Page 1

ProfiHub B2FO2+

User Manual

Page 2

Draws your attention to important information on handling the product, a particular part of

the documentation or the correct functioning of the product.

Copyright © 2016 PROCENTEC

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior

written permission of the publisher.

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning sign

and are marked as follows according to the level of danger:

Warning

This device and its components may only be used for the applications described in this manual and only in

connection with devices or components that comply with PROFIBUS and an RS 485 interface. This product can

only function correctly and safely if it is transported, stored, set up, installed, operated and maintained as

recommended.

Qualified Technicians

Only qualified technicians should be allowed to install and work with this equipment. Qualified technicians are

defined as persons who are authorized to commission, to ground, to tag circuits and systems in accordance

with established safety practices and standards. It is recommended that the technicians carry a Certified

PROFIBUS Installer or Certified PROFIBUS Engineer certificate.

Disclaimer of Liability

We have checked the contents of this manual as much as possible. Since deviations cannot be precluded

entirely, we cannot guarantee full agreement. However, the content in this manual is reviewed regularly and

any necessary corrections included in subsequent editions. Suggestions for improvement are welcomed.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 1/38

Page 3

PROCENTEC

Klopperman 16

2292 JD WATERINGEN

The Netherlands

Tel.: +31-(0)174-671800

Fax: +31-(0)174-671801

Email: info@procentec.com

Important information

Purpose of the Manual

This manual explains how to put the ProfiHub B2FO2+ into operation.

Recycling and Disposal

The parts of the ProfiHub can be recycled. For further information about environment-friendly recycling and

the procedure for disposing of your old equipment, please contact:

Document Updates

You can obtain constantly updated information on PROCENTEC products on the Internet at

www.procentec.com. You can also contact PROCENTEC Customer Support:

• By phone at +31-(0)174-671800

• By fax at +31-(0)174-671801

• By email at support@procentec.com

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 2/38

Page 4

Contents

Important information ........................................................ 2

1. Product description ....................................................... 5

1.1 Introduction ........................................................................................................................ 5

1.2 Product features.................................................................................................................. 6

1.3 Application areas ................................................................................................................. 7

1.4 Additional benefits .............................................................................................................. 7

1.5 Channel Structure ............................................................................................................... 8

1.6 Grounding System ............................................................................................................... 8

1.7 Cable lengths for PROFIBUS DP ........................................................................................... 9

1.8 Cable types for PROFIBUS DP .............................................................................................. 9

1.9 Cable lengths for fiber optic ............................................................................................... 10

1.10 Cable types for fiber optic .................................................................................................. 10

1.11 Status LEDs ......................................................................................................................... 10

1.12 The red Error LED ............................................................................................................... 11

1.13 Comparison table ............................................................................................................... 12

2. Installation Instructions ProfiHub B2FO2+ .................. 13

2.1 Location .............................................................................................................................. 13

2.2 Position............................................................................................................................... 13

2.3 Mounting ............................................................................................................................ 13

2.4 Power Supply...................................................................................................................... 14

2.5 Grounding of the power ..................................................................................................... 15

2.6 Alarm contact ..................................................................................................................... 15

2.7 Fiber optic backbone .......................................................................................................... 16

2.8 Calculating the delay time .................................................................................................. 16

2.9 Spur Segments ................................................................................................................... 17

2.10 Termination ........................................................................................................................ 17

2.11 Baudrate switch ................................................................................................................. 18

2.12 Robust Repeating mode ..................................................................................................... 19

2.13 Channel Redundancy.......................................................................................................... 19

3. Technical Data ProfiHub B2FO2+ ................................. 21

4. Sales offices and distributors ....................................... 24

5. Order codes .................................................................. 29

6. Glossary ........................................................................ 30

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 3/38

Page 5

7. About PROCENTEC ....................................................... 33

8. Revision history ............................................................ 34

9. Notes ............................................................................ 35

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 4/38

Page 6

1. Product description

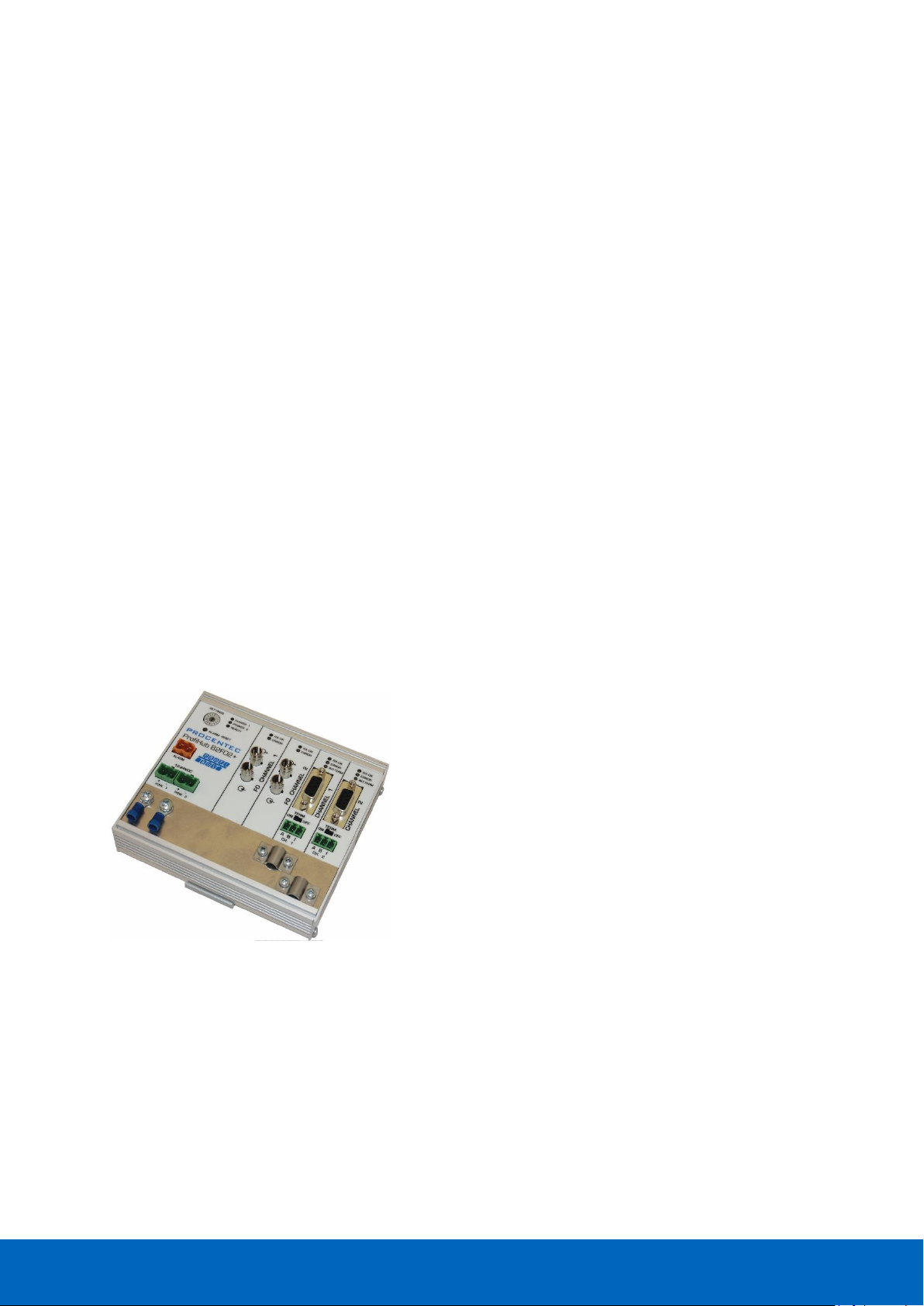

1.1 Introduction

ProfiHub B2FO2+ is an advanced, flexible and robust network component for PROFIBUS DP installations, to

create fiber optic backbone structures and long multi-device star/tree segments.

PROFIBUS DP is a high speed communication bus that must comply with strict rules concerning spur lines,

because of possible reflections that could lead to communication disturbances. If spur lines or star segments

are required, costly investments in repeaters have to be done.

The innovative ProfiHub B2FO2+ is the perfect component for such applications. It is an economic solution to

realise reliable spur lines in high speed DP networks. They have the functionality of 2 galvanic isolated

transparent repeaters and an optical link module in one device. This allows network structures with extended

spur lines that individually can handle a maximum of 31 devices and a length equal to the main bus. The

ProfiHub B2FO2+ refreshes a received message on one Channel and transfers it to all the other Channels

(chicken foot topology).

Because the ProfiHub B2FO2+ creates isolated segments, the devices can now be removed and added during

operation. Also most electrical bus problems and EMC disturbances in a spur do not spread to the other

segments. The intelligent logic and isolation circuits of the ProfiHubs do not change the bit width. This means

the ProfiHubs do not have limitations in serial placement. The logic also detects the transmission speed

automatically.

To assist the installation work, termination is integrated and can be switched on/off. The grounding concept is

also selectable: direct or capacitive grounding. The ProfiHubs are powered by a 12 to 24 DC Voltage. For

troubleshooting, maintenance and commissioning the ProfiHubs are equipped with LEDs on the outside, which

indicate the status of each Channel (Data and Error).

