Page 1

... more than 50 years of know-how you can measure!

Made in Switzerland

Operating Instructions

Paper Roll Hardness Tester

Page 2

Operating Instructions

1. Getting Started 3

2. Safety and Liability 4

2.1 General Information 4

2.2 Liability 4

2.3 Safety Instructions 4

2.4 Correct Usage 4

3. Real Tests 5

3.1 Preparation 6

3.2 Define a Roll ID for the Test Series 6

3.3 Measure the Roll Hardness Profile 7

3.4 Terminate the Series and review 7

3.5 Entering a Roll ID manually 8

3.6 Accept or modify limits 8

3.7 Review list 9

4. Technical Specifications 9

5 Part Numbers and Accessories 10

5.1 Units 10

5.2 Parts and Accessories 10

6. Maintenance and Support 10

6.1 Self test function 10

6.2 Checking the calibration on the anvil 10

6.3 Support Concept 10

6.4 Standard Warranty and Extended Warranty 10

7 Paperlink Software 11

7.1 Starting Paperlink 11

7.2 Viewing the data 11

7.3 Adjusting the max/min settings 13

7.4 Adjusting the date and time 13

7.5 Exporting data 13

7.6 Deleting and restoring data 14

7.7 Further Functions 14

7.8 Pre-define Roll IDs 15

7.9 Technical Information Paperlink software 15

Page 3

3 © 2009 by Proceq SA

1. Getting Started

Note: First time user: Complete the tutorial OR see a demo by a qualified Proceq

representative. If you only need to do simple measurements, please go to chapter

3.3.

Charging the PaperSchmidt

The PaperSchmidt uses a built-in Lithium Polymer accumulator. In case of a low battery alert, you

can still record approximately 100 to 200 impacts. When the display indicates a low battery, connect

the PaperSchmidt to the charger or to a PC. Approximately 90 minutes of charging will bring your

PaperSchmidt to its full capacity. The PaperSchmidt can be recharged at any time.

Power ON

Press the SELECT button to power on.

