Page 1

Masking System

Cinomask F-100

A Picture to

Remember

Assembly Instructions

INSTALLATION INSTRUCTIONS

Carefully remove and unwrap all t he contents of box. Referring to the parts list, make

sure you have everything needed to proceed with the installation of the masking

system. If any parts are missing, contac t Prismasonic immediately.

Inspect the parts to make sure there are no shipping defects. If you notice a problem

with the item itself, or the screen’s mechanical system, contact Prismasonic

immediately.

Part List:

Wooden Assemblies

Framewo rk Bar (6 pcs)

Aluminum Brackets

Extension Bracket (2 pcs)

Frame Holder M (18 pcs)

Wall M ount (2 pcs)

Wall M ount Side (4 pcs)

Wall Socket, 16 mm (8 pcs)

Hardware

Cap Screw, M4 x 35 (8 pcs)

Cap Screw, M5 x 16 (8 pcs)

Cap Screw, M5 x 30 (10 pcs)

Cap Screw, M6 x 12 (8 pcs)

Cap Screw, M6 x 16 (4 pcs)

Cap Screw cle ar, M6 x 20 (18 pcs)

Cap Screw, M8 x 16 (4 pcs)

Set Screw, M8 x 6 (4 pcs)

Tor x S cre w, black (12 pcs)

Tor x S cre w, clear (4 pcs)

Tools & Misc.

L-wrench, 3 mm (Do not exist if ordered with a scre en)

L-wrench, 4 mm (Do not exist if ordered with a scre en)

L-wrench, 5 mm

Torx Driver (Do not exist if ordered with a sc reen)

Screw Driver

Velvet Stickers (4 pcs)

