Page 1

3-Channel, 4-Model Memory

FM Computer Racing System

4680 JR XR3i manual 7/17/02 12:14 PM Page 1

Page 2

2

Model Select . . . . . . . . . . . . . . . . 14

Model Name Entry . . . . . . . . . . . 14

Frame Rate Select . . . . . . . . . . . . 15

Auxiliary Channel

3 Function Select . . . . . . . . . . . . . 16

Grip Button C Function Select 17

Data Reset . . . . . . . . . . . . . . . . . . . 19

Copy Model Data . . . . . . . . . . . . 20

Accessing the Function Mode . . . 21

Throttle Deadband . . . . . . . . . . . . 22

Exponential . . . . . . . . . . . . . . . . . . 23

End-Point Adjustment . . . . . . . . 24

Programmable Mixing . . . . . . . . 26

Lap-Timer . . . . . . . . . . . . . . . . . . . 27

Sub-Trim . . . . . . . . . . . . . . . . . . . 28

Servo Reversing . . . . . . . . . . . . . 29

Accessing the Direct Trim Mode 30

Steering Trim . . . . . . . . . . . . . . . . 31

Throttle Trim . . . . . . . . . . . . . . . . . 32

Grip Lever B: Steering Dual-Rate

Trim Adjustment STG . . . . . . . . . 33

Grip Lever A: Brake Endpoint

Adjustment BRK . . . . . . . . . . . . . 34

Auxiliary Channel 3 Access . . . . 35

XR3i Data Sheets . . . . . . . . . . . . . . . 36

Frequency Chart . . . . . . . . . . . . . . . 38

Warranty and Service Information 39

Introduction . . . . . . . . . . . . . . . . . . . . . 2

XR3i Quick Start Setup . . . . . . . . . . . 3

Direct Trim Access . . . . . . . . . . . . . . 4

Servo Trim Adjustment . . . . . . . . . 4

System Features . . . . . . . . . . . . . . . . . 5

Transmitter . . . . . . . . . . . . . . . . . . . 5

Receiver . . . . . . . . . . . . . . . . . . . . . . 5

Servos . . . . . . . . . . . . . . . . . . . . . . . 5

System Specifications . . . . . . . . . . . 6

Components . . . . . . . . . . . . . . . . . . 6

Transmitter . . . . . . . . . . . . . . . . . . . 6

Receiver . . . . . . . . . . . . . . . . . . . . . . 6

Servos . . . . . . . . . . . . . . . . . . . . . . . 6

Control Identification

and Location . . . . . . . . . . . . . . . . . . . . 7

R/C Safety Precautions . . . . . . . . . . . 8

Steering Tension Adjustment . . . . . 9

Charging Jack . . . . . . . . . . . . . . . . . . 9

Receiver/Servo Connections

and Installation . . . . . . . . . . . . . . . . . 10

Operating Your Model . . . . . . . . . . 11

Servo Layout . . . . . . . . . . . . . . . . . . 11

Key Input and Display . . . . . . . . . . . 11

Display Screens . . . . . . . . . . . . . . . . 12

Normal Display . . . . . . . . . . . . . . 12

Up-Timer . . . . . . . . . . . . . . . . . . . _?

Low-Battery . . . . . . . . . . . . . . . . . 12

Lithium Battery . . . . . . . . . . . . . . . 12

Memory Backup . . . . . . . . . . . . . 12

Accessing the System Mode . . . . 13

Table of Contents

Introduction

Thank you for purchasing the XR3i 3-channel radio system.

This system has been designed to provide R/C racers with a

high quality, user-friendly radio system that can be relied

upon year after year, race after race. The XR3i's grip dial

accessible auxiliary third channel is ideal for use as a

mixture channel in gas boats or as a transmission shifter for

vehicles such as the Traxxas®T-Maxx. It is important that

you carefully read this manual before attempting to operate

your XR3i system.

For your convenience, a blank data sheet has been included

in the back of this manual. Once you have input all the

necessary data for a particular model into your transmitter,

we strongly recommend that you immediately write that

information down on the data sheet provided. This will

insure that in the rare case of a memory failure, you will not

lose the models' setup data.

For those who would like to get out to the track quickly

with just the basic radio setup, please refer to the Quick Start

section that follows.

4680 JR XR3i manual 7/17/02 12:14 PM Page 2

Page 3

3

Included in this manual are in-depth instructions detailing

all the steps and procedures needed to correctly program

each of the XR3i's features. Quick Start covers the basic

programming information necessary to get you to the

track fast. Later, when you want to learn more about the

specific features of the XR3i, refer to the appropriate page(s)

in this manual for more detailed programming information.

Note: If the Auxiliary Channel 3 is required, refer

to the Auxiliary Channel 3 System Mode

(page 16) for instructions.

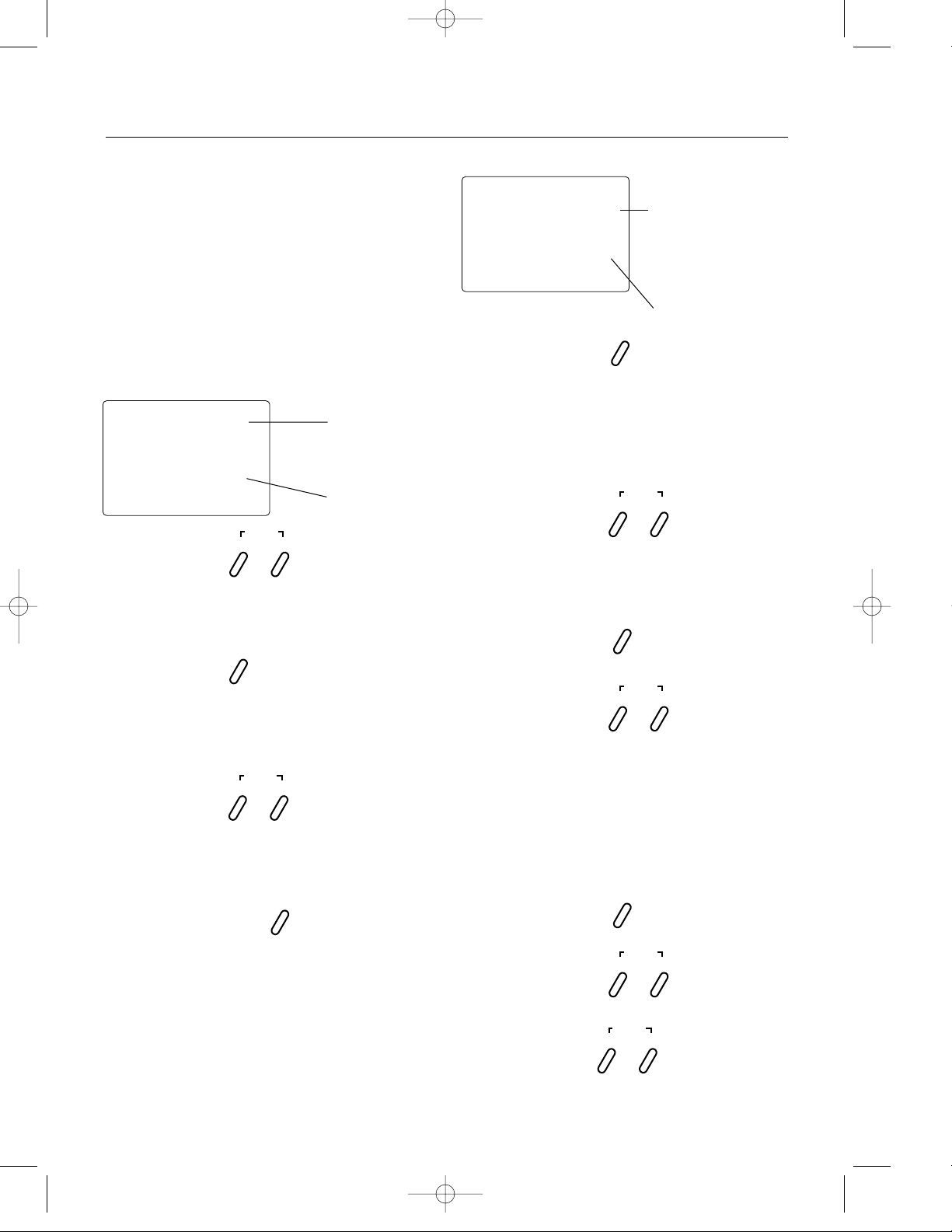

Servo Reversing

1. With the transmitter power switch on, press the Scroll key

to enter the Function mode.

2. Press the Scroll key until "REV.NORM" appears on

the screen. The "ST" indicates the steering servo

reversing screen.

3. Press the Increase or Decrease key to move the cursor to

the desired servo direction (Rev.Norm).

4. Press the Channel key once to access the throttle servo

reversing screen.

5. To select the direction of the throttle servo,

repeat Step 3 above.

6. Repeat Steps 2 and 3 to adjust Auxiliary Channel 3

if needed.

End-Point (Travel) Adjustment

1. From the Servo Reverse function, press the Scroll key

three times to access the End-Point (Travel) Adjustment

function (the EPA screen with "ST" will appear).

Steering Adjustment

2. Rotate the steering wheel in the desired direction (left or

right) to be adjusted.

3. Press the Increase or Decrease keys to select the desired

travel value.

Throttle Adjustment

4. Press the Channel key once. "TH" will appear on

the screen.

5. Pull the trigger for foward or push the trigger for brake

adjustment.

6. Press the Increase or Decrease keys to select the desired

travel value.

Auxiliary Channel 3 Adjustment

If a third channel is not required, proceed to Step 8.

7. Press the Channel key once. "AUX" will appear on

the screen.

8. Press the Increase or Decrease keys to select the desired

travel value.

