Page 1

SPEEDY VS-140 Vacuum Hand Laying Device

VS-140-110

2

Order-No:

5270.0008

Serial-No.:

SPEEDY VS-140 Vacuum Hand Laying Device

VS-140-110

V2

Translation of original operating instructions

Page 2

Contents

VS-140-110

V2

06/08/14

2 / 24

1 Contents

1 Contents ............................................................................................................................... 2

2 EC-Declaration of conformity............................................................................................... 4

3 Safety .................................................................................................................................... 6

3.1 Instructions for the Owner .............................................................................................. 6

3.2 Instructions for the Installation, Maintenance and Operating Personnel ....................... 6

3.3 Hazard Alert Symbols ...................................................................................................... 6

3.4 Installation Site Requirements ........................................................................................ 6

3.5 Intended Use ................................................................................................................... 7

3.6 Emissions ......................................................................................................................... 7

3.7 Special Hazards ................................................................................................................ 7

3.8 Workplaces ...................................................................................................................... 7

3.9 Instructions for the Operator .......................................................................................... 7

3.10 Equipment for Personal Protection ............................................................................. 7

3.11 Behaviour in Emergencies ............................................................................................ 7

3.12 Checking the Safety Devices ........................................................................................ 8

3.12.1 Checking the Vacuum Gauge .................................................................................... 8

3.12.2 Cleaning the air filter................................................................................................. 8

3.13 Safety Marking ............................................................................................................. 9

4 Technical Data ..................................................................................................................... 10

4.1 Dimensioned Drawing.....................................................................................................10

4.2 Technical Data ................................................................................................................. 11

5 Description .......................................................................................................................... 12

5.1 Components of the Lifting Device .................................................................................. 12

5.2 Controls ........................................................................................................................... 12

5.2.1 Push switch .............................................................................................................. 12

5.2.2 Operating lever ........................................................................................................ 12

5.3 Vacuum generator .......................................................................................................... 12

5.4 Suction pads.................................................................................................................... 12

Page 3

Contents

VS-140-110

V2

06/08/14

3 / 24

6 Installation ........................................................................................................................... 14

6.1 Preparing for use ............................................................................................................ 14

6.2 Switching off at the end of the day ................................................................................ 15

7 Operating............................................................................................................................. 16

7.1 Safety Instructions ..........................................................................................................16

7.2 Lifting, Transporting and Lowering Loads ...................................................................... 17

7.2.1 Lifting Loads ............................................................................................................ 17

7.2.2 Transporting Loads .................................................................................................. 17

7.2.3 Lowering Loads ....................................................................................................... 17

7.3 Handle height adjustment .............................................................................................. 17

8 Troubleshooting .................................................................................................................. 18

9 Maintenance ........................................................................................................................ 19

9.1 General ............................................................................................................................19

9.2 Maintenance Plan ...........................................................................................................19

9.3 Suction Pads / Seals........................................................................................................ 20

9.4 Leak Test ........................................................................................................................ 20

9.5 Safety procedures ........................................................................................................... 21

9.6 Hints to the identification plate ..................................................................................... 22

9.1 Hints to the renting/leasing of PROBST devices ............................................................ 22

10 Spare Parts ......................................................................................................................... 23

Page 4

EC-Declaration of conformity

VS-140-110

V2

06/08/14

4 / 24

2 EC-Declaration of conformity

DESCRIPTION:

SPEEDY VS-140 Vacuum Hand Laying Device

VS-140-110

Manufacturer:

Probst GreiftechnikVerlegesysteme GmbH

Gottlieb-Daimler-Strasse 6

D-71729 Erdmannhausen

info@probst.eu www.probst.eu

Complies with the following provisions applying to it

EC-machinery directive 2006/42/EG

DIN EN ISO 12100

Safety of machinery - General principles for design - Risk assessment and risk reduction (ISO 12100:2010)

DIN EN ISO 13857

Safety of machinery ― Safety distances to prevent hazard zones being reached by upper and lower limbs (ISO

13857:2008)

DIN EN 349 (ISO 13854)

Minimum distance to avoid squeezing any parts of the body

Page 5

EC-Declaration of conformity

VS-140-110

V2

06/08/14

5 / 24

DIN 45635-13

Measurement of airborne noise emitted by machines (displacement-, turbo- and jet-compressors).

