Pressure Dew Point Monitoring Device !

TPK 21 LT

Functional description and operating instructions

Table of contents

1.

Scope of Delivery

1

2.

General dangers and precautions

2

2.1.

Safety instructions for electrical connection

2

2.2.

Safety instructions for compressed air systems

3

3.

Important application notes

4

3.1.

Avoiding damage to the measuring probe

4

3.2.

Calibration and measuring accuracy

4

3.3.

Intended application

5

4.

Humidity measurement in compressed air systems

5

5.

Function

5

6.

Mounting of the device

6

6.1.

Safety instructions

6

6.2.

Application notes

6

6.3.

Procedure for installation

7

6.4.

Mounting

7

7.

Connection at the compressed air network

8

7.1.

Direct stationary assembly at the compressed air line

8

7.2.

Stationary assembly via hose

8

7.3.

Application of a pre-filter / water separator

9

7.4.

Mounting examples

9

7.5.

Adjustment of measurement chamber choke

10

7.6.

Connection of power supply

11

7.7.

TPK Start-up

12

7.8.

For the rarest of the cases…

12

8.

Operation

13

8.1.

Views of unit

13

8.1.1.

Front view

14

8.1.2.

Side view (from the right)

15

8.1.2.1.

Connection to power supply

15

8.1.3.

View (from below)

16

Table of contents

8.2.

Display

16

8.2.1.

Description of display

17

8.2.1.1.

Description of main screen

17

8.2.1.2.

Description info screen

18

8.2.2.

Adjustment of display fields

19

8.2.2.1.

Possible display variation concerning the different fields

20

8.3.

Personalising Password

22

8.4.

Adjustment of national languages

27

8.5.

Information

30

8.6.

Switching the heating(Heater) system On and Off

33

8.7.

Factory settings

36

8.8.

Outputs

39

8.9.

Touchscreen calibration

44

8.10.

Measurement value simulation

47

8.11.

Statistics Reset

52

8.12.

Reset Fault Memory

55

8.13.

Quit Alarm

58

8.14.

Quit Service

61

8.15.

Filter

64

8.16.

Units setting

67

8.17.

Setting the Date / Time

70

8.17.1.

Setting the Date

70

8.17.2.

Setting the Time

74

9.

Configuration of Relay Adjustments

78

9.1.

Setting Source (Output Parameters)

80

9.2.

Setting the Relay Switching Characteristics

81

9.3.

Setting the Limit Values

82

10.

Configuration of Analog Output

84

10.1.

Selection of desired Source (Output Parameter)

86

10.2.

Selection of the desired analog output value

87

Table of contents

10.3.

Configuration of lower analog output value

88

10.4.

Configuration of upper analog output value

89

11.

Configuration of Alarm Output

90

11.1.

Setting of desired alarm value 1

91

11.1.1.

Setting of desired measurement - channel (source)

91

11.1.2.

Setting Pre-alarm

93

11.1.3.

Setting Main-alarm

98

11.1.4.

Setting delay

103

12.

Setting of desired alarm value 2

105

12.1.

Technical Datas

107

13.

Appendix

109

13.1.

Menu structure

110

13.1.1.

Menu item: Main

110

13.1.2.

Menu item: Out

111

13.1.3.

Menu item: Alarm

112

13.2.

System References and Messages

113

13.3.

EG-Conformance Details

114

13.4.

Guarantee

114

13.5

Accessories

115

13.5.1.

Connecting optional accessories

116

13.5.2.

PIN - Assignment for Conctor

117

13.5.3.

Voltage supply from an external source of supply

119

13.6.

Trouble Shooting Guide

120

13.6.1.

The measured value is flow dependent and too high (i.e. too humid)

120

13.6.2.

The measured value is too high (i.e. too humid)

120

13.6.3.

The measured value is too low (i.e. too dry)

121

13.6.4.

The measured value varies significantly

121

13.7.

Service and Calibration

122

1 Scope of Delivery

1

!

Please read the operating instructions before using this device. In addition to the

operating instructions, important information is provided regarding installation,

initial start-up and troubleshooting in each of the relevant chapters.

The pressure dew-point monitor is supplied ready to use. The scope of delivery includes the

AC adaptor, stylus, stylus holder (which may be attached to the dew-point meter) and

relevant operating instructions.

You may also require:

-

Mounting tools, screws and wall plugs

-

6 / 4 mm compressed - air - hose (WARNING! Use only PTFE hoses!).

-

further nipples, reducers and adapter pieces, if the device is to be integrated into a pipeline.

- Electrical accessories for connection to higher-level overriding control devices.

- Optional accessories, such as external indicator lights, terminal adapters and PC cables!

(see accessories overview).

2 General dangers and precautions

2.1 Safety instructions for electrical connection

2

Please read the following warnings prior to initial start-up! The symbols used in the

operating instructions are intended to call your attention to the safety risks. It is not

enough to simply observe the symbol. It is important to read the full text provided in

the safety instructions!

This symbol indicates a potential risk to humans, equipment or the environment. The

information provided must be strictly observed in order to prevent risks.

This symbol indicates important instructions for use and tips that are important in

order to successfully complete tasks, and which must be strictly observed to ensure

good results.

!

!

!

The device must only be supplied with extra-low voltage. The device's other

electrical connections must also only be connected with electronic components

that are operated via an extra-low voltage supply.

Contact with live parts may result in death. Installation of the controller and

maintenance work must therefore only be carried out by trained personnel. The

power supply must be turned off for installation and servicing.

Also avoid touching the plug or any other electronic components when the

power is switched off. Electrostatic phenomena may damage electronic

components.

The product is not intended to control systems with safety-related functions. Even

during normal operation there is a risk of unexpected malfunction, for example

due to a surge or the failure of a component. The user must make sure that no

damage can occur as a result of a malfunction or undefined device status. This

can be achieved, for instance, through the use of redundant components or

safety circuits.

Incorrect screw tightening torques at the connecting terminals or the use of

unsuitable tools can damage the terminal, resulting in damage to insulation or

the contacts. Poorly connected cables can come loose during operation, posing

a considerable risk to safety. Contact resistance at clamp connections results in

increased heat production that can cause a fire to start. Incorrectly wired

connections can destroy electrical components and result in other damage.

!

2.2 Safety instructions for compressed air systems

3

In the case of unforeseen events, the energy stored in compressed air can cause

material damage or result in injury. The risk increases with the operating

pressure of the system. All work must therefore be performed by appropriately

trained personnel. Appropriate care is necessary when performing any work on

the compressed-air system in order to avoid damage!

The loud venting noise produced upon uncontrolled opening of pressurised lines

can damage hearing or startle other people in the vicinity.

At high flow rates, foreign bodies in the air stream can behave like projectiles

and cause injury to the skin or eyes.

The built-in measuring chamber with sensor is designed to handle pressures of

up to 17 bar. This maximum permissible operating pressure must not be

exceeded. Upstream components must be dimensioned according to the

system's operating pressure and temperature.

The warranty will become null and void if the sensor housing is opened, the

sintered cap removed or in the event of improper handling or the use of force.

!

3 Important application notes

3.1 Avoiding damage to the measuring probe

3.2 Calibration and measuring accuracy

4

Measuring devices are sensitive and must be handled with care:!

Avoid shocks, impacts and vibrations.

The sintered filter protects the sensor against mechanical stress and contamination.

Do not remove the filter. Only use the probe if the sintered filter is undamaged!

Prior to installation, check that there is no condensation, oil or dirt at the measuring

point! Should this be the case, repair and dry out the system!

The measuring system is not suitable for use with compressed air with a high oil content,

as directly covering the sensor with a film of oil impairs its response, blocks the pores of

the filter and damages the filter choke.

As a rule of thumb: If you have any questions, contact the manufacturer.

Do not attempt to experiment with the device as you may cause faults and damage

to occur!

!

Prior to delivery, the pressure dew-point sensor is adjusted and tested by means of a complex

calibration procedure involving several temperatures and humidity points. It is not possible for

the end user to calibrate the device.

Please observe the permissible temperature range for use. Excessive temperatures reduce the

measuring accuracy. The probe will be damaged if the temperature limit is exceeded.

The specified data, in particular the desired measuring accuracy, are valid at a temperature of

20°C. In principle, the lower the temperature at the sensor, the more accurate the measurement

result. If possible, measurements should be taken in a cool area, or the gas should be cooled to

ambient temperature.

With proper use, the probe will have a lifespan of many years. Nevertheless, to prevent errors,

it is important that the sensor be calibrated once a year, according to the manufacturer's

specifications. This particularly applies when the probe is used in critical applications within the

lower dew-point measuring range.

3.3 Intended application

4 Humidity measurement in compressed air systems

5 Function

5

The new TPK 21 LT is intended to be used to measure the pressure dew points, pressure

and temperature of clean, oil-free compressed air, which is free of any abrasive,

corrosive, caustic, toxic, flammable and combustible components. For the scope of

application and the calibrated measuring range, please refer to the technical data.

