PRM NEWAGE 415 Series, 416-9820, 416-2000, 416-2010, 415-2180 Workshop Manual

...

415B12L062

WORKSHOP

MANUAL

PRM NEWAGE LIMITED

BARLOW ROAD

COVENTRY

CV2 2LD

ENGLAND

TELEPHONE: +44 (0)24 7661 7141

FAX: +44 (0)24 7661 1845

EMAIL: mail@prm-newage.com

WEBSITE: www.prm-newage.com

415B12L062 Manual

Issue: 1.2

Created By: S HYLANDS

Updated: February 2019

This manual contains proprietary information of PRM Newage Limited. It is intended solely for the information

and use of parties operating and maintaining the equipment described herein. Such proprietary information

may not be used, reproduced, or disclosed to any other parties for any other purpose without the express

written permission of PRM Newage Limited.

PRM Newage Ltd operates a policy of product improvement and therefore reserves the right to change

specifications without prior notification. Whilst every effort is made to ensure complete accuracy of the

information in this manual no liabilities for inaccuracies or the consequences thereof can be accepted by the

manufacturer or the distributor who supplied the manual.

The following international symbols are used in this service manual:

WARNING! THIS SYMBOL WARNS OF POSSIBLE PERSONAL INJURY

CAUTION! THIS SYMBOL WARNS OF POSSIBLE DAMAGE TO TRANSMISSION

2

CONTENT

INTRODUCTION ....................................................................................................................................................... 5

GENERAL DATA ........................................................................................................................................................ 5

Description ........................................................................................................................................................... 5

Specification ........................................................................................................................................................ 5

