Page 1

ComBricks HE+

User Manual

Page 2

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 2/104

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning sign

and are marked as followed according to the level of danger:

Draws your attention to important information on handling the product, a particular part of the

documentation or the correct functioning of the product.

Warning

This device and its components may only be used for the applications described in this manual and only in

connection with devices or components that comply with PROFIBUS and RS 485 interface.

This product can only function correctly and safely if it is transported, stored, set up, installed, operated and

maintained as recommended. ComBricks HE+ is a CE class A product. In a domestic environment it may cause

radio interference in which case the user may be required to take adequate measures.

Warranty

Warranty is void if you open ComBricks HE+.

Qualified Technicians

Only qualified technicians should be allowed to install and work with this equipment. Qualified technicians are

defined as persons who are authorized to commission, to ground, to tag circuits and systems in accordance

with established safety practices and standards. It is recommended that the technicians carry a Certified

PROFIBUS Installer or Certified PROFIBUS Engineer certificate.

Disclaimer of Liability

We have checked the contents of this manual as much as possible. Since deviations cannot be precluded

entirely, we cannot guarantee full agreement. However, the content in this manual is reviewed regularly and

necessary corrections will be included in subsequent editions. Suggestions for improvements are welcome.

Copyright © 2011-2017 PROCENTEC

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior

written permission of the publisher.

ComBricks is a registered trademark of PROCENTEC. Other products or company names are or may be

registered trademarks and are the property of their respective companies.

Page 3

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 3/104

Important information

Purpose of the Manual

This user manual provides information how to work with ComBricks HE+.

Recycling and Disposal

The parts of the ComBricks HE+ can be recycled. For further information about environment-friendly recycling

and the procedure for disposing of your old equipment, please contact:

Document Updates

You can obtain constantly updated information on PROCENTEC products on the Internet at

www.procentec.com

You can also contact PROCENTEC Customer Support:

• by phone at +31-(0)174-671800

• by fax at +31-(0)174-671801

• by email at support@procentec.com

PROCENTEC

Klopperman 16

2292 JD WATERINGEN

The Netherlands

T: +31-(0)174-671800

F: +31-(0)174-671801

E: info@procentec.com

Page 4

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 4/104

Content

Important information ........................................................................................... 3

1. Product description ....................................................................................... 8

Introduction .......................................................................................................................................8

Application areas ...............................................................................................................................8

Product features ................................................................................................................................9

Modular PROFIBUS repeaters..........................................................................................................10

1.4.1 Cable Redundancy ...........................................................................................................................11

1.4.2 Typical applications .........................................................................................................................11

ProfiTrace OE – Remote monitoring in a web browser ...................................................................12

1.5.1 Web server ......................................................................................................................................12

1.5.2 Email ................................................................................................................................................13

1.5.3 Channel List .....................................................................................................................................13

1.5.4 Comparison between ComBricks and ProfiTrace 2 .........................................................................13

1.5.5 Offshore applications ......................................................................................................................13

1.5.6 Mining applications .........................................................................................................................14

1.5.7 Robot cells .......................................................................................................................................15

1.5.8 Logistics ...........................................................................................................................................15

1.5.9 Traffic control ..................................................................................................................................16

1.5.10 Cranes ..............................................................................................................................................16

1.5.11 Other applications ...........................................................................................................................17

CommDTM .......................................................................................................................................17

2. Quick Start ................................................................................................... 18

Configure the repeater modules .....................................................................................................19

Wire the repeater modules .............................................................................................................19

Power the Head Station ...................................................................................................................19

Customizing the IP address through the web server .......................................................................19

Customizing the IP address through the Discovery Tool .................................................................20

Checking the modules and administrative info in the web server ..................................................21

Testing ProfiTrace OE on the PROFIBUS installation .......................................................................22

Resetting the Head Station ..............................................................................................................22

3. Installation instructions ............................................................................... 24

Location ...........................................................................................................................................24

Position ............................................................................................................................................24

Inserting modules ............................................................................................................................24

Removing modules from DIN rail ....................................................................................................25

Wiring Ethernet ...............................................................................................................................26

Power Supply ...................................................................................................................................26

3.6.1 Procedure ........................................................................................................................................27

3.6.2 Testing and commissioning .............................................................................................................27

Repeater modules ...........................................................................................................................28

Configuring repeater modules .........................................................................................................28

3.8.1 Customizing the PROFIBUS network (NW0/NW1) ..........................................................................28

3.8.2 Redundancy (RED) ...........................................................................................................................29

3.8.3 Hardware or software settings (H/S) ...............................................................................................29

Page 5

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 5/104

Wiring repeater modules.................................................................................................................30

3.9.1 Screw terminals ...............................................................................................................................31

3.9.2 DB9 connector .................................................................................................................................31

3.9.3 Testing and commissioning .............................................................................................................31

4. Web server .................................................................................................. 32

Status 33

Channel list ......................................................................................................................................35

System log .......................................................................................................................................36

General configuration ......................................................................................................................37

Network configuration ....................................................................................................................38

IP configuration ...............................................................................................................................39

Output Control ................................................................................................................................40

Password setup and login ................................................................................................................41

4.8.1 Access rights ....................................................................................................................................41

4.8.2 Password best practice ....................................................................................................................42

4.8.3 External protocols ............................................................................................................................43

4.8.4 Clearing password(s) .......................................................................................................................43

License update .................................................................................................................................43

Document download page ..............................................................................................................44

Email account configuration ............................................................................................................45

4.11.1 Alive email .......................................................................................................................................46

4.11.2 Email troubleshooting .....................................................................................................................47

Device management ........................................................................................................................47

4.12.1 Backup settings to SD-Card..............................................................................................................47

4.12.2 Restore settings from SD-Card ........................................................................................................48

4.12.3 Restore settings to factory defaults ................................................................................................48

4.12.4 Clear all data ....................................................................................................................................48

4.12.5 Restart the device ............................................................................................................................48

5. ProfiTrace OE ............................................................................................... 49

Live List ............................................................................................................................................49

5.1.1 Updating the GSD file library ...........................................................................................................50

Statistics ...........................................................................................................................................50

Message recording ..........................................................................................................................51

Event configuration .........................................................................................................................52

Tag name configuration ...................................................................................................................54

Oscilloscope images .........................................................................................................................55

Oscilloscope configuration ..............................................................................................................56

5.7.2 Oscilloscope images .........................................................................................................................58

5.7.3 Oscilloscope errors ..........................................................................................................................58

Bar graph .........................................................................................................................................59

Streaming with ProfiTrace 2 ............................................................................................................59

Summary of Statistics and Events ....................................................................................................61

6. Head Station ................................................................................................ 64

Overview ..........................................................................................................................................64

Relay contact ...................................................................................................................................65

SD card .............................................................................................................................................65

6.3.1 Inserting/replacing the SD card .......................................................................................................65

Page 6

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 6/104

6.3.2 Life cycle of the SD card ...................................................................................................................65