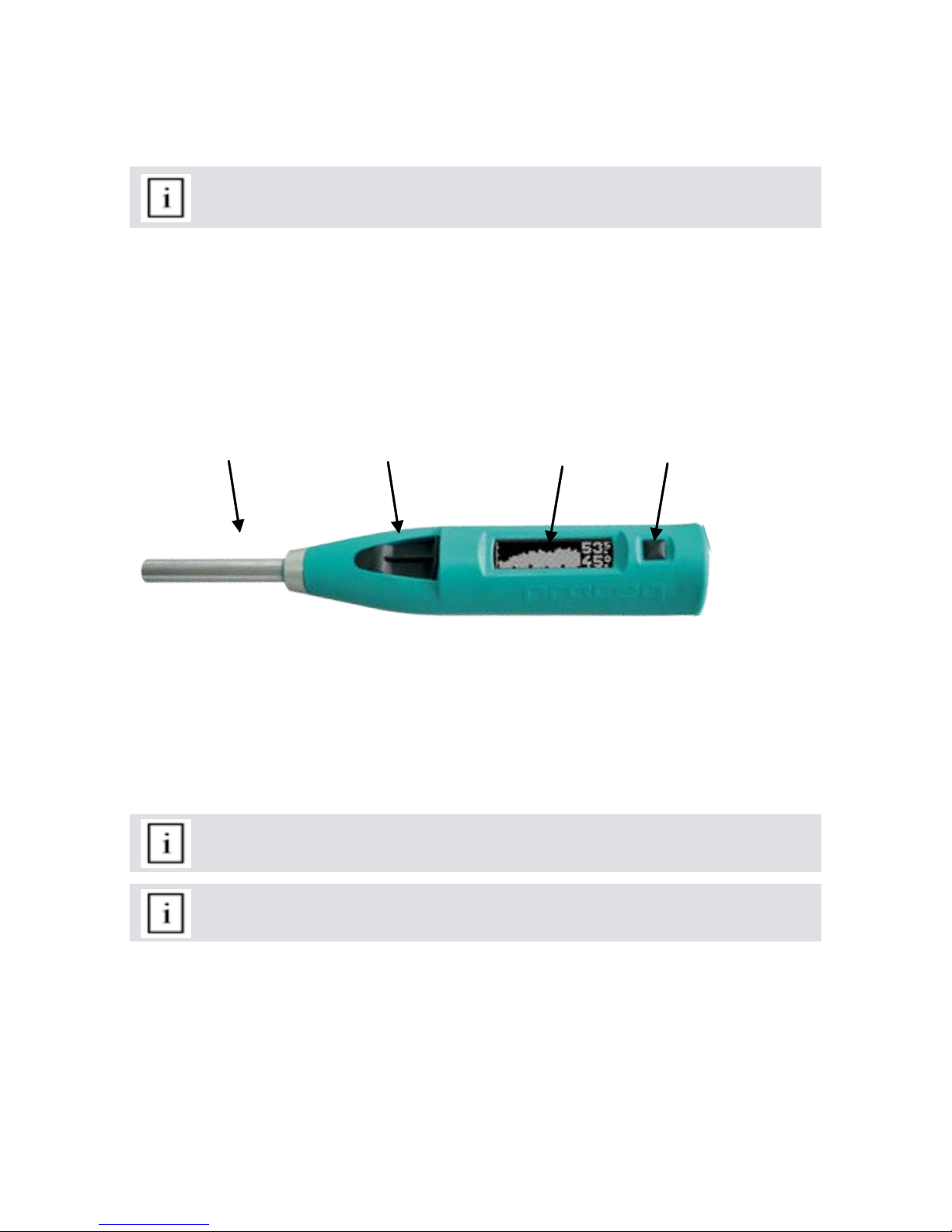

Plunger USB port LC Display SELECT button

Check the calibration of the hammer

Perform a calibration check on your hammer as described in chapter 6.

Congratulations! Your new PaperSchmidt is fully operational and you can now continue with your

measurements.

Performing a reset

In case a reset is required, this can be done by performing an impact with the select button

pressed.

Note: This will remove any lower and upper limits that may have been set.

Note: Should your instrument be fully discharged, start with a reset after recharging.

Power OFF

The PaperSchmidt will shut down automatically after 5 minutes of inactivity.

Standards and Regulations Applied

The following standard has been applied in the PaperSchmidt.

TAPPI T 834 om-07 (Determination of containerboard roll hardness)

The following recommendation has been taken into consideration in the PaperSchmidt.

TAPPI TIP 1004-01 (TAPPI Roll Number for inventory/tracking systems and bar codes)

This standard recommends a 12 digit roll number. The PaperSchmidt is able to accept roll identifier

names (Roll IDs) in this format.

Page 4

4 © 2009 by Proceq SA

2. Safety and Liability

2.1 General Information

This manual contains important information on the safety, use and maintenance of the PaperSchmidt.

Read through the manual carefully before the first use of the instrument. Keep the manual in a safe

place for future reference.

2.2 Liability

Our “General Terms and Conditions of Sales and Delivery” apply in all cases. Warranty and liability

claims arising from personal injury and damage to property cannot be upheld if they are due to one

or more of the following causes:

Failure to use the instrument in accordance with its designated use as described in this manual.•

Incorrect performance check for operation and maintenance of the instrument and its compo-•

nents.

Failure to adhere to the sections of the manual dealing with the performance check, operation •

and maintenance of the instrument and its components.

Unauthorised modifications to the instrument and its components. •

Serious damage resulting from the effects of foreign bodies, accidents, vandalism and force •

majeure.

All information contained in this documentation is presented in good faith and believed to be correct.

Proceq SA makes no warranties and excludes all liability as to the completeness and/or accuracy of

the information.

2.3 Safety Instructions

The equipment is not allowed to be operated by children or anyone under the influence of alcohol,

drugs or pharmaceutical preparations. Anyone who is not familiar with this manual must be supervised when using the equipment.

Carry out the stipulated maintenance properly and at the correct time. •

Following completion of the maintenance tasks, perform a functional check.•

2.4 Correct Usage

The instrument is only to be used to determine the roll hardness profile of paper and film rolls.•

Replace faulty components only with original replacement parts from Proceq.•

Accessories should only be installed or connected to the instrument if they are expressly autho-•

rized by Proceq. If other accessories are installed or connected to the instrument then Proceq will

accept no liability and the product guarantee is forfeit.

