GALAXY SERIES CNC ROUTERS

Quick Start Guide

www.probotix.com

844-472-9262

HOW TO GET HELP

Online Support

http://www.probotix.com/wiki/

http://www.probotix.com/forum/

Telephone Support

844-472-9262

MACHINE FOOTPRINTS

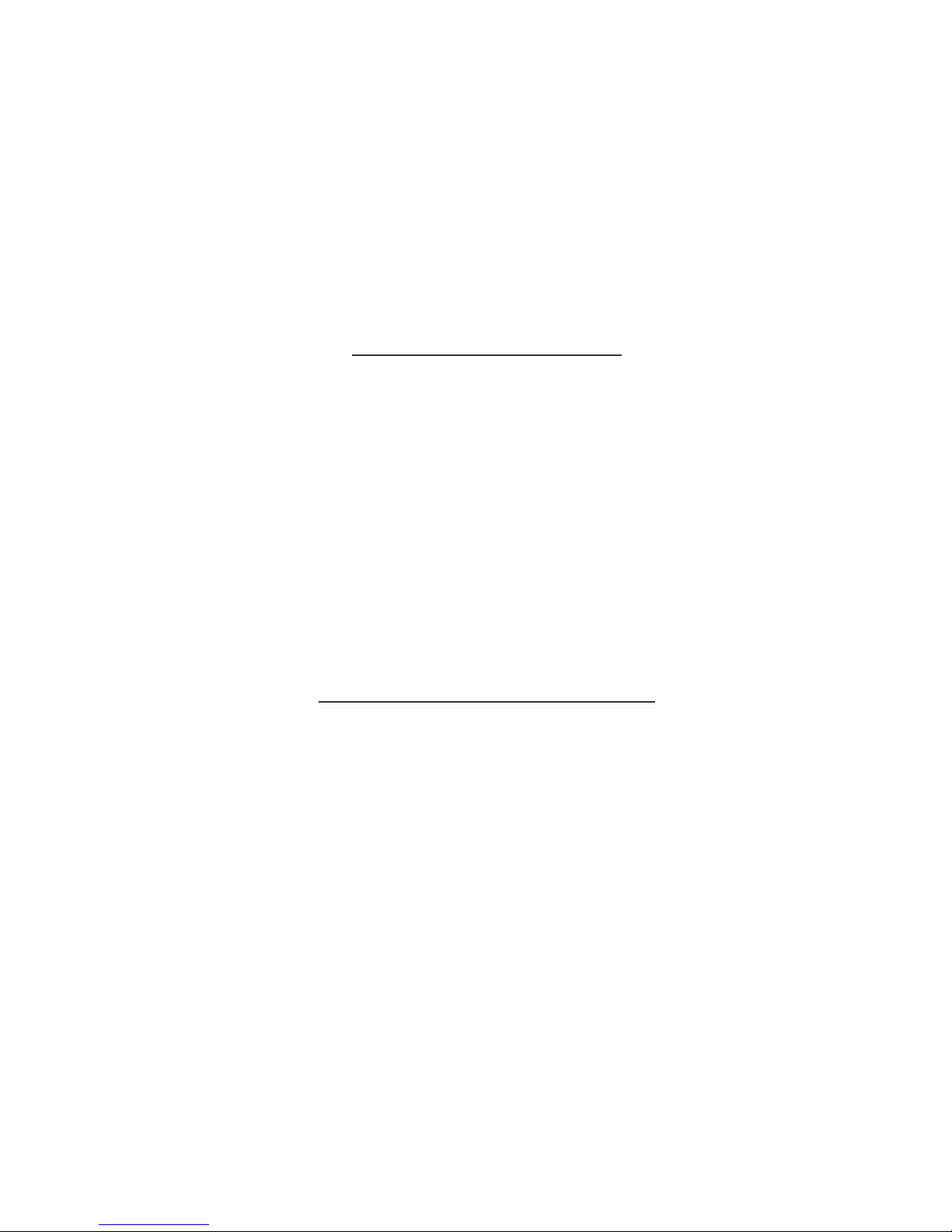

BUILDING A TABLE - COMET

34”

36”

A

C

G

B

E

H

A

3/4” MDF or Plywood, 34” x 36”

D

31.5”

F

B

3/4” MDF or Plywood, 24.5” x 34.5”

