PRO ACTIV SPEEDY 4all, 4you SPEEDY 4all EVO, 4you EVOSPEEDY 4teen Operating Instructions Service Booklet

Page 1

Operating instructions SPEEDY 4all & 4you & 4teen

0

MOBILITY MADE SIMPLE!

Operating instructions

Service booklet

SPEEDY 4all & 4you

SPEEDY 4all EVO & 4you EVO

SPEEDY 4teen

Page 2

Operating instructions SPEEDY 4all & 4you & 4teen

1

Contents

1Preface ............................................................................................................................................... 5

2Legend ................................................................................................................................................ 5

3CE Declaration of Conformity / other information ............................................................................... 5

3.1Classification ............................................................................................................................... 5

3.2Declaration of Conformity ........................................................................................................... 5

3.3Manufacturer ............................................................................................................................... 5

4Scope of delivery ................................................................................................................................ 5

5Introduction ......................................................................................................................................... 6

6Product description / purpose ............................................................................................................. 6

7Acceptable usage and operating conditions / places of use .............................................................. 6

8Technical specifications ..................................................................................................................... 6

8.1Product weight ............................................................................................................................ 6

8.2Load weight ................................................................................................................................ 6

8.3Obstacle height and turning circle .............................................................................................. 6

8.4Basic equipment & dimensions .................................................................................................. 7

8.5Service life .................................................................................................................................. 7

9Rating plate ........................................................................................................................................ 7

10Commissioning ................................................................................................................................... 7

11Hand-over ........................................................................................................................................... 8

12Safety instructions – prior to driving / use .......................................................................................... 8

13Safety instructions – while driving / using .......................................................................................... 9

14Safety instructions regarding obstacles ........................................................................................... 10

15Safety instructions regarding dangerous locations and dangerous situations ................................. 11

16Safety instructions – after driving / use ............................................................................................ 11

17

Individual setting options ........................................................................................................... 11

17.1Adapting the seating height at the back ................................................................................... 11

17.2Adjusting the seat height at the front / angle of seat ................................................................ 13

17.2.1Adapting by positioning the caster wheels in the caster fork ....................................... 13

17.2.2Adaptation by replacing the caster fork ....................................................................... 13

17.2.3General instructions ..................................................................................................... 14

17.3Adjusting the tipping point ........................................................................................................ 14

17.3.1Inlet types ..................................................................................................................... 14

17.3.2Adaptation via horizontal positioning of the wheel plate .............................................. 15

18Back system ..................................................................................................................................... 16

18.1Backrest angle .......................................................................................................................... 16

18.1.1Notes on the sitting posture ......................................................................................... 16

Page 3

Operating instructions SPEEDY 4all & 4you & 4teen

2

18.1.2Adjustment range ......................................................................................................... 17

18.1.3Adjusting the backrest angle ........................................................................................ 17

18.2Adjustable back padding & their adjustment options ................................................................ 18

18.3Ergonomic back shell & its setting options ............................................................................... 21

19Seat system ...................................................................................................................................... 21

20Clothing guard .................................................................................................................................. 22

20.1Overview of terms ..................................................................................................................... 22

20.2Removal and attachment of the clothing guard ........................................................................ 23

20.3

Adjusting the clothing guard position ................................................................................. 25

20.4Clothing guard size ................................................................................................................... 25

21Drive wheels ..................................................................................................................................... 26

21.1Removing and attaching the drive wheels ................................................................................ 26

21.2

Checking and adjusting the wheel tracking of the drive wheel .......................................... 27

21.3

Wheel camber .................................................................................................................... 28

21.4Air pressure .............................................................................................................................. 28

21.5Wheelbase extension ............................................................................................................... 28

21.6Other ......................................................................................................................................... 29

22Caster wheels ................................................................................................................................... 29

22.1

Replacing the caster wheels .............................................................................................. 29

22.2Caster wheels flapping ............................................................................................................. 30

22.3

Replacing the caster wheel forks ....................................................................................... 31

22.3.1Caster fork with screwed axle ...................................................................................... 32

22.3.2Caster forks with quick-release axle ............................................................................ 32

22.4

Setting the caster wheel for rotary axle ............................................................................. 32

23Foot rests .......................................................................................................................................... 34

23.1

Angle adjustment of the footplate ...................................................................................... 34

23.2Footrest continuous .................................................................................................................. 34

23.3Footrest folding up to one side ................................................................................................. 35

23.4Footrest, fold up to the rear ...................................................................................................... 36

23.5Divided footrest ......................................................................................................................... 38

23.6Swing away footrest .................................................................................................................. 38

24Anti-tippers ....................................................................................................................................... 40

24.1Operating and passive position ................................................................................................ 40

24.2

Removing and attaching the headrest ............................................................................... 41

24.3

Height adjustment of the anti-tipping support .................................................................... 42

25Brakes .............................................................................................................................................. 44

Page 4

Operating instructions SPEEDY 4all & 4you & 4teen

3

25.1Knee lever brake ....................................................................................................................... 44

25.1.1Opening and closing the brake .................................................................................... 44

25.1.2

Setting the brake ................................................................................................... 44

25.2Integral brake ............................................................................................................................ 46

25.2.1Opening and closing the brake .................................................................................... 46

25.2.2

Setting the brake ................................................................................................... 47

25.3Stop Lock hub brake ................................................................................................................. 49

25.3.1Opening and closing the brake .................................................................................... 49

25.4Drum brake ............................................................................................................................... 50

25.4.1Opening and closing the brake .................................................................................... 50

26Push handles .................................................................................................................................... 50

26.1Back tube with integrated handles ............................................................................................ 50

26.2Aluminium push handles screwed fixed in back tube ............................................................... 50

26.3Push handles, horizontally screwed in back tube ..................................................................... 51

26.4Safety push handles with continuous height adjustment .......................................................... 51

26.5Safety push handles back-positioned ....................................................................................... 52

26.6Safety instructions .................................................................................................................... 52

27Transport restraint system ................................................................................................................ 52

27.1Standard specifications ............................................................................................................. 52

27.2Wheelchair tiedown and occupant-restraint systems ............................................................... 53

27.3Safety and handling instructions ............................................................................................... 54

28Storage ............................................................................................................................................. 56

29Transport .......................................................................................................................................... 56

30Malfunctions ..................................................................................................................................... 56

31Cleaning and care ............................................................................................................................ 56

32Maintenance ..................................................................................................................................... 57

32.1General instructions .................................................................................................................. 57

32.2Service schedules ..................................................................................................................... 57

32.3Proof of maintenance ................................................................................................................ 58

33Disposal & Recycling ........................................................................................................................ 58

34Re-use .............................................................................................................................................. 58

35Warranty ........................................................................................................................................... 59

36Liability .............................................................................................................................................. 59

37Appendix: Tightening torques, securing details and tools ................................................................ 60

38Appendix: Medical product passport / record of training .................................................................. 61

39Appendix: Hand-over certificate ....................................................................................................... 62

39.1Required compliance criteria to authorise use ......................................................................... 62

Page 5

Operating instructions SPEEDY 4all & 4you & 4teen

4

39.2 Check list for training the user .................................................................................................. 63

40Appendix: Inspection lists ................................................................................................................. 64

Page 6

Operating instructions SPEEDY 4all & 4you & 4teen

5

1 Preface

Dear Customer,

Congratulations on purchasing your new

PRO ACTIV product. You have bought a

quality product which has been especially

customised to meet your requirements. We

have put together some instructions about its

proper and safe use in the following document.

Please read these instructions before using the

product.

These operating instructions refer to standard

components. If you have individual solutions or

non-standard components on your product,

your dealer or we at PRO ACTIV would be

happy to deal with any questions you may

have about handling it.

The difference between the products Speedy

4all & 4you, Speedy 4all EVO & 4you EVO and

Speedy 4teen are in the possibility of the

individual design of the frame geometry and

the selection of options. If there is a difference

in the selection of options, this is mentioned in

the respective chapter. Otherwise the

operating instructions are identical.

If you have any further questions about this or

any of our other products, we would be glad to

be at your disposal.

Enjoy your trips and the best possible mobility.

Your PRO ACTIV team

2 Legend

The symbols used in these operating

instructions have the following meanings:

Manufacturer

Warnings, tips and safety instructions

Serial number

Additional information

Assembly instructions for the dealer (see

table of contents)

3 CE Declaration of Conformity /

other information

3.1 Classification

The SPEEDY 4all & 4you, Speedy 4all EVO &

4you EVO and Speedy 4teen rigid frame

wheelchair (referred to as a "product" below) is

classified as a class I product.

3.2 Declaration of Conformity

PRO ACTIV Reha-Technik GmbH declares in

the context of an individual declaration of

conformity that the respective product has

been developed and manufactured according

to the relevant provisions of

EC Directive 93/42/EEC 2007.

If the product is adapted in a manner which

has not been agreed by PRO ACTIV RehaTechnik GmbH, this declaration becomes void.

3.3 Manufacturer

PRO ACTIV Reha-Technik GmbH

Im Hofstätt 11

D-72359 Dotternhausen

Tel. +49 7427 9480-0

Fax +49 7427 9480-7025

E-Mail: info@proactiv-gmbh.de

Web: www.proactiv-gmbh.com

4 Scope of delivery

The delivery includes the product configured in

accordance with the order, with operating

instructions including record of training / handover certificate and inspection lists. You can

view the basic equipment in chapter "Technical

specifications". As per your order, the product

is equipped with additional recommended

accessories, such as push handles, antitippers and waist belt.

Please check that the delivery is complete after

you have received your product.

The product is tested to ensure it is completely

functional prior to shipping. If your product has

been damaged during transit, please contact

your dealer or PRO ACTIV immediately.

