Page 1

53100338

V4

GB

Operating Instructions

Translation of original operating instructions

Concrete Step Handles

TSZ-UNI

Page 2

Operating Instructions

TSZ-UNI

Contents

2 / 22

V4

DE

1 Contents

1 Contents .................................................................................................................................. 2

2 EC-Declaration of Conformity ...................................................................................................... 4

3 Safety...................................................................................................................................... 5

3.1 Safety symbols ........................................................................................................................ 5

3.2 Explanation of basic concepts .................................................................................................... 5

3.3 Definition skilled worker / specialist ............................................................................................ 5

3.4 Safety Marking ........................................................................................................................ 6

3.5 Personal safety requirements .................................................................................................... 7

3.1 Protective equipment .............................................................................................................. 7

3.2 Accident prevention ................................................................................................................. 7

3.3 Function Control ...................................................................................................................... 7

3.3.1 General ................................................................................................................................ 7

3.4 Safety procedures .................................................................................................................... 8

3.4.1 General ................................................................................................................................ 8

3.5 Hydraulic excavator and other lifting equipments ......................................................................... 8

4 General .................................................................................................................................... 9

4.1 Authorized use ........................................................................................................................ 9

4.2 Survey and construction .......................................................................................................... 11

1.1 Technical Data ...................................................................................................................... 11

5 Installation ............................................................................................................................. 12

1.2 Mechanical connection ........................................................................................................... 12

5.1.1 Suspension lug....................................................................................................................... 12

5.1.2 Load hook and chains ........................................................................................................... 12

6 Adjustments ........................................................................................................................... 12

6.1 Adjustment - gripping range .................................................................................................... 12

6.1.1 Accessories – height adjustable support .................................................................................. 13

7 Operation .............................................................................................................................. 15

7.1 Operating for devices with automatic release ............................................................................ 15

7.2 Picture of the automatic release ............................................................................................... 15

7.3 Gripper change (steelfinger grippers TSZ-UNI-WB-SQ) ................................................................. 16

7.4 Handling with steelfinger grippers (WB-SQ) ............................................................................... 17

Page 3

Operating Instructions

TSZ-UNI

Contents

3 / 22

V4

GB

8 Maintenance and care .............................................................................................................. 19

8.1 Maintenance ......................................................................................................................... 19

8.2 MECHNICAL .......................................................................................................................... 19

8.2.1 Additional with steelfinger grippers (WB-SQ) .......................................................................... 20

8.3 Trouble shooting .................................................................................................................... 20

8.4 Repairs ................................................................................................................................. 21

8.5 Safety procedures .................................................................................................................. 21

8.6 Hints to the identification plate .............................................................................................. 22

8.7 Hints to the renting/leasing of PROBST devices ....................................................................... 22

Page 4

Operating Instructions

TSZ-UNI

EC-Declaration of Conformity

4 / 22

V4

GB

2 EC-Declaration of Conformity

EC-Declaration of conformity

Description:

Type:

Order-Nr.:

Concrete Step Handles

TSZ-UNI

53100338

Manufacturer:

Probst GreiftechnikVerlegesysteme GmbH

Gottlieb-Daimler-Strasse 6

D-71729 Erdmannhausen

info@probst.eu www.probst.eu

Complies with the following provisions applying to it

EC-machinery directive 2006/42/EG

Based on the following harmonized standards (in excerpts):

DIN EN ISO 12100

Safety of machinery - General principles for design - Risk assessment and risk reduction (ISO 12100:2010)

DIN EN ISO 13857

Safety of machinery ― Safety distances to prevent hazard zones being reached by upper and lower limbs (ISO

13857:2008)

DIN EN 349

Minimum distance to avoid squeezing any parts of the body (ISO 13854).

Authorized person for EC-dokumentation:

Name: J. Holderied

Address: Probst GreiftechnikVerlegesysteme GmbH; Gottlieb-Daimler-Str. 6; D-71729 Erdmannhausen

Signature, informations to the subscriber:

Erdmannhausen, 14.01.2015..........................................................................

(M. Probst, Managing director)

Page 5

Operating Instructions

TSZ-UNI

Safety

5 / 22

V4

GB

3 Safety

3.1 Safety symbols

Danger to life!

Identifies imminent hazard. If you do not avoid the hazard, death or severe injury will result.

Hazardous situation!

Identifies a potentially hazardous situation. If you do not avoid the situation, injury or damage to property can

result.

Prohibition!

Identifies imminent a prohibition. If you do not avoid the prohibition, death and severe injury, or damage to

property will result.

3.2 Explanation of basic concepts

Gripping range:

● specify the minimum and maximum product measurements of the gripping good, which can

be gripped with this device.

Gripping good (s):

● is the product, which will be gripped or transported.

Opening width:

● consists of the gripping range and the measure to drive over the gripping good.

gripping range + measure to drive over the gripping good = opening width

Immersion depth:

● is the maximum gripping height of gripping goods, conditional of the height of the gripping

arms of the device.