C

2pcs 1x4 Pine, 34” Long

D

2pcs 1x4 Pine, 34.5” Long

E

2pcs 1x4 Pine, 25.5” Long

F

2pcs 1x4 Pine, 33” Long

G

4pcs 4x4 Pine, 27.25” Long

H

4pcs 3.5” Tall Locking Castors

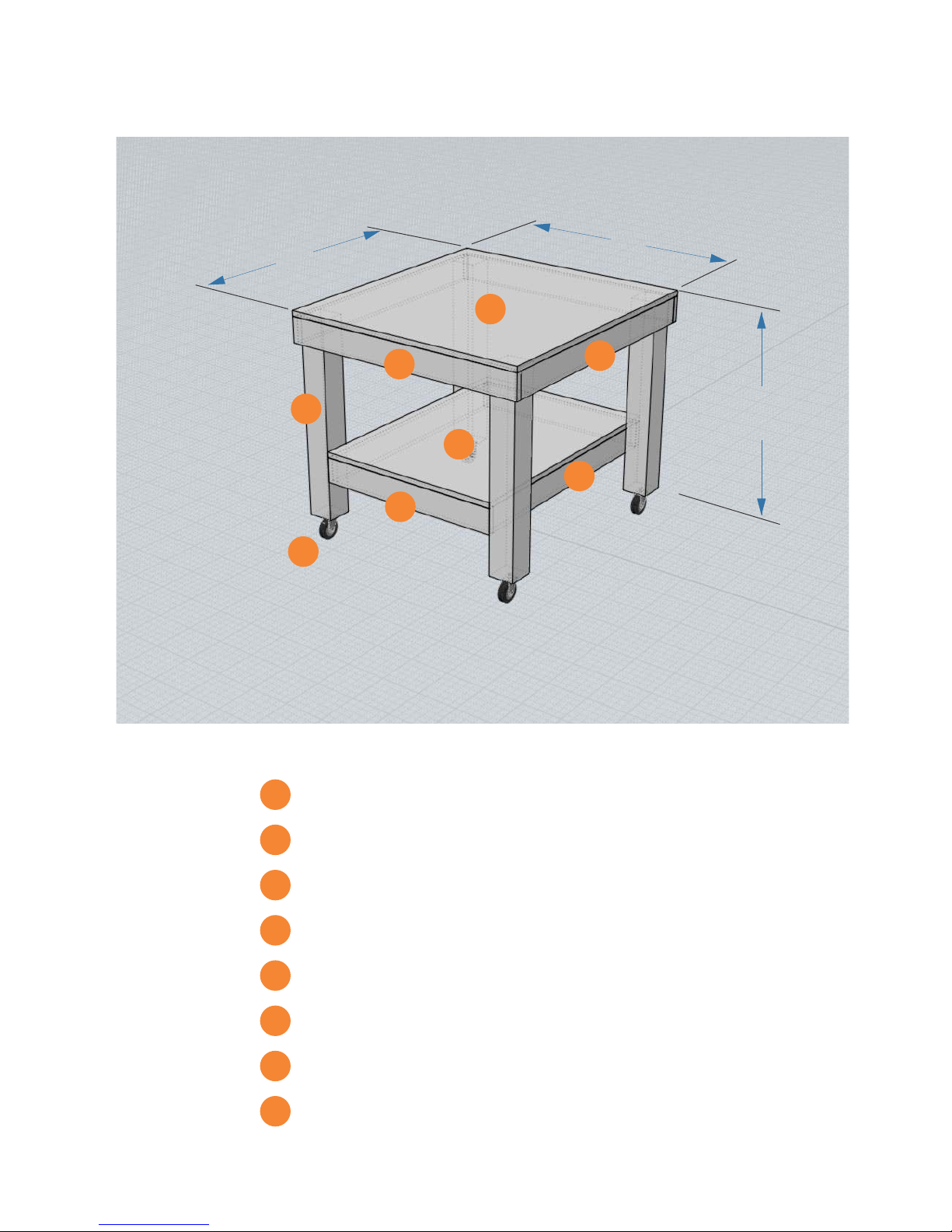

BUILDING A TABLE - ASTEROID

36”

G

H

C

E

B

46”

A

D

31.5”

F

A

3/4” MDF or Plywood, 46” x 36”

B

3/4” MDF or Plywood, 37.5” x 34.5”

