views”.

In one measuring sequence a maximum of 62 lines can be scanned and

stored in one file.

NOTE! A rebar will only be shown up to 90 % of the limits

of Figure 3.

Area-Scan Mode

Profometer

630 AI

Profometer

650 AI

The Area-Scan Mode is mainly used to show the first layer rebar covers

on large areas, e.g. of concrete slabs in car parks. It is best suited for a

combination with half-cell potential measurements; e. g. combined with

Profometer Corrosion measurements; in this case the line height and grid

width should be the same for both measurements.

The main differences with the Multi-Line Mode is that instead of the single rebars, only the lowest cover value inside every cell is displayed; the

single cell area is defined by the Line Height (same meaning as for MultiLine Mode ) and the Grid Width. This latest should be set at least 1.1

times larger than the maximum rebar spacing of the first layer rebars, in

order to be sure that at least one rebar is located within one cell.

NOTE! Since the Area-Mode is used on rather large areas,

“Return to start on new line” should not be set.

The measuring procedure including turning the probe cart and changing

cursor position is the same as for Multi-Line Mode.

Figure 14 is a plan view, where the cover values are shown as rectangles

of different colors. Red means the cover is smaller than the minimum set.

Page 21

21 © 2017 Proceq SA

A cover will only be shown up to 90 % of the cover ranges indicated in Figure 3.

Figure 14: Screen of Area-Scan Mode

After storage (tap 7 ), the data can be seen in the Statistics View, the

Multi-Line View and also in the Snapshot View if at least one diameter

was measured (see “3.2.3. Cover Meter Display Views”). Erroneous or

non valid readings can be deleted simply by double tapping on the corresponding field and choosing the “Mask” option; a cross will appear into

the masked fields and the corresponding cover values will not be taken

into account in the Statistical View.

Figure 15: Area-Scan option to mask a field by double-tapping on it

Cross-Line Mode

Profometer

650 AI

1 2

3

4

56781011

18

19

1617

15

14

13

9

12

Figure 16: Cross-Line Mode

1

File name: enter the file name and tap return. Saved measurements

will be stored with this file name. If several measurements are made

under the same filename, a suffix increments after each measurement and follows the file name.

2

Probe connected, current time, battery status and warning triangle

for zeroing the probe when needed: after 5 minutes in orange, after

10 minutes in red..

NOTE! Tap on the triangle to perform zeroing.

Page 22

© 2017 Proceq SA 22

3

Display of selected Settings:

• Measuring Range

• Type of correction (None, AI, NRC, CAL)

• 1

st

and 2nd layer rebar size and spacing

• Cover Offset (if set)

• Probe Direction X: Undefined direction

^, v, <, >: On vertical wall, probe head towards

up, down, left, right

_, ˉ: On horizontal surface, on soffit

Zoom in by placing thumb and index finger together on the

screen and spreading them apart. This can be used in both the

horizontal and vertical directions when making a measurement.

Zoom out by placing thumb and index finger apart on the

screen and pinching them together.

Pan the image from left to right by dragging.

4

Measured values displayed: Cover / Diameter

5

Settings: switches to the settings menu

6

Rebar Diameter: measuring of rebar diameter

7 Store measured data

8 Restart: all data of current measurement are deleted

9 Delete current line

10 Move to next line / Rotate probe

11 Switch from X scan to Y scan and vice versa

12 Zoom to fit the whole scan

13 Actual Cover

14 Distance to the nearest rebar

15 Nos. / Measured diameter

16 Skip distance

17 Skip button

18 Coils indicator

19 Speed bar

The Cross-Line Mode is used to display the rebars of the first and second

layer arranged in a rectangular mesh. The measuring procedure including

turning the probe cart and changing cursor position is the same as for

Multi-Line Mode. In fact it is a Multi-Line scanning in X- and Y direction,

where the user can switch between horizontal and vertical scans by tapping on 11.

In addition to the Multi-Line settings the grid width to define the spacing

between the Y-lines must be set.

3.2.3. Cover Meter Display Views

Measured data can be displayed in six different views: Snapshot, Statistics, Single-Line, Multi-Line, Area-Scan and Cross-Line View. All

the settings stored with the measurements can be changed afterwards.

The views will change accordingly; to store the measuring series with the

changes tap Store.