9. Press the Scroll and Channel keys at the same time to exit

the function mode.

st

—

REV•NORM

SCROLL

ENTER

CHANNEL

CHANNEL

CHANNEL

SCROLL

SCROLL

INCREASE

CLEAR

DECREASE

INCREASE

CLEAR

DECREASE

INCREASE

CLEAR

DECREASE

INCREASE

CLEAR

DECREASE

Channel

ST = Steering

TH = Throttle

AUX =

Auxiliary

Channel 3

(optional)

Servo Direction

st

R/B

100

EPA

Adjustment Position

ST = Steering

TH = Throttle

AUX = Auxiliary Channel 3

(optional)

Current Value

L/F = Left/Forward

R/B = Right/Brake

CHANNEL

SCROLL

ENTER

CHANNEL

XR3i Quick Start Setup

4680 JR XR3i manual 7/17/02 12:14 PM Page 3

Page 4

4

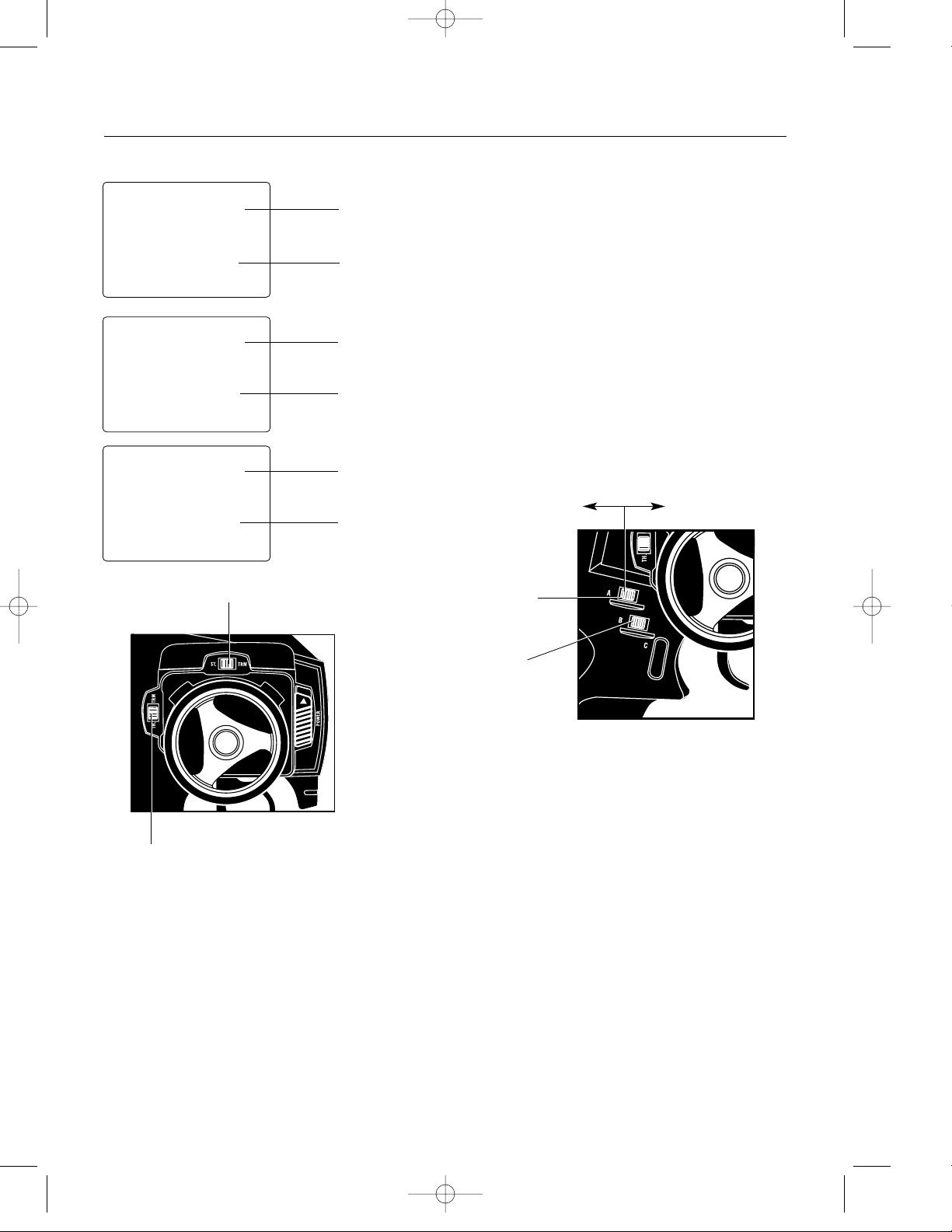

Servo Trim Adjustment

Steering

1. With the transmitter power switch on, move the digital

steering trim lever in the desired position to be adjusted.

The steering trim value screen will appear automatically.

Throttle

2. With the transmitter power switch on, move the digital

throttle trim lever in the desired position to be adjusted.

The throttle trim value screen will appear automatically.

Auxiliary Channel 3 (If active)

3. With the transmitter power switch on, move the

digital grip lever A in the desired position to be adjusted.

The Auxiliary Channel 3 value screen will appear

automatically.

stc

0

TRIM

thc

0

TRIM

ST.

Steering Trim

Function

Throttle Trim

Function

Current Value

Current Value

Throttle Trim

Steering Trim

brk

50

Brake Function

Current Value

Decrease

Diagram A

Increase

Grip Lever A

Brake Trim

Grip Lever B

Steering

Dual-Rate Trim

EPA

R/B

Direct Trim Access

4680 JR XR3i manual 7/17/02 12:14 PM Page 4

Page 5

5

Transmitter

• 3 channels

• FM modulation

• Easy-to-read LCD graphics display

• 4-model memory

• 3-character model name entry

• Electronic digital trim levers for throttle and steering

• Two assignable electronic grip levers

• Auxiliary third channel accessible through Grip Lever A

• Direct display trim function

• Servo reversing

• Sub-trim

• Steering dual-rate

• Exponential (steering and throttle)

• Steering end-point adjustment

(two points: left and right)

• Brake/throttle endpoint adjustment

• Throttle deadband adjustment

• 50-lap timer

• Low-battery alarm

• Plug-in crystals

• Charge jack receptacle (rechargeable batteries

not included; order JRPB958)

R-135 Receiver

• 3 channels

• FM modulation

• 27MHz/75MHz available

• Battery Eliminator Circuitry (BEC)

• Patented ABC&W interference technology

Z590M Servo

• Metal gears for durability

• Great high torque car/buggy steering servo

• Indirect drive feedback potentiometer for additional

vibration protection

• Surface Mount Technology (SMT)

Z270 Servo

• Low current drain

• Indirect drive feedback potentiometer for additional

vibration protection

• Surface Mount Technology (SMT)

• Durable nylon gear train

System Features

4680 JR XR3i manual 7/17/02 12:14 PM Page 5

Page 6

6

Transmitter XR3i

Receiver R-135

Servos Z590M x 1

Z270 x 1

Accessories BEC switch harness with

battery case, servo accessories

(for each servo),

instruction manual

R-135 Receiver

Z270 Servo

Components

Model number XR3i

Encoder 3-channel computer system

RF output 27MHz/75MHz

Modulation FM

Output power 190Mw

Current Drain 180mA

Power source 1.5V x 8 dry cell

(1.2V x 8 Ni-Cd optional)

Output pulse 1000–2000 (1500 neutral)

XR3i Transmitter

Torque 49 ounce inch (@6.0V)

Speed .19 sec/60° (@6.0V)

Weight 1.50 oz

Size (WxLxH) 0.73" x 1.51" x 1.37"

Motor 3-pole ferrite

Torque 85 ounce inch (@6.0V)

Speed .15 sec/60° (@6.0V)

Weight 1.6 oz

Size (WxLxH) 0.73" x 1.55" x .146"

Motor 3-pole ferrite

Model number NER-135

Type 3-channel/FM

ABC&W circuitry

Frequency 27MHz/75MHz

Sensitivity 5qs minimum

(microseconds)

Selectivity 8 KHz/50dB

Weight 1 oz

Size (WxLxH) 1.25" x 1.75" x 0.81"

Receiver Antenna 20"

Power supply 4.8–6.0V DC

Z590M Servo

System Specifications

4680 JR XR3i manual 7/17/02 12:14 PM Page 6

Page 7

7

Antenna

Steering Wheel

Electronic Digital

Throttle Trim Lever

Dot Matrix

Multi- Data

LCD Display

Three-Character

Name Input

Digital Voltage

Reading

Electronic Digital

Grip Lever A

Electronic Digital

Grip Lever B

Grip Button C

Charge Jack

Power Switch

Scroll Button

= Enter Function

= Clear Function

Channel Button

Increase Button

Decrease Button

Electronic Digital

Steering Trim Lever

Throttle Trigger

Adjustable

Steering Tension

Battery Cover *

(8 "AA" batteries required)

*To remove battery cover, press down on the arrow and push the cover in

the direction of the arrow. Remove the battery case and install 8 "AA"

batteries in the direction shown as molded into the battery case. If transmitter

voltage fails to register, check for correct battery installation and voltage.

Control Identification and Location

4680 JR XR3i manual 7/17/02 12:14 PM Page 7

Page 8

8

5. Before operating your model, make sure your frequency is

clear. If someone else is operating on the same frequency,

both models will go out of control, possibly causing

damage to the models, as well as others.

6. If at any time while operating your R/C model you sense

abnormal model functioning, end your operation

immediately. Do not operate your model again until

you are certain the problem has been corrected.

Caution: Control of your model is impossible without

sufficient voltage for the transmitter and receiver. A

weak transmitter battery will decrease your range of

operation, and a weak receiver battery will slow servo

movement and decrease your range of operation.

Check your receiver pack voltage often to avoid losing

control of your model. When using a model that

operates both the electric motor and the receiver from

the same battery (Battery Eliminating Circuitry or BEC),

you should discontinue use when the top speed sharply

decreases or you'll quickly lose control of your model.

For safe and reliable performance of your R/C model, please

carefully read and follow the guidelines below.

1. Radio control models are not toys. They are capable

of inflicting serious injury to people and property.

Use caution at all times when operating your model.

2. You are responsible for the safe operation of your R/C

model. You must properly install, test and operate your

model with a clear sense of that responsibility. Do not

take risks that might endanger yourself or others.

3. Running an R/C car in the streets is very dangerous to

both drivers and models. Avoid running your model in

areas occupied by full-size automobiles. To locate areas

where you can safely operate your model, contact your

local hobby shop for R/C tracks or clubs in your area.

4. When running an R/C boat, keep it away from any swim-

mers, full-size boats and wildlife. Also, watch carefully for

fishing lines that may get tangled in the propeller.