C

2pcs 1x4 Pine, 46” Long

D

2pcs 1x4 Pine, 34.5” Long

E

2pcs 1x4 Pine, 37.5” Long

F

2pcs 1x4 Pine, 33” Long

G

4pcs 4x4 Pine, 27.25” Long

H

4pcs 3.5” Tall Locking Castors

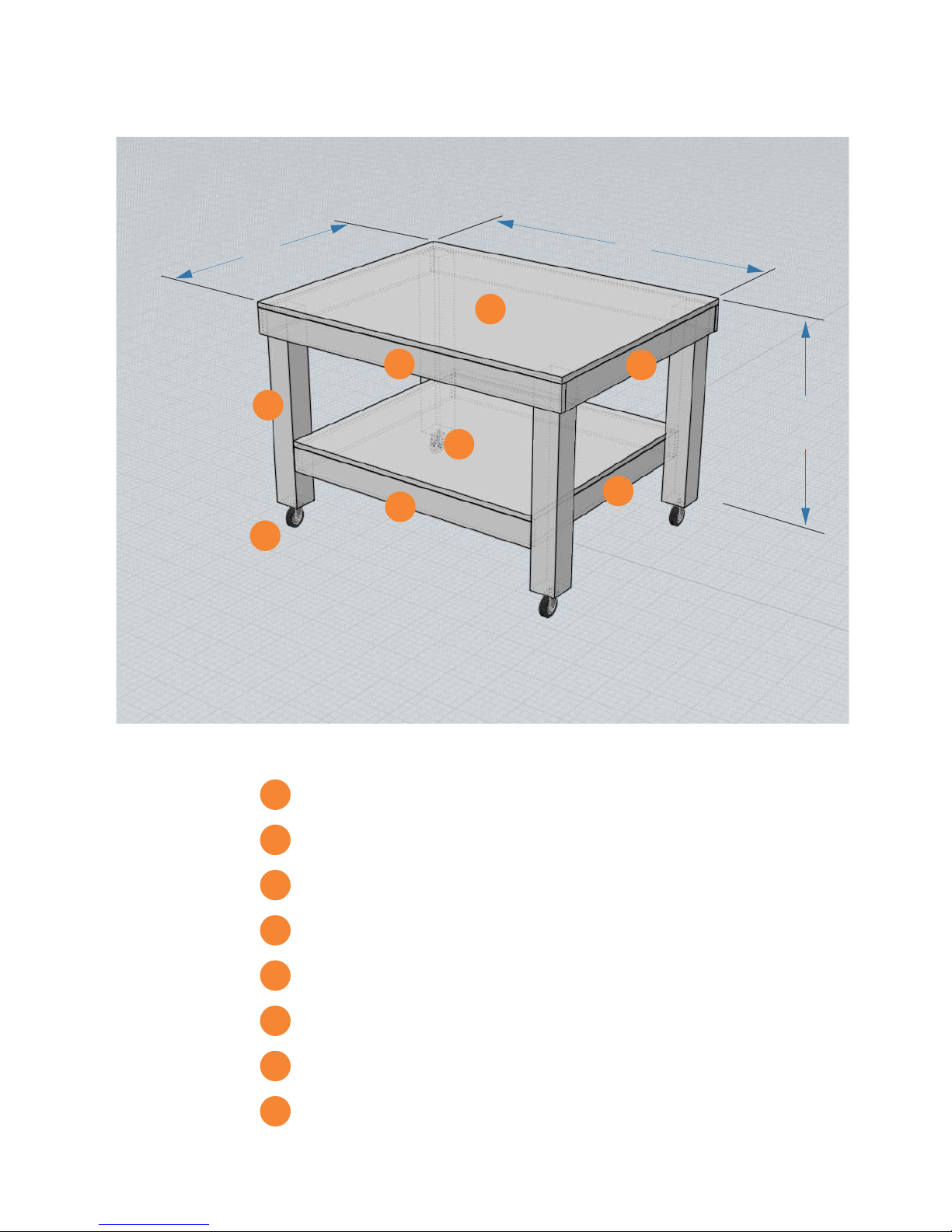

BUILDING A TABLE - METEOR

34”

64.5”

A

D

G

C

B

E

H

A

3/4” MDF or Plywood, 34” x 64.5”

B

3/4” MDF or Plywood, 25.5” x 63”

31.5”