DIN EN 1012-1 / DIN EN 1012-2

Compressors and vacuum pumps; Safety requirements part 1 and 2.

DIN EN 60204-1 (IEC 60204-1)

Safety of machinery, electrical equipment of industrial machines. Part 1: General requirements

2006/95/EG (Low voltage standard)

2004/108/EG (Electromagnetic compatibility)

DIN EN 55014-1 (IEC/CISPR 14-1)

Electromagnetic compatibility – Requirements for household appliances, electric tools, and similar apparatus.

Part 1: Emission.

DIN EN 55014-2 (IEC/CISPR 14-2)

Electromagnetic compatibility – Requirements for household appliances, electric tools, and similar apparatus.

Part 2: Immunity.

Authorized person for EC-dokumentation:

Name: J. Holderied

Address: Probst GreiftechnikVerlegesysteme GmbH; Gottlieb-Daimler-Str. 6; D-71729 Erdmannhausen

Signature, informations to the subscriber:

Erdmannhausen, 06.08.2014..........................................................................

(M. Probst, Managing director)

Page 6

Safety

VS-140-110

V2

06/08/14

6 / 24

3 Safety

3.1 Instructions for the

Owner

The lifting devices SPEEDY VS-S series are manufactured according to current technical

standards and are safe. Nevertheless, they will present hazards

● if they are not operated by qualified or at least trained staff,

● if they are used contrary to the approved applications.

This may result in

● injuries to or death of operators and other persons,

● damage to lifting device and other valuable goods.

3.2 Instructions for the

Installation,

Maintenance and

Operating Personnel

The device must be installed and maintained by qualified personnel, mechanics and

electricians.

Each person in your company involved in the installation, commissioning, operation,

maintenance or repair of the device

● must have read and understood these operating instructions

● and especially the chapter "Safety" herein.

Your company must ensure by internal measures

● that the operators of the lifting device are properly trained,

● that they have read and understood the operating instructions,

● that the operating instructions are available to them at all times.

The responsibilities for the tasks carried out with the device must be clearly defined

and observed. Ambiguity regarding responsibilities must not exist.

3.3 Hazard Alert Symbols

Danger

Attention

Prohibition

Die Sicherheitshinweise sind in dieser Anleitung sind wie folgt gekennzeichnet:

Danger to life!

Identifies imminent hazard. If you do not avoid the hazard, death or severe injury will

result.

Hazardous situation!

Identifies a potentially hazardous situation. If you do not avoid the situation, injury or

damage to property can result.

Prohibition!

Identifies imminent a prohibition. If you do not avoid the prohibition, death and severe

injury, or damage to property will result.

3.4 Installation Site

Requirements

The lifting device may not be operated in rooms which contain explosive atmospheres.

The ambient temperature of 40 °C must not be exceeded.

Ensure by internal instructions and checks that the installation site is always kept clean

and tidy.

Page 7

Safety

VS-140-110

V2

06/08/14

7 / 24

3.5 Intended Use

Prohibition

Lifting devices of the SPEEDY VS-S are designed for lifting and moving stone and

concrete slabs. Operation requires two persons.

The maximum lifting capacity must not be exceeded.

The lifting device may be used only in vertical position.

Transport of persons and animals with the load or the lifting device itself is forbidden!

Unauthorised modification of the lifting device is forbidden for safety reasons!

The operating, maintenance and service instructions in this manual must be

observed.

3.6 Emissions

The equivalent continuous sound pressure level of the device is

approx. 80 dB(A).

3.7 Special Hazards

Danger

Since the load is held by a vacuum, it will fall off as soon as this vacuum is lost.

This can happen if the vacuum generator fails.

If the vacuum generator fails, lower the load immediately if this is possible.

If this is not possible, immediately leave the dangerous area near the load.

The device generates a very strong suction which can draw in hair and clothing. Do not

look into the suction opening when the device is switched on. Parts of body can be

sucked in.

3.8 Workplaces

The device is operated always by two persons. The workplace of the operators is in

front of the control handles.

Stand so that you can constantly observe the vacuum gauge.

3.9 Instructions for the

Operator

As an operator of the lifting device, you must be trained before you start to use the

device. You must have read and understood the operating instructions and especially

the chapter "Safety".