NOTE! Each View can be changed in a measuring mode in

order to add data. Tap on Set the cursor to the new

starting position and continue with the measurements (see

“3.2.3. Cover Meter Display Views” ). All data and settings

will be stored in the reopened file.

Page 23

23 © 2017 Proceq SA

Snapshot View

Profometer

600

Profometer

630 AI

Profometer

650 AI

The Snapshot View can be displayed if at least one diameter was measured and stored in one of the measurement Modes.

The cover values are shown as vertical bars to scale and the diameter as

a figure, both in the unit set. The Minimum Cover is not displayed in the

Snapshot View.

Figure 17: Snapshot View

Statistics View

Profometer

600

Profometer

630 AI

Profometer

650 AI

The Statistics View can be displayed for measurements done and stored

in one of the measurement Modes. It shows the statistical calculation of

the cover values measured.

For measurements with the Cross-Line Mode the statistical evaluation of

the cover readings is done for each layer independently. Hence there is a

Statistical View each for the scanning in the X- and Y-direction.

NOTE! In practice only the cover values and statistical evaluation of the 1st layer rebars (closer to the surface) is of interest.

On the horizontal axis the cover values in the unit set are displayed. The

vertical bars show the percentage of the respective cover values measured and stored. The vertical cursor bar can be moved to any cover value.

The figure on the left of the cursor bar shows the percentage of measured

cover values smaller than the cursor position. The value on the right shows

percentage of measured cover values larger than the cursor position. The

cover value is displayed at the bottom of the cursor bar and at the top the

percentage of measured covers for that cover is shown. Minimum required

cover is shown as a vertical dotted line in red (if set). Covers below the minimum are shown as red bars, covers above the minimum as yellow bars.

There are two different Statistics Views, the Normal (see Figure 18) and

the DBV-Evaluation (see Figure 19). Tap on the statistical values windows to switch from Normal to DBV.

Statistics values box “Normal” showing Median, Mean, Number of covers measured, lowest/

highest, Standard Deviation.

Change from X- to Y-direction view (for Cross-Line Mode data only) by tapping on / .

The actual window is shown on top right (either of scan direction SX or SY)

Figure 18: Statistics View Normal

Page 24

© 2017 Proceq SA 24

The DBV-Evaluation is an evaluation of the cover readings according

to the German Concrete and Construction Association DBV (Deutscher

Beton- und Bautechnik Verein). It is also recommended by RILEM.

The DBV-Evaluation requires at least 20 cover readings. The distribution

function F(c

min

) as well as the threshold values c(5 %) and c(10 %) are

calculated. The c(x%)–values are displayed in green when the measuring

series is accepted, respectively in red if not.

Statistics values box DBV:

Above the measuring series is accepted, below not.

Cover values above the calculated upper

boundary are not considered and shown as

bars with a yellow frame only (see on the right

side bars at cover values 17 mm, 18 mm and

19 mm).

Figure 19: Statistics Views DBV-Evaluation

For more details of the DBV-Evaluation please refer to the Info sheet

“Statistics according to DBV-Evaluation” available as pdf-file on the Profometer Touchscreen under Information/Documents and in the download

section of www.proceq.com.

Single-Line View

Profometer

630 AI

Profometer

650 AI

The Single-Line View can be displayed if measurements have been

done and stored in the Single-Line, Multi-Line or Cross-Line Mode (not

from Area-Scan Mode). It shows the rebar positions in a cross section.

The rebars are shown to scale depending on the diameter set. To show

them as a circle zoom the horizontal and vertical axis to the same scale.

However, for measurements over a long distance, like in a tunnel the

scale of the horizontal axis will be much smaller and the rebars shown

as vertical bars.

Figure 20: Single-Line View with cover curve

Figure 20 shows a Single-Line View with Metric Unit, Minimum Cover (dotted horizontal line in red) and Cover Curve (dotted curve in yellow). In case

a diameter was measured its value is shown in blue above the rebar in the

unit set. In case the diameter was manually set it is shown in orange.

Figure 21 shows a Single-Line with the Signal Strength Curve (dotted

Page 25

25 © 2017 Proceq SA

curve in yellow) set. The vertical axis shows the signal strength; hence

the Minimum Cover line is not shown.