F

C

2pcs 1x4 Pine, 34” Long

D

2pcs 1x4 Pine, 63” Long

E

2pcs 1x4 Pine, 25.5” Long

F

2pcs 1x4 Pine, 61.5” Long

G

4pcs 4x4 Pine, 27.25” Long

H

4pcs 3.5” Tall Locking Castors

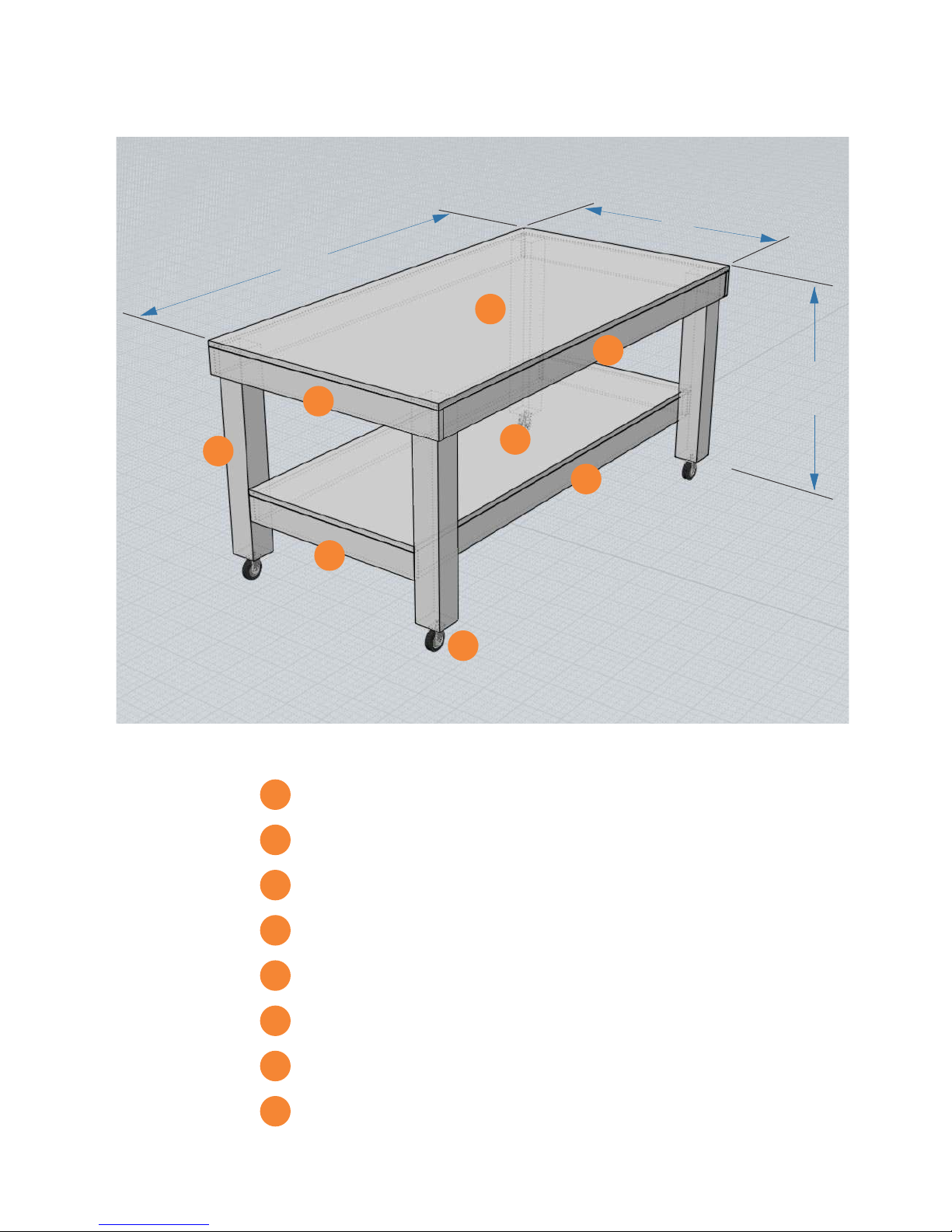

BUILDING A TABLE - NEBULA

46”

64.5”

A

D

G

C

B

E

H

A

3/4” MDF or Plywood, 46” x 64.5”

B

3/4” MDF or Plywood, 37.5” x 63”

31.5”