6.3.3 Directories and files .........................................................................................................................65

Switch navigation of the Head Station ............................................................................................67

LEDs on the Head Station ................................................................................................................68

7. Scope Repeater Modules (RS485) ............................................................... 69

Two slots in one module ..................................................................................................................69

Channel structure ............................................................................................................................70

EMC barrier......................................................................................................................................71

Grounding system............................................................................................................................71

Baudrate detection ..........................................................................................................................71

PROFIBUS DP cable lengths .............................................................................................................72

PROFIBUS DP cable specifications ...................................................................................................72

PROFIBUS DP cable types ................................................................................................................73

Redundancy .....................................................................................................................................74

Mixing with other repeaters ............................................................................................................74

LEDs of the repeater module ...........................................................................................................75

8. CommDTM ................................................................................................... 77

Installing drivers, CommDTM and server ........................................................................................77

Setting up the PCD server ................................................................................................................77

Using the CommDTM ......................................................................................................................78

9. OPC .............................................................................................................. 81

Installing the OPC drivers ................................................................................................................81

Selecting OPC tags ...........................................................................................................................82

Activating the OPC server ................................................................................................................84

10. SNMP ........................................................................................................... 86

List of data items .............................................................................................................................86

Viewing the MIB file ........................................................................................................................87

11. Firmware updates ........................................................................................ 89

Updating the Head Station ..............................................................................................................89

Updating modules ...........................................................................................................................90

12. Tips and tricks .............................................................................................. 91

Ident number lookup .......................................................................................................................91

Solution for secured email connections ..........................................................................................91

IP address adjustment tool ..............................................................................................................91

Free WiFi channel detector .............................................................................................................91

Some SNMP tools ............................................................................................................................91

13. Sales offices and distributors ....................................................................... 92

14. Order codes ................................................................................................. 97

15. Glossary ....................................................................................................... 98

16. Certificates ................................................................................................. 101

Page 7

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 7/104

17. About PROCENTEC ..................................................................................... 102

18. Notes ......................................................................................................... 103

Page 8

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 8/104

1. Product description

Introduction

ComBricks™ - The first PROFIBUS and PROFINET-based automation system that unites network components

with permanent monitoring and ProfiTrace.

ComBricks HE+ (Harsh Environments) is a modular system that allows a mix of automation components on a

backplane. Repeater modules can be inserted next to a PROFIBUS slave and at the same time, in a web browser

over Ethernet, the condition of the installation can be remotely inspected with ProfiTrace OE.

Application areas

• Remote maintenance station with ProfiTrace OE

• Modular repeater backbone

• Transparent data hub (repeaters, fiber optic, RS 485-IS, DP slave, PROFINET, etc.)

In this manual of ComBricks HE+ you may find references to

modules that are not available yet, but will become available

later. These modules are only available on the regular

ComBricks platform. Please check our website for current

status of different modules.

Fig. 1 - ComBricks modules in many applications. Please note: Not all modules are available yet for ComBricks HE+

Page 9

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 9/104

Product features

• Drives 4 high-speed slots

• Robust housing

• Improved EMC protection

• Powerful web server

• ProfiTrace OE for monitoring 4 networks

• Multi-language

• Free CommDTM / DP-V1 master

• DIN-rail mounting

• IP 20

Page 10

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 10/104

Modular PROFIBUS repeaters

The current trend in PROFIBUS projects is to use segmentation with repeaters, fiber optic and ProfiHubs to

bridge the common faults of the end-user concerning his cabling difficulties. ComBricks HE+ adds another

important element; the creation of modular and random repeater hubs which can be monitored remotely with

a permanent internal ProfiTrace (see Fig. 1).

ComBricks HE+ is based on an internal backplane which can hold up to 2 physical modules. Each physical

module can have one or two repeater modules. This means a total of max 4 galvanic isolated transparent

segments. Every channel can handle 31 PROFIBUS stations and a maximum of 1200 m cable length (depending

on the baudrate). Fig. 2 illustrates some configurations. In contrast with the original ComBricks, this HE+

version is NOT hot-swappable. Always power down the system before adding or removing physical modules.

See paragraph 2.1.

Each channel has a fail-safe circuit which ensures that the remainder of the PROFIBUS network continues to

operate correctly and that the availability of the installation remains optimal. So if one channel has a shortcircuit, the other channels are not affected.

The connection of the bus cable allows for a high degree of flexibility as the repeater modules contain both a 9pin and screw connector.

It is possible to dynamically exchange field equipment during operation. ComBricks HE+ is ideal for flow meters,

pH analyzers, actuators, drives and especially motor control centers that make use of drawer systems.

Fig. 2 - Repeater configuration examples

Double Scope repeaters Maximum 2 Double Scope modules

Page 11

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 11/104

1.4.1 Cable Redundancy

The bus redundancy technology of the repeater modules is very advanced. A redundant system can be built

using 3 parallel cables. This architecture provides extremely high availability. Most suppliers only allow 2 cables

(see Fig. 3).

1.4.2 Typical applications

• Repeaters with permanent ProfiTrace

• Removable drives and motors

• Star, tree and bus structured networks

• Motor control centers (drawers)

• Redundancy for high availability

• EMC vulnerable applications

• Spur lines

• Isolator for sensitive devices

Fig. 3 - Redundancy configuration example

Maximum 3 redundant channels

Page 12

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 12/104

ProfiTrace OE – Remote monitoring in a web browser

Permanent and simultaneous monitoring of 4 PROFIBUS networks is a powerful feature of ComBricks HE+.

Global projects and a shortage of (qualified) technical staff members are causing significant capacity problems.

ComBricks HE+ offers a solution by remotely monitoring PROFIBUS installations over the Internet and alerting

the user by email.

The user can simply connect surrounding PROFIBUS networks and every network can be set to a unique

baudrate. The modular technology of ComBricks HE+ enables the network to be monitored when multiple

repeater modules are installed. All transparent messages from the backplane are constantly analyzed.

Using DIP switches or the web server, repeater modules can be assigned to a network group. This ensures

isolated communication from the repeaters which are assigned to other network groups; the networks are not

combined or connected in any way. Only the Head Station can see all networks groups.

1.5.1 Web server

A web server with a ProfiTrace shell visualizes the information in an understandable format (ProfiTrace OE).

Because of the web browser, additional software is NOT required and a constant connection with a PC to the

ComBricks HE+ is NOT necessary.

The monitoring and logging is performed by the repeater modules. ComBricks is the first system that has

integrated a busmonitor in network components. Deploying ComBricks repeaters for regular automation

means automatic availability of ProfiTrace OE.

Monitoring 4 networks

Monitoring 4 networks

Monitoring 4 networks

Worldwide access

to any COMbricks

Page 13

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 13/104

1.5.2 Email

Email messages provide real-time alerts in the event of detected faults in the PROFIBUS communication. These

email alerts are easy to set up in the web server.