Device:

● is the description for the gripping device.

Product dimensions:

● Are the dimensions of the gripping good (e.g. length, breadth, height

of the product).

Dead weight:

● is the own weight (without gripping good) of the device.

Load capacity:

● specify the maximum possible load of the device (lifting of gripping goods).

3.3 Definition skilled worker / specialist

Only skilled workers or specialists is it allowed to carry out the installation,- maintenance, - and repair work on these

device!

Skilled workers or specialists must have for the following points (if it applies for

these device), the necessary professional knowledge.

● for mechanic

● for hydraulics

● for pneumatics

● for electrics

Page 6

Operating Instructions

TSZ-UNI

Safety

6 / 22

V4

GB

3.4 Safety Marking

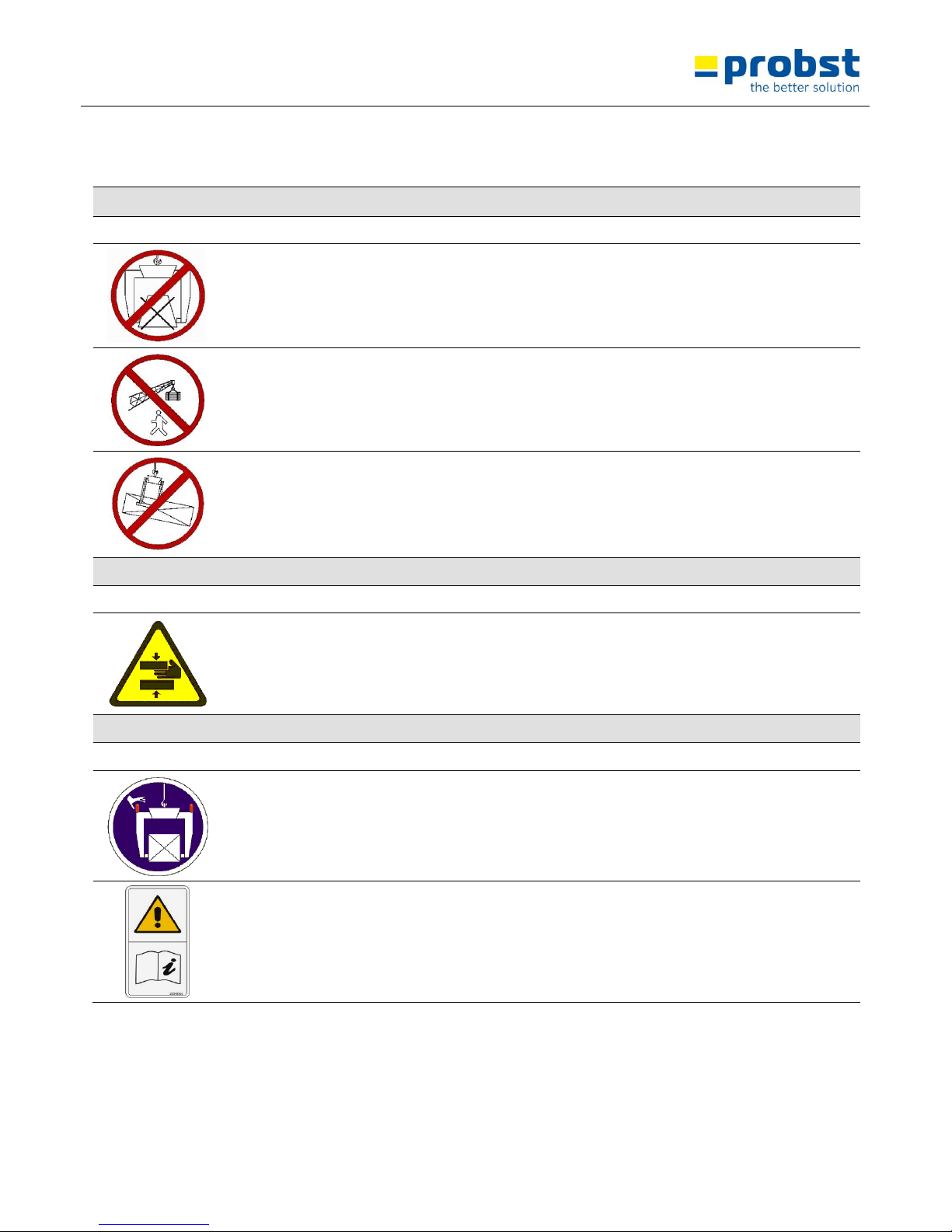

PROHIBITION SIGN

Symbol

Meaning

Order-No.:

Size:

The transportation of non rectangular goods is not allowed!

2904.0213

2904.0212

2904.0211

30 mm

50 mm

80 mm

It is not allowed to be under hanging loads. Danger to life!