Fig. 1 - ProfiHub B2FO2+

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 5/38

Page 7

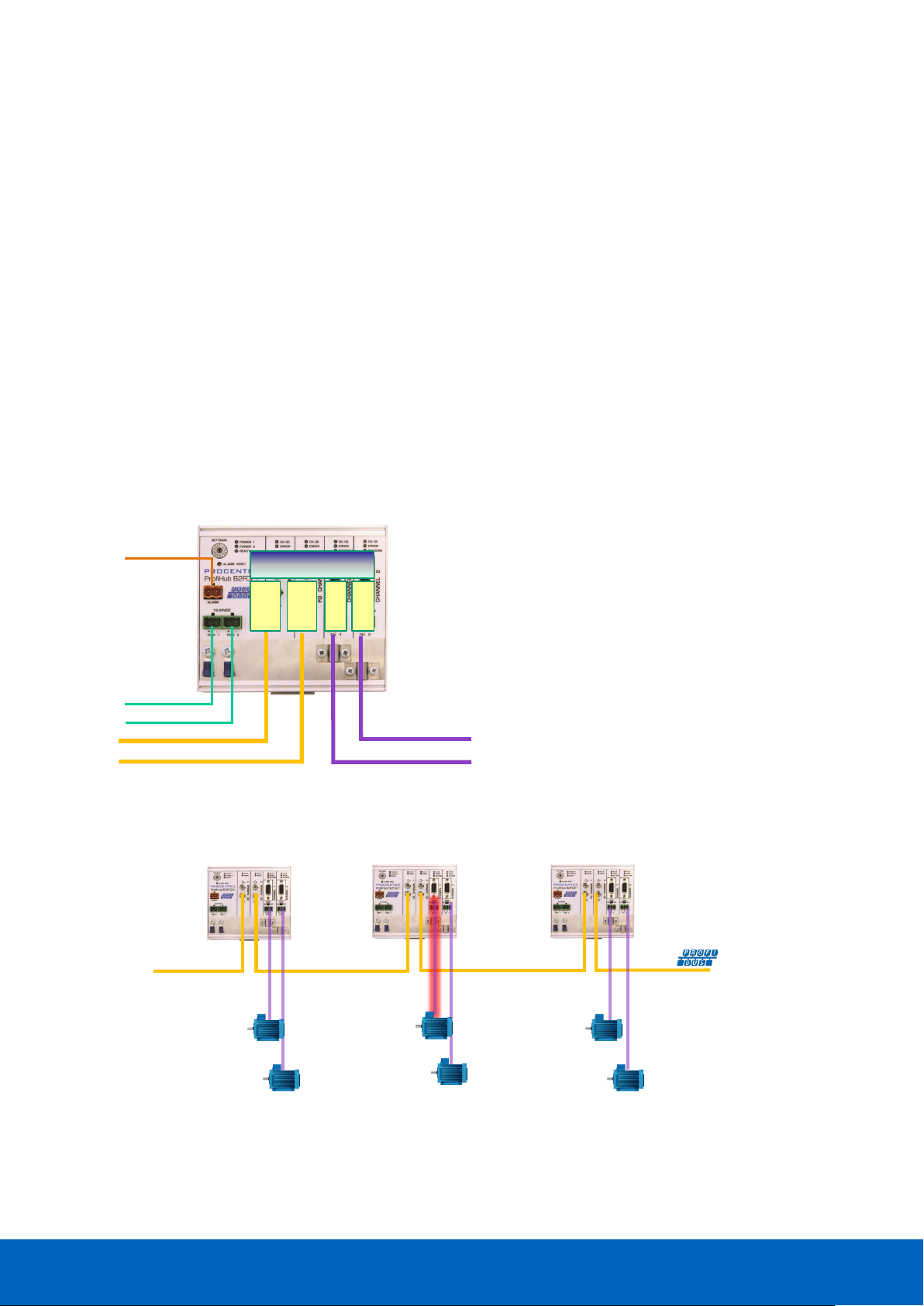

Intelligent Internal

Backbone

C1 C2

Copper Channel 1 and 2

Power supply 2

Power supply 1

Alarm contact

FO1

FO2

FO Channel 1 and 2

DP Fiber Optic Backbone

Wiring problems

do not spread to

the other spur lines

Each spur line

can be 200m

at 1,5 Mbps

1.2 Product features

2 Galvanic isolated outgoing channels (repeater segments).

2 Fiber Optic channels.

Transparent for all PROFIBUS DP protocols.

DP - RS 485 specifications for each channel.

Cable redundancy for copper channel 1 and 2

9.6 Kbps to 12 Mbps.

31 devices per channel.

3000 m cable length for FO channel 1 and 2

1200 m spur line length for copper channel 1 and 2 (depends on transmission speed).

Redundant power supply

No limit in serial placement or cascading of ProfiHubs.

Alarm contact, with manual reset button.

No address required.

Integrated termination facilities (switches).

Configurable grounding system (direct or capacitive).

IP 20 classification

Increased temperature range

Fig. 2 - ProfiHub connections

Fig. 3 - Long spur lines to instruments and the possibility to remove/insert them during operation. Short circuit protection on each

spur line is automatically provided

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 6/38

Page 8

ProfiHub B2+FO2

1.3 Application areas

Create Fiber Optic backbones

Dynamic spur lines to actuators, flow meters and pH analyzers.

Removable drives and motors.

Pull/Plug motor control centers (drawers).

Roof mounted devices in tank farms.

Barrier for non-galvanic isolated equipment.

Networks with requirement for High Availability/uptime

Large star/tree structured networks.

1.4 Additional benefits

Hot slave insertion and removal during operation.

Short circuit protection on each Channel.

Option to create a redundant path to other supporting Hubs or ComBricks

Compact and robust construction.

Status and error display (per Channel).

Suitable for all DP cables.

Conveniently arranged networks.

Easy extendable installations.

On-board DB9 female connector on each channel for maintenance activities.

Cost Savings

Fig. 4 - Creating a fiber optic backbone increases network reliability and network overview. It is also possible to mix ProfiHubs with

ComBricks

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 7/38

Page 9

RS 485

Circuit

A

B

Isolation

Circuit

Powered

Termination

Isolated Area

CC

DGND

Indirect grounding

Term.

Switch

RX-OK

ERROR

Intelligent

Backbone

I

To direct grounding of

other Channels

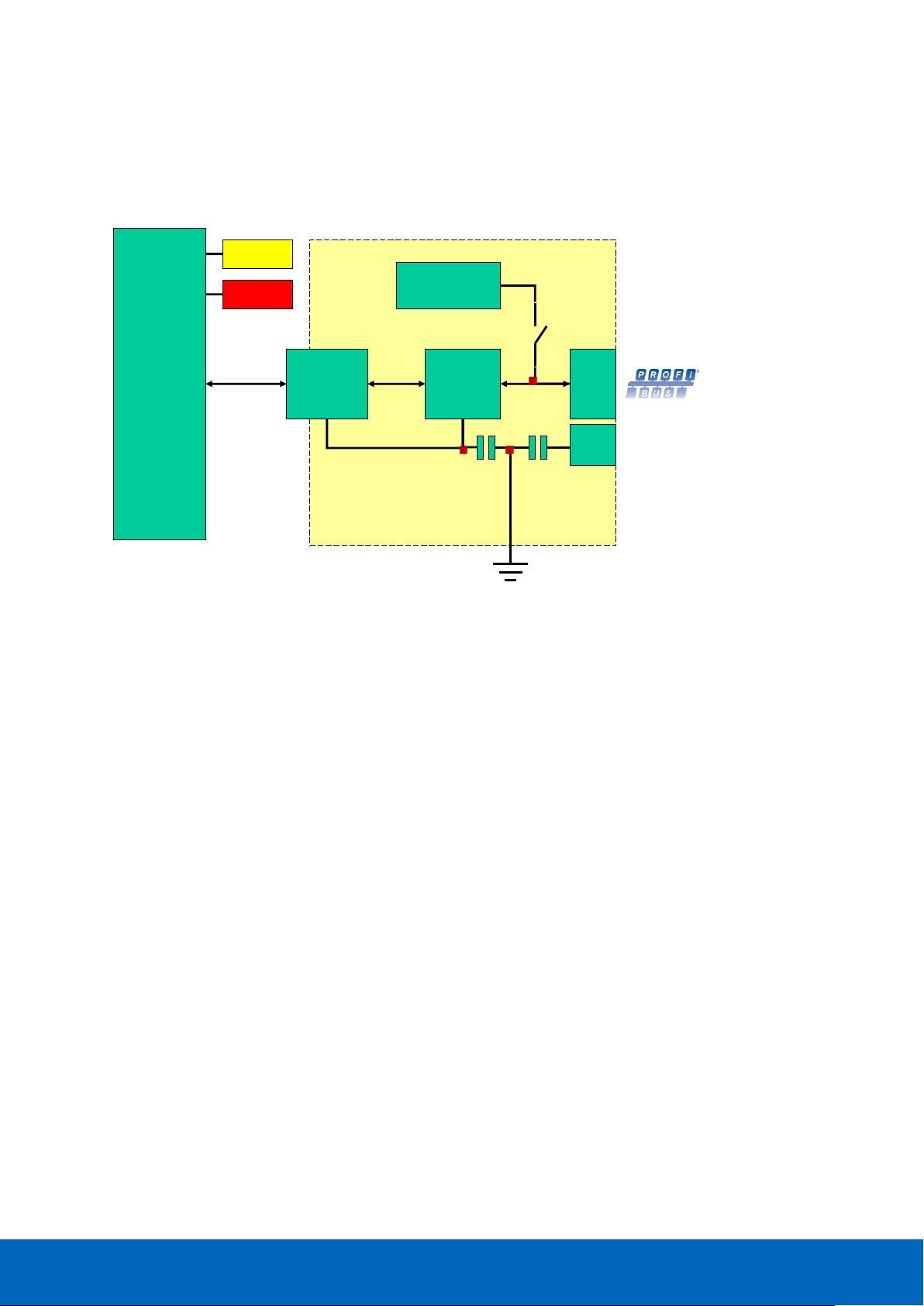

1.5 Channel Structure

Each copper channel is electrically isolated and internally connected to the transparent intelligent backbone.