Electrical Parts

Power Cor d

Power Con verter

Remote Controller

----------------------------------------------------

Page 2

Masking System

Cinomask F-100

Assembly Instructions

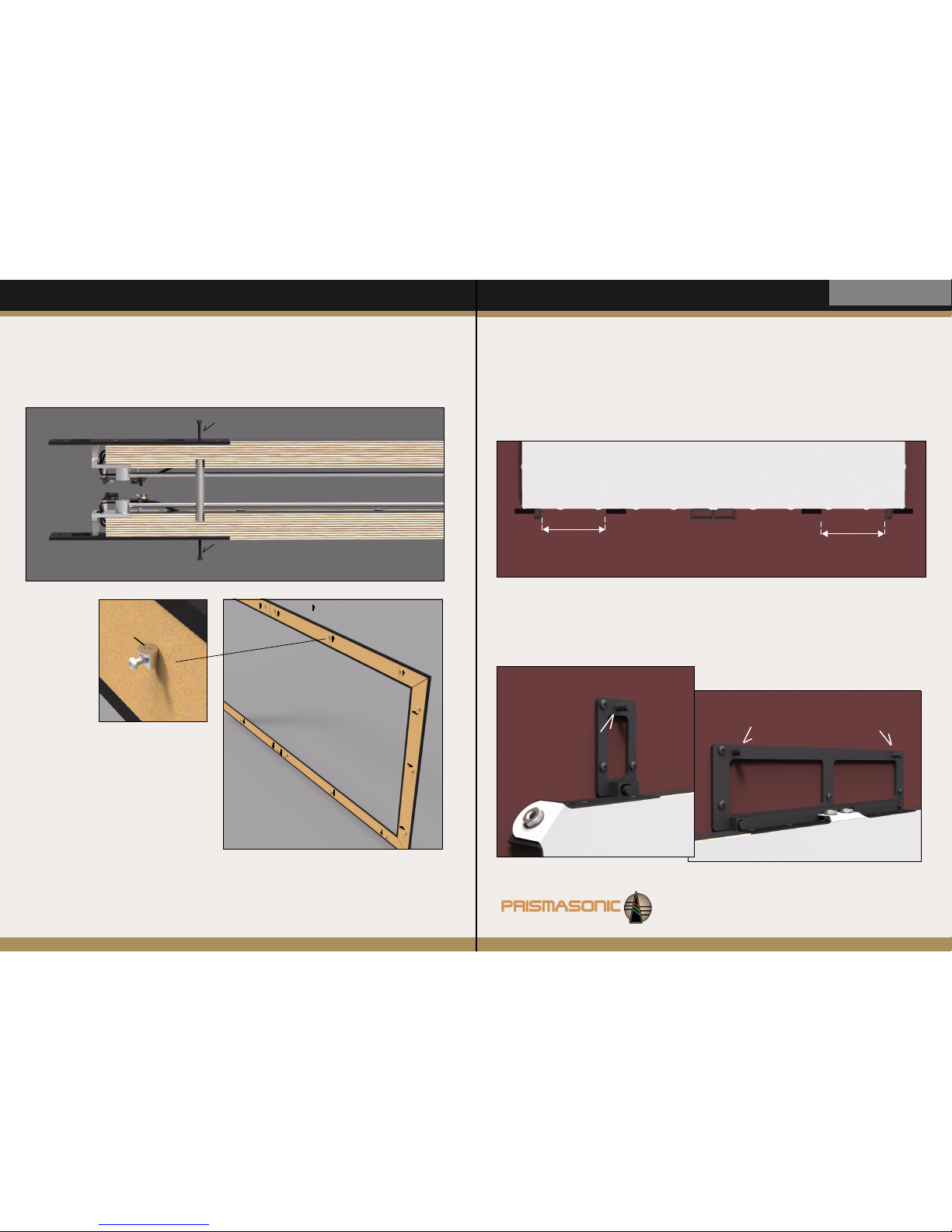

STEP 3

First attach the four velvet stickers exactly as presented in Fig 3. All four

stickers are in line right below the bottom horizontal screen framework bar.

The stickers at corners are also in contact with the side wall plates, while the

center ones are separated from the plates with a distance as informed in a

picture. The stickers are for preventing the parasitic reflections of optoelectrical transmitters of mask travel detection from wall to system, thus

making the performance 100% reliable with all wall materials.

635 mm : 156”

526 mm : 136”

421 mm : 116”

635 mm : 156”

526 mm : 136”

421 mm : 116”

Fig 3

STEP 4

Now attach the total eight wall Socke ts to remaining screw holes of every four Wall Plate S (Fig 4a) and both

two Wall Plate (Fig 4b). Tighten the sockets securely and make sure the heels of sockets come in contact with

the plates.

Fig 4b

Fig 4a

Assembly Instructions:

STEP 2

If you are upgrading the Cinoscreen F-100 / FAT100, remove the Velve t Fram es from the

Cinoscreen while it is hanging on the wall. Also

remove all the existing Frame H olders from the

back side of frames and replace them with Frame

Holder M parts. By using Cap Screws, clear m6 x

20, prepare to attach the new holders to frames

exactly as shown in Fig 2. Tighten the screws

securely using L-wrench, 4 mm.

In the horizontal frames the screw holes of new

frame holders are pointing from center to side,

whilst in the vertical frames only the holder in the

middle is pointing from center to side, and the two

others in side are pointing from side to center.

STEP 1

First unpack the items from shipping tubes and boxes. As shown with an arrows in Fig 1,

remove the two delivery bars from each horizontal and vertical Framework Bars, which

connect the two bars to each other. Use L-Wrench, 3 mm for the screws to release the

bars.

screw hole

Fig 2

= Direction to where the screw hole

of part is pointing

Fig 1

Page 3

STEP 6

Now attach the top-right Framework Bar (Fig 6). First string the Wall Mount Side to Wall socket after which

connect the other end to extension Bracket by three To rx Sc rew s, 5 x 35. Tighten the screws securely using

Tor x D riv er

. Also now screw the Set Screw, m6 x 8 to the screw hole at location Fi g 5e to an extent which

prevents the bar falling from the Wall Socket.

Finally do the same procedure as mirror image for the bottom horizontal framework bars, which are much

similar to the upper bars except for the electrical control boards and wiring they include.

Fig 6

Fig 5

c)

STEP 5

Starting from the horizontal Framework Bar at top-left, f irst attach the Wall Mo unt to Extension Bracket by

using two Cap Screws, m6 x 16 (Fig 5a). Next using three Tor x S cre w, black connect the Extension Bracket to

the slot of framework bar (Fig 5b). After this, by using Tor x sc re w, clear attach Wall Mount Side to the pre

assembled corner bracket as shown in Fig 5 c. Finally string the wall mounts to Wall Socke ts of Wall Plates,

exactly as shown in Fig 5. By using L-Wrench, 4 mm insert and tighten the Set Screw, m6 x 8 in the screw hole

at location d) to an extent which prevents the bar falling from the socket.

NOTE! The pre assembled bars, which are assembled in top can be identified not including the electrical control

boards on them.

d)

e)

a)

a)

b)

Assembly Instructions

Masking System

Cinomask F-100

Fig 7

STEP 7

To finalize the masking framework assembly, attach the two vertica

framework bar assemblies to the horizontal bars (Fig 7). In every

four corner use Cap Screw, m8 x 16 (marked with a) in close up),

and two Cap Screws, m5 x 16 (marked with b) in close up). Tighte

n

the screws securely using L-Wrench, 5 mm and L-Wrench, 4 mm.

Make sure that after installation the loosen wire ends of both

vertical bar assemblies are locating in bottom corners, so that

they can be further connected to the m otor control boards.

STEP 8

Attach the connector ends on left-bottom toget her as shown in Fig 8a.