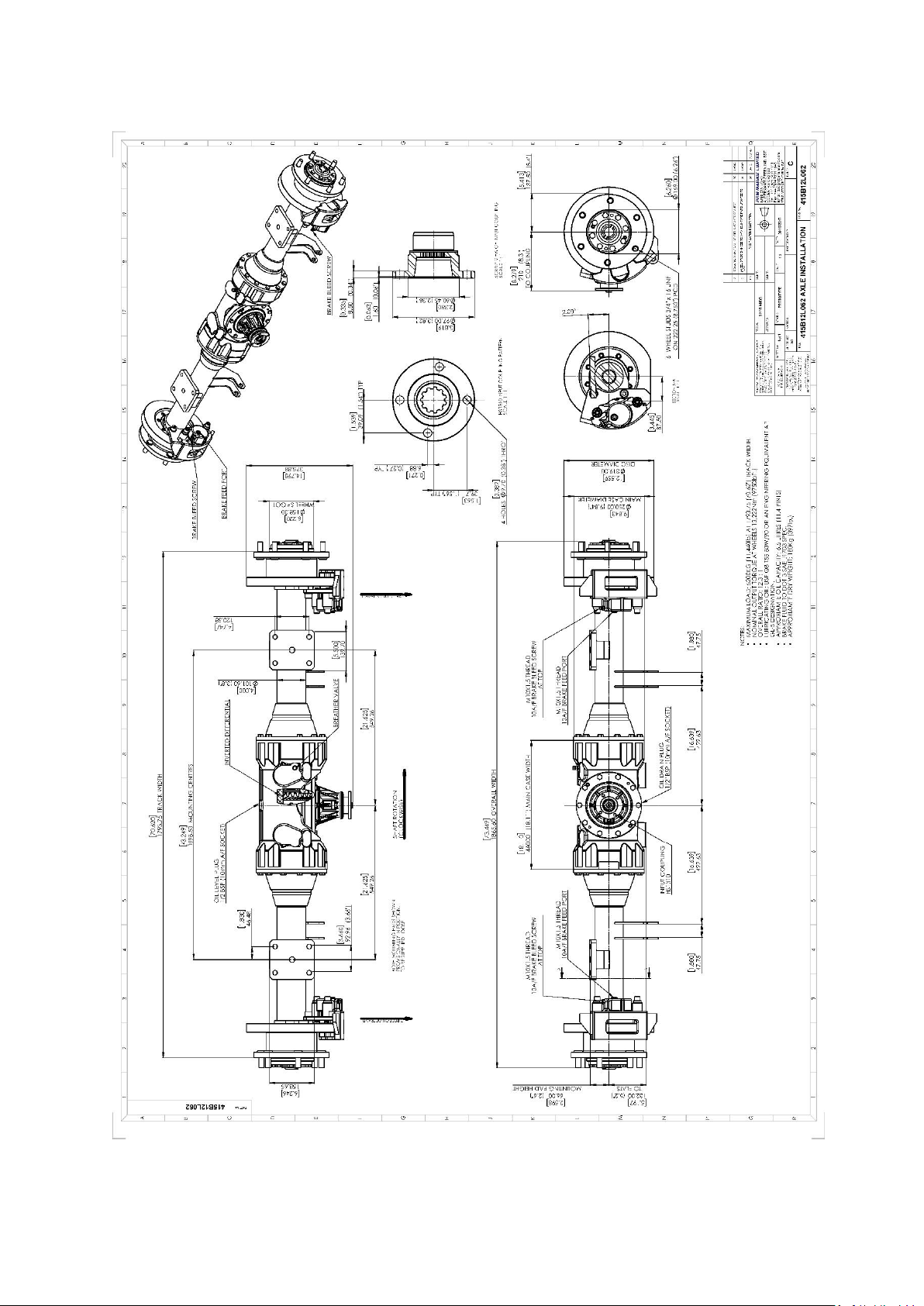

Installation Drawing ............................................................................................................................................. 6

IDENTIFICATION ....................................................................................................................................................... 7

GENERAL SERVICE INFORMATION ........................................................................................................................... 8

Routine Maintenance .......................................................................................................................................... 8

Lubricants ............................................................................................................................................................ 8

Greases ................................................................................................................................................................ 8

Brake Fluid ........................................................................................................................................................... 8

Liquid Sealant ...................................................................................................................................................... 8

Fastener Tightening Torques ............................................................................................................................... 9

Axle Backlash ....................................................................................................................................................... 9

Tooling ................................................................................................................................................................. 9

SERVICING AND REPAIRS ....................................................................................................................................... 10

Seals ................................................................................................................................................................... 10

Bearings ............................................................................................................................................................. 10

Cleaning ............................................................................................................................................................. 10

INSPECTION ........................................................................................................................................................... 11

Main Case and Arms .......................................................................................................................................... 11

Gears .................................................................................................................................................................. 11

Bearings ............................................................................................................................................................. 11

Threaded Parts .................................................................................................................................................. 11

PROCEDURES ......................................................................................................................................................... 11

Section ‘A’ – 415B12L062 Axle Assembly .......................................................................................................... 12

REMOVING & SERVICING THE CROWN WHEEL AND PINION. ........................................................................... 15

Section ‘B’ – Main Case and Differential Assembly ........................................................................................... 17

Servicing the Main Case and Differential Assemblies ...................................................................................... 19

Removing the Differential ................................................................................................................................ 19

Servicing the Differential Assembly ................................................................................................................. 19

Section ‘C’ – Planet Carrier Assembly ................................................................................................................ 20

Servicing the Planet Carrier Assemblies ........................................................................................................... 21

Removing the Annulus Gear ............................................................................................................................ 22

Section ‘D’ – Axle Arm, Hub and Brake Assemblies ........................................................................................... 22

Servicing the Axle Arm, Hub and Brake Assemblies ......................................................................................... 24

Servicing the Brake Assemblies ........................................................................................................................ 24

SPARES KITS ........................................................................................................................................................... 25

3

SPIRAL BEVEL GEAR TOOTH CONTACT .................................................................................................................. 27

Correct Pattern .................................................................................................................................................. 27

Incorrect Pattern ............................................................................................................................................... 27

NOTES ................................................................................................................................................................ 29

4

INTRODUCTION

Spare parts for Newage axles may only be obtained from the original equipment manufacturer and

not directly from Newage. Always quote your vehicle/machine serial number and axle serial number

– see section titled 'Identification'.

If possible, the repair/service should be carried out in a clean environment. Where this is not possible, and the work must be completed on site, appropriate measures must be taken to ensure that

dirt or foreign matter does not enter the unit. Newage axles are designed to operate in the arduous

conditions found in the construction industry; providing they are maintained regularly they will provide the service our customers expect from Newage products.

GENERAL DATA

Description

The 415 series axle is a double reduction unit featuring a Hydraulic Disc Braking system.