The termination is switchable and powered by the ProfiHub. The shielding of the PROFIBUS cable can be

directly grounded or indirectly grounded (see paragraph 1.6).

Fig. 5 - Channel structure

1.6 Grounding System

The ProfiHub B2FO2+ can be grounded by 3 methods:

1) Direct grounding on the Ground Rail

2) Indirect grounding (through a capacitor)

3) Combination of direct and indirect.

The power supply must be grounded directly on the Ground Rail. The shielding of the PROFIBUS cables can be

directly or indirectly grounded. If you do not want to ground all or some cables to the common ground, i.e.

compensating current, the cable shielding must be connected to pin ‘I’ which stands for Indirect grounding. A

capacitor with a parallel high value resistor will separate the 2 potentials (see Fig. 5), ensuring protection of

the signal against non-DC disturbances.

If by accident on 1 channel the Direct Grounding is connected with the Indirect Grounding, the connection to

the Direct Grounding bypasses the capacitor in the Indirect Ground connection. The current on the shield will

flow to Direct Ground.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 8/38

Page 10

Parameter

Value

Wires

2 (twisted)

Impedance

135 .. 165 Ohm at 3 to 20 MHz

Capacity

< 30 pF/m

Loop resistance

< 110 Ohm/km

Wire diameter

> 0.64 mm

Wire area

> 0.32 mm2

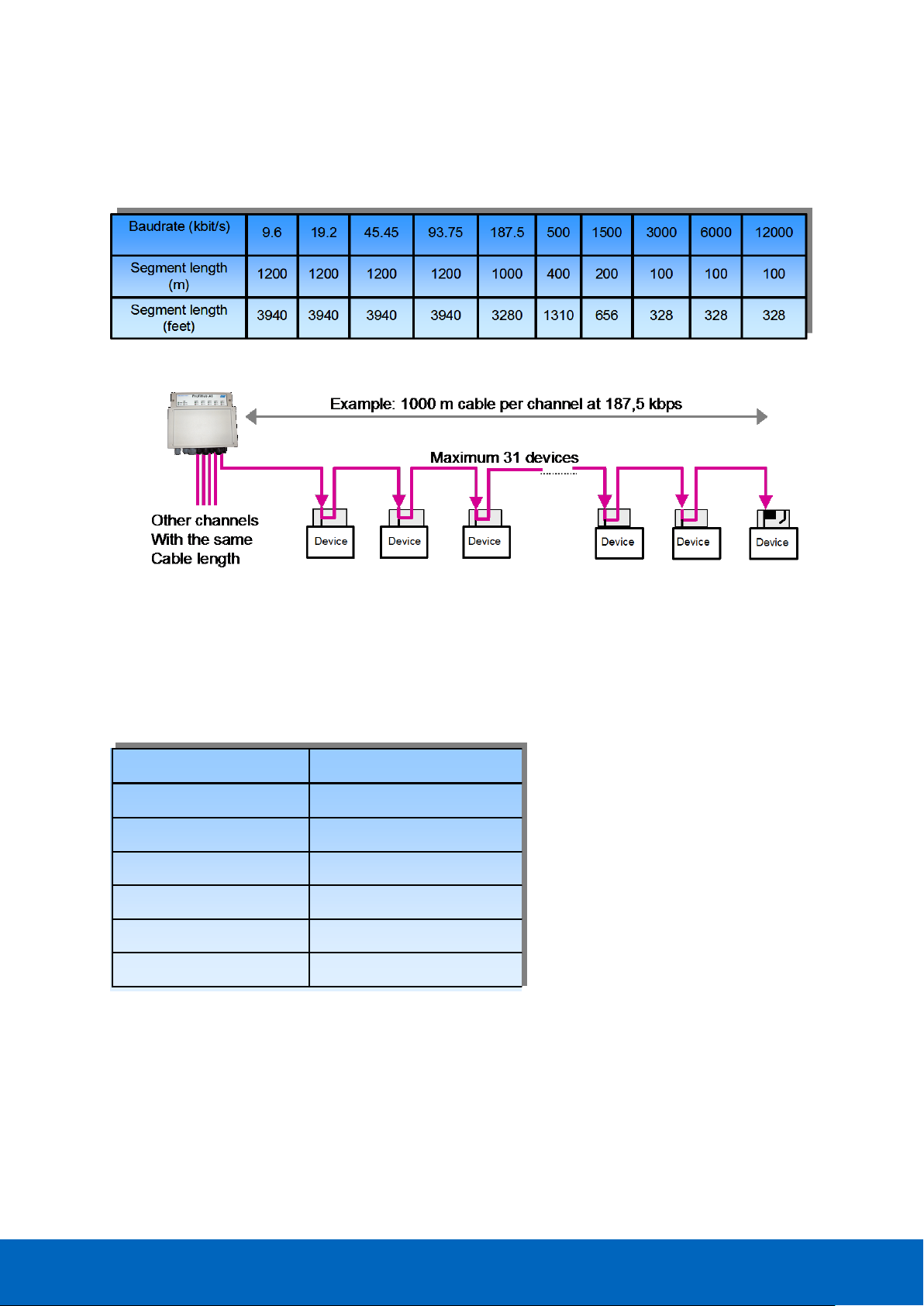

Fig. 6 - Cable lengths for PROFIBUS DP

Fig. 7 - PROFIBUS DP cable specifications

1.7 Cable lengths for PROFIBUS DP

The copper cables on Channels 1 and 2 must comply with the PROFIBUS DP cable specifications for RS 485 (Fig.

6).

1.8 Cable types for PROFIBUS DP

The cable type must comply with the PROFIBUS DP cable specifications for RS 485 (Fig. 7).

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 9/38

Page 11

G62.5/ 125

G50 / 125

ISO / IEC 11801 (OM1)

ISO / IEC 11801 (OM2 or better)