2904.0210

2904.0209

2904.0204

30 mm

50 mm

80 mm

Do not lift any components off-centre.

2904.0216

2904.0215

2904.0214

30 mm

50 mm

80 mm

WARNING SIGN

Symbol

Meaning

Order-No.:

Size:

Danger of squeezing the hands.

2904.0221

2904.0220

2904.0107

30 mm

50 mm

80 mm

REGULATORY SIGN

Symbol

Meaning

Order-No.:

Size:

Manual guiding is only allowed for machines with handles.

2904.0227

2904.0226

2904.0225

30 mm

50 mm

80 mm

Read operating instructions before operating.

2904.0366

2904.0365

30x57 mm

50x95 mm

Page 7

Operating Instructions

TSZ-UNI

Safety

7 / 22

V4

GB

3.5 Personal safety requirements

● Each operator must have read and understood the operating instructions.

● Only qualified, authorized personal is allowed to operate the device and all devices which are connected

(lifting equipment).

● The manual guiding is only allowed for machines with handles.

3.1 Protective equipment

The protective equipment must consist, according to the safety regulations of

the following parts:

● Protective clothing

● Safety gloves

● Safety shoes

3.2 Accident prevention

● The workplace has to be covered for unauthorized persons, especially children.

● Take care in case of thunderstorm!

● The workplace has to be sufficiently illuminated.

● Take care with handling wet, dirty and not solidified components.

● The working with the device in case of atmospheric editions under 3° C (37,5° F) is forbidden!

Because the goods could be fall down caused by dampness or freezing.

3.3 Function Control

3.3.1 General

● Before using the device check the functions and the working condition.

● Maintenance and lubrication are only permitted when device is shut down!

● Do not use the device, until all faults which can cause safety hazards are removed.

● If there are any cracks, splits or damaged parts on any parts of the device, immediately stop using it.

● The operating instructions must be available at the workplace every time.

● Do not remove the data-plates of the machine.

● Unrecognisable information signs must be replaced.

Page 8

Operating Instructions

TSZ-UNI

Safety

8 / 22

V4

GB

3.4 Safety procedures

3.4.1 General

● The use of the device is only permitted in proximity to the ground. Do not swing it over peoples heads.

● The manual guiding of is only allowed for devices with handles.

● The operator is not allowed to leave the control unit as long as the device loaded with load. The load must

always be in the range of vision of the operator.

● While using the device is the stay of persons in the working area forbidden. Except it is indispensable. Caused

of the way of using the device, e.g. if the device must be leaded by hand.