Page 7

Operating instructions SPEEDY 4all & 4you & 4teen

6

5 Introduction

Before starting your journey, familiarise

yourself with these operating instructions

paying particular attention to the safety

information and hazard warnings contained

within them.

Why not let therapists and doctors advise

you, your carers and assistants on how to use

the product and what you are safe to do with

the product based on your current ability.

Clarify with them as well which wheelchair

techniques you can learn on the basis of your

ability. Under no circumstances should you do

anything with or in the product which you have

not learnt to and have not mastered.

You, your carers and assistants should

also seek advice from your therapists and

doctors as well as your specialist retailer on

the use and settings on your product as well as

available safety accessories (e.g. anti-tippers

and waist belt). It is then important that you

also follow this advice.

Overestimating your own ability or

underestimating a dangerous situation or

action with the product can have serious

consequences for you and other people.

If you are not sure how to handle the

product or if technical faults occur, please

contact your dealer or PRO ACTIV before

using it.

Make sure that when combining your

product with equipment made by other

manufacturers (e.g. seat cushion, drive

devices, etc.) that the serviceability of the

individual components and the unit made up of

them is ensured. You can get information on

the suitability of a combination from the

manufacturer of the external components or

from your specialist retailer.

6 Product description / purpose

Using the product as intended is essentially

based on replacing the walking ability of a

person who has difficulty walking or cannot

walk on a paved path by driving with the

wheelchair as far as is technically feasible. In a

figurative sense, "walking" means walking

speed when using a wheelchair.

7 Acceptable usage and operating

conditions / places of use

Only use the product on paved surfaces. Avoid

driving on unpaved or loose surfaces (e.g. on

loose gravel, in sand, mud, snow, ice or

through deep puddles of water), as this may

result in incalculable risks.

The maximum permitted load of the product in

its standard design is a 120 kg payload.

Individual customisation can be made to

accommodate a higher load; this will be

indicated on the ratings plate. Please ensure

that the load limit indicated on the ratings plate

is not exceeded, even when transporting

objects and carrying out strength exercises in

the product.

8 Technical specifications

8.1 Product weight

The total weight starts from 9 kg with the basic

equipment.

8.2 Load weight

Maximum load weight:

Up to 120 kg payload

8.3 Obstacle height and turning circle

Maximum drive-over / negotiable obstacle

height: 10 cm

Turning circle:

approx. 1.3 m without manoeuvring back

and forth

Page 8

Operating instructions SPEEDY 4all & 4you & 4teen

7

approx. 1.1 m with manoeuvring back and

forth (much dependent on the number of

manoeuvres)

8.4 Basic equipment & dimensions

In the basic equipment, the product is

equipped with seat and back system, side

sections, caster wheels, drive wheels including

tyres and handrims, knee lever brake and

footrest.

Dimensions, Speedy 4all:

Seat width: 30-52 cm

Seat depth: 36-48 cm

Back height: 20-48 cm

Wheel camber: 1°, 4°, 6°

Back angle: Seat tube / back tube opening

angle 70°-95°

Dimensions, SPEEDY 4you:

Seat width: 30-52 cm

Seat depth: 36-54 cm

Back height: 23-48 cm

Wheel camber: 1°, 4°, 6°

Back angle: Seat tube / back tube opening

angle 70°-95°

Dimensions, SPEEDY 4all EVO:

Seat width: 30-52 cm

Seat depth: 36-48 cm

Back height: 20-48 cm

Wheel camber: 1°, 4°, 6°

Back angle: Seat tube / back tube opening

angle 70°-95°

Dimensions, SPEEDY 4you EVO:

Seat width: 30-52 cm

Seat depth: 36-54 cm

Back height: 23-48 cm

Wheel camber: 1°, 4°, 6°

Back angle: Seat tube / back tube opening

angle 70°-95°

Dimensions, SPEEDY 4teen:

Seat width: 26-38 cm

Seat depth: 32-48 cm

Back height: 20-48 cm

Wheel camber: 1°, 4°, 6°, 8°

Back angle: Seat tube / back tube opening

angle 70°-95°

8.5 Service life

The service life of the product is 6 years in

accordance with the medical products law.

9 Rating plate

The rating plate is located on the frame of the

product. The rating plate includes the precise

model, the serial number and other technical

specifications.

When contacting your dealer or PRO ACTIV

with regard to your product, please always

have the serial number and year of

construction on the rating plate at hand.

The rating plate includes the following data:

Manufacturer

CE marking

Operating instruction present for the

product

Serial number

10 Commissioning

The product will be handed over to you ready

for use by a PRO ACTIV dealer or a field

representative or by a product consultant from

PRO ACTIV.

You will be fully instructed in the use of the

product based on the operating instructions

included in delivery. If you wish (recommended

by PRO ACTIV), you will be presented with a

record of training and a hand-over certificate

as written evidence and in addition the

Page 9

Operating instructions SPEEDY 4all & 4you & 4teen

8

operating instructions and any other

accessories for your own use. The form for the

record of training and the hand-over certificate

can be found in chapters 38 and 39.

It is recommended that you take along an

assistant to the training so that, if required,

they can assist you later when handling the

product.

During the initial commissioning of the product,

drive at minimum speed and become

accustomed to the driving characteristics of the

product. Always adapt the speed and driving

manoeuvres to match your own abilities and

external circumstances. You will get a feel for

how to use the product safely after a short

time. Before driving up or down slopes or hills

with the product, you should be proficient in the

safe handling of the product on the flat.

11 Hand-over

The hand-over must be done by your dealer or

a field representative or by a product

consultant from PRO ACTIV. During the handover, the record of training (chapter 38) and

the hand-over certificate including the

associated check list (chapter 39) must be

filled in. The dealer should send a copy of the

completed documents to PRO ACTIV for filing

either as a scanned file via e-mail, by fax or in

the post. These documents are available as

pdf files which can be completed in the

download area at www.proactiv-gmbh.com

under the link "more documents >>".

12 Safety instructions – prior to

driving / use

When getting into the wheelchair, do not

tread on the footrests as this may tip the chair

over.

Before every trip, check the condition of

the wheels (e.g. visual inspection of the spokes

and rims, check the tyres for damage, foreign

bodies and crack formation). If you have any

doubts about the serviceability of the product,

stop using it.

Check tyre pressures at regular intervals.

Ensure that you comply with the

manufacturer's specifications which can be

found on the tyres. Tyre pressure which is too

low affects on the driving behaviour of the

product and has a negative effect on the

braking efficiency.

Before starting out, check that the

product's brake works. If all existing brakes are

not fully functional, no trips may be taken.

Check the stable condition of the seat and

back upholstery at regular intervals and in case

of doubt, have your dealer assess its condition.

Always ensure that your feet cannot slip

off the footrest when using the product, if

necessary by using a special securing device.

Before using the product, ensure that the

anti-tippers are in the operating position and in

good working order. In this case, it must not be

possible to swivel the anti-tippers to the side

when in operating position without having to

unlock them first.

The lower edge of the anti-tipper wheels

may not be any more than 5 cm from the

ground. If a larger gap is required or

necessary, then you need to work with your

therapists and doctors to practice and learn to

handle the increased risk of tipping.

Due to environmental effects, it is possible

that the properties and therefore secure

attachment of the push handle covers may

change detrimentally. For this reason, it is

important to check the handles are tightly fitted

and fixed in position prior to use. If this should

no longer be the case, then the push handles

may not be used until they have been fixed

.

Every time before you use the product,

make sure that the anti-tippers and push

handles are firmly attached and the quickrelease axles on the caster and drive wheels

are also securely locked in place.

Depending on its optional extras, the

product may have folding / closing

mechanisms which pose a risk of crushing

Page 10

Operating instructions SPEEDY 4all & 4you & 4teen

9

injuries (e.g. trapping your fingers). For this

reason, please allow your specialist retailer to

explain how to work these mechanisms and

then have a go yourself under instruction.

If required, you can have a suitable waist

belt fitted to your product. Please make sure

that the waist belt is set up so that it does not

have any negative impact on breathing, does

not strangle you should you fall or tip out of the

product and which you can easily remove

yourself.

When travelling, always carry a repair kit

and tyre pump for repairs in event of

punctured / flat tyre. A alternative to this is a

pump spray that fills your tyre with a foam that

hardens in the tyre.

13 Safety instructions – while

driving / using

Please note that some parts of your

product can become extremely hot in at hot

ambient temperatures (e.g. a sauna). This

means that above 50°C, the product may be

damaged and above 40°C there is already the

risk of burns for the user, which should not be

underestimated, particularly for people with

impaired sensitivity. For this reason, the

product should not be exposed to such

extreme temperatures. PRO ACTIV cannot

accept any liability or provide any warranty for

personal injury and material damage caused

by such stresses. There are also certain risks

that exist at extremely low temperatures, which

must be minimised by wearing appropriately

insulating clothes for example.

You may only drive on slopes where the

product can be safely controlled with the

handrims.

Use particular caution when approaching

stairs, edges, drops or other hazard areas.

Due to the high risk of tipping up and

being injured, you should never try to ride an

escalator in the product.

When driving round a bend, reduce your

speed to a minimum.

Do not ride parallel to slopes due to the

risk of tipping.

Please note that the knee lever wheel

lock, the integrated brake and the Stop Lock

brake which your product is fitted with is a

parking brake which may only be applied when

the product is at a standstill. These are not

service brakes which are suitable for reducing

speed.

Do not attach objects (carrier bags, etc.)

to the product.

Make sure that the passive illumination

(reflectors) are always on your product, are in

perfect condition and are clearly visible.

