Page 1

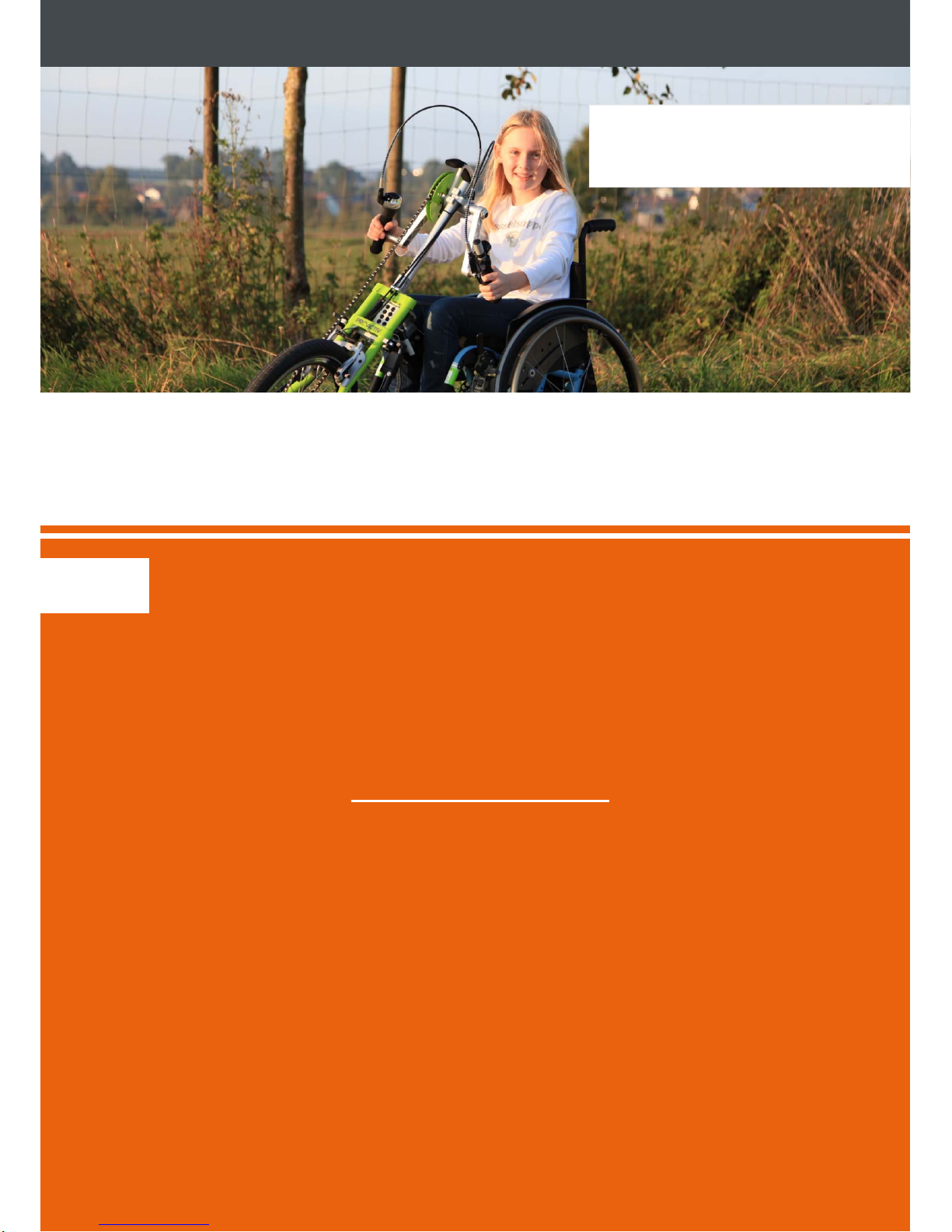

Operating instructions SPIKE adaptive bike

0

MOBILITY MADE SIMPLE!

Operating instructions

Service booklet

SPIKE Adaptive bike

Page 2

Operating instructions SPIKE adaptive bike

1

Contents

1Preface ............................................................................................................................................... 3

2Legend ................................................................................................................................................ 3

3CE Declaration of Conformity / other information ............................................................................... 3

3.1Classification ............................................................................................................................... 3

3.2Declaration of Conformity ........................................................................................................... 3

3.3Manufacturer ............................................................................................................................... 3

4Scope of delivery ................................................................................................................................ 3

5Introduction ......................................................................................................................................... 4

6Product description / purpose ............................................................................................................. 4

7Acceptable usage and operating conditions / places of use .............................................................. 4

8Technical specifications ..................................................................................................................... 5

8.1Product weight ............................................................................................................................ 5

8.2Load weight ................................................................................................................................ 5

8.3Obstacle height and turning circle .............................................................................................. 5

8.4Basic equipment & dimensions .................................................................................................. 5

8.5Service life .................................................................................................................................. 5

9Rating plate ........................................................................................................................................ 6

10Commissioning ................................................................................................................................... 6

11Hand-over ........................................................................................................................................... 6

12Safety instructions – prior to driving / use ......................................................................................... 7

13Safety instructions – while driving / using .......................................................................................... 7

14Safety instructions regarding obstacles ............................................................................................. 9

15Safety instructions regarding dangerous locations and dangerous situations ................................... 9

16Adapter & adaptation ........................................................................................................................ 10

17Functional elements ......................................................................................................................... 10

17.1Parking stand ............................................................................................................................ 10

17.1.1Active and passive positions ........................................................................................ 10

17.1.2

Parking stand height adjustment ......................................................................... 10

17.2

Pedal bearing support & crank ......................................................................................... 11

17.2.1Seating position ........................................................................................................... 11

17.2.2Pedal bearing position ................................................................................................. 12

17.2.3Crank length and grip width ......................................................................................... 13

17.3Grips ......................................................................................................................................... 13

17.4Gear shift .................................................................................................................................. 14

17.4.1Hub gears .................................................................................................................... 14

Page 3

Operating instructions SPIKE adaptive bike

2

17.4.2 Pedal bearing gearshift ................................................................................................ 14

17.5 Brake ......................................................................................................................................... 15

17.5.1 Rim brake ..................................................................................................................... 15

17.5.2 Back-pedal brake for hub drives .................................................................................. 15

17.5.3 Parking brake ............................................................................................................... 15

17.6 Components ............................................................................................................................. 16

18Storage ............................................................................................................................................. 16

19Transport .......................................................................................................................................... 16

20Malfunctions ..................................................................................................................................... 17

21Cleaning and care ............................................................................................................................ 17

22Maintenance ..................................................................................................................................... 17

22.1 General instructions .................................................................................................................. 17

22.2 Service schedules ..................................................................................................................... 18

22.3 Proof of maintenance ................................................................................................................ 18

23Disposal & Recycling ........................................................................................................................ 18

24Re-use .............................................................................................................................................. 19

25Warranty ........................................................................................................................................... 19

26Liability .............................................................................................................................................. 19

27Appendix: Tightening torques and securing details ......................................................................... 20

28Appendix: Medical product passport / record of training .................................................................. 21

29Appendix: Hand-over certificate ....................................................................................................... 22

29.1 Required compliance criteria to authorise use ......................................................................... 22

29.2 Check list for training the user .................................................................................................. 23

30Appendix: Inspection lists ................................................................................................................. 24

Page 4

Operating instructions SPIKE adaptive bike

3

1 Preface

Dear Customer,

Congratulations on purchasing your new

PRO ACTIV product. You have bought a

quality product which has been especially

customised to meet your requirements.

We have put together some instructions about

its proper and safe use in the following

document. Please read these instructions

before using the product.