F

C

2pcs 1x4 Pine, 46” Long

D

2pcs 1x4 Pine, 63” Long

E

2pcs 1x4 Pine, 37.5” Long

F

2pcs 1x4 Pine, 61.5” Long

G

4pcs 4x4 Pine, 27.25” Long

H

4pcs 3.5” Tall Locking Castors

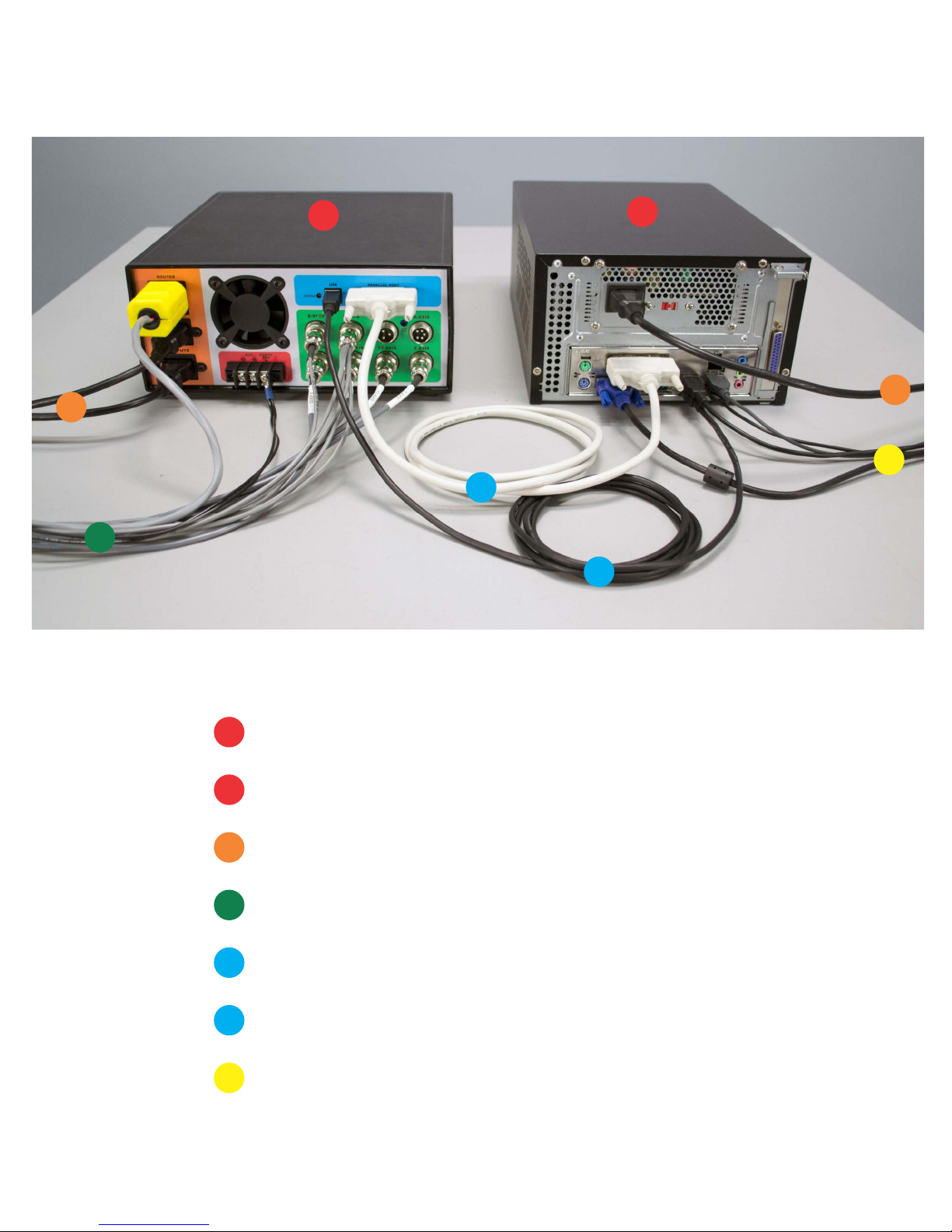

CONNECTION DIAGRAM (ROUTER)

C

D

A

B

C

G

E

F

A

B

C

D

E

F

G

UNITY CONTROLLER

COMPUTER

110VAC POWER

MACHINE HARNESS

PARALLEL CABLE

USB CABLE

KEYBOARD, MOUSE, MONITOR, JOG PENDANT

CONNECTION DIAGRAM (VFD SPINDLE)

J

C

D

H

A

I

E

B

C

G

F

A

B

C

D

E

F

G

H

UNITY CONTROLLER

COMPUTER

110VAC POWER

MACHINE HARNESS

PARALLEL CABLE

USB CABLE

KEYBOARD, MOUSE, MONITOR, JOG PENDANT

VFD

I

VFD CONTROL CABLE

J

220VAC

UNITY CONTROLLER PORTS

C

B

A

O

N

M

D

F

L

E

G H I

K

J

A: AC INPUT - Primary power input for power supply.

B: AC INPUT - Power input here is switched by relay to the (C) ROUTER output.

C: ROUTER - Connect to the green power cable from the machine harness. On-screen spindle controls, as well as

M3/M5 g-codes will control this output. When a VFD spindle is used instead of a router, this outlet

can be used with for a shop vac and is controlled by M8/M9.

D: USB - Connect to USB connector on PC.

E: PARALLEL PORT - Connect to the primary (built onto the motherboard) DB-25 connector on the PC.

F, G, H, I, J: MOTOR CONNECTIONS - Connect to each of the labeled motor connections from the machine harness.

J: A-AXIS - For optional rotary axis.

K: VFD - Connect to 3-pin VFD pigtail for speed control of a VFD spindle.

L: LIMITS - Connect to the 8-pin limit switch connector from the machine harness.

M: E-STOP - Connect to the 2-pin e-stop connector from the machine harness.

N: EARTH GND - It is recommended that the machine is grounded to earth. Connect the two black wires from the

machine harness to this connection. If using a VFD, ground the machine frame to the VFD earth ground

terminal instead. Additional earth grounding may be necessary when working with certain spindles or

certain types of materials that may cause excess EMI or static electricity.

O: AUX - This is a 5V logic level signal that can be connected to a PowerSwitch Tail or other 5V@20mA relay circuit.

This signal is controlled by the flood coolant controls in the software (M8/M9). Do not use if running a VFD

spindle.

VFD WIRING DETAIL

JUMPER

SET TO “VI”

220VAC@20AMP

EARTH GND

2

1

34

SPINDLE

U,V,W

VI

24V

DCM/ASM

2

3

1

1) 24V PWR (RED)

2) GND (BLK)

3) 0-10V (WHT)

TO SPEED

CONTROL BOARD

TO MACHINE FRAME

NOTICE: Internal wiring of Chinese spindles is not consistent. If spindle spins in reverse, swap U & V.

You MUST verify visually or physically the proper rotation of the spindle to ensure the machine cuts properly!

VFD WIRING DETAIL

(SUNFAR E300)

220VAC@20AMP

SPINDLE

EARTH GND

2

1

34

U,V,W

VI

CM

24V

2

3

1

1) 24V PWR (RED)

2) GND (BLK)

3) 0-10V (WHT)

TO SPEED

CONTROL BOARD

TO MACHINE FRAME

NOTICE: Internal wiring of Chinese spindles is not consistent. If spindle spins in reverse, swap U & V.

You MUST verify visually or physically the proper rotation of the spindle to ensure the machine cuts properly!

VFD WIRING DETAIL

(SUNFAR E500)

AI

24V

GND

220VAC@20AMP

2

1

34

SPINDLE

U,V,W

1) 24V PWR (RED)

2) GND (BLK)

3) 0-10V (WHT)

2

3

1

TO SPEED

EARTH GND

CONTROL BOARD

TO MACHINE FRAME

NOTICE: Internal wiring of Chinese spindles is not consistent. If spindle spins in reverse, swap U & V.