It is a Single-Line View from measurements done in the Multi-Line View,

because at position

10

the 1 refers to the measuring row displayed. Tap

on

10

to display the Single-Line View of the next row.

10

Tap to switch among

different views.

Figure 21: Single-Line View with Signal Strength Curve

The spacing among the rebars as well as the distance from the start line

to the first rebar and from the last rebar to the end line are displayed

as figures in the unit set, but only if the spacing on the screen is large

enough. If not shown zoom in until the figures appear.

For more details like changing a diameter or masking a rebar refer to

Single-Line Mode in chapter “3.2.2. Cover Meter Measurement Modes”.

To set a new diameter you may have to measure it first at the particular

location of the structure in the Locating Mode and set it manually.

Multi-Line View

Profometer

630 AI

Profometer

650 AI

The Multi-Lline View can be displayed only if measurements have been

done and stored in the Multi-Line or Area-Scan Mode. It is a plan view, in

most cases of the first layer rebars. A Multi-Line View of the second layer –

main layer in columns and girders – may also be of interest. Rebars can be

masked and unmasked in the corresponding Single-Line View (see “3.2.2.

Cover Meter Measurement Modes”); masked rebars will be displayed in

dark grey with a dotted line and their cover values will not be taken into

account in the Statistical View.

Tap to switch among

different views.

Figure 22: Multi-Line View with cover values displayed

Masked rebars

Figure 23: Multi-Line View with masked rebars

Page 26

© 2017 Proceq SA 26

Tap to switch among

different views.

Figure 24: Multi-Line View with diameter values displayed (if measured)

To sharpen the

color spectrum set

“Sharpen”

By changing the Oand G-slider positions

the color spectrum

can be changed (see

Cross-Line View).

Tap to switch among

different views.

Figure 25: Multi-Line View with Signal Strength color spectrum

Area-Scan View

Profometer

630 AI

Profometer

650 AI

The Area-Scan View is in fact a simplified Multi-Line View which only

shows the lowest cover values in a predefined grid. It is mainly used in

combination with potential field measurements; e. g. combined with Profometer Corrosion measurements. Erroneous or non valid readings can be

masked and unmasked (see “3.2.2. Cover Meter Measurement Modes”);

a cross will appear into the masked fields and the corresponding cover

values will not be taken into account in the Statistical View.

Figure 26: Area-Scan View (X- and Y-axis with different scale)

Figure 27: Area-Scan View (zoomed to show X- and Y-axis in the same

scale)

Page 27

27 © 2017 Proceq SA

Cross-Line View

Profometer

650 AI

The Cross-Line View can be displayed only if measurements have been

done and stored in the Cross-Line Mode. It is a plan view of the first

and second layer rebars. Rebars can be masked and unmasked in the

corresponding Single-Line View (see “3.2.2. Cover Meter Measurement

Modes”); masked rebars will be displayed in dark grey with a dotted line

and their cover values will not be taken into account in the Statistical

View.

Tap to switch among

different views.

Masked rebars

Tap to switch among

different views.

Two diameters and two NRCspacings (if set) are shown.

Left of / it’s the value of the

SX (scanning in X-direction

of the rebars running in

Y-direction), right of / it’s the

value of the SY (scanning

in Y-direction of the rebars

running in X-direction).

Either cover, diameter or

signal strength spectrum is

displayed.

Tap to switch among

different views.

Tap on

to change the global diameter of the active layer (SX or SY)

Figure 28: Cross-Line Views: Cover, Diameter, Signal Strength

In the signal strength spectrum view two sliders are shown on the right.

• With the O-slider (Offset) the signal strength range is set (from full

actual signal strength range to higher strength only).

• With the G-slider (Gain) the signal strength resolution is set. The

signal strength is accordingly displayed in colors from full color

spectrum to part of it only, e. g. blue to violet only.

Page 28

© 2017 Proceq SA 28

Three demo files are stored on the Profometer 6 Touchscreen in the explorer under Demo Files and the document “Profometer 650 AI Demo

Files Tutorial.pdf” under Information\Documents.