Page 5

5 © 2009 by Proceq SA

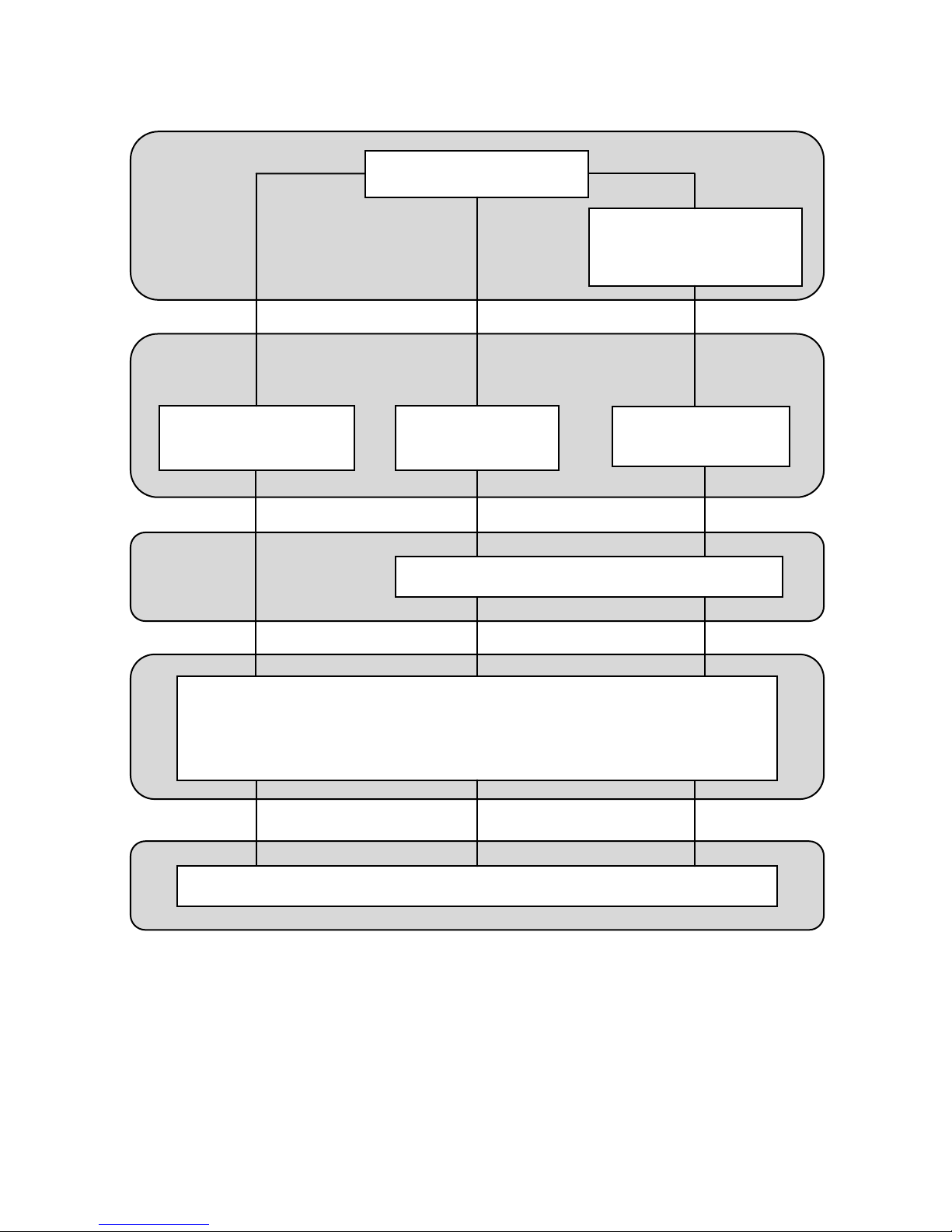

3. Real Tests

3.6 Accept or modify limits

C omplete G etting S tarted

7.8 Pre-define R oll IDs in

P aperlink a nd download to

hammer

Method 1: P erform a n

impact (Roll ID = Counter)

Method 2: Ma nually

enter R oll ID

Method 3: S e le ct a pre-

defined R oll ID

3.3 Meas ure the R oll H ardness Profile

3.4 T erminate the S eries and review

3.1 Preparation

3.2 Define a R oll ID for the T es t S eries

Page 6

6 © 2009 by Proceq SA

3.1 Preparation

If desired, define Roll IDs for the paper rolls under test using Paperlink and download these onto the

PaperSchmidt (See 7.8)

3.2 Define a Roll ID for the Test Series

The data list is the starting point for a new test series. Navigate within the data list by rolling the PaperSchmidt either away from you or towards you.

