Page 1

5271.0008

V1

GB

Operating Instructions

Translation of original operating instructions

VACUUM-POWER-HANDY

VPH-150

Page 2

Contents

2 / 24

5271.0008

V1

GB

Contents

1 EC-Declaration of Conformity ............................................................................................................................... 4

2 Safety ...................................................................................................................................................................... 5

2.1 Safety symbols ................................................................................................................................................ 5

2.2 Explanation of basic concepts ....................................................................................................................... 5

2.3 Definition skilled worker / specialist .............................................................................................................. 5

2.4 Safety Marking ................................................................................................................................................ 6

2.5 Personal safety requirements ........................................................................................................................ 7

2.6 Protective equipment..................................................................................................................................... 7

2.7 Accident prevention ....................................................................................................................................... 7

2.8 Safety at work ................................................................................................................................................. 7

2.8.1 General ....................................................................................................................................................... 7

2.9 Function Control ............................................................................................................................................. 8

2.9.1 General ....................................................................................................................................................... 8

2.9.2 Electric ........................................................................................................................................................ 8

3 General .................................................................................................................................................................... 9

3.1 Authorized use ................................................................................................................................................ 9

3.2 Survey and construction ............................................................................................................................... 11

3.3 Technical data ................................................................................................................................................ 11

4 Installation ............................................................................................................................................................. 12

4.1 Mechanical connection ................................................................................................................................. 12

4.1.1 Lifting eye / Suspension bolt .................................................................................................................... 12

4.1.2 Load hook and chains ............................................................................................................................... 12

4.2 Assembly of the Wheel Set VPH-RS .............................................................................................................. 12

4.3 Assembly of Stop for Wheel Set VPH-RS-AS ................................................................................................ 13

5 Adjustments .......................................................................................................................................................... 14

5.1 Adjustment of VPH and the assembly ..........................................................................................................14

6 Operation .............................................................................................................................................................. 15

6.1 Operating Elements ....................................................................................................................................... 15

6.2 Suction Plate .................................................................................................................................................. 15

6.3 General ........................................................................................................................................................... 15

6.4 Battery ............................................................................................................................................................ 15

6.5 Lifting, Transport and Installation (hoist operation) .................................................................................. 16

6.6 Lifting, Transport and Installation (manual operation) ............................................................................... 17

6.7 Tile laying ....................................................................................................................................................... 17

6.8 Damages of suction plate ............................................................................................................................. 18

7 Maintenance and care .......................................................................................................................................... 18

7.1 Maintenance ................................................................................................................................................. 18

7.1.1 Mechanical .................................................................................................................................................... 18

7.2 Suction plate ................................................................................................................................................. 19

7.3 Fault finding .................................................................................................................................................. 19

7.4 Repairs .......................................................................................................................................................... 20

7.5 Safety procedures ........................................................................................................................................ 20

7.6 Hints to the type plate ................................................................................................................................... 21

7.7 Hints to the renting/leasing of PROBST devices .......................................................................................... 21

Page 3

EC-Declaration of Conformity

3 / 24

5271.0008

V1

GB

8 Vacuum pump ...................................................................................................................................................... 22

8.1 General .......................................................................................................................................................... 22

8.2 Safety Advice ................................................................................................................................................ 22

8.3 Description .................................................................................................................................................... 22

8.3.1 Charge battery ......................................................................................................................................... 23

8.4 Maintenance ................................................................................................................................................. 23

8.5 Technical Data ............................................................................................................................................... 24

Page 4

EC-Declaration of Conformity

4 / 24

5271.0008

V1

GB

1 EC-Declaration of Conformity

Description:

Type:

Order number:

VACUUM-POWER-HANDY

VPH-150

5271.0008

Manufacturer:

Probst GmbH

Gottlieb-Daimler-Straße 6

71729 Erdmannhausen, Germany

info@probst-handling.de

www.probst-handling.de

The machine described above complies with the relevant requirements of the following EU directives:

EC-machinery directive 2006/42/EC

2014/30/EU (Electromagnetic compatibility)

The following standards and technical specifications were used:

DIN EN ISO 12100

Safety of machinery - General principles for design - Risk assessment and risk reduction (ISO 12100:2010)

DIN EN ISO 13857

Safety of machinery - safety distances to prevent hazard zones being reached by upper and lower limbs (ISO 13857:2008)

DIN EN 1012-1 / DIN EN 1012-2

Compressors and vacuum pumps; Safety requirements part 1 and 2.

DIN EN 60204-1 (IEC 60204-1)

Safety of machinery, electrical equipment of industrial machines. Part 1: General requirements.

Authorized person for EC-documentation:

Name: J. Holderied

Address: Probst GmbH; Gottlieb-Daimler-Straße 6; 71729 Erdmannhausen, Germany

Signature, information to the subscriber:

Erdmannhausen, 11.07.2018..........................................................................

(M. Probst, Managing director)

Page 5

Safety

5 / 24

5271.0008

V1

GB

2 Safety

2.1 Safety symbols

Danger to life!

Identifies imminent hazard. If you do not avoid the hazard, death or severe injury will result.