1.5.3 Channel List

The Channel List gives a detailed overview of all repeater channels (segments) and all connected stations,

including the current status (e.g. diagnostics, configuration faults, losts).

1.5.4 Comparison between ComBricks and ProfiTrace 2

The application area for ComBricks HE+ (ProfiTrace OE) compared to ProfiTrace 2 is completely different.

ProfiTrace OE should be seen as an alarm watchdog or monitor and ProfiTrace 2 as the mobile analyzer to do

on-site fault-finding.

ProfiTrace 2

(troubleshooting on-site)

ComBricks HE+

(watchdog)

- USB (power supply)

- Mobile

- Software

- C1 Master

- Triggers and filters

- Large file recording

- Reporting

- Fast

- Ethernet / Internet

- Permanent installation

- Web server

- Multi network monitor

- Multi access

- Email and Log

1.5.5 Offshore applications

With satellite internet offshore PROFIBUS networks can be remotely monitored. Emails can inform the

mainland about the status of the installation.

These applications simplify maintenance and eliminate the hassle to fly an expert over to fix a possible

problem.

On the LAN local technicians can also monitor the networks.

Page 14

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 14/104

1.5.6 Mining applications

Because of the depth, gasses and inaccessible areas, ComBricks HE+ is an excellent solution to keep the control

room and the experts on a distance to monitor the PROFIBUS installations. Multiple WLAN routers can bring

Ethernet up to the surface.

With DTM technology the devices can also be diagnosed and parameterized.

Fig. 4 - Offshore applications

Page 15

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 15/104

1.5.7 Robot cells

Robot cells are hazardous environments with many safety zones. Crossing a safety border can cause a machine

shutdown and restarting can take a long time. Measuring PROFIBUS remotely decreases costs and improves

human safety.

1.5.8 Logistics

In demanding high-speed applications, ComBricks HE+ is ideal. The technician does not have to touch the

installation and can measure the network from a distance. This is also convenient if the installation is behind a

high-security zone such as baggage handling systems at airports, or parcel handling systems.

Fig. 5 - Robot cells

Fig. 6 - Baggage handling or parcel systems

Page 16

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 16/104

1.5.9 Traffic control

When distance and downtime are critical factors, ComBricks HE+ can be very helpful. Difficult to reach speed

indicators above the highway can be monitored from the road-side control cabinet, or even from the control

room.

1.5.10 Cranes

Many harbour cranes use PROFIBUS. There cranes are huge and sometimes hard to reach. The whole crane can

be monitored remotely, which is especially useful if the crane is equipped with a WIFI connection.

Fig. 7 - Traffic control applications

Fig. 8 - Crane applications

Page 17

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 17/104

1.5.11 Other applications

• Cross border installations

• Water treatment

• Long commissioning and test cycles

• 24-7 service contracts

CommDTM

The FREE ComBricks CommDTM offers FDT 1.2 based asset management tools a powerful Ethernet passthrough to access PROFIBUS devices which are connected on ComBricks HE+ repeater modules.

The internal DP-V1 class 2 masters are able to communicate on 2 of the 4 networks. When a CommDTM

connection is closed, the user can enter another network. The 2 active DP-V1 masters are managed by 1 or 2

PC Ethernet connections.

The CommDTM provides the same auto baudrate detection facilities as the famous ProfiCaptain. It detects all

busparameters before it goes online. An available master address is required.

Fig. 9 - CommDTM structure

CommDTM

CommDTM

Device DTM

PROFIBUS DP

Device DTM

PROFIBUS PA

FDT Applications ProfiTrace OE

Page 18

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 18/104

2. Quick Start

This checklist lists all the steps to a quick usage of ComBricks HE+.

STEP 1 Click all modules into place, before applying power. (2.1)

STEP 2 Provide the Head Station with the latest firmware, using the USB cable. (11.1)

STEP 3 Configure the repeater modules to their appropriate networks, or set the

dipswitch to ‘Software settings’. (3.8)

STEP 4 Wire the repeater modules with PROFIBUS cables. (3.9)

STEP 5 Power the Head Station. (3.6)

ComBricks HE+ is now operational, ProfiTrace OE is autonomously logging PROFIBUS events. After

these basic steps ComBricks HE+ can be further configured through the web server.

STEP 6 Connect an Ethernet cable to the Head Station and the network or a PC. (3.5)

STEP 7 Set the IP address to the required value. (2.4 + 2.5)

STEP 8 Check the modules and administrative info in the web server. (2.6)

STEP 9 Test ProfiTrace OE on the PROFIBUS installation. (5.1)

Page 19

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 19/104

Configure the repeater modules

Configure the repeater modules to their appropriate networks. This can be done with the dipswitches located

at the front of the module (see 3.8.1) or with the software settings in the web server (see 3.8.3). Add the

modules to the ComBricks HE+ system before applying power!

Wire the repeater modules

Connect the PROFIBUS cables to the repeater modules (see 3.9).

Power the Head Station

Provide power to the Head Station through one of its 2 power connectors (see 3.6).

Customizing the IP address through the web server

The default IP address of the Head Station is 192.168.1.254. Follow the steps below to customize the IP address

of the Head Station:

STEP 1 Insert an Ethernet cable in the Head Station which is connected to

the enterprise LAN or directly to the PC.

STEP 2 Make sure the IP address of your PC is on the same subnet as the switch

(192.168.1.xxx).

STEP 3 Open your web browser and enter 192.168.1.254 in the address field.

This is the default IP address of the ComBricks HE+.

STEP 4 The web server of the ComBricks HE+ will appear.

STEP 5 Click in the menu on the left on "IP config".

STEP 6 Update the IP settings and confirm it by clicking on "Save" (see Fig. 12).

STEP 7 The web page will now reload with the new IP address.

Page 20

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 20/104

The Notification link name is included in the event emails so that the user can directly jump to the specific

ComBricks unit without knowing its local IP number. An example is: www.boiler5.oag.com. The router of the

network or the internet server has to reroute this name to an IP number.

Customizing the IP address through the Discovery Tool

The ComBricks Discovery Tool can be downloaded from www.procentec.com.

After start-up all the available ComBricks HE+ units can be discovered and directly customized with the

required IP address (see Fig. 11).

The Discovery Tool works on an enterprise LAN, WLAN or with a direct cable between ComBricks HE+ and PC.

If you are not sure which ComBricks unit you are customizing, the LEDs can be set to blink with a button in the

Discovery tool. The LEDs on the corresponding Head Station will blink for 5 seconds to give the user a visual

confirmation.

It is recommended to have only one network interface connection active (only wireless or only

wired). In some cases the Discovery tool does not list all the ComBricks HE+ units when multiple

network interfaces are active.

Fig. 10 - Customizing the IP address in the web server

Current IP address

Tick this box if DHCP

is required

New IP address and

other settings

Page 21

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 21/104

Checking the modules and administrative info in the web server

After customizing the IP address, the modules can be checked in the web server. Click on "Status" to see an

overview of the available modules and their respective description + version numbers (see Fig. 12).