Try out different slider positions to get familiarized with the display of the

signal strength color spectrum, e. g. the extreme positions:

O- and G-slider lowest position:

Full color spectrum, full Signal

Strength range (of actual measurements)

O- and G-slider highest position:

Full color spectrum, highest

Signal Strength (shallower rebars) only

O- highest, G-slider lowest position:

Blue/violet only, highest Signal

Strength (shallower rebars) only

O- lowest, G-slider highest position:

Only grey color displayed, Signal Strength beyond actual one

To sharpen the color spectrum set “Sharpen”.

3.2.4. Practical Hints

Measuring diameter and cover

The procedure for evaluating the diameter of the reinforcing bar and

cover is as follows:

• Map out the actual grid on the surface of the element using the Locating Mode or Single-Line Mode.

• Evaluate the rebar layout and determine the ideal location for measuring diameter and cover according to the minimum spacing requirements (see Figure 29); if the spacing S

1

of parallel rebars is between

5 cm and 13 cm (2.0 ” to 5.2 ”), set the respective Neighboring Rebar

Correction value first.

• Measure the diameter and use the derived value as setting for cover

measurement

NOTE! The Determination of the rebar diameter is limited to a

maximum cover of about 63 mm (2.50 inch)

Do not use the Spot Range when measuring a diameter

S

2

S

1

S

1

>75 mm

>3 ”

MC

S

1

> 5 cm / 2 inch (with Neighboring Rebar Correction)

S

1

> 13 cm / 5.2 inch (without Neighboring

Rebar Correction)

S

2

> 15 cm / 6 inch

Figure 29: Minimum spacing for diameter measurement

Diameter measurement accuracy is a complicated function of both first

and second layer rebar size and spacing; for all practical purposes, when

the minimum spacing requirements are met (see Figure 29 as stated in

the Technical Specifications, S

1

> 5 cm / 2 inch, S2 > 15 cm / 6 inch) it

can be summarized as stated the Technical Specifications, that is to say

±1 rebar size.

When a certain diameter assessment is required for structural purposes

it is advisable to use Profometer 6 diameter estimation as a prelimi-

nary homogeneity check, in order to define how many possible different

rebar sizes are involved. A direct observation on an open spot is then

advisable on every different location.

In multiple layer arrangements (see Figure 30) the deeper rebars may affect the diameter measurements on the shallow ones, causing the measured values to be overestimated (see Figure 30).

Page 29

29 © 2017 Proceq SA

Figure 30: Multiple reinforcement layers

In overlapping areas the measured diameter will be generally 1,4 times

higher than the actual single rebar size (see Figure 31).

Ds ~ 1.4 D

r

C

D

s

Ds= Set Diameter

Real Diameter D

r

Figure 31: Apparent diameter on overlapping rebars

In any of the two cases mentioned above, or more generally whenever

the requirements of the minimum spacings are not met, the diameter

to be set in order to have correct cover readings is the one that is

measured by the Profometer 6, regardless of the actual rebar size

(apparent diameter).

Rebar Orientation

The strongest signal results when the Center Line (CL) of the probe is

parallel to a bar. The CL E of the Profometer 6 probe is the longitudinal

axis of the probe. This property is used to help determine the orientation

of the rebars by rotating the probe slowly and searching for the maximum

signal.

Welded Meshes

The instrument cannot detect whether the rebars are welded to one another or connected with binding wires. The two reinforcement types with

the same dimensions however create different signals.

The setting of the bar diameter must be slightly higher than the actual

diameter of the mesh rebar. The input depends on the bar diameter and

on the mesh width. This input value should be determined by means of a

test measurement on an open system with specific rebar mesh wire arrangements. Measure on each arrangement with different covers to find

out the diameter setting at which the correct cover is indicated.

Welded reinforing mesh

a

1

[mm]

a2

[mm]

current d

[mm]

d to be set

[mm]

100

150

100

150

5

6

8

7

Figure 32: Examples for diameter settings at welded meshes to measure

correct cover values

NOTE! The “Standard Range” must be selected. With the

“Large Range” or “Spot Range” selected, locating of the

rebars may be completely wrong.

Page 30

© 2017 Proceq SA 30

Diameter Measurements on welded Reinforcement Meshes

In most cases a diameter can be measured but the displayed value is far

too large and cannot be used. The only way to determine the diameter is

by an inspection hole.

Scanning on Small Surfaces and Near to Edges

On small areas and near edges you may have to place a cover sheet for

scanning with the probe cart.

For correct cover measurements

the sheet thickness must be set as

Cover Offset value.