Ensure that only authorised persons use the device. You are responsible for others in

the operating range of the equipment.

Local safety requirements are fully applicable. The safety instructions in this document

complement these local regulations and do not supersede them.

3.10 Equipment for

Personal Protection

When operating the device always wear:

● safety shoes (with steel toecaps),

● tough gloves.

3.11 Behaviour in

Emergencies

Danger

An emergency situation exists when

● power suddenly fails (device switches off),

● the vacuum pressure drops in the red danger zone on the scale of the vacuum

gauge.

Lower the load immediately if possible. If this is not possible, immediately leave the

dangerous area near the load, since it will be dropped from the device.

Page 8

Safety

VS-140-110

V2

06/08/14

8 / 24

3.12 Checking the Safety

Devices

The lifting device is equipped with following safety device:

vacuum gauge with red danger zone

Check this device at the beginning of each shift (when operating in shifts) or once a

week (when operating continually).

3.12.1 Checking the

Vacuum Gauge

Switch on the lifting device.

Place the lifting device on a flat floor and apply vacuum.

When the vacuum has built up, the pointer of the vacuum gauge must reach a vacuum

of at least -0,2 bar.

3.12.2 Cleaning the air

filter

Inspect the air filter at least once per week and clean it (by blowing out the dirt) as

necessary.

Attention

If the air filter is dirty, the manometer will show a higher value than is actually available

at the suction plates.

The air filter must therefore be inspected and cleaned regularly in order to maintain

the operational safety of the device.

Correct any faults before using the device.

If faults occur during operation, switch the device off and correct the faults before

continuing work with the

device.