In contrast to the regular ComBricks system, modules can NOT be inserted and removed during operation.

On the top of the screen the location information info is also visible (see Fig. 12). If the administrative

information has to be altered, it can be done by clicking on "General config".

On the bottom of the screen the connected clients with this ComBricks HE+ are displayed.

All connections are listed here:

• Web connections

• FTP connections

• CommDTM connections

• Telnet connections

• ProfiTrace Streaming

connections

Head Stations

MAC and IP

addresses

MAC and IP

addresses

Scan and

configuration

options

Fig. 12 - Overview of the available modules

Location information

Messages from

the user

Inserted modules in

the system

Connected PCs and

other communication

devices

Fig. 11 - ComBricks Discovery Tool

Page 22

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 22/104

Testing ProfiTrace OE on the PROFIBUS installation

When the repeaters are wired to the PROFIBUS installation, ProfiTrace OE can be tested in the web server.

Click on "Live List" and the respective networks. A Live List with devices should appear (see Fig. 13).

See Chapter 5 for more information on how to use ProfiTrace OE.

Resetting the Head Station

By means of the "Menu Nav" switch on the front of the Head Station (see Fig. 14). ComBricks HE+ can be reset,

warm started or loaded with configuration data. Please follow the procedure described in 6.5.

The following selections are possible:

• Read settings from SD card

• Save settings on SD card

• Clear password

• Reset to factory defaults

• Warm start

Fig. 13 - ProfiTrace OE Live List

Monitoring 4

networks

Monitoring 4

networks

Monitoring 4

networks

Monitoring 4

networks

Same live List as

ProfiTrace 2

Page 23

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 23/104

Fig. 14 - Menu switch

Page 24

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 24/104

3. Installation instructions

Location

ComBricks HE+ can be installed everywhere in a non-hazardous area that complies with IP 20 (DIN 40 050) and

the specified temperature range of -20 o to +60

o

Celsius.

Position

ComBricks HE+ can only be installed on a horizontal DIN rail with the front plates facing forward (see Fig. 15

for an example). In this position the generated heat of the modules can escape through the grid in the top of

the housing. It is also easier to read the status LEDs. Do not install the ComBricks in any other position, this

could lead to overheating of the device.

Inserting modules

Adding modules to the ComBricks HE+ set must always be done when the set is unpowered. Adding a module

when powered can potentially lead to damage to the backplane system and electronics!

Click the module on the DIN rail first. Then push and click the module towards each other (see ).

When the modules are inserted the correct way, a sharp clicking sound should be heard during the push. Then

fasten the screw on the front.

Fig. 15 - ComBricks HE+ mounted on a DIN rail

Page 25

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 25/104

Removing modules from DIN rail

To remove a module, unscrew the front screw. Then press down the DIN rail clip on the bottom, using two

fingers or a screw driver. Tilt the unit forward, releasing it from the DIN rail. Then lift it up.

Fig. 16 - Move the modules on the DIN rail towards each other until they click.

Page 26

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 26/104

Wiring Ethernet

The Ethernet connector is located on the front of the Head Station. The connector contains LEDs that indicate

linkup (green) and reception of data (orange).

It is recommended to use a cable/RJ45 plug with grounding/foil due to the nature of industrial applications.

The Ethernet interface complies with standard Ethernet guidelines. The maximum cable length from ComBricks

to switch/device is 100 meter.

The MAC address is printed on the side of the Head Station.

Power Supply

The Head Station contains two 3-pin screw type power connectors on the front. If power redundancy is not

required, either one can be used. The power inputs are identical; there is no primary or secondary. They are

however numbered in the Web server (refer to Fig. 23) as Power supply 1 and 2.

The layout is as follows (when the wires are pointing down):

1 = - (left)

2 = + (middle)

3 = SH (right)

Fig. 17 - Wiring Ethernet

Ethernet port

Page 27

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 27/104

The power supply must comply with the following specifications:

• Voltage: 12 .. 24 VDC

• Current: Min. 800 mA

• Wire diameter: < 2.5 mm

2

3.6.1 Procedure

To connect the 24 VDC supply to the 3-pin screw-type terminal, proceed as follows:

To connect the power supply a 3 mm screwdriver is required.

3.6.2 Testing and commissioning

If the power is switched ON it can be diagnosed by the following indicator

procedure:

• All LEDs on the Head Station should be shortly ON.

• The RDY LED should be shortly Blinking.

• The SD LED should be ON (if an SD card is inserted).

• The RDY LED should be ON (also on other inserted Modules).

Fig. 18 - Head Station power supply

Redundant power

connection 2

Redundant power

connection 1

STEP 1 Strip the insulation of the conductors of the 24 VDC power supply.

STEP 2 Secure the conductors in the screw-type terminal.

STEP 3 Insert the entire connector block in the power socket (see Fig. 18).

Page 28

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 28/104

Repeater modules

One physical Scope module (order code 101-301220) consists of two separate repeater segments. This module

uses two slots in the virtual backplane of the ComBricks HE+. Fig. 19 shows the Channel List of a ComBricks

HE+ set. The two sides can both be configured individually as independent channel segments.

Configuring repeater modules

The repeaters can be configured using the dipswitches located at the front of the module or the web server.

3.8.1 Customizing the PROFIBUS network (NW0/NW1)

Set these dipswitches to the following positions to customize a network number for a specific PROFIBUS

network.

NW0

NW1

Network

LEFT

LEFT

1

RIGHT

LEFT

2

LEFT

RIGHT

3

RIGHT

RIGHT

4

One physical

module, two

slots used

Fig. 19 - Channel list of a ComBricks HE+ system

Page 29

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 29/104

When software settings are enabled (with the H/S switch) these dipswitches have no effect.

3.8.2 Redundancy (RED)

Set this dipswitch to enable the redundancy group for the channel.

RED

Redundancy

LEFT

OFF

RIGHT

ON

When software settings are enabled (with the H/S switch) this dipswitch has no effect.

3.8.3 Hardware or software settings (H/S)

Set this switch to enable hardware (dipswitches) or software settings.

H/S

Settings

LEFT

Hardware

RIGHT

Software

When software is enabled, all switch settings are

overruled. The settings can be modified in the webserver

of the Head Station, and will be saved there.

Page 30

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 30/104

Wiring repeater modules

The PROFIBUS cable should be wired to the repeaters according to the PROFIBUS guidelines with suitable cable

for the application you are using.

Regular and SCOPE repeater modules are

equipped with screw terminals and a DB9

connector for the bus connection. Both are

linked with each other, but it is not

recommended to use them both1.

Fig. 21 illustrates 3 recommended

connection topologies for the repeater

modules.

1

Because of the PROFIBUS spur lines limitations it is not recommended to use the screw terminal

simultaneously with the DB9 connector.

