Page 1

RESIDENTIAL BOILERS FOR SOLID FUEL

TECHNICAL DATA

The boilers are intended to be installed in ground premises with a possibility of easy

refueling with coal.

They are intended for heating in systems with local heat-supply, as well as for warming up

of household drinking water.

Model Maximum heat

power, kW

MA18 19 1,5 22 35

GA 26 28 1,5 25 62

GA33 36 1,5 30 70

LB 44 2,5 30 84

SLB 36 2,5 30 64

Max. pressure of

the water, bar

Minimum draught,

Pa

Volume of the

water jacket, l

The boilers consist of the following elements:

The main part the boiler is the heat exchanger. The heat exchanger represents a welded construction of

steel sheet material. In its lower part a combustion chamber is formed.

The ash-pan is set under the combustion chamber. The ash residue is gathered and allows simplified

operation when cleaning of the equipment.

The input orifice (nozzle) is located above and the output orifice (nozzles) - in the in the back part of

the boiler and represent two terminals with external thread G 1 "(G 1

which the boiler is connected to the heating system.

The chimney stack is located at the top of the boiler and used lead away the flue gases through a

chimney.

The steel heat exchanger is insulated with mineral insulation, which limits the heat loss to the

environment.

The external decorative side panels are made of steel sheet and are coloured powder coated.

The boilers PRITY LB PRITY SLB and have the possibility to work with wood pellets after

installation of the respective pellet burner on the door of the combustion chamber.

1/4

" for LB and SLB), through

Page 2

In this case they have the following characteristics:

PRITY LB PRITY SLB

Necessary draught of the chimney, Pa 30 30

Water content, l 84 64

Temperature of the flue gases at nominal heat power, °C 309 300

Diameter of the chimney stack, mm 150 150

Nominal heat power, kW 40 33

Minimum heat power, kW 15 15

Efficiency, % 80 82

Average emission of CO, % 0,32 0,32

Average dust emission, mg/m3 58 56

Class boiler 1 1

Set range of temperature controller, °C 30÷80 30÷80

Type of the fuel – wooden pellets with humidity till 10% Wooden pellets with

humidity till 10%

Wooden pellets with

humidity till 10%

INSTALLATION INSTRUCTIONS

The boiler is placed on a stable fireproof horizontal floor. To protect the floor, a stable fireproof

base can be used, which shall stick out before the boiler at least 50 cm in front and 30 cm at the side.

In the radiating area of the boiler, at a distance of 80 cm around it no objects burnable and

damageable by the radiated heat shall be there.

Before connecting the boiler to the chimney, consult a specialist.

The connecting elements (rosette and chimney) must be fixed tightly and firmly, so that they may

not get into in the passage section of the chimney. The smoking pipes shall have the same size as the

connecting pipe of the boiler.

It is advisable that the boiler work with a separate chimney. If other heating appliances are

connected to the same chimney, it must be calculated for that.

3

Fresh air must get in the boiler at least 4 m

/h for each kilowatt from its heat output. When

necessary a flow from adjacent premises or outside air is ensured.

The burning process of the boiler must not feel shortage of air on the action of gravitational or

forced aspirations, since this is a prerequisite for insufficient combustion or returning of flue gases in

the premises.

It follows a connection of the water-hating pellet boiler to the heating installation through

suitable fittings and fixture according to the prepared beforehand thermo-technical project.

The requirements for installation of the pellet burner and the feeder screw

(auger) for fueling from a tank to the burner are given in its manual for

installation and operation.