Page 9

Safety

VS-140-110

V2

06/08/14

9 / 24

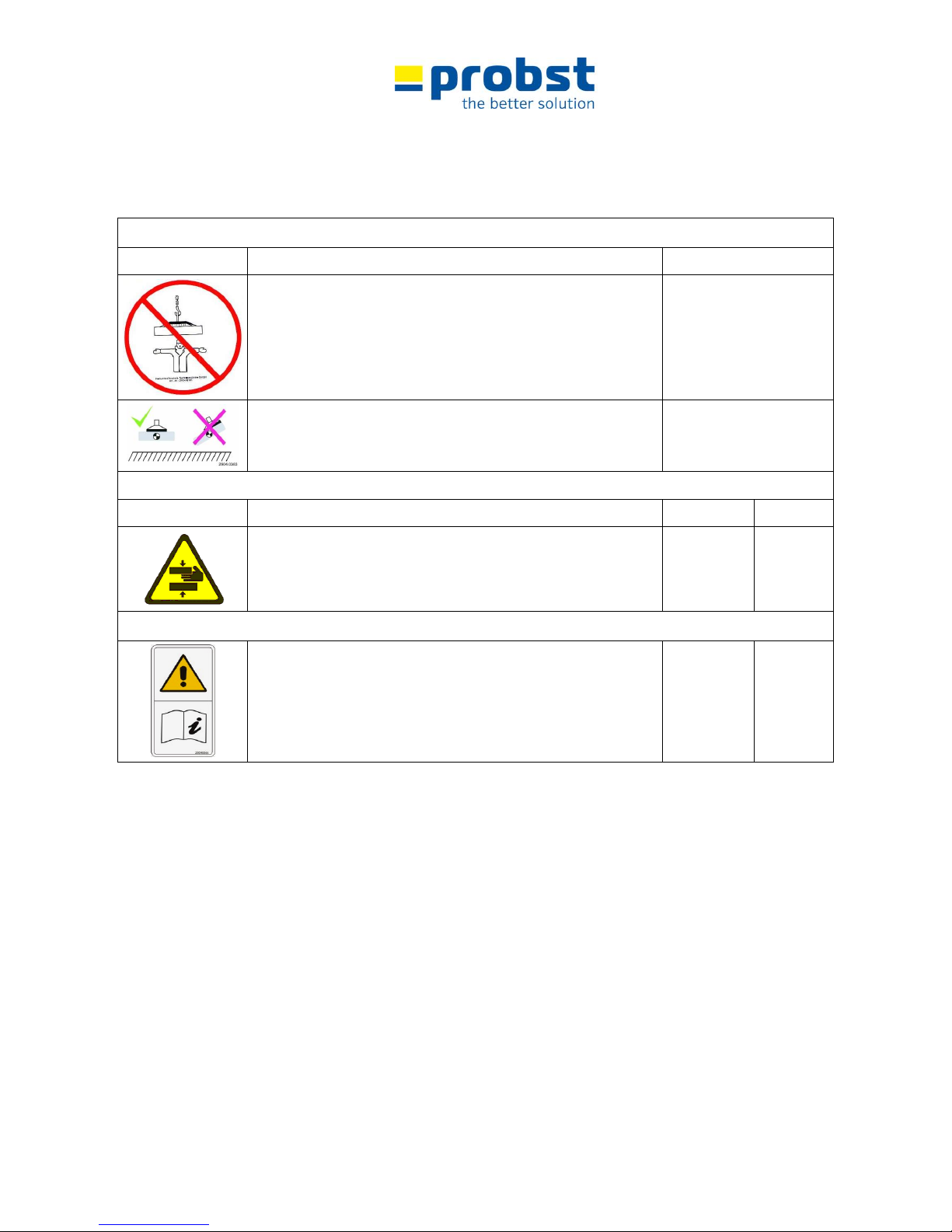

3.13 Safety Marking

WARNING SIGN

Symbol

Meaning

Order-No.:

It is not allowed to be under hanging loads. Danger to life!

2904.0101

Do not lift any components off-centre.

2904.0058

WARNING SIGN

Symbol

Meaning

Order-No.:

Size:

Danger of squeezing the hands.

2904.0221

2904.0220

2904.0107

30 mm

50 mm

80 mm

REGULATORY SIGN

Read operating instructions before operating.

2904.0366

2904.0365

30x57 mm

50x95 mm

Page 10

Technical Data

VS-140-110

V2

06/08/14

10 / 24

4 Technical Data

4.1 Dimensioned Drawing

Pos

Description

Pos

Description

1

Operator handles

6 Cover of the device

2

Upper part of the device with blower motor

7 Operating lever

3

Suction plate

8 Push switch

4

Ventilating flap

9 Vacuum gauge

5

Lower part of the device

1

2

3 4 5

6 7 8

9

Page 11

Technical Data

VS-140-110

V2

06/08/14

11 / 24

4.2 Technical Data

Blower motor, Power

1500 W

Blower motor, Voltage / Frequency

110 V 50 / 60 Hz

Temperature range

0°C ... 40 °C

Lifting load (at -200 mbar low pressure)

depending on size of suction plate

Dead weight*

~14 kg ( ~ 31 lbs)

Dimension of the suction plate

390 x 290 mm

Standard Suction Plates SPS for VS-S

Type

Length mm (in)

Width mm (in)

Carrying Capacity kg (lbs)

Order-Nr.

SPS 40 VS

300 (11 ¾")

250 (9 ¾")

40 * (90) *

4271.0013

SPS 75 VS

400 (15 ¾")

300 (11 ¾")

75 * (165) *

4271.0008

SPS 90 VS

500 (19 ¾")

300 (11 ¾")

90 * (200) *

4271.0012

SPS 120 VS

700 (27 ½")

300 (11 ¾")

120 * (265) *

4271.0011

Replacement seal:

(easy to attach without glueing)

Order-Nr.

for SPS 50 VS-140 **

4271.0023

for SPS 80 VS-140 **

4271.0029

for SPS 100 VS-140 **

4271.0031

for SPS 140 VS-140 **

4271.0030

* Value at -200 mbar low pressure

** inkl. Spannband

Page 12

Description

VS-140-110

V2

06/08/14

12 / 24

5 Description

5.1 Components of the Lifting Device

Parts with safety functions appear in bold type

Pos

Description

Pos

Description

1

Operator handles

6 Cover of the device

2

Upper part of the device with blower motor

7 Operating lever

3

Suction pad

8 Push switch

4

Ventilating flap

9 Vacuum gauge

5

Lower part of the device

5.2 Controls

5.2.1 Push switch

The push switch is used for switching the unit on and off.

5.2.2 Operating lever

Attention

The operating lever is used for releasing the load by opening the venting valve.