Throughout these operating instructions, the

operation of standard components is

explained. If you have individual solutions or

non-standard components on your product,

your dealer or we at PRO ACTIV would be

happy to deal with any questions you may

have about handling it.

If you have any further questions about this or

any of our other products, we would be glad to

be at your disposal.

Enjoy your trips and the best possible mobility.

Your PRO ACTIV team

2 Legend

The symbols used in these operating

instructions have the following meanings:

Manufacturer

Warnings and safety instructions

Serial number

Additional information

Assembly instructions for the dealer (see

table of contents)

3 CE Declaration of Conformity /

other information

3.1 Classification

The SPIKE adaptive bike (referred to as a

"product" below) is classified as a class I

product.

3.2 Declaration of Conformity

PRO ACTIV Reha-Technik GmbH declares in

the context of an individual declaration of

conformity that the respective product has

been developed and manufactured according

to the relevant provisions of

EC Directive 93/42/EEC 2007.

If the product is adapted in a manner which

has not been agreed by PRO ACTIV RehaTechnik GmbH, this declaration becomes void.

3.3 Manufacturer

PRO ACTIV Reha-Technik GmbH

Im Hofstätt 11

D-72359 Dotternhausen

Tel. +49 7427 9480-0

Fax +49 7427 9480-7025

E-Mail: info@proactiv-gmbh.de

Web: www.proactiv-gmbh.com

4 Scope of delivery

The product may only be operated with an

adapter supplied by PRO ACTIV which is

suitable for the wheelchair.

The delivery includes the product configured in

accordance with the order, with operating

instructions including record of training / handover certificate and inspection lists. You can

view the basic equipment in chapter "Technical

specifications". As per your order, the product

is equipped with additional recommended

accessories, such as e.g., lighting and clip-on

fender.

Please check that the delivery is complete after

you have received your product.

The product is tested to ensure it is completely

functional prior to shipping. If your product has

been damaged during transit, please contact

your dealer or PRO ACTIV immediately.

Page 5

Operating instructions SPIKE adaptive bike

4

5 Introduction

Before starting your journey for the first

time, familiarise yourself with these operating

instructions paying particular attention to the

safety information and hazard warnings

contained within them.

If you are not sure how to handle the

product or if technical faults occur, please

contact your dealer or PRO ACTIV before

using it.

When operating the product, the

wheelchair operating instructions must also be

observed. Information on limit values must not

be exceeded. If the values contained in the two

operating instructions differ, the lower limit is

the one which applies.

Never leave the product unattended.

6 Product description / purpose

The product is attached to a manual

wheelchair as a mechanically propelled drive

unit which supports the wheelchair user in

being mobile. It is easier to cover longer

distances with ergonomic movement

processes using one's own wheelchair. This

expands the activity radius. Through the

product's larger drive wheel (compared with

the caster wheels of the wheelchair) and the

wheelchair's steering wheels which are raised

from the ground uneven routes and barriers

can overcome more easily and without danger.

The downhill speed can be regulated via the

product's braking systems, so that downhill

slopes can be travelled on safely.

For safety reasons, the product may only be

operated by persons who

have been trained in its use by the dealer

or PRO ACTIV.

can move and control their hands and

arms so that they are able to operate the

controls and perform the full steering

movement without restrictions while

driving.

are physically and mentally capable of

safely operating the device in all operating

situations and can meet the legal

requirements for use on public roads.

7 Acceptable usage and operating

conditions / places of use

Observe the instructions on permitted

operating conditions in the operating

instructions for your wheelchair which the

product has been adapted to.

Use the product on paved surfaces. Avoid

driving on unpaved or loose surfaces (e.g. on

loose gravel, in sand, mud, snow, ice or

through deep puddles of water), as this may

result in incalculable risks.

The wheelchair with the adapted product must

be equipped in accordance with road traffic

regulations when operated on public roads and

spaces.

The maximum permitted load of the product in

its standard design is 75 kg towed capacity

and 5 kg payload. Individual customisation can

be made to accommodate a higher load; this

will be indicated on the ratings plate. Please

ensure that the load limit indicated on the

ratings plate is not exceeded when

transporting objects.

We recommend: The wheelchair can be

equipped with a anti-roll back device and that

this is activated before driving on slopes. The

anti-roll back device can also be used if a

wheelbase extension is used on the

wheelchair.

Page 6

Operating instructions SPIKE adaptive bike

5

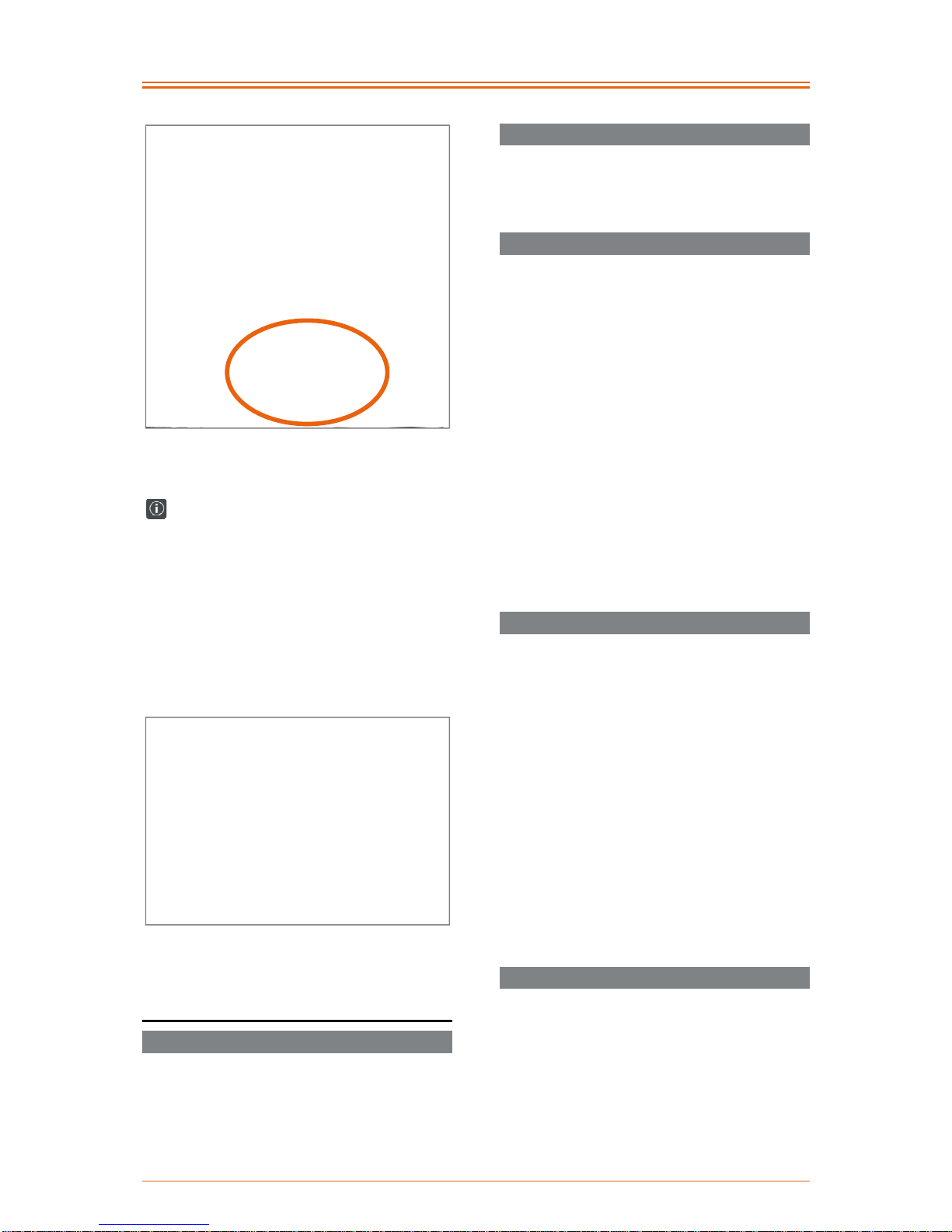

Figure 1: Anti-roll back device

We recommend: The wheelchair should be

equipped with a wheelbase extension. Before

driving with the traction system, the wheelchair

wheels should then be positioned in the

wheelbase extension. This allows a more

optimised distribution of the weight between

the drive wheel of the product and the

wheelchair wheels to be achieved. This

minimises the risk of the product wheel slipping

on slopes.