Network 1: NW0=L, NW1=L

Network 2: NW0=R, NW1=L

Network 3:NW0=L, NW1=R

Network 4:NW0=R, NW1=R

Dipswitch or web

server settings

Redundancy for the

current network

Fig. 20 - Dipswitches and LEDs of the repeaters

Fig. 21 - Repeater connection tolopogies

Page 31

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 31/104

3.9.1 Screw terminals

The channels have 1 screw terminal and a termination switch. In most cases, the channel starts here so the

termination must be set to ‘ON’. If the channel is not the beginning, use the DB9 connector, see Fig. 21

example B.

Only in configuration A of Fig. 21 the on-board termination should be set to ON. In configuration B the

repeater module is in the middle of the segment, so the termination must be OFF. In configuration C the

termination is set to ON only at the connector.

Pin layout of the screw terminals

Pin “A”: Green wire

Pin “B”: Red wire

Pin “I”: Indirect cable shielding

3.9.2 DB9 connector

The ComBricks Scope Repeater modules are equipped with a standard 9-pin PROFIBUS plug (1-on-1 with the

screw terminal).

When the DB9 connector is utilized and located at the beginning or end of the segment, it is recommended to

use the termination on the DB9 connector and NOT on the repeater module (see Fig. 21 - configuration C)2

If you choose to use the DB9 connector, it is recommended to use the PROCENTEC ProfiConnector (any type),

because this connector has the correct shape to fit over the green connector. See our website for more

information about this connector.

To connect the PROFIBUS cable to the repeater modules (screw terminals) a 2.5 mm screwdriver

(max. 0.4 mm) is required.

3.9.3 Testing and commissioning

If the channel recognizes valid PROFIBUS messages from one or more connected devices, the RX LED of this

channel should be blinking and ER should be OFF.

When the termination of a specific channel is set to ON, the green SW LED should be ON.

2

The PROFIBUS connector is the best place to activate the termination. When you remove the connector from

the module you still have the termination in the plug which is attached to the bus cable. It is true that the

termination is not powered by 5V (which is always required), but it is better to have an unpowered termination

than no termination at all.

Page 32

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 32/104

4. Web server

To access the web server of ComBricks, open your web browser and enter the IP address that has been setup

(after purchase or reset the default IP address is 192.168.1.254). In the Discovery Tool you can find a button to

access the web server with the default Windows browser.

If a User password has been setup a screen will appear to login first in order to access the web

server. If only the Administrator password has been setup it is not necessary to login to directly, but

when settings are altered you must be logged in (See paragraph 4.8)

Some web pages described in this manual

are only accessible with certain Head Station

types, licenses or firmware versions.

After the web page has been loaded, the pages of the web server can be browsed by clicking on the items in

the menu on the left side of the screen. The next paragraphs will explain the primary web server pages.

The web server can handle 20 simultaneous client

connections. When all 20 are utilized, the connection

with the ComBricks could become relatively slow.

The minimum version requirements for Web browsers are:

- Firefox 2.0 (24 October 2006)

- Internet Explorer 6.0 (27 Augustus 2001)

- Google Chrome 1.0 (24 April 2009)

Page 33

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 33/104

Status

The 'Status' screen is the first web page that appears when the web server is accessed. This page gives an

overview of the available modules and their respective description + version numbers (see Fig. 22).

Modules can be inserted and removed during operation. Changes in hardware should be directly visible in the

Status screen.

The 'User message' with custom messages/info is also displayed here.

On the top of the screen the network and site info can be inspected.

On the bottom of the screen the connected clients with this ComBricks are visible.

Location information

Messages from

the user

Inserted modules in

the system

Connected PCs and

other communication

devices

Fig. 22 - Status screen

Page 34

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 34/104

Power redundancy

status

SD card status

Current consumed by

the modules

Fig. 23 - Example of a module status

Page 35

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 35/104

Channel list

A helpful utility is the Channel list. This page visualizes a graphical overview of all stations in the network and to

which network module they are connected. It is almost comparable with a logical topology scan (see Fig. 24).

Fig. 24 - Channel list

Network filters

Show colour

legend

Inserted network

modules and the

available channels

Communicating

devices with Live List

colours

Inserted network

modules and the

available channels

Page 36

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 36/104

System log

The system log saves ComBricks events. When this page is accessed all the ComBricks events are displayed. It

can be downloaded as text file and cleared/deleted (see Fig. 25). You cannot change the system log in the web

server.

The 'System log' is:

• reloaded after a power down and continues its logs after a power-up.

• auto/live updating when this screen is accessed.

• autosaved on the SD card. The interval time for autosaving can be adjusted on the ‘General Config’ page.

Download and clear

functions

System events

Fig. 25 - System log

Page 37

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 37/104

General configuration

The basic settings of the ComBricks are customized on the 'General configuration' page. For optimal use of

ProfiTrace OE, it is important that the time is synchronized and the site info is sufficiently filled in (see Fig. 26).

If your ComBricks is connected to Internet or a local NTP server, use the NTP server synchronization for

automatic date & time update. This keeps your ComBricks always set to the right time. If the ComBricks clock

differs more than 10 seconds from the NTP clock, a line in the system log is added.

The automatic time update occurs when the set interval has passed. The maximum interval that can be set is

1440 minutes, which corresponds to 24 hours. Please note that there is no option for auto-updating to Daylight

Saving Time (DST). This is because this is not used in Factory Automation. When an NTP server is used, the time

is always assumed to be winter time.

The display refresh rate has to be tuned to the bandwidth of the Ethernet connection. By default it is set to a 1

second automatic refresh. If the bandwidth is limited, it is recommended to increase this time or to switch the

automatic refresh OFF.

Language selection

Remote info which is

displayed on every

web page

Settings related to the

Ethernet bandwidth

and start page

Time synchronization

options. Use NTP for

automatic synchronization.

Fig. 26 - General configuration

Page 38

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 38/104

It is possible to select the start page which is first displayed when browsing to the Head Station IP address. You

can select the Main Status page, System Log page, Live List, Statistics, Channel list Message Recording or

Network Event log. You can also select for which network this should apply.

The interface language can be changed in the Preferred Language drop-down box. More languages are

available as a separate download called ‘Language Pack’ on the website of PROCENTEC.

Network configuration

The network names and the assignment of the repeater modules are customized here. For optimal use of

ProfiTrace OE, it is important that correct and understandable network names are defined (see Fig. 27). The

network names are used in multiple components: ProfiTrace Live List, event emails, message recording, etc.

Each of the 4 Live Lists can be individually setup to a different time-out. The default value is 5 seconds. The

time indicates how long a slave will be displayed as green when it has lost communication to the master. After

the set time it will turn yellow if it has no communication anymore.

The network assignment of the repeater modules is also displayed and can be adjusted if software settings are

enabled (see Fig. 27). It is possible to assign a module to Network 1 to 4, or to disconnect it from the

backplanes. This makes it possible to create a multiplexed system, or temporarily remove certain slaves from

the PROFIBUS network.