You MUST verify visually or physically the proper rotation of the spindle to ensure the machine cuts properly!

LIMIT SWITCHES

The Y1 and Y2 limit switches have been removed to protect them during

transport. Reinstall them as seen above before running the machine.

GETTING STARTED

Simple Start Up Procedure:

Ÿ Start computer

Ÿ Launch LinuxCNC from icon on desktop

Ÿ Turn power on Unity Controller

Ÿ Verify red E-Stop indicator follows physical e-stop

Ÿ Click orange Machine Power button

Ÿ Click the Home All button

Ÿ Click folder icon to open g-code file

Ÿ Load tool into spindle or router

Ÿ Mount stock on the table

Ÿ Jog machine to place tool on origin of part

Ÿ Perform touch-off sequence (all 3 axis)

Ÿ Verify spindle power switch is on

Ÿ Hit the Run button

Ÿ Watch in awe

*There are additional instruction in the wiki for using the Z

Touch-off puck and the ATLaS Automatic Tool Length

Sensor.

CAM SOFTWARE

You can use any CAM software to generate g-code for LinuxCNC. Most CAM software

programs will have appropriate post processors named either LinuxCNC or EMC2. You

can use generic g-code post processors as well. We also have post processors on our

wiki specifically for our machines. If using the ATLaS Automatic Tool Length Sensor, you

need to make sure the post processor you are using is inserting the proper tool change

routine.

G54 COORDINATE SYSTEM

CNC machines use a numbered coordinate system. G54 is the default coordinate

system. Some post processors carelessly do not insert a coordinate system. The

results of not specifying a coordinate system in the g-code is unpredictable and

dangerous. Be sure the coordinate system is being inserted into the g-code preamble.

TOUCHING OFF

After you mount your stock to the table and insert the tool you will be cutting with, use

the jog controls to move the tool to the origin of the part. This is the same location you

told the CAM software you wanted the origin to be. It could be on one of the corners of

the part, or top center of the part. Then choose each axis and click the

button.

The axis that we are setting the origin for.

The current position of the

tool relative to the stock at

this moment. May be zero,

may be the thickness of the

piece of paper you are

sliding under the tool.

This needs to match the

coordinate system that the

CAM software is inserting

into the g-code.

G64 PATH OPTIMIZATION

Except for in the case of full 90 degree arcs, CAM software will break any curves in

your designs up into a bunch of tiny segments. This will create jittery motion, will create

tool marks in the part, shorten your tool life, and can extend the cut times significantly.

Fortunately, LinuxCNC has a mode called G64 path optimization.

When G64 is turned on, LinuxCNC will perform a look-ahead and calculates the angle

of the next segment(s), only slowing down as little as possible to round the corner(s). It

tries to maintain the programmed velocity as close as possible, while not violating the

velocity and acceleration capabilities of the machine. If G64 is programmed without a P

parameter, LinuxCNC will take its liberty and round over those corners as much as it

needs, the faster the feedrate, the greater the deviation from the programmed location.

While cutting a square at only 10IPM will be a near perfect square, cutting that same

square at 100IPM will result in 3 extremely rounded corners. In LinuxCNC, G64 is

turned on by default (look for it under active g-codes under the MDI tab), but it does not

have this P parameter (tolerance) by default.

The simple solution is to type G64 P0.010 into the MDI command box and hit go. This

will tell LinuxCNC to yes, turn on path optimization, but do not deviate more than 0.010"

from where I told you to go. The tolerance you use will depend upon the types of parts

you are making. You will want to set it to 0.010 or more for decorative type things,

especially while 3D carving. For more precise parts, You will use 0.001. G61 cancels

G64 and will cause the machine to come to a complete stop at the end of every

segment.

One more thing... You can put that G64 line in the preamble of your post processor so

that it inserts it into every g-code file. It is modal, so it stays the same unless explicitly

changed with another G64 Pxxx, or canceled with a G61. It also resets when the

software is restarted. The most efficient way to manage this is to create seperate post

processor for each tolerance level you want to use.

Do not confuse G64 Path Optimization with the G54 Coordinate System

More information about this and other

topics can be found on the wiki:

http://www.probotix.com/wiki/

MAINTENANCE

Daily Use:

Put a couple of drops of 3-in-1 oil on each of the six linear rails before homing the

machine each day. This will allow a tiny amount of oil to be sucked up into the

bearing housings before cutting any parts.

Use the included linear motion grease on the leadscrews. A light coating is enough,

as Delrin is self-lubricating. You can use WD-40 and an air nozzle to remove debris

from the screw. Be sure to dry the screw of the WD-40 before re-applying grease

as WD-40 is a solvent and will dissolve the grease.

The Grease Zerks on the z-axis bearings are not used.

All of the other bearings are sealed. The most important thing is to keep any dust

cleaned off of the machine, especially if you are cutting abrasive materials such as

MDF, fiberglass, or carbon fiber.