Figure 2: Removable wheelbase extension

8 Technical specifications

8.1 Product weight

The total weight starts from 7.3 kg with the

basic equipment.

8.2 Load weight

Maximum load weight:

75 kg towing capacity and 5 kg payload

8.3 Obstacle height and turning circle

Maximum drive-over / negotiable obstacle

height: 10 cm (must be ensured through an

appropriate adapter assembly / setting,

steering wheels must be removed

( recommended equipment of the

wheelchair: steering forks with quick-release

axle))

Turning circle:

approx. 3.5 m without manoeuvring back

and forth

approx. 2.3 m with manoeuvring back and

forth (much dependent on the number of

manoeuvres)

8.4 Basic equipment & dimensions

In its basic equipment, the product comprises

one drive unit with docking plate, handles with

brake fittings, chain guard and rim brake.

Dimensions, SPIKE adaptive bike:

Product height: approx. 70-90 cm (depending

on the length of the pedal bearing support)

Product width: approx. 41-50 cm (depending

on the grip width, parking stand in passive

position)

Grip width: 36-45 cm

Crank length: 135-175 cm

8.5 Service life

The service life of the product is 6 years in

accordance with the medical products law.

Page 7

Operating instructions SPIKE adaptive bike

6

9 Rating plate

The rating plate is located on the pedal

bearing. The rating plate includes the precise

model, the serial number and other technical

specifications.

When contacting your dealer or PRO ACTIV

with regard to your product, please always

have the serial number and year of

construction on the rating plate at hand.

The rating plate includes the following data:

Manufacturer

CE marking

Operating instruction present for the

product

Serial number

10 Commissioning

The product will be handed over to you ready

for use by a PRO ACTIV dealer or a field

representative or by a product consultant from

PRO ACTIV. They will fit, if not already done,

the required fastening elements to your

wheelchair to hold the adapter and, if required,

any other accessories. The height of the

parking stand is also adjusted correctly.

Finally, you will be fully instructed in the use of

the product based on the operating instructions

included in delivery. If you wish (recommended

by PRO ACTIV), you will be presented with a

record of training and a hand-over certificate

as written evidence and in addition the

operating instructions and any other

accessories for your own use. The form for the

record of training and the hand-over certificate

can be found in chapters 28 and 29.

It is recommended that you take along an

assistant to the training so that, if required,

they can assist you later when handling the

product.

During the initial commissioning of the product,

drive at minimum speed and become

accustomed to the driving characteristics of the

product. Always adapt the speed and driving

manoeuvres to match your own abilities, the

external circumstances and the legal

regulations. You will get a feel for how to use

the product safely after a short time. Before

driving up or down slopes or hills with the

product, you should be proficient in the safe

handling of the product on the flat.

11 Hand-over

The hand-over must be done by your dealer or

a field representative or by a product

consultant from PRO ACTIV. During the handover, the record of training (chapter 28) and

the hand-over certificate including the

associated check list (chapter 29) must be

filled in. The dealer should send a copy of the

completed documents to PRO ACTIV for filing

either as a scanned file via e-mail, by fax or in

the post. These documents are available as

pdf files which can be completed in the

download area at www.proactiv-gmbh.com

under the link "more documents >>".

Page 8

Operating instructions SPIKE adaptive bike

7

12 Safety instructions –

prior to driving / use

The operating instructions of the

connected wheelchair must be strictly

observed when using the product.

If your wheelchair is operated in

combination with the product, any existing antitipping supports must be put into their passive

position or removed (see the wheelchair's

operating instructions). If the wheelchair is then

used without the product, the anti-tipping

supports must be brought back into their

operating position again to ensure tipping

stability.

Before every trip, check the condition of

the wheels (e.g. visual inspection of the spokes

and rims, check the tyres for damage, foreign

bodies and crack formation). If you have any

doubts, the wheelchair-product combination

must not be operated any further. In this case,

contact your dealer or PRO ACTIV.

Check tyre pressures at regular intervals.

Ensure that you comply with the

manufacturer's specifications which can be

found on the tyres. Tyre pressure which is too

low affects handling and has a negative effect

on the braking action for wheelchairs).

Before starting your trip check that the

product's brake functions. If all existing brakes

are not fully functional, no trips may be taken.

Before every trip, check that the product is

firmly attached to the adapter and that the

adapter is firmly attached to the wheelchair.

The product may not be operated on the

wheelchair if any of the connections are not

tight and secure. In this case, contact your

dealer or PRO ACTIV.

Always ensure that your feet cannot slip

off the feet plate of the wheelchair when using

the product, if necessary by using a special

fixation device.

If present, check the function of the front

and rear lights as well as the effectiveness of

the side and rear reflectors before every trip.

Lights and reflectors must be clearly visible

during the journey and must not be covered by

other objects. Especially trips that take place in

the dark or in the twilight, the lighting must be

functional and visible. For longer trips in the

dark, we recommend that you also take along

extra batteries.

To minimise the risk of suffering serious

head injuries in the event of a fall, a helmet

should always be worn when driving with the

product.

When travelling, always carry a repair kit

and tyre pump for repairs in event of

punctured / flat tyre. A alternative to this is a

pump spray that fills your tyre with a foam that

hardens in the tyre.

13 Safety instructions – while

driving / using

Always hold onto the crank handles with

both hands while driving. If the driving situation

requires you to take one hand off the crank

handles, this is only permitted when the speed

has been reduced to the minimum possible

beforehand.

Increase the speed slowly up to the

desired speed.

Use particular caution when approaching

stairs, edges, drops or other hazard areas.

When waiting at potential hazard areas

(e.g. while waiting at a pedestrian crossing, on

hills or slopes or at ramps of any type), always

hold down the service brakes.

When driving round a bend, reduce your

speed to a minimum.

Do not ride parallel to slopes due to the

risk of tipping.

Page 9

Operating instructions SPIKE adaptive bike

8

You may only drive on slopes where the

wheelchair-product combination can be safely

controlled by steering and braking of the

product.

Due to the increased turning circle, it can

be difficult to turn in buildings, in front of or in

lifts or other buildings, as the standard in such

buildings assumes a maximum turning circle of

1.5 m.

Do not attach objects (carrier bags, etc.)

to the product. These could prevent safe

operation of the product while driving.

When driving on areas which are used for

pedestrians, observe the maximum permitted

speed (walking speed 6 km/h) and keep a

sufficient distance (at least the width of a

wheelchair) from the kerbs or other obstacles

and other road users.

When driving on public roads and

footpaths, the provisions of the road traffic

regulations (German StVO) must be observed.

Avoid driving on unpaved or loose

surfaces (e.g. on loose gravel, in sand, mud,

snow, ice or through deep puddles of water).

When travelling on poorly maintained

paths (e.g., large gravel, potholes) there is an

increased risk of puncturing your tyres as well

as tipping.

If you encounter new driving situations

which are unknown to you, approach them with

great care. If you consider that the risk is too

high, you must immediately abort the driving

manoeuvre and, if required, call for help to

assist you in extracting yourself from this

situation.