The Federal Communications Commission (FCC) requires

that changes in transmitter frequency must be preformed

only by an authorized service technician (Horizon Service

Center). Any transmitter frequency changes made by a noncertified technician may result in a violation of the FCC rules.

R/C Safety Precautions

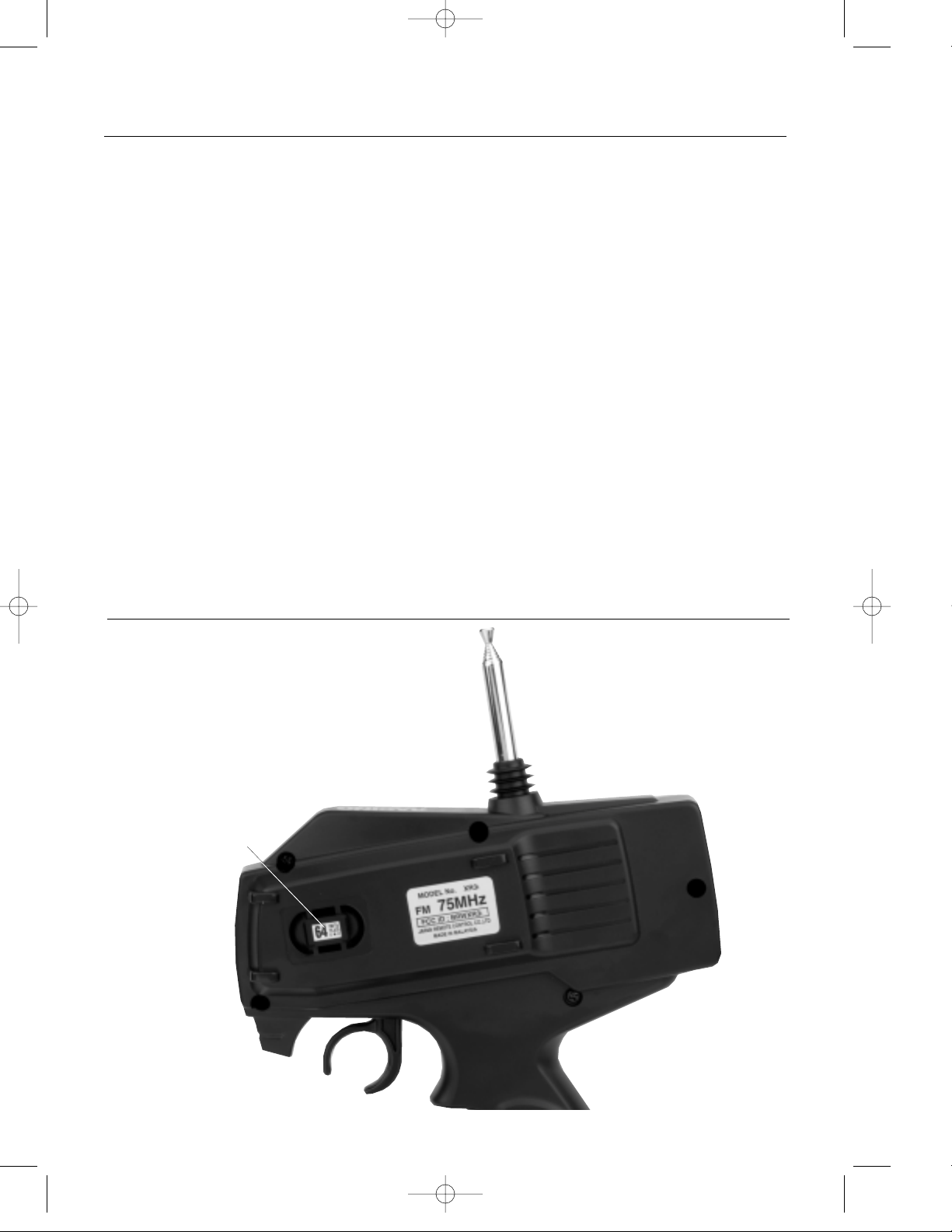

Transmitter Crystal Replacement Notice

Crystal

4680 JR XR3i manual 7/17/02 12:14 PM Page 8

Page 9

9

Charging Jack

Located on the left-hand side of the transmitter is the

charging jack that accepts only JR wall chargers. Please do

not attempt to use any other brand of wall charger, as it may

be reverse polarity and can cause damage to your system.

Only use the JR wall charger when the XR3i is equipped with

Ni-Cd batteries (JRPB958, available separately).

Charger Pigtail For Transmitter

Black To Positive

Red To Negative

JR TRANSMITTER CHARGE JACK POLARITY:

Steering Tension Adjustment

Steering tension is adjustable via the recessed screw located

beneath the steering wheel (see page 7 for exact location).

Turning the screw clockwise increases the steering tension.

4680 JR XR3i manual 7/17/02 12:14 PM Page 9

Page 10

10

Your R-135 receiver is equipped with Battery Eliminator

Circuitry (BEC). The receiver gets its power from the model’s

Ni-Cd battery pack, thus saving the weight of an additional

receiver battery. Ni-Cd batteries from 4.8–8.4V (4–7 cells)

can be used safely. Higher voltage packs may damage the

receiver and servos.

Note: When using a separate receiver Ni-Cd as

a power source, the operating voltage range

is 4.8–6.0V (4- to 5-cell).

Attention: Make sure the male and female connectors

have the correct polarity (+/-) before connecting.

The servo lead and receiver case are molded so that

the lead can only be inserted correctly. Be sure to

orient the servo plug correctly for proper insertion.

You may use a separate receiver battery to power the receiver

(such as for some electric boats or in gas-powered vehicles).

A Ni-Cd pack plugged into the battery socket on your receiver

will operate your receiver. You can also use alkaline batteries

with the included battery box.

If you use a mechanical speed controller, please make sure it

has the correct connector for a BEC system (red connector).

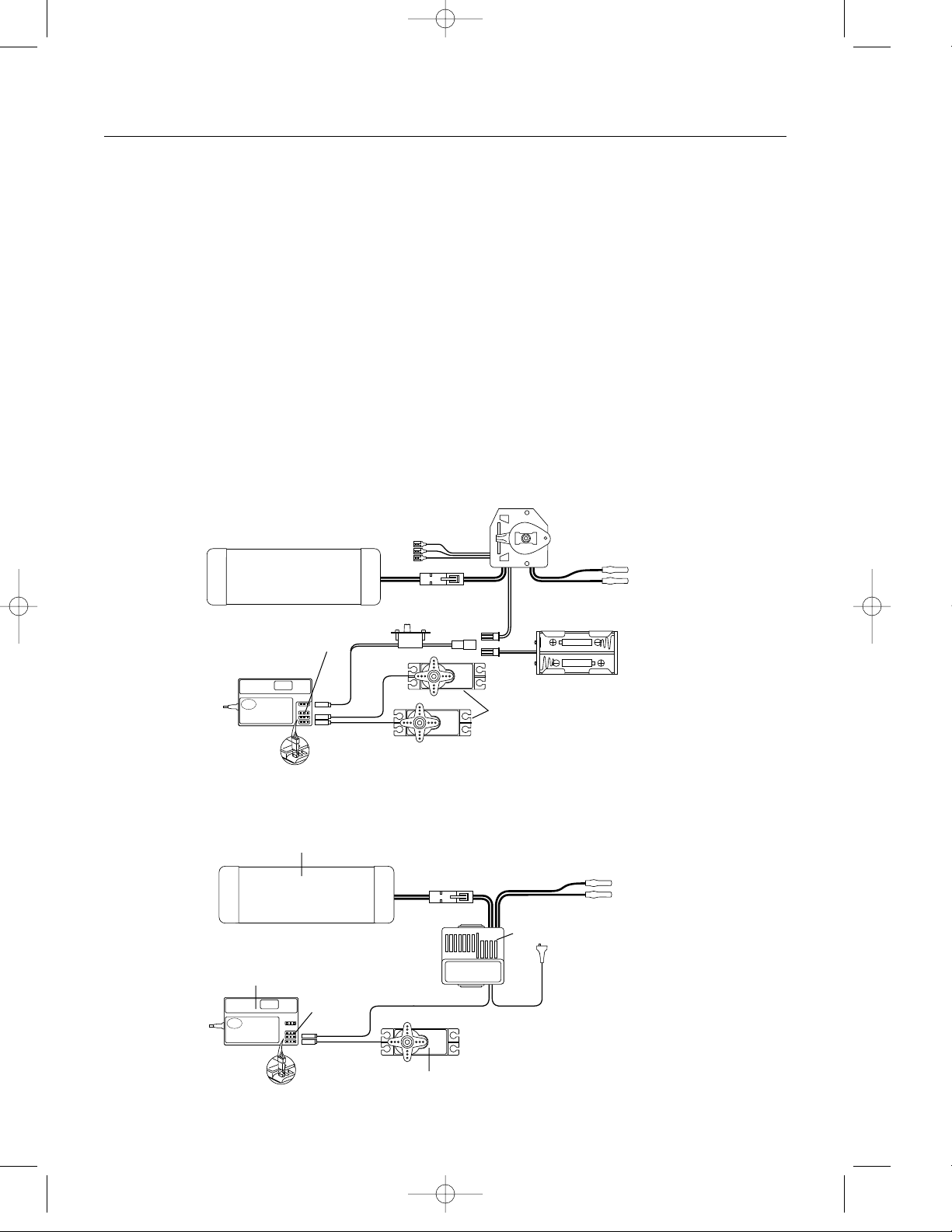

See Figure A below for a typical setup. Most electronic speed

controllers are set up for BEC operation and plug directly

into your receiver (Figure B). See Figure B for a typical

setup and check your speed controller‘s manual for

correct installation.

Figure A – Connections to BEC receiver with mechanical speed controller. Ni-Cd battery and speed controller

are not included in the radio set.

Figure B – Connections to BEC receiver with electronic speed controller. Ni-Cd battery and speed controller

are not included in the radio set.

To Resistors

Mechanical

Speed Control

BEC Connector

Switch

R-135 Receiver

R-135

Z270/Z590M Servos

To Motor

Battery Box

(for use with optional separate

receiver battery power)

7.2V–8.4V Battery

7.2–8.4V Battery

R-135 Receiver

Third Channel

(Optional)

R-135

Z270/Z590M Servo

ESC

To Motor

Third channel

(Optional)

Receiver/Servo Connections and Installation

4680 JR XR3i manual 7/17/02 12:14 PM Page 10

BEC

BEC

Page 11

11

It’s important to learn the proper sequence for switching

on/off your radio system.