Page 3

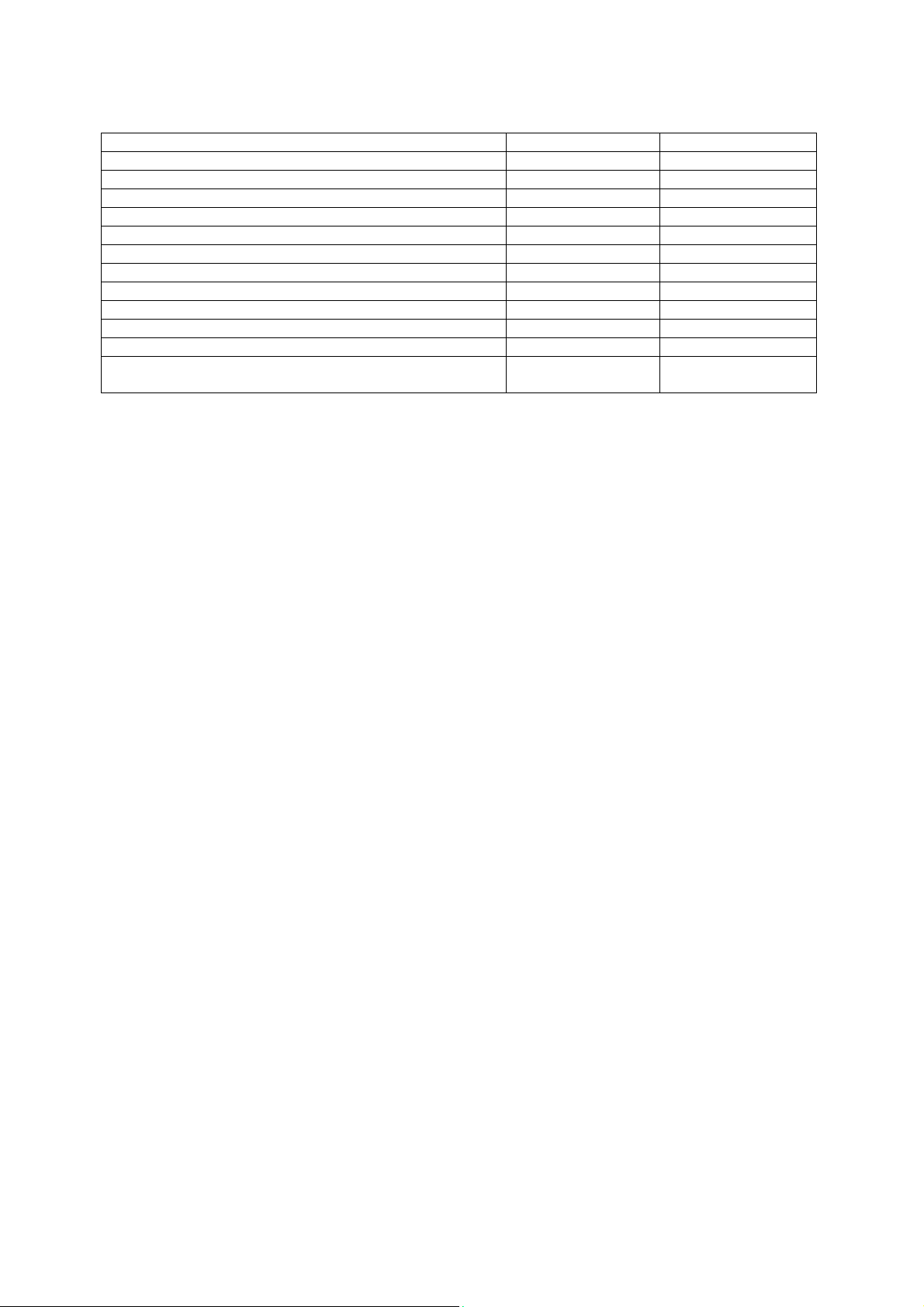

EXEMPLARY DIAGRAMS OF

OPERATION OF A BOILER IN

AN OPEN SYSTEM

Open water heating system with an open

expansion vessel and a pump

Economical open gravitational self-adjusting

water heating system with an open expansion

vessel without a pump.