Dipswitch settings are always primary to software settings.

Hardware or

software settings

Customizable

network names

Network selection:

1, 2, 3, 4 or

Not Connected

Fig. 27 - Network configuration

Page 39

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 39/104

IP configuration

The IP Configuration screen offers some basic IP settings.

The DHCP functionality can be enabled. If the ComBricks will be connected to a network where a DHCP server is

active, the settings can be automatically set into the ComBricks by enabling this feature. The IP address will be

set by the DHCP server.

If a fixed IP address is needed, enter it manually in the ‘IP address’ box. By default the IP address is

192.168.1.254. Next, enter the subnet mask, default gateway and DNS server according to the settings of the

network. For more information, contact the network administrator.

Please note that changing the DNS server address requires a soft-reboot of the Head Station before the new

setting becomes active. Soft-resetting the Head Station does not affect repeater modules; this is a separate

process. You can safely soft-reset the Head Station without disrupting the repeater-functionality.

Current IP address

Tick this box if DHCP

is required

New IP address and

other settings

Fig. 28 - IP configuration

Page 40

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 40/104

Output Control

With the Output Control feature the user can directly respond to an event with the onboard relay in the Head

Station or the channels from output modules in the backplane (currently not yet available for the HE+ system).

The web server offers 10 customizable controls that can be set to the following behavior:

• Not active

• Manual ON/OFF Live toggle of the output channels

• Time Time ON and Time OFF

• PROFIBUS event Syncs, retries, bus voltage too low, redundancy failure, PA failure,

fiber optic failure etc.

• System event Redundant power change or ComBricks failures

After power down/up, the ComBricks loads and restores these settings.

It is recommended to have a security policy concerning passwords with this feature, because the

user is able to control REAL output points.

PROFIBUS events

or ‘triggers’

Fig. 29 - Output control

Page 41

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 41/104

Password setup and login

Passwords are NOT activated when the

product is purchased or reset and all menu

items are accessible and adjustable.

ComBricks supports 2 types of passwords;

• The Administrator password has to be set first.

• The passwords can have a length between 1 and 16 characters.

Fig. 30 illustrates the password setup web page.

4.8.1 Access rights

After a password(s) has been setup, it complies with the access rights from Table 1.

NO

Passwords

Administrator

User

(Admin. is set)

Login required at

web server access

NO

NO3

YES

Visiting web pages

YES

YES

YES

(may be limited)

Clear "System log"

YES

YES

YES

(may be limited)

Restart the device in the

"Device management"

YES

YES

YES

(may be limited)

Output Control

YES

YES

YES

(may be limited)

Changing passwords

YES

YES

NO

Adjusting all other settings

YES

YES

NO

Table 1 - Access rights after password setup

3

When only the Administrator login has been activated, the user can always enter the web server without a

valid login. When settings need to be altered, the administrator is required to login.

User: Is limited to read information

Administrator: Has access to the full web server and can adjust settings

Page 42

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 42/104

Fig. 30 - Password setup

4.8.2 Password best practice

We encourage you to at least setup the Administrator password if more than 1 person has access to the

network.

• Activate the password(s) immediately after installation or at the office before it is transported to the final

destination.

• Use different passwords for the Administrator and User.

• Never share passwords with anyone.

• Always use strong passwords. Avoid: test, 123456, <your company name>, <your first name>, ComBricks,

procentec, etc.

• Change passwords immediately if they may have been compromised.

• If passwords must be written down, store it in a secure place and destroy it when it is no longer needed.

• Be careful about where passwords are saved on computers. Some dialog boxes, such as those for remote

access, present an option to save or remember passwords. Selecting this option poses a potential security

threat.

Limit the access of users

Admin and/or user

password setup

Page 43

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 43/104

4.8.3 External protocols

The following login information is required for external protocols, for example for FTP and TELNET.

An FTP connection to the ComBricks can be made to transfer files to or from the SD card. Any FTP client can be

used to setup the FTP connection. ComBricks uses port 21.

Some FTP clients require a password for the FTP connection. If you have not set a password, ComBricks will

accept any password during the connection phase, so you can provide any password.

Please note that the FTP process has a low priority in the ComBricks, so transfer of larger files to or from the SD

card may be slow.

4.8.4 Clearing password(s)

There are 3 ways to restore the password(s) to their default setting:

• Change the passwords with no text written in the text field (Administrator login required).

• Restore to factory default settings in the "Device management" page (Administrator login required).

• Restore to factory default settings with the switch on the front of the Head Station (see paragraph 6.5).

License update

It is possible to upgrade the license in the Head Station, for example from a 1B license to a 1C license. This

makes it possible to monitor more networks. In case the user wants to update the license of the Head Station,

it can be done on the License Update page via an internet connection or simply copying the content of a license

file. You can also see the current details of the activated license.

User: user or admin

Administrator: <your password>

Details and

limitations of the

license

Update the license

here

Fig. 31 - License update page

Page 44

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 44/104

Document download page

To provide the user with documentation, firmware and software, the SD card has been provided with a

document download page, see Fig. 32.

• Download the latest version of the document download page from www.procentec.com

• The content of the .ZIP file has to be copied to a directory \DOC on the SD card.

• If the directory does NOT exist, create it and copy the content of the .ZIP file to it.

• Reload the web server to update the information.

• There should be an item called "Downloads" on the bottom of the left menu

It is possible to replace the PROCENTEC download page with a customized version. Replace index.html with

your own version and you can point to directories/files which are located on the SD card. If you are interested

in such activities, we recommend you to inspect the structure of the PROCENTEC index.html first. Please note

that the FTP process has a low priority in the ComBricks, so transfer of larger files may be slow.

Link to download

from SD card

Link to download the latest

version from Internet

Fig. 32 - Software and document downloads

Page 45

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 45/104

Email account configuration

The email account information has to be entered if the user wants to have ComBricks signal events by email.

The required information is generally the same as any other email related setup (see Fig. 33).

Setting up the email server parameters is not enough.

The events that generate the emails have to be setup

in the ‘Event config’ menu (see paragraph 5.4).

The SMTP server has to support unencrypted connections, because the current ComBricks firmware

does NOT support encrypted connections such as SSL/TLS. The DNS address (IP config menu) has to

be modified according to the DNS addresses of your internet provider.

You can setup multiple email groups. Each group can receive emails triggered by different events, which can be

set up in ‘Event config’ in paragraph 5.4.

Direct testing of

server settings, per

group

E-mail server

parameters

Daily test email

enabled

Fig. 33 - Email configuration

Page 46

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 46/104

The server parameters have to comply with the email server parameters listed in Table 1.

Table 1 - Email server parameters

Server parameters

Mandatory

Additional information

Size

Groups 1 - 4

At least one

group

If you enter multiple addresses (max. 3)

separate them with the ; character.

200

Cc

Optional

If you enter multiple addresses (max. 3)

separate them with the ; character.