Hazardous situation!

Identifies a potentially hazardous situation. If you do not avoid the situation, injury or damage to property

can result.

Prohibition!

Identifies imminent a prohibition. If you do not avoid the prohibition, death and severe injury, or damage to

property will result.

Important information or useful hints for the usage.

2.2 Explanation of basic concepts

Gripping range:

specify the minimum and maximum product measurements of the gripping good, which

can be gripped with this device.

Gripping good(s):

is the product, which will be gripped or transported.

Opening width:

consists of the gripping range and the measure to drive over the gripping good.

gripping range + measure to drive over the gripping good = opening width

Immersion depth:

is the maximum gripping height of gripping goods, conditional of the height of the

gripping arms of the device.

Device:

is the description for the gripping device.

Product dimensions:

Are the dimensions of the gripping good (e.g. length, breadth, height

of the product).

Dead weight:

is the own weight (without gripping good) of the device.

Carrying capacity/working

load limit (WLL*):

specify the maximum possible load of the device (for lifting of gripping goods).

2.3 Definition skilled worker / specialist

Only skilled workers or specialists are allowed to carry out the installation-, maintenance-, and repair work on this device!

Skilled workers or specialists must have for the following points (if it applies for this

device), the necessary professional knowledge.

for mechanic

for hydraulics

for pneumatics

for electrics

*= WLL (english:) Working Load Limit

Page 6

Safety

6 / 24

5271.0008

V1

GB

2.4 Safety Marking

PROHIBITION SIGN

Symbol

Meaning

Order-No.

Size

It is not allowed to stand under hanging loads. Danger to life!

2904.0210

2904.0209

2904.0204

Ø30 mm

Ø50 mm

Ø80 mm

Working with this device is only permitted in proximity to the

ground.

The sucked load must never be lifted more than 1.8 m

(measured from the top edge of the load to the ground).

Swinging the device over persons is prohibited.

2904.0765

100 x70 mm

WARNING SIGN

Symbol

Meaning

Order-No.

Size

Danger of squeezing the hands.

2904.0221

2904.0220

2904.0107

30 x 30 mm

50 x 50 mm

80 x 80 mm

REGULATORY SIGN

Symbol

Meaning

Order-No.

Size

Each operator must have read and understood the operating

instructions (and all safety instructions).

2904.0665

2904.0666

Ø30 mm

Ø50 mm

Loads have to be sucked in centered. With a suitable device (height

adjustable stop) loads can also be sucked in eccentrically.

2904.0744

107 x 32 mm

Safety chains has to fit tightly to the load.

Safety chains should never hang loosely under the load!

2904.0690

2904.0689

2904.0688

25 x 55 mm

70 x 41 mm

146 x 85 mm

OPERATING INFORMATIONS

Symbol

Meaning

Order-No.

Size

Maximum working load limit of the suction plate (VPH-100)

2904.0575

80 x 40 mm

Maximum working load limit of the suction plate (VPH-150)

2904.0207

80 x 35 mm

Label with device title

2904.0129

200 x 50

mm

Page 7

Safety

7 / 24

5271.0008

V1

GB

2.5 Personal safety requirements

Each operator must have read and understood the operating instructions (and all safety instructions).

Only qualified, authorized personal is allowed to operate the device and all devices which are connected

(lifting device/carrier).

The manual guiding is only allowed for devices with handles.

2.6 Protective equipment

The protective equipment must consist, according to the safety regulations

of the following parts:

Protective clothing

Safety gloves

Safety shoes

2.7 Accident prevention

The workplace has to be covered for unauthorized persons, especially children.

Take care in case of thunderstorm!

The workplace has to be sufficiently illuminated.

Take care with handling wet, dirty and not solidified components.

The working with the device in case of atmospheric editions under 3 °C (37,5 °F) is forbidden!

Because the goods could be fall down caused by dampness or freezing.

2.8 Safety at work

2.8.1 General

Working with this device is only permitted in proximity to the ground.

The sucked load must never be lifted more than 1.8 m (measured from the top edge of the load to the

ground). Swinging the device over persons is prohibited. Danger to life!

The manual guiding of is only allowed for devices with handles.

The operator is not allowed to leave the control unit as long as the vacuum lifting device loaded with

load (stone slab). The load must always be in the range of vision of the operator.

Always keep an eye on the vacuum gauge. Never lift loads when the vacuum is below the required under

pressure (mbar). If the pointer of the pressure gauge moves into the red danger zone, lower the load

immediately! Danger! Load could fall down!

Page 8

Safety

8 / 24

5271.0008

V1

GB

While using the vacuum lifting device is the stay of persons in the working area forbidden. Except it is

indispensable. Caused of the way of using the vacuum lifting device , e.g. if the device must be leaded by

hand.

While using the vacuum lifting device be sure that there are no persons in the working area. Danger to

Life!!

The device must never be subjected to a force acting in a lateral direction due to diagonal pulling.

Do not lift any components off-centre, because that could fall down. Danger of tilting!

Release the load only when it is completely safely resting on the surface. Keep fingers away from the

load when you release it as they can be crushed!