You must not make telephone calls while

driving.

Operating the product can affect other

devices, for example theft protection barriers in

department stores.

By performing regular checks, ensure that

the safety bolts of the adapter are always in

the correct position while driving (see operating

instructions "Adapter & adaptation").

When driving, never jerk the handlebars to

the left or the right, as this may cause the

wheelchair-product combination to tip over

sideways in certain circumstances.

While driving, never grab onto the

wheelchair wheels, in the area of the product

wheel, in the area of the chain / sprockets /

chain wheels or into other rotating parts; if you

do you may cause injuries.

Only brake the product using the service

brakes.

During long trips the brakes of the product

may heat up. Therefore, do not touch the

brakes during or immediately after the trip (e.g.

when detaching or loading the product).

If the situation allows it, the speed should

be reduced by carefully applying the service

brake. Abrupt braking can cause the upper

body to fall forwards which can thereby result

in injuries or loss of vehicle control.

The product is only designed to be used

to transport persons with limited mobility and

must not be used for any other purpose, e.g.

by playing children or to transport goods.

If the weight load on the drive wheel falls

(e.g. when driving on slopes) or when driving

on loose / slippery surfaces, the braking action

of the wheel may be considerably reduced.

The driving style and speed should be adjusted

so that the product can be safely stopped at all

times using the brakes.

Towing or using a trailer is not permitted.

Make sure that cables and lines are not

kinked or caught up somewhere. This could

cause them to be damaged which could lead to

the brakes and gear shift not working correctly.

In this case, the product must no longer be

operated.

Page 10

Operating instructions SPIKE adaptive bike

9

14 Safety instructions regarding

obstacles

Driving on steps with the product is

forbidden.

Obstacles like curbs, for example, should

always be negotiated driving forwards and

always using the minimum speed required.

The maximum obstacle height which can

be negotiated is 10 cm. This value can,

however, be reduced due to the specifications

of the type of wheelchair or its settings.

Therefore, you should observe the values

given in the wheelchair's operating instructions

or the restrictions dependent on the settings.

When driving over or passing obstacles, it

is important that you avoid any product or body

parts catching on the obstacle as this may lead

to falling causing serious injuries to the user

and third parties as well as damage to the

product.

Always drive over curbs or other obstacles

so that you cross them to the front or at right

angles. If you drive at them on an angle, or

only have one rear wheel on the obstacle,

there is an increased risk of tipping over to the

side which can result in serious injuries to the

user and third-parties as well as damage to the

product and the wheelchair.

15 Safety instructions regarding

dangerous locations and

dangerous situations

The operator of the product determines the

route to be driven taking the operating

instructions, their driving knowledge and

physical abilities into consideration.

The personal driving skills are particularly

important in the following dangerous locations

which are provided as examples; the product's

user must use their judgement before driving in

such locations:

quay walls, landing and berthing locations,

paths and locations close to water,

unsecured bridges and dykes.

narrow paths, slopes (e.g. ramps and

driveways), narrow paths on a slope,

mountainous routes.

narrow and / or steeply sloping paths along

main roads or near cliffs.

routes which are covered in leaves, snow

or ice.

ramps and lifting equipment on vehicles.

When driving in a circle or turning on hills

or downward slopes, there may be an

increased tendency to tip over to the side due

to the changes in the centre of gravity. Always

perform these driving manoeuvres with

increased caution and only at slow speed. If

required, the driving manoeuvre must not be

performed or only with the help of an assistant.

When crossing main roads, intersections

and level crossings, extreme caution is

needed. Crossing rails in the road or at level

crossings must never be undertaken while

driving parallel, otherwise the wheels could

become caught which would result in the

wheelchair and the product being unable to

manoeuvre.

When driving on ramps and lifting

equipment on vehicles, extreme caution is

needed. During the lifting or lowering operation

of a ramp or the lifting equipment, the service

brake should be operated. This prevents rolling

away.

The grip of the tyres on the ground is

reduced in the wet. There is an increased risk

of slipping. Adjust your driving, braking and

steering behaviour accordingly.

Page 11

Operating instructions SPIKE adaptive bike

10

16 Adapter & adaptation

Where necessary and ordered, a suitable

adapter for your wheelchair is included with the

delivery.

Please read the operating instructions and

assembly instructions "Adapter & adaptation"

before using the product.

The product may only be adapted and

detached on dry, stable and flat surfaces.

17 Functional elements

17.1 Parking stand

17.1.1 Active and passive positions

By pressing down and turning the operating

lever, the parking stand positions can be

changed from the active to the passive

position, or vice versa.

Figure 3: Press down and turn the operating lever

Figure 4: Parking stand in the active position

Figure 5: Parking stand in the passive position

17.1.2 Parking stand height adjustment

The height adjustment of the parking stand is

important in order to bring the docking plate of

the product into the correct (heigh) position to

the adapter.

For setting the height of the parking stand, the

following must be observed: the dimension

from the floor to the lower edge of the front of

the insertion maul (on the wheelchair side)

should correspond with the dimension from the

ground to the upper edge of the insertion bolt

(on the product side). As soon as there is a

deviation from these two dimensions due to the

hole pattern, the dimension from the ground to

the upper edge of the insertion bolt may be up

Page 12

Operating instructions SPIKE adaptive bike

11

to max. 1 cm larger. In this case, the product

can be inserted into the adapter by tipping

slightly to the rear (via the parking stand).

Figure 6: Measurement from the ground to the lower

edge of the front of the insertion maul

Figure 7: Dimension from the ground to the lower

edge of the insertion bolt

Figure 8: Position of the product and wheelchair

with the parking stand height adjustment set

correctly

The height adjustment of the parking stand

is carried out by undoing the M6 oval head

screw (AF 4 mm) and adjusting the position of

the adjustment inlet along the specified row of

holes in the parking stand and inlet. Finally,

tighten the oval head screw up to 7 Nm of

torque.

Figure 9: M6 oval head screw and adjustment inlet

to adjust the height of the parking stand

17.2 Pedal bearing support & crank

17.2.1 Seating position

The seating position and therefore the pedal

position and the crank length depend on the

upper-body stability or the core musculature. A

suitable adjustment to the arm length will have

been made during the consultation /

measurement procedure.

M6 oval head

screw

Adjustment

inlet

Front of the

insertion

maul

Dimension

from the

ground to

the lower

edge of the

front

Insertion

bolt

Dimension from

the ground to

the lower edge

of the insertion

bolt

Page 13

Operating instructions SPIKE adaptive bike

12

With weak core musculature, the seating

position should normally be chosen so that the

upper body remains still in an upright position

when operating the crank while driving. This is

particularly important if you have low seating

stability due to missing or weak core

musculature. A rocking motion (forwards and

backwards) of the upper body or the head

should be avoided where possible. The height

of the pedal bearing in this case is selected to

be slightly higher (chest height or higher).

Sporty drivers with the appropriate trunk

stability relieve their arm musculature by

moving their trunk at the same time. The height

of the pedal bearing in this case can be

selected to be slightly lower (chest height or

lower).

Figure 10: Elbows are not completely straight, upper

body is in an upright position

Figure 11: Distance between the crank and the thigh

The cranks must not touch the knee or

thigh when they are being turned.

The elbows should not be completely

extended when the crank handles point

completely forward away from the body.

A suitable restraint system must be used if

you have poor seating stability due to a lack of

or weak core musculature. The selection of the

suitable system must be made in conjunction

with your doctor or therapist and / or defined

and implemented by your dealer. There are

various systems available such as chest straps

or four-point safety belts. Also, the dealer can

frequently individually make a system or adapt

one that has been purchased.