Before Operation

Switch on the transmitter, then the receiver.

After Operation

Switch off the receiver, then the transmitter. This ensures

that you will always have a signal to the receiver and that

your R/C model will not operate out of control when you turn

off the transmitter.

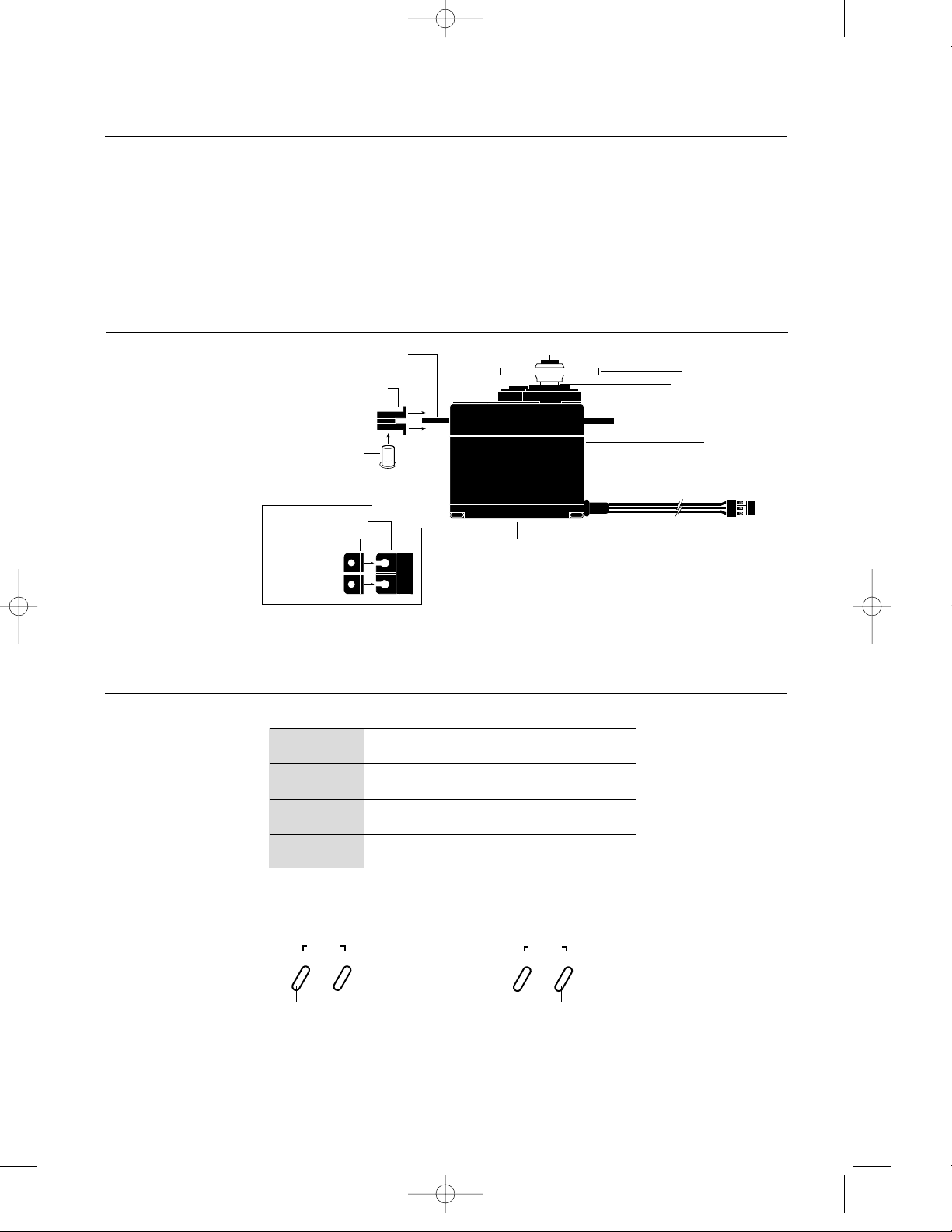

Servo Mounting Flange

Rubber Grommets

Rubber Grommets

Servo Case

Servo Lead with Connector

Servo Output Shaft

Servo Mounting Flange

Servo Arm/Horn

Servo Arm Retaining Screw

Servo Eyelet

Z270/Z590M

Servo

Top View

To enter the Function mode, press the Scroll key

while the transmitter is on.

Press the Increase and Decrease keys

simultaneously to clear the screen or return

to factory preset.

To enter the System mode, press the Scroll

and Channel keys simultaneously and hold

while turning on the transmitter.

KEY

SCROLL

CHANNEL

INCREASE

DECREASE

Moves up through the available functions

Selects the desired channel

Increases the value of the selected function

Decreases the value of the selected function

USE

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

Operating Your Model

Servo Layout

Key Input and Display

Note: Rubber grommets

and (sometimes) eyelets

are used in fuel-powered

vehicles.

4680 JR XR3i manual 7/17/02 12:14 PM Page 11

Page 12

12

Normal Display

When the power switch is turned on, the LCD screen will

read as shown below. This screen is referred to as the

Normal Display.

Note: If any of the electronic trim buttons are moved

while in this screen, the screen will automatically

change to display the trim in use. This is called the

Direct Trim mode. For more information on the feature,

please see page 30 of this manual.

Up-Timer

Note:If the Lap-Timer is enabled, an up-timer display

may alternatively be selected over the normal display

screen by pressing the Channel key. Pressing the

Channel key again will bring back the model name.

(For more information on this feature, please see

page 27.)

Low Battery/Lithium Battery Backup

When the voltage of the 8 "AA" batteries drops below 9.0V,

the XR3i's display screen will alternate between the Normal

and Low-Battery screen (BAT), and a continuous beeping

will occur, indicating that the batteries need to be replaced

before further use. The Low-Battery screen is active during

any operating modes.

Lithium Battery

Your XR3i radio system is equipped with a five-year lithium

battery backup system. This system is designed to protect

and retain all radio programming in the event that the

transmitter batteries drop below the required 9.0 volts, or

the transmitter battery case is removed during battery

changes. If after five years it becomes necessary to replace

the lithium battery, return your system to the Horizon Service

Center for repair (see address, page 39).

Memory Backup

If the Memory Backup screen appears, this indicates the

possibility of a ROM problem or the lithium battery is dead.

If you switch the power off and on again, but the transmitter

is in the default mode with all data lost, it is strongly

suggested that the XR3i transmitter be returned to the

Horizon Service Center for servicing (see Warranty

Information page 39).

bat

8.9V

md !

10.2V

0

10.2V

bak

ER

LAP

Display Screens

4680 JR XR3i manual 7/17/02 12:14 PM Page 12

Page 13

13

To enter the System mode, press both the Scroll and

Channel keys at the same time while turning on the

transmitter power switch. By pressing the Scroll key, you can

now choose Model Select, Model Name Input, Frame Rate,

Auxiliary Channel 3 function, Grip button C function, Data

Reset or the Model Copy function as shown here on the

System Mode flow chart. Information for each function is

located on the page number listed next to the function name

on the flow chart.

To exit the System mode, press the Scroll and Channel keys

at the same time or simply turn off the transmitter.

Note: If you turn the transmitter off and immediately

enter System mode again, you will be returned to the

last System mode function used instead of the model

select function. While in System mode, there is no RF

output generated by the transmitter. Adjustments can be

performed with reduced battery power consumption.

If you exit System mode by pressing the Scroll and

Channel key at the same time, RF output will not be

enabled until you first turn off the transmitter.

Model Name Entry

(page 14)

21

Aux

0

Auxiliary Channel 3

Function

(page 16)

frm

F

Frame Rate

(page 15)

md !

1

mdl

1

Model Select

(page 14)

20

clr

1

cpy

2

gbc

0

Data Reset

(page 19)

25

Grip Button C

Function

(page 17)

Copy Model Data

(page 20)

26

Accessing the System Mode

4680 JR XR3i manual 7/17/02 12:14 PM Page 13

Page 14

14

The XR3i has memory for four models. This feature allows

for four different models to be operated with the same transmitter (additional receivers and servos must be purchased

separately) or one model with four different race setups.

Accessing the Model Select Function

1. Press the Scroll and Channel keys at the same time

and hold.

2. Turn the transmitter power switch on to enter System

mode.

3. If "MDL" does not appear on the screen, press the Scroll

key until "MDL" appears.

4. Press the Increase or Decrease keys to select the desired

model number (1, 2, 3, or 4).

5. Press the Scroll key to access the Model Name Entry

function.

6. To exit System mode, either turn the transmitter power

switch off or press the Scroll and Channel keys at the

same time.

The XR3i allows a three-character name to be input for

each of the four models available. The current model with

name will then be displayed in the Normal display screen.

This feature is useful to help identify different models,

setups, etc.

Accessing the Model Name

Entry Function

1. Press the Scroll and Channel keys at the same time

and hold.

2. Turn on the transmitter power switch to enter the

System mode.

3. Press the Scroll key until "MD1" appears on the screen

with the first character flashing.

4. Press the Increase or Decrease keys to select the correct

letter/number for the first character (flashing). To clear the

character, pressing the Increase and Decrease keys at the

same time.

5. To change the remaining two characters, press the

Channel key until the desired character to be changed

is flashing.

6. Press the Scroll key to access the Frame Rate function.

7. To exit the System mode, either turn the transmitter power

switch off or press the Scroll and Channel keys at the

same time.

Press and hold the

Scroll and Channel keys

at the same time while

turning transmitter

power switch on.

Press the Increase

or Decrease keys to

select the desired

model to be used

(1, 2, 3, or 4).

Press and hold the Scroll

and Channel keys at the

same time while turning

transmitter power switch

on. Next, press the Scroll

key until the flashing

“M” appears.

Press the Channel

key to select the

character to be

changed.

Press the Increase or

Decrease keys to

select the correct

letter/number to be used.

md !