The carrying capacity / working load limit (WLL) and the nominal width the vacuum lifting device must

not be exceeded.

Do not pull out stuck or tightened loads with the device.

The jerky raising or lowering of the device with or without load is prohibited!

Unnecessary vibrations must be avoided. Just like driving fast with the carrier/ hoist over uneven terrain!

Danger to life: Load could fall off or load handling equipment could be damaged!

In general, only drive at walking speed with the load lifted!

2.9 Function Control

2.9.1 General

Before using the device check the functions and the working condition.

Maintenance and lubrication are only permitted when device is shut down!

Do not use the device, until all faults which can cause safety hazards are removed.

If there are any cracks, splits or damaged parts on any parts of the device, immediately stop using it.

The operating instructions must be available at the workplace every time.

Do not remove the type plate of the machine.

Unrecognisable information signs (such as regulatory or prohibition signs) must be replaced.

2.9.2 Electric

Check all electric cables for connection

Defective electrical parts may be exchanged only by qualified personnel in the dead condition.

The electric cables must be free of breaks and abrasion. Take care that there are no outstanding

edges, where the hoses could get stuck.

Page 9

General

9 / 24

5271.0008

V1

GB

3 General

3.1 Authorized use

The device “VACUUM-POWER-HANDY VPH” is only for lifting, transporting and installing natural stone and concrete slabs,

large slabs, drain joint stones, steps, as well as tiles in close proximity to the ground. The goods to be lifted must have no

porous surfaces.

The device is equipped with a suspension lug for crane hook.

The stated maximum load can only be achieved with a vacuum of at least 500 mbar!

The device can only be used in a vertical hanging.

Some of the suction plates, which can be attached to the device, reduce its carrying capacity.

The working load limit (WLL) is stated on each suction plate.

Never exceed the working load limit!

Without additional accessoires the device has to pe operated by two persons.

With suitable equipment the device can be operated by one person.

For more information see Chapter “Survey and construction”.

The device is only designed for the use specified in this documentation.

Every other use is not authorized and is forbidden!

All relevant safety regulations, corresponding legal regulations, especially regulations of the declaration

of conformity, and additional local health and safety regulations have to be observed.

Prior to every operation the user must ensure that:

The equipment is suited to the intended operation, the functioning and the working condition of the

equipment is examined, and the load is suitable to be handled.

Any doubts about instructions should be raised with the manufacturer prior to use.

ATTENTION: The use of this device is only permitted in proximity to the ground ( chapter “Safety at

work”)