17.2.2 Pedal bearing position

A subsequent adjustment of the pedal bearing

position can only be achieved by exchanging

the pedal bearing support, the angle

adjustment possible on the steering head as

well as the length adjustment and the spacing

of the adapter tube on the adaptation points on

the wheelchair frame (see operating

instructions "Adapter & adaptation").

To adjust the height, two M6 clamp screws

(AF 5 mm) must be loosened on the pedal

bearing housing. Then the pedal bearing

housing can be moved along the pedal bearing

support to the correct position. Then tighten up

the four M6 clamp screws (AF 5 mm) to 7 Nm

torque and secure them with thread lock fluid.

Page 14

Operating instructions SPIKE adaptive bike

13

Figure 12: M6 clamp screws on the pedal bearing

housing for the height adjustment of the pedal

bearing position and the replacement of the pedal

bearing support

The replacement of the pedal bearing

support is carried out by undoing the two M6

clamp screws (AF 5 mm) on the pedal bearing

housing and the two M6 clamp screws (AF

5 mm) on the upper fork bridge (figures 12

and 13). Then the new pedal bearing support

is inserted into the fork bridge with another

length and the two M6 clamp screws

(AF 5 mm) are tightened to 7 Nm and secured

with thread lock fluid. Finally, the pedal bearing

housing is positioned on the pedal bearing

support and retained at the desired height. In

order to fix the pedal bearing housing, the two

M6 clamp screws (AF 5 mm) on the pedal

bearing support are tightened to 7 Nm and

secured with thread lock fluid.

Figure 13: M6 clamp screws on the top fork bridge

for replacing the pedal bearing support

If you want to make a change to the pedal

bearing position, please contact your dealer or

PRO ACTIV.

Please note that, after a large adjustment

to the chain pedal bearing position, the lines

and the cable lengths must be adjusted.

17.2.3 Crank length and grip width

The crank length can be chosen from different

lengths individually to suit the length of the

arms and mobility of the user. Different widths

of pedal bearing shafts and spacers between

the crank handles and the rotary axles of the

hand grips are available to adjust the

grip width.

If you want to make a change to the crank

length or grip width, please contact your dealer

or PRO ACTIV.

Figure 14: Crank length and grip width

17.3 Grips

The grips must be held firmly with both hands

whilst driving and always held so that the

cables and lines are oriented upwards.

Grip width

Crank

length

Pedal bearing

shaft

M6 clamp screws on the

top fork bridge

Hand grip

rotary axle

Crank

handles

M6 clamp screws on the

pedal bearing housing

Page 15

Operating instructions SPIKE adaptive bike

14

Figure 15: Correct grip hold

17.4 Gear shift

17.4.1 Hub gears

The hub drive can be changed while driving

and also when stationary. No crank movement

is needed to change or only a small reduction

in torque is needed while driving.

The Shimano Nexus hub drives are operated

by turning the grip shift. The gear selected is

shown in the display on the control panel.

Figure 16: Shifting using the grip shift for the

Shimano Nexus Inter8 hub drive

With the Shimano Nexus Inter8 hub drives

there is another operation option via the

operating machine that enables shifting using

the chin (option). To change up move the gear

lever 45° up and to change down move it 45°

down. After completing the gear change, the

gear lever moves back to its starting position.

There is no display for the gear selected

available.

Figure 17: Shifting via the PRO ACTIV operating

machine with the Shimano Nexus Inter8 hub drive

For more information on hub drives, please

see the instructions provided by the gear

manufacturer.

17.4.2 Pedal bearing gearshift

The pedal bearing gearshift ("Mountaindrive"

gear reduction for hills) is switched on by

pressing the control buttons on the left and

right of the pedal bearing. Here, you can

choose between a 1:1 gear ratio (the left

control button in the direction of travel) or a

2.5:1 gear ratio (the right control button in the

direction of travel).

Figure 18: Left control button of the pedal bearing

gearshift

Left control

button

Press

Left-hand:

1:1 gear ratio

Change down

Change up

Gear lever

Gear display

Gear changes

by twisting

the grip to the

left and right

Page 16

Operating instructions SPIKE adaptive bike

15

The pedal bearing gearshift should be

lubricated once or twice a year with the

supplied original semi-fluid grease using the

syringe. The semi-fluid grease is filled through

the slotted screw.

Figure 19: Slotted screw to lubricate

Figure 20: Original semi-fluid grease in the syringe

For more information, please see the

instructions provided by the manufacturer.

17.5 Brake

Generally, the product is braked via the backpedal brake of the hub drive and a rim brake.

Where possible, driving in a manner that

allows you to reduce your speed gradually if

required.

17.5.1 Rim brake

The brakes are operated using the brake lever.

Figure 21: Brake lever

In the event of abrupt hard braking, there

is a risk that you might fall forward with your

upper body and thereby cause injuries to

yourself.

Please make sure that the braking

surfaces on the rim and the brake pads on the

rim breaks do not come into contact with oils or

greases which could otherwise impair the

braking effect. If rims or brake pads do come

into contact with oils or greases, the brake

pads must be replaced and the rim must be

professionally cleaned with brake cleaner (e.g.

Weicon surface cleaner).

You can find further information in the brake

manufacturer's instructions.

17.5.2 Back-pedal brake for hub drives

A back-pedal brake is already integrated into

the Shimano Nexus Inter3, 7 and 8 speed hub

drives.

This brake is operated by moving the cranks

against the acceleration direction. The brake

force applied is adjusted by the strength of the

backwards movement of the cranks.

17.5.3 Parking brake

The parking brake is implemented via the

mounted rim brake (option). The operation of

the parking brake is carried out using an

operating lever on the pedal bearing support. If

the operating lever is pressed to the left, the

rim brake is activated. When pressed further to

the left, the brake force increases even more. If

the operating lever is pressed to the right, the

rim brake is opened again.

Slotted screw

Brake leve

r

Page 17

Operating instructions SPIKE adaptive bike

16

Figure 22: Parking brake can be operated from the

operating lever (opened)

17.6 Components

You will be instructed about the functions and

operation of the gears, brakes and other brand

components during the hand-over / training.

You can also get information later from the

component manufacturers' operating

instructions enclosed, or if needed, by asking

your dealer or PRO ACTIV. The operating

instructions from the component manufacturers

can also be downloaded online.

In the download area of www.proactiv-

gmbh.com under the links "more

documents

>>", we have put together the most

important documents. More extensive

information can be found on the

manufacturers' websites:

Shimano components:

http://si.shimano.com

Mountain Drive pedal bearing gear shift:

http://www.haberstockmobility.com/de/produkte/schlumpfgetriebe/schlumpf-mountain-drive.html

Sigma:

http://www.sigmasport.com

Subject to changes to the links provided by the

component manufacturers.

18 Storage

Store the product on an easy to clean surface

in a dry environment, preferably at room

temperature (+15°C to +25°C).

For storage please also comply with the notes

in other sections of these operating instructions

and the component manufacturers' operating

instructions included with delivery.

If the product is not used or is stored over

a longer period, if necessary, before using it

again, we recommend having a dealer give it a

general function and safety check.

19 Transport

When loading or transporting, the product can

be held on the pedal bearing support.

When transporting in vehicles it must be

noted that the product is not approved for use

as a seat in vehicles or disabled person's

vehicles when combined with a manual

wheelchair. All vehicle occupants must only sit

on the seats installed in the vehicle during the

journey with the associated restraint systems.

Failing to observe this leads to increased risk

of injury for the user as well as for third-parties.

The product and all associated

components must be secured during transport

so that they are not damaged (e.g. by falling

over) and do not become a hazard to persons

or other products.