1

Character to

be Adjusted

Current Model

Number

mdl

1

Model Select

Fuction

Current Model

Number

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

Model Select

(System Mode)

Model Name Entry

(System Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 14

Page 15

15

The Frame Rate function allows you to select one of two

transmitter frame rates available: Normal "N" - the default or

Fast "F". The Normal Frame Rate should be selected if you

are using only non-digital servos. The Fast Frame Rate may

be selected if you are using at least one digital servo.

Note: The Frame Rate function offers quicker

response times in the “F” or Fast mode. Some

types of non-JR servos are not compatible in the

“F” Fast mode and require the radio to be operated

in the “N” Normal mode.

Accessing the Frame Rate Function

1. Press the Scroll and Channel keys at the same time

and hold.

2. Turn on the transmitter power switch to enter the System

mode.

3. Press the Scroll key until "FRM" appears on the screen.

4. Press the Increase or Decrease key to select the desired

frame rate (N or F).

5. Press the Scroll key to access the Auxiliary Channel 3

function.

6. To exit the System mode, either turn the transmitter power

switch off or press the Scroll and Channel keys at the

same time.

Press and hold the

Scroll and Channel

keys at the same time

while turning the

transmitter power

switch on. Next, press

the Scroll key until

“FRM” appears.

Press the Increase or Decrease key to select the

desired frame rate.

Current

Frame Rate

frm

F

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

Frame Rate Select (System Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 15

Page 16

16

The Auxiliary Channel 3 function of the XR3i allows you to

select from two different types of Channel 3 servo travel

movements or to inhibit the Auxiliary Channel 3 function.

Use the information below to select the correct Auxiliary

Channel 3 function type for your particular installation. It is

suggested the 0 function be selected for most applications.

(Factory preset)

00

= The 0 or Inhibit function allows the Brake End-Point

Adjustment function, page 34, to be used. This function

is designed to be used with most types of electric and

gas-powered R/C cars. This feature is extremely popular,

as it allows the amount of panic braking accessible through

the throttle trigger's braking position to be adjusted during

operations for maximum effectiveness. When activated,

the braking values will be visible via the Direct Trim function,

page 30.

LLNN

= The LN or linear servo travel function is designed

to be used when an engine fuel mixture servo is required.

This function is most commonly used with gas-powered

R/C racing boats and is accessible through Grip Dial A. In

this function, the maximum travel of the servo is determined

by the End-Point Adjustment function, page 24. The servo

neutral position can be altered proportionally via the Grip

Dial A for mixture adjustment. When activated, fuel mixture

trim values are visible for the direct trim function, page 35.

22PP

= The 2P or 2 position Servo Travel function is designed

to be used as a transmission gear shift channel. This feature

is designed for use with vehicles such as the Traxxas

®

T-Maxx. This function is accessible through Grip Button C

or Grip Dial A if Grip Button C is occupied by another

function. In this function, the servo's travel values are determined by the End-Point Adjustment function, page 24.

Accessing the Auxiliary

Channel 3 Function

0 = Inhibited (Grip Dial A braking is active)

LN = Linear servo movement

2P = 2-position servo movement

1. Press the Scroll and Channel keys at the same time

and hold.

2. Turn on the transmitter power switch to enter

System mode.

3. Press the Scroll key until "AUX" appears on the screen.

4. Press the Increase or Decrease key to select the correct

Auxiliary Channel 3 function type to be used.

5. Press the Scroll key to access the Grip Button C Select

function.

6. To exit the System mode, either turn the transmitter power

switch off or press the Scroll and Channel keys at the

same time.

aux

2P

Auxiliary Channel 3

Function

Non-linear

Two-Position

Movement

(Traxxas shiftable

transmission use)

Press and hold the

Scroll and Channel

keys at the same time

to enter the System

mode. Next Press the

Scroll key until "AUX"

appears.

Press the Increase

or Decrease key to

select the desired

Auxiliary channel

3 function type to

be used.

aux

LN

Auxiliary Channel 3

Function

Linear Movement

(fuel mixture servo)

aux

0

Auxiliary Channel 3

Function

Channel 3 is Inhibited

(Grip Dial A braking

function is now

activated)

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

Auxiliary Channel 3 Function Select (System Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 16

Page 17

17

The Grip Button C function of the XR3i allows you to select

from 3 different functions available. Use the information

below to select the correct Grip Button C assignment for your

particular installation.

"0": Off. (Default) If "AUX " is "2P ", then "2P " replaces"0" in this screen.

"Eb": ESB (Emergency Steering Button.) To cancel the "STG" regulation

for panic steering.

"LA": Lap timer.

Note: If "LA" or "Eb" is selected and "2P" is assigned

to the Auxiliary Channel 3 function, the Auxiliary

Channel 3 function is moved to Grip Dial A.

(Factory preset)

00

= The 0, or off function, is the default setting and does not

assign a function to Grip Button C. If the Auxiliary Channel 3

function is set to "2P" or 2-position, "2P" will appear in this

screen in place of "0" and Grip Button C will function as the

gear select button.

EEBB

= The Eb or Emergency Steering Button function is

designed to override the value of Grip Dial B and provide

100% steering rate. This feature is useful if you have reduced the steering rate to make your vehicle easier to drive

but need full steering in an emergency situation such as a

collision.

{Figure 24-Insert new drawing of Grip Button C and Eb value

Callout GBC -

Callout Eb - Indicates

Emergency Steering Button is

activated}

LLAA

= The LA or Lap-Timer function is designed to be used

when you want to enable the recording of individual lap time.

The Lap-Timer function is described on page 27.

{Figure 24-Insert new drawing of Grip Button C and LA value

Callout GBC - Indicates Grip Button C function

Callout LA - Indicates Lap Timer button is activated}

gbc

LA

Grip Button

Function

Lap-Timer

gbc

0

Grip Button C

Function

Grip Button C is

Inhibited

gbc

EB

Grip Button C

Function

Emergency

Steering Button

is Activated

gbc

LA

Grip Button C

Function

Lap-Timer Button is

Activated

Grip Button C Function Select (System Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 17

Page 18

INCREASE

CLEAR

DECREASE

SCROLL

ENTER

CHANNEL

18

Accessing the Grip Button C Function

1. Press the Scroll and Channel keys at the same time

and hold.

2. Turn on the transmitter power switch to enter

System mode.

3. Press the Scroll key until "GBC" appears on the screen.

4. Press the Increase or Decrease key to select the correct

Grip Button C function type to be used.

5. Press the Scroll key to access the Data Reset function.

6. To exit the System mode, either turn the transmitter power

switch off or press the Scroll and Channel keys at the

same time.

Press and hold the

Scroll and Channel

keys at the same time

to enter the System

Mode. Next Press the

Scroll key until "GBC"

appears.

0 = Inhibited

Eb = Emergency Steering Button

LA = Lap-Timer

Press the Increase or

Decrease key to

select the desired

Grip Button C

function type to

be used.

4680 JR XR3i manual 7/17/02 12:14 PM Page 18

Page 19

19

The Data Reset function allows you to reset all the programming in the selected model (1, 2, 3 or 4) to the factory default

settings. Before using the Data Reset function, it is important

to enter the Model Select function and check to make sure

the current model number indicated (1, 2, 3 or 4) is the

model to which you want to reset to the factory default

settings. The Model Select function is described on page 14.

Accessing the Data Reset Function

1. Press the Scroll and Channel keys at the same time

and hold.

2. Turn on the transmitter power switch to enter the

System mode.

3. Press the Scroll key until "CLR" appears on the screen.

4. Press the Increase and Decrease keys at the same time to

reset the data. To confirm that the selected model's

programming has been reset, a beep will sound and the

model number selected (1, 2, 3 or 4) will stop flashing.

5. Press the Scroll key to access the Copy Model

Data function.

6. To exit the System mode, either turn the transmitter power

switch off or press the Scroll and Channel keys at the

same time.

clr

1

Model to

be Reset

Press and hold the Scroll

and Channel keys at the

same time while turning

the transmitter power

switch on. Next, press

the Scroll key until

“CLR” appears.

Press the Increase and Decrease keys at the

same time to reset (clear) all settings for the

selected model to the factory default settings

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

Data Reset (System Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 19

Page 20

Accessing the Copy Model

Data Function

1. Press the Scroll and Channel keys at the same time

and hold.

2. Turn on the transmitter power switch to enter the

System mode.

3. Press the Scroll key until "CPY" appears on the screen.

4. Press the Increase or Decrease key to select the desired

model number you want the current model data copied to.

This model number being select should be blinking.

5. Press the Increase and Decrease keys at the same time

to copy the current model data into the selected model

number. To confirm that the selected model has been

copied to, a beep will sound and the model number

selected (1, 2, 3 or 4) will stop flashing.

6. To exit the System mode, either turn the transmitter power

switch off or press the Scroll and Channel keys at the

same time.

20

The Copy Model Data function allows you to copy the

current model data into the model memory of the blinking

model selected. Before using the Copy Model Data function,

be sure you know what model number you want to copy the

data to as all data in this selected model will be lost. If the

current model being copied from uses the default name, the

model name from the model being copied to will be retained.

cpy

2

Model being

copied to

Press and hold the

Scroll and Channel

keys at the same time

while turning the

transmitter power

switch on. Next,

press the Scroll key

until “CPY” appears.

Press the Increase and Decrease keys at the

same time to copy model data from the current

model to the selected model.

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

Copy Model Data (System Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 20

Page 21

21

To enter the Function mode, it is necessary to first turn on

the transmitter's power switch. Next, press the Scroll key

until a beep is heard. The display will change to show the

first function listed on the Function mode flow chart as

shown below. Press the Scroll key to scroll down through

the functions one by one, as shown in the flow chart. Once

the desired function has been reached, use the Channel key

to select the appropriate channel (if applicable). To adjust

the values of the function, simply press the Increase (+) or

Decrease (-) keys until the desired value is displayed on the

screen. To exit function mode, press the Scroll and Channel

keys at the same time. The next time you enter Function

mode, you will be returned to the last function accessed.