There are 3 methods to define a Roll ID for a new test series.

Method 1 – Perform an impact

It is not necessary to define a specific Roll ID. Simply begin a measurement series by performing an

impact directly from the data list. Whatever upper/lower limits were previously set will be adopted

automatically for this series. In this case the actual 4-digit value of the internal impact counter is used

as a Roll ID and will appear in the review list once the series has been terminated.

Roll ID = Counter

Method 2 – Manual entry of the Roll ID

Method 3 – Select a pre-defined Roll ID

Note: A single pre-defined name can be used for a whole batch of rolls. In this case,

each time you move on to the next roll, select the same name again from the review

list and the device will increase an index which is used to identify that particular roll

in the list.

Scroll to “NEW” and press the SELECT button.

Enter the Roll ID on the PaperSchmidt (see 3.5)

Accept or modify the upper/lower limits (see 3.6)

and begin measuring the roll hardness profile.

Scroll to the desired pre-defined Roll ID in the upper section of the data list and press the SELECT

button.

Accept or modify the upper/lower limits (see 3.6)

and begin measuring the roll hardness profile.

The upper section contains empty series with

pre-defined Roll IDs.

The lower section contains completed series

which can be reviewed.

Page 7

7 © 2009 by Proceq SA

3.3 Measure the Roll Hardness Profile

Each factory has its own recommendations for measuring the roll hardness. However, the method

is very similar in all cases and some general principles can be applied. Begin at one end of the roll,

not too close to the edge. To carry out an impact, place the hammer perpendicular to the paper roll.

Push the hammer against the surface of the roll at a moderate speed until the impact is triggered. (For

best results, impact at the same angle and apply the same pressure for each reading.) Repeat this

procedure at a regular spacing to obtain a profile across the entire roll.

“TIP” the plunger to display the running profile. The minimum and maximum measured values are displayed on

the right. (TIP = Slightly depress the plunger, but not far

enough to impact.)

The rebound value is displayed on the screen after each

impact along with the number of impacts in the current

series. (A series may contain up to 99 impacts.)

Pressing the SELECT button gives you the option of terminating a series (SUM icon) or deleting the last impact

if it was an obvious outlier (Dustbin icon). Scroll to the

desired icon and press the SELECT button again.

A confirmation screen prevents terminating a series prematurely. Use cancel (X-symbol) or confirm (tick-symbol).

If an outlier is deleted, the display returns to the previous

value and the series counter is reduced by one.

3.4 Terminate the Series and review

At the end of the roll, terminate the series by pressing the SELECT button. Then press on the “Sum”

icon as shown above and confirm the action. This will take you to the statistics screen where you can

review all of the significant data for the test series.

Mean R value Standard deviation

Range (Max-Min) No. of impacts

Tilt the PaperSchmidt to show the roll hardness profile. The screen can show a roll hardness profile

of up to 50 impacts. However, a single series may contain up to 99 impacts for very large rolls. To see

beyond the 50 impacts simply TILT the PaperSchmidt to show the impacts to the right. A marker on

the scale at the bottom of the profile shows the “50th” impact position on both screens.

50th impact 50th impact

Exit the summary display mode by pressing the SELECT button if you want to enter or select a new

roll ID. Simply proceed to a next measurement series if you don’t use specific roll IDs.

Page 8

8 © 2009 by Proceq SA

3.5 Entering a Roll ID manually

Having selected “NEW” from the data list, the user may define a Roll ID for the test series manually.

The Roll ID can be up to 12 characters long. The screen begins with the last Roll ID that was entered,

or with the impact counter value following a reset.

TILT to scroll to the character you wish to change and press the SELECT button to access the •

character select screen.

ROLL and TILT to the desired character and press the SELECT button to set it. •

Repeat this procedure to enter the complete Roll ID.•

Scroll to the “ENTER” symbol at the far right of the Roll ID and press the SELECT button.•

Deleting a character

TILT to scroll to the character you wish to delete and press the SELECT button to access the •

character select screen.