When driving on areas which are used for

pedestrians, observe the maximum permitted

speed (walking speed 6 km/h) and keep a

sufficient distance (if possible the width of a

wheelchair) from the kerbs or other obstacles

and other road users.

Avoid driving on unpaved or loose

surfaces (e.g. on loose gravel, in sand, mud,

snow, ice or through deep puddles of water).

When travelling on poorly maintained

paths (e.g., large gravel, potholes) there is an

increased risk of puncturing your tyres as well

as tipping.

When travelling on poorly maintained

paths with potholes and loose stones, drive

carefully to try to prevent the caster wheels

from becoming locked.

If you encounter new driving situations

which are unknown to you, approach them with

great care. If you consider that the risk is too

high, you must immediately abort the driving

manoeuvre and, if required, call for help to

assist you in extracting yourself from this

situation.

Page 11

Operating instructions SPEEDY 4all & 4you & 4teen

10

The product can affect other devices, for

example theft protection barriers in department

stores.

The product is only designed to be used

to transport persons with limited mobility and

must not be used for any other purpose, e.g. to

transport goods.

When reversing, the anti-tippers should

always be used as there is an increased risk of

tipping over. If this is not possible, then ask

other people to help ensure that there is no risk

of tipping over.

The product may only be propelled using

the handrims. If you drive propelling the chair

with the tyres (thumbs or fingers on the tread

of the tyre), there is the risk of crushing or

otherwise injuring fingers and thumbs.

Do not reach into the area of the spokes or

other tight spaces in the vicinity of the wheels.

There is an increased risk of being injured

here, particularly while in motion. If you have

limited coordination of your limbs, then you

should protect the spokes with a spoke shield

for example to minimise the risks.

Smoking when riding is forbidden as the

seat and back system may be damaged from

ash which falls down.

14 Safety instructions regarding

obstacles

Obstacles like curbs, for example, should

always be negotiated driving forwards and

always using the minimum speed required.

The maximum obstacle height which can

be negotiated is 10 cm.

When driving over or passing obstacles, it

is important that you avoid any product or body

parts catching on the obstacle as this may lead

to falling causing serious injuries to the user

and third parties as well as damage to the

product.

Always drive over curbs or other obstacles

so that you cross them to the front or at right

angles. If you approach them at an angle, or

only have one rear wheel on the obstacle,

there is an increased risk of tipping over to the

side which can result in serious injuries to the

user and third-parties as well as damage to the

product.

If the product user needs to be

transported over an obstacle, such as a step,

and there are suitable facilities such as a ramp

or a lift available, then these should be used. If

such facilities are not available, then the

obstacle is to be overcome by being carried by

two helpers. When carrying the product, it may

not be lifted by the side sections, the drive

wheels or the footrests. We recommend

holding the product on the frame and back

cross bar.

Before overcoming an obstacle (steps,

threshold, etc.) the anti-tippers need to be

swivelled from operating to passive position so

that they do not make contact with the step you

are trying to get over. Otherwise this could lead

to a serious fall. After overcoming the obstacle,

the anti-tippers need to be put back in

operating position (Chapter 24).

For overcoming obstacles such as kerb s

or steps, the product needs to be actively

tipped. The castor wheel may otherwise jam at

right angles to the obstacle and could block.

This could damage the caster wheel or the

caster fork and cause injury. If actively tipping

it is not possible, then the obstacle should not

be approached or you need to request

assistance from an accompanying person.

Particular attention needs to be paid to this

when using an auxiliary drive.

Page 12

Operating instructions SPEEDY 4all & 4you & 4teen

11

15 Safety instructions regarding

dangerous locations and

dangerous situations

The operator of the product determines the

route to be driven taking the operating

instructions, their driving knowledge and

physical abilities into consideration.

The personal driving skills are particularly

important in the following dangerous locations

which are provided as examples; the product's

user must use their judgement before driving in

such locations:

quay walls, landing and berthing locations,

paths and locations close to water,

unsecured bridges and dykes.

narrow paths, slopes (e.g. ramps and

driveways), narrow paths on a slope,

mountainous routes.

narrow and / or steeply sloping paths along

main roads or near cliffs.

routes which are covered in leaves, snow

or ice.

ramps and lifting equipment on vehicles.

When driving in a circle or turning on hills

or downward slopes, there may be an

increased tendency to tip over to the side due

to the changes in the centre of gravity. Always

perform these driving manoeuvres with

increased caution and only at slow speed. If

required, the driving manoeuvre must not be

performed or only with the help of an assistant.

When crossing main roads, intersections

and level crossings, extreme caution is

needed. Crossing rails in the road or at level

crossings must never be undertaken when

travelling parallel to them, as otherwise the

wheels could become caught which would

result in the product being unable to

manoeuvre.

When driving on ramps and lifting

equipment on vehicles, extreme caution is

needed. When lifting or lowering a ramp or

lifting equipment, the parking brake of the

product should be applied.

The grip of the tyres on the ground is

reduced in the wet. There is an increased risk

of slipping. Adjust your driving, braking and

steering behaviour accordingly.

16 Safety instructions – after

driving / use

Apply the parking brake before leaving the

product.

When getting out of the wheelchair, do not

tread on the footrest due to the risk of tipping

up.

17 Individual setting options

17.1 Adapting the seating height at the

back

The product is equipped with an axle plate that

permits a seat height adjustment in steps of 1

cm.

Figure 1: Wheel plate for rear seat height

adjustment

In order to adjust the seat height, first remove

the drive wheels via the quick release

axles(see chapter 21.1) and turn the product

around so that you have direct access to the

wheel plates. Then proceed as follows:

1. Open the aluminium locking nuts (AF 41

mm) on both sides and keep turning them

out on the drive wheel bearings until the

position gate positioned underneath it can

Wheel plate

Page 13

Operating instructions SPEEDY 4all & 4you & 4teen

12

be pushed out of the wheel plates onto the

drive wheel bearings.

Figure 2: Aluminium locking nuts and drive wheel

bearing

Figure 3: Position gate

Figure 4: Different position gates – depending on

the equipment of the product and user weight

Figure 5: Aluminium locking nuts and position gate

pushed onto the drive wheel bearing

2. Position the axle tube to the desired and

equal height on both sides and fix the axle

tube in this position using the position

gates by pushing the position gates on the

right and left sides into the wheel plates.

Figure 6: Axle tube fixed with position gate

3. Position the aluminium locking nuts back

onto the drive wheel bearings in such a

manner that these rest slightly against the

position gate and then set the drive wheel

track correctly (see chapter 21.2).

When changing the rear seat height each time:

the wheel track of the drive wheels must

be checked and readjusted if necessary

(see chapter 21.2).

the caster wheel axle must be readjusted

(see chapter 22.4).

Drive wheel bushin

g

Aluminium locking nuts

Position gate

Position gate pushed onto

the drive wheel bearing

Page 14

Operating instructions SPEEDY 4all & 4you & 4teen

13

the brakes must be readjusted (see

chapter 25).

if necessary, the height of the anti-tipping

support may have to be readjusted (see

chapter 24.3).

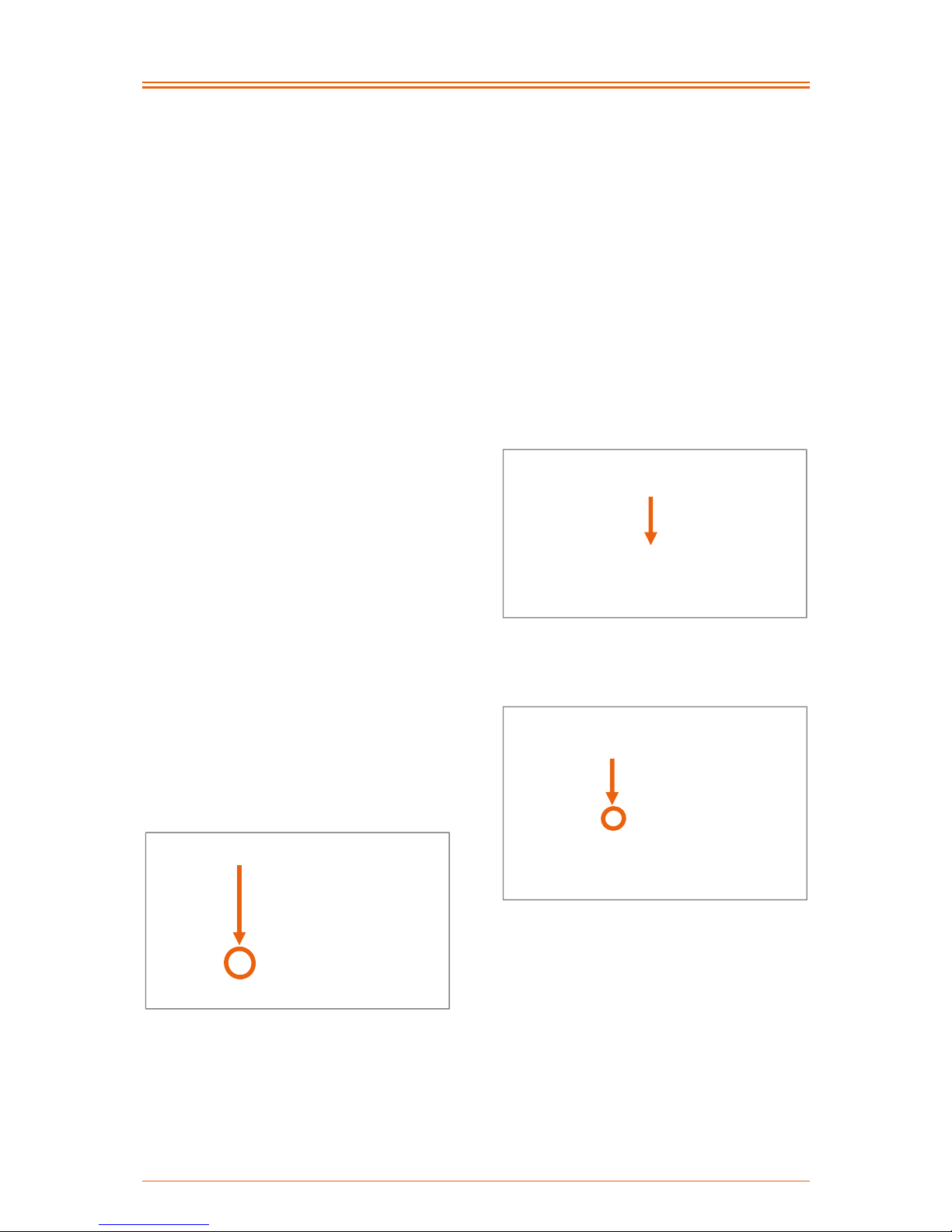

17.2 Adjusting the seat height at the

front / angle of seat

If the seat height has to be adjusted, the angle

of the seat or the front seat height can be

adjusted. This setting is carried out via the

position of the caster wheels in the caster

wheel fork and the caster fork size.