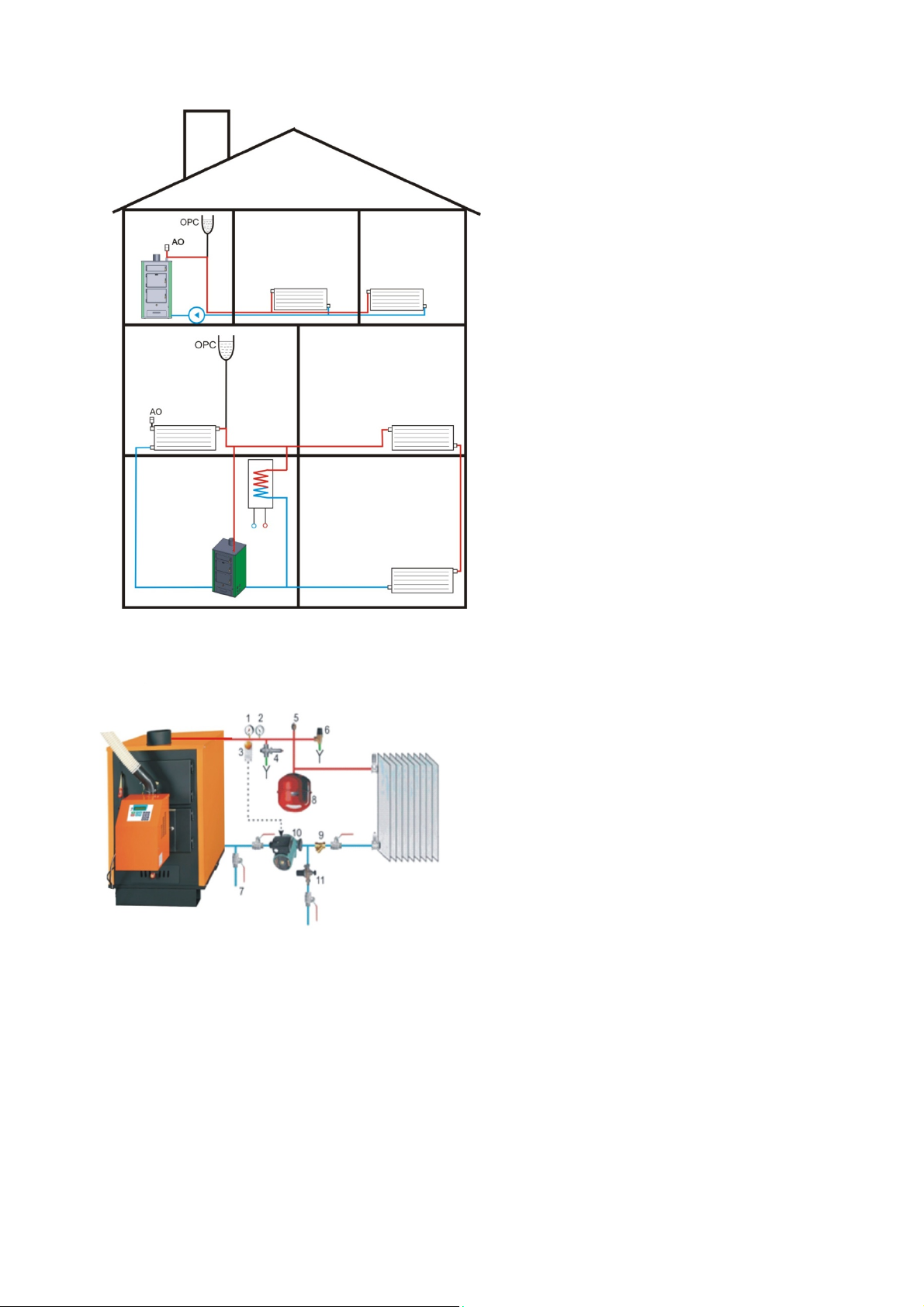

EXEMPLARY DIAGRAM OF OPERATION

OF A BOILER

IN A CLOSED SYSTEM

1. Manometer

2. Thermometer 120º С.

3. Electrical thermostat.

4. Thermal safety valve.

5. Automatic deaerator.

6. Safety hydraulic valve

7. Drainage.

8. Closed expansion vessel.

9. Filter.

10. Circulation pump.

11. Automatic supplementing group

GENERAL RULES AND RECOMMENDATIONS

1. Before the building of the installation, it is recommended that the heat losses be calculated by a

specialist for the concrete case.

2. With an open system the installation must be connected to the atmosphere with an open expansion

vessel. Between the boiler and the expansion vessel no stop elements must be fixed.

3. De-aeration of each branch and element of the installation in each moment of its operation shall be

ensured.