High Humidity Environments & Storage:

If you use your machine in a high humidity environment, ie in a shed or other nonairconditioned environment, or if you plan to store it without use, rust can form on

the linear rails, leadscrews, and the black-oxide machine fasteners. Coat these

surfaces with grease or WD-40 often. Again, be sure to dry the screws and rails of

the WD-40 before re-applying grease and oil before use. The black-oxide machine

fasteners will not need to wiped dry.

Bearing Replacements:

Depending on the amount of use and the loads on the machine for your application,

the linear bearings and leadscrew ball bearings will need to be replaced eventually.

You will notice excess slop, marks on the rails, or jerky motion on the affected axis.

Replace them annually for worry free operation.

Anti-backlash Nuts:

The Delrin anti-backlash nuts are designed to wear and may need to be replaced

periodically, depending upon the amount of use and abuse your machine receives.

When they fail, you will notice backlash on the affected axis. You can check them

by pulling and pushing on each axis and observing slop between the leadscrew

and the drive nuts. The replace them, you will need to remove the leadscrews.

Replace them annually for worry free operation.

ESCAPE

E-STOP

F1

TOGGLE E-STOP

F2

TOGGLE MACHINE POWER

F3

MANUAL MODE

F4

AUTO MODE

F5

MDI MODE

F6

RESET INTERPRETER

F7

TOGGLE MIST

F8

TOGGLE FLOOD

F9

TOGGLE SPINDLE FORWARD

F10

TOGGLE SPINDLE REVERSE

F11

DECREASE SPINDLE SPEED

F12

INCREASE SPINDLE SPEED

X

SELECT X-AXIS

Y

SELECT Y-AXIS

Z

SELECT Z-AXIS

LEFT/RIGHT ARROW

JOG X-AXIS

UP/DOWN ARROW

JOG Y-AXIS

PAGE UP/DOWN

JOG Z-AXIS

HOME

HOME SELECTED AXIS

END

TOUCH-OFF SELECTED AXIS

</>

DECREASE/INCREASE JOG SPEED

C

SELECT CONTINUOUS JOGGING

I

SELECT INCREMENTAL JOGGING AND TOGGLE BETWEEN INCREMENTS

1-9,0

FEED OVERRIDE 10%-90%, 0 IS 100%

@

TOGGLE COMMANDED/ACTUAL POSITION DISPLAY

#

TOGGLE ABSOLUTE/RELATIVE POSITION DISPLAY

O

OPEAN A PROGRAM

R

RUN THE OPENED PROGRAM

P

PAUSE PROGRAM

S

RESUME PAUSED PROGRAM

A

STEP ONE LINE IN PAUSED PROGRAM

B

TAKE SPINDLE BREAK OFF

ALT-B

PUT SPINDLE BRAKE ON

ALT-S

START LOGGING

ALT-P

PAUSE LOGGING

ALT-F

SAVE LOG FILE

CTRL-P

PRINT LOG FILE (ONLY WITH XGRAPH)

LINUXCNC KEYBOARD SHORTCUTS

G-CODE QUICK REFERENCE

Motion

G0

G1

G2, G3

G38.2

G80

G81

G82…G89

G33

G33.1

G76

Plane Selection (affects G2, G3, G81…G89, G40…G42)

G17

G18

G19

Distance Mode

G90

G91

Feed Rate Mode

G93

G94

G95

Units

G20

G21

Cutter Radius Compensation

G41, G42

G41.1, G42.1

G40

Tool Length Offset

G43

G43.1

G49

Return Mode in Canned Cycles

G98

G99

Path Control Mode

G61

G61.1

G64

Stopping

M0

M2

M1, M30, M60

Spindle Control

M3, M4

M5

G96

G97

Coolant

M7

M8

M9

Other Modal Codes

F

S

T

M50…M53

G54…G59, G59.1…G59.3

Flow-control Codes

O …

Non-modal Codes

M6

G4

G10 L2

G28

G30

G53

G92

G92.1

G92.2

G92.3

M101…M199

(…)

(MSG,…)

(DEBUG,…#123…#<foo>)

(PRINT,…#123…#<foo>)

I J K or R

R L P

R L P Q

K

K

P Z I J R K Q H L E

D

D L

H

I K

P

S

D S

P0 (off) or P1 (on)

sub/endsub, while/endwhile,

if/else/endif, do/while, call,

break/continue/return

T

P

P X Y Z A B C

X Y Z A B C

P Q

Rapid motion

Coordinated motion ("Straight feed")