The 1st reduction Spiral Bevel Pinion and Crown Wheel driving a 4 Pinion Differential. Final drive is

transmitted via the 2nd reduction in-board Planetary Assemblies. The Axle Shafts are fully floating

(i.e. not subjected to wheel loads) with each Wheel Hub supported on opposed taper Roller Bearings.

Specification

Overall Ratio

12.33:1

Input Flange

To suit Hardy Spicer 1310 Coupling

Wheel Fixing

6 studs: 3/4” x 16 UNF-3A on 222.25 mm (8.75”) PCD

Dynamic Axle Load Rating

Maximum load rating 5200 Kg (11440 lbs) based on 1793.75 mm (70.62”) wheel track

Service Brake

See Torque/Pressure Graph

Park Brake

Not Applicable.

Approximate weight

180 kg (397 lb) dry

Oil Capacity

6.5 litres (11.4 Pints)

5

Installation Drawing

6

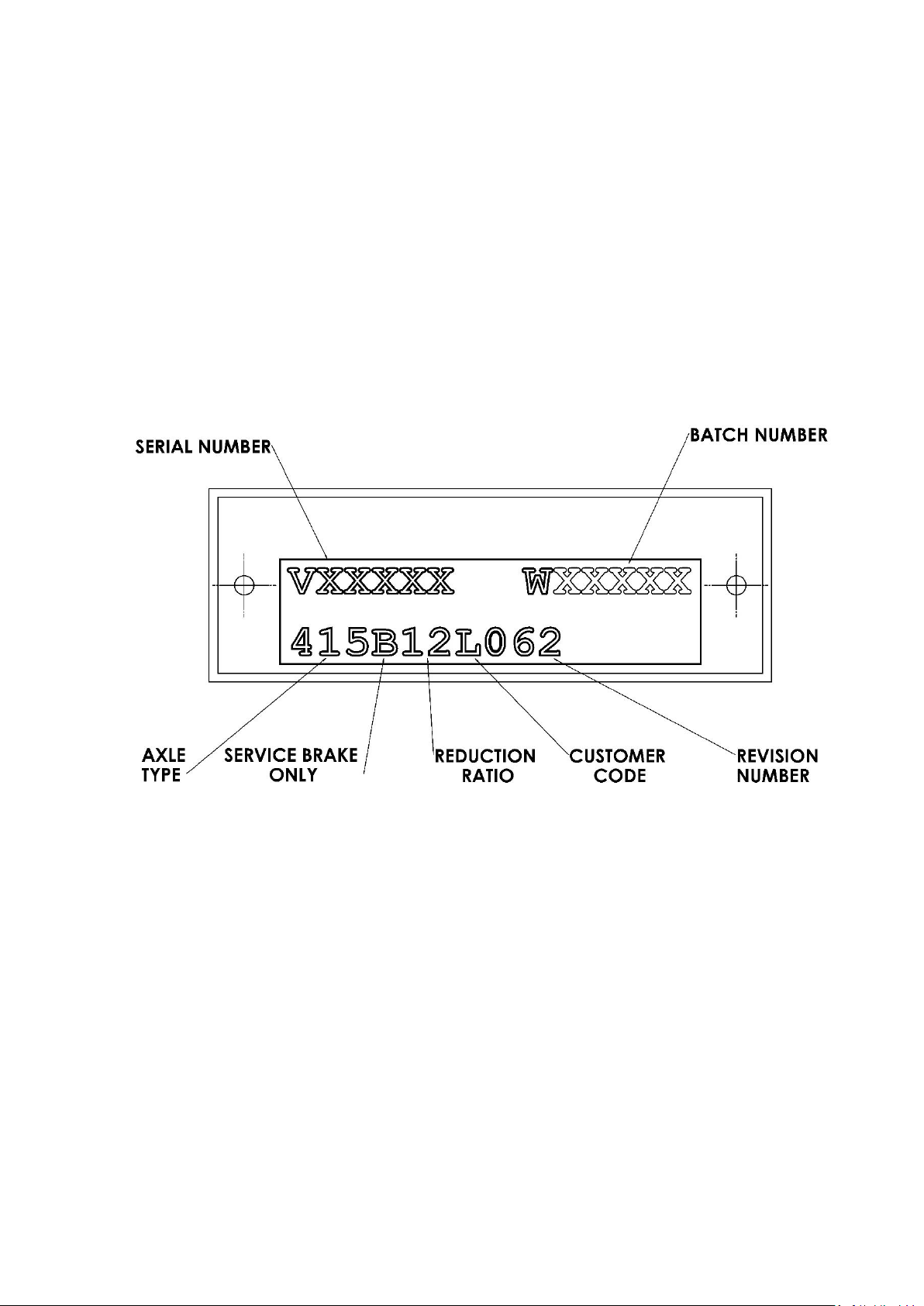

IDENTIFICATION

If spares are required, please quote the axle model, the vehicle/machine model and serial number

from the blue plate. 415 Axles are produced in a variety of configurations for individual customer

requirements; therefore, it is important to identify the Axle correctly.

The part number allocated to each Axle describes the basic specification as below:

7

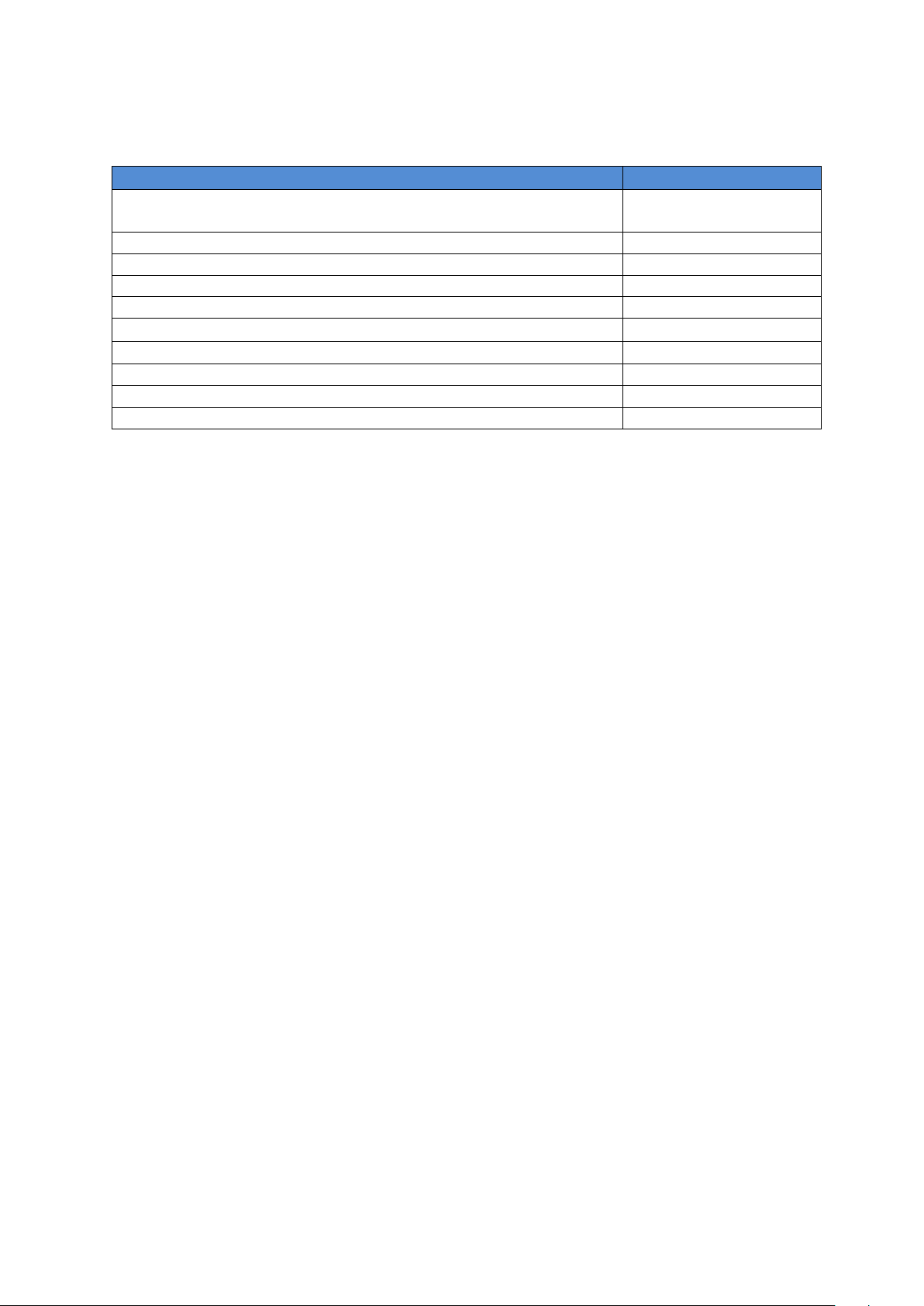

GENERAL SERVICE INFORMATION

Check

Frequency

Axle Oil change

After initial 300 Hrs

then every 1,000 Hrs

Axle Oil Level check

Monthly

Axle Shaft Bolts

Monthly

Brake Fluid change

Annually

Brake Fluid Level check

Monthly

Check Axle Arm/Main Case joint securing Bolts

Monthly

Check Wheel Hub Bearing adjustment

1,000 Hrs

Check Wheel Nut

Weekly

Visual check for oil leaks around joints and Seals

Weekly

Prop Shaft Bolts

Monthly

Routine Maintenance

Lubricants

Only those lubricants shown below, or their direct equivalents must be used:

SAE 80W-90 Gear oil for operation in ambient temperatures

between 0°C and 30°C (32°F -86°F)

NOTE: An alternative engineering approved Gear oil may be used. Consult ‘PRM Newage’ before

filling the axle.

The oil is added via the combined Filler/Level Plug positioned on the rear of the axle Main Case.

When installing new Unitized Hub Seals, ensure the outer surface of the seal and the inner diameter

bore of the Hub is free from grease. Use Loctite SF7063 Solvent Cleaner to degrease both before

fitment of the seal.

Greases

Smear grease between Oil Seal lips and ‘O’ Rings at major overhauls (with exception to the Wheel

Hub seals), or whenever a repair to these areas is performed.

Only those greases shown below, their direct equivalents or alternative engineering approved grease

must be used: Texaco Multifak EP2

Brake Fluid

The Axle Brakes operate with the fluid specification: FMVSS 116 DOT 4, SAEJ1703 and ISO4925 Brake

Fluid

NOTE: An ISO VG32 Mineral Hydraulic Fluid Should NOT be used under any circumstance.