When loading make sure that the cables

and lines are not caught up, become kinked or

otherwise damaged. The product may not be

used with damaged cables and / or lines.

To the right:

Open brake

To the left:

Close brake

Page 18

Operating instructions SPIKE adaptive bike

17

20 Malfunctions

In the event of any malfunctions which cannot

be solved by yourself based on the operating

instructions included in the scope of delivery,

please contact your specialist retailer or

PRO ACTIV directly.

Malfunctions must be solved before any

further use or, if they occur during the journey,

this must be interrupted immediately.

21 Cleaning and care

Regular cleaning of the product is prescribed

to prevent the components becoming clogged

up due to dirt. Moreover, regular cleaning

prevents corrosion and increased wear. In

particular, the product should be carefully

cleaned after every major use, e.g. summer or

winter holidays.

To avoid corrosion and therefore malfunctions

or breakages of components, the product may

not be exposed to any aggressive

environmental influences. If this cannot be

avoided, the product should be cleaned

immediately after such use and moving parts

need to be greased.

For all cleaning processes, only use

commercially available, household cleaning

agents. Do not use any abrasive cleaning

agents or aggressive, acidic cleaners, to

prevent scratching or fading of the coating or

the anodised parts.

In case the product becomes wet when using,

please dry it after use.

The drive wheel should be regularly cleared of

contamination. It is recommended that you use

a soft sponge or a soft brush.

The product must not be cleaned using

steam or high pressure.

If you need care products for your product,

please contact PRO ACTIV.

22 Maintenance

22.1 General instructions

The product is not a maintenance-free device.

Therefore, please observe the following

instructions about maintenance.

For tyres with tread: As soon as there is

one or more points with less than 1 mm of

tread on the product or the adapted

wheelchair, the tyres must be changed since

otherwise there is an increased risk of an

accident.

For tyres without thread: As soon as there

is one or more points where the tyre carcass or

the accident protection is visible on the product

or the adapted wheelchair, the tyres must be

changed since otherwise there is an increased

risk of an accident.

When maintaining the brakes and the

gear components, it is imperative that the

operating instructions of the manufacturer

which were included in delivery are followed.

Only manufacturer's original parts may be

used when ordering spare parts.

Repairs and conversions to the product

may only be carried out by your dealer or

PRO ACTIV.

Tightening torques and securing details for

fastening elements as shown in the table in

chapter 27 must be observed.

Page 19

Operating instructions SPIKE adaptive bike

18

22.2 Service schedules

There is some maintenance work or checks

which should be carried out by the user

themselves at regular intervals (approximately

every 4 weeks depending on the frequency of

use):

The chain should be cleaned and

lubricated with chain oil (observe the

manufacturer's instructions).

Check the tyres for damage, foreign bodies

and any cracks that form.

Check the cable housings are seated

correctly and tightly in the gear cable

holders.

Cables and lines should be checked for

kinks and crushing.

Check the brake pads.

Check the tyre pressure and correct if

needed (the tyre pressure should always

be as printed on the tyre covers).

If you should discover any problems

during these checks, please immediately

contact your dealer or PRO ACTIV. Service

and repair work on the product may only be

carried out by your dealer or PRO ACTIV.

In addition to these maintenance tasks /

checks by the user, PRO ACTIV has

prescribed maintenance tasks to be carried

out by the dealer or PRO ACTIV for safe

operation of the product and to minimise the

risk to the user or third-parties.

The initial inspection is performed after running

200 kilometres or 5 months after delivery

(whichever comes first). The maintenance

schedule can be found in the inspection lists in

chapter 30.

Subsequent inspections are then always

performed after 1,000 kilometres running or

after a period of 1 year (whichever comes first).

The maintenance schedule can be found in the

inspection lists in chapter 30.

After extreme loads, e.g. during holidays where

the product was used on sand, near sea water

or in snow, it is recommended that an

additional deep clean and inspection is

performed by your dealer or PRO ACTIV.

To maintain the operating licence and the

warranty validity, the performance of the

maintenance tasks must be documented. Any

faults identified during maintenance work must

be rectified and documented as such before

further use of the product.

Even if your product does not show any signs

of wear, damage or malfunctions, the regular

safety-related checks on your product must be

carried out in accordance with the

maintenance schedule.

22.3 Proof of maintenance

To provide proof of the maintenance, you can

use the inspection lists in chapter 30. The

inspection lists are also available as pdf files

which can be filled in within the download area

of www.proactiv-gmbh.com

under the link

"more documents >>". In any event, keep all

documents / service reports as a means of

proof, and get any service work which was not

carried out by PRO ACTIV documented.

Please bring these operating instructions /

service booklet to every service.

23 Disposal & Recycling

At the end of the service life, the product can

be disposed of by PRO ACTIV or your dealer

in a proper, environmentally-friendly manner.

The disposal or recycling must be carried out

by a waste disposal company or a municipal

waste disposal centre.

Special guidelines may apply on-location with

regard to the disposal or recycling. These must

be clarified and considered when disposing

(this may also include the cleaning or

disinfection of the product before the disposal).

In the following section, you will find a

description of the materials for the disposal

and recycling of the product and its packaging:

Page 20

Operating instructions SPIKE adaptive bike

19

Aluminium: frame, rim

Steel: fastening points, screws, nuts

Plastic: handles, tyres, bags for packing

Cardboard / paper: packaging

24 Re-use

If your product has been provided to you by

your funding provider and you no longer

require it, you should report this fact to your

health insurance company or your dealer. Your

product can then be simply and economically

re-used.

Before any re-use, a safety check must be

carried out on the product by PRO ACTIV. In

addition to the instructions contained in

chapter 21 (Cleaning and care), a thorough

cleaning of the grips and all controls must be

carried out.

Before the product can be reused, it must be

prepared with care. A disinfection agent must

be sprayed onto all surfaces that the user may

make contact with. For this purpose, a liquid

disinfection agent based on alcohol must be

used for the quick residue-free disinfection

(e.g., Exporit 4712). Please observe the

manufacturers instructions for use for the

disinfection agent that you use.

This will also be done by PRO ACTIV as part

of the safety check. The safety-related check

must be initiated by the funding provider.

25 Warranty

PRO ACTIV guarantees that the product was

free of any defects at the time it was handed

over. This warranty expires 24 months after the

product was delivered.

Further information can be found in

PRO ACTIV's general terms and conditions at

www.proactiv-gmbh.com

.

Any modifications to the product which

have not been expressly approved by

PRO ACTIV will invalidate the warranty. Such

modifications may cause unforeseeable safety

risks and are therefore not permitted.

26 Liability

As the manufacturer of the product,

PRO ACTIV is not responsible for its safety if:

the product is handled improperly

the product is not maintained in

accordance with the maintenance

schedule laid down by PRO ACTIV

the product is commissioned and used

contrary to the instructions in these

operating instructions

repairs or other work are carried out by

non-authorised persons

third-party parts are installed or connected

to the product

Further information can be found in

PRO ACTIV's general terms and conditions at

www.proactiv-gmbh.com

.

Page 21

Operating instructions SPIKE adaptive bike

20

27 Appendix: Tightening torques and securing details

The following table shows the torques for shaft screws with a metric control thread (valid if the drawing

or assembly instructions do not state different values!):

Dimension

Torque MA in Nm depending on how tight the screws are

Stability 8.8 Stability 10.9

M4 2.1 3.1

M5 4.2 6.1

M6 7.3 11

M8 17 26

M10 34 51

M12 59 87

M10 x 1 36 53

Securing details: All screws on PRO ACTIV products should be secured with thread lock fluid "medium

strength" (e.g., Weicon AN302-42), where there are no securing clamps on the screw connections

present or there is a lubrication requirement with grease or copper paste.