200

From

Yes

Depending on the email server you are using,

this has to be an existing email address.

100

Subject

Optional

Can be anything you want it to be.

100

SMTP server

Yes

Has to be setup according to the requirements

of the email server.

100

SMTP server port

Yes

Standard value for most servers has already

been entered, but has to be setup according to

the requirements of the email server.

User name

Optional

A User name can be entered if the SMTP server

requires it. Click on "SMTP-Username and

password" first.

50

Password

Optional

A password can be entered if the SMTP server

requires it. Click on "SMTP-Username and

password" first.

50

When you have filled in all server parameters, click on "Save". The settings can be tested by clicking on "Send

test email with saved settings".

Save the settings first before sending the test email.

It might take a couple of minutes before the test email has been received by the recipient.

If the test-email has not been received, please check if it has been blocked by a Spam filter.

4.11.1 Alive email

ComBricks can send a periodic alive-email to the recipient group(s) entered in the Group: field. If no events are

triggered for a longer period, ComBricks will not send emails. This also happens when ComBricks has no

connection to the mail server for some reason. The alive email is an automated check to see that the

connection is still active.

ComBricks can auto-send an email with adjustable interval of anything between one hour and 365 days.

Page 47

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 47/104

4.11.2 Email troubleshooting

• Check if ComBricks has access to the internet. You can easily test this by going to the Download page in the

ComBricks menu and download a datasheet from the web.

• Compare the DNS settings with the requirements of the email server you are using.

• Make sure your email server supports unsecured connections (secured connections are not possible).

• Check the email settings and generate the test email. Start with only 1 email address.

• If the test email works, please check that your events have been correctly enabled and an event is really

triggered.

Device management

The Device Management page allows the user to perform backup, restore and restart actions for the

ComBricks. For some actions Administrator login is required.

4.12.1 Backup settings to SD-Card

When this button is clicked, all customizable settings of each individual network and of the Head Station are

saved to SD-Card. These settings include Message recording settings, name and identification tags, scope

settings and IP and email settings.

This feature allows a quick and easy replacement of a defective Head Station. If a Head Station needs to be

replaced, and settings have been backed up on SD card, remove the SD card from the slot and place it in the

new Head Station. Then continue with paragraph 4.12.2.

Save and load

ComBricks settings

Fig. 34 - Device management

Page 48

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 48/104

4.12.2 Restore settings from SD-Card

When you replaced the SD card with information from another Head Station, click ‘Restore settings from SD

Card’ to load all information into the new Head Station. Then click ‘OK’ on the confirmation window.

Settings are loaded and activated instantly; no restart is required.

4.12.3 Restore settings to factory defaults

This button clears all entered information and restores the ComBricks Head Station to the default factory

values. The new IP address is 192.168.1.254

4.12.4 Clear all data

When a ComBricks set has been installed and is ready for normal operation, it may have recorded several

events which are not ‘real’ faults. This can happen during wiring or commissioning phase. Press ‘Clear all data’

to start the ComBricks logging and recording functions with a clear memory. Then click ‘OK’ on the

confirmation window.

IMPORTANT NOTE: This will also clear all Message Recording and log files.

It will not clear the settings, details or other ComBricks data.

4.12.5 Restart the device

To restart the device, for example to let it read new dipswitch settings or DNS server settings, click the ‘Restart

the device’ button. Then click ‘OK’ on the confirmation window.

This ‘soft’-reset will not affect PROFIBUS communication on the repeater modules; the repeater functionality

will continue during reset.

Page 49

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 49/104

5. ProfiTrace OE

ProfiTrace OE (Over Ethernet) is a web based version of ProfiTrace. It offers the basic functionality of regular

ProfiTrace, such as Live List, Statistics and Message recording.

Live List

The Live List is a matrix that continuously lists all the available devices. It is directly visible which devices are

‘troublemakers’. With different background colors, the status of the devices is displayed (see Fig. 35):

• Green: Device is in Data Exchange

• Yellow: Device is lost (the time-out is adjustable, see paragraph 4.5)

• Red: Parameter fault

• Purple: Configuration fault

• No color: On the bus but not in Data Exchange

The Live List can also generate the product name of the devices when a diagnostic message is captured

(synchronized with the GSD library).

The button ‘Display Legend’ pops up a window explaining all colours in more detail.

Monitoring 4

networks

Monitoring 4

networks

Monitoring 4

networks

Monitoring 4

networks

Same live List as

ProfiTrace 2

Fig. 35 - ProfiTrace Live List

Page 50

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 50/104

5.1.1 Updating the GSD file library

The procedure below describes how to update the GSD file information in ComBricks HE+ so that all devices in

the Live List have a full model name.

Statistics

The statistics matrix is a powerful feature of the analyzer. This field can really indicate what the condition of

the installation is. It displays all the important information that a user, especially a maintenance technician, is

really interested in (see Fig. 36):

• Retry messages

• Fall-outs (losts)