Page 10

General

10 / 24

5271.0008

V1

GB

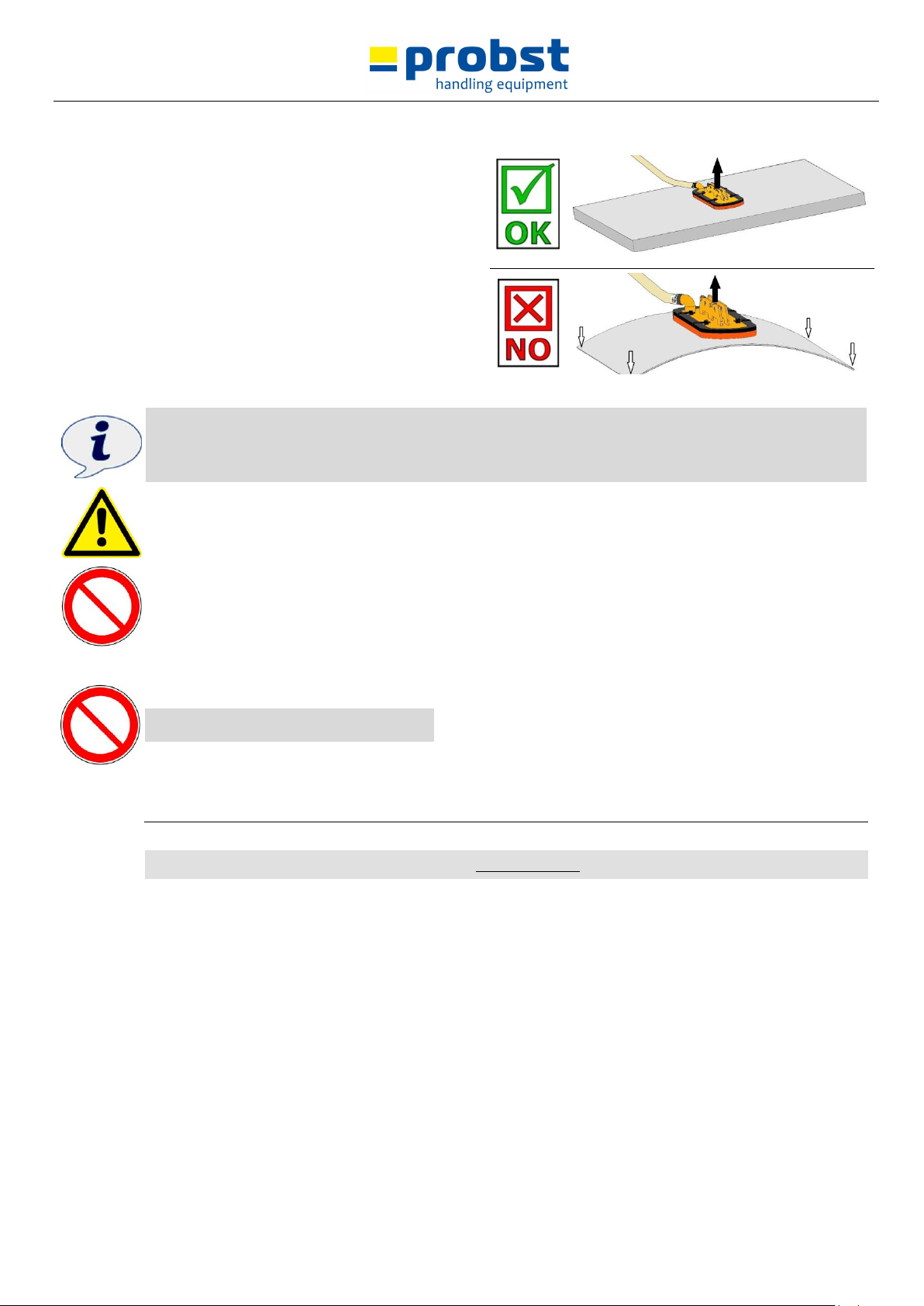

The load (stone slabs) which is to be sucked and

transported, must have sufficient inherent stability,

otherwise there is risk of breakage when lifting!

Stone slabs must not be bend when lifting - especially take

care with thin and large-sized stone slabs!

Generally, the load (stones slab) is only to be sucked in the

middle, otherwise the load hangs diagonally under the

device and the load could break - especially when lifting

large stone slabs with a small suction plate.

Standard suction plates are not suitable for the transport of

glass plates!

Only suction plates of the manufacturer PROBST shall be used!!!

Some suction plates which can be mounted to the device will reduce its carrying capacity.

The maximum load is indicated on each suction plate.

Use only suction plates which are approved for this device!

Do not exceed the maximum carrying capacity of the suction plates!

Danger: Load (stone slabs) will fall down!

NOT ALLOWED ACTIVITIES:

Unauthorized alterations of the device and the use of any self-made additional equipment could cause

danger and are therefore forbidden!

Never exceed the carrying capacity and the nominal width/nominal size of the device.

All unauthorized transportations with the device are not allowed:

Transportation of people and animals.

Transportation of other loads and materials than described in this manual.

Never suspend any goods with ropes, chains or similar at the device.

Page 11

General

11 / 24

5271.0008

V1

GB

3.2 Survey and construction

1

2

3

4

5

8

6

7

10

9

1. Handle

2. Lifting eye

3. Battery-adapter cable with terminals

4. Vacuum pump

5. Pressure gauge

6. Air filter

7. Chain box

8. Suction plate

9. Wheel Set VPH-RS, allow to use the device by one person (optionally)

10. Stop for Wheel Set VPH-RS-AS, for large-size tiles (optionally)

3.3 Technical data

Type

Carying capacity/WLL [kg] valve at 500 mbar under-pressure

Dead weight [kg]

VPH-150

150

19,5

Page 12

Installation

12 / 24

5271.0008

V1

GB

4 Installation

4.1 Mechanical connection

Use only original accessories, in case of doubt consult the manufacturer.

Take care that the carrying capacity / working load limit (WLL) of the lifting device/carrier is not exceeded,

through the load of the device, the attaching devices (turning device, fork sleeves etc.) and the additional

load of the gripping goods!

Mechanical gripping devices always have to be gimballed, so they can swing freely in any position.

In no case it is allowed to mount mechanical gripping devices with lifting devices/carriers in a rigid way!

Break of the suspension may occur within short time. Death, severe injuries and material damage can

result!

4.1.1 Lifting eye / Suspension bolt

The device is equipped with a lifting eye / suspension bolt and can be mounted on various carrier /

lifting devices.

Take care that the lifting eye / suspension bolt is safely joined with the lifting tackle (e.g. crane hook,

belt) and cannot slide down.

4.1.2 Load hook and chains

Fit suspension ring in the load hook of the lifting device/carrier.

Ensure that the single chains strands are not twisted or knotted.

Attaching the device to the lifting device/carrier, take care that all local safety regulation is observed.

4.2 Assembly of the Wheel Set VPH-RS

Page 13

Installation

13 / 24

5271.0008

V1

GB

4.3 Assembly of Stop for Wheel Set VPH-RS-AS

Page 14

Adjustments

14 / 24

5271.0008

V1

GB

5 Adjustments

5.1 Adjustment of VPH and the assembly

Page 15

Operation

15 / 24

5271.0008

V1

GB

6 Operation

6.1 Operating Elements

Main switch –on / off. This is to turn the pump on and off.

Caution! The suction guide line is automatically bled when the VPH is switched off.

For a description of the other elements, please refer to the Appendix: Operating Instructions for the Battery

Diaphragm Pump!

To suction and release the load:

Main Switch ON = suction load, hold

Main switch OFF = release load (remove feet from danger area beforehand!)