Page 22

Operating instructions SPIKE adaptive bike

21

28 Appendix: Medical product passport / record of training

Product specifications:

Serial number:

Customer data:

Surname, forename:

Street:

Postcode, city:

Phone:

Paying organisation:

Training carried out by:

Medical supplies dealer

PRO ACTIV field

representative

Record of training

I was / we were instructed in accordance with the associated hand-over certificate about the operation

of the product listed and informed about possible operator errors. I was / we were also advised about

situations where the assistance of another person is required. The operating instructions were handed

to me / us.

Instructor

Name, date, signature

1. Person being trained

Name, date, signature

2. Person being trained

Name, date, signature

3. Person being trained

Name, date, signature

For minors, or persons who are not responsible for their actions, legal guardians / supervisors / responsible persons are to be

trained in the use, this is confirmed by their signature. The data is recorded in the feedback system of PRO ACTIV RehaTechnik GmbH, as the manufacturer of the above named product. It will be managed in accordance with Section 16 BDSG

(Federal Data Protection Law).

Stamp / Date / Dealer's signature

Page 23

Operating instructions SPIKE adaptive bike

22

29 Appendix: Hand-over certificate

29.1 Required compliance criteria to authorise use

Topics

Completed

/ fulfilled

Remarks

The product is suitable for the customer based on

their own judgement and the customer

information received regarding the disabilityrelated restrictions.

The use intended by the customer is fully

consistent with the intended use as described in

the operating instructions (see the Product

description / intended use chapter).

The product's equipment is suitable to allow the

customer safe use with maximum reduction of

risks (see check list on the following page).

The customer was informed about the current /

applicable regulations in accordance with the

road traffic regulations.

The customer's driving ability was checked during

a test drive in difficult driving situations and found

to be appropriate (see the check list on the

following page).

The user, according to their own statements, or

those of the legal representative or guardian and

the assessment of the person providing the

training, is able to meet the requirements of

public traffic in full and to act accordingly. This

ability to act, which is the basis for reducing the

risk for the user and other road users to an

acceptable level, is also completely achievable

taking current illnesses / disabilities into full

account.

The operating instructions, and explicitly all of the

warning and safety instructions contained therein,

were discussed during the training in detail and

understood by the user. The user was then

handed these operating instructions.

Page 24

Operating instructions SPIKE adaptive bike

23

29.2 Check list for training the user

Topics

Completed

/ fulfilled

Advised of the applicable legal regulations when driving on public roads.

All mechanical function controls were explained and their function demonstrated.

Adaptation of the adapter to the wheelchair and removing the adapter from the wheelchair was

demonstrated and then performed by the user themselves and / or their assistant.

Adaptation and uncoupling the product to / from the wheelchair was demonstrated and then

performed by the user themselves and / or their assistant.

Adaptation of the wheelbase extension on the wheelchair – if fitted – was demonstrated and

then performed by the user themselves and / or their assistant.

Repositioning the wheelchair drive wheels from the standard position in the wheelbase

extension sockets – if fitted – was demonstrated and then performed by the user themselves

and / or their assistant.

How the parking stand works was demonstrated and then performed by the user themselves

and / or their assistant.

The operation of the parking brake – if fitted – was demonstrated and then performed by the

user themselves and / or their assistant.

Use of the service brakes was demonstrated and then performed by the user themselves and /

or their assistant.

The operation and function of the gears was demonstrated and then performed by the user

themselves and / or their assistant.

The operation of the lights – if fitted – was demonstrated and then performed by the user

themselves and / or their assistant.

Test drive: Forwards and, if required, backwards travel through 4 cones spaced at 1.5 m or 2 m

Test drive: Driving on the level, uphill and downhill in the direction of travel

Test drive: Emergency stop from high driving speed

Information for care, cleaning and maintenance of the product have been provided and

understood by the user and / or assistant.

Information on the wheel with regard to inflation pressure and tread depth have been provided

and understood by the user and / or assistant.

Information on regular checks of the brakes have been provided and understood by the user

and / or assistant.

Information on checking the gears including cables and lines and the maintenance of the chain

have been provided and understood by the user and / or assistant.

The contents of the operating instructions from PRO ACTIV and the other component

manufacturers were completely worked through based on the product training and were

understood by the user and / or assistant.

The use of the product is only permitted when all topics listed in "Required compliance criteria for

those permitted to use" have been met by the user and all the points have been ticked off in the

"Check list for training the user".

Page 25

Operating instructions SPIKE adaptive bike

24

30 Appendix: Inspection lists

Initial inspection: After 200

km or 5 months

Kilometre reading:___________________

OK /

carried out

not OK resolved

Check all screws / fastening elements are firmly seated

Functional and safety check of all lights (if fitted), steering

and adaptation to the product and the adapted wheelchair /

wheelchairs

Functional and safety check of the brakes and, where

necessary, replacement of the brake fluid, brake pads,

brake cables and tyres on the product and wheelchair.

Check, adjust / set, clean and oil the gear components

Check the spoke tension of the drive wheel and, if required,

correct the tension / re-centring

resolved = the fault was corrected

Comments:

Stamp:

Date / Signature

Page 26

Operating instructions SPIKE adaptive bike

25

Subsequent inspection: After a further 1000 km or 1 year after the last inspection or after heavy

use

Kilometre reading:___________________

OK /

carried out

not OK resolved

Check all screws / fastening elements are firmly seated

Clean and oil / grease all pivot points and bearings

Visual inspection of the frame and attachments for crack

formation, deformation, etc.

Functional and safety check of the brakes and, where

necessary, replacement of the brake fluid, brake pads,

brake cables

Check, adjusting, cleaning and oiling the gear components

including pedal bearing gearshift (if fitted)

Check the spoke tension of the drive wheel and, if required,

correct the tension / re-centring

Functional and safety check of the drive wheel and, where

necessary, replacement of the tyre on the product

Functional and safety check of all lights (if fitted), steering

and adaptation on the product and the adapted

wheelchair / wheelchairs

Test drive / functional test

resolved = the fault was corrected

Comments:

Stamp:

Date / Signature

Page 27

Operating instructions SPIKE adaptive bike

26

Subsequent inspection: After a further 1000 km or 1 year after the last inspection or after heavy

use

Kilometre reading:___________________

OK /

carried out

not OK resolved

Check all screws / fastening elements are firmly seated

Clean and oil / grease all pivot points and bearings

Visual inspection of the frame and attachments for crack

formation, deformation, etc.

Functional and safety check of the brakes and, where

necessary, replacement of the brake fluid, brake pads,

brake cables

Check, adjusting, cleaning and oiling the gear components

including pedal bearing gearshift (if fitted)

Check the spoke tension of the drive wheel and, if required,

correct the tension / re-centring

Functional and safety check of the drive wheel and, where

necessary, replacement of the tyre on the product

Functional and safety check of all lights (if fitted), steering

and adaptation on the product and the adapted

wheelchair / wheelchairs

Test drive / functional test

resolved = the fault was corrected

Comments:

Stamp:

Date / Signature

Page 28

Operating instructions SPIKE adaptive bike

27

Subsequent inspection: After a further 1000 km or 1 year after the last inspection or after heavy

use

Kilometre reading:___________________

OK /

carried out

not OK resolved

Check all screws / fastening elements are firmly seated

Clean and oil / grease all pivot points and bearings

Visual inspection of the frame and attachments for crack

formation, deformation, etc.