17.2.1 Adapting by positioning the caster

wheels in the caster fork

Smaller adaptations of the front seat height or

angle of seat can be carried out via the

positioning of the caster wheel in the caster

fork. Generally, the caster wheel forks have

three possible positions that can be used to

change the front seat height in steps of 15 mm.

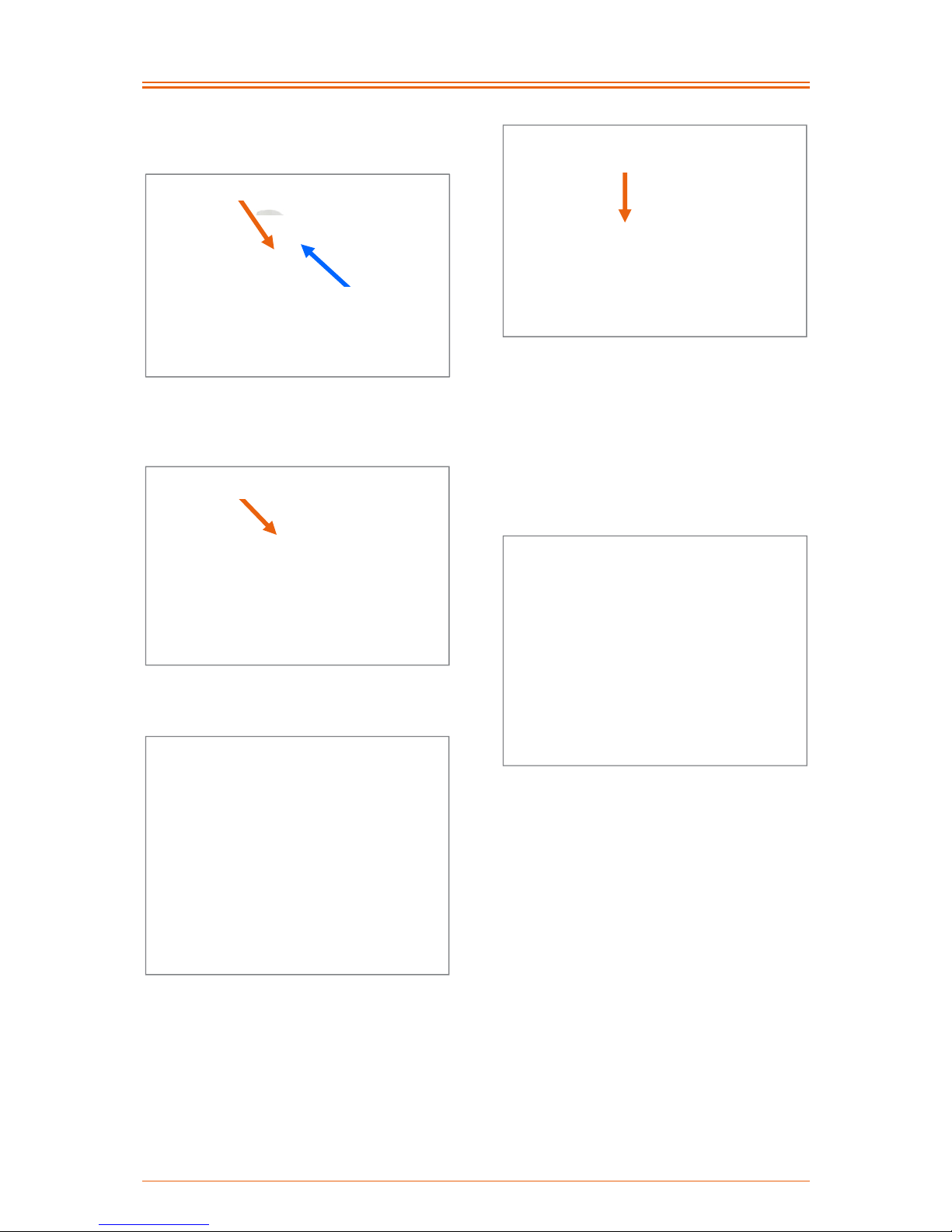

If the angle of seat has to be increased or

the front seat height increased, the caster

wheel is mounted in the caster fork in a

lower position.

If the angle of seat has to be reduced or

the front seat height decreased, the caster

wheel is mounted in the caster fork in a

higher position.

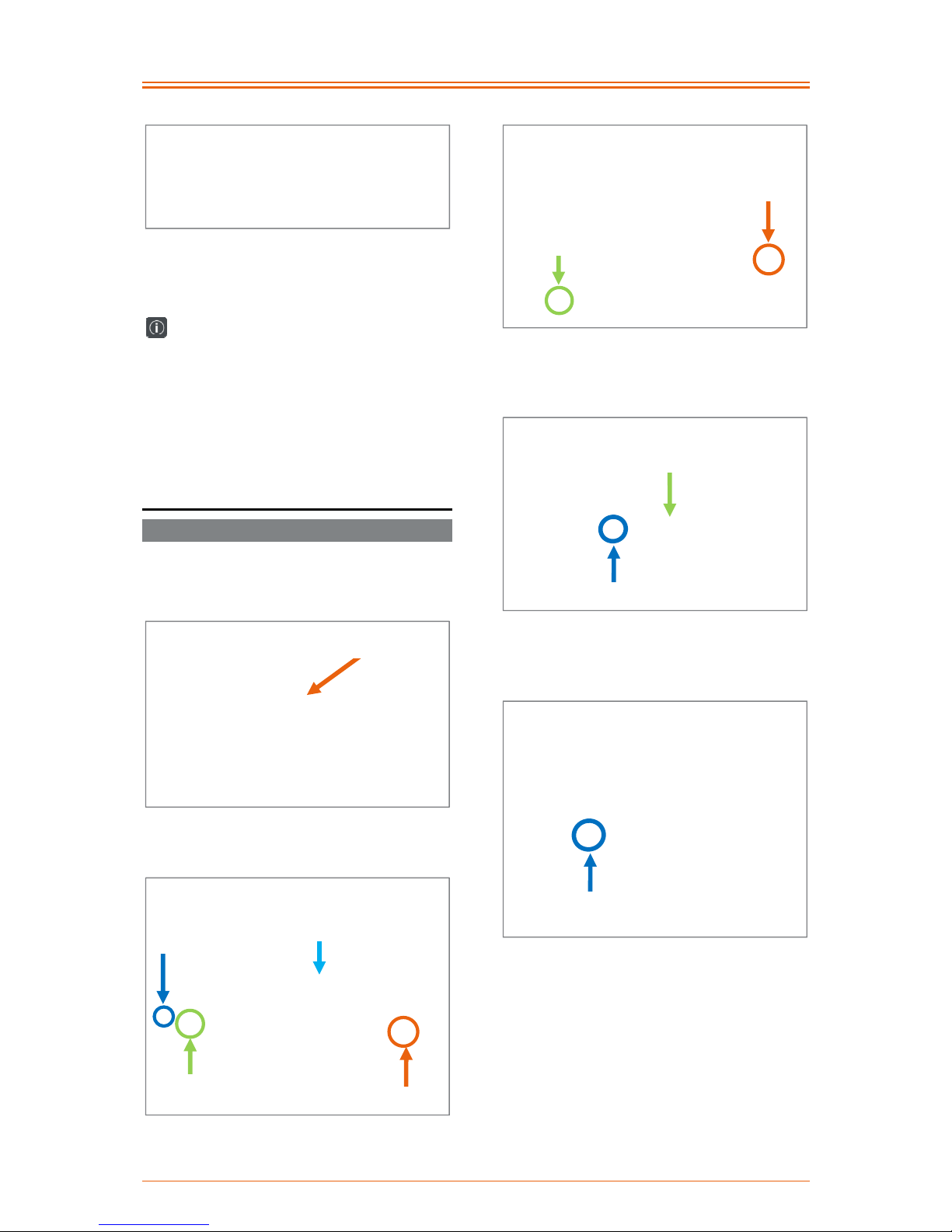

Figure 7: Three positions in the caster fork for

positioning the caster wheel and its effect on the

front seat height

The instructions for disassembly and assembly

of the caster wheels can be found in chapter

22.1.