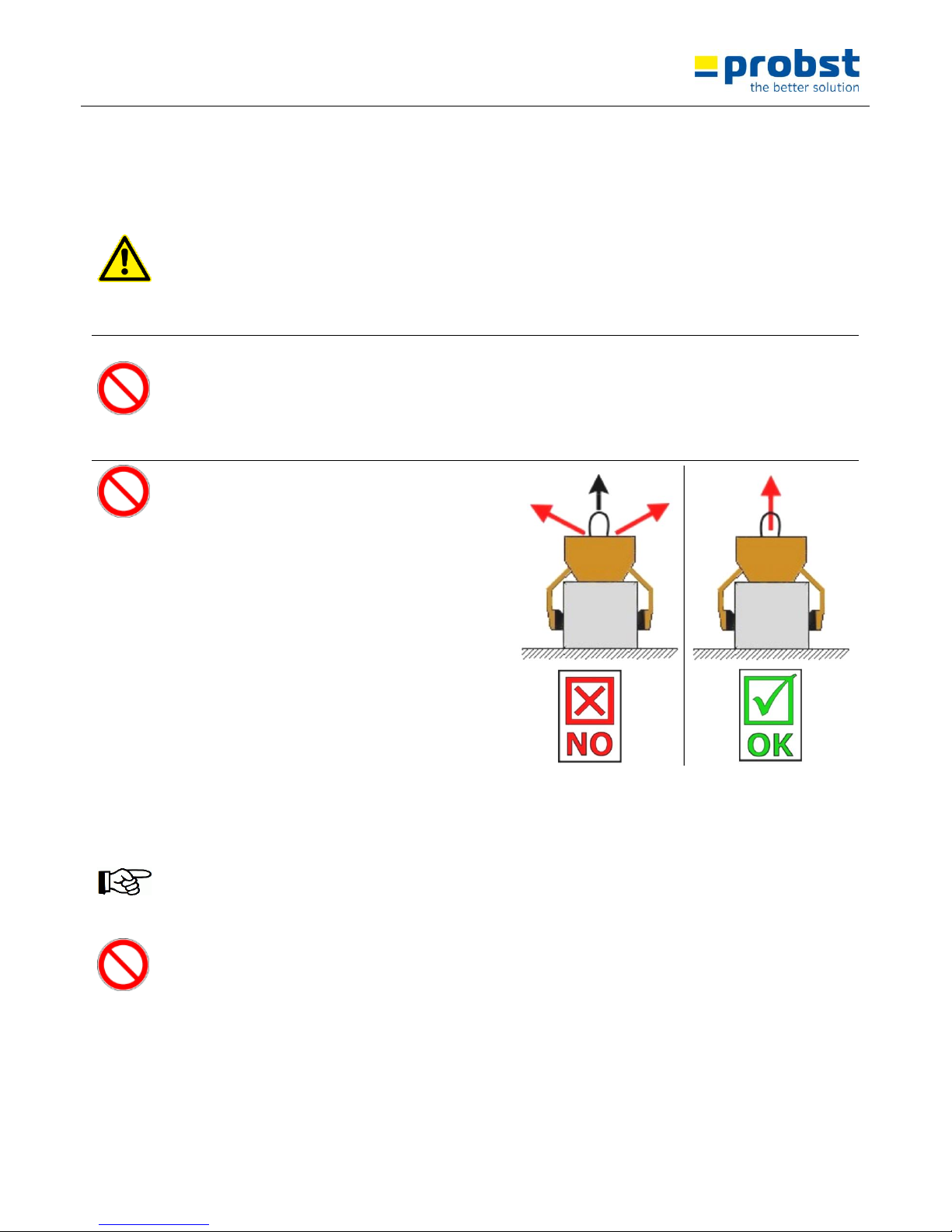

● The jerky lifting and lowering of the device with and without load. e.g. caused through driving fast with the

support frame/lifting device over uneven grounds is forbidden. Because the gripping good could fall down.

Unchecked movements of the device.

● While using the device be sure that there are no

persons in the working area. Danger to Life!

● Do not pull out stuck or tightened loads with the

device.

● Do not lift any components off-centre, because

that could fall down.

● The device should not be opened if the opening

path of the gripping arm is blocked by a resistance

(e.g. other concrete blocks or the like)!

● Never exceed the carrying capacity and the

nominal width of the device.

● Never pull or drag loads sideways. Otherwise parts

of the device could be damaged.

(see Fig. A )

Fig. A

3.5 Hydraulic excavator and other lifting equipments

● Hydraulic excavator and other lifting equipments have to be in good, safe working condition.

● Only authorized and qualified personnel is allowed to operate the excavator and other lifting equipments.

● The operator staff must have all the necessary qualifications.

● Never exceed the maximum capacity of the hydraulic excavator and other lifting equipments.

Page 9

Operating Instructions

TSZ-UNI

General

9 / 22

V4

GB

4 General

4.1 Authorized use

The device (TSZ-uni) is specially designed for gripping, transporting and the following laying of gripping goods

such as, steps, kerb stones, contact angle, L-stones, as well ashlar rocks (via the assembly of the accessories

“steelfinger grippers WB-SQ”) in conjunction with a corresponding lifting device (e.g. excavator).

This device is series-produced equipped with the following elements:

suspension lug for the crane hook (lifting equipment operation)

handles for the guidance of the device

automatic release for the fully automatic switch over from „full“ to “empty” .

exchangeable rubber bars (as gripping elements)

Accessories:

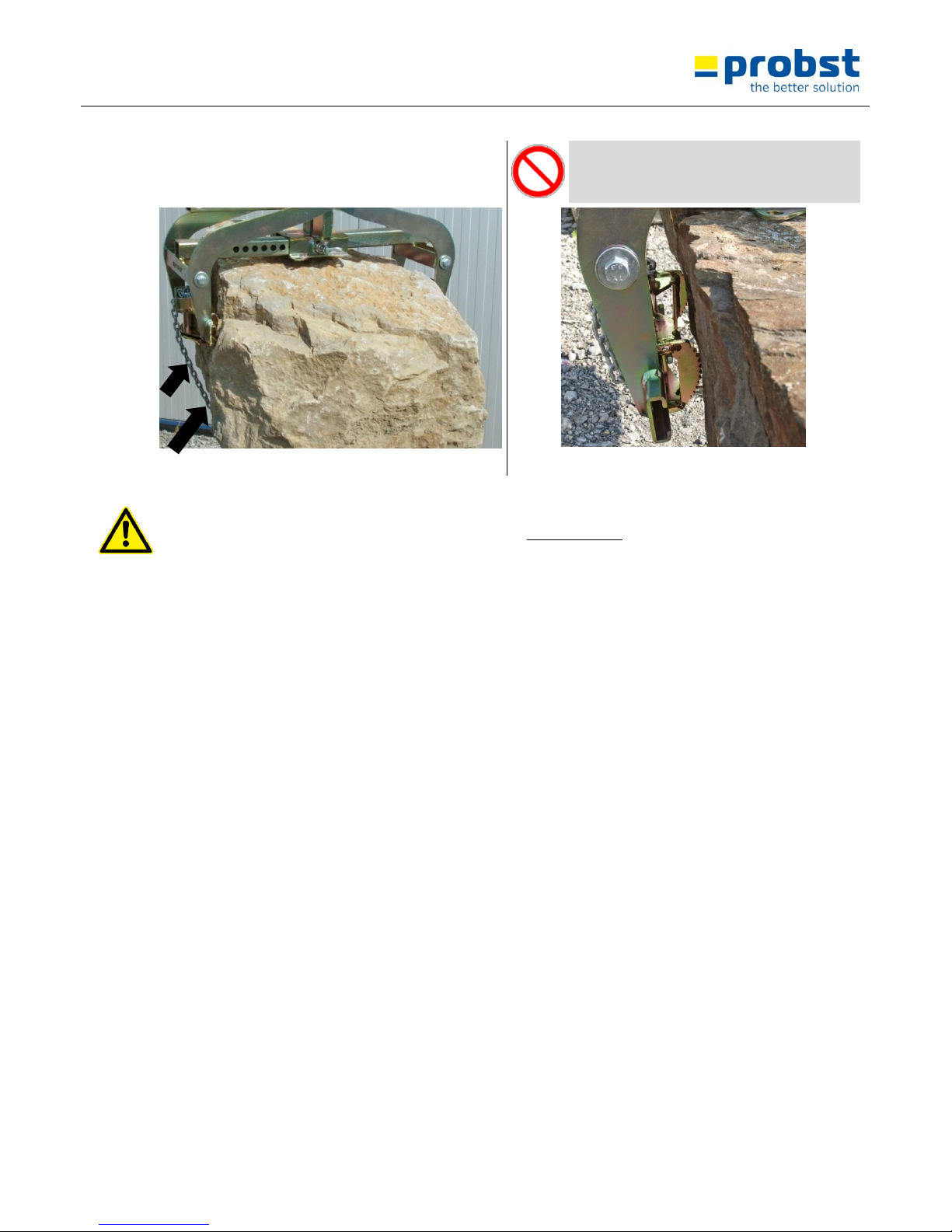

● steelfinger grippers WB-SQ (43101110) for movements of roughly-cut ashlar rocks .

● Height adjustable support (for gripping in batch operation)

● The device is only designed for the use specified in this documentation.

● Every other use is not authorized and is forbidden!

● All relevant safety regulations, corresponding legal regulations, especially regulations of the declaration of

conformity, and additional local health and safety regulations have to be observed.

Prior to every operation the user must ensure that:

● the equipment is suited to the intended operation, the functioning and the working condition of the

equipment is examined, and the loads are suitable to be handled.

Any doubts about instructions should be raised with the manufacturer prior to use.

ATTENTION: The use of this device is only permitted in proximity to the ground.

Page 10

Operating Instructions

TSZ-UNI

General

10 / 22

V4

GB

Only stone elements with parallel and plane surface are allowed to be picked-up and handled.

Because the gripping good could fall down.

NOT ALLOWED AKTIVITIES:

Unauthorized alterations of the device and the use of any self-made additional equipment

could cause danger and are therefore forbidden!!

Never exceed the carrying capacity and the nominal width/gripping range of the device.

All unauthorized transportations with the device are not allowed:

● Transportation of people and animals.

● Transportation of other loads and materials than described in this

manual.

● Never suspend any goods with ropes, chains or similar at the device.

● Transportation of non rectangular and round gripping goods, because

they could fall down. (see figure to the right).

● Gripping of gripping goods with packaging foil, because they could fall

down.

● Transportation of material with “feet”, “bellies” and “blind spacers”.

Page 11

Operating Instructions

TSZ-UNI

General

11 / 22

V4

GB

4.2 Survey and construction

Fig.1

1

Suspension lug

2

Handles

3

Adjustment of gripping

range

4

Assembly plate for height

adjustable support

(43100867)

5

Spring bolt (for gripping

range adjustment)

6

Rubber gripper bar (PGL3)

7

Automatic release

TSZ-uni (standard)

Fig. 2

TSZ-uni (with accessories A 43100867 )

Fig. 3

A

Height adjustable support

(43100867)

1.1 Technical Data

Type:

Gripping range W

Inside height E

Carrying capacity

Gripper lenght L

Dead weight

TSZ-uni

50 – 600 mm

(2- 23½")

185 mm

(7¼")

600 kg

(1.320 lbs)

350 mm

(13¾")

~ 30 kg

(~ 64 lbs)

Page 12

Operating Instructions

TSZ-UNI

Installation

12 / 22

V4

GB

5 Installation

1.2 Mechanical connection

5.1.1 Suspension lug

● The device is equipped with a suspension lug and can be mounted on various support frames/lifting devices.

● Take careful that the suspension lug is safety joined with the crane hook and can not slip down.

● The maximum carrying capacity of the support frame/lifting device is not allowed to cross over by the

dead weight of the device and the maximum load.