Mode Key Channel Key

sts

0

TRIM

aus

0

TRIM

ths

0

TRIM

L/F L/F

R/B

R/B

tdb

0

∞

0

∞

0

∞

stl

st

LN

EXP

thf

LN

EXP

st

100

EPA

MIX

aux

100

EPA

th

100

EPA

thb

MIX

40

20

LAP

st aux

SB-TRM

th

SB-TRM

Throttle

Deadband

(page 22)

Channel Key

Exponential

(page 23)

Channel

Key

Channel

Key

Channel

Key

Channel

Key

Channel

Key

Channel

Key

Channel

Key

Mixing

(page 26)

Lap-Timer

(page 27)

End-Point

Adjustment

(page 24)

Sub-Trim

(page 28)

Servo Reversing

(page 29)

—

REV•NORM

—

REV•NORM

—

REV•NORM

Accessing the Function Mode

4680 JR XR3i manual 7/17/02 12:14 PM Page 21

Page 22

22

The throttle deadband feature is used to reduce/eliminate the

dead throttle area that exists at neutral to the starting point of

throttle and from neutral to the starting point of braking. This

area is sometime known as deadband. As more throttle trim

(also known as static brake) is applied, more of the dead

trigger area right off neutral exists. To eliminate the throttle

deadband, adjust a forward value such that your vehicle's

wheels just start to turn when the trigger is slightly squeezed.

This provides the most accurate feel and eliminates the dead

area in the throttle. To eliminate the braking deadband,

adjust the brake value such that your vehicle starts to slow

down when the trigger is slightly pushed. This provides

the most accurate brake feel and eliminates the dead area

when braking.

Values: 0% to 100%

Clear = 0%

Accessing the Throttle

Deadband function

1. Turn the transmitter power switch on.

2. Press the Scroll key to access Function mode.

3. Press the Scroll key until "TDB" appears on the screen

4. Move the trigger accordingly to adjust the forward or

braking deadband.

5. Press the Increase or Decrease key to select the desired

value necessary to eliminate dead area.

6. Press the Scroll key to access the Exponential function.

7. To exit the Function mode, either turn off the transmitter

power switch or press the Scroll and Channel keys at the

same time.

L/F

tdb

0

∞

0

∞

R/B

tdb

Forward Adjustment

(depends on

trigger position)

Current Value

Brake Adjustment

(depends on

trigger position)

Current Value

Press the Scroll key

until "TDB" appears on

the screen.

Press the Increase or Decrease key to select the

desired value necessary.

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

Throttle Deadband (Function Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 22

Page 23

23

The Exponential feature of the XR3i allows you to alter

the response rate of the steering or throttle control around

neutral without affecting the maximum amount of steering

or throttle available. The adjustment range is from -100% to

0% (Linear) to +100%. Exponential is factory set to linear for

both steering and throttle. Exponential is often used to settle

down a car that is twitchy around center without giving up

maximum steering response. The XR3i provides both positive (increase sensitivity at neutral) and negative (decrease

sensitivity at neutral) exponential values.

Accessing the Exponential function

1. Turn the transmitter power switch on.

2. Press the Scroll key to access the Function mode.

3. Press the Scroll key until "EXP" appears in small letters

on the left side of the screen.

4. Press the Increase or Decrease keys to select the desired

exponential value.

5. Press the Scroll key to access the travel End-Point

Adjustment function

6. To exit the Function mode, either turn off the transmitter

power switch or press the Scroll and Channel keys at the

same time.

st

ln

EXP

Steering Exponential

Adjustment

Current Value

thf

ln

EXP

Forward Throttle Exponential

Adjustment

Current Value

thb

ln

EXP

Braking Exponential

Adjustment

Current Value

Press the Scroll key

until "EXP" appears on

the screen.

Press the Increase and Decrease keys to select

the desired exponential value.

Values: -100% to Linear (LN) to +100%.

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

Exponential (Function Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 23

Page 24

24

The End-Point Adjustment feature of the XR3i allows the

maximum travel of both the steering, throttle and Auxiliary

Channel 3 (optional) servos to be increased or decreased in

each direction to achieve the exact servo movement needed.

The End-Point Adjustment range is from 0% to 125% and is

factory set to 100% for both channels. The value displayed

on the screen depends on the current position of the steering

wheel, trigger, or trim lever to be adjusted. This feature is

very useful either to maximize servo travel or to reduce servo

over-travel to eliminate servo binding (servo moves further

than control mechanism allows), without the need for

mechanical linkage adjustment.

The screens below are accessed by turning the wheel to the

desired direction to be adjusted (left or right), by moving the

trigger to the forward or backward (brake) position, or by

moving the Grip Lever A to the forward or back positions.

L/F

st

100

EPA

L/F

aux

100

EPA

R/B

aux

100

EPA

R/B

st

100

EPA

L/F

th

100

EPA

R/B

th

100

EPA

Steering Left

End-Point Adjustment

Current Value

Values: 0 to 125

Clear = 100

Steering Right

End-Point Adjustment

Current Value

Values: 0 to 125

Clear = 100

Forward Throttle

End-Point Adjustment

Current Value

Values: 0 to 125

Clear = 100

Backward Throttle (Brake)

End-Point Adjustment

Current Value

Values: 0 to 125

Clear = 100

Left/Right Travel

Adjustment (function LN)

or Forward Travel

Adjustment

(function 2P) accessible

through Grip Button C

Functions

LLNN& 22PP

Functions

22PP

only

Current Value

Values: 0 to 190

Clear = 100

Rearward Travel Adjustment

(function 2P) accessible

through Grip Button C

Current Value

Values: 0 to 190

Clear = 100

Channel 3 Screens

(Optional)

End-Point Adjustment (Function Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 24

Page 25

25

Accessing The End-Point

Adjustment Function

1. Turn on the transmitter power switch.

2. Press the Scroll key to enter Function mode.

3. Press the Scroll key until "EPA" appears in small letters

on the left side of the screen.

4. Press the Channel key to select the desired channel to

be adjusted.

Steering = ST R/B(steering right) or ST L/F (steering left)

Throttle = TH L/F (forward) or TH R/B (braking or reverse)

Auxiliary Channel 3 (optional) = AUX L/F or AUX R/B

(function 2P only)

5. Move the steering wheel, trigger or Grip Button C in the

desired direction for adjustment (left/right, forward/reverse

or brake). Press the Increase or Decrease key to achieve

the desired amount of travel. Move the wheel, trigger or

Grip Button C in the opposite direction to adjust the travel

in the opposite direction.

Note: For Auxiliary Channel 3 function, if LN is

selected, only L/F is adjustable.

6. Press the Scroll key to access the Mixing Adjustment

function.

7. To exit the Function mode, either turn off the transmitter

power switch or press the Scroll and Channel keys at the

same time.

Note: When setting the end point adjustment values

for the steering function, it is suggested that, if possible,

the maximum travel values be set to an equal value

in both directions to maintain proper steering control.

Press the Scroll key

until "EPA" appears on

the screen

Press the Channel key

to select the channel to

be adjusted

Move the wheel/trigger or Grip Button C in the desired direction and press

either the Increase or Decrease keys to achieve the desired travel value

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

4680 JR XR3i manual 7/17/02 12:14 PM Page 25

Page 26

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

26

The XR3i offers two different mixing adjustments that allows

for mixing one channel to another channel. The mixes

available are Steering-to-Auxiliary Channel Mixing and

Throttle-to-Auxiliary Channel Mixing. Each direction is

independently adjustable. Popular use of this function

includes 4-wheel steering and independent front and rear

wheel brakes.

For example, Throttle-to-Auxiliary channel mixing can be

used for independent front and rear wheel brakes. Each time

the throttle/brakes is moved, the auxiliary channel will move

in the direction and to the value input being given by the

throttle channel. Mixing is proportional, so small inputs to

the throttle will result in small output from the auxiliary

channel. The adjustment range is from -125% to 0% to

125%. If the rate is negative, the channel is mixed in the

opposite direction.

Both mixes share a single mixing "offset." The purpose of

the mixing offset is to redefine the neutral position of the

auxiliary channel, which can be set using Grip Lever A when

"LN" is selected in the Auxiliary Channel 3 function. If the

"LN" selection is turned off in the Auxiliary Channel 3

function with a offset value currently present, the value will

continue to act as a mixing offset until the value is either

cleared or changed. If a mix is not required, it is strongly

suggested the mixing rate be set for 0%, which is the default.

Accessing The Mixing

Adjustment Function

1. Turn on the transmitter power switch.

2. Press the Scroll key to enter Function mode.

3. Press the Scroll key until "MIX" appears in the screen.

4. Press the Channel key to select the desired mix to

be used.

STR or STL = Steering-to-Auxiliary Channel 3 Mixing.

THF or THB = Throttle-to-Auxiliary Channel 3 Mixing.

5. Move the steering wheel or trigger in the desired direction

for adjustment (left/right, forward/reverse or brake).

Press the Increase or Decrease key to achieve the desired

amount of mixing. Move the wheel or trigger in the

opposite direction to adjust the mixing in the opposite

direction.

6. Press the Scroll key to access the Lap-Timer function

(if enabled) or Sub-Trim function.

7. To exit the Function mode, either turn off the transmitter

power switch or press the Scroll and Channel keys at the

same time.

Steering-to-Auxiliary

Channel Mixing

Adjustment

Throttle-to-Auxiliary

Channel Mixing

Adjustment

—

stl

MIX

thb

MIX

Press the Scroll key

until "MIX" appears on

the screen.

Press the Channel

key to select the

desired mix.

Move the wheel or trigger in the desired direction

and press either the Increase or Decrease keys to

achieve the desired mixing value.

10

∞

10

∞

Programmable Mixing (Function Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 26

Page 27

27

The Lap-Timer function of the XR3i allows the recording of

individual lap times based on a 999 second up-timer. Up to

50 laps and times from 3.0 to 99.9 seconds can be stored in

memory for review at a later time. The Lap-Timer function

will only be enabled and shown in Function mode if Grip

Button C (System Mode) is set to "LA." With the Lap-Timer

enabled, pressing the channel key will alternate between the

Normal display screen and Up-Timer display screen.

The Lap-Timer is started by pressing Grip Button C. Once

active, as shown by the blinking word "LAP," pressing Grip

Button C again will begin recording the time of the next lap.

Note: A 3.0 second lap is the quickest lap allowed.

This prevents accidental double pushing of Grip Button

C when recording lap times. If more than 50 laps are

recorded, each new lap will overwrite the oldest lap

held in memory.)