!

In the industrial sector, quality requirements for compressed air are becoming ever stricter.

Humidity and condensation are not permitted in compressed air and often cause damage to

machines and lead to reduced production quality. Compressed-air dryers are commonly used.

When used correctly, these reduce the moisture content of the air and ensure the production

of high-quality compressed air.

However, problems with dryers are often detected very late on, usually when damage has

already occurred. A large quantity of humidity will have already entered the compressed-air

network, and considerable efforts will be required to dry the system out again. The high

quality standards of the industrial sector call for continuous, reliable and stable long-term

monitoring of the humidity content. This is the only way to detect problems early, before any

damage has occurred.

With its large measuring range, the new TPK series is the ideal measuring system for

monitoring refrigeration, adsorption and membrane dryers. The device is primarily intended

for stationary applications but is also suitable for use as a portable measuring device thanks

to its simple connection system.

If compressed air is not dried before being fed into the compressed-air network, significant

quantities of condensate can form in the pipe network, resulting in the malfunctioning of

valves and pneumatic components, ultimately leading to loss of production. The pressure dew

point in compressed-air systems is therefore a key factor in determining air quality and should

be measured in all systems.

The new TPK series offers the ideal device for monitoring compressed-air quality (humidity,

pressure and temperature) and giving timely warning, before any damage has occurred.

The series has a built-in measuring chamber with a protection filter and filter choke, as well as

a plug connection for a 7.2 mm NW compressed-air socket. Power is supplied via the mains

adapter provided. Initial set-up of the measuring system therefore requires no interference

with the compressed-air network, nor any electrical installation work. Alternatively, the

measuring system can be installed on the compressed-air line to avoid the loss of scavenging

air.

6 Mounting of the device

6.1 Safety instructions

6.2 Application notes

6

The device must only be used for its intended purpose.

Installation of the controller and maintenance work must only be carried out by

trained personnel. The power supply must be turned off for installation and

servicing. The applicable safety regulations must be observed! All work on the

compressed-air system must be carried out under pressure-free conditions.

The device must only be operated with extra-low voltage. This also applies to all

external connections, such as the relay outputs.

!

The air quality at the site of installation must be checked prior to assembly. Repairs

must be made to the system in the case of any water or oil leakages. Contact with

large quantities or water or oil may damage the sensor.

The compressed air must be drawn from the upper side of the pipe. The device

must be mounted above the compressed-air line so that any condensation

produced in the event of failure cannot flood the measuring chamber.

Use only suitable materials. The materials used must be impermeable to water

vapour. Therefore please do not use regular polyurethane hoses! The only

recommended material for flexible hose connections is PTFE ("TEFLON"). All metals

are suitable down to -30°Ctpd. Below this, stainless steel is the preferred choice.

Avoid using excessively long sample-gas lines or unnecessary connectors.

The sensors on upstream components must not diffuse water vapour into the

surrounding environment! Please use only high-quality components, e.g. ball

valves with PTFE seals.

Carefully seal all points of connection with the sensor or measuring chamber.

However, never use anaerobic liquid sealants, as these maydamage the sensor

element!

Heavy particle loads will clog the filter or filter choke over time, resulting in a

delayed response. In critical cases, an additional fine filter must be installed

upstream of the measuring device.

!

6.3 Procedure for installation

6.4 Mounting

7

If using compressed air of unknown quality, use a condensate separator or particle

filter. Additional components must be suitable for the intended use!

In EMC-critical environments the measuring chamber should be electrically isolated

from the metal pipes of the compressed-air network. The use of a PTFE or

Polypropylene double nipple is an example of a suitable solution.

Installation involves the following steps:

- Mounting of the device, if necessary.

- Connection to the compressed-air network

- Adjustment of the filter choke, if necessary

- Connection to the power supply

- Initial start-up

- Setting of the switching points

- Testing and function control

If the device is operated as a portable device or is connected using a standard coupling, as

described below, no further mounting is required.

When mounting onto a machine, the device can be kept level by using mounting brackets. A

drilling template can be found in the appendix of this manual.

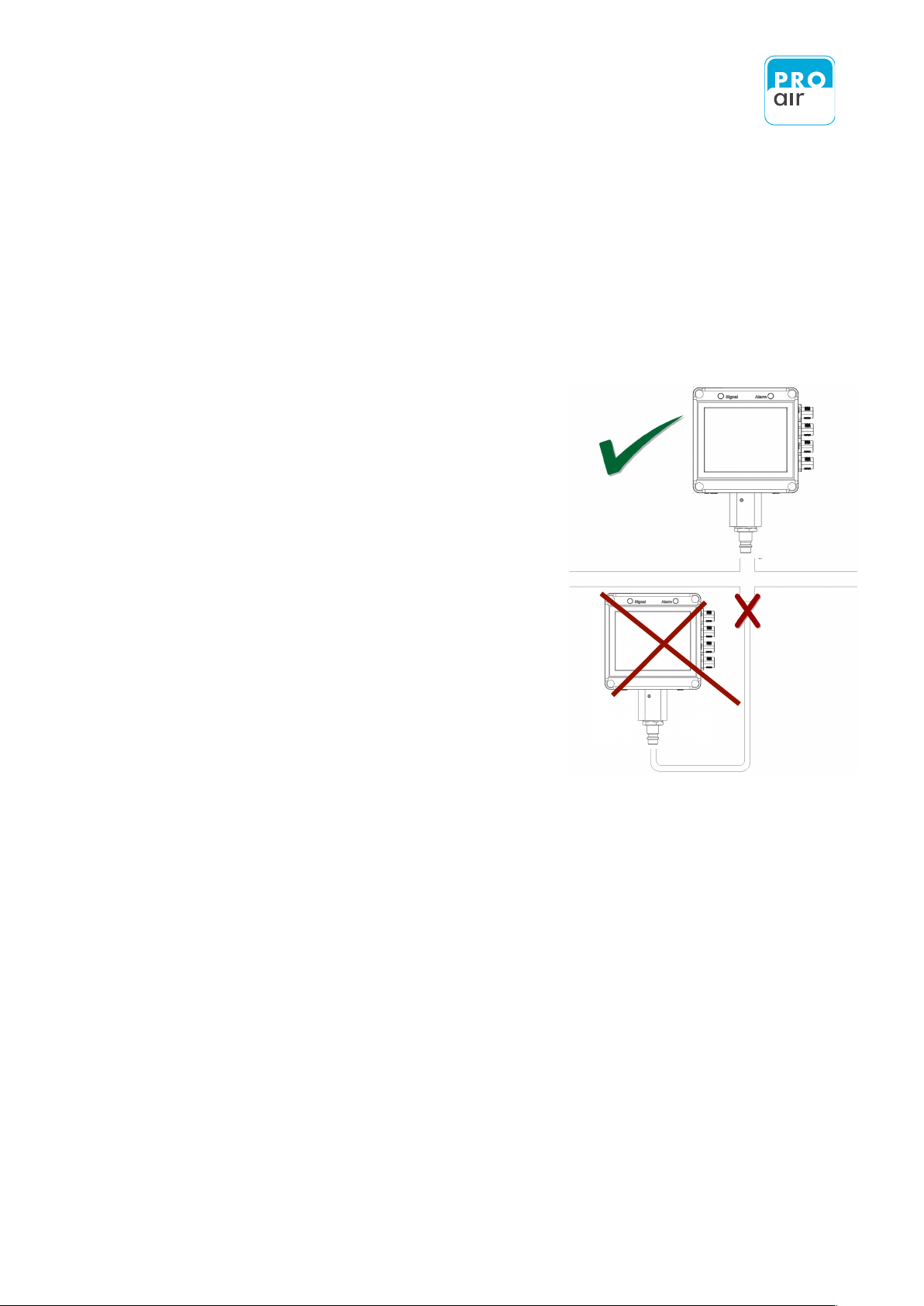

7 Connection at the compressed air network

7.1 Direct stationary assembly at the compressed air line

7.2 Stationery assembly via hose

8

In the case of stationary use, the device is usually installed downstream of the dryer/filter,

enabling the entire system to be monitored. It may also be installed at any point further

downstream in the distribution system in order to

monitor subsegments or the air supply entering a

particular machine.

In order to avoid unnecessary compressed-air

consumption through loss of scavenging air, the

measuring chamber with the sensor should preferably

be directly installed into the compressed-air line.

To prevent the accumulation of condensation in the

event of a fault, the measuring chamber must be

screwed vertically into the line from the top.

Extremely high flowrates or sudden pressure changes

should be avoided, as these may damage the sensor

element.

If a spur line is required for connection, this should

only be a few centimetres long, otherwise the

response will be impaired, especially at low dew-point

values. If longer spur lines are used, the choke must be opened onto the measuring chamber

and set to approximately 60 l/h.

Long, vertical spur lines impair the response or result in incorrect measured values.