6.2 Suction Plate

The suction plate brings the vacuum onto the load. It is used to lift various objects.

Only use suction plates intended for the VPH.

Never exceed the permitted maximum carrying capacity of the suction plate!

6.3 General

Do not let go off the handle of the device VPH whilst a load is being lifted.

Never pull the load diagonally or drag it.

Do not try to free loads which are stuck using the VPH.

If there is a power failure, put down the load straight away if possible. Move away from the danger area

immediately.

Only suction and lift suitable loads (Check for stability and surface density).

Always keep an eye on the pressure gauge. Never lift a load under - 0,5 bar. If the pointer in the pressure

gauge moves into the red zone below - 0,5 bar, put down the load immediately.

Set down the goods on clear, even surfaces only. Otherwise they could slip when released.

Only release the load when it is fully and securely standing or lying down.

Keep your fingers away from the load when relevant it to prevent them from being crushed!

Always load the suction plates evenly.

6.4 Battery

LED-board:

yellow = charged completely

green = normal status

red-green changing = battery low, charge

red = do not use, battery is empty

Page 16

Operation

16 / 24

5271.0008

V1

GB

6.5 Lifting, Transport and Installation (hoist operation)

When using the device in hoist operation the safety chain has to be used in any case!

1. Position the device directly above the load. Avoid pulling it diagonally, make

sure the load is evenly distributed.

2. Place the device onto the load.

3. Switch the device on using the main ON / OFF switch.

4. The load is now sucked.

5. Look at the pressure gauge. As soon as a vacuum of -0.5 bar is reached, you can

lift the load. On no account lift it earlier, as the load would fall off.

When lifting, make sure that only one part at a time is being lifted! Carefully

release any bits left hanging on with a screwdriver before lifting the load any

further.

Do not remove any bits with your hands, risk of crushing!

6. Lift the device with the sucked load a little (approx. 20 cm).

7. Put the safety chain A out of the chain box B (see Ill.)

8. Throw the safety chain under the lifted load.

In doing so never reach you hands under the lifted load! Danger of crushing!

9. Firmly mount the safety chain on the other side of the device in the slot C (see Ill.).

10. Place the end of the safety chain in the chain box B.

The safety chain has to fit tightly on the load, to make sure, that the load will be held by the

safety chain in case of vacuum loss or vacuum failure (e.g. caused by energy failure), (see

Ill.).

The load-securing chain should never hang loosely under the load, otherwise the load

could fall down in case of vacuum loss or vacuum failure (e.g. caused by energy failure),

(see Ill.).

11. Now transport the device with the sucked load to the destination point.

12. Carefully lower the load (approx. 20 cm to the ground), unhook the safety chain and pull it out from under the

load.

In doing so never reach you hands under the lifted load! Danger of crushing!

13. Put the load-securing chain back in the chain box.

14. Lower the load and place it on clear, even surfaces, so that the load does not slip or tip.

15. Switch off the diaphragm pump using the main ON / OFF switch.

Page 17

Operation

17 / 24

5271.0008

V1

GB

Caution! Once the machine is switched off, the suction lead is automatically bled and so the vacuum

disappears. Always keep feet well away from the danger area!

6.6 Lifting, Transport and Installation (manual operation)

1. Position the device directly above the load. Avoid pulling it diagonally, make sure the load is evenly distributed.

2. Place the device onto the load.

3. Switch the device on using the main ON / OFF switch.

4. The load is now sucked.

5. Look at the pressure gauge. As soon as a vacuum of -0.5 bar is reached, you can lift the load. On no account lift it

earlier, as the load would fall off.

When lifting, make sure that only one part at a time is being lifted! Carefully release any bits left hanging on with a

screwdriver before lifting the load any further.

Do not remove any bits with your hands, risk of crushing!

6. Now transport the device with the sucked load to the destination point.

7. Lower the load and place it on clear, even surfaces, so that the load does not slip or tip.

8. Switch off the diaphragm pump using the main ON / OFF switch.

Caution! Once the machine is switched off, the suction lead is automatically bled and so the vacuum

disappears. Always keep feet well away from the danger area!

6.7 Tile laying

Recommended device configuration:

VPH basic device+

VPH-RS wheel set+

VPH-RS-AS, height adjustable stop, to put the tile in different angle positions, tilted to the front.

Example for tile laying

Only with the height adjustable stop VPH-RS-AS loads can be sucked in eccentrically.

Otherwise the load can become detached or break!

Page 18

Maintenance and care

18 / 24

5271.0008

V1

GB

6.8 Damages of suction plate

Avoidance of damages:

To avoid damages of the rubber seal on the suction plate (chinks, abrasion) take notice, that:

during the operation (lifting, transporting and lowering) with the device, the suction plate does not brush or pump

against other products or materials.

Otherwise the rubber seal on the suction plate could be damaged (danger of pressure loss).

Product could fall down. Danger of accidents!

7 Maintenance and care

7.1 Maintenance

To ensure the correct function, safety and service life of the device the following points must be executed in

the maintenance interval.