Page 4

4. All the elements of the installation must be ensured against freezing, especially if the expansion

vessel or other parts of it have been located in non-heated premises.

5. In the installations with forced circulation the pump must be provided with UPS – an accumulator

with a transducer 12 V/220/V50 Hz on autonomous regime.

It is recommended that the circulation pump be switched on and off by a thermostat, duplicated with a

manual electrical switch.

6. The first service cleaning of the pump filter must be done immediately after testing the installation.

7. If an old installation is used, then it must be repeatedly sluiced to remove the accumulated residue,

which would precipitate on the surfaces of the water jacket.

8. Coal with increased sulphur content shall not be used and don’t allow the coal get wet.

9. Fresh and wet wood or vegetation shall not be used. The logs shall be stored at least two years in a

dry and airy place.

10. The circulating water shall not be drained out during the non-heating season.

During the 3-4 kindlings it is possible to form condensation on the surfaces of the water jacket. The

forming soot decreases the sudden temperature difference and the quantity of the condensate.

OPERATION INSTRUCTIONS

The boiler is operated only by adult persons, who are acquainted beforehand with the operation

instructions. It is not allowed the presence of children without supervision in proximity of the boiler,

especially when it is on an operating mode.

Fuel

As a fuel only natural wood chemically untreated, as well as black stone coal must be used. For the

pellet burners use only wood pellet type C according to item 1 of EN 303-5 with humidity

below 10%.

It is important that the wood be dry.

Dry are called those logs which have humidity under 20 %. This is achieved when they stay in a dry

and airy place at least for 2 years. The logs are kept chopped and arranged, as their thickness must be

between 5 and 15 cm.

Why humid wood shall not be used?

1. The humidity in the wood decreases their warmth of burning. A big part of the heat is spent

on evaporation of the water, and the rest can turn out insufficient to ensure the necessary

heating. For example, 20 kg humid wood can mean 10 kg dry wood and 10 litres water,

added to the fire.

2. The water vapour decreases the combustion temperature and contributes to the formation of

soot which accumulates and forms a black hard layer on the walls of the combustion

chamber, the glass ceramics, the pipes and the chimney.

3. The pollution of the environment increases because the gases leave the chimney unburned.

Kindling of the boiler when operating with wood and coal

- The kindling of the boiler is done with entirely open valve of the flue gases.

- It is forbidden burning fluids to be used for kindling

- Put kindlings and logs on the grate throughout the whole depth of the boiler through the door for

refueling, so that they kindle.

- Put a thin layer of coal on the burning logs.

Page 5

- After its kindling, the firebox is refueled with more fuel. After achieving the necessary power, it

is good the valve of the flue gases to be closed, so that the eventual loss of heat through the chimney is

avoided.

- The boiler is refueled according to the needs of heat and the intensity of burning, always when a

necessary amount of embers is available.

Adjusting elements

The valve for the flue gases on the chimney adjusts the quantity of the flue gases getting out from

the boiler to the chimney. It is adjusted by the handle, located on the upper part of the boiler on the

connecting pipe of the chimney pipes. When operation with pellets the valve must be entirely open.

The adjusting of the primary air is done by a thermostat depending on the temperature of the water

in the boiler. The adjusting process is carried out by the adjusting button with a marked scale 0-9. The

markings on the button are only informative. The adjusting is done in the following way. The boiler is

warmed up till the desired temperature. By means of the button the valve for the primary air of the

thermostat is closed. On falling in temperature the valve of the primary air begins to open by itself.

When operating with pellets, the valves for primary air are entirely closed.

Condensation and tarring

On initial introducing of the cold boiler in operation, water condenses on its walls, which trickles

in the firebox and creates impression that the boiler is leaking. The condensation disappears after

sticking ash inside of the boiler. On operation with decreased power, at a low temperature of the water

in the boiler, usually under 60°C and on using humid fuel water condenses from the flue gases, which

starts running on the cooled walls of the boiler. The low temperature operation affects adversely also

on the life of the water heat exchanger and the flue (smoke) pipes.

Chimney

The chimney is intended to draw the combustion products out of the fireplace and to throw them

away in the atmosphere outside the limits of the abode.