This lever may be actuated only when the load is resting on a solid surface.

When the lever is actuated, the vacuum is released immediately and the unit can be

lifted off the workpiece.

5.3 Vacuum generator

The vacuum is generated by an electrically driven blower.

5.4 Suction pads

Danger

The suction pads are designed to lift various items. Only items with smooth, air-tight

surfaces are suitable for vacuum lifting.

To generate vacuum, the suction pad must be in contact with and attached to the

load.

The suction pad must always be positioned in the centre of the workpiece in order to

ensure even distribution of the load. If the suction pad is positioned off-centre, the

workpiece may suddenly drop from the unit during lifting and lowering operations,

since the load is then one-sided.

Only suction plates of the manufacturer PROBST shall be used!

Page 13

Description

VS-140-110

V2

06/08/14

13 / 24

● The device is only designed for the use specified in this documentation.

● Every other use is not authorized and is forbidden!

● All relevant safety regulations, corresponding legal regulations, especially regulations of the declaration of

conformity, and additional local health and safety regulations have to be observed.

Prior to every operation the user must ensure that:

● the equipment is suited to the intended operation, the functioning and the working condition of the

equipment is examined, and the loads are suitable to be handled.

Any doubts about instructions should be raised with the manufacturer prior to use.

ATTENTION: The use of this device is only permitted in proximity to the ground.

Some suction plates which can be mounted to the device will reduce its carrying capacity.

The maximum load is indicated on each suction plate.

Use only suction plates which are approved for this device!

Do not exceed the maximum carrying capacity of the suction plates!!!

Danger: Load (stone slabs) will fall down!

● The load (stone slabs) which is to be sucked and

transported, must have sufficient inherent stability,

otherwise there is risk of breakage when lifting!

● Stone slabs must not be bend when lifting - especially

take care with thin and large-sized stone slabs!

● Generally, the load (stones slab) is only to be sucked in

the middle, otherwise the load hangs diagonally under

the device and the load could break - especially when

lifting large stone slabs with a small suction plate.

● Standard suction plates are not suitable for the

transport of glass plates!

NOT ALLOWED AKTIVITIES:

Unauthorized alterations of the device and the use of any self-made additional equipment

could cause danger and are therefore forbidden!!

Never exceed the carrying capacity and the nominal width/nominal size of the device.

All unauthorized transportations with the device are not allowed:

● Transportation of people and animals.

● Transportation of other loads and materials than described in this manual.

● Never suspend any goods with ropes, chains or similar at the device.

Page 14

Installation

VS-140-110

V2

06/08/14

14 / 24

6 Installation

6.1 Preparing for use

Attention

Move the operator handles (1) to the working position as follows: remove the spring

clips (2) from the pins, pull out the pins, move the handles to the desired position (Pos.

1), insert the pins and secure them with the spring clips.

Danger

Connect electric power to the lifting device. Before connecting, check that the local

voltage and frequency agree with the values shown on the rating plate. If this is not

the case, do not connect the power.

The locally provided power cable (3) must be capable of carrying the rated current of

the lifting device.

Secure the cable (3) to the operator handle (1) with the aid of the Velcro strip (4)

provided for this purpose, to secure the plug-and-socket connection against accidental

releasing (e.g. step on the cable: losing of the load).

Transport position

Working position

Page 15

Installation

VS-140-110

V2

06/08/14

15 / 24

6.2 Switching off at the

end of the day

Before switching off the device with the push switch, allow it to run for at least 30

seconds with the venting valve open

This loosens and removes any dirt which may have been deposited on the vacuum

blower.

For transport, swing the operator handles (1) down as follows:

remove the spring clips (2) from the pins, pull out the pins, move the handles to the

transport position (Pos. 2), insert the pins and secure them with the spring clips.

This lifts the suction pad from the ground, protecting it from damage during transport.

Transport position

Page 16

Operating

VS-140-110

V2

06/08/14

16 / 24

7 Operating

7.1 Safety Instructions

● The ground or floor in the working area should by clean and dry or rough enough

to ensure that the operating personnel cannot slip.

● The device is intended only for manual transport of paving stones or slabs. Never

suspend it from a crane or mechanical shovel, etc.