The device may be alternatively connected to the compressed-air supply via a Teflon connection

line through the built-in measuring chamber with choke. To ensure correct functioning and

guarantee measuring accuracy there must be a throughflow of air. The basic flow rate can be set

at the choke. In order to avoid unnecessarily high loss of scavenging air, the flow at the rated

pressure can be set to 60 l/h by means of a flow meter. Check from time to time that there is air

flowing at the adjusting screw. If the choke is closed, the measuring device displays values that

are too high or triggers an alarm

7.3 Application of a pre-filter / water separator

7.4 Mounting examples

9

Depending on the state of the compressed-air system and distribution network, it is possible for

dirt, condensate or oil to leak out from the measuring point. In order to avoid damage to the

probe in such critical areas of application, a water separator with a fine filter can be connected

upstream of the device. The upstream components must not alter the moisture content of the air or

unduly impair the response. We can provide you with a list of suitable components upon request.

The device is suitable for a variety of applications. The flexible design of the measuring chamber

allows it to be easily adapted to the intended use:

Connection to a 7.27,2 mm NW quick coupler:

This connection can be quickly and easily performed

within minutes, without any complex installation.

-

An NW 7.2 plug-in nipple with a 3/8" thread is

connected to the underside of the device.

-

The device is connected directly to the coupling, and no

further mounting is required.

-

The choke is set to approximately 60 l/h (factory setting,

as delivered).

!

Permanent connection to a compressed air line:

This type of connection is ideal when there is only a short

distance to the main line because no purge air is consumed.

-

Underneath, a 3/8" double nipple is mounted and

connects to the pipe.

-

In the case of direct connection to a main line, the choke is

closed.

-

For greater connection distances or spur lines, the choke is

set to approximately 60 l/h.

7.5 Adjustment of measurement chamber choke

10

Connection via a compressed-air hose:

This connection variant is ideal, for example, if the device is

intended for portable use or mounted onto a machine or

panel.

-

Underneath, the 3/8" thread is fitted onto a 6/4 mm

hose.

-

The choke is set to approximately 60 l/h for stationary

applications (factory setting, as delivered). If used as a

portable device for rapid measurements the setting should

be changed to approximately 240 l/h.

-

NOTE: Use only PTFE hose for the connection.

The choke's factory default setting is a 60 l/h basic flow rate at a pressure of 10 bar. So long

as the choke has not been adjusted, no adjustment is usually required, provided that this is the

desired flow rate.

Depending on the type of connection, the choke can be closed to avoid the loss of scavenging

air. This is done by fully tightening the Allen screw using the socket spanner provided.

If used as a portable device for rapid measurements the basic flow rate should be set to

approximately 240 l/h. To do this, the choke is opened until the screw is in line with the top

edge of the measuring chamber. The venting noise can clearly be heard in this position. The

response is faster with a high basic flow rate.

To reset the choke to 60 l/h for stationary applications, a flow meter is required, which is fitted

over the screw using a flat seal. The desired flow rate is achieved by repeatedly adjusting and

checking the flow.

Precise adjustment of the desired flow rate is particularly important in the case of stationary

applications, because too high a flow rate results in high operating costs.

7.6 Connection of power supply

11

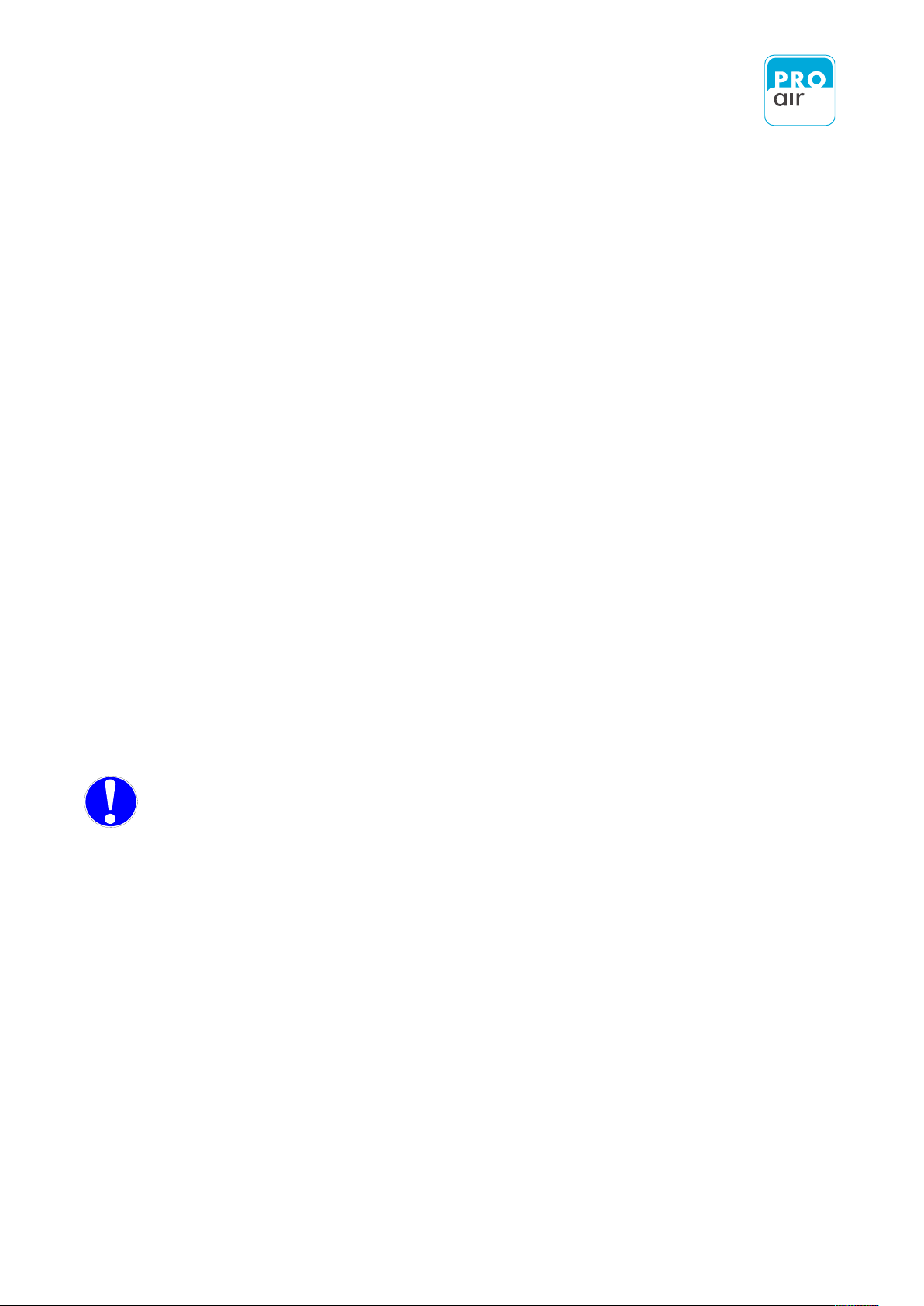

The device is operated with extra-low voltage. A suitable mains adapter is

provided.

The power supply unit is plugged into the lower M12 socket.

No complex electrical installation is necessary, and the device is immediately

ready for operation

The AC adaptor with Europlug is of a high-quality design with a wide-range

input. It is suitable for a 90 - 240 V power supply and is therefore suitable for

Europe-wide use.

How to connect with mains adapter

Do not try to force the connector

when plugging it in.

!

Connection Diagram FGPx remote probe

Follow the guidelines for plugs and

sockets!!

DC 24 V

7.7 TPK Start-up

7.8 For the rarest of the cases…

12

The device immediately starts up when plugged into the power supply. There are no other

switches. The first measured values are displayed immediately after turning on the device. The

measured values are likely to fall immediately following connection to the compressed-air network.

The values will stabilise after a short time. Depending on the system, the following values should

be set:

- For refrigeration dryers: approx. 0 to 7°Ctdp

- For an additional membrane dryer: approx. -20 to -10°C

If the device does not start up, please check the following points:

- Is power arriving at the mains socket ?

- Is the mains plug correctly plugged in ?

- Is the M12 socket of the power supply correctly connected to the device ?

- Does the power supply unit deliver 24 V DC voltage (external power supply units ?

If you have examined all the possible causes and still have not managed to rectify the

malfunction, please immediately contact our customer service department. Do not

open the device, as this will invalidate the warranty claim !

!

8 Operation

8.1 Views of unit

13

General information on the description of the operating procedures

All images of the displays, numerical values and configurations are used by way of

example to explain and clarify the information provided. The actual display on your

device may differ according to the selected settings or ambient conditions.

!