IEC 60793-2-10 type A1b

IEC 60793-2-10 type A1a

TIA / EIA 492AAAA

TIA / EIA 492AAAB-A

ITU-651.1

ITU-651.1

OFF

Blinking

ON

POWER 1 / 2

Power is not switched

on or an internal error

Power supply not

stable, redundant power

supply interrupted or an

internal failure

Power supply OK

READY

Power is not switched

on or an internal error

Trying to detect the

transmission speed, but

has not locked it yet

The transmission

speed has been detected

FRNC cable

Shipboard cable

Festoon cable

Flexible cable

Food cable

Robust cable

Trailing cable

Hybrid cable

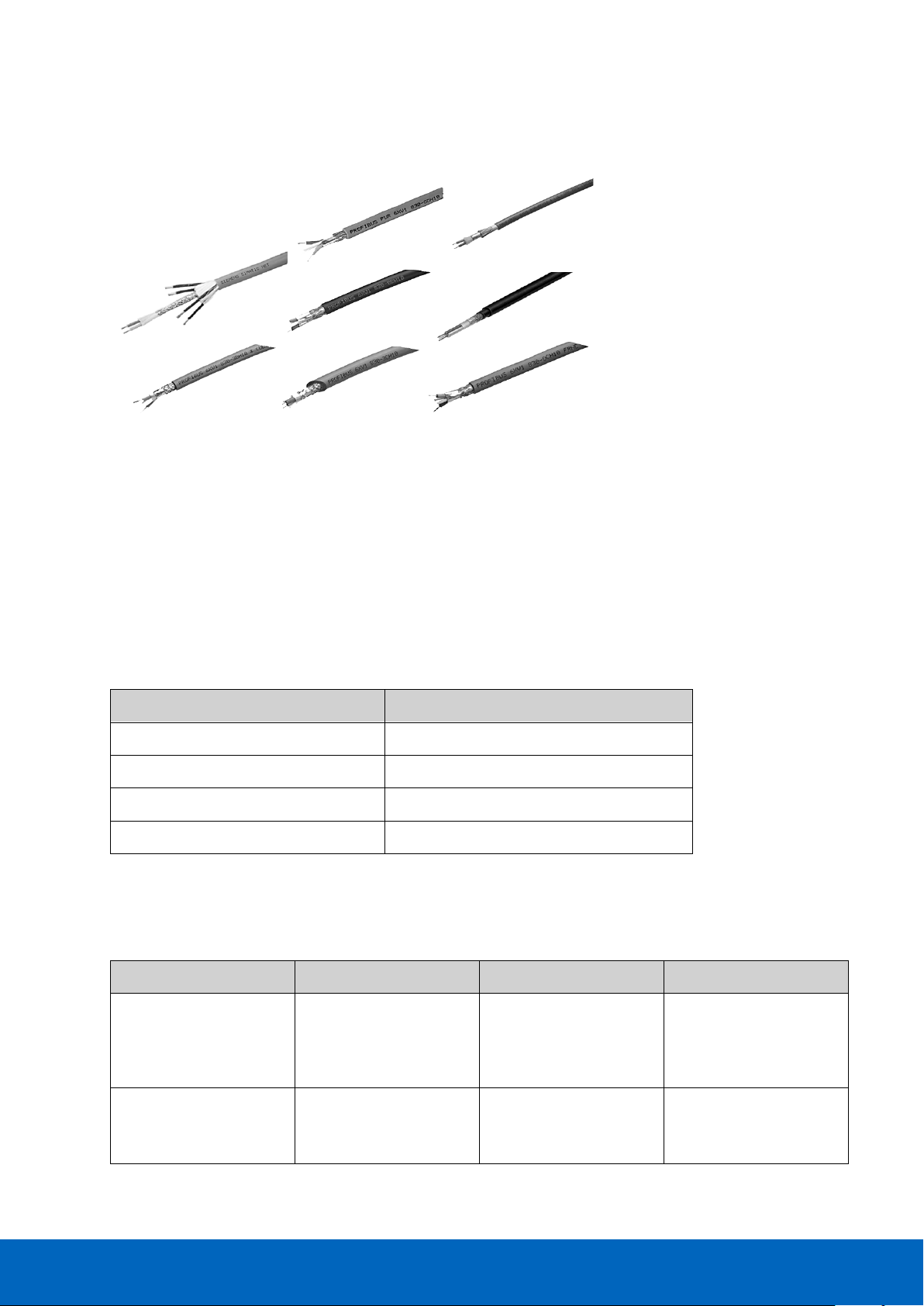

Fig. 8 - Cables with different protection sheaths

The ProfiHub B2FO2+ can handle cables based on multiple protection sheaths with an overall cable diameter

between 6 to 12 mm (Fig. 8).

1.9 Cable lengths for fiber optic

The maximum cable length for fiber optic cables is 3 kilometers if G62.5 / 125 cable is used.

1.10 Cable types for fiber optic

The following cable types can be used with the ProfiHub B2FO2+:

1.11 Status LEDs

The Status LEDs on the ProfiHub are very useful for diagnostics.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 10/38

Page 12

FO RX-OK

No communication

detected on this channel

1 or more devices

communicating on this

channel

Internal error

FO ERROR

No problem has been

detected

Problem in the cabling

has been detected.

Problem in the cabling

has been detected

Channel RX-OK

There is no

communication detected

on this channel

1 or more devices

communicating on this

channel

Internal error

Channel ERROR

No problem has been

detected

Problem in the cabling

has been detected

Problem in the cabling

has been detected

INT. TERM

Termination for this

channel is OFF

Internal error

Termination for this

channel is ON

1.12 The red Error LED

The red error LEDs will blink shortly if a corrupt message enters the ProfiHub. More specifically, this can be a

Parity error (the parity checksum of the byte is incorrect) or a Framing error (the FCS byte is different than the

real message). It is necessary to investigate further with an oscilloscope to find out what the problem is. This

can easily be done with ProfiTrace.

Another reason for the red error LED is a problem in the redundant cabling (if the ProfiHub is set to redundant).

If the redundant line is fixed, press the ‘Alarm Reset’ button.

It can also be that the baudrate is not locked (no PROFIBUS master on the bus) or the baudrate was set

manually and incorrectly with the rotary switch.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 11/38

Page 13

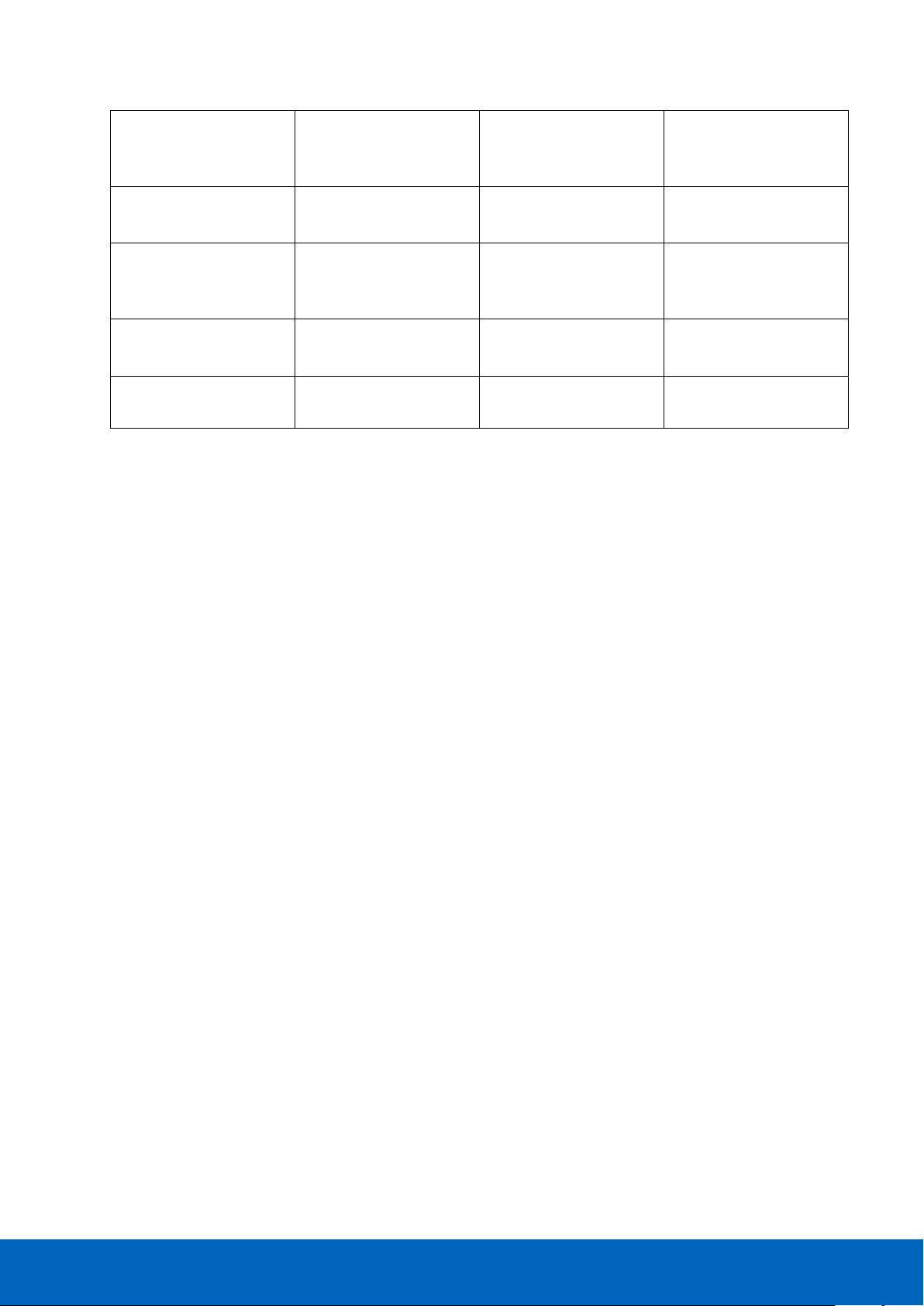

ProfiHub B5

ProfiHub B2+

ProfiHub B2FO2+

Area

IP 20

IP 20

IP 20

Redundant power supply

No

Yes

Yes

Temperature range

-20 to +60˚ Celsius

-4 to +140˚ Fahrenheit

-25 to +70˚ Celsius

-13 to +158˚ Fahrenheit

-25 to +70˚ Celsius

-13 to +158˚ Fahrenheit

Housing

Metal

Metal

Metal

Mounting

DIN-rail

DIN-rail

DIN-rail

Weight

475 g

375 g

375 g

Dimensions

167 x 111 x 32 mm

109 x 111 x 32 mm

128 x 111 x 38 mm

PROFIBUS connectors

Screw terminals and DB9

connectors

Screw terminals and DB9

connectors

ST/BFOC, screw terminals

and DB9 connectors

Alternative connectors

No

No

No

Termination LEDs

Yes

Yes

Yes

Ground rail

Yes

Yes

Yes

Redundant channel

No

Yes

Yes

Offshore approvals

None

None

None

UL approvals

None

UL: ITE E365044

None

1.13 Comparison table

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 12/38

Page 14

2. Installation Instructions ProfiHub B2FO2+

2.1 Location

The ProfiHub B2FO2+ can be installed everywhere in a non-hazardous area that complies with IP 20 (DIN 40

050) and the specified temperature range of -25 to +70o Celsius or -13 to +158° Fahrenheit.