5.1.2 Load hook and chains

● Fit suspension ring in the load hook of the lifting equipment.

● Ensure that the single chains are not twisted and may be easily pulled through the jaws

● Attaching the device to the lifting equipment take care that all local safety regulation is observed.

● It is not allowed to exceed the carrying capacity of the lifting equipment with the device and the maximum

load.

6 Adjustments

6.1 Adjustment - gripping range

Before the product can be lifted and transported, the gripping range has to be adjusted to the dimensions of

the product.

● Caution while adjusting of the gripping range. There is danger of injuring the hands!

● The adjustment of the gripping range may never take place on both sides at the same time.

Always adjust the gripping range first to the one and then on the other side.

● Pull the spring bolt (5) upwards, rotate around 180° and lock in position (in nick).

● Move the rectangular tube (3), until the gripping range is approx. 5 cm larger than the gripping good.

● Pull the spring bolt (5) upwards again and rotate around 180°.

● Move the rectangular tube (3) so long, until the spring bolt engages in one of the holes.

● The adjustment of the gripping range has to follow general symmetrical.

That means, it must be used in each case the same adjustable hole with both rectangular tubes (3).

Page 13

Operating Instructions

TSZ-UNI

Adjustments

13 / 22

V4

GB

● When gripping L-stones, the gripping range must be adjust asymmetrical (because of the center of gravity of

the L-stone, so that when lifting, the L-stone is in horizontal position).

That means, it must NOT be used the same adjustable hole with both rectangular tubes (3) (a asymmetrical

positioning of the adjustable holes up to 2 holes is allowed).

Fig. 1

3

Adjustment positions at the adjustable

hole in both rectangular tubes

4

Height adjustable support

5

Spring bolt

6.1.1 Accessories – height adjustable support

When using the device (TSZ-uni) in batch operation, for gripping of single stone slabs (batched one upon the

other), we advise to use the accessories “height adjustable support” (43100867)! – see Fig. 1

Therefore, the inside height must not always adjusted again for gripping goods with the same dimensions (see

Figure 1). When picking up in batch operation the top stone slab may only be lifted!

● Caution while adjusting of the gripping range. There is danger of injuring the hands!

Page 14

Operating Instructions

TSZ-UNI

Adjustments

14 / 22

V4

GB

● The “height adjustable support (A) is attached to the “mounting plate of the height adjustable support”

see Fig. 2 (and Fig. 3)

● Adjust the “height adjustable support (A) with the adjusting screws and regard the both “height adjustable

supports (A)” have the same height and that the rubber gripper bars are positioned in the middle area of

stone thickness. see Fig. 1

Fig. 1

Fig. 2

Fig. 3

3

Adjustment positions at the adjustable

hole in both rectangular tubes

4

Height adjustable support

5

Spring bolt

Page 15

Operating Instructions

TSZ-UNI

Operation

15 / 22

V4

GB

7 Operation

7.1 Operating for devices with automatic release

● The device is connected to the lifting equipment/support frame (e.g. excavator).

● Before lifting the device, the gripping range has to be adjusted.

● The device is placed over the product, set down, the device closes round the product and it can be lifted.

● Set down on the ground again, the device opens automatically, the automatic release locks it into position so that the

device can be lifted without closing up.

● Placed over the next product, the automatic release disengages itself and the product can be lifted.

● The device therefore is a ONE-MAN-MACHINE.

Shut-down the device without lifting equipment/support frame only on even ground. The gripping arms must

be opened enough, to ensure a secure standing of the device.

Otherwise exists danger of overturning!

7.2 Picture of the automatic release

The device is mounted with a automatic release, that means the opening and closing of the gripping arms results through

the set down and lifting of the device.

Pictures the positions of the automatic release

● Device is lifted through the support

frame.

● Gripping arms are opened.

● Device is set up on the gripping

good.

● Gripping arms are opened.

● Device is lifted through the support

frame.

● Gripping good is clamped and can

be transported to the destination.

/

● Device is set down with the

gripping good (on the ground).

● Gripping arms are opened.

● Device is lifted through the support

frame.

● Gripping arms are opened.

(laydown position of the device on

the ground)

Page 16

Operating Instructions

TSZ-UNI

Operation

16 / 22

V4

GB

7.3 Gripper change (steelfinger grippers TSZ-UNI-WB-SQ)

For movements of roughly-cut ashlar rocks with the device (TSZ-uni) change the standard rubber grippers

(Figure A) againt stellfinger grippers (Figure B)

1.) Unscrew both standard rubber grippers and then

pull them out of the holders (Figure A)

2.) Figure B showws the device (TSZ-uni)

without rubber grippers.

Figure A

Figure B

3.) The steelfinger grippers must be installed as shown in Figure C. Take notice, that "Part 1" (with chain box)

may be mounted only on the left side of the device, thus at the "wide external gripper arm"!