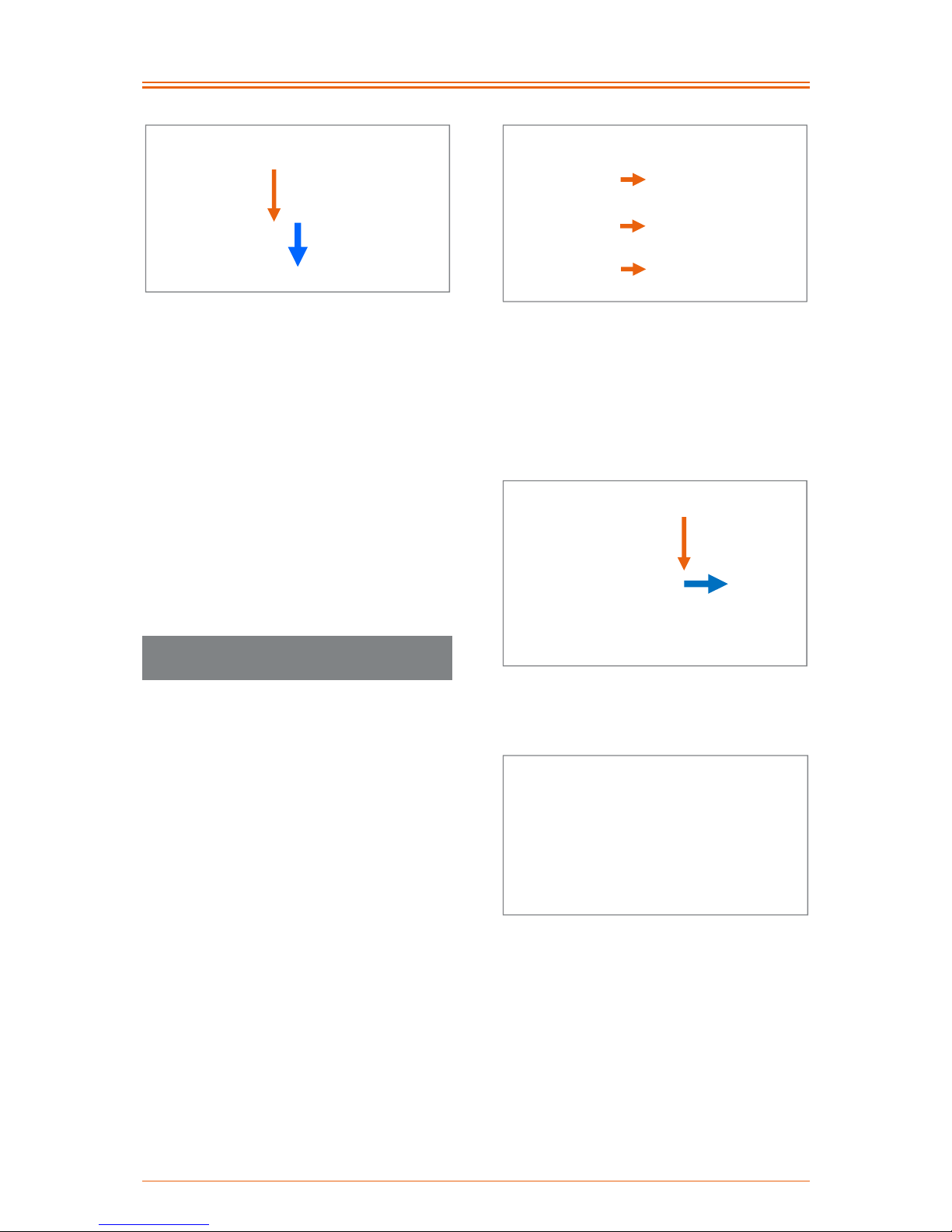

17.2.2 Adaptation by replacing the caster

fork

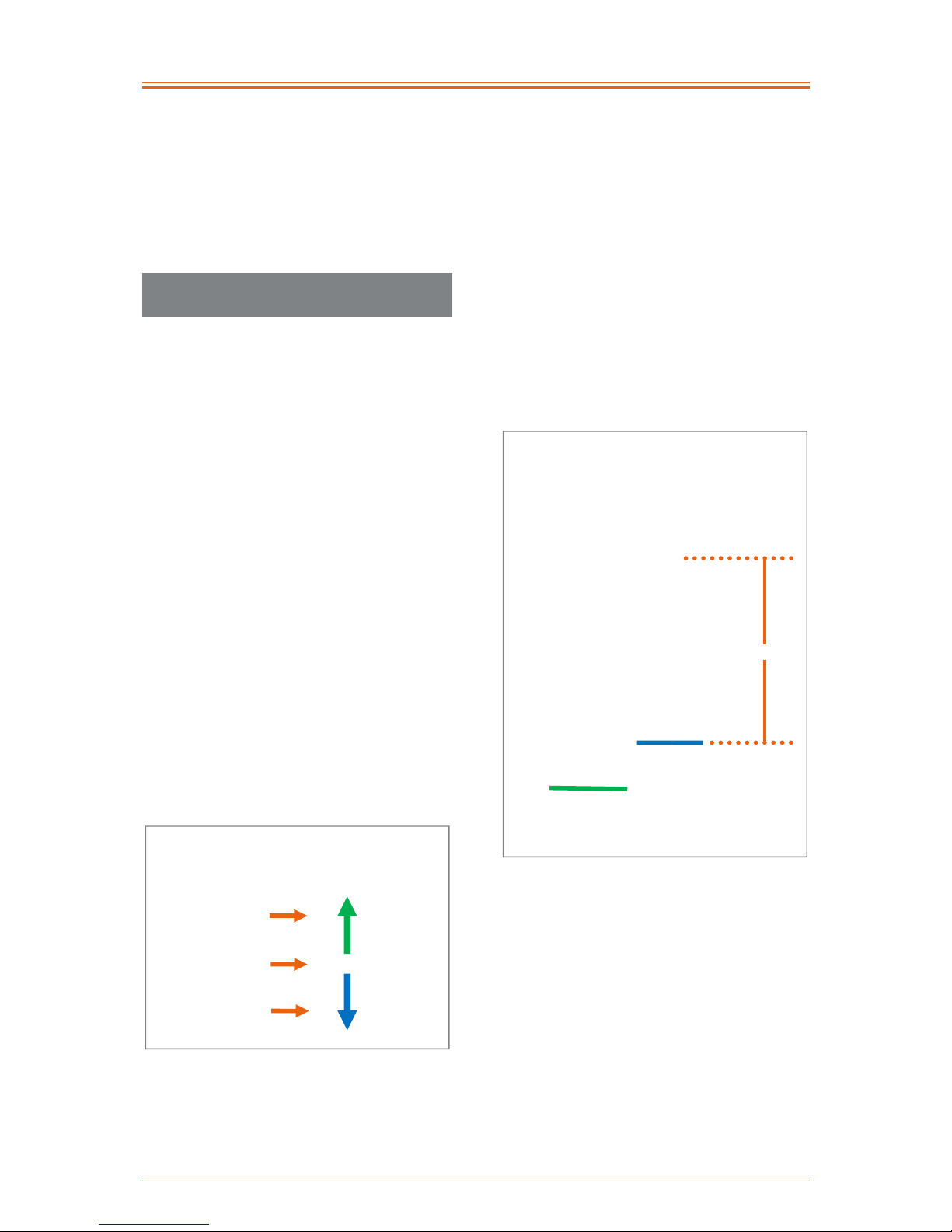

If the adjustment range of the cater fork

present is insufficient, you can use the use the

next longer or shorter one.

In doing so, the bottom position of the fork size

1 is equivalent to the top position of fork size 2

and the bottom position of fork size 2 to the top

position of fork size 3.

Figure 8: Caster fork sizes with marking of the same

seat height settings with different caster fork sizes

The instructions for replacing the caster forks

can be found in chapter 22.3.

Top position

Middle position

Bottom

p

osition

Angle of

seat / front

seat height

increase

Angle of

seat / front

seat height

reduce

Size 3

185 mm

Size 2

155 mm

Size 1

125 mm

125 mm

Page 15

Operating instructions SPEEDY 4all & 4you & 4teen

14

17.2.3 General instructions

When changing the angle of seat or front seat

height each time:

the wheel track of the drive wheels must

be checked and readjusted if necessary

(see chapter 21.2).

the caster wheel axle must be readjusted

(see chapter 22.4).

the brakes must be readjusted (see

chapter 25).

the backrest angle must be readjusted

(see chapter 18.1).

make sure the clearance under the footrest

is sufficient. Experience shows that this

should not be less than 4 cm. (see

chapter23).

if necessary, the height of the anti-tipping

support may have to be readjusted (see

chapter 24.3).

17.3 Adjusting the tipping point

An optimum tipping property of the product is

reached when the axle mount of the drive

wheels is close to the body centre of gravity. A

product adjusted like this can be driven with

little effort and it also makes it possible to

manage a slightly uneven surface or edges by

tipping slightly. Driving on both drive wheels

(doing a wheelie) is relatively easy to learn.

Inexperienced wheelchair users are prevented

from tipping over backwards by anti-tippers.

In any case, the setting should be made to suit

your individual requirements and ability to

ensure you can drive your chair safely.

17.3.1 Inlet types

Setting the tipping point is carried out by

changing the horizontal position of the wheel

plate on the bottom frame tube.

Figure 9: Terminology

The wheel plate is mounted to the frame using

three M6 fixing screws and one inlet in the

frame. With the inlets, differentiate between the

long and short inlets. The selection of the inlets

is orientated, amongst others, on the seat

width, weight of the wheelchair user, type of

wheel plate or equipment (e.g., one-hand

operation, wheelbase extension). Depending

on the inlet length, then the procedure for

adapting the tipping point also differentiates.

