Trade Name

Chemical name

Chemical family

Use

ABS

Acrylnitril-Butadien Styrol Copolymer

Thermoplastic Styrol

IDENTIFICATION OF THE MATERIAL

3D-Printing

Technical Data Sheet

ABS by Procatec GmbH

Layer hight

Nozzle temperature

Bed temperature

90 °C

Print speed

Melt temperature

≈ 93°C

≈ 90°C

5,5

1,03 g/cm³

Glass transition temperature

Melt flow rate

Density

MATERIAL PROPERTIES *

250 °C

Nozzle size

Print parameters of the test procedure

0,2mm

0,6mm

60mm/s

ISO 75-1/-2

ISO 306

ISO 1133

ASTM D-792

* These data were taken from the raw material manufacturer

Printer

Original Prusa i3 MK2

Test method

Your solution in 3D printing

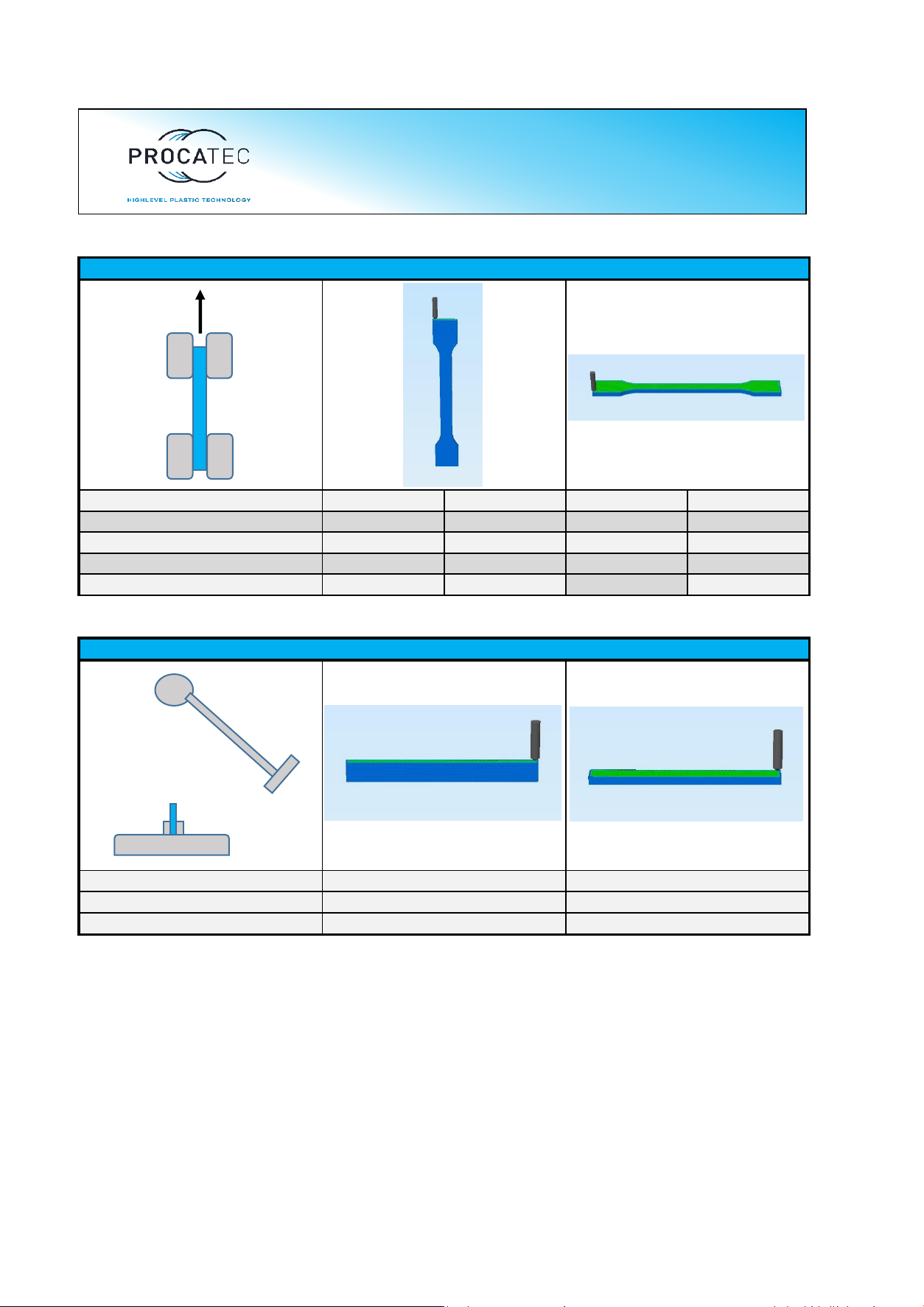

Test method ISO 527

Test method ISO 179-1 / eU

Elongation at brake (%)

2,1 ± 0,2

MECHANICAL PROPERTIES | TENSILE TEST

5,6 ± 1,2

4,5 ± 0,5

100%

50%

100%

18,6 ± 1,8

13,2 ± 0,4

27,5 ± 1,6

Infill

Tensile strength (N/mm²)