Side view

(from the right)

Front view

View

(from below)

View

Isometric

DC 24 V

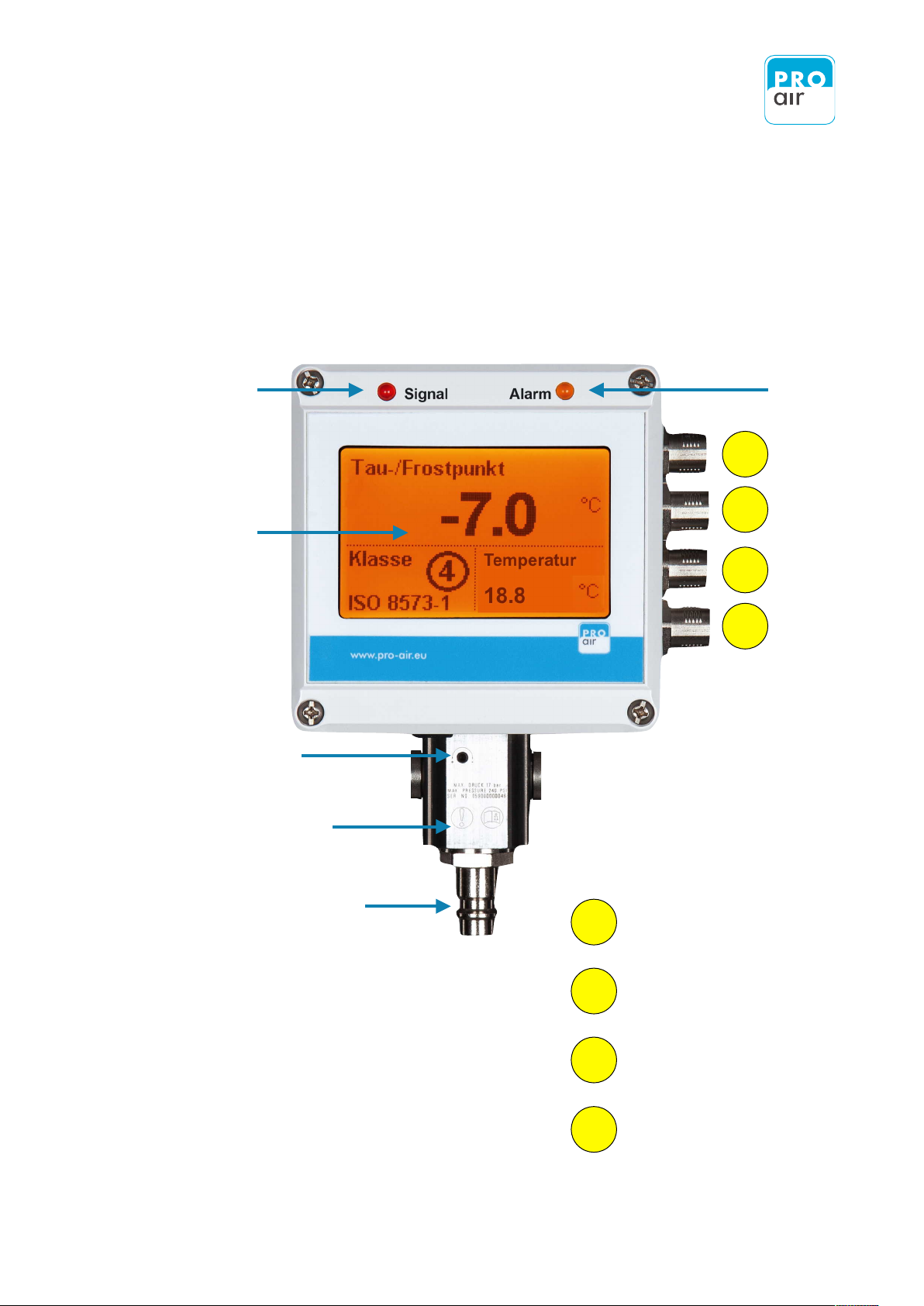

8.1.1 Front view

14

Warning- / Signal LED

LCD touch-display

Choke-adjustment screw

Built-in measuring chamber

Standard NW 7,2 plug-in nipple

(suitable for direct connection to the

compressed-air coupling)

Alarm LED

1

2

3

4

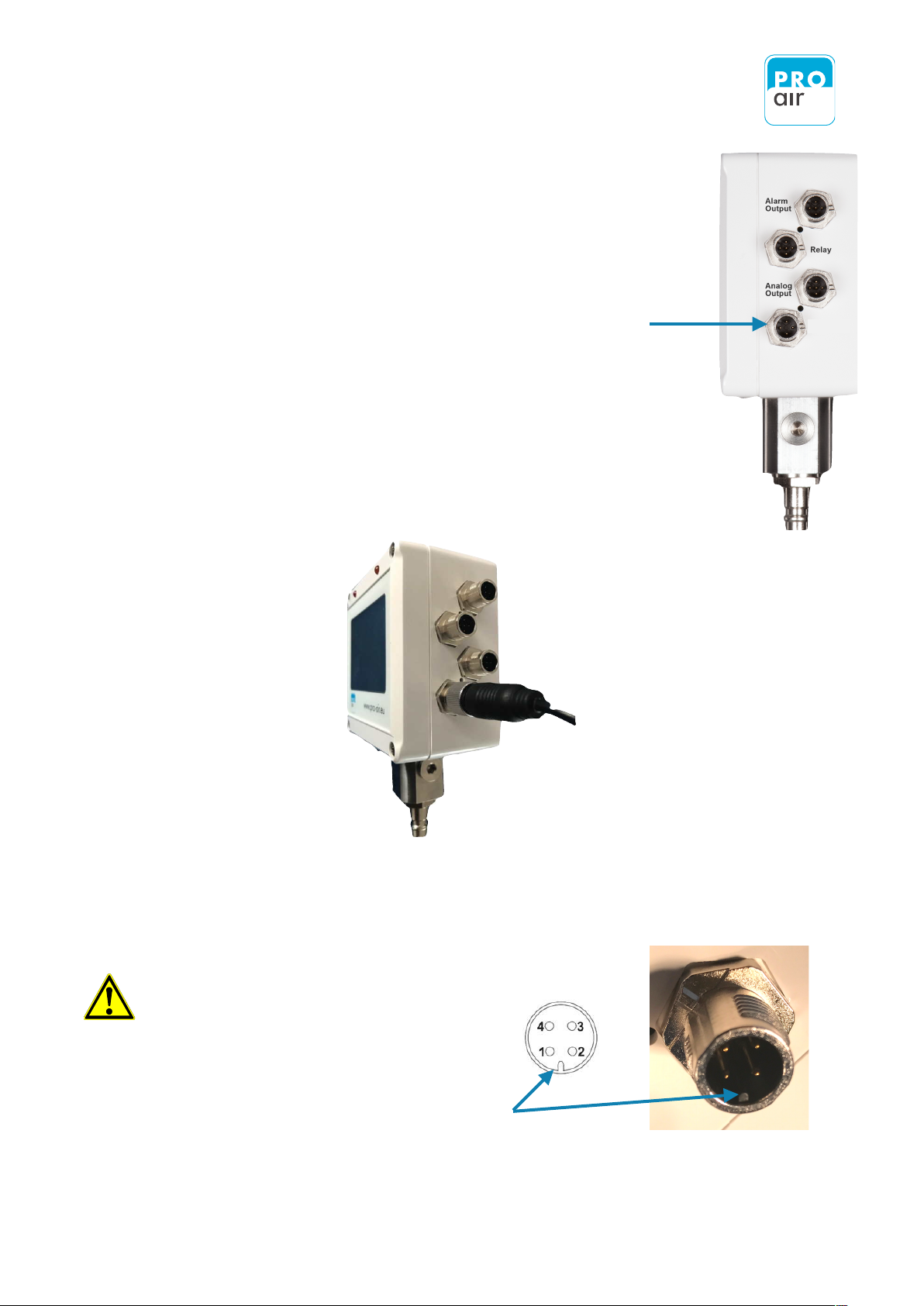

Assignment of the M-12 connection sockets:

Alarm output connection

Relay output connection

Analog output connection

Connection for external mains

adapter

1

2

3

4

8.1.2 Side View (from the right)

8.1.2.1 Connection to power supply

15

Assignment of the M-12 connection sockets:

Connection for external mains adapter

Analog output connection

Relay output connection

Alarm output connection

1

2

3

4

The external mains adapter can be connected to the lower M-12 connection socket.

4

DC 24 V

8.1.3 View (from below)

8.2 Display

16

Connection to the compressed-air network

The built-in touch display is a monochrome FSTN dot-matrix display with white

backlight and a resolution of 160 x 110.

All values may be set or changed accordingly via the screen using the stylus provided

or with careful finger movements.

Caution: The use of pointed objects, such as ballpoint pens or pencils, can

destroy the display and invalidate the warranty!

!

