ProAir 600 Operation Maintenance & Technical Manual

ProAir 600

Heat Recovery Ventilation Systems

OPERATION

MAINTENANCE

&

TECHNICAL

MANUAL

ProAir Systems, Tuam Business Park, Weir

Rd., Tuam, Co. Galway.

Tel 093 60892

www.proair.ie

Email proair@proair.ie

Contents

Contents..................................................................................................................................................................2

System Description ................................................................................................................................................3

Control....................................................................................................................................................................5

Installation..............................................................................................................................................................6

Maintenance ...........................................................................................................................................................9

Technical Specification. .......................................................................................................................................14

Technical performance values..............................................................................................................................15

PA 600 parts list ...................................................................................................................................................17

Electrical schematic..............................................................................................................................................18

2

System Description

The whole house ventilation system has been professionally designed and

manufactured in Ireland by ProAir Heat Recovery Ventilation Systems Ltd. It has been

installed and tested in accordance with the relevant EN standards and in conformity to

Part F and B of the DOE SI 497 of 1997 & DOE SI 581 of 2002 Regulations.

It has been designed to:

• Continuously ventilate all the rooms in your house in a controlled manner to give a

healthy environment.

• Remove moisture & odours thereby preventing condensation build-up, mould

growth etc.

• Provide a draught free environment with the required amount of filtered fresh air

for the occupants.

• Minimise the energy losses by recovering the heat from the extracted stale air &

transferring up to 90% of this heat to the incoming fresh air.

The principle behind energy efficient whole house ventilation is to continuously

supply fresh air & extract stale air, such that the air is changed in the house around ten

times per day. Air is supplied to living areas (bedrooms living room) and extracted

from service areas (bathrooms, kitchen, utility).

It is normal to feel a very slight air movement at supply points. This air will be within

2 degrees of the average temperature of your house (17-19°C) but may still feel cool.

This is because of the movement of the air and because your body temperature will be

normally around 37°C.

The temperature of the supply air is dependant on the average of all the extract points.

If one extract point is at low temperature (because a bathroom window was opened in

winter and forgotten) then this will bring down that average and cause supply air

temperature to be low throughout the system.