Local safety requirements are fully applicable. The following safety instructions

supplement the local regulations and do not supersede them:

● Wear safety shoes, gloves and ear protection.

● Never exceed the maximum lifting capacity of the device.

● Do not stand below the load. Always keep clear of the load.

● Never carry people or animals with the load or the lifting device itself!

● Operate only when you can view the entire working area. Look out for other

persons in the working area. Never manoeuvre loads above people.

● Do not release the handles while a load is attached.

● Do not pull loads to the side or drag them along with the lifting device.

● If the load has become jammed, do not attempt to tear it free with the lifting

device.

● In the case of a fault in the vacuum generator, lower the load immediately if

possible. Immediately leave the danger area near the load.

● Pick up and lift only appropriate loads (check for stability and porosity).

● Always keep an eye on the vacuum gauge. Never lift loads when the vacuum is

below –200 mbar. If the pointer of the pressure gauge moves into the red danger

zone, lower the load immediately.

● Place workpieces only on clear, level surfaces, since they may otherwise slide

away when released.

● Release the load only when it has been fully lowered to the ground. Do not reach

under the load when lowering it, since serious injuries may result!

● Always distribute load evenly on the suction surfaces.

● Ensure that the vacuum generator cannot be switched off while transporting

loads.

● Check all suction hoses and clamps for proper installation and tighten the clamps

if necessary.

● If you set down the unit with the motor running, take care not to place it on an

airtight surface, since this will block the flow of cooling air. Instead, place the unit

on a support (such as a block of wood).

● Always switch off the unit if you do not intend to use it again within two minutes

Page 17

Operating

VS-140-110

V2

06/08/14

17 / 24

7.2 Lifting, Transporting

and Lowering Loads

The following operating steps must be checked by a qualified mechanic prior to use of

the device by the operating personnel. Correct any faults before the device is used.

7.2.1 Lifting Loads

● Switch the blower on.

● Position the lifting device directly above the load. Do not pull to the sides.

Distribute load evenly.

● Lower the lifting device onto the load.

● The suction pad grips the load.

● Watch the pressure gauge. As soon as a vacuum pressure of -200 mbar has been

reached (pointer of the vacuum gauge is in the green range) you can lift the load.

Never attempt to lift the load with a lower vacuum since it will be dropped.

● When lifting items from a stack, ensure that only one piece is actually lifted.

● The duty cycle (lifting/venting) should not exeed 2/3 to 1/3.

● Maximum lifting period 30 seconds, followed by 15 seconds with inlet free.

7.2.2 Transporting Loads

Avoid jerky movement of the load.

The operator who actuates the operating lever must always inform the second

operator clearly and unambiguously of his intended actions.

7.2.3 Lowering Loads

Lower the load to a safe and clear, level surface so the load cannot slip or tip over.

Pull the operating lever to release the load.

7.3 Handle height

adjustment

The operator handles can be adjusted for operators of differing heights. This may be

done only when the device is resting on the ground.

Remove the spring clips, move the pins to the desired position and secure the pins

again with the spring clips.

Page 18

Troubleshooting

VS-140-110

V2

06/08/14

18 / 24

8 Troubleshooting

The device may be installed and maintained only by qualified personnel such as

mechanics and electricians.

After any repair or maintenance work, check the safety devices as described in the

section “Safety”.

Fault

Cause

Remedy

Vacuum generation does not

work

no current supply

check the current supply

if the thermal protection switch

trips, allow the unit to cool

When the temperature has dropped to

normal (after about 30 minutes) the unit

is ready for use again.

The unit must not be opened during the

guarantee period as this will entail loss of

guarantee cover.

In order to avoid tripping of the thermal

protection switch, follow the instructions

in the section "Safety Notes".

Vacuum does not reach

-200 mbar

Workpiece has cracks, openings

or is porous

Work piece not suitable for this device

Seal damaged

Replace seal

Vacuum gauge defective

Replace vacuum gauge

Air filter dirty

Clean the air filter

Page 19

Maintenance

VS-140-110

V2

06/08/14

19 / 24

9 Maintenance

9.1 General

The device may be installed and maintained only by qualified personnel such as

mechanics and electricians.

Always disconnect the electric power before starting any maintenance work.

The fans must not be opened during the guarantee period as this will entail loss of

guarantee cover.