Coordinated helical motion ("Arc feed") CW or CCW

Straight Probe

Cancel motion mode

Drilling Cycle

Other canned cycles

Spindle-synchronized motion

Rigid Tapping

Multipass lathe threading cycle

Select XY plane

Select XZ plane

Select YZ plane

Absolute distance mode

Incremental distance mode

Inverse time feed rate

Units per minute feed rate

Units per revolution

Inches

Millimeters

Start cutter radius compensation left or right

Start cutter radius compensation left or right, transient tool

Cancel cutter radius compensation

Use tool length offset from tool table

Use specified tool length offset for transient tool

Cancel tool length offset

Retract to R position

Retract to prior position

Exact Path mode

Exact Stop mode

Continuous mode with optional path tolerance

Pause Program

End Program

Other stop codes

Turn spindle clockwise or counterclockwise

Stop spindle

Constant surface speed mode (foot/minute or meter/minute) with top speed

RPM mode

Turn mist on

Turn flood on

Turn all coolant off

Set Feed Rate

Set Spindle Speed

Select Tool

Feed Override, Spindle Override, Adaptive Feed, Feed Hold

Select coordinate system

Change tool

Dwell (seconds)

Coordinate system origin setting

Return to home

Return to secondary home

Motion in machine coordinate system

Offset coordinate systems and set parameters

Cancel offset coordinate systems and set parameters to zero

Cancel offset coordinate systems but do not reset parameters

Apply parameters to offset coordinate systems

User-defined M-codes

A comment "…" to the user

Display the message "…" to the user (e.g., in a popup)

Display the message (with variables substituted) like MSG

Display the message (with variables substituted) to stderr

ORIGIN

Z

Y

This position is expressed as:

X3.0 Y2.0 Z1.0

1.00”

3.00”

2.00”

X

31-5000 - G code user parameters. These parameters are global in the G code file, and

available for general use. Volatile.

5061-5069 - Coordinates of a "G38.2" Probe result of X, Y, Z, A, B, C, U, V & W. Volatile.

5070 - "G38" probe result - 1 if success, 0 if probe failed to close. Used with G38.3 and

G38.5. Volatile.

5161-5169 - "G28" Home for X, Y, Z, A, B, C, U, V & W. Persistent.

5181-5189 - "G30" Home for X, Y, Z, A, B, C, U, V & W. Persistent.

5211-5219 - "G92" offset for X, Y, Z, A, B, C, U, V & W. Persistent.

5210 - 1 if "G92" offset is currently applied, 0 otherwise. Persistent.

5211-5219 - G92 offset (X Y Z A B C U V W).

5220 - Coordinate System number 1 - 9 for G54 - G59.3. Persistent.

5221-5230 - Coordinate System 1, G54 for X, Y, Z, A, B, C, U, V, W & R. R denotes the XY

rotation angle around the Z axis. Persistent.

5241-5250 - Coordinate System 2, G55 for X, Y, Z, A, B, C, U, V, W & R. Persistent.

5261-5270 - Coordinate System 3, G56 for X, Y, Z, A, B, C, U, V, W & R. Persistent.

5281-5290 - Coordinate System 4, G57 for X, Y, Z, A, B, C, U, V, W & R. Persistent.

5301-5310 - Coordinate System 5, G58 for X, Y, Z, A, B, C, U, V, W & R. Persistent.

5321-5330 - Coordinate System 6, G59 for X, Y, Z, A, B, C, U, V, W & R. Persistent.

5341-5350 - Coordinate System 7, G59.1 for X, Y, Z, A, B, C, U, V, W & R. Persistent.

5361-5370 - Coordinate System 8, G59.2 for X, Y, Z, A, B, C, U, V, W & R. Persistent.

5381-5390 - Coordinate System 9, G59.3 for X, Y, Z, A, B, C, U, V, W & R. Persistent.

5399 - Result of M66 - Check or wait for input. Volatile.

5400 - Tool Number. Volatile.

5401-5409 - Tool Offsets for X, Y, Z, A, B, C, U, V & W. Volatile.

5410 - Tool Diameter. Volatile.

5411 - Tool Front Angle. Volatile.

5412 - Tool Back Angle. Volatile.

5413 - Tool Orientation. Volatile.

5420-5428 - Current relative position in the active coordinate system including all offsets

and in the current program units for X, Y, Z, A, B, C, U, V & W, volatile.

5599 - Flag for controlling the output of (DEBUG,) statements. 1=output, 0=no output;

default=1. Volatile.

5600 - Toolchanger fault indicator. Used with the iocontrol-v2 component. 1: toolchanger

faulted, 0: normal. Volatile.

5601 - Toolchanger fault code. Used with the iocontrol-v2 component. Reflects the value of

the toolchanger-reason HAL pin if a fault occured. Volatile.

COMET

ASTEROID

METEOR

NEBULA

A

4x Legs (6060)

692

692

692

692

B

Front/Back (3060)

704

987

704

987

C

Top Sides (3060)

832

832

1528

1528

D

Bottom Sides (3060)

718

718

1414

1414

ALUMINUM STAND ASSEMBLY

Aluminum Stand Assembly

C

B

FRONT

A

B

C

D

B

D

B

Extrusion Lengths (mm)

All rails are mounted inside the legs flush to the outside, except for the C rails, which mount

to the outside. The B rails are front/back of the machine. The upper rails should be flush

with the top while the lower rails can be adjusted up and down as needed.

ALUMINUM STAND MULTI-MOUNTS

KVM ARM

If you also have the KVM arm, you can mount it to the frame as seen above.

Loading...

Loading...