2.2 Position

The ProfiHub B2FO2+ can be installed in every position, but it is recommended to install it with the cables

pointing down. In this position it is also easier to read the status LEDs.

2.3 Mounting

The ProfiHub B2FO2+ can be mounted on 35 mm DIN-rail with a minimum width of 130 mm. Mounting

brackets are available for mounting the B2FO2+ directly on a wall.

The supplied rubber studs need to be placed on the back of the housing of the ProfiHub B2FO2+ for extra

fixation. This is to prevent the product to potentially slide off the DIN-rail. See Fig. 9 for an example.

Fig. 9 - Rubber studs on backside of housing

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 13/38

Page 15

Power

Connectors

Power LEDs

Groundingpoints

Power

Connectors

Power LEDs

Alarm contact

Groundingpoints

2.4 Power Supply

The two 2-pin screw type power connectors are located on the left of the ProfiHub B2FO2+ (Fig. 10).

1 = + (left)

2 = - (right)

Fig. 10 - Power connectors and LEDs

Both power connectors are linked 1-on-1 to the internal power supply of the B2FO2+. If one power supply fails,

the other takes over without delay time. When redundancy is not required, it is sufficient to use one power

connector. Please note that when using only one power supply, a voltage of max. 0.25 V will exist on the other

unconnected power connector, as shown in Fig. 11.

If only one power supply is used, the alarm contact is closed. If two power sources are connected, the contact

is open. As soon as one of the power supplies fails, the contact will close and the Power Indicator LED will blink.

Fig. 11 - Maximum voltage on unconnected Power Connector

The power supply must comply with the following specifications:

Limited Power Source (LPS) or NEC Class 2 or CEC Class 2

Voltage: 12 - 24 VDC

Current: min 275 mA

Wire diameter: < 2.5 mm2

Procedure

To connect the 24V supply to the 2-pin screw-type terminal, proceed as follows:

Strip the insulation from the cable or the conductors for the 24V power supply.

Add cable crimp terminals/wire ferrules to the conductors.

Secure the crimp terminals in the screw-type terminal.

To connect the power supply, you need a 3 mm screwdriver.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 14/38

Page 16

Testing:

If the power is switched on it can be diagnosed by the following indicators:

LEDs should be blinking in a circular animation for a short time.

The POWER LED of the respective power connector (1, 2 or both) is ON.

The READY LED is ON or Blinking, depending on baud rate lock.

2.5 Grounding of the power

It is recommended to use a power supply with a ground lead (3-wire). Connect the ground lead of the

power lead to the Ground Rail of the ProfiHub B2FO2+. Connect the Ground Rail to the common ground with a

separate ground lead. See Fig. 12 for an example.

Fig. 12 - Connection to Ground Rail

2.6 Alarm contact

The ProfiHub B2FO2+ features a potential-free relay contact. This alarm contact can be used to monitor the

power supplies. Example applications are: Connect a LED tower, alarm buzzer, SMS server or use it as a digital

signal for the PLC.

If only one power supply is used, the alarm contact is closed. If two power sources are connected, the contact

is open. As soon as one of the power supplies fails, the contact will close and the Power Indicator LED will blink.

In the case of an interrupted power supply you can reset the contact by pressing the ‘Reset’ button. The

contact will open and the LEDs will stop blinking.

The maximum power to be connected to the alarm contact is 24 VDC. The maximum switching current is 500

mA.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 15/38

Page 17

ProfiHub B2+FO2

2.7 Fiber optic backbone

Use the FO channels to create a fiber optic backbone to other ProfiHubs with FO channels or to ComBricks.

Connect the DP copper cable from the master or DCS to one of the two copper channels (Fig. 13).

Fig. 13 - PROFIBUS DP backbone connection

Pin layout of the screw terminals:

Pin “A”: Green wire

Pin “B”: Red wire

Pin “I”: Indirect cable shielding

Note: Connecting the Indirect cable shielding is not required when the ground clips are used.

Testing

If a channel recognizes valid PROFIBUS messages from one or more connected devices, the RXOK LED of the

corresponding channel should be blinking.

2.8 Calculating the delay time

Fiber optic applications require a delay time calculation to adjust the MinTSDR and Slottime (Tslot)

busparameters in the configuration of the master(s). The B2FO2+ complies with the following formulas:

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 16/38

Page 18

Communication Status LEDs

Channel

Connectors

Channel

Connectors

Channel

Connectors

Channel

Connectors

Example: 1.5 Mbps, 3 km FO cable, 2 FO modules

FO cable delay =(5 ∗ 10

−6

)

× FO cable length × Baudrate

FO cable delay = 0.000005 × 3 × 1500000 = 22.5 TBit

The delay of the module itself is 1.8. This results in the following formula for Tdelay:

Tdelay = (FO cable delay +(2 × Module delay time))× 2

Tdelay = (22.5 +(2 × 1.8)) × 2 = 𝟓𝟐. 𝟐 Tbit

This is the delay between 2 fiber optic interfaces.

Outcome: Make sure the MinTSDR is at least 52.2 bittimes. Change the Max TSDR and Tslot to

appropriate numbers accordingly.

2.9 Spur Segments

Connect the spur segments to the connectors of Channel 1 and 2 (Fig. 14). The second method is to place a

PROFIBUS standardized plug on the DB9 connector of the specific Channel.

Fig. 14 - PROFIBUS DP spur connectors

Pin layout of the screw terminals:

Pin “A”: Green wire

Pin “B”: Red wire

Pin “I”: Indirect cable shielding, for reducing EMC and noise in demanding areas

Note: Connecting the Indirect cable shielding is not required when the ground clips are used.

Testing

If a Channel recognizes valid PROFIBUS messages from one or more connected devices, the RXOK LED of the

Channel should be blinking.

2.10 Termination

The termination of the Channels have been set to ON by default, because it is assumed that the new segment is

started at the ProfiHub (Fig. 15).

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 17/38

Page 19

Channel

Connectors

Channel

Connectors

Termination LEDs

Baudrate switch

Alarm reset button

Fig. 15 - Termination switches

The termination LED of the corresponding Channel is activated when the termination switch is set to ON.

When the DB9 connector is used and the cable starts at the ProfiHub, it is recommended to use the

termination on the DB9 plug and NOT the ProfiHub. This way, the connector can be removed while maintaining

termination on the bus.

2.11 Baudrate switch

The ProfiHub B2FO2+ recognizes the transmission speed by default. If it is required that the ProfiHub B2FO2+ is

locked to a certain transmission speed, the baudrate switch should be set to the required value (Fig. 16).

To set the rotary switch, use a 3 mm screwdriver.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 18/38

Fig. 16 - Baudrate speed switch

Page 20

Switch values:

0 = Normal repeating, Auto detect (default)

1 = 9.6 kbps

2 = 19.2 kbps

3 = 45.45 kbps

4 = 93.75 kbps

5 = 187.5 kbps

6 = 500 kbps

7 = 1500 kbps

8 = 3000 kbps

9 = 6000 kbps

A = 12000 kbps

B = Robust repeating, Auto detect

C = Robust repeating, redundancy on copper channel 1 and 2

D .. F = Reserved for future use

Please note that the position of the rotary switch is only sampled during start-up. Changing the position of the

switch will not have effect during operation.

The auto baudrate detect feature will search for the correct baud rate within 10 seconds of receiving the first

telegram. This baud rate lock will be lost after 50 seconds of incorrect or no message reception.

2.12 Robust Repeating mode

The B2FO2+ has two repeating modes: normal (default) and Robust Repeating (rotary switch setting B or C). In

normal mode the bits are transferred directly on the other channel with a minimal delay (see Delay Times in

the Technical Data chapter). In Robust mode, the first byte is checked to verify if the following bits are a real

PROFIBUS message. If the byte is illegal, the message will not be transferred to the other channel. This helps

network stability in EMC sensitive environments.

ATTENTION:

Using the ProfiHub B2FO2+ in Robust Repeating mode causes a delay in processing the telegrams. It is required

to increase the default MinTSDR in the PLC busparameters slightly. Recommended is to increase the MinTSDR

with a value according to the Delay Time table, column ‘Robust Mode’, described in the Technical Data chapter.

Generally a MinTSDR of 25 is sufficient. If long fiber optic cables or many optical link modules (OLMs) are used,

check paragraph 2.8 for an example of the MinTSDR calculation.