In this case no Cover Offset value

must be set

Figure 33: Scanning near to the edge

4. Profometer Corrosion

4.1 Measuring Principle

4.1.1. Corrosion and Half-cell Potential

Under normal conditions reinforcement steel is protected from corrosion

by a thin, passive film of hydrated iron oxide.

This passive film is decomposed due to the reaction of the concrete with

atmospheric carbon dioxide (CO2, carbonation), or by the penetration of

substances aggressive to steel, in particular chlorides from de-icing salt

or salt water.

At the anode ferrous ions (Fe++) are dissolved and electrons are set free.

These electrons drift through the steel to the cathode, where they form

hydroxide (OH-) with the generally available water and oxygen. This principle creates a potential difference that can be measured by the half-cell

method.

Figure 34: Principle of steel corrosion in concrete with oxygen availability

Page 31

31 © 2017 Proceq SA

The basic idea of the potential field measurement is to measure the potentials at the concrete surface, in order to get a characteristic picture of

the state of corrosion of the steel surface within the concrete. For this

purpose a reference electrode is connected via a high-impedance voltmeter to the steel reinforcement and is moved in a grid over the concrete

surface.

The reference electrode of the Profometer Corrosion system is a Cu/

CuSO4 half-cell. It consists of a copper rod immersed in a saturated copper sulphate solution, which maintains a constant, known potential.

Figure 35:

Measuring Principle

4.1.2. Typical Potential Range

Typical orders of magnitude (for information only) for the half-cell potential of steel in concrete measured against a Cu/CuSO4 reference electrode are in the following range (RILEM TC 154-EMC):

• water saturated concrete without O2: -1000 to -900 mV

• moist, chloride contaminated concrete: -600 to -400 mV

• moist, chloride free concrete: -200 to +100 mV

• moist, carbonated concrete: -400 to +100 mV

• dry, carbonated concrete: 0 to +200 mV

• dry, non-carbonated concrete: 0 to +200 mV

In general terms the probability of corrosion rises with low (negative) potentials; active corrosion can be expected at locations where a negative

potential is surrounded by increasingly positive potentials, i.e. locations

with a positive potential gradient. Potential differences of around +100mV

within a 1m measurement area, together with negative potentials can be

a clear indication of active corrosion.

The actual potential absolute value (corrosion threshold) below which active corrosion can be expected may vary significantly on different structures. It is however useful to mention the thresholds suggested by ASTM C

876-09, Appendix X1, assigning a 90% probability of corrosion ongoing to

the areas more negative than -350 mV, and a 90% probability of no corrosion to the areas more positive than -200 mV, judging uncertain the behavior in the regions in between the two thresholds. Be sure to note the conditions stated by ASTM as to the applicability of these threshold values.

4.1.3. Factors affecting the Potential Measurement

Provided that the corrosion conditions are equal (chloride content or carbonation of the concrete at the steel surface) the main influences upon

the half-cell potentials are:

Moisture

See the chart above for moist, carbonated concrete and dry, carbonated

concrete. Moisture has a large effect on the measured potential leading

to more negative values.

Page 32

© 2017 Proceq SA 32

Concrete cover thickness (Measure with Profometer / Profoscope)

The potential that can be measured at the surface becomes more positive with increasing concrete cover. Variations in the concrete cover can

cause deviations in the measurements. Very low concrete cover can lead

to more negative potentials which would seem to indicate high levels

of corrosion. Therefore it is advisable to make concrete cover measurements along with the half-cell measurements.

Electrical resistivity of the concrete

Low electrical resistivity leads to more negative potentials that can be

measured on the surface and the potential gradients become flatter.

In this case the measurement grid for potential measurements may be

coarser, as the risk of undetected anodic areas with flatter gradients becomes lower. However, as the resolution between corroding and passive

areas is reduced, this may lead to an overestimation of the actively corroding surface area.

High electrical resisitivity leads to more positive potentials that may be

measured on the surface and potential gradients become steeper.

In this case the measuring grid must be made finer, in order to be able to

locate an anode with a very steep gradient. However, the mere potentials

may be misinterpreted as passive areas when only considering the absolute value of the potential.