TILT to the delete symbol and press the SELECT button. (See below)•

The character is deleted. Any characters to the right of the character deleted will shift left.•

3.6 Accept or modify limits

This function is a rapid way to check if the roll hardness profile is within a pre-defined tolerance.

After selecting a pre-defined Roll ID or after entering a Roll ID manually, the actual upper and lower

limit values are displayed, e.g. 28R is the lower limit, 56R is the upper limit.

TILT to adjust the value and press SELECT.

(It may also be blank if you were previously working with no limits. To work without limits, adjust them

to 0R resp. 100R.) To accept the limits displayed press the SELECT button. To modify the limit values,

scroll the cursor to the limit you wish to change and press SELECT.

Note: If the lower limit is higher than the upper limit, they will be reversed automatically

The cursor position is shown inverted.

The screen can show up to 10 characters.

Arrows at the bottom indicate if there is more to the left or

right.

The character select screen is arranged in 3 rows to

allow the user to locate the desired characters quickly.

The character select screen has a special symbol (highlighted), that allows the user to delete the selected character from the Roll ID

Page 9

9 © 2009 by Proceq SA

Display warnings

3.7 Review list

A previous series can be reviewed directly from the data list. The lower portion of the data list shows

the last 20 completed measurement series identified by name.

This symbol identifies a file which contains data.

Scroll to the series you wish to review and press the select button. You are given the option to look at

the summary data or to delete the series. If you choose to delete the series, the confirmation window

will be displayed.

If you wish to look at the summary data, you will be taken

directly to the statistics screen. (See 3.4)

Note: Only the last 20 completed measurement series can be reviewed in the data

list. The PaperSchmidt stores many more. The remaining series can only be seen

once the data has been put into Paperlink.

4. Technical Specifications

Mechanical Data

Impact energy 0.735 Nm

Hammer mass 115 g

Spring constant 0.262 N/mm

Spring extension 75 mm

Dimensions of housing 55 x 55 x 250 mm (340 mm to tip of plunger)

Dimensions (plunger visible part) 105 x ø15 mm (radius of spherical tip 25mm)

Weight 570 g

Memory Data

No. of impacts in a series Maximum 99

No. of series names 50 series names. Each name can be up to 12 characters long.

Memory capacity Dependent on length of test series, Example 1: 401 series with 10

values per series, Example 2: 246 series with 20 values per series

Electrical Data

Display 17 x 71 pixel, graphic

Power consumption ~13 mA measuring, ~4 mA set-up and review, ~0.02 mA idle

Accumulator duty > 5000 impacts between charges

Charger connection USB type B (5V, 100 mA)

Accumulator capacity ~150 mAh

Environmental conditions

Operating temperature 0 to 50°C

Storage temperature -10 to 70°C

When carrying out a measurement (See 3.3) the display

will give a warning if any of the limits are exceeded. In

this example, the limit sign next to the R indicates that the

lower limit has been exceeded. If the upper limit has been

exceeded, the arrow points upwards.

In the roll profile view (after TIP function and in the summary view), impacts which exceed the limits will blink.

Page 10

10 © 2009 by Proceq SA

5 Part Numbers and Accessories

5.1 Units

Part No. Description

342 10 000

PaperSchmidt consisting of battery charger with USB-cable, CD with Paperlink

software, carrying strap, documentation, carrying bag

5.2 Parts and Accessories

341 10 113 Cover for USB port

342 10 310 Plunger complete with plunger spring

342 10 400 Testing Anvil PaperSchmidt

341 80 105 Carrying bag

351 90 018 USB cable 1.8m

341 80 112 USB charger, global

341 80 203 Carrying strap (loop)

Please contact your Proceq business unit or authorized service centre for pricing and availability.

6. Maintenance and Support

6.1 Self test function

The PaperSchmidt performs a number of self checks and gives an alert when there is a problem.

These three alerts show the

battery status:

Low battery, Battery full,

Battery charging

Low impact energy: The impact

spring is out of tolerance and should

be replaced. It is recommended to

return the PaperSchmidt to an authorized service centre.

6.2 Checking the calibration on the anvil

The PaperSchmidt checks for correct impact energy with each and every impact. Nevertheless, it is

recommended to check the calibration on a regular basis.