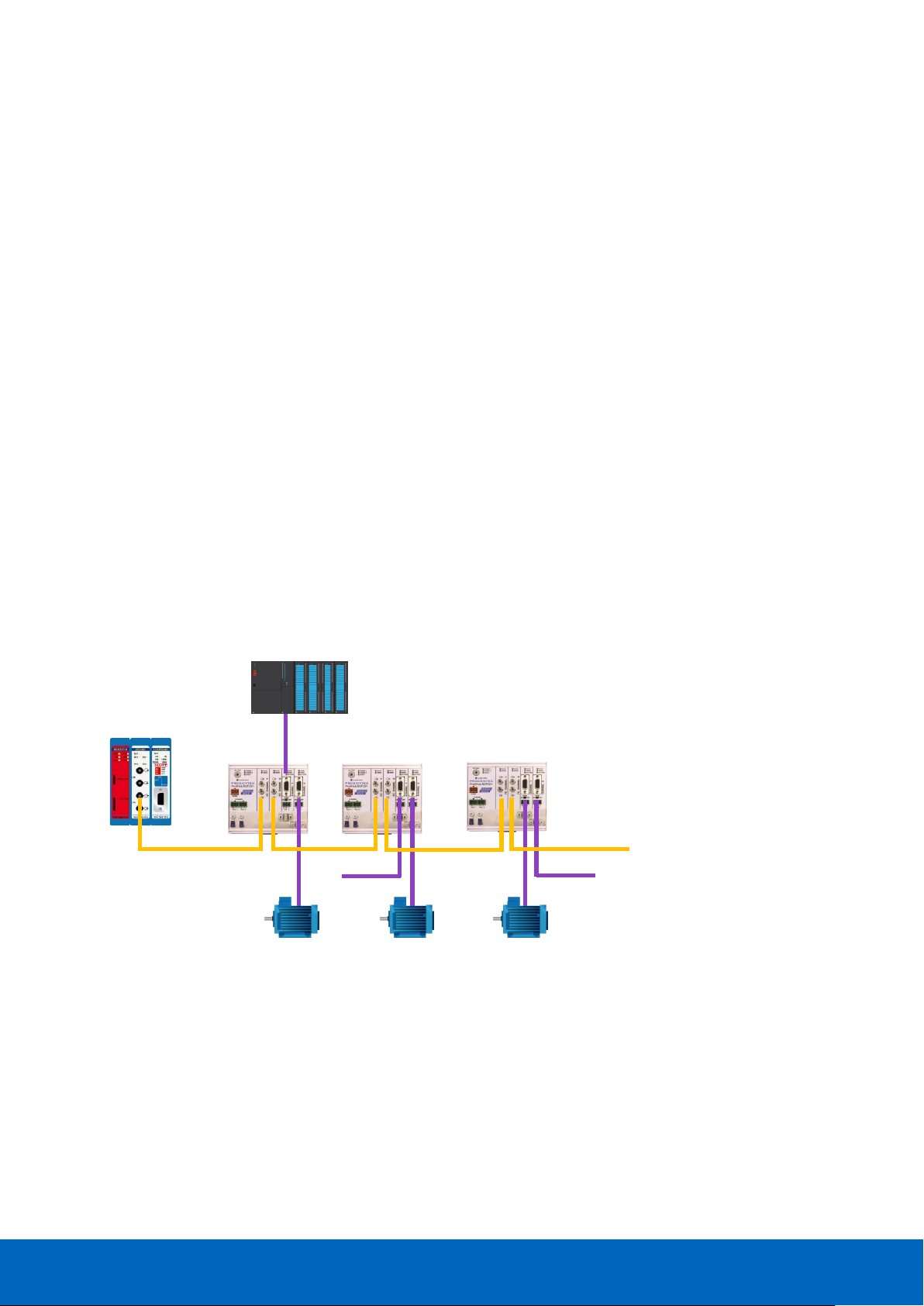

2.13 Channel Redundancy

To use the Redundancy option of the B2FO2+, set the rotary switch to the ‘C’ position. This enables the two

copper channels (1 and 2) to be one redundant path to another B2FO2+, a B2+, to a redundant ComBricks, or

to any other supporting product. See Fig. 17 for an example.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 19/38

Page 21

ProfiHub B4+FO2

COMbricks

ProfiHub B2+FO2

Fig. 17 - Redundant path between multiple ProfiHubs

The telegrams are transferred onto both redundant channels. The logic inside the ProfiHub determines which

telegram is used to be transferred onto the other channels. A message received by a redundant channel is

repeated on all other channels, except the other redundant channel. A message received by a normal channel

is repeated on all other channels.

When one redundant cable breaks, the other cable ensures safe delivery of the telegram. In this event the

built-in alarm contact will close. The red ‘ERROR’ LED will blink with an interval of 100ms. When the redundant

path is fixed, press the ‘ALARM RESET’ pushbutton to reset the alarm.

ATTENTION:

Using the ProfiHub B2FO2+ in Redundancy mode causes a delay in processing the telegrams. It is required to

increase the default MinTSDR in the PLC busparameters slightly. Recommended is to increase the MinTSDR

with a value according to the Delay Time table, column ‘Robust Mode’, described in the Technical Data chapter.

Generally a MinTSDR of 25 is sufficient. If long fiber optic cables or many optical link modules (OLMs) are used,

check paragraph 2.8 for an example of the MinTSDR calculation.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 20/38

Page 22

Technical Data ProfiHub B2FO2+

Dimensions and weight

Dimensions L x W x H (mm) with screws

Weight

128 x 111 x 38 mm

375 gr

Ambient conditions

Operating temperature

Isolation class

-25 to +70o Celsius

-13 to +158o Fahrenheit

IP 20 (DIN 40 050)

Protocol specifications

Supported Protocols

Transmission speed

Transmission speed detection

Transmission speed switch

Transmission speed detection time

Data delay time

Delay time jitter

Cascading depth

DP-V0, DP- V1, DP-V2, FDL, MPI, FMS, PROFIsafe, PROFIdrive

and any other FDL based protocol.

9.6 kbps to 12 Mbps (including 45.45 kbps)

Auto detect (default) or selectable with rotary switch

0 = Normal repeating (Auto detect) (default)

1 = 9.6 kbps

2 = 19.2 kbps

3 = 45.45 kbps

4 = 93.75 kbps

5 = 187.5 kbps

6 = 500 kbps

7 = 1500 kbps

8 = 3000 kbps

9 = 6000 kbps

A = 12000 kbps

B = Robust repeating (auto detect)

C = Robust repeating, redundancy on channel 1 and 2

D .. F = Same as 0

< 10 s (if it is set to auto detect)

At baudrate: Normal mode: Robust mode:

9.6 - 93.75 kbps ≤1.7 Tbit ≤13.25 Tbit

187.5 - 500 kbps ≤1.8 Tbit ≤13.30 Tbit

1.5 Mbps ≤1.9 Tbit ≤13.40 Tbit

3 Mbps ≤2.2 Tbit ≤13.60 Tbit

6 Mbps ≤3.0 Tbit ≤14.00 Tbit

12 Mbps ≤4.0 Tbit ≤15.00 Tbit

Max. ¼ bit time

No limits

3. Technical Data ProfiHub B2FO2+

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 21/38

Page 23

Technical Data ProfiHub B2FO2+

PROFIBUS Fiber Optic cable specifications

Cable types

Fiber Optic type

Cable lengths

Connectors

Redundancy

G62.5 / 125 ISO/IEC 11801 (OM1)

IEC 60793-2-10 type A1b

TIA/EIA 492AAAA

ITU-651.1

G50 / 125 ISO/IEC 11801 (OM2 or better)

IEC 60793-2-10 type A1a

TIA/EIA 492AAAB-A

ITU-651.1

Multimode 850 nm

G62.5 / 125: 3000 m (baud rate independent)

G50 / 125: to be defined

4x ST / BFOC

No

PROFIBUS copper cable specifications

Cable lengths

Cable thickness

Wire diameter

Wire type

Number of devices

Termination

Redundancy

1200 m at 9.6 kbps to 93.75 kbps

1000 m at 187.5 kbps

400 m at 500 kbps

200 m at 1.5 Mbps

100 m at 3 Mbps to 12 Mbps

10 mm (when the ground rail is used)

< 2.5 mm2

Stranded or Solid core

Maximum 31 per Channel (including ProfiHubs, OLMs etc)

Integrated and switchable.

Powered according to IEC 61158 (390/220/390 Ohms)

- All Channels (default on)

Yes (copper channel 1 and 2)

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 22/38

Page 24

Technical Data ProfiHub B2FO2+

Power supply specifications

Power source

Nominal supply voltage

Redundant power supply

Current consumption

Reverse polarity protection

Cable thickness

Wire diameter

Limited Power Source (LPS) or NEC Class 2 or CEC Class 2

12 to 24 VDC

Yes

Min 275 mA at 12 V power supply (all Channels fully loaded)

Yes

10 mm (when the ground rail is used)