Force break (N)

Elongation at max force (%)

50%

10,1 ± 0,2

409,0 ± 11,4

2,1 ± 0,2

Impact energy (mJ)

1728,4 ± 208,8

2257,8 ± 428,1

Impact strength (kJ/m²)

55 ± 10

44 ± 6,8

MECHANICAL PROPERTIES | CHARPY Impact Test

Infill

100%

100%

2,4 ± 0,3

5,6 ± 1,2

4,5 ± 0,5

761,2 ± 75,5

536,5 ± 15,1

1115,8 ± 62,6

2,4 ± 0,3

Your solution in 3D printing

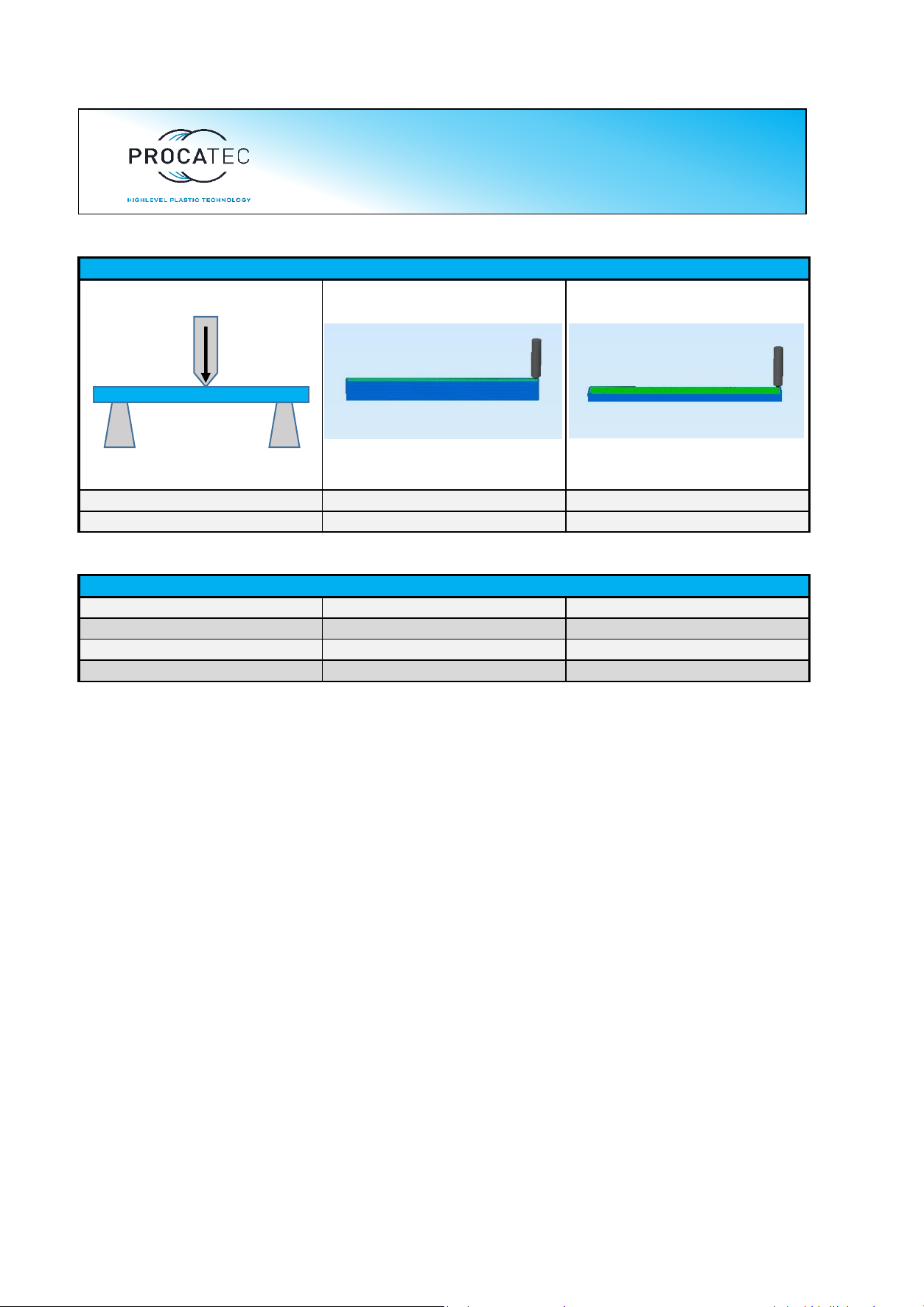

Test method ISO 178

Maximum force (N)

86,9 ± 1,5

83,3 ± 3,2

Infill

100%

100%

Diameter 1,75

1,75 ± 0,05 mm

PROCATEC

FILAMENT SPECIFICATION

Test method

max. roundness deviation 2,85

0,05 mm

PROCATEC

Diameter 2,85

2,85 ± 0,05 mm

PROCATEC

max. roundness deviation 1,75

0,05 mm

PROCATEC

MECHANICAL PROPERTIES | FLEXURAL TEST

Your solution in 3D printing

Loading...

Loading...