Used only original spare parts, otherwise the warranty expires.

All operations may only be made in unpressurised, electro less and closed state of the device!

7.1.1 Mechanical

SERVICE INTERVAL

Maintenance work

First inspection after

25 operating hours

Control and tighten all screws and connections.

(The implementation is only allowed by an expert).

All 50 operating hours

Tighten all screws and connections (take care that the tightening torques according to

the property class of the screws are observed).

Check all existing safety elements (such as linchpins) for perfect function and replace

defective safety elements. 1)

Check all joints, bolts, guidance’s and gears for correct function, if necessary adjust or

replace it.

Check all grippers (if available) for signs of wear.

Grease all slidings (if available) when the device is in opened position with a spatula.

Grease all grease nipples (if available) with a grease gun.

Minimum 1x per year

(at rough conditions shorten the

interval)

Check of all the suspension parts, bolts and straps. Check for corrosion and safety by an

expert.

1)

Page 19

Maintenance and care

19 / 24

5271.0008

V1

GB

7.2 Suction plate

Clean the sealing lips with compressed air and/or water jet once per week to remove any objects and dirt

such as sand, stone particles, dust etc. Clean slot in the sealing lip with a cloth and / or blow out with

compressed air.

(If applicable): Clean the groove in the sealing lip with a wipe and/or blow out with compressed air.

Damaged or worn sealing lips (cracks, holes, deformation) must be replaced immediately.

Use only cold solvent for cleaning the device. Do not use benzene or caustic liquids, since these will

damage the hoses.

7.3 Fault finding

Fault

Cause

Remedy

A vacuum of - 0,5 bar cannot be

achieved.

The item to be lifted has splits, recesses

or is porous.

The item is not suitable to be lifted with the

device

The foam rubber is damaged.

Replace the foam rubgber.

The pressure gauge is faulty.

Replace the pressure gauge.

The hose ors screws are leaky.

Replace the relevant parts.

VPH just wont work/ or no

Vacuum available

Battery

Check the battery is fully charged

value

Check the fuse is of the correct value ( 8amp )

and is not blown

seal

Check the seal around baseplate, if possable

remove the seal and clean around the edge of

the plate, and in the groove of the seal, but do

not glue the seal on.

vacuum pipe

Check the fitting that interfaces the vacuum

pipe to the plate and check that it is fully

tightened and has not come loose.

air filter and the fittings

Check the air filter and the fittings such as pipe

clips etc, and make sure they are tightly sealed.

ON / OFF switch

Make absolutely sure that the ON / OFF switch

is working ok.

wires on solinoid valve

Check the wires on the solinoid valve are

connected ok.

short circuit on solinoid

Check the diode on the solinoid ( 1N4001 etc )

has not gone short circuit, you can remove this

completely or just cut it out, Do not replace this

component

pipes to the vacuum pumps

Check all pipes to the vacuum pumps are not

damaged.

foreign bodies

Check that there is a vacuum or pressure on the

pumps and that they have not been damaged

by the ingression of foreign bodies.

Page 20

Maintenance and care

20 / 24

5271.0008

V1

GB

Load cannot be sucked.

Prescribed negative pressure

cannot be achieved no more.

Negative pressure diminishes

itself too fast, when switching

the device off.

Leakage at vacuum plate by deposited

dirt between rubber seal and suction

plate.

Rubber seal wore or porously (aging

after effect of UV radiation)

Remove rubber seal from suction plate.

Clean suction plate and slot in rubber seal.

Draw up and fasten rubber seal on suction plate

again.

If necessary exchange rubber seal.

7.4 Repairs

Only persons with the appropriate knowledge and ability are allowed to repair the device.

Before the device is used again, it has to be checked by an expert.

7.5 Safety procedures

It is the contractor’s responsibility to ensure that the device is checked by an expert in periods of

max. 1 year and all recognized errors are removed ( see BGR 500).

The corresponding legal regulations and the regulations of the declaration of conformity have to be

observed!

We recommend that after checking the device, the badge “Safety checked” is put on the device.

(Order-No.: 2904.0056+inspection sticker with date).

You can receive these badges from us.

The check by an expert must be proved!

Device

Year

Date

Expert

Company

Page 21

Maintenance and care

21 / 24

5271.0008

V1

GB

7.6 Hints to the type plate

Type, serial-number and production year are very important for the identification of your device. If you need

information to spare-parts, warranty or other specific details please refer to this information.

The maximum carrying capacity/working load limit (WLL) is the maximum load which can be handled with

the device. Do not exceed this carrying capacity/working load limit (WLL).

If you use the device in combination with other lifting equipment (Crane, chain hoist, forklift truck,

excavator) consider the deadweight of the device.

Example:

7.7 Hints to the renting/leasing of PROBST devices

With every renting/leasing of PROBST devices the original operating instructions must be included

unconditionally (in deviation of the users country's language, the respective translations of the original

operating instructions must be delivered additionally)!

Page 22

Vacuum pump

22 / 24

5271.0008

V1

GB

8 Vacuum pump

8.1 General

This vacuum pump is equipped with a rechargeable 12 Volt 6.5 Ah lead battery, and the pump is powered by an in-built lead

battery.