< 2.5 mm2

Alarm contact

Voltage

Current

Max. 24 V DC

0.5 A

Others

MTBF

T.b.d.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 23/38

Page 25

4. Sales offices and distributors

HEADQUARTERS

PROCENTEC T: +31-(0)174-671800

Klopperman 16 F: +31-(0)174-671801

2292 JD WATERINGEN E: info@procentec.com

Netherlands I: www.procentec.com

ARGENTINA

eFALCOM T: +54 237 46 31 151

Alcorta 2411 F: +54 237 46 31 150

B1744 - Moreno E: santiago.falcomer@efalcom.com

Buenos Aires I: www.efalcom.com.ar

Argentina

AUSTRALIA

IS Systems Pty Limited T: +61 2 4964 8548

14 Laverick Ave., F: +61 2 4964 8877

Tomago E: fritz.woller@issystems.com.au

NSW, Australia, 2322 I: www.issystems.com.au

Pentair Flow Control Pacific T: +61 2 4448 0466

1 Percival Road F: +61 2 4423 3232

Smithfield E: sharee.hazell@pentair.com.au

NSW, Australia, 2164 I: www.profibuscentre.com.au

BELGIUM and LUXEMBOURG

Bintz Technics N.V. T: +32 2 720 49 16

Brixtonlaan 23 F: +32 2 720 37 50

B-1930 Zaventem E: bloemen@bintz.be

Belgium I: www.bintz.be

BRAZIL

Westcon Instrument. Indl Ltda T: +55 11 5561-7488

Rual Alvaro Rodrigues, 257 F: +55 11 5093-2592

São Paulo – SP E: paolo@wii.com.br

Brazil - CEP 04582-000 I: www.wii.com.br

CANADA

Streamline Process Management Inc. T: +1 403 225 1986

#3, 4351 – 104 Ave SE F: +1 587 585 2828

Calgary, Alberta T2C 5C6 E: admin@streamlinepm.com

Canada I: www.streamlinepm.com

CHILE

RP Ingenieria Limitada T: +56-(0)41-2469350

Tucapel 92 oficina 52 F: +56-(0)41-2522592

Concepción E: rodrigopinto@rpingenieria.cl

Chile I: www.rpingenieria.cl

CHINA

PROCENTEC Beijing T: +86(10)84766911 or 84787311

Room E-1115 WangJingYuan YouLeHui F: +86(10)84766722

ChaoYang E: info@procentec.net

Beijing I: www.procentec.net

China

CZECH REPUBLIC

FOXON s.r.o. T: +420 484 845 555

Polní 367 F: +420 484 845 556

460 01 Liberec 12 E: foxon@foxon.cz

Czech Republic I: www.foxon.cz

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 24/38

Page 26

DENMARK

ProSaiCon T: +45 70 20 52 01

Jernbanegade 23B F: +45 70 20 52 02

DK 4000 Roskilde E: hfj@prosaicon.dk

Denmark I: www.prosaicon.dk

EGYPT

Mas Trading T: +2 02 2524 2842

37, 105 Street F: +2 02 2524 2843

Al-Etihad Square E: aya.elshafei@masautomation.com

Egypt I: www.masautomation.com

ESTONIA

Saksa Automaatika OU T: +372 605 2526

Peterburi Tee 49 F: +372 605 2524

Tailinn E: info@saksa-automaatika.ee

EE-11415 Estonia I: www.saksa-automaatika.ee

FINLAND

Hantekno Oy T: +358 40 8222 014

Kalliotie 2 E: info@hantekno.com

04360 Tuusula I: www.hantekno.fi

Finland

FRANCE

AGILiCOM T: +33 247 76 10 20

Bâtiment B F: +33 247 37 95 54

1, rue de la Briaudière E: jy.bois@agilicom.fr

Z.A. La Châtaigneraie I: www.agilicom.fr

37510 BALLAN-MIRE

France

GERMANY

PROCENTEC GmbH T: +49-(0)721 831 663-0

Benzstrasse 15 F: +49-(0)721 831 663-29

D-76185 Karlsruhe E: info@procentec.de

Germany I: www.procentec.de

INDIA

UL Engineering Services & Software Pvt Ltd T: +91-202 696 0050

Nirman Classic, F: +91-202 696 2079

Katraj-Kondhwa Road, E: dileep.miskin@ulepl.com

Katraj, Pune-411046 I: www.ulepl.com

India

IRELAND

PROFIBUS Ireland T: +353-61-202107 or +35361240240

Automation Research Centre F: +353-61-202582

University of Limerick E: info@profibus.ie

National Technology Park, Plassey I: www.profibus.ie

Limerick

Ireland

ISRAEL

Instrumetrics Industrial Control T: +972-9-8357090

8 Hamlacha St. F: +972-9-8350619

New Industrial Zone E: info@instrumetrics-ic.co.il

Netanya, 42170 I: www.inst-ic.co.il

Israel

ITALY

PROCENTEC Italy T: +39 030 200 8610

Via Branze n. 43/45 F: +39 030 238 0059

25123 Brescia E: www.procentec.it

Italy W: www.procentec.it

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 25/38

Page 27

Genoa FIELDBUS Competence Centre Srl T: +39 010 86 02 580

Via Greto di Cornigliano, 6R/38 F: +39 010 65 63 233

16152 Genova E: procentec@gfcc.it

Italy W: www.gfcc.it

JAPAN

TJ Group T: +81-3-6450-3739

C/O Japanese PROFIBUS Organisation F: +81-3-6450-3739

West World Building 4F E: info@profibus.jp

3-1-6 Higashi-Gotanda,

Shinagawa-ku,

Tokyo, 141-0022

Japan

KOREA

Hi-PRO Tech. Co., Ltd. T: +82 82-31-216-2640

#2802, U-Tower, 1029 F: +82 82-31-216-2644

Youngduk-dong, Giheung-gu E: chays@hiprotech.co.kr

Yongin-Si, Kyunggi-do, I: www.profibus.co.kr

446-908 Korea

LEBANON

Industrial Technologies S.A.L. (ITEC) T: +961 1 491161

Point Center, Boulevard Fouad Chehab F: +961 1 491162

Sin El Fil E: sales@iteclb.com

Beirut I: www.iteclb.com

Lebanon

MEXICO

Grid Connect Inc. T: +1 530-219-2565 (Spanish)