To stop the Lap-Timer, press the Increase and Decrease keys

at the same time. To restart the Lap-Timer, press Grip Button

C. To reset the Up-Timer, press the Channel key to show the

Up-Timer display screen. With the Up-Timer stopped, press

the Increase and Decrease keys at the same time to reset.

To review or reset lap times you must be in the Lap-Timer

function mode screen. Upon entering this function, the

screen will always show the last lap time recorded. Use the

Increase or Decrease keys to view the desired lap(s).

Note: If a recorded lap time is greater than

99.9 seconds, "OVR" will be displayed.)

To reset all lap times, press the Increase and Decrease keys

at the same time.

Accessing The Lap-Timer Function

1. Turn on the transmitter power switch.

2. Press the Scroll key to enter Function mode.

3. Press the Scroll key until "LAP" appears in the screen.

4. Press the Increase or Decrease keys to view the desired

lap time(s).

5. To reset all lap times press the Increase and Decrease

keys at the same time.

6. Press the Scroll key to access the Sub-Trim function.

7. To exit the Function mode, either turn off the transmitter

power switch or press the Scroll and Channel keys at the

same time.

Press the Scroll key

until "LAP" appears on

the screen.

Press the Increase or Decrease keys

to view the desired lap time(s).

401

20

LAP

Recorded Lap

Time to 1/10th of

a second

(i.e. 40.1 sec.)

Current

Lap Number

—

A minus sign indicates a pre-existing lap. Current lap times have no sign.

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

Lap-Timer (Function Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 27

Page 28

28

The Sub-Trim function of the XR3i is an electronic trimming

feature that allows the neutral position of the servo on either

the steering, throttle or auxiliary channel (optional) to be

moved, while allowing the electronic trim lever for that

channel to remain in the center position. This feature is very

useful as it allows the servo arm/wheel position to be moved

to help with control linkage installation, eliminating the need

to make mechanical linkage adjustments.

Although the Sub-Trim function is a very useful feature, it is

suggested that only small amounts of sub-trim be used so

that no unwanted, non-equal servo travel is created. It is

suggested that less than 30 points of Sub-Trim be used

during adjustment. If more than 30 points of Sub-Trim are

required, it is suggested that a mechanical linkage

adjustment be performed.

Accessing the Sub-Trim Function

1. Turn on the transmitter power switch.

2. Press the Scroll key to enter Function mode.

3. Press the Scroll key until "TRIM" appears in small letters

to the left of the screen.

4. Press the Channel key to select the channel to be adjusted

(Steering, Throttle or Auxiliary Channel 3).

5. Press the Increase or Decrease keys until the proper servo

position is achieved.

6. Press the Scroll key to access the Servo Reversing

function.

7. To exit the Function mode, either turn off the transmitter

power switch or press the Scroll and Channel keys at the

same time.

sts

0

TRIM

Current Channel

STS = Steering

THS = Throttle

AUS = Auxiliary

Channel 3

Current Value

Press the Channel key

to select the desired

channel to be adjusted.

STS = Steering

THS = Throttle

AUS = Auxiliary

Channel 3

Press the Scroll key

until "TRIM" appears

on the screen.

Press the Increase or Decrease keys to achieve

the desired Sub-Trim Value.

Values: R/B 125 0 R/F 125

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

Sub-Trim (Function Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 28

Page 29

29

The Servo Reversing feature of the XR3i is a very convenient

feature when setting up a new model. The purpose of the

servo reversing function is to change the direction of the

servo rotation in relation to the wheel/trigger movement. The

Servo Reversing function is available for the steering, throttle

and Auxiliary Channel 3 of the XR3i.

Accessing the Servo

Reversing Function

1. Turn the transmitter power switch on.

2. Press the Scroll key to access Function Mode.

3. Press the Scroll key until "REV.NORM" appears in small

letters to the right of the screen.

4. Press the Channel key to select the channel to be changed

(ST = Steering, TH = Throttle, AUX = Auxiliary Channel 3).

5. Press the Increase or Decrease keys to move the cursor to

the desired direction.

6. To exit the Function mode, either turn off the transmitter

power switch or press the Scroll and Channel keys at the

same time.

Current Channel

ST = Steering

TH = Throttle

AUX = Auxiliary

Channel 3

Current Servo

Direction

st

—

REV•NORM

Press the Channel key

to select the desired

channel to be adjusted.

STS = Steering

THS = Throttle

AUX = Auxiliary

Channel 3

Press the Mode key

until “REV. NORM”

appears on the screen.

Press the Increase or Decrease keys to move

the cursor to the desired servo direction.

SCROLL

ENTER

CHANNEL

INCREASE

CLEAR

DECREASE

Servo Reversing (Function Mode)

4680 JR XR3i manual 7/17/02 12:14 PM Page 29

Page 30

30

The Direct Mode function of the XR3i is accessible through

the use of the electronic throttle or steering trim levers, as

well as the two electronic grip levers (A&B) located on the

upper portion of the grip handle. This function allows for

quick trim adjustment of these controls.

To access the Direct Trim Mode function, turn on the

transmitter power switch. Next, move the desired trim lever

to be adjusted. The appropriate screen for the selected trim

lever will be displayed. To adjust, simply move the trim lever

in the desired direction until the correct amount of trim is

achieved. Once the desired trim is achieved, the screen will

return to the Normal display screen after approximately two

seconds from the last trim input. If the Increase or Decrease

keys are pressed any time during the two seconds, the

system will return to the previous screen in use.

stc

0

thc

0

aux

0

brk

50

EPA

stg

70

∞

RATE

Steering Trim

(page 31)

Only present when Aux. function “O” is selected

Only present when Auxiliary function “LN” is selected

Throttle Trim

(page 32)

Steering Dual-Rate

(Grip Lever B)

(page 33)

Brake Travel Adjustment

(Grip Lever A),

(page 34)

(Only visible when the

Auxiliary Channel 3

function “O” has been

selected.) Refer to

Auxiliary Channel 3

function, page 16, for

clarification.

Auxiliary Channel 3

Trim Adjustment

(LN mode only)

Refer to Auxiliary

Channel 3 function,

page 35, for

clarification.

*Note: When Auxiliary Channel 3 function 2P is

selected, the two screens above are not present.

*

*

TRIM

TRIM

R/B

Accessing the Direct Trim Mode

4680 JR XR3i manual 7/17/02 12:14 PM Page 30

Page 31

31

The XR3i electronic Steering Trim lever, located just above

the steering wheel, allows the center position of the servo

to be manipulated in either direction to achieve precise

centering of the steering assembly. Steering travel end-point

adjustment values (page 24) remain completely independent

from the steering trim, unless the trim value exceeds the

selected end-point values. (For example, if trim values are

set at 30 and end-point values at 15, steering trim will override/alter the end-point value.)

Each click will provide 0.3° of trim to the center of the

steering servo with a maximum of 12° allowed.

Note: Each click will not always result in a

change of the value displayed.

To adjust the steering trim servo position, move the

electronic Steering Trim lever either to the left or the right.

As soon as the trim is moved, the "STC" Steering Trim

screen will appear and will continue to be displayed unless

the trim lever is untouched for a period of two seconds. To

reset the trim value to 0, press the Increase and Decrease

keys at the same time while the "STC" screen is displayed.

TRIM.

Values: L/F 30 0 R/B 30

stc

0

Steering Trim

Screen

Current Value

Press the Increase and Decrease keys at the

same time to reset the steering trim to zero.

Steering Trim Location

Right Trim Left Trim

INCREASE

CLEAR

DECREASE

Steering Trim

Steering Trim (STC)

4680 JR XR3i manual 7/17/02 12:14 PM Page 31

ST.

Page 32

32

The XR3i's electronic Throttle Trim lever, located to the left

of the steering wheel, allows the center position of the servo

to be manipulated in either direction to achieve precise

centering of the throttle trigger neutral position. Throttle

end-point adjustment values (page 24) remain completely

independent from the throttle trim, unless the trim value

exceeds the selected end-point values. (For example, if the

trim value is set at 40 and the end-point values at 30,

Throttle Trim will override/alter the end-point value.)

Each click will provide 0.3° of trim to the throttle servo with a

maximum of 24° allowed.

Note: Each click will not always result in a change

of the value displayed.

To adjust the Throttle Trim servo position, move the

electronic steering trim lever either up or down. As soon as

the trim is moved, the "THC" Throttle Trim screen will appear

and will continue to be displayed unless the trim lever is

untouched for a period of two seconds. To reset the trim

value to zero, press the Increase and Decrease keys at the

same time while the "THC" screen is displayed.

TRIM.

Values: L/F 60 0 R/B 60

stc

0

Current Value

Press the Increase and Decrease keys at the same

time to reset the throttle trim value to zero.

Throttle Trim Location

Throttle Trim

Decrease

Increase

INCREASE

CLEAR

DECREASE

Throttle Trim (THC)

4680 JR XR3i manual 7/17/02 12:14 PM Page 32

ST.

Page 33

INCREASE

CLEAR

DECREASE

33

The Steering Dual-Rate adjustment, located at Grip Lever B,

allows the Dual-Rate value (maximum servo travel) to be

increased or decreased within a range from 100% through

20% of the total end point value established in the steering

EPA function. This function is very useful in race conditions

as it allows you to custom tailor the steering radius and

sensitivity for the current track conditions.

Please note that since the Dual-Rate value shown in the

"STG" screen is the percentage of the end-point value

established in the Steering EPA function, the value will

not always increase or decrease each time Grip Lever B

is moved.

If the Emergency Steering button function (page 17) is

active, pressing Grip Button C will restore the steering dual

rate to 100% until the button is released.

To adjust the Steering Dual-Rate value, move the electronic

Grip Lever B either left (-) or right (+). As soon as the trim is

moved, the “STG” Steering Dual-Rate screen will appear and

will continue to be displayed unless the Grip Lever B is

untouched for a period of two seconds. To reset the trim

value to the factory preset setting of 70%, press the Increase

and Decrease keys at the same time while the "STG" screen

is displayed.

stg

70

∞

RATE

Current Value

(20% to 100%)

Press the Increase and Decrease keys at the same time to

reset the steering dual rate trim to the factory preset (70%).