Figure 10: Long and short inlet with wheel plate

The short inlet has a thread in the end face

and the long inlet does not.

Short inlet

Long inlet

Wheel plate

Wheel plate

Inlet in the frame

behind the wheel plate

M6 fixing screws

Page 16

Operating instructions SPEEDY 4all & 4you & 4teen

15

Figure 11: Long inlet without and short inlet with

thread in the end face

The following features indicate if a long or a

short inlet is installed: With the short inlet, a

tube plug is applied to the end of the frame, the

long inlet does not have one.

Figure 12: Tube plug at the end of the frame means

"short inlet"

Figure 13: No tube plug at the end of the frame

means "long inlet"

17.3.2 Adaptation via horizontal

positioning of the wheel plate

In order to adjust the tipping position, first

remove the drive wheels via the quick release

axles(see chapter 21.1) and turn the product

around so that you have direct access to the

wheel plates. Then proceed as follows:

1. Slightly undo the aluminium locking nuts

on both sides.

Figure 14: Aluminium locking nuts

2. This step affects the fixing of the inlets:

If you have long inlets

in the frame, on

each side turn one M6 screw into a tipping

position not required during the adjustment

in order to fix the inlets during the

adjustment process. These inlets must not

be moved during the adjustment as they

cover all tipping points due to their length.

However, the screws prevent the inlets

from twisting and thus, the thread of the

inlets and the tipping point position of the

frame are no longer resting precisely on

top of one-another.

If you have short inlets

in the frame,

remove the tube plugs on both sides and

turn the long M6 screws into the thread of

the inlet in the frame from behind in order

to fix the inlet and to be able to move it into

position afterwards during the adjustment.

These inlets must be moved into position

during the adjustment as they must be

positioned directly behind the wheel plates

due to their length.

The tube plugs are inserted very tight

and must be disassembled using a

screwdriver or a blade.

Aluminium locking nuts

Short inlet

Long inlet

Thread

No tube plug with

long inlet

Tube plug with

short inlet

Page 17

Operating instructions SPEEDY 4all & 4you & 4teen

16

Figure 15: Short inlet with M6 screw screwed in

(outside the frame for better illustration)

3. Remove the three fixing screws (AF 5 mm)

on both wheel plates.

Figure 16: M6 fixing screws

4. Now set the wheel plates at the desired

tipping position on both sides of the frame.

If you have short inlets

in the frame, using

the long M6 screws that you have

previously screwed into the thread from

behind, you have to position this accurately

behind the wheel plates so that the tipping

point positions in the frame and thread rest

accurately against one another in the

frame and thread.

The long inlets

do not have to be moved.

5. Then fix both wheel plates again, each

with three M6 fixing screws and tighten

these slightly (2 Nm).

6. With long inlets

in the frame, now you can

remove the additional fixing screws again

(see step 2).

If you have short inlets

in the frame, now

you can remove the long M6 screws from

the threads of the inlets and reinsert the

tube plugs a the ends of the frame.

7. Position the aluminium locking nuts back

onto the drive wheel bearings in such a

manner that these rest slightly against the

position gate and then set the drive wheel

track correctly (see chapter 21.2).

8. Now tighten the respective three M6 fixing

screws to the wheel plates to 7 Nm.

After each change to the tipping point:

the wheel track of the drive wheels must

be checked and readjusted if necessary

(see chapter 21.2).

the caster wheel axle must be readjusted

(see chapter 22.4).

the brakes must be readjusted (see

chapter 25).

Extreme settings, such as drive wheels

mounted far to the front is only permitted for

users with advanced wheelchair skills that are

able to exercise an active weight shift to the

front.

In order to minimise the risk of tipping to

the rear, we recommend the use of anti-tipping

supports, even with anti-tipping device

settings.

18 Back system

Avoid falling into the seating and back

padding as the risk of an adjustment, falling or

a defect is increased significantly.

18.1 Backrest angle

18.1.1 Notes on the sitting posture

For a good sitting posture, we recommend

positioning the backrest vertical to the ground,

where possible.

With low backrest with adaptable belt cover

due to a disability, under certain

circumstances, it may also be a benefit for a

good sitting stability to slightly tilt the backrest

to the front and to slacken the top belt of the

M6 fixing screws

Page 18

Operating instructions SPEEDY 4all & 4you & 4teen

17

back padding so that the slack in the upper

area is greater (see chapter 18.2).

The adjustment possibility of the backrest

angle supports active sitting and ensures for

flexibility of the wheelchair user. An example in

the following:

if the angle of the seat has been changed

(see chapter 17.2), the angle of the

backrest can be respectively readjusted.

When driving on slopes and when

transporting baggage (e.g., backpacks) on

the backrest, the centre of gravity shifts

more to the rear and the risk of tipping

increases. Then this can be counteract ed

by a respective angle adjustment of the

backrest to the front.

For comfortable sitting, the backrest can

be locked in the position furthest to the

back (defined by stop pins, see chapter

18.1.2) so that the backrest is tilted slightly

to the rear.

18.1.2 Adjustment range

On equipment of the product with a backrest

with angle adjustment, the inclination of the

backrest can be locked in 7 positions.

For safety reasons, the adjustment range of

the backrest is limited by a stop pin when

supplied. The stop pin allows a maximum

inclination of 7° to the rear from a vertical

position.

Figure 17: Stop pin

Observe that the centre of gravity is

shifted further to the rear by the enlargement of

the angle between the backrest and the seat

system and thus, the tipping point of the

product is reached much sooner.

18.1.3 Adjusting the backrest angle

To adjust the backrest angle, relieve this

(otherwise there is a risk of tipping) and then

loosen the locking pin that engage in the

locking holes of the side section on the left and

right. For this purpose, grasp under the seat

upholstery and in the middle, pull the cord to

the front that is linked to the locking pin.

Figure 18: Locking pin (view from the inside of the

frame) linked to the cord

Figure 19: Locking pin (view from outside) engages

in the locking hole in the side section

Locking pin

Locking pin

Stop pin

Page 19

Operating instructions SPEEDY 4all & 4you & 4teen

18

Figure 20: Cord for operating the locking pin and

thus for adjusting the angle of the backrest

If you have released both locking pins by

pulling on the cord, you can adjust the backrest

as desired and re-engage it by letting go of the

cord. In doing so, before applying load again,

make sure that both locking pins have

engaged safely into the desired locking holes

(the same position on the right and left).

Depending on the adjustment of the

backrest angle, check the tight engagement of

the backrest via the locking pins.

18.2 Adjustable back padding & their

adjustment options

The back system "Adjustable back padding"

comprises one belt system and one back

upholstery. The slack of the backrest can be

adapted to the individual requirements via the

belts with tensioning loops.

First remove the back upholstery that has been

covered over which has been attached using

hook-and-loop straps. The belt system located

underneath has been set in the factory that the

top and the bottom belts have a slack of

approx. 2 cm. The middle belt has been pulled

tight for a good lumbar support.

Figure 21: Belt system of the adaptable back

padding with three belts

For adjusting the slack of the belt system,

the tensioning loops of the respective belt are

held on their strap and pulled strongly to the

right until the belt slackens.

Figure 22: Pull the tensioning loop to the right on its

strap

Figure 23: Tensioning loop open completely

Now the belt can be pulled tight for setting a

small slack or loosened for a large slack (Fig.

24 and 25). The belt does not have to be

threaded out of the tensioning loops for this.

Cord

Pull from the

middle to

the front

Top belt

Bottom belt

Middle belt

Tensioning loop with strap

Pull to the

right

Page 20

Operating instructions SPEEDY 4all & 4you & 4teen

19

Figure 24: Reduce the slack

Figure 25: Increase the slack

In order to put the tensioning loops back onto

the back system loosely again, pull the loop

section at the back to the left. You should dose

your pulling force with care in order not to

adjust the set slack again.

Figure 26: Then re-apply the tensioning loops back

on the back system

Figure 27: Tensioning loops applied slightly to the

back system

Then re-mount the back upholstery using the

fleece hook-and-loop straps.

If the belt should have mistakenly been

threaded out during the adjustment, see the

following figures for threading the belt in

correctly:

Figure 28: Step 1 threading in the belt

Figure 29: Step 2 threading in the belt

Pull to the right:

increase the slack

Pull the rear loop part

to the left

Pull the rear loop part to the left:

reduce the slack

Page 21

Operating instructions SPEEDY 4all & 4you & 4teen

20

Figure 30: Step 3 threading in the belt

Figure 31: Step 4 threading in the belt; simple

threading in of the belt through the tensioning loops

The belts must always be threaded through the

tensioning loops twice as otherwise, the belts

will slacken when using the product and with

intensive loading, the middle web of the

tensioning loops will bend through intensively.

Figure 32: Step 5 threading in the belt; returning the

belt through the tensioning loop to obtain the

required "double passage"

Figure 33: Step 6 threading in the belt

Figure 34: Step 7 threading in the belt

Figure 35: Step 8 threading in the belt

Figure 36: Step 9 threading in the belt

Leave the loops

Page 22

Operating instructions SPEEDY 4all & 4you & 4teen

21

Figure 37: Step 10 threading in the belt

18.3 Ergonomic back shell & its setting

options

The back system "Ergonomic back shell"

comprises an aluminium shell, Velcro crossstraps and a back padding.

There is already a slack integrated in the back

shell due to the shape of the back shell.

Nothing can be adjusted here.

However, lumbar support can be achieved

using three Velcro cross-straps. For this

purpose, the back padding is removed over the

Velcro straps. Now the cross-straps can be

tensioned to the respective individual

requirements by undoing and reapplying the

Velcro strap system.