E: tomf@gridconnect.com

I: www.gridconnect.com

NETHERLANDS

PROCENTEC B.V. T: +31 (0)174 671800

Klopperman 16 F: +31 (0)174 671 801

2292 JD Wateringen E: info@procentec.com

Netherlands I: www.procentec.com

NORWAY

AD Elektronikk AS T: +47 64 97 60 60

Boks 641 F: +47 64 97 60 70

N-1401 SKI E: kai@ade.no

Norway I: www.ade.no

PERU

ControlWare T: +51 1637 3735

Jr. Los Silicios 5409 F: +51 1528 0454

Los Olivos - L39 E: info@controlware.com.pe

Peru I: www.controlware.com.pe

POLAND

INTEX Sp. z o.o. T: +48 32 230 75 16

ul. Portowa 4 F: +48 32 230 75 17

44-102 Gliwice E: intex@intex.com.pl

Poland I: www.intex.com.pl

ROMANIA

S.C. SVT Electronics S.R.L. T: +40 365 809 305

Brǎila 7 F: +40 365 809 305

540331 Tg-Mure E: sajgo.tibor@svt.ro

Romania I: www.svt.ro

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 26/38

Page 28

SAUDI ARABIA

ASM Process Automation T: +966 2 691 2741

Al-Zahra Dist. – Attas st. F: +966 2 682 8943

cross section with helmy Kutby St. E: info@asmestablishment.com

Villa no.25 I: www.asmestablishment.com

Jeddah-21553

Saudi Arabia

SINGAPORE / SOUTH EAST ASIA

Allegro Electronics T: +65 62878063

236 Serangoon Avenue 3 07-98 E: sales@allegro.com.sg

Singapore 550236 I: www.allegro.com.sg

SLOVAKIA

ControlSystem s.r.o. T: +421 486115900

Stúrova 4 F: +421 486111891

977 01 BREZNO E: jan.snopko@controlsystem.sk

Slovakia E: jan.snopko@controlsystem.sk

SOUTH AFRICA

IDX ONLINE CC T: +27(11) 548 9960

1 Weaver Street F: +27(11) 465-8890

Fourways E: sales@idxonline.com

Johannesburg I: www.idxonline.com

South Africa - 2191

SPAIN

LOGITEK, S.A T: +34 93 588 6767

Ctra. de Sant Cugat, 63 Esc. B Planta 1ª E: xavier.cardena@logitek.es

Rubí (BARCELONA), 08191 I: www.logitek.es

Spain

SWEDEN

P&L Nordic AB T: +46 451 74 44 00

Box 252 F: +46 451 89 833

S-281 23 Hässleholm E: hans.maunsbach@pol.se

Sweden I: www.pol.se/profibus

SWITZERLAND

Berner Fachhochschule T: +41 (0) 34 426 68 32

PROFIBUS Kompetenzzentrum F: +41 (0) 34 426 68 13

Jlcoweg 1 E: max.felser@bfh.ch

CH-3400 Burgdorf I: www.profitrace.ch

Switzerland

TAIWAN

Full Data Technology T: +886-2-87519941/9097

6F., No.200, Gangqian Rd. F: +886-2-87519533

Neihu District, Taipei City E: sales@fulldata.com.tw

114, Taiwan I: www.fulldata.com.tw

TURKEY

Emikon Otomasyon T: +90 216 420 8347

DES Sanayi sitesi 103 sokak F: +90 216 420 8348

B-7 blok No:16 Yukari Dudullu / Umraniye E: tolgaturunz@emikonotomasyon.com

Istanbul 34776 I: www.emikonotomasyon.com

Turkey

UNITED ARAB EMIRATES

Synergy Controls T: +971 4 3262692

907, IT Plaza Silicon Oasis : F: +971 4 3262693

DubaiI E: sales@synergycontrols.ae

United Arab Emirates

UNITED KINGDOM and N. Ireland

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 27/38

Page 29

Verwer Training & Consultancy T: +44 (0)1625 871199

5 Barclay Road E: andy@verwertraining.com

Poynton, Stockport I: www.verwertraining.com

Cheshire SK12 1YY

United Kingdom

Hi-Port Software T: +44 (0)8452 90 20 30

The Hub 2 Martin Close F: +44 (0)2392 552880

Lee-on-Solent E: sales@hiport.co.uk

Hampshire PO13 8LG I: www.hiport.co.uk

United Kingdom

iTech T: +44 (0)1292 311 613

Unit 1 F: +44 (0)1292 311 578

Dukes Road E: sales@itech-troon.co.uk

Troon I: www.itech-troon.co.uk

Ayrshire KA10 6QR

United Kingdom

Parkelect Ltd. T: +44 2890 777743

84 Dargan Road F: +44 2890 777794

Belfast E: jgillan@parkelect.co.uk

BT3 9JU I: www.parkelect.co.uk

N. Ireland

UNITED STATES

Grid Connect Inc. T: +1 630 245-1445

1630 W. Diehl Road F: +1 630 245-1717

Naperville, Illinois 60563 E: sales@gridconnect.com

USA I: www.gridconnect.com/procentec.html

VIETNAM

Bavitech Corporation T: +84-8-3547 0976

42 Truong Son Street F: +84-8-3547 0977

Ward 2, Tan Binh District E: hai.hoang@bavitech.com

Ho Chi Minh City I: www.bavitech.com

Vietnam

For the up to date list of the Sales Offices and Distributors see www.procentec.com/company/distributors/.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 28/38

Page 30

Component

Order code

Remarks

ProfiHub B2FO2+

17220

ProfiHub B2FO2+

With Alarm contact

With redundant power input

5. Order codes

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 29/38

Page 31

Address

Unique number of a device connected to the network. With PROFIBUS this can

be 0 to 126. 127 is a broadcast address.

Analyzer

Software tool to observe the protocol traffic. Combi-Analyzers can also inspect

the signal quality.

Other term: Bus Monitor.

Example: ProfiTrace.

Backbone

The primary bus cable. Most of the time only the control systems, ProfiHubs and

fiber optic couplers are connected to this cable. The field devices are connected

behind the ProfiHubs and fiber optic couplers.

Bit Time (Tbit)

The bit time Tbit is the time, which elapses during the transmission of one bit. It

depends on the baudrate and is calculated as follows Tbit = 1 (bit) / baudrate

(bps).

Examples:

12 Mbps --> Tbit = 83 ns

1.5 Mbps --> Tbit = 667 ns

Busparameters

Settings that define the timing behaviour on the bus. They are defined in the

master. Examples: Tslot, MaxTSDR.

C

Capacitance.

DGND

Digital Ground.

DIN

German Institute for Standardization (www.din.de).

DP-V0

DP-V0 is the basic stage of the PROFIBUS DP communication protocol. DP-V0

devices (master and slaves) perform the following basic functionalities:

- Cyclic exchange of I/O data between controlling and slave devices

- Device, Identifier (module) and Channel related Diagnosis

- Parameterization of DP-slaves

- Configuration of DP-slaves

DP-V1

DP-V1 is the first stage of extension of PROFIBUS DP after DP-V0. DP-V1 devices

shall comply with the following features:

- Device related diagnosis is replaced by status and alarms.

- The first three octets of the user parameterization data are now standardized

- Optionally these devices may support:

- Acyclic communication (MS1, MS2)

- If alarms are used, MS1 shall be supported

6. Glossary

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 30/38

Page 32

DP-V2

DP-V2 is the second stage of extension of PROFIBUS DP after DP-V1. DP-V2

devices shall comply with the following features:

- Data Exchange Broadcast (DxB) for slave to slave communication

(publisher/subscriber principle).

- Isochronous Mode (time tick synchronized operating slaves, e.g. drives)

- Up- and/or download of Load Region Data (domains)

- Clock Control (synchronization within slaves) and Time Stamping

- Redundancy.

Electromagnetic

Compatibility

See EMC.

EMC

The extent to which an electric or electronic device will tolerate electrical

interference from other equipment (immunity), and will interfere with other

equipment. Within the European Community as well as in other countries it is

regulated by law that electric and electronic components and equipment comply

with basic standards such as IEC 61000-6-2 or IEC 61326 or corresponding

individual product standards.

Hub

A Hub refreshes a signal and passes the information on to all nodes which are

connected to the Hub. Data frames which were received on one port are

transferred to all the other ports (chicken foot topology).

MPI

Multiple Protocol Interface. Protocol defined by Siemens which uses the layer 1

and 2 of PROFIBUS (FDL).

PCB

Printed Circuit Board.

PROFIBUS DP

Acronym for "PROFIBUS for Decentralized Peripherals". Specification of an open

fieldbus system with the following characteristics:

- Polling master-slave-system (cyclic communications, MS0)

- Flying masters with robin round token passing coordination (MM)

- Connection based (MS1) and connectionless (MS2, MS3) acyclic communication

between masters and slaves

Options (e.g.):

- Data exchange broadcast (DXB), i.e. slave to slaves communication

- Isochronous mode of slaves

- Clock synchronization

- Redundancy

PROFIBUS DP is standardized within IEC 61158 and IEC 61784, communication

profile families 3/1 and 3/2

The term "PROFIBUS DP" also is a synonym for the RS485 based deployments

within factory automation.

Repeater

Active physical layer device that receives and retransmits all signals over a

different port to increase the distance and number of devices for which signals

can be correctly transferred for a given medium.

Spur line

A cable attached to a bus segment with a T-connection . Spurs are not

recommended with PROFIBUS DP. They are prohibited with 12 Mbps and

PROFIsafe operations. German term is "Stichleitung".

Stub line

See Spur line.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 31/38

Page 33

Tbit

See Bit Time.

Termination

A (powered) resistor network at both ends of a segment to prevent reflections

(with PROFIBUS DP the termination must be powered).

Topology

In a communications network, the pattern of interconnection between network

nodes; e.g. bus, ring, star configuration.

PI

PROFIBUS International.

The International PROFIBUS Organization based in Karlsruhe.

PNO

PROFIBUS Nutzer Organization.

The German PROFIBUS Organization based in Karlsruhe.

Drop cable

See Spur line.

Reflection

Part of the original signal that is transmitted back along the cable. It corrupts the

original signal.

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 32/38

Page 34

7. About PROCENTEC

PROCENTEC is a specialist in PROFIBUS and PROFINET technology and develops products to optimize the

production processes of end users. Our innovative solutions ensure that our customers successfully operate

in the world of industrial automation and enjoy maximum results from their processes.

PROCENTEC globally supplies all the components required to install a measurable and controllable network.

Our products measure, signal and connect the various elements of a process installation and ensure it runs

optimally. We develop and produce all products in the Netherlands and export them through our worldwide

distribution network. PROCENTEC also is the international accredited Competence and Training center for

PROFIBUS and PROFINET. We provide training courses that help employees using those techniques optimally

for their business objectives. In addition we also provide the necessary support to end users during their

implementation procedures, certification processes, audits and malfunctions.

We are of the opinion that the industrial markets need the confidence of believing in the reliable PROFIBUS /

PROFINET technology and applications, to ensure their processes are not threatened in any way and the

continuity remains guaranteed. In view of the possible negative consequences and impact in that industry, we

therefore think that those companies have the right to the best solutions and honest expert advice. Based on

that belief, PROCENTEC continues to innovate and develop, which makes us the most reliable service provider

and knowledge partner for our customers. We do all of this with total dedication.

We believe that it is important to communicate with our customers, partners, distributors and suppliers in a

transparent and decent way. We are empathic, truly interested and passionate in everything we do. Quality,

continuity, service and sustainability are essential to us. That enables us to provide our customers with

groundbreaking and tailor-made solutions.

Products Training courses Services

• ProfiTrace • PROFIBUS training courses • Competence center

• ComBricks • PROFINET training courses • Support & Consultancy

• ProfiHub • Product training courses • Network certification & Audits

• PROFINET tools • Testlab & Democenter

• Cables and connectors

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 33/38

Page 35

8. Revision history

Version 1.0

- Initial release

Version 2.0.0

- Updated the manual to the new corporate style

Version 2.1.0

- Added paragraph Fout! Verwijzingsbron niet gevonden., Fout! Verwijzingsbron niet gevonden. and

REF _Ref448397007 \n \h Fout! Verwijzingsbron niet gevonden.

- Added text for increasing MinTSDR in paragraph Fout! Verwijzingsbron niet gevonden.

- Removed Certificates, List of Distributors and Next Versions chapter

- Minor textual changes

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 34/38

Page 36

9. Notes

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 35/38

Page 37

ProfiHub B2FO2+ User Manual – v2.1.0 | 29 December 2016 | © PROCENTEC 36/38

Page 38

PROCENTEC BV

Klopperman 16

2292 JD Wateringen

The Netherlands

T: +31 (0)174 671 800

F: +31 (0)174 671 801

E: support@procentec.com

W: www.procentec.com

Loading...

Loading...