Functional and safety check of the brakes and, where

necessary, replacement of the brake fluid, brake pads,

brake cables

Check, adjusting, cleaning and oiling the gear components

including pedal bearing gearshift (if fitted)

Check the spoke tension of the drive wheel and, if required,

correct the tension / re-centring

Functional and safety check of the drive wheel and, where

necessary, replacement of the tyre on the product

Functional and safety check of all lights (if fitted), steering

and adaptation on the product and the adapted

wheelchair / wheelchairs

Test drive / functional test

resolved = the fault was corrected

Comments:

Stamp:

Date / Signature

Page 29

Operating instructions SPIKE adaptive bike

28

Subsequent inspection: After a further 1000 km or 1 year after the last inspection or after heavy

use

Kilometre reading:___________________

OK /

carried out

not OK resolved

Check all screws / fastening elements are firmly seated

Clean and oil / grease all pivot points and bearings

Visual inspection of the frame and attachments for crack

formation, deformation, etc.

Functional and safety check of the brakes and, where

necessary, replacement of the brake fluid, brake pads,

brake cables

Check, adjusting, cleaning and oiling the gear components

including pedal bearing gearshift (if fitted)

Check the spoke tension of the drive wheel and, if required,

correct the tension / re-centring

Functional and safety check of the drive wheel and, where

necessary, replacement of the tyre on the product

Functional and safety check of all lights (if fitted), steering

and adaptation on the product and the adapted

wheelchair / wheelchairs

Test drive / functional test

resolved = the fault was corrected

Comments:

Stamp:

Date / Signature

Page 30

Operating instructions SPIKE adaptive bike

29

Subsequent inspection: After a further 1000 km or 1 year after the last inspection or after heavy

use

Kilometre reading:___________________

OK /

carried out

not OK resolved

Check all screws / fastening elements are firmly seated

Clean and oil / grease all pivot points and bearings

Visual inspection of the frame and attachments for crack

formation, deformation, etc.

Functional and safety check of the brakes and, where

necessary, replacement of the brake fluid, brake pads,

brake cables

Check, adjusting, cleaning and oiling the gear components

including pedal bearing gearshift (if fitted)

Check the spoke tension of the drive wheel and, if required,

correct the tension / re-centring

Functional and safety check of the drive wheel and, where

necessary, replacement of the tyre on the product

Functional and safety check of all lights (if fitted), steering

and adaptation on the product and the adapted

wheelchair / wheelchairs

Test drive / functional test

resolved = the fault was corrected

Comments:

Stamp:

Date / Signature

Page 31

Operating instructions SPIKE adaptive bike

30

Subsequent inspection: After a further 1000 km or 1 year after the last inspection or after heavy

use

Kilometre reading:___________________

OK /

carried out

not OK resolved

Check all screws / fastening elements are firmly seated

Clean and oil / grease all pivot points and bearings

Visual inspection of the frame and attachments for crack

formation, deformation, etc.

Functional and safety check of the brakes and, where

necessary, replacement of the brake fluid, brake pads,

brake cables

Check, adjusting, cleaning and oiling the gear components

including pedal bearing gearshift (if fitted)

Check the spoke tension of the drive wheel and, if required,

correct the tension / re-centring

Functional and safety check of the drive wheel and, where

necessary, replacement of the tyre on the product

Functional and safety check of all lights (if fitted), steering

and adaptation on the product and the adapted

wheelchair / wheelchairs

Test drive / functional test

resolved = the fault was corrected

Comments:

Stamp:

Date / Signature

Page 32

Operating instructions SPIKE adaptive bike

31

Subsequent inspection: After a further 1000 km or 1 year after the last inspection or after heavy

use

Kilometre reading:___________________

OK /

carried out

not OK resolved

Check all screws / fastening elements are firmly seated

Clean and oil / grease all pivot points and bearings

Visual inspection of the frame and attachments for crack

formation, deformation, etc.

Functional and safety check of the brakes and, where

necessary, replacement of the brake fluid, brake pads,

brake cables

Check, adjusting, cleaning and oiling the gear components

including pedal bearing gearshift (if fitted)

Check the spoke tension of the drive wheel and, if required,

correct the tension / re-centring

Functional and safety check of the drive wheel and, where

necessary, replacement of the tyre on the product

Functional and safety check of all lights (if fitted), steering

and adaptation on the product and the adapted

wheelchair / wheelchairs

Test drive / functional test

resolved = the fault was corrected

Comments:

Stamp:

Date / Signature

Page 33

Operating instructions SPIKE adaptive bike

32

Subsequent inspection: After a further 1000 km or 1 year after the last inspection or after heavy

use

Kilometre reading:___________________

OK /

carried out

not OK resolved

Check all screws / fastening elements are firmly seated

Clean and oil / grease all pivot points and bearings

Visual inspection of the frame and attachments for crack

formation, deformation, etc.

Functional and safety check of the brakes and, where

necessary, replacement of the brake fluid, brake pads,

brake cables

Check, adjusting, cleaning and oiling the gear components

including pedal bearing gearshift (if fitted)

Check the spoke tension of the drive wheel and, if required,

correct the tension / re-centring

Functional and safety check of the drive wheel and, where

necessary, replacement of the tyre on the product

Functional and safety check of all lights (if fitted), steering

and adaptation on the product and the adapted

wheelchair / wheelchairs

Test drive / functional test

resolved = the fault was corrected

Comments:

Stamp:

Date / Signature

Page 34

Operating instructions SPIKE adaptive bike

33

Subsequent inspection: After a further 1000 km or 1 year after the last inspection or after heavy

use

Kilometre reading:___________________

OK /

carried out

not OK resolved

Check all screws / fastening elements are firmly seated

Clean and oil / grease all pivot points and bearings

Visual inspection of the frame and attachments for crack

formation, deformation, etc.

Functional and safety check of the brakes and, where

necessary, replacement of the brake fluid, brake pads,

brake cables

Check, adjusting, cleaning and oiling the gear components

including pedal bearing gearshift (if fitted)

Check the spoke tension of the drive wheel and, if required,

correct the tension / re-centring

Functional and safety check of the drive wheel and, where

necessary, replacement of the tyre on the product

Functional and safety check of all lights (if fitted), steering

and adaptation on the product and the adapted

wheelchair / wheelchairs

Test drive / functional test

resolved = the fault was corrected

Comments:

Stamp:

Date / Signature

Page 35

Operating instructions SPIKE adaptive bike

34

Subsequent inspection: After a further 1000 km or 1 year after the last inspection or after heavy

use

Kilometre reading:___________________

OK /

carried out

not OK resolved

Check all screws / fastening elements are firmly seated

Clean and oil / grease all pivot points and bearings

Visual inspection of the frame and attachments for crack

formation, deformation, etc.

Functional and safety check of the brakes and, where

necessary, replacement of the brake fluid, brake pads,

brake cables

Check, adjusting, cleaning and oiling the gear components

including pedal bearing gearshift (if fitted)

Check the spoke tension of the drive wheel and, if required,

correct the tension / re-centring

Functional and safety check of the drive wheel and, where

necessary, replacement of the tyre on the product

Functional and safety check of all lights (if fitted), steering

and adaptation on the product and the adapted

wheelchair / wheelchairs

Test drive / functional test

resolved = the fault was corrected

Comments:

Stamp:

Date / Signature

Page 36

Operating instructions SPIKE adaptive bike

35

Your dealer:

PRO ACTIV Reha-Technik GmbH

Im Hofstätt 11

72359 Dotternhausen – Germany

Tel. +49 7427 9480-0

Fax +49 7427 9480-7025

E-Mail: info@proactiv-gmbh.de

www.proactiv-gmbh.com

No. 000 000 1518

© 11/2014 PRO ACTIV Reha-Technik GmbH. All rights reserved.

in accordance with Directive 93/42/EEC for medical products

Loading...

Loading...