Figure D

Part 1

Part 2

External gripping

arm

Page 17

Operating Instructions

TSZ-UNI

Operation

17 / 22

V4

GB

7.4 Handling with steelfinger grippers (WB-SQ)

Before each use of the device, check the steelfinger grippers for mobility, abrasion and contamination

Worn (no longer sharp-edged) or bent steelfinger grippers must be replaced! Otherwise it exists slipping danger

of the gripping good!

1.) Position the device (TSZ-uni) direct over the gripping

good (ashlar rock).

2.) Put the device (TSZ-uni) at the gripping good (ashlar

rock). Then lift the device (TSZ-uni) approx. 20 cm

(7.8").

3.) Remove the safety chain from the chain box and

throw it under the lifted gripping good (ashlar rock)

see Figure A

4.) Suspend the security chain on the other side of the

device (at the hook ). see Figure B

Never grip with the hands under the gripping good (ashlar rock) – danger of squeezing the hands!

Figure A

Figure B

Page 18

Operating Instructions

TSZ-UNI

Operation

18 / 22

V4

GB

5.) The safety chain must fit tightly (and centric) to the

gripping good (ashlar rock), so that gripping good with

is secured by the security chain! see Figure C

The safety chain must never be used as a

"lifting tackle" to attach the device (TSZ-uni)

on the support frame (e.g. excavators)!

Figure C

Figure D

Before lifting the gripping good (ashlar rock) be sure that the steelfinger grippers do have a good hold/grip and

that the load is distributed evenly, otherwise there is a high risk of accident!

Touch/guide the device (ZSZ-uni) only on the handles and put the feet out of the danger zone.

Page 19

Operating Instructions

TSZ-UNI

Maintenance and care

19 / 22

V4

GB

8 Maintenance and care

8.1 Maintenance

To ensure the correct function, safety and service life of the device the following points must be executed in

the maintenance interval.

Used only original spare parts, otherwise the warranty expires.

All operations may only be made in closed state of the device!

8.2 MECHNICAL

SERVICE INTERVAL

Maintenance work

First inspection after

25 operating hours

● Control and tighten all screws and connections.

(The implementation is only allowed by an expert).

All 50 operating hours

● Tighten all screws and connections (take care that the tightening torques according

to the property class of the screws are observed).

● Check all joints, bolts, guidance’s and gears for correct function, if necessary adjust or

replace it.

● Check all Grippers (if available) for signs of wear.

● Grease all slidings (if available) when the device is in opened position with a spatula.

● Grease all grease nipples (if available) with a grease gun.

Minimum 1x per year

(at rough conditions shorten

the interval)

● Check of all the suspension parts, bolts and straps. Check for corrosion and safety by

an expert.

Rubber gripper bar

Regular control for dirt (e.g. little stone particles) in the upper area (see points in figure detail „X“ in Fig. 2) of

the rubber gripper bar (6) see Fig. 1 / Fig. 2

Problem: Dirt can damage the rubber gripper bar (6) when gripping (when little stone particles are pressed into

the rubber gripper bar).

Redress: Remove the dirt in this area at the rubber gripper bar (6), or when heavy polluted, dismount and clean

the rubber gripper bar.

Fig. 1

Fig. 2

Page 20

Operating Instructions

TSZ-UNI

Maintenance and care

20 / 22

V4

GB

8.2.1 Additional with steelfinger grippers (WB-SQ)

Before each start-up:

● Check all steelfinger grippers for mobility, abrasion and contamination.

Worn (no longer sharp-edged) or bent steelfinger grippers must be replaced!

Regular:

● Cleaning of the device with high pressure cleaner (warm water).

Weekly:

● Lubricate and oil mobile parts

AUTOMATIC-RELEASE

Never grease the automatic-release, if necessary use oil!

8.3 Trouble shooting

ERROR

CAUSE

REPAIR

The clamping-power is not big enough,

the load is slipping out

(optional)

The grippers are worn

Replace the grippers

(optional)

The maximum load is exceed

Reduce the weight of. the load

(Adjustment of the gripping range)

(optional)

The actual opening width is not

correct

Adjust the gripping range

according to the load you want to

transport

(Property of material)

The surface of the material is dirty

or the material is not suitable /

allowed for this device.

Check the surface of the material

or ask the manufacturer, if you the

material is allowed for this device.

Unbalanced load

The device is not loaded

symmetrically

Adjust the position of the load

(Adjustment of the gripping range)

(optional)

The adjustment of the gripping

range is not symmetrical.

Correct the adjustment of the

gripping range

Automatic release does not work

mechanical (optional)

Automatic release does not work

Clean automatic release with high

pressure-cleaner

Oil the automatic release (never

with grease)

Change the inset of the automatic

release

Page 21

Operating Instructions

TSZ-UNI

Maintenance and care

21 / 22

V4

GB

8.4 Repairs

● Only persons with the appropriate knowledge and ability are allowed to repair the device.