8.2.1 Description of Display

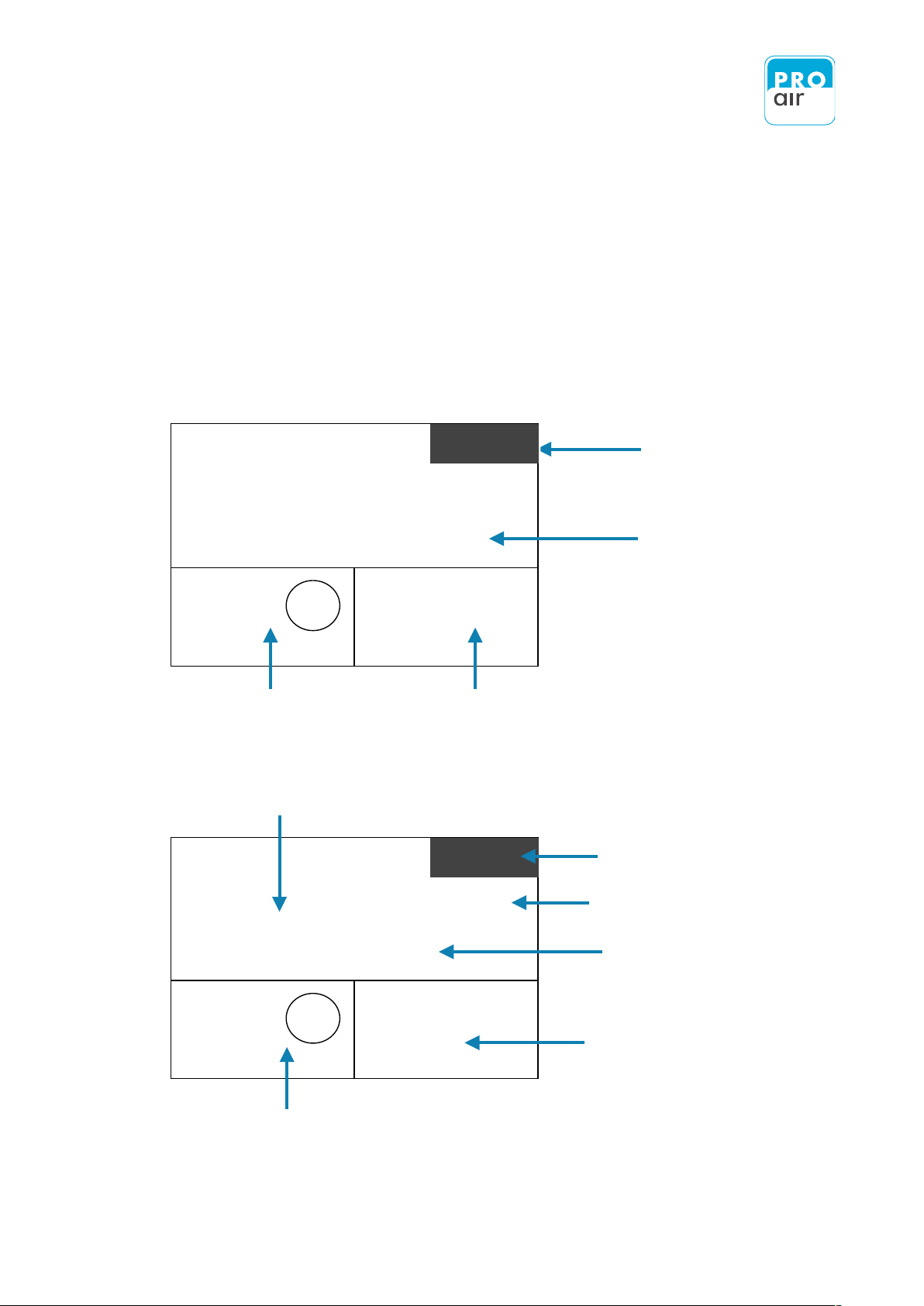

8.2.1.1 Description of the Main Screen

17

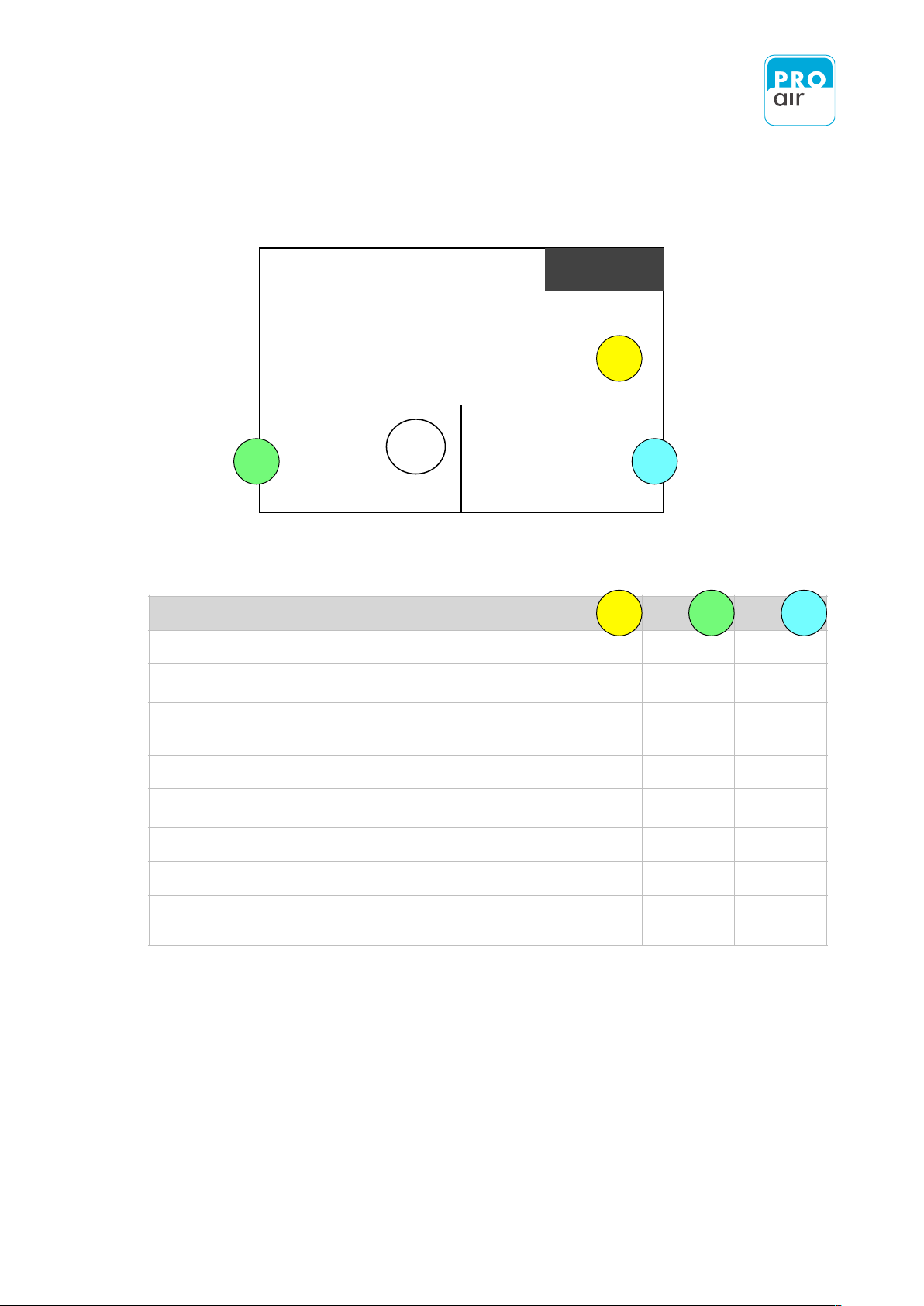

Once the device is connected to the power supply, a welcome screen with the logo

and company name briefly appears and then the main screen is displayed.

The screen is divided into 3 fields (a main field and 2 smaller fields).

All fields can be individually adjusted.

Main Screen

Info Screen

Field 1

Field 2

displays the physical measuring value

Info Screen (temporary), please notice

next page

Unit actual measuring value

Currently measured value

This field shows a further current

measured value with physical unit.