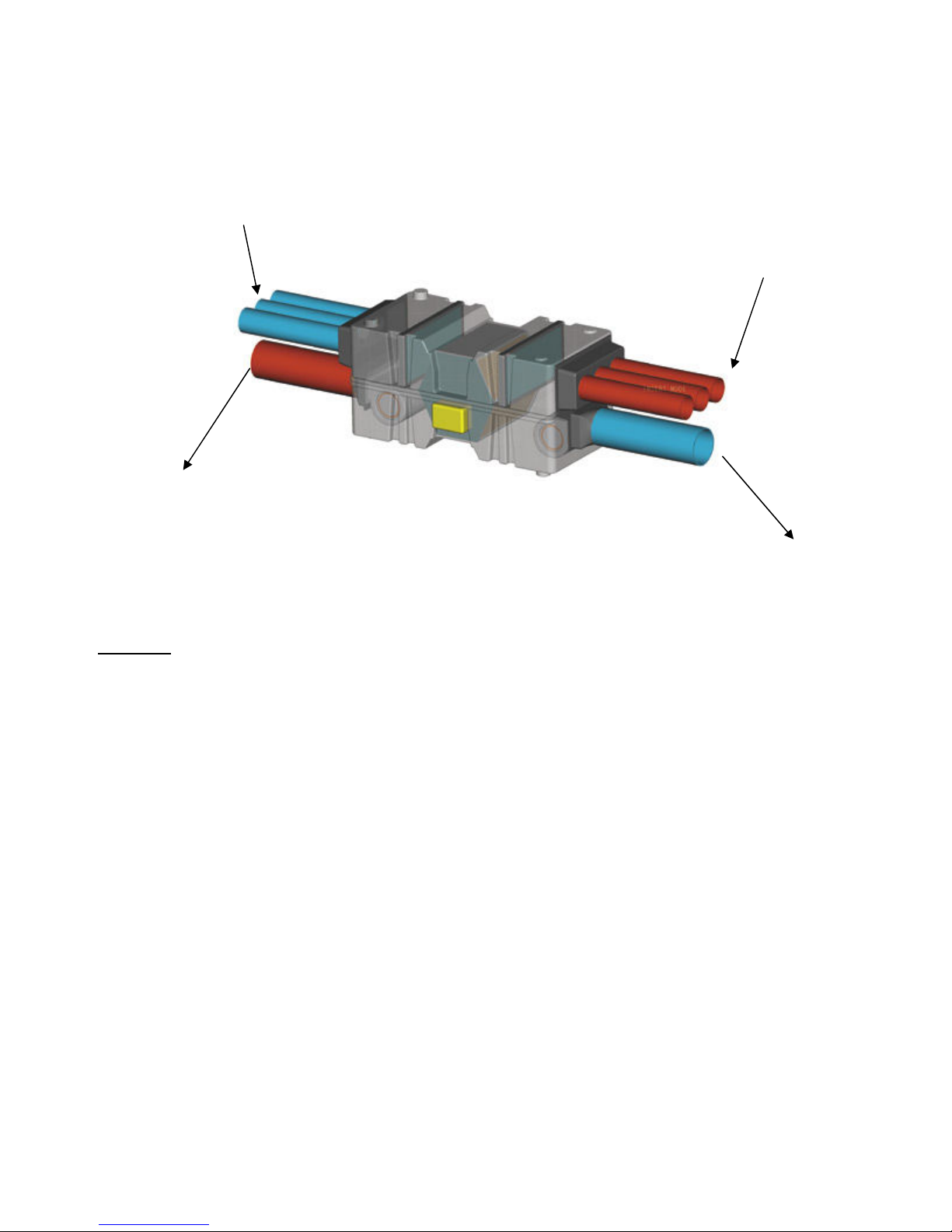

The ProAir system in your house is the PA 600 model shown in fig.1 It is designed to

operate 24 hours / day, 7 days/week, running at a low speed while the house is

normally occupied. At other times when there is higher than normal water vapour

generated (cooking & showers) the system can be triggered, extract higher volumes of

air, for a pre-defined period.

3

These two modes (low and occasional boost) will provide you with the regulation airchanges required for you and your dwelling. The medium mode is available for special

situations such as spring cleaning, or when extra people are in the house.

Fresh from outside@ 2°C RH 81%

Extract from

bathrooms & kitchen @ 20°C RH 66%

Exhaust to outside

@ 3°C RH 74%

Supply to bedrooms & living areas @18.5°C

Figure 1

When air is heated the relative humidity of the air reduces as shown above. This

allows water to be picked up and expelled to outside in one of two ways.

1. Exhausted directly with the stale air as water vapour.

2. Condenses in the heat exchanger exhaust passages and drains to outside via a

15mm hose connected from the bottom of the HRV unit to outside.