Figure 38: Ergonomic back shell (view from behind)

Figure 39: Ergonomic back shell without back

padding with Velcro cross-straps

Then mount the back upholstery using the

Velcro straps.

19 Seat system

Avoid falling into the seating and back

padding as the risk of an adjustment, falling or

a defect is increased significantly.

The seat system generally either comprises a

spring suspended Body Contour seat

upholstery or an open belt system.

With a seating system from Body Contour

seat upholstery, there is no adjustment

option. The Body Contour seat upholstery has

a springing effect and when seating,

automatically forms a slack.

Figure 40: Body Contour seat upholstery

The open belt system can be subsequently

adjusted. The slack of the seating surface can

be changed using fleece hook-and-loop straps.

Velcro cross-straps

Page 23

Operating instructions SPEEDY 4all & 4you & 4teen

22

Figure 41: Open belt system with fleece hook-andloop straps for adjusting the slack

It is mandatory to use a seat cushion on

the seating system. At cold temperatures, the

seat cushion prevents lower abdomens from

undercooling and protects against dirt and

wetness. Moreover, the seat cushion also

ensures for equal pressure distribution.

20 Clothing guard

20.1 Overview of terms

In the following, you can see an overview of

terms for all models SPEEDY 4all, SPEEDY

4you and SPEEDY 4teen.

Figure 42: Back jointed shaft

Figure 43: Clothing guard removed from the product

Figure 44: Clothing guard mounted on the product

(without drive wheel)

Figure 45: Locking pin engages in the locking hole

in the side section (view without clothing guard)

Figure 46: Locking pin engaged in the mounting bar

of the clothing guard (view with clothing guard)

Side panel guide

Back jointed shaft

Back jointed shaft

Locking pin

Side panel guide

Locking pin engaged in

the mounting bar

Mounting bar

Recess for

"side panel guide"

Recess for "back

jointed shaft"

Mount for the

"locking pins"

Page 24

Operating instructions SPEEDY 4all & 4you & 4teen

23

In the following, you can see an overview of

terms for all EVO models SPEEDY 4all EVO

and SPEEDY 4you EVO.

Figure 47: Back jointed shaft

Figure 48: Clothing guard removed from the product

Figure 49: Clothing guard mounted on the product

(without drive wheel)

Figure 50: Side section mount, bolted

20.2 Removal and attachment of the

clothing guard

Removal and attachment of the clothing guard

on models SPEEDY 4all, SPEEDY 4you and

SPEEDY 4teen:

For the removal of the clothing guard, first the

locking pin must be pulled out of the mounting

bar. For this purpose, grasp under the seat

upholstery and in the middle, pull the cord to

the front that is linked to the locking pin and

keep it in this position.

Figure 51: Locking pin (view from the inside of the

frame) linked to the cord

Figure 52: Cord for pulling the locking pin

Back jointed shaft

Back jointed shaft

Side section

mount, bolted

Side section mount, bolted

Mount for "side section

mount, bolted"

Recess for

"back jointed shaft“

Front side section

mount

Rear section part

mount

Locking pin

Cord

Pull from the

middle to the

front

Page 25

Operating instructions SPEEDY 4all & 4you & 4teen

24

Observe: In case you are sitting in the

product when removing the clothing guard, you

have to relieve the backrest before pulling the

cord.

Now, first the clothing guard can be removed

from the side panel guide for the mounting bar

(then the cord can be released again) and

pulled from behind the back joint shaft.

Figure 53: Clothing guard pulled from the side panel

guide to the front

For mounting the clothing guard, first this is

connected to the rear of the back joint shaft

with the mounting bar, then the mounting bar is

inserted at the front in the side panel guide and

pressed downwards until the locking pins

engage in the mounting bar.

Figure 54: Mounting bar attached to the back joint

shaft

Removal and attachment of the clothing guard

on EVO models SPEEDY 4all EVO and

SPEEDY 4you EVO:

For removing the clothing guard, first this is

"bolted side section mount" at the front and

then pulled from the back joint shaft from

behind.

Figure 55: Clothing guard pulled out of the "bolted

side section mount" to the front

For attaching the clothing guard, first this is

attached to the back joint shaft with the rear

side section mount and then the front side

section mount is inserted in the "bolted side

section mount".

Figure 56: Rear side section mount attached to the

back joint shaft

Page 26

Operating instructions SPEEDY 4all & 4you & 4teen

25

20.3 Adjusting the clothing guard

position

After adjusting the drive wheel position, an

adaptation of the clothing guard position to the

wheel arch is also necessary.

For adapting the clothing guard position, on

each of the clothing protection guards, loosen

the two or four M5 fixing screws (AF 3 mm)

from the clothing guard mount.

Figure 57: Clothing guard mount

Figure 58: M5 fixing screws and slots of the

mounting bar (SPEEDY 4all, -4you and -4teen)

Figure 59: M5 fixing screws and slots of the

mounting bar (SPEEDY 4all EVO and -4you EVO)

Now the mounting bar (with SPEEDY 4all, 4you and -4teen) or the front and rear side

section mounts (with SPEEDY 4all EVO and 4you EVO) can be moved into the desired

position along the slots of the clothing guard

and the mounting bar or the side section

mount. Then the clothing guard mounts are

positioned accordingly and the M5 fixing

screws are screwed back into the clothing

guard mount with 4 Nm.

Figure 60: Slots of the clothing guard

20.4 Clothing guard size

The clothing guard is available in three

different sizes. The dimensions of the wheel

arches differentiate with the different sizes:

Aluminium: 30 mm (Size 1), 36 mm

(Size 2), 46 mm (Size 3)

Carbon: 30 mm (Size 1), 36 mm (Size 2),

42 mm (Size 3)

Figure 61: Dimensions of the wheel arches

Slots of the clothing guard

M5 fixing screws

M5 fixing screws

Clothing

guard mount

Slots of the

side section mount

Slots of the

mounting bar

Dimensions of the wheel arches

Page 27

Operating instructions SPEEDY 4all & 4you & 4teen

26

The size of the clothing guard can be read-off

the notches on the bottom edge of the clothing

guard. One notch means size 1, two notches

mean size 2 and three notches mean size 3.

Figure 62: Size marking on the clothing guard

After changing to a wider tyre size or after

changing the wheel camber, it may be

necessary to change to another clothing guard

size. Where required, such a change may be

arranged by your dealer.

21 Drive wheels

We recommend: The spoke guard

prevents hands and fingers entering and being

trapped in the wheels when riding. The risk of

injury is thus minimised.

Figure 63: Spoke guard for minimising the risk of

hands and fingers getting trapped

21.1 Removing and attaching the drive

wheels

Figure 64: Locking knob of the quick-release axle in

the middle of the wheel axle

To remove the drive wheels grip through the

spokes around the wheel hub with your fingers.

By pressing the locking knob in the middle of

the wheel axle with your thumb, the wheels

can then be removed.

When attaching the drive wheels, the locking

knobs must be pressed and the drive wheels

with quick-release axle must be inserted in the

drive wheel bearings. Special attention should

be paid here to ensure that the knob springs

out again after attaching the wheel as

otherwise it is not secured. You will know that if

you can see the index groove.

Figure 65: Quick release axle with index groove

Before using the product, check if the

wheels are secured and that the quick release

axles are locked.

Locking knob of the

quick-release axle

Index groove

Size marking for size 2

Page 28

Operating instructions SPEEDY 4all & 4you & 4teen

27

21.2 Checking and adjusting the wheel

tracking of the drive wheel

Well adjusted wheel tracking significantly

improves the easy running characteristics of

the product. To check the tracking, proceed as

follows:

Position the product on a flat surface and apply

the parking brake on both sides.

Measure the axle heights (from the ground to

the drive wheel axle) and write this dimension

onto both tyres at front and back.

Figure 66: Drawing the axle height on the front and

back of both tyres

Afterwards measure the distance between the

drive wheels front and back at the height of

the axles along the markers. Ideally, the

distance between the two drive wheels should

be the same size at the front and back. In

general it can be said that the distance

between the drive wheels at the front may not

be larger than at the back. Apart from that, the

distance at the back may not be more than

5 mm larger that at the front. If this is not the

case, the wheel tracking needs to be

corrected.

Figure 67: Distance between the markers on the

tyres (at axle height), back

To adjust the track proceed as follows:

1. Loosen the aluminium locking nuts on both

sides (AF 41 mm).

Figure 68: Drive wheel bushing and aluminium,

locking nut, product view from behind

2. Correctly adjust the track by turning the

drive wheel bushing (AF 22 mm). Here it

can be said that: If you turn the drive wheel

bushing in the direction of travel, the track

at the front will become more narrow.

When turning against the direction of

travel, the behaviour is exactly the

opposite.

3. Make sure that the distance at the front to

the frame on the right and left is the same.

•

A

xle height

Markings

Distance

Drive wheel bushing

Aluminium locking nuts

Drawing the axle height onto tyres

Page 29

Operating instructions SPEEDY 4all & 4you & 4teen

28

Figure 69: Distance at the front to the frame

4. Measure the distance between the drive

wheels at the front and back again at the

axle height (along the markers) so that the

distance between the rive wheels is not

any larger at the front than at the back.

Apart from that, the distance at the back

may not be more than 5 mm larger that at

the front.

Figure 70: Distance between the markers on the

tyres (at axle height), back

5. If all the distances are correct, then use an

open-ended spanner (AF 22 mm) to hold

the running wheel bushing in position and

tighten the aluminium locking nut (AF 41

mm) with a tightening torque of 70 Nm.

21.3 Wheel camber

The wheel camber increases the lateral

stability of the product but also increases the

overall width of the product.