(individually adaptable)

This field shows for example the actual humidity class acc.

to ISO 8573-1 or a further measured value with physical

unit. (individually adaptable)

Class

4

ISO 8573-1

Temperature

22.1

o

C

o

C

Dew-/Frostpoint

- 7.0

H HOLD

Class

4

ISO 8573-1

Temperature

22.1

o

C

o

C

Dew-/Frostpoint

- 7.0

H HOLD

8.2.1.1 Description Info Screen

18

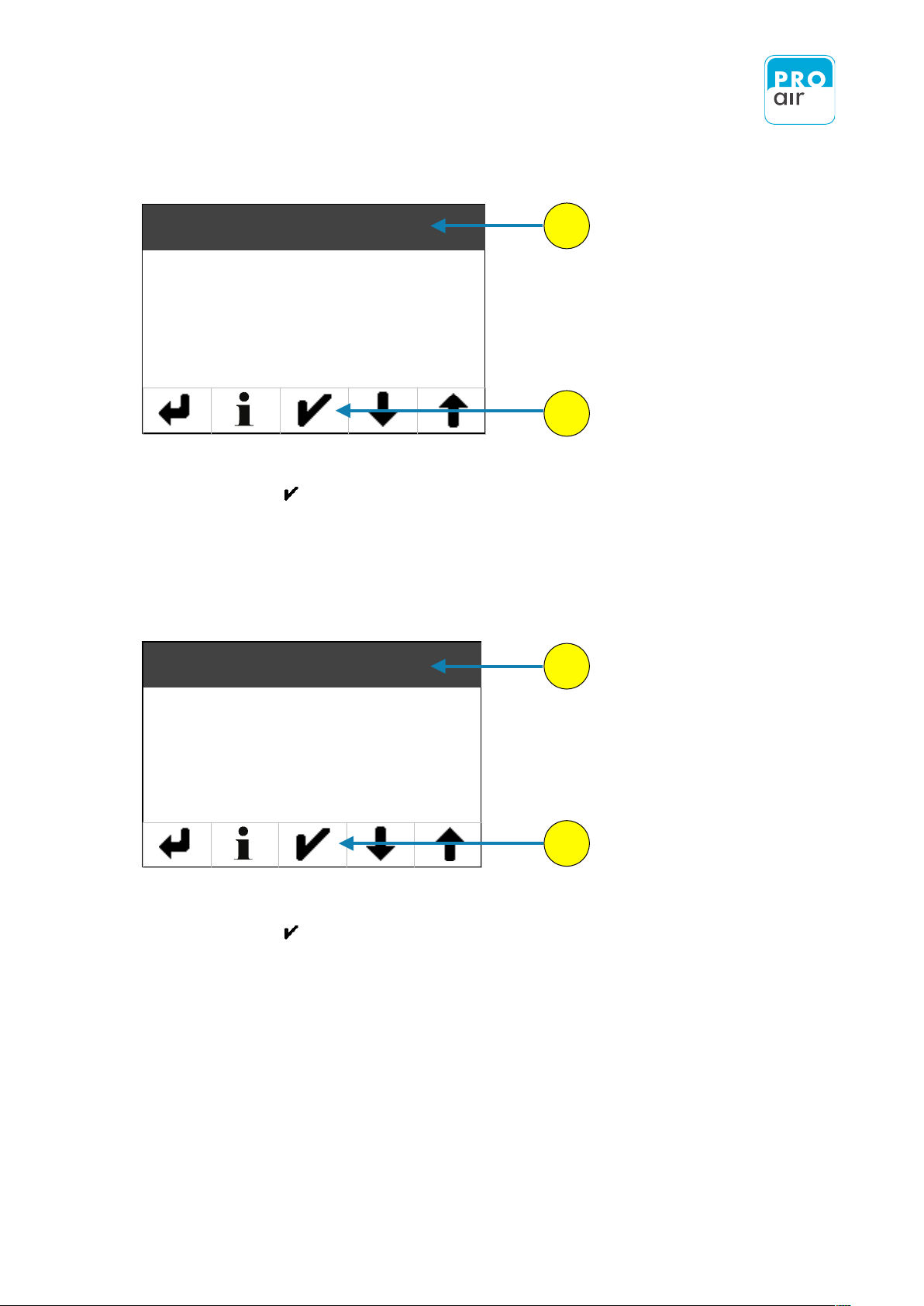

After restarting the device or during bake-out of the sensor an "Information Screen" is

displayed in the upper right-hand corner of the display with the following background.

Dew points in the range of -60 to -20°C at room temperature correspond to relative

humidity values of 0.08 to 5.37% RH. To ensure accurate measurement at the lowest

humidity values, the slightest drift effect of the humidity sensor element must be

compensated for.

Moreover, in order to guarantee the long-term stability of the dew-point sensor the sensor

element is periodically baked out. The sensor is heated every 13 h for approximately

5 minutes and then allowed to cool down to ambient temperature.

During heating "HHOLD" appears on the display, and "CHOLD" is indicated during

cooling. The operation is indicated on the display:

The „Info Screen“ displays the current auto-calibration status:

H HOLD: Heat (The sensor element is being heated)

HOLD (The measured value is being saved)

C HOLD: Cold (The sensor is cooling down)

HOLD (The measured value is being saved)

H HOLD

C HOLD

!

Bake-out is performed every time the device is connected to the mains supply, then

every 13 h. During the entire cycle, the last measured values are retained and are

qualitatively available at the outputs. No further measurements are made during the

heating phase. Therefore no alarm signal will be emitted during this period of time in

the event that a maximum permissible value is exceeded. Only after the heating/

cooling cycle has finished will the device resume measurement and alarm evaluation.

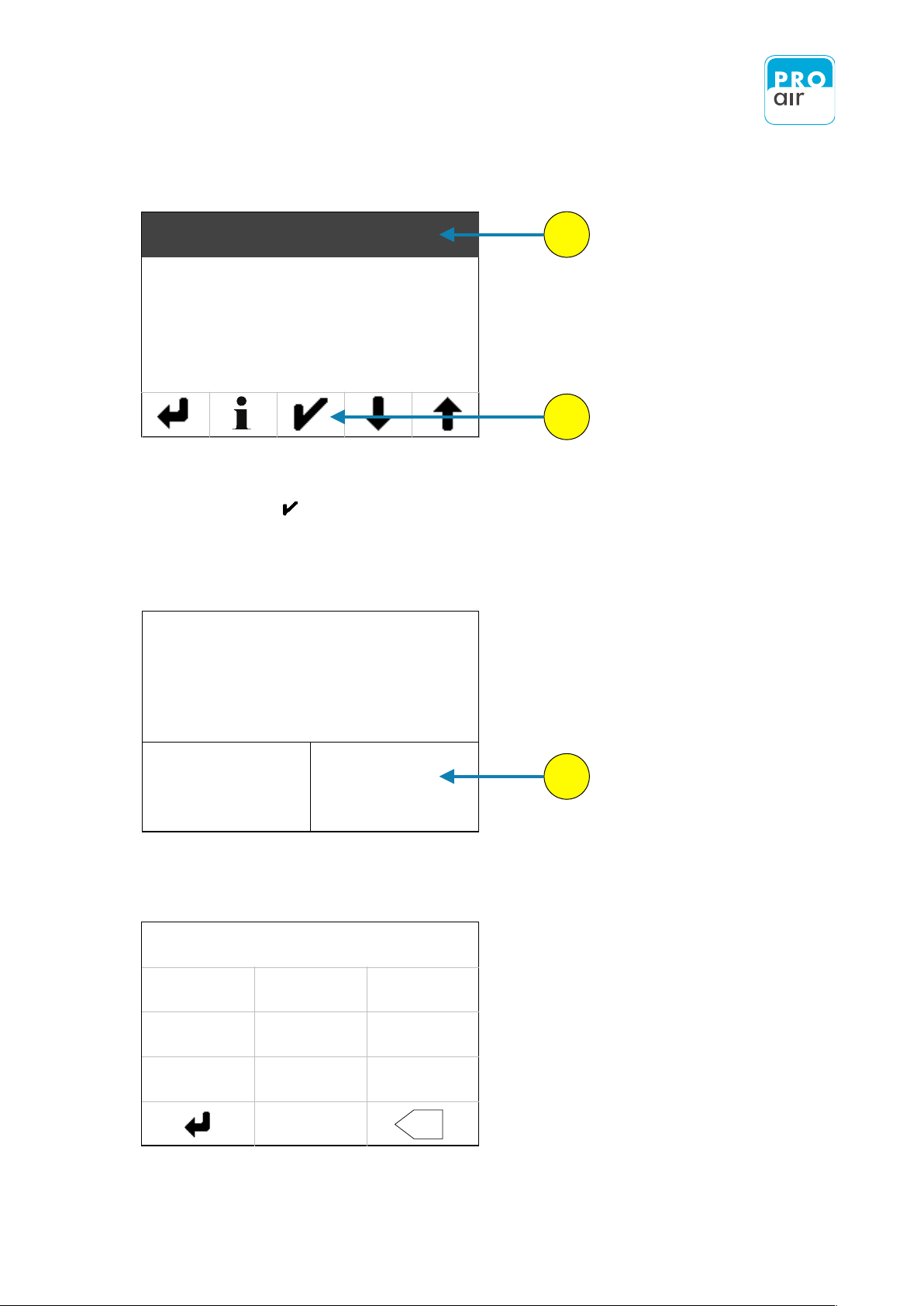

8.2.2 Adjustment of display fields

19

To adjust one of the fields according your specific needs, select the desired field by

tapping it with the stylus provided or your finger.