The upward draught or the “pulling” of the chimney is a result of the combination between its

height and the difference in the temperatures of the flue gases and the air outside. The column of hot

flue gases in the chimney has smaller weight than the equivalent column cold air outside, so that the

pressure in the lower end in the warm chimney is smaller than the atmospheric (air) pressure outside.

This quite small difference in the pressures creates the draught.

The lower draught is a prerequisite for difficult kindling or returning of flue gases, and it is

overcome through quick kindling and burning of dry, thin and fast-burning sticks and twigs. After

kindling of the fire and warming up of the chimney, its draught increases. For economical regime and

Page 6

high efficiency after the warming up of the chimney, the draught must be decreased to 5-10 Pa, so that

there may be no return of the flue gases (smoking) with a closed door.

The main causes of insufficient draught are the following:

- layering of soot inside the chimney, which decreases its diameter and increases the

resistance of the rising flue gases;

- a cracked wall of the chimney or a loose rosette, from where air is sucked from the

premisses instead from the combustion chamber;

- pipes pushed deeply in the chimney, as in this way they decrease the diameter or plug up the

chimney;

- The use of a single chimney with a small draught by several stoves on the same level of in

close proximity;

- Smoking also appears when the weather outside has suddenly got warmer - The warm gases

from the kindling of the fire can’t escape through the cold chimney. In this case a bigger

amount of quickly burning sticks and paper is used. The same effect takes place while

attempting to kindle a fire on the first (ground) floor, provided the same or an adjacent

chimney is already being used by a fireplace on the top floor;

- when the ceiling is not air-tight or there are open windows on an upper floor, the effect

“staircase-chimney” takes place, creating a reverse draught;

- When a chimney is located in an area of overpressure caused by a wind.

On correct connection, servicing and maintenance the boiler must not give off smoking emissions

in the premises. If nevertheless this occurs, the premises are aired and the cause of the filling with

smoke must be found out and removed.

Don’t burn: garbage, stuck or painted softwood, plywood or boards of wooden parts, wooden

sleepers or other refuse containing artificial chemical admixtures, since poisons don’t burn, but

only change their composition and when they are thrown away in the atmosphere, they lead to

unpredictable consequences.

Cleaning.

Cooling of the boiler occurs slowly, at the expense of naturally getting cold.

The cleaning of the ash residue must be done with personal protective equipment – gloves and

suitable (appropriate) clothes.

To remove the solid waste after burning, a movable grate and an ash-pan is used. The ash-pan

must be emptied even before it is filled with a purpose to avoid plugging up of the supplying feeding

of the air under the grate. The ash is kept in nonburnable vessels with a cover.

When operation with the pellets is recommended at least once in every two days the customer to

turn off temporarily the burner, to wait until the boiler has cooled to safe levels of temperature, to

clean the internal heat exchanging surfaces of the accumulated ash, to clean the burner, to carry out the

ashes, after which in reverse order to close the doors of the boiler and to turn the burner on.

After continuous operation ash and soot are accumulated on the walls of the boiler, especially on

the heat exchanger and on the smoke pipes, whereupon the heat transfer is decreased and the boiler

loses power. As a whole the quantity of the ash and the soot depends on the quality of the used fuel

and the working conditions. If the boiler has insufficient power or it is operated at a low temperature,

the amount of the soot in the process of burning increases considerably. In the same way the shortage

of the draught in the chimney influences, as well. The surface of the water heat exchanger is cleaned

by means of a steel brush.

A main rule in the operation: It is better a shorter burning at full power than continuous

burning at low power.

Page 7

The characteristics of the operation of the pellet burner and the auger for fueling from the tank

to the burner are given in its manual for installation and operation.

After termination of the heating season, the boiler and the chimney are cleaned thoroughly. The

steam-boiler room shall also be cleaned and be dry.

Do dot perform any unauthorized modifications in the design!

During repairs only original spare parts by the producers shall be used.

The guarantee is not valid for fireplaces with bulging water jackets, which are a result of the

increased pressure in the system beyond the admissible one on incorrect installation.

It is recommended that the installation be done by a skilled specialist

Last update 10.05.2012

Loading...

Loading...