The recharging control system lets you see how charged up the battery is.

8.2 Safety Advice

The voltage must comply with that stated on the vacuum pump data plate. The pump must only be powered by a 12

Volt direct current.

Before working on the pump, including changing the supply hose, remove the plug from the socket.

The lead wires have to be in perfect condition. Any damaged parts have to be replaced immediately.

Only use original spare parts.

Do not plug in the pump to the mains if it is raining or damp.

When opening covers or removing parts, except for when this can be done by hand, live parts can be exposed.

Connections can also be live.

Before carrying out any maintenance work, repairs or replacing any parts, the pump must be disconnected from all

power sources if it needs to be opened.

Do not use the pump in rooms or in surroundings in which gases, fumes or dust are present or could be present.

Protect the device for wetness and dampness.

Do not use the pump if safe working conditions cannot be guaranteed. It would not be safe to continue if:

The pump is clearly damaged.

The pump no longer works.

It has been stopped for a long period or in unfavourable conditions.

It is damaged during transportation.

Never switch the pump on straight away if it is brought in from a cold room to a warm one.

The condensation could damage your pump. Let it come to room temperature without switching it on.

8.3 Description

The pump consist of the following parts:

Robust aluminium casing with a mounting to fix it onto the Probst stand.

Two 12 Volt diaphragm pumps.

Main switch – on / off function – using the main switch you can switch the pump on or off. By switching it off, the

suction lead is automatically ventilated.

Fuse holder with fine wire fuse.

The Vacuum pump is fitted with a charging control system. 3 LEDs show you how charged the battery is.

Page 23

Vacuum pump

23 / 24

5271.0008

V1

GB

Yellow LED above 14.5 Volt Voltage- Battery is overcharged

Green LED 11.5 – 14.5 Volt Voltage- Normal

Red LED under 11.5 Volt Voltage Battery needs charging

On the underpart of the pump you will find a socket. You can charge up the battery in this socket without having it

dismantled.

On the underpart of the pump you will also find a connection for the suction hose. When the suction hose and the filter

are inserted, the other end of the hose is attached to the suction plate.

On the filter element there is an arrow which indicates the air current. Please make sure that the air current is pointing

towards the vacuum pump.

8.3.1 Charge battery

To ensure the perfect working of the pump, it is important that the lead rechargeable battery is always charged up.

To charge the battery:

Proceed as follows:

Set the main switch to 0.

Remove the lead hoses (suction hose)

Insert the battery charger on the underside into the in-built socket.

Plug the battery charger into the 220 Volt mains.

Once the battery has been successfully charged, disconnect the battery charger.

Put the connection hoses in and switch on the pump at the main switch.

(if everything is okay, the green LED will light up on the charging control panel).

As soon as the in-built battery falls under 11.5 Volt, the red LED will light up. The battery will then need recharging.

When you have finished, switch off the machine and remove the hoses (in compliance with all regulations).

8.4 Maintenance

The pump is basically maintenance-free.

All necessary spare parts are available for the vacuum pump.

Repaires should be only carried out by authorized experts.

Disconnect from the mains before starting any repairs.

The diaphragms are the parts which will wear out first. When replacing the diaphragms, the valves and the seals should

also be replaced.

As and when required, it would pay to use suitable filters in order to improve the life of the pump considerably.

MAKE SURE THAT THE BATTERY IS NEVER TOTALLY FLAT.

REMEMBER THAT WHEN THE MACHINE IS NOT IN USE, THE BATTERY WILL STILL BE GOING FLAT.

MAKE SURE THAT NO LIQUIDS OR SOLIDS GET INTO THE PUMP.

Page 24

Vacuum pump

24 / 24

5271.0008

V1

GB

8.5 Technical Data

Pump / Solenoid Valve

Type of Pump

7012 V (2)

Line Voltage

12 Volt DC

Power Inut

1.4 A

Conveying Caacity

18 NL/min.

Final Vacuum Minimum

70 %

2/2 Way Solenoid Valve

12V 6.5 Watt Solenoid

Part / Device

Diaphragm

NBR Perbunan

Valves

Neopren

Pump Casing

Glass-fibre reinforced polyamide

Solenoid Valve Casing

Brass

Hoses (internal)

Silicone

Hoses (external)

PVC fabric hose

Lead Battery

Type

12V6,5Ah

Charging Voltage Float in V/Cell

2.3-2.35

Charging Load Cycles in V/Cell

2.4-2.45

Transport

decree road GGVS – no.

decree railway GGVE – no.

Page 25

8

7

6

5

4

3

2

1

Akku-Adapterkabel lose

loose battery adapter cable

F

F

580

E

E

D

C

248

443

D

C

145

574

Tragfähigkeit / Working Load Limit WLL:

150

kg /

330

lbs

B

B

Eigengewicht / Dead Weight:

19,7

kg /

43,5

lbs

1427 / 1565 / 1710

Product Name:

VACUUM-POWER-HANDY VPH-150

© all rights reserved conform to ISO 16016

A

Datum

Erst.

Gepr.