The wheel camber will be carried out according

to the order and can be subsequently changed

by replacing the drive wheel bearings (with

integrated wheel camber). If you want to make

a change to the wheel camber, please contact

your dealer or PRO ACTIV.

21.4 Air pressure

Check the tyre inflation pressure at regular

intervals as well as after extreme influence of

temperature. The maximum and if applicable,

minimum tyre pressure is printed on the side of

the tyre.

If the tyre pressure is too low, then optimal

functionality of the knee lever brake is not

ensured. Apart from that, there is an increased

risk of a flat tyre.

The tyre pressure increase with the

temperature. If the pressure is too high, the

tyre may burst. For this reason, product tyres

may not be exposed to unusually high

temperatures such as in a sauna or under

glass in the summer.

21.5 Wheelbase extension

Figure 71: Overview of terms

Distance at front to

frame the same

size on both sides

Markings

Distance

Front mouth

Axle of the wheelbase extension

Rear mouth

Page 30

Operating instructions SPEEDY 4all & 4you & 4teen

29

Figure 72: Overview of terms

Figure 73: Pin torque support mounted on the

product (product view from the side without drive

wheel)

For attaching the wheelbase extension, pull

the actuating cable and keep it in this position.

Guide the front mouth underneath the

wheelchair axle and insert this on both sides

on the "Pin torque support". Now lift the

wheelbase extension until the rear mouth

surrounds both sides of the wheelchair axle.

Then the actuating cable can be released. Now

the wheelbase extension is fixed tight.

Figure 74: Wheelbase extension attached (view

from the side without drive wheel)

Figure 75: Wheelbase extension attached (view

from behind)

For removing the wheelbase extension, pull

the actuating cable and keep it in this position.

Release the rear mouth from the wheelchair

axle on both sides by moving the wheelbase

extension down slightly. Then pull the front

mouth from the "Pin torque support" on both

sides. Now the actuating cable can be

released.

For changing the drive wheels between the

wheelchair axle and the axle of the wheelbase

extension, see chapter 21.1.

21.6 Other

If tyres, inner tubes or handrims need to be

replaced, please contact your specialist

retailer.

22 Caster wheels

22.1 Replacing the caster wheels

For the disassembly a caster wheel, unscrew

the M6 axle fixing screw (AF 4 mm) on one

side.

Actuating cable

Wheelchair axle

Pin torque support

Front mouth on the "Pin torque support"

Rear mouth on

the wheelchair

axle

Page 31

Operating instructions SPEEDY 4all & 4you & 4teen

30

Figure 76: M6 axle fixing screw on caster wheel axle

Figure 77: Caster wheel with aluminium axle

Now you can see the aluminium axle with a

hexagon socket (AF 4 mm). This hexagon

socket is used to fix the axle in place, while the

second axle fitting screw (AF 4 mm) is

unscrewed. To do this, insert an Allen key

(AF 4 mm) into the hexagon socket on the

aluminium axle and hold it still. At the same

time, unscrew the remaining M6 axle fixing

screw (AF 4 mm) on the other side.

Now the caster wheel can be removed from

the fork. One spacer each is mounted to the

right and left on the caster wheel that you are

now able to remove in order for it to be reused

later when reinstalling the new caster wheel.

Figure 78: Spacer on the caster wheel

When attaching the caster wheel, proceed as

described above in reverse order. Please

make sure that the spacers on the right and left

on the caster wheel are re-installed in the

caster fork before assembly. The tightening

torque of the axle fixing screws (AF 4 mm) is 7

Nm. We recommend that you only use screws

with polymer dry locking coating. Screws

without polymer dry locking coating must be

secured with screw locking fluid.

22.2 Caster wheels flapping

Uncontrolled swivelling backwards and

forwards of the caster wheels around their

axes on the caster fork (while moving) is called

"fluttering".

If the caster wheels start fluttering, then

immediately reduce the speed you are

travelling at to avoid the caster wheels

jamming sideways so as to avoid the risk of

falling over.

The speed limit at which a caster wheel can

start fluttering, reduces with:

increasing size of the caster wheels

increase weight of the caster wheels

falling load on the caster wheels

decreasing caster length of caster wheels

The following options are available to

counteract caster fluttering:

Fluttering can be reduced by reducing the

caster wheel diameter. This means

installing a small caster wheel in a different

wheel position in the caster wheel fork

(seat height thus remains the same) would

Aluminium axle with

hexagon socket

Spacer

M6 axle fixing screws

Page 32

Operating instructions SPEEDY 4all & 4you & 4teen

31

be one way of reducing fluttering.

However, please note that using a smaller

caster wheel makes it more difficult to

overcome obstacles and makes tipping

necessary more often. The smaller the

caster wheel is, the more driving skill is

required.

Another way to reduce fluttering would for

example be to use a light caster wheel with

the same diameter or, as described above,

with a smaller diameter.

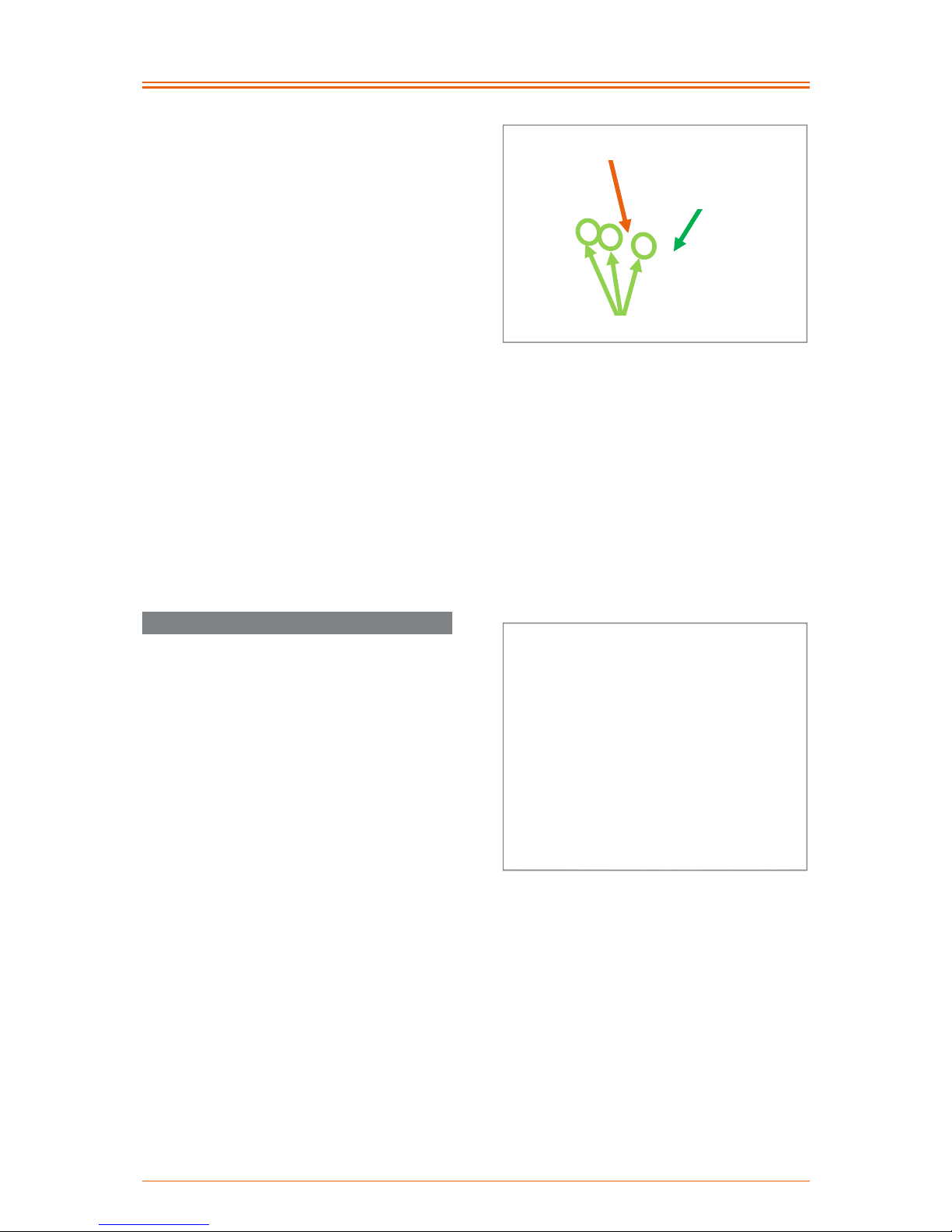

Figure 79: Caster length

It would also be possible to increase the

caster length. The caster length is the

distance between the rotary axle of the

caster wheel fork projected onto the floor

and the wheel contact point. The wheel

contact point of the caster wheel trails

behind the rotary axle as it were. The

caster length has a stabilizing effect on

moving in a straight line. Increasing the

caster length can be attained by mounting

the caster wheel in a different wheel

position on the caster wheel fork (the in

doing so, the front seat height or the angel

of the seat changes, see chapter 17.2).

Another option would be to tilt the caster

wheel axle (see chapter 22.4) from the

vertical position in the lower area in the

direction of travel. The inclination of the

caster wheel axle can be adjusted up to

approx. 4 mm over the length of the caster

wheel bearing block from the vertical

position. This increases the castor length

and the tendency to vibrate reduces.

Figure 80: Increased castor length via the inclination

of the caster wheel for rotary axle

22.3 Replacing the caster wheel forks

A distinction needs to be made between the

caster wheel forks with a screwed axle and

those with a quick-release axle.

Caster wheel for rotary axle

Caster length

Wheel contact

point

Increased castor length

Wheel contact

point

Caster wheel for rotary axle tilted

maximum in the direction of travel

max.

4 mm

Page 33