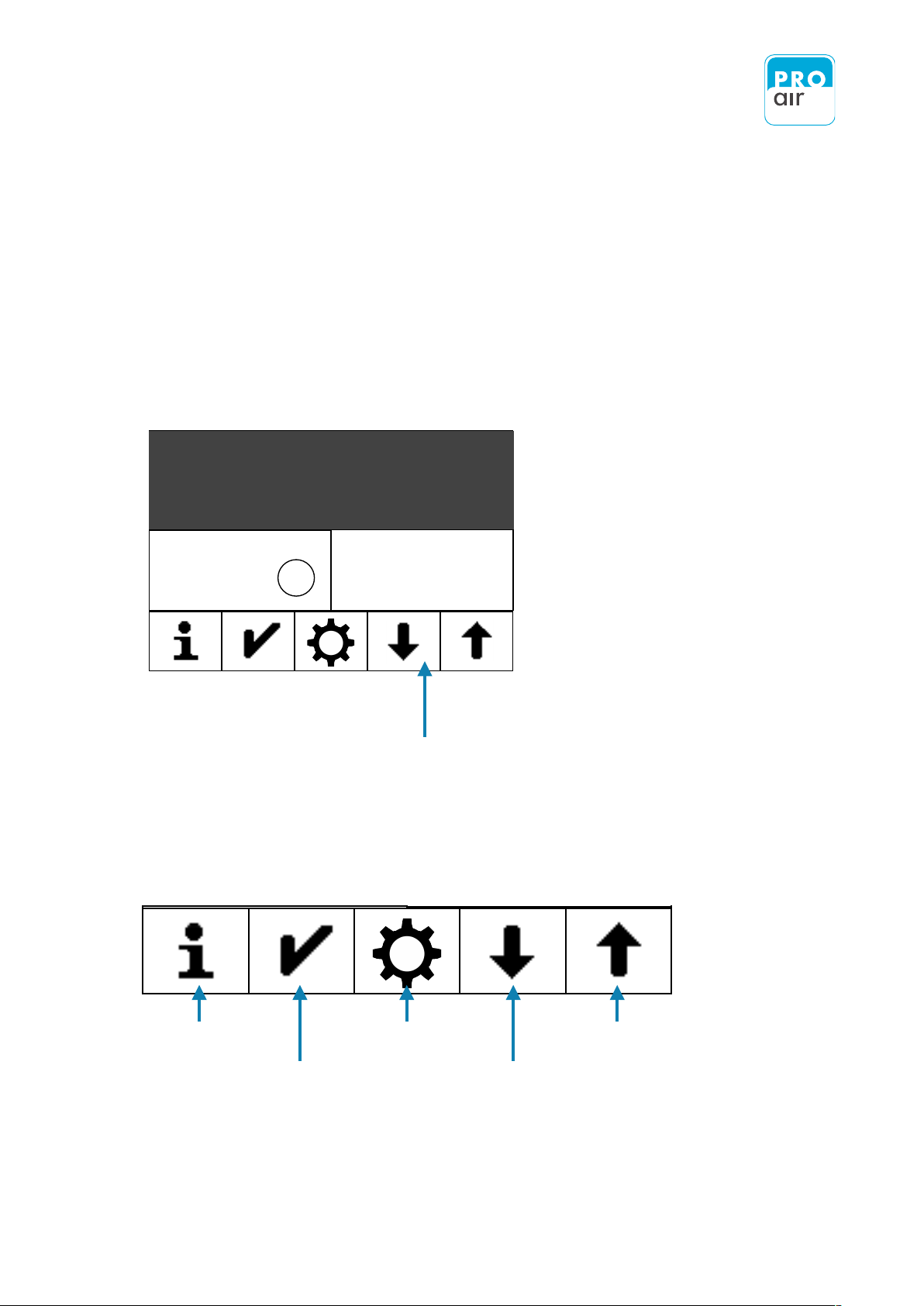

The display now appears as follows (the main field has been selected as an example).

In the lower third of the display an

additional menu bar appears that

allows further settings to be defined.

Klasse

ISO 8573-1

1.17

bar

Tau-/Frostpunkt

- 7.0

o

C

4

Druck

Information

Settings

Scroll - up

Enter - Confirm

Scroll - down

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

8.2.2.1 Possible display variation concerning the different fields

20

Each field can be adjusted on site to meet your specific needs.

The procedure is as follows:

1. Select the desired field on the display (the background turns dark and control

keys appear at the bottom of the display).

2. Scroll up or down to the desired setting using the two arrow keys.

3. Confirm the setting using the "Confirm" key. The display jumps back to the

home screen, where the modified field contents can be seen.

example: Changing the display value in the main field

1

2

3

Select the main field

Scroll up or down to the desired display value

Confirm the desired value

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

1

21

Physical variable

Possible units

Field

Field

Field

Pressure dew point / Frostpoint

o

C, oF

X

Alarm values (settings)

Pre-alarm / Main alarm /

Service

X

X

Date / Time

Various settings are

possible in the main

menue

X

X

Relay - settings

On/Off

X

X

Statistics

Minimum- / Maximum- /

mean value

X

X

Temperature

o

C, oF

X

Relative Humidity

%

XXX

Compressed air class according to

ISO 8573-1

X

123

Class

4

ISO 8573-1

Temperature

22.1

o

C

o

C

Dew-/Frostpoint

- 7.0

H HOLD

1

3

2

8.3 Personalising Password

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

24

The following display of the settings menu appears (Level 3):

8. If the „Password“ field is not already highlighted, select the field and

A display will appear with the following warning:

Select "Yes" to confirm and continue.

8

9

10

Password

Language

Info

Heater

No

Yes

If you forget the password, you have to send

the device to our service to reset it to the

factory default state. Are you sure ?

PIN

_ _ _ _ _ _

123

456

789

0

X

25

If the password has already been changed, enter it now.

If the device is still in its factory settings, enter 111111.

A screen appears that allows you to enter a password of your choice.

Please confirm the new password

!

The required input is indicated in the Password menu in the upper left corner of the

display.

Current PIN

_ _ _ _ _ _

123

456

789

0

X

Confirm PIN

_ _ _ _ _ _

123

456

789

0

X

New PIN

_ _ _ _ _ _

123

456

789

0

X

26

After correctly entering the new password, the display automatically jumps back to the

following display.

The„Back“ key takes you back to the previous level

until you are back at the home screen.

Password

Language

Info

Heater

8.4 Adjustment of national languages

27

The currently available languages are English, German and French. These can be easily

selected via the menu.

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear at

the bottom of the display).

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

1.17

bar

Dew-/Frostpoint

- 7.0

o

C

4

Pressure

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN - - - - - -

1 2 3

4 5 6

7 8 9

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

28

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

29

The following display of the settings menu appears (Level 3):

8. If the „Language“ field is not already highlighted, select the field and

confirm with. .

Select the desired language (the field will be highlighted) and confirm your choice with .

The „Back“ key takes you back to the previous level until you are back at the home screen.

8

9

Password

Language

Info

Heater

English

Deutsch

Français

10

8.5 Information

30

The menu item „Information“ shows all the important device informations at a glance.

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

1.17

bar

Dew-/Frostpoint

- 7.0

o

C

4

Pressure

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN - - - - - -

1 2 3

4 5 6

7 8 9

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

31

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

32

The following display of the settings menu appears (Level 3):

8. If the „Info“ field is not already highlighted, select the field and

confirm with. .

A screen is displayed which provides you with an overview of the most important information.

8

Password

Language

Info

Heater

8.6 Switching the heating (Heater) system On and Off

33

The menu „Heater“ allows you to turn the sensor heating system on or off.

With some primary control systems the heating process can lead to system malfunctions. This

menu enables you to turn off the factory-set heating process.

With typical use in the upper dew-point range of over -10°C the trace heater should be

switched on. In the case of measurements at below -10°C, the trace heater may be switched

off if necessary.

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

1.17

bar

Dew-/Frostpoint

- 7.0

o

C

4

Pressure

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN - - - - - -

1 2 3

4 5 6

7 8 9

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

34

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

35

The following display of the settings menu appears (Level 3):

8. If the „Heater“ field is not already highlighted, select the field and

confirm with .

The following display appears, which allows you to determine the status of the heating system

by selecting "On" or "Off".

Confirm your entry with .

The „Back“ key takes you back to the previous level until you are back at the home screen.

Password

Language

Info

Heater

OFF

ON

8.7 Factory Settings

36

The menu item "Factory settings" can be used to reset the device to its factory default settings.

CAUTION! This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

1.17

bar

Dew-/Frostpoint

- 7.0

o

C

4

Pressure

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN - - - - - -

1 2 3

4 5 6

7 8 9

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

37

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menue item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menue item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

38

The following display of the settings menu appears (Level 3):

8. Please scroll down with „Scroll-down“ key until you see the following screen.

9. If the „Factory Setting“ field is not already highlighted, select the field and

confirm with .

The „Back“ key takes you back to the previous level until you are back at the home screen.

Select „Yes“ if you want to return the device to

its factory settings (NOTE: all saved data will

be lost) and confirm by pressing „Enter“ .

!

8

9

Password

Language

Info

Heater

Factory Settings

Outputs

Touchscreen Calibration

Manual Value Override

Ye s

No

8.8 Outputs

39

This menu item is used to test the relay and alarm functions. Each output can be switched

manually.