After any repair or maintenance work, check the safety devices as described in the

section "Safety".

9.2 Maintenance Plan

Interval

Daily

Weekly

Monthly

Every 6

months

Every 12

months

Inspect the safety devices:

- Vacuum gauge OK?

X X

Electrical equipment OK? Cable glands tight?

X

Vacuum hoses in good condition (no cracks, not kinked, no

abrasion, free of leaks)?

X X

All connections (hose clamps, etc.) tight?

X

Instruction plate, rating plate and load plate still mounted on

the device?

X

Operating instructions available?

Operating personnel familiar with operating instructions?

X

Inspect load-carrying part (such as suspension) for

deformation, wear and other damage.

x

Clean and inspect suction pads. Must be free of cracks, lip

must be smooth, etc. Replace if necessary.

X X

Clean the air filter

X

Is the inspection sticker up to date?

X

General condition of the device.

X

Leak test

X X

Page 20

Maintenance

VS-140-110

V2

06/08/14

20 / 24

9.3 Suction Pads / Seals

Remove any foreign bodies and contamination such as adhesives, glue, sawdust, dust,

etc. sticking to the seals at least once a week. Use glycerine to clean the seals.

Immediately replace damaged seals (tears, holes, waves).

Do not use petrol (gasoline).

Use cleaning agent to clean the device (do not use petrol (gasoline) or aggressive or

corrosive fluids to clean the device. The hoses will otherwise become leaky or be

destroyed).

Suction plates must always be replaced completely. The bolts of the suction plate can be

loosened more easily by heating.

9.4 Leak Test

Check the device for leaks at least every three months.

● Apply the suction pad to a flat air-tight surface.

● Switch the vacuum blower on and wait until a vacuum of at least -200 mbar

is reached.

If this vacuum level is not reached, check:

● whether the seals or hoses are damaged,

● that the connectors are tight,

● that the filter element is clean.

Page 21

Maintenance

VS-140-110

V2

06/08/14

21 / 24

9.5 Safety procedures

● It is the contractors responsibility to ensure that the

device is checked by an expert in periods of max. 1

year and all recognized errors are removed ( BGR

500).

● The corresponding regulations of the declaration of

conformity have to be observed!

● We recommend, that after checking the

device the badge „Safety checked“ is put

on the device.

(Order-No.: 2904.0056 + inspection

sticker with date)You can receive these

badges from us.

The check by an expert must be proved!

Device

Year

Date

Expert

Company

Page 22

Maintenance

VS-140-110

V2

06/08/14

22 / 24

9.6 Hints to the identification plate

Type, serial-number and production year are very important for the identification of your device. If you need

information to spare-parts, warranty or other specific details please refer to these information.

The max. carrying capacity is the maximum load which can be handled with the device. Do not exceed this

carrying capacity.

If you use the device in combination with other lifting equipment (Crane, chain hoist, forklift truck,

excavator) consider the deadweight of the device

Example:

9.1 Hints to the renting/leasing of PROBST devices

With every renting/leasing of PROBST devices the original operating instructions must be included

unconditionally (in deviation of the users country's language, the respective translations of the original operating

instructions must be delivered additionally)!

Page 23

Spare Parts

VS-140-110

V2

06/08/14

23 / 24

10 Spare Parts

This equipment is guaranteed in accordance with our General Conditions of Business. This also applies to spare

parts where these are original parts supplied by us. We will assume no liability for damage caused by the use of

non-original spare parts and accessories.

Wear and consumable parts are not covered by the guarantee.

Page 24

Spare Parts

VS-140-110

V2

06/08/14

24 / 24

* When the sealing ring is replaced, a new clamping strip and clamp must always be fitted.

Pos.

Bezeichnung / Description

Art.-No.