● Before the device is used again, it has to be checked by an expert.

8.5 Safety procedures

It is the contractors responsibility to ensure that the device is checked by an expert in periods of max. 1

year and all recognized errors are removed ( see BGR 500).

The corresponding legal regulations and the regulations of the declaration of conformity have to be

observed!

We recommend, that after checking the device the badge „Safety checked“ is put on the device.

(Order-No.: 2904.0056+inspection sticker with date).

● You can receive these badges from us.

The check by an expert must be proved!

Device

Year

Date

Expert

Company

Page 22

Operating Instructions

TSZ-UNI

Maintenance and care

22 / 22

V4

GB

8.6 Hints to the identification plate

Type, serial-number and production year are very important for the identification of your device. If you need

information to spare-parts, warranty or other specific details please refer to this information.

The maximum carrying capacity is the maximum load which can be handled with the device. Do not exceed this

carrying capacity.

If you use the device in combination with other lifting equipment (Crane, chain hoist, forklift truck, excavator)

consider the deadweight of the device.

Example:

8.7 Hints to the renting/leasing of PROBST devices

With every renting/leasing of PROBST devices the original operating instructions must be included

unconditionally (in deviation of the users country's language, the respective translations of the original operating

instructions must be delivered additionally)!

Page 23

W min. 50

69

(im WA hängend)

W max. 600

(

186

)

Et ca. 185

ca.

177

ca.

598

(im WA hängend)

550

Bkl

350

Tragfähigkeit / load capacity: 600 kg

A

B

C

D

E

F

8

7

6

5

4

3

2

1

4

5

6

7

8

F

E

D

C

B

1

31,5 kg

Schutzvermerk nach DIN 34 beachten!

Nachdruck nur mit unserer Genehmigung!

Gewicht:

Bei Änderungungen Rücksprache TB !

Kunde:

WA:

1

Joerg.Werner

3.6.2014

Klaus.Scholl

18.10.2004

Gepr.

Erst.

Name

Datum

von

Blatt

Ers. d.

Ers. f.

53100251

Urspr.

Zust.

1

D53100338

Artikelnummer/Zeichnungsnummer

Trittstufenversetzzange TSZ-uni m. WA

Benennung

Page 24

20000026

20440006

33100003

20100084

20030011

33100003

20440006

20000026

20540033

43100861

21600002

20100016

43100282

20540033

43100859

21600002

43100858

43100860

20100084

33100003

20440006

20030011

20000026

20030011

20000026

20440006

33100003

20100084

20030011

43100856

36370019

36370019

A

B

C

D

E

F

8

7

6

5

4

3

2

1

4

5

6

7

8

F

E

D

C

B

1

31,5 kg

Schutzvermerk nach DIN 34 beachten!

Nachdruck nur mit unserer Genehmigung!

Gewicht:

Bei Änderungen Rücksprache TB !

Kunde:

WA:

1

Joerg.Werner

3.6.2014

Klaus.Scholl

18.10.2004

Gepr.

Erst.

Name

Datum

von

Blatt

Ers. d.

Ers. f.

53100251

Urspr.

Zust.

1

E53100338

Artikelnummer/Zeichnungsnummer

Trittstufenversetzzange TSZ-uni m. WA

Benennung

Page 25

Proof of maintenance

Warranty claim for this machine only apply for performance of the mandatory maintenance works (by an

authorised specialist workshop)! After each completed performance of a maintenance interval the

included form must be fill out, stamped, signed and send back to us immediately

1)

.

1) via e-mail to service@probst.eu / via fax or post

Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device type: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Article -No.: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device-No.: _ _ _ _ _ _ _ _ _ _ _ _

Year of make: _ _ _ _

First inspection after 25 operating hours

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

All 50 operating hours

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Minimum 1x per year

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Page 26

Proof of maintenance

Warranty claim for this machine only apply for performance of the mandatory maintenance works (by an

authorised specialist workshop)! After each completed performance of a maintenance interval the

included form must be fill out, stamped, signed and send back to us immediately

1)

.

1) via e-mail to service@probst.eu / via fax or post

Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device type: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Article -No.: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device-No.: _ _ _ _ _ _ _ _ _ _ _ _

Year of make: _ _ _ _

First inspection after 25 operating hours

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

All 50 operating hours

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Minimum 1x per year

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Page 27

Proof of maintenance

Warranty claim for this machine only apply for performance of the mandatory maintenance works (by an

authorised specialist workshop)! After each completed performance of a maintenance interval the

included form must be fill out, stamped, signed and send back to us immediately

1)

.

1) via e-mail to service@probst.eu / via fax or post

Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device type: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Article -No.: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device-No.: _ _ _ _ _ _ _ _ _ _ _ _

Year of make: _ _ _ _

First inspection after 25 operating hours

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

All 50 operating hours

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Minimum 1x per year

Date:

Maintenance work:

Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Loading...

Loading...