Liquid Sealant

The Main Case/Axle Arm joint faces must be sealed with either of the following:

• Threebond 1207D Silicone Liquid Gasket

NOTE: An alternative engineering approved silicon sealant may be used.

For locking features, the following compound must be used:

• Loctite 243

NOTE: An alternative engineering approved locking compound may be used.

8

Fastener Tightening Torques

Fastener

A/F

(mm)

Torque (Nm.)

Torque (lb.

Ft)

Across

Flats

Newton Me-

tres

Pounds

Force Feet

Main Case Assembly

Axle Arm/Main Case High Tensile Bolts (M12)

19

146

107

Axle Shaft/Wheel Hub High Tensile Bolts (M12)

19

146

107

Brake Calliper mounting Grade S Cap Bolt (M16)

14

230

170

Calliper Carrier Cap Bolts (M16)

14

257

190

Differential assembly Nut (M10)

17

77

57

Pinion Housing Bolt (M10)

17

84

62

Drain and Level Plug (1/2” BSP)

10

16

12

Hub Assembly Lock Nut (M65) – (Special Tool

required TMFS13)

---

135

100

Input Drive Flange Drag Torque after collapsing

Spacer

30

1.92/2.48

17/22 lbin

Assembly

Pinion/Wheel

Drive Flange

P.C.D

Backlash

416-9820

416-2000

416-2010

415-9810 (415-

2180 & 250-

0910)

(HS 1310)

79.40mm

(3.125”)

0.22-

0.30mm

(0.009-

0.012”)

Axle Backlash

Tooling

The following tooling is used to aid in the servicing of the axle. These are available from the Original

Equipment Manufacturer.

TMFS13 Socket Spanner for Wheel Hub Bearing Lock Nut 010N651. The TMFS13 tool is available

from SKF stockists (M65 Stub Axle Locknut socket 19mm (3/4”) drive)

9

Loading...

Loading...