1

Betätigungshebel BH 90.800 / operating lever

4271.0036

2

Rundlitze mit Kugelpressnippel / round stranded wire with ball for bowden cable

siehe/see Pos.7

3

Runddrahthülle / cover for bowden wire

siehe/see Pos.7

4

Klett-/Velourband / belt

-----

5

Lamellenstopfen / plug

4271.0055

6

Unterteil / lower part

4271.0056

7

Bowdenzug / Bowden wire

2100.0157

8

Stellschraube / adjusting screw

4271.0057

9

Druckfeder-1.50 / pressure spring

4271.0058

10

Blechschraube / tappino screw

-----

11

V-Dichtring 90 s über Saugplatte / gasket between suction pad and device V-Ring 90 s

4271.0010

12

Federsteckpolzen verzinkt / spring bolt

4271.0052

13

Ein- und Ausschalter / on/off switch

2410.0194

14

Kondensator / condenser

4271.0062

15

Stopfen / plug

4271.0063

16

Manometer VAM 63/1-175H / vacuum gauge

2213.0016

17

Belüftungsklappe / ventilation flap

4271.0064

18

Gebläseeinheit komplett montiert für 230 V / fan unit (complete) for 230 V

4271.0061

19

Dichtung für Gebläse / seal for fan

4271.0059

20

Oberteil / upper part

4271.0060

21

Deckel für Speedy VS2 / cover for VacuMaster Speedy

4271.0065

22

Gebläse für Speedy VS2 230 V / fan for VacuMaster Speedy 230 V

4271.0034

Gebläse für Speedy VS2 110 V / fan for VacuMaster Speedy 110 V

4271.0035

23

Bedienbügel BB / operator handles

4271.0066

-

Sauggreifer komplett / suction pad (complete)

-----

-

Dichtring für Sauggreifer* / sealing lip for suction pad*

-----

-

Spannschloss für Dichtring* / clamp for sealing lip*

-----

-

Spannband für Dichtring 1,28 m* / clamping strip for sealing lip; 1,28 m*

-----

Page 25

42710065

24100194

42710062

42710060

42710059

42710034 - 230V / 50Hz

42710035 - 110V / 60Hz

42710059

A

B

C

D

E

F

8

7

6

5

4

3

2

1

4

5

6

7

8

F

E

D

C

B

1

4,6 kg

Schutzvermerk nach DIN 34 beachten!

Nachdruck nur mit unserer Genehmigung!

Gewicht:

Bei Änderungen Rücksprache TB !

Kunde:

WA:

230 V/50 Hz

1

Michael.Wunder

5.12.2013

Gepr.

Erst.

Name

Datum

von

Blatt

Ers. d.

Ers. f.

Urspr.

Zust.

E42710061

Artikelnummer/Zeichnungsnummer

Gebläseeinheit kompl. für Speedy VS-S

und QJ

Benennung

Page 26

Proof of maintenance

The claim under guarantee for this device only exists and is subject to the proper execution of

the mandatory maintenance works. (In case of warranty request please always attach a copy

of the proof of maintenance)

Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device type: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Article -No.: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device-No.: _ _ _ _ _ _ _ _ _ _ _ _ Year of make: _ _ _ _

First inspection after 25 operating hours

Date: Maintenance work: Inspection by company:

Company stamp

………………………………………………………………

Name Signature

All 50 operating hours

Date: Maintenance work: Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Minimum 1x per year

Date: Maintenance work: Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Page 27

Proof of maintenance

The claim under guarantee for this device only exists and is subject to the proper execution of

the mandatory maintenance works. (In case of warranty request please always attach a copy

of the proof of maintenance)

Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device type: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Article -No.: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device-No.: _ _ _ _ _ _ _ _ _ _ _ _ Year of make: _ _ _ _

First inspection after 25 operating hours

Date: Maintenance work: Inspection by company:

Company stamp

………………………………………………………………

Name Signature

All 50 operating hours

Date: Maintenance work: Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Minimum 1x per year

Date: Maintenance work: Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Page 28

Proof of maintenance

The claim under guarantee for this device only exists and is subject to the proper execution of

the mandatory maintenance works. (In case of warranty request please always attach a copy

of the proof of maintenance)

Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device type: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Article -No.: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Device-No.: _ _ _ _ _ _ _ _ _ _ _ _ Year of make: _ _ _ _

First inspection after 25 operating hours

Date: Maintenance work: Inspection by company:

Company stamp

………………………………………………………………

Name Signature

All 50 operating hours

Date: Maintenance work: Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Minimum 1x per year

Date: Maintenance work: Inspection by company:

Company stamp

………………………………………………………………

Name Signature

Company stamp

………………………………………………………………

Name Signature

Loading...

Loading...