Perform a series of 10 impacts on the anvil (Proceq Part Nr. 342 10 400)•

Check that the average R-value lies within the tolerance shown on the label.•

If it is out of tolerance, it should be returned to an authorized service centre for recalibration.•

The EURO anvil p/n 310 09 040 can also be used.

6.3 Support Concept

Proceq is committed to providing a complete support service for this instrument by means of our

global service and support facilities. It is recommended that the user register the product on www.

proceq.com to obtain the latest on available updates and other valuable information.

6.4 Standard Warranty and Extended Warranty

The standard warranty covers the electronic portion of the instrument for 24 months and the mechanical portion of the instrument for 6 months. An extended warranty for one, two or three years for

the electronic portion of the instrument may be purchased up to 90 days of date of purchase.

Page 11

11 © 2009 by Proceq SA

7 Paperlink Software

7.1 Starting Paperlink

Locate the file “Paperlink_Setup” on your computer or on the CD and click on it. Follow the instructions you see on the screen.

Application settings

The menu item “File – Application settings” allows the user to select the language and the date and

time format to be used.

Connecting to the PaperSchmidt

Connect the PaperSchmidt to a USB port, then click on the icon to bring up below window:

Leave the settings as default or if

you know the COM port you can enter it manually.

Click on “Next >”

The USB driver installs a virtual COM port which is used to communicate with the PaperSchmidt.

When a PaperSchmidt has been found, you will see another window. Click on the “Finish” button to

establish the connection.

7.2 Viewing the data

The data stored on your PaperSchmidt will be displayed on the screen:

Page 12

12 © 2009 by Proceq SA

The test series is identified by the “Impact counter” value and by a “Roll ID” if assigned.

The user may alter the Roll ID directly in the “Roll ID” column.•

The “Date & Time” when the measurement series was made.•

The “Mean value”.•

The “Total” number of impacts in this series.•

The “Lower limit” and “Upper limit” set for that series.•

The “Range” of the values in this series.•

The “Std dev.” Standard deviation of the measurement series.•

Click on the double arrow icon in the impact counter column to see the profile.

If limits have been set, they are displayed as above with a blue band. It is also possible to adjust the

limits directly in this window by clicking on the blue limit values.

Note: The user may also add a comment to the measurement series. To do so, click

on “Add”.

Note: The user may alter the order in which the measurements are shown. Click on

“measurement order” to switch to “ordered by value”.

Summary window

In addition to the above “Series” view, Paperlink also offers a “Summary” window. This is useful when

comparing a batch of rolls of the same type. Click on the respective tab to switch between views.

Note: To include or exclude a series from the summary, click on the summary symbol

in the impact counter column. This symbol is either “black” or “greyed out”, which

shows whether or not the particular series is included in the summary. The summary

view can be adjusted in a similar way to the detailed view of a series.”.

Page 13

13 © 2009 by Proceq SA

7.3 Adjusting the max/min settings

Maximum and Minimum settings that were used in the PaperSchmidt at the time of the measurement

series can be adjusted subsequently in Paperlink. This can be done either by right clicking directly

on the item in the appropriate column, or by clicking on the blue setting item in the detailed view of a

measurement series. In each case a selection box will appear with the choice of setting.

7.4 Adjusting the date and time

Right click in the date and time

column.

The time will be adjusted for the

selected series only.

7.5 Exporting data

Paperlink allows you to export selected series or the entire project for use in third party programs.

To export selected series, click in the table of the measurement series you wish to export. It will be

highlighted as shown.

Click on the “Copy as text” icon. The data for this measurement series is copied to the

clipboard and can be pasted into another program such as Excel. If you wish to export

the individual impact values of the series, you have to display them by clicking on the

double arrow icon as described above before you “Copy as text”.

Click on the “Copy as picture” icon – For exporting the selected items only into another

document or report. This performs the same action as above, but the data is exported in

the form of a picture and not as text data.

“Export as text” icon – Allows you to export the entire project data as a text file that can

then be imported into another program such as Excel. Click on the “Export as text” icon.

This will open the “Save As” window where you can define the location in which you wish

to store the *.txt file.

Note: Paperlink has two “tabs” with two display formats. “Series” and “Summary”.

When performing this operation, the project data will be exported in the format defined by the active “Tab”, i.e. either in “series” or “summary” format.