Make sure the parts snap securely to each other. Now connect the

power for the first time to the socket, marked by b) in Fig 8. There is an

extra notch on a framework slot under the aluminum bracket (Fig 8c) to

offer enough space to feed the DC plug into the socket.

Fig 8

a)

b)

Bottom view

c)

Page 4

STEP 9

By pressing (and holding) the ‘CLOSE’

button of Remote Controller (pointing it to

the receiver board) (Fig 9a), and

simultaneously pulling the left mask from

the velvet bar, drive the mask fabric close

until the bar reaches the sliding brackets in

top and bottom (Fig 9). Prepare to attach

the mask bar to both upper and lower slide

brackets using Cap Screws, m6 x 12

(marked by

b in a close up). Tighten the four

screws securely with L-Wrench, 4 mm.

Now push the yellow switches of two

detector boards, which are locating on the

bottom-left framework bar marked by c) in

Fig 9, to ‘ON’ position. After this the left

side mask is not reacting to remote

controller until the velvet frames have

been installed in STEP 12 and 13.

a)

c)

Fig 9

b)

Assembly Instructions

Masking System

Cinomask F-100

STEP 11

Redo the STEP 8 and STEP 9 exactly similarly

now to the right side of screen. Again make sure

the yellow switc hes of two detector boards on

the right part of screen becomes to ‘ON’ position

after performing the steps.

STEP 10

Connect the loosen wire ends of ‘right- bottom’ framework bar to the receiver board (Fig 10 and Fig 9a).

Make sure the connectors snap securely to each other.

Fig 10

STEP 12

Starting from left vertical Ve lvet Fra me, attach the frame to the vertical f ramework bar only from center

holder of frame. String the Cap Screw m5 x 30 through the hole and using L-wrench 4mm tighten the

screw securely against the frame holder exactly as shown in Fig 12a (velvet frame is drawn transparent in

a close up pictures). Similarly, only from center, attach the upper left horizontal fram e to the horizontal

framework bar (Fig 12b). There are three slots in the horizontal framework bar to where the frame

holders are inserted before the screw can be tightened against the holder thread.

In corner the two Cap Screws,

m4 x 35 are used for pushing

the elastic joint of corner

seamlessly together (Fig 12c).

Before tightening, the frame

ends in corner are first

adjusted by hand to match

each other. By using the L-

wrench, 3mm, tighten the

screws to an extent that the

velvet joint becomes firmly

together.

c)

c)

b)

a)

Fig 12

Page 5

Assembly Instructions

Masking System

Cinomask F-100

Yo u a re d on e! Enjoy your new 2.40:1 setup. In the use, the aspect ratios between the

terminal stops are adjusted simply by releasing the control button to match the

aspect ratio of each media.

----------------------------------- -----------------------------------------------------------

STEP 13

Exactly similarly attach the right side velvet frames to framework. The elastic joint of left and right horizontal

frames have been designed to be tight. After matching the frame ends by hand (as instructed in a tip below), the

parallel positions with each other can be fine tuned by the two Cap Screws m5 x 30 (Fig 13a), which are pushing

the both frame ends upwards. Finally attach the lower horizontal frames to their places. Still remove the cover

sheet from the circ ular IR window of left bottom fr ame. The screen with the masking system is now ready for the

use.

TIP! A tight center joint of horizontal frames can be connected together without difficulty by pulling the both center

ends away from framework bars until they match to each other, after which they can be released to go back down

against the framework (Fig 13b). Before doing this the both frames must have been attached from center to the

framework bars (Fig 12b).

Fig 13

a)

b)

Top vie w

STEP 14

Now power the system up from either left or right side motor control board (Fig 8b and Fig 14). By pressing and

holding the ‘OPEN’ button of remote controller, drive the masks to full open (2.40:1) position. The opto electrical

sensors stop the masks automatically after they disappear under the main velvet frames. After this drive the masks

to full close (1.33:1) position, where they again auto matically stop. If the side mask travels from open to close are

not quite synchronous to each other, their speed can be further adjusted. This is done with Screw Driver by

opening (~5-10 rounds to counter clock wise) the trimmer screw of mo tor control board marked by a) in Fig 14,

but only at the side which was moving slower. The iterative tuning back and forth can be performed to find the

perfect synchrony.

Similarly the calibration can be done to the close to open movement. Now, however, the trimmer screw marked

by b) in Fig 14 is closed (~3-5 rounds to clock wise) at the side which was moving faster. And again the iterative

tuning back and forth can be operated to find the synchrony.

NOTE! The system is good to be powered down while adjusting the trimmer screws with screw driver

a)

b)

left side board

Fig 14

a)

b)

right side board

Masks have been driven to full open 2.40:1 position

Loading...

Loading...