RH 36%

4

Figure

2

Control

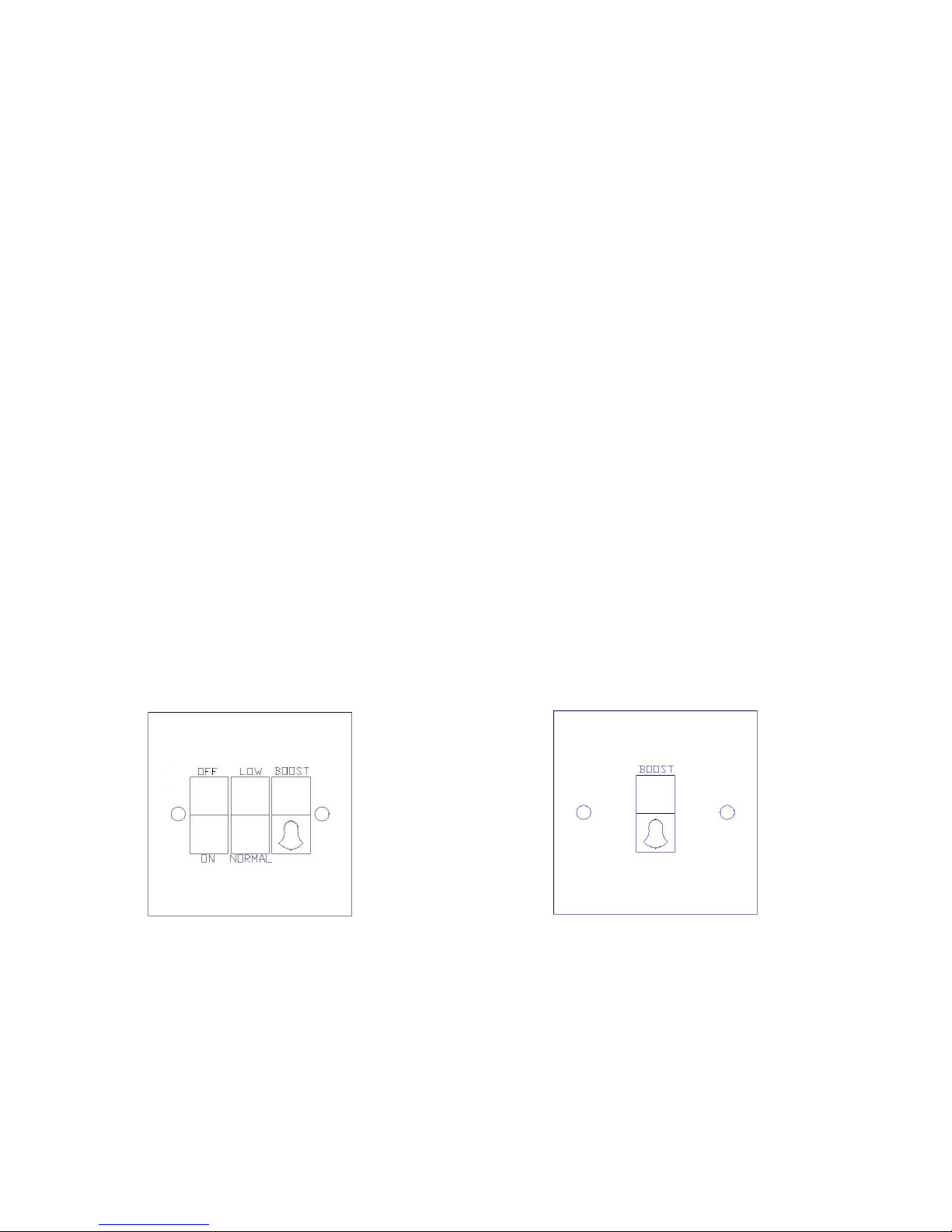

In the utility room, or at some central point in the house you will find a switch as

shown below in Figure 2. This is the master controller. The system is controlled by

progressive switching. The options for controlling the unit are as follows:

Off: As with any other electro-mechanical system it can be switched off as

required, but it is recommended to run the system as much as possible.

On: In this position the other two switches are functional

Low Speed: Operate during normal occupancy at this position.

Medium Speed: Operate in this position during abnormal occupancy as described

above.

Boost Speed: Momentary depression of this switch provides a pre-set timed boost

for high water vapour generation (Cooking & showers). It is normal

that this switch does not stay on. The default pre-set time is 24

minutes, but this can be set to any time you like by the ProAir

technician.

While the system is in the boost mode, the low/normal switch is non-

operational.

The system goes back to the low or medium mode after the pre-set

time has elapsed.

At other locations throughout the house you will find switches as shown in Figure 3.

These are mimics of the boost switch on the main controller and allow you to go to

boost mode from outside your shower.

Pressing more than one boost switch together does not cause a problem. Whoever gets

there first triggers the timer.

5

Figure 3

Installation

The system consists of

• Air Handling Unit (AHU) unit usually located in the attic

• Intake and exhaust vents leading to outside

• Ducting to facilitate the transport of air to and from this unit to the various rooms

• Ceiling terminals for the delivery and extraction of air in rooms

• Control switches

The Air Handling Unit (AHU) is located in either the attic or a utility area. It contains

a high efficiency counter-flow heat exchanger, fans to drive air in and out and filters to

clean the air. It is mains powered (220V) from a standard 13Amp socket. It is

suspended by light chain from the rafters and supported slightly proud of the ceiling

joists. This is for two reasons, (a) to prevent any vibration and (b) to allow house

insulation under the unit.

The outer casing is made of polypropylene and is insulated on the inside where

possible to minimise noise levels and heat loss. It is just off level. This helps the egress

of water through the condensate drain. This is a 15mm plastic hose from the unit to the

outside. It has been provided to assist in the disposal of any water that may result from

condensation.

One end of the unit is connected to outside in order to take in fresh air and exhaust

stale air. There are a few options for this:

1. Duct connections to slate vents.

2. Duct connections to soffits

3. Duct connections to gables

4. A combination of any of above

The outdoor and intake vents have been reasonably separated to ensure that the

exhaust air is not collected as fresh air.

6

Loading...

Loading...