Urspr.

26.4.2018

26.4.2018

Zust.

8

7

6

5

4

3

Name

M.Wunder

M.Wunder

2

Benennung

Vakuum-Power-Handy VPH 150

2-Mann-Bedienung

Artikelnummer/Zeichnungsnummer

D52710008

Ers. f.

Ers. d.

1

Blatt

1

von

A

1

Page 26

8

7

6

5

4

3

2

1

F

F

20540040

24100076

21600016

E

E

D

C

31600005

42710098

siehe separate Liste

see separate list

D

C

A

42710001

B

B

20540040

21050020

© all rights reserved conform to ISO 16016

42700050

siehe separate Liste

see separate list

8

7

6

5

4

3

Zust.

Erst.

Gepr.

Urspr.

Datum

26.4.2018

26.4.2018

Name

M.Wunder

M.Wunder

2

Benennung

Vakuum-Power-Handy VPH 150

2-Mann-Bedienung

Artikelnummer/Zeichnungsnummer

E52710008

Ers. f.

Ers. d.

1

Blatt

1

von

A

1

Page 27

8

7

6

5

4

3

2

1

F

F

25290008

E

E

D

C

42700070

D

C

42730012

A

B

B

© all rights reserved conform to ISO 16016

Datum

Erst.

Gepr.

Urspr.

15.7.2015

15.7.2015

Zust.

8

7

6

5

4

Name

M.Wunder

M.Wunder

Benennung

Saugplatte SPSHP 150-44/25 VPH

mit HP-Dichtung

Artikelnummer/Zeichnungsnummer

E42700050

Ers. f.

Ers. d.

Blatt

1

von

1

Page 28

8

7

6

5

4

3

2

1

21000261

F

20000248

20000248

F

20100014

E

33503991

E

D

C

20100016

33503990

D

20100016

C

33503991

A

20000126

B

Bei Änderungen Rücksprache TB !

Gewicht:

Schutzvermerk nach DIN 34 beachten!

Nachdruck nur mit unserer Genehmigung!

Datum

Erst.

Gepr.

WA:

Kunde:

Urspr.

4.6.2012

26.4.2018

8

7

6

5

4

Zust.

Name

Michael.Wunder

M.Wunder

Benennung

Kettenspeicher für VPH / MJ II

Artikelnummer/Zeichnungsnummer

E42710098

Ers. f.

Ers. d.

3,2 kg

Blatt

1

von

B

1

Page 29

8

7

6

5

4

3

2

1

F

E

F

E

940,47

D

C

50

50

50

50

50

567,53

100

300

D

50

167,5

C

886,5

718,5 717,5

1436

Tragfähigkeit / Working Load Limit WLL:

150

kg /

330

lbs

B

B

Eigengewicht / Dead Weight:

376

7,6

kg /

17

lbs

Product Name:

Wheel Set VPH-RS

© all rights reserved conform to ISO 16016

A

Datum

Erst.

Gepr.

Urspr.

15.11.2013

21.5.2015

4

3

2

1

Zust.

8

7

6

5

4

3

Name

Michael.Wunder

M.Wunder

2

Benennung

VPH-Mobil, Radsatz für VPH,

TK 150 kg

Artikelnummer/Zeichnungsnummer

D42710072

Ers. f.

Ers. d.

1

Blatt

1

von

A

1

Page 30

8

7

6

5

4

3

2

1

21070146

F

F

33506086

D

E

E

D

C

20400002

20000011

20100015

C

20400002

42710156

B

33506085

B

20540024

A

20400002

20000010

20100015

© all rights reserved conform to ISO 16016

20400002

Zust.

8

7

6

5

4

3

Erst.

Gepr.

Urspr.

Datum

16.5.2018

17.5.2018

Name

M.Wunder

M.Wunder

2

Benennung

Anschlag für Radsatz VPH

VPH-RS-AS

Artikelnummer/Zeichnungsnummer

E42710154

Ers. f.

Ers. d.

1

Blatt

1

von

A

1

Page 31

AS52710008 VPH-150

AS52710009 VPH-100

Für Kunde und Service, A-Zng für Montage siehe

A52710008

29040665

29040056

29040209

29040129

Auf beiden Seiten / on both sides

29040744

29040221

VPH-150 | 52710008:

29040207

29040690

Auf beiden Seiten /

On both sides

P 22.06.2018_V0

Einige der Abbildungen sind möglicherweise optionales Zubehör des Gerätes/Some of pictures may be optional equipment of the device.

VPH-100 | 52710009:

29040575

1 / 1

Page 32

Proof of maintenance

Warranty claim for this machine only apply for performance of the mandatory maintenance works (by an

authorised specialist workshop)! After each completed performance of a maintenance interval the

included form must be fill out, stamped, signed and send back to us immediately

1)

.

1) via e-mail to service@probst-handling.de / via fax or post

Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device type: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Article -No.: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device-No.: _ _ _ _ _ _ _ _ _ _ _ _

First inspection after 25 operating hours

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

All 50 operating hours

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Minimum 1x per year

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Year of make: _ _ _ _

Loading...

Loading...