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

1.17

bar

Dew-/Frostpoint

- 7.0

o

C

4

Pressure

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN - - - - - -

1 2 3

4 5 6

7 8 9

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

40

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menue item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menue item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

41

The following display of the settings menu appears (Level 3):

8. Please scroll down with „Scroll-down“ key until you see the following screen.

9. If the „Outputs“ field is not already highlighted, select the field and

confirm with .

8

9

Password

Language

Info

Heater

Factory Settings

Outputs

Touchscreen Calibration

Manual Value Override

42

Two choices appear („Output“ and „State“)

10. If the „Output“ field is not already highlighted, select the field and

confirm with .

11. A list will appear of all the test possibilities.

12. Scroll up or down using the "Scroll-down" and "Scroll-up" keys until you find the

output value that you wish to test.

None

Relay 1

Relay 2

Pre Alarm

Main Alarm

Analog Out

10

11

Output

State

Relay 2

Pre Alarm

None

Relay 1

43

13. Select the desired output (the field will be highlighted), and the display will automatically

jump to the next level.

14. If the „State“ field is not already highlighted, select the field and confirm with .

You can now select the status of the previously selected output.

NOTE: For each relevant menu item you can press to call up the help text in

your selected language.

!

The „Back“ key takes you back to the previous level until you are back at the home screen.

14

15

OFF

ON

Output

State

8.9 Touchscreen Calibration

44

This menu item is used to calibrate the touchscreens. Calibration should be performed if the

screen responds inaccurately when touched.

To calibrate the touchscreen, proceed as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

1.17

bar

Dew-/Frostpoint

- 7.0

o

C

4

Pressure

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN - - - - - -

1 2 3

4 5 6

7 8 9

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

45

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

675

4

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

46

The following display of the settings menu appears (Level 3):

8. Please scroll down with „Scroll-down“ key until you see the following screen.

9. If the „Touchscreen Calibration“ field is not already highlighted, select the field and

confirm with .

To calibrate the touchscreen, proceed as follows

Step

Display

To Do

1

Please touch the mark

Tap the screen until the view changes

2

Upper left corner

Touch the target cross on the screen for around 2 seconds

3

Upper right corner

Touch the target cross on the screen for around 2 seconds

4

Bottom left corner

Touch the target cross on the screen for around 2 seconds

5

Bottom right corner

Touch the target cross on the screen for around 2 seconds

The display will then automatically jump back to the home screen.

8

9

Password

Language

Info

Heater

Factory Settings

Outputs

Touchscreen Calibration

Manual Value Override

8.10 Measurement Value Simulation

47

This menu item is used to test the relay and alarm functions. Measured values can be

simulated in order to test the switching characteristics of the outputs.

This menu item enormously facilitates initial start-up, since it is not necessary to set real

conditions in the compressed air system in order to check the correct settings.

There is therefore no interference with operation

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

1.17

bar

Dew-/Frostpoint

- 7.0

o

C

4

Pressure

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN - - - - - -

1 2 3

4 5 6

7 8 9

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

48

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menue item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menue item „Device“ " you will find all of the basic settings for the device.

7

6

5

4

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

49

The following display of the settings menu appears (Level 3):

8. Please scroll down with „Scroll-down“ key until you see the following screen.

9. If the „Manual Value Override“ field is not already highlighted, select the field and

confirm with .

8

9

Password

Language

Info

Heater

Factory Settings

Outputs

Touchscreen Calibration

Manual Value Override

50

Two choices appear („UMC Channel“ und „Set Value“)

10. If the „UMC Channel“ field is not already highlighted, select the field and

confirm with .

12. A list appears of all of the measurement parameters for which a measured value can

be simulated.

Scroll up or down using the "Scroll-down" and "Scroll-up" keys until you find

the Relay and Alarm output value that you wish to test.

None

Temperature

Rel.Humidity

Dew-/ Frostpoint

10

11

UMC Channel

Set Value

Rel. Humidity

Dew- /Frostpoint

None

Temperature

51

13. Select the desired output (the field will be highlighted), and the display will automatically

jump to the next level.

14. If the „Set Value“ field is not already highlighted, select the field and

confirm with .

You can now enter a measured value for which the simulation should be performed.

NOTE: For each relevant menu item you can press to call up the help text in

your selected language.

!

The „Back“ key takes you back to the previous level until you are back at the home screen.

„Undo“,

e.g. for incorrect

entriest

„Enter“,

e.g. to confirm an input

X

0,00

123

456

-

789

0

.

X

UMC Channel

Set Value

8.11 Statistics Reset

52

On the main screen you can display the MIN/MAX/MEAN statistical data.

This menu item resets these values in the measured-value view so that new statistics can be

recorded.

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

1.17

bar

Dew-/Frostpoint

- 7.0

o

C

4

Pressure

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN - - - - - -

1 2 3

4 5 6

7 8 9

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

53

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

7

6

5

4

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

54

The following display of the settings menu appears (Level 3):

8. Please scroll down with „Scroll-down“ key until you see the following screen.

9. If the „Reset statistics“ field is not already highlighted, select the field and

confirm with .

10. Press „Yes“ or „No“ to select your desired choice.

Confirm your selection by pressing .

8

9

Password

Language

Info

Heater

Reset statistics

Clear System Messages

Ye s

No

8.12 Reset of Fault Memory

55

The device has an internal fault memory that makes it easier for you and for us as

manufacturers to comprehend any malfunctioning of the device after the event has occurred.

This fault memory runs in the background and is stored on the SD card.

This menu item allows the fault memory of the device to be reset. This frees memory on the

SD card.

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

1.17

bar

Dew-/Frostpoint

- 7.0

o

C

4

Pressure

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN - - - - - -

1 2 3

4 5 6

7 8 9

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

56

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

7

6

5

4

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

57

The following display of the settings menu appears (Level 3):

8. Please scroll down with „Scroll-down“ key until you see the following screen.

9. If the „Clear System Messages“ field is not already highlighted, select the field and

confirm with .

10. Press „Yes“ or „No“ to select your desired choice.

Confirm your selection by pressing .

9

8

Password

Language

Info

Heater

Reset statistics

Clear System Messages

Ye s

No

8.13 Quit Alarm

58

You can choose in the menu „(Alarm) Auto Off“. If this possibility is not activated, the device

will store the alarm until it will be reset.

This menu item should be reset the alarm manually.

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

3

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys

appear at the bottom of the display).

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN - - - - - -

1 2 3

4 5 6

7 8 9

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

59

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ field is not already highlighted, select the field and

confirm with .

4

5

6

7

Main

Out

Alarm 1

Alarm 2

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

Device

Filter

Unit

Clock

60

The following display of the settings menu appears (Level 3):

Password

Language

Info

Heater

8

8. Please scroll down with „Scroll-down“ key until you see the following screen.

9. If the „Quit Alarm“ field is not already highlighted, select the field and

confirm with .

Ye s

No

10. Press „Yes“ or „No“ to select your desired choice.

Confirm your selection by pressing .

9

Reset Statistics

Clear System Messages

Quit Alarm

Quit Service Request

8.14 Quit Service Request

61

The Service-LED will be activated, when recalibration or any other service is due.

This information will be stored until the user resets.

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN

- - - - - -

123

456

789

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

1.17

bar

Dew-/Frostpoint

- 7.0

o

C

4

Pressure

22

The password can be personalised. The factory default is 111111.

CAUTION: Please make a note of the new password. If the password is forgotten, the

device must be reset to the factory settings. This will result in the loss of all settings!

!

The procedure is as follows:

1. Select one of the three segment fields (the background turns dark and control keys appear

at the bottom of the display).

2. Select „Settings“

The following display appears:

PIN - - - - - -

1 2 3

4 5 6

7 8 9

0

X

3. Enter your personal PIN code (if it has already been changed). If the device is

still in its factory settings, key in 111111 .

1

2

3

Class

ISO 8573-1

22.1

o

C

Dew-/Frostpoint

- 7.0

o

C

4

Temperature

62

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menue item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ field is not already highlighted, select the field and

confirm with .

4

5

6

Main

Out

Alarm 1

Alarm 2

23

You are now in the settings menu (Level 1).

4. If the „Main“ field is not already highlighted, select the field and

confirm with .

Under the menu item „Main“ you will find all of the device settings, as well as the settings for

displaying the measured values.

The following display of the settings menu appears (Level 2):

6. If the „Device“ setting field is not already highlighted, select the field and

confirm with .

Under the menu item „Device“ " you will find all of the basic settings for the device.

4

5

6

7

Main

Out

Alarm 1

Alarm 2

Device

Filter

Unit

Clock

Device

Filter

Unit

Clock

7

63

The following display of the settings menu appears (Level 3):

Password

Language

Info

Heater

8

8. Please scroll down with „Scroll-down“ key until you see the following screen.

9. If the „Quit Service Request“ field is not already highlighted, select the field and

confirm with .

Ye s

No

10. Press „Yes“ or „No“ to select your desired choice.

Confirm your selection by pressing .