• Diagnostic messages

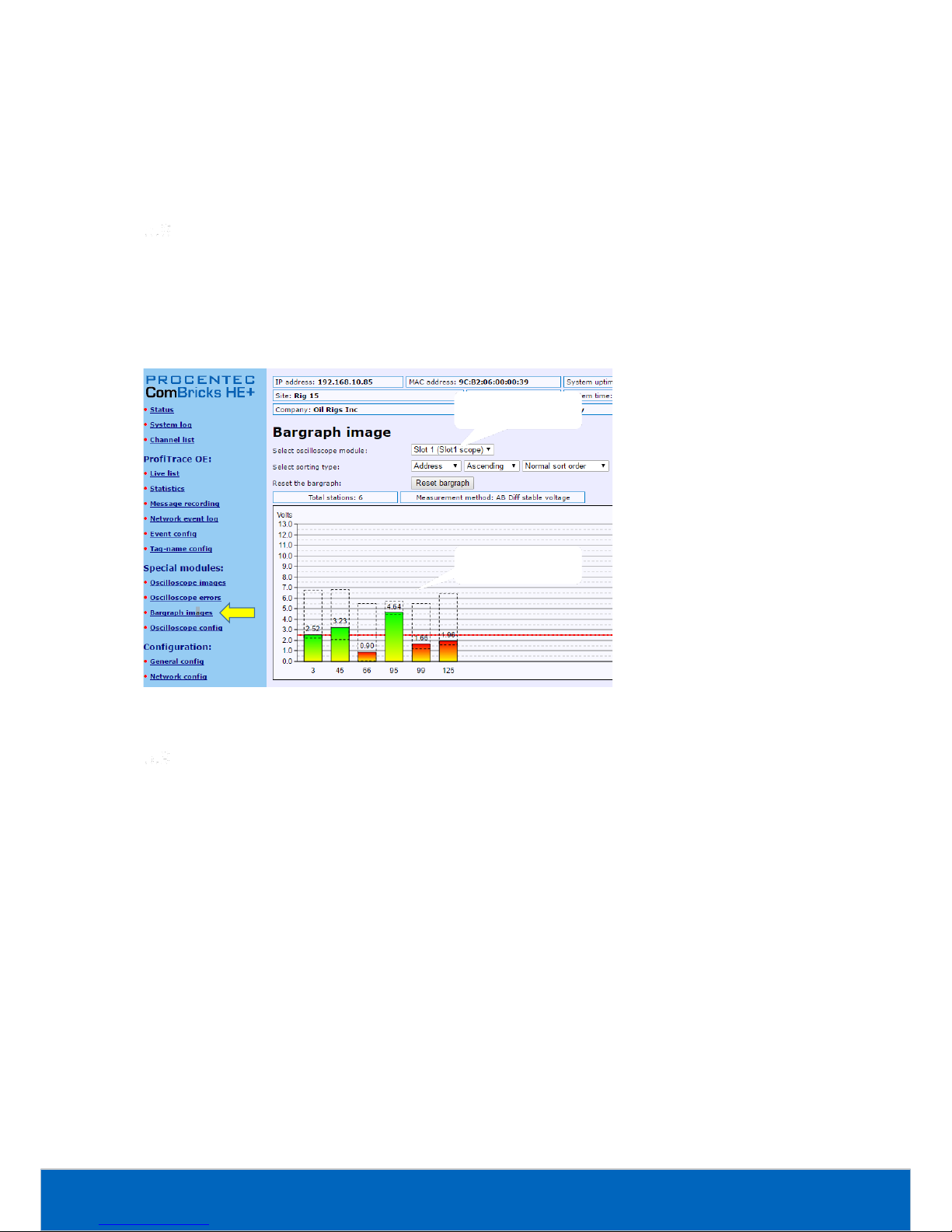

• Location of the connected devices, etc.

STEP 1 Start regular ProfiTrace (2.6 or higher, no license required).

STEP 2 Copy all GSD files you require into the ProfiTrace GSD directory.

This is usually ".....\ProfiTrace_Vx_x_x\GSD\".

STEP 3 Create a ComBricks GSD library. (Settings > Create ComBricks GSD library)

A question is asked if you want to re-scan the GSD files. Select YES followed by

(re)Scan GSDs. Click ‘Close’ when the process has been finalized.

STEP 4 A pop-up box allows us to select the destination folder. Select a (temporary)

destination folder for the file GSD.BIN, for example the Windows desktop.

STEP 5 GSD.BIN has to be copied to the SD card of the ComBricks HE+. You can do this

by inserting it in your PC or via FTP (admin account).

STEP 6 After inserting the SD card back into the Head Station or closing the FTP session,

the GSD information is directly available in the Live List. Paragraph 12.1 describes a

method of testing the updated GSD.BIN.

Page 51

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 51/104

Paragraph 5.10 describes the statistics and when they occur.

Because of this feature, the user does not have to inspect messages or do difficult operations to ensure the

quality of the installation.

If the statistics do not show deviations, the installation appears to be running correctly.

Here it stops for the technician who is only interested in a quick feedback. The advanced technician can

proceed with a message recording and an inspection of the signal quality.

Message recording

The message recording in ProfiTrace OE follows a different strategy than ProfiTrace 2. Within ProfiTrace 2, the

user needs to setup the message recording first and is he responsible to start it himself.

Because ComBricks HE+ is a unit for permanent monitoring, it automatically starts a message recording when

an event has been detected. The following event automatically starts a message recording again.

When the unit is purchased or reset, it is automatically triggered on the statistic "Lost". This is enabled by

default directly after startup. The user can change the settings during operation (see Fig. 37).

The recorded files can be opened with an offline ProfiTrace 2 (no license required).

Fig. 36 - ProfiTrace OE Statistics

Same statistics as

ProfiTrace 2

Page 52

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 52/104

The automatic triggering can generate 1000 .PTC files per network. After 1000 files have been

generated, the follow-up event will delete the oldest file and replace it with the latest event. This

system secures the storage space of the SD card.

.PTC files can be opened with ProfiTrace 2.5.3 and higher (offline and no licenses required).

The file name consists of the MAC address (in Hexadecimal) of the Head Station, the network number and the

file number (0-999).

Event configuration

For generating emails and entries in the network log, the event configuration has to be set for each network.

Fig. 38 shows an example with multiple event options. Paragraph 5.10 describes the events and when they

occur.

Fig. 37 - Setup recording trigger

Automatic

re-triggering

Recorded files from

network 1

Monitoring 4

networks

Recording range

Trigger settings. Lost

is default

Page 53

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 53/104

To reduce an unwanted overload of emails or log entries, the events can be set to Off, Once or Interval.

Event parameter

Description

Retrigger required

Off

No event generation.

Once

Event will be generated once (1-shot).

Yes

Interval

Event will be generated once within the customized

interval time. After the interval time the event is

automatically retriggered to be generated in the next

interval. If no trigger was captured in the new interval

period, no event will be generated.

No

Fig. 38 - Event configuration

Multiple options for

an event:

- Off

- Once

- Interval

Event configuration

for e-mail and log

Every network can be

configured

individually

Event configuration

for e-mail and log

Page 54

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 54/104

Tag name configuration

Every ComBricks HE+ module and every station in every network can be tagged with a name.

The first block of tag names is used to assign tags to the ComBricks HE+ modules.

Each tag must have the format slot:name, where slot is the slot number. The tag names are limited to 16

characters. The Colon (:) and quote (‘ or “) characters cannot be used.

The second to the fifth block of tag names are used to assign tags to individual stations in each network.

Tag names are stored on the SD card. Use the ‘Backup’ and ‘Restore’ feature to reload the names if you change

the Head Station, see paragraph 4.12.

The tag names are visible in the Channel List page if you hover over a module or station address. It is also

possible to show the tag names in the Live List:

Tag names of modules are also

displayed in drop-down references to

modules and in tables on the

following pages:

• Oscilloscope Images

• Oscilloscope Error Images

• Oscilloscope configuration

• Bar Graphs

• PA measurements

• Network Configuration

• Output Control configuration

Fig. 39 - Tag name configuration screen

Page 55

ComBricks HE+ User Manual | June 2017 | © PROCENTEC 55/104

Oscilloscope images

SCOPE repeater modules have an integrated oscilloscope to measure the signal quality of the telegrams. The

oscilloscope has an interface with the web server to display the signals from the devices which are connected

to its channel. After opening the web page, all oscilloscope signals are displayed and updated live.

The SCOPE repeater is the most easy to use PROFIBUS oscilloscope available:

• You do NOT have to touch the installation

• Works automatically, even saves images to SD card

• Oscilloscope data is never mistaken with the wrong segment

• No probe wiring

• No spur lines

By clicking on the oscilloscope waveform of a device, the oscilloscope triggers on the respective device and

displays its signals in a new page.

The SCOPE repeater is only able to do differential measurements.