Decrease

Increase

Grip Lever B

Steering Dual

Rate Trim

Grip Lever B: Steering Dual-Rate Trim Adjustment (STG)

4680 JR XR3i manual 7/17/02 12:14 PM Page 33

Page 34

34

Brake End-Point Adjustment

The Brake End-Point Adjustment, located at Grip Lever A,

allows the maximum servo travel on the braking side of the

throttle trigger to be increased or decreased from 100% to

0% (off). This function is very useful in race conditions as it

allows the racer to custom tailor the "panic" brake value to

maximize the car's braking power for the current track

conditions. Please note that since the Brake End-Point value

shown in the "BRK" screen is a percentage of the total

braking value established in the End-Point Adjustment

function (page 24), the value will not always increase or

decrease each time the Grip Lever A is moved.

Note: If Grip Lever A is assigned an Auxiliary

Channel 3 function by selecting "LN" or "2P"

with Grip Button C in use, the Brake End-Point

Adjustment will not be available.

To adjust the brake endpoint value, move the electronic Grip

Lever A either left (-) or right (+). As soon as the grip lever is

moved, the BRK End-Point Adjustment screen will appear

and will continue to be displayed unless the Grip Lever A is

untouched for a period of two seconds.

Current Value

(100% to 0%)

brk

50

EPA

Move the grip lever A to the left or right to decrease or increase values.

R/B

Decrease

Increase

Grip Lever A

Brake Trim

Grip Lever A: Brake End-Point Adjustment BRK/Auxiliary

Channel 3 Access

4680 JR XR3i manual 7/17/02 12:14 PM Page 34

Page 35

35

When selected, Grip Lever A can be used to access the

Auxiliary Channel 3 function of the XR3i for use as a fuel

mixture channel.

When the LN (linear) Auxiliary Channel 3 function is

selected, Grip Lever A can be used to change the neutral

position of the servo to lean or richen the engine's fuel

mixture. Once the desired fuel mixture has been achieved,

the Grip Lever A value indicated on this screen can be

transferred manually to the Sub-Trim function (page 28) and

the value of the AUX screen can be returned to zero. Please

refer to diagram A to the right for proper grip lever operation.

Auxiliary Channel 3 Access

(Transmission Shift Selector)

When the 2P Auxiliary Channel function is selected, the Grip

Lever A can be used to move the Auxiliary 3 Channel servo

to one of two positions (left/right or forward/reverse) when

LA or Eb is selected for the Grip Button C function. Please

refer to diagram A below for proper shifting procedures.

Note: The End-Point Adjustment function

(page 24) is used to set the forward and reverse

gear servo travel positions.

aux

0

Auxiliary Channel 3 Fuel Mixture Control (LN selected)

Current Value

Forward Gear Reverse Gear

(Transmission Use)

(Fuel Mixture Use)

Decrease

Increase

Grip Lever A

Brake Trim

Auxiliary Channel 3 Access

(Fuel Mixture)

Diagram A

4680 JR XR3i manual 7/17/02 12:14 PM Page 35

Page 36

36

STEERING THROTTLE AUX

THROTTLE DEADBAND F__________% B__________%

EXPONENTIAL __________% F__________% B__________%

END-POINT ADJUSTMENT L__________ R__________ F__________ B__________ L__________ R__________

MIXING L__________% R__________% F__________% B__________%

SUB-TRIM

SERVO REVERSING REV/NORM REV/NORM REV/NORM

Function Mode

MODEL NUMBER 1 2 3 4

MODEL NAME

FRAME RATE N/F

AUX FUNCTION O/2P/LN

GRIP BUTTON C O/Eb/LA

System Mode

TRIM STEERING THROTTLE AUX. CHANNEL 3

VALUES –/+ –/+ –/+

GRIP LEVER B

STEERING D/R %

BRAKE EPA AUX FUNCTION “LN”

GRIP

LEVER A VALUES %

Direct Mode

STEERING THROTTLE AUX

THROTTLE DEADBAND F__________% B__________%

EXPONENTIAL __________% F__________% B__________%

END-POINT ADJUSTMENT L__________ R__________ F__________ B__________ L__________ R__________

MIXING L__________% R__________% F__________% B__________%

SUB-TRIM

SERVO REVERSING REV/NORM REV/NORM REV/NORM

Function Mode

MODEL NUMBER 1 2 3 4

MODEL NAME

FRAME RATE N/F

AUX FUNCTION O/2P/LN

GRIP BUTTON C O/Eb/LA

System Mode

TRIM STEERING THROTTLE AUX. CHANNEL 3

VALUES –/+ –/+ –/+

GRIP LEVER B

STEERING D/R %

BRAKE EPA AUX FUNCTION “LN”

GRIP

LEVER A VALUES %

Direct Mode

XR3i Data Sheet

4680 JR XR3i manual 7/17/02 12:14 PM Page 36

Page 37

37

STEERING THROTTLE AUX

THROTTLE DEADBAND F__________% B__________%

EXPONENTIAL __________% F__________% B__________%

END-POINT ADJUSTMENT L__________ R__________ F__________ B__________ L__________ R__________

MIXING L__________% R__________% F__________% B__________%

SUB-TRIM

SERVO REVERSING REV/NORM REV/NORM REV/NORM

Function Mode

MODEL NUMBER 1 2 3 4

MODEL NAME

FRAME RATE N/F

AUX FUNCTION O/2P/LN

GRIP BUTTON C O/Eb/LA

System Mode

TRIM STEERING THROTTLE AUX. CHANNEL 3

VALUES –/+ –/+ –/+

GRIP LEVER B

STEERING D/R %

BRAKE EPA AUX FUNCTION “LN”

GRIP

LEVER A VALUES %

Direct Mode

STEERING THROTTLE AUX

THROTTLE DEADBAND F__________% B__________%

EXPONENTIAL __________% F__________% B__________%

END-POINT ADJUSTMENT L__________ R__________ F__________ B__________ L__________ R__________

MIXING L__________% R__________% F__________% B__________%

SUB-TRIM

SERVO REVERSING REV/NORM REV/NORM REV/NORM

Function Mode

MODEL NUMBER 1 2 3 4

MODEL NAME

FRAME RATE N/F

AUX FUNCTION O/2P/LN

GRIP BUTTON C O/Eb/LA

System Mode

TRIM STEERING THROTTLE AUX. CHANNEL 3

VALUES –/+ –/+ –/+

GRIP LEVER B

STEERING D/R %

BRAKE EPA AUX FUNCTION “LN”

GRIP

LEVER A VALUES %

Direct Mode

XR3i Data Sheet

4680 JR XR3i manual 7/17/02 12:14 PM Page 37

Page 38

38

FREQUENCY (MHZ)CHANNEL FREQUENCY (MHZ)CHANNEL FREQUENCY (MHZ)CHANNEL

26.995 ..........................1

27.045 ..........................2

27.095 ..........................3

27.145 ..........................4

27.195 ..........................5

27.255 ..........................6

75.410 ........................61

75.430 ........................62

75.450 ........................63

75.470 ........................64

75.490 ........................65

75.510 ........................66

75.530 ........................67

75.550 ........................68

75.570 ........................69

75.590 ........................70

75.610 ........................71

75.630 ........................72

75.650 ........................73

75.670 ........................74

75.690 ........................75

75.710 ........................76

75.730 ........................77

75.750 ........................78

75.770 ........................79

75.790 ........................80

75.810 ........................81

75.830 ........................82

75.850 ........................83

75.870 ........................84

75.890 ........................85

75.910 ........................86

75.930 ........................87

75.950 ........................88

75.970 ........................89

75.990 ........................90

FREQUENCY CHART

Frequency Chart

The Federal Communications Commission (FCC) requires

that changes in transmitter frequency must be preformed

only by an authorized service technician (Horizon Service

Center). Any transmitter frequency changes made by a noncertified technician may result in a violation of the FCC rules.

Transmitter Crystal Replacement Notice

4680 JR XR3i manual 7/17/02 12:14 PM Page 38

Page 39

39

4. Include detailed information explaining your operation

of the system and problem(s) encountered. Provide an

itemized list of equipment enclosed and identify any

particular area/function, which may better assist our

technicians in addressing your concerns. Date your

correspondence and be sure your complete name and

address appear on this enclosure.

5. Include you name, mailing address and a phone number

where you can be reached during the business day.

6. Within your letter, advise us of the payment method you

prefer to use. The Horizon Service Center accepts only

VISA or MasterCard. Please include your card number

and expiration date.

Warranty Repairs

To receive warranty service, you must include your original

dated sales receipt to verify your proof-of-purchase date.

Providing that warranty conditions have been met, your radio

will be repaired without charge.

Normal Non-Warranty Repairs

Should your repair cost exceed 50% of the retail purchase

cost, you will be provided with an estimate advising you of

your options.

Ship your system to:

Horizon Service Center

4105 Fieldstone Road

Champaign, IL 61822

Phone: (217) 355-9511

Note: Be sure to keep your original dated sales

receipt in a safe place as you will be required to

provide proof of purchase date for the equipment

to be serviced under warranty.

Warranty Coverage

Your new JR Remote Control Radio System is warranted

to the original purchaser against manufacturer defects in

material and workmanship for 3 years from the date of

purchase. During this period, Horizon Service Center will

repair or replace, at our discretion and at no cost to the

purchaser, any component that is found to be factory

defective. This warranty is limited to the original purchaser

of the unit and is not transferable.

This warranty does not apply to any unit that has been

improperly installed, mishandled, abused or damaged in a

crash or to any unit which has been repaired or altered by

any unauthorized agencies. Under no circumstances will the

buyer be entitled to consequential or incidental damages.

This limited warranty gives you specific legal rights; you

also have other rights which may vary from state to state.

As with all fine electronic equipment, do not subject your

radio system to extreme temperatures, humidity or moisture.

Do not leave it in direct sunlight for long periods of time.

Repair Service Directions

In the event that your JR radio needs service, please follow

the instructions listed below.

1. Check all on/off switches to be sure they are off. This will

speed the repair process of checking battery condition.

2. Return your system components only (transmitter,

receiver, servos, etc.). Do not return your system installed

in a model car, boat, etc.

3. Preferably, use the original carton/packaging

(molded foam container) or equivalent to ship your

system. Do not use the system carton itself as a shipping

carton. You should package the system carton within a

sturdy shipping container using additional packing material to safeguard against damage during transit. Include

complete name and address information inside the carton,