Temperature

The main effect of temperature on potential measurements is given by

its influence on the electrical resistivity. High temperature will cause

concrete resistivity to be lower and low temperature will cause concrete

resistivity to be higher; the resulting effect on potential value is as described in the previous paragraph “Electrical resistivity of the concrete”.

In order to measure the potential there must be a contact between the

probe and the ectrolytes in the pore system of the concrete. Therefore a

measurement below the freezing point is not recommended and can lead

to incorrect readings.

Oxygen content at the reinforcement

With decreasing oxygen concentration and increasing pH-value at a steel

surface its potential becomes more negative. In certain cases of concrete

components with a high degree of water saturation, low porosity and/or

very high concrete cover and thus low oxygen supply, the potential at the

steel surface may be highly negative even though no active corrosion is

taking place. Without checking the actual corrosion state this may lead

to misinterpretation of the potential data.

The air permeability of the concrete may be tested with Proceq’s Torrent

instrument.

4.1.4. Application Limits of the Potential Measurement Technique

The potential field measurement even with a coarse grid delivers good

results for chloride induced corrosion. This type of corrosion is typified by

pitting developing into troughs. Corrosion due to carbonation is typified

by the development of smaller macro-elements and is only possible to

determine by using a very fine grid if at all.

Corrosion of pre-stressed steel reinforcement is not possible to detect if

it is located within a protective tube.

The potential field measurement alone offers no quantitative conclusions

about the rate of corrosion. Empirical studies have shown that there is a

direct relationship between the corrosion rate and the electrical resisitivity. However corrosion rate readings are of limited value as the rebar corrosion rate varies considerably with time. It is more reliable to work with

corrosion readings taken over a period of time.

Page 33

33 © 2017 Proceq SA

4.2 Profometer Corrosion Operation

4.2.1. Preliminary Operations

Prepare the electrode(s)

Rod Electrode - Before filling, remove the cap with the wooden plug and

soak it in water for about an hour to allow the wood to saturate and swell.

Wheel Electrode - The wooden plug is not intended to be removed. Immerse the wheel in water well before you intend to use it to allow water to

soak into the plug. The felt hoops and the felt hoop connector should be

saturated with water before measuring.

Copper Sulphate (Rod and Wheel) - Prepare the saturated solution by

mixing 40 units by weight of copper sulphate with 100 units by weight of

distilled water. In order to ensure that the solution remains saturated, add

an additional teaspoonful of copper sulphate crystals into the electrode.

The electrode should be filled as completely as possible with a minimum

of air in the compartment. This ensures that the solution is in contact with

the wooden plug even when measuring in an upwards direction.

NOTE! When handling copper sulphate be careful to take

note of the safety instructions on the packaging.

Selecting the correct grid and marking the surface

One method is to use a relatively large grid for a first estimate, e.g. 0.50

x 0.50 m up to a max of 1.0 x 1.0 m using the coarse grid. (See “4.2.2.

Corrosion Settings”).

Suspect areas can be further investigated using a finer grid (e.g. 0.15 x

0.15 m), to identify the extent of the surface that will require corrective

maintenance.

Vertical elements usually require a smaller grid (e.g. 0.15 x 0.15 m). The

same applies to slender elements, for which the grid will be defined by

the geometry, (e.g. steps, beams and joints etc.).

For large horizontal surfaces (parking decks, bridge decks etc.) a grid of

0.25 x 0.25 m to 0.5 x 0.5m is typically sufficient.

It is recommended to mark out a grid on the surface corresponding to

the grid you wish to use. For small areas where point measurements

will be made with the Rod Electrode this can be done by using a tape

or by drawing the grid on the element. For large areas such as parking

and bridge decks the wheel electrode is preferable. The integrated path

measurement ensures the correct grid in the direction of measurement.

To ensure the correct grid between parallel measurement paths marks

can be drawn on the surface. Please note the 4-Wheel Electrode ensures

a stable parallel grid and requires less marks to be drawn on the surface.

Choosing the appropriate electrode

Depending on the surface under test, it is necessary to choose which

type of electrode will be employed. For small areas or areas that are difficult to access, the small and light Rod Electrode will typically be used.

For more accessible horizontal, vertical or overhead surfaces, it is much

faster to use the 1-Wheel Electrode. For large horizontal surfaces the

4-Wheel Electrode is recommended for the reason of the significantly

faster automatic measurement in a pre-defined grid.