To open the file in Excel, locate the file and right click on it and “Open with” – “Microsoft Excel”. The

data will be opened in an Excel document for further processing. Or drag and drop the file into an

open Excel window.

Page 14

14 © 2009 by Proceq SA

7.6 Deleting and restoring data

The menu item “Edit – Delete” allows you to delete one or more selected series from the downloaded

data.

Note: This does not delete data from the PaperSchmidt, only data in the current

project.

The menu item “Edit – Select all”, allows the user to select all series in the project for exporting etc.

Restoring original downloaded data

Select the menu item: “File – Restore all original data” to restore the data to the original format as

it was downloaded. This is a useful feature if you have been manipulating the data, but wish to go

back to the raw data once again. A warning will be given to say that the original data is about to be

restored. Confirm to restore.

Note: Any names or comments that have been added to series will be lost.

Deleting data stored on the PaperSchmidt

Select the menu item “Device – Delete all Data on Device” to delete all data stored on the PaperSchmidt. A warning will be given to say that the data is about to be deleted on the device. Confirm

to delete.

Note: Please note, this will delete every measurement series and cannot be undone.

It is not possible to delete individual series.

7.7 Further Functions

The following menu items are available via the icons at the top of the screen:

“Upgrade” icon - Allows you to upgrade your firmware via the Internet or from local files.

“Open project” icon – Allows you to open a previously saved project. It is also possible to

drop a *.pqr file onto Paperlink to open it.

“Save project” icon – Allows you to save the current project. (Note this icon is greyed out if

you have opened a previously saved project.

“Print” icon – Allows you to print out the project. You may select in the printer dialog, if you

want to print out all of the data or selected readings only.

Page 15

15 © 2009 by Proceq SA

7.8 Pre-define Roll IDs

Select the menu item “Device - Series names…” to create pre-defined roll names which can be

downloaded onto the PaperSchmidt before testing a batch of rolls.

This will bring up the following window.

Simply type in the names for the series and they are transferred automatically onto the PaperSchmidt.

Up to 50 series names can be defined in this way. Each name can be up to 12 characters long.

Note: Please note, that also “copy and paste” works with data from Excel.

7.9 Technical Information Paperlink software

System requirements: Windows XP, Windows Vista, USB-Connector. An Internet connection is necessary for automatic updates, if available. An Internet connection is necessary for firmware updates

(using PqUpgrade), if available. PDF Reader is required to show the “Help Manual”.

Page 16

Proceq Europe

Ringstrasse 2, Postfach 336

CH - 8603 Schwerzenbach

Switzerland

Tel.: +41 ( 0 )43 355 38 00

Fax: +41 ( 0 )43 355 38 12

info-europe@proceq.com

Proceq USA, Inc.

117 Corporation Drive

Aliquippa, PA 15001, USA

Phone +1 724 512 0330

Fax +1 724 512 0331

info-usa@proceq.com

Proceq Asia Pte Ltd

12 New Industrial Road

#02 - 02A Morningstar Centre

Singapore 536202

Phone +65 - 6382 – 3966

Fax +65 - 6382 - 3307

info-asia@proceq.com

Proceq Asia Pte Ltd Shanghai Rep Office

Unit G, 10th Floor, Huamin Empire Plaza

No. 728, Yan An Road(W)

Shanghai 200050

Tel: +86 21-63177479 / 62122680 / 62122698

Fax: +86 21 63175015

info-china@proceq.com

Proceq Rus LLC

Ul. Kompozitorov, 10

lit.A, pom.345-N

194356 St. Petersburg, Russia

Phone: + 7 812 335 92 34

Fax: + 7 812 335 92 34

info-russia@proceq.com

Proceq Middle East

P.O. Box: 262419

Jebel Ali Free Zone

Dubai, United Arab Emirates

Phone: +971 4 8865877

info-middleeast@proceq.com

Proceq SAO Ltd.

South American Operations

Rua Haddock Lobo, 746 - 5 andar

Cerqueira Cesar, São Paulo - SP, Brasil

Cep. 01414-000

Phone: +55 11 3083 38 89

info-southamerica@proceq.com

www.proceq.com

Subject to change without notice.

Copyright © 2009 by Proceq SA, Schwerzenbach

820 342 01 E ver 10 2009

... more than 50 years of know-how you can measure!

Loading...

Loading...