Connect to the reinforcement

The ground cable must be connected to the reinforcement of the surface

to be measured. This is usually done by chiseling or drilling to the reinforcement. In some cases it may be possible to use existing building elements

that are connected to the reinforcement (e.g. water pipes, earth points). The

connection to the reinforcement should be made with the least possible resistance. To this end it may be beneficial to grind the reinforcement (e.g using an angle grinder) and to connect the cable with welding tongs. A secure

connection can be also obtained by drilling a 25 mm hole into the concrete

above the rebar, then drill a 4 mm hole into the rebar and insert a self tapping

screw with attached lead into the hole in the steel. The connection should be

tested for continuity. This requires at least one other point of the reinforcement to be exposed and to check the resistance between the two with an

Ohmmeter. The connections should be situated as far as possible in opposing corner areas of the surface under test. The measured resistance should

not be more than 1 Ω above the resistance of the cable used.

Page 34

© 2017 Proceq SA 34

Coated surfaces

It is not possible to make a measurement through an electrically isolating

coating (e.g. an epoxy resin coating, sealing sheets or asphalt layers.)

It is possible to make a measurement through thin dispersion coatings,

that are often used, for example on the walls and ceiling of underground

car parks, however this can cause a small shift of the potentials.

It is always necessary to check whether or not a measurement can be

made through a coating.

To do this, potentials should be measured at a few locations

• in the first place through the coating and

• with the coating removed

If possible, areas with largely varying potentials should be chosen. If

there is no alteration of the potential, or if a shift of the potential can be

compensated by a correction (e.g. V = ± 50 mV), then a measurement

can be made directly on the coating. If not, then the coating must be

removed before making the measurement.

Pre-moistening

The contact between the pore solution of the concrete and the probe can

be impaired by a dried out concrete skin. This can greatly increases the

electrical resisitivity of the concrete.

It is therefore recommended to moisten the surface approximately 10 to

20 minutes before carrying out the measurement.

If this is not possible, it must be ensured that the sponge on the Rod

Electrode or the felt hoops on the wheel electrode are sufficiently moistened. In this case, when making a measurement, the probe must be held

against the surface until a stable end value is reached. (If the surface is

dry at the beginning of the measurement, it has to be moistened by the

sponge on the probe so a stable value will not be present initially.)

This is only possible with the Rod Electrode.

Proceq provides an additional sponge that connects to the rod electrode

in order to increase the overall surface contact area, to prevent testing

immediately above a large aggregate.

In the case of the wheel electrode with its continual automatic measure-

ment, it is not possible to monitor whether or not the measured value is

stable. Therefore it is recommended to pre-moisten the surface in sections and to measure in intervals of a few minutes.

4.2.2. Corrosion Settings

Enter Settings from the Main Menu (see “2.2 Main Menu”); scroll up and

down the screen by dragging your finger up or down the screen. The

current setting is displayed on the right hand side. Tap on an item to

modify it.

Measuring Mode

(Electrode)

Adjustable after

data storage

Settings Rod Wheel(s)

Probe Type

• •

No

Grid X Spacing

• •

No

Grid Y Spacing

• •

No

Enable Grid Limits

• •

No

Unit

• •

Yes

Measurement Path

•

No

Coarse Grid Factor

•

No

Auto Save

•

No

Direction of Next Line

• •

No

Potential Max Threshold

(Highest)

• •

Yes

Potential Min Threshold

(Lowest)

• •

Yes

Potential Range Palette

• •

Yes

Minimum Passive Limit

• •

Yes

Maximum Active Limit

• •

Yes

Half-cell Solution

• •

No

Page 35

35 © 2017 Proceq SA

Probe Type

Select between Rod, One Wheel and Four wheel depending on the

electrode connected

Grid X Spacing

It determines the horizontal width of the measured cell (wheel electrode)

or the horizontal distance between measured points (rod electrode).

Grid Y Spacing

It determines the vertical distance between two adjacent measuring lines

(wheel electrode) or the vertical distance between measured points (rod

electrode). In case of four wheel electrode it should be set equal to the

distance between the wheels (150 mm, 250 mm or custom).

Enable Grid Limits

If set the user can define the maximum extent of the investigated area.

Unit

Select Metric or Imperial

Measurement Path