Prior PureFocus850 User Manual

More to PRIOR than meets the eye

Version issue No. - 1.7

For more information visit www.prior.com

PureFocus850

User manual

Version issue No. - 1.7

Thank you for purchasing this product from Prior Scientic – we’re condent it will be a

reliable and useful addition to your microscopy system. Please take the time to read and

understand this manual before using this product – it contains not only important operating

instructions but also vital safety information. This product must be used only as specied in

this manual. If you wish to use it dierently, contact Prior Scientic beforehand.

Please do not hesitated to contact us with any comments or

questions regarding this product.

Visit Prior Scientic online at www.prior.com

More to PRIOR than meets the eye

For more information visit www.prior.com

1

Contents

Section 1

Safety Information 2

Section 2

Product description 3

Section 3

Unpacking the system 4

Section 4

Introduction

4.1 Working principle 6

4.2 Sample types 8

4.3 Types of microscope system 9

Section 5

Installation

5.1 Installing the head 10

5.2 Initalizing the head 11

5.3 Controller Motor Connections 14

5.4 Setting up for stepper focus control 15

5.5 Setting up for piezo focus control 15

Section 6

Operation

6.1 Controller keypad and digipot 16

6.2 Controller display 16

6.3 Inital setup and operation 17

6.4 Routine operation with the GUI 20

Section 7

ASCII command set 25

Section 8

Replacement, Repairs, Returns and Spare Parts 34

Section 9

Troubleshooting 35

Appendices

Appendix 1: PF850 FTDI USB Field Issues and Solution 36

Version issue No. - 1.7

2

Section 1

Safety information

Class 1 laser product, laser wavelength 850nm, laser output < 0.77mW

CLASSIFIED TO BS EN 60825-1:2014

It is important to follow these safety warnings to avoid potential injury or damage. Please read and

understand these warnings, operating instructions and specications before using the PureFocus850. If you

have any questions do not hesitate to contact Prior Scientic. If you intend to use this unit in a manner not

specied by Prior in this manual, contact Prior beforehand.

SAVE THIS MANUAL AS IT CONTAINS IMPORTANT INFORMATION AND INSTRUCTIONS.

Before using the system, please follow and adhere to all warnings, safety and operating instructions located

either on the product or in this User’s Manual.

• Do not expose the product to water or moisture.

• Do not expose the product to extreme hot or cold temperatures.

• Do not expose the product to open ames.

• Do not allow objects to fall on or liquids to spill on the product.

• Do not touch the glass plate tted between the circular dovetail and the top plate. Any dust, dirt,

ngerprints will cause degradation of image quality

• Do not poke inside the open aperture in the base plate of the unit. There are delicate optical

components which are easily damaged if touched.

• WARNING. This unit emits visible laser light from the aperture in the base plate of the unit. The total

continuous power does not exceed 1mW thus it falls into a CLASS 1 Laser Product. As such the

user should not stare directly into the laser beam although the normal eye reex response will oer

protection. The laser power is less than most commercially available laser pointers sold in novelty

shops.

• DANGER. Under no circumstances unscrew the lid of the unit. Disassembly of the unit will void the

warranty. This product does not contain consumer serviceable components. Service and Repair should

be performed by authorised service centres only.

• Use only the proper type of power supply cord set (provided with the system) for this unit. Failure to do

so could instantly destroy the electronics and laser diode. The unit requires 24VDC at 2 Amperes.

• Always switch o the unit using the on/o rocker switch SW1 or unplug the PSU (CON3) when plugging/

unplugging the stepper motor (CON4) or DIGIPOT (CON2). It is safe to plug/unplug the USB connector

(CON1) with the unit powered.

Keep this manual in a safe place as it contains important safety information and

operating instructions.

More to PRIOR than meets the eye

For more information visit www.prior.com

3

Section 2

Product description

The Prior Scientic PureFocus850 is an advanced, integrated, unit comprising of an IR laser diode,

precision optical components, detector and signal processing electronics with on-board micro

controller. The system allows optimum visual focus to be found and maintained on a microscope

system for a range of dierent sample types, microscope objectives and imaging methods.

The PureFocus system allows powerful automated autofocus functionality to be added to existing

microscope systems by installing the unit into the innity space (between objective and tube lens).

The system has been designed to t on many popular microscopes using innity corrected

optics, both upright and inverted types, using the relevant mounting kit. The PureFocus controller

outputs signals suitable for controlling piezo or motor focus drives and is compatible with Prior piezo

actuators and Prior stepper motors, by simply attaching to the ne focus knob of the microscope.

With the laser autofocus system the user has the ablitiy to work with a range of sample types with a

reective surface, including permanently mounted glass slides, live specimens in aqueous solution,

metallurgical, semiconductors and other samples with multiple reective layers. The system can also

work with plastic vessels such as well plates.

PureFocus works with both epi and transmitted illumination, and can be used for uorescence

applications with the 850nm source being outside of most uorescence bands.

A fully standalone system gives the end user the option of using the PureFocus controller with digipot,

display and buttons allowing all basic functionality option without the need for a host PC. The inbuilt

signal processing electronics generates focus correction information internally every 1ms allowing for

fast focus capture and tight closed loop action. For more advanced functionality PureFocus can be

fully remote controlled via USB communication, using our ASCII commands may be sent.

Version issue No. - 1.7

4

Section 3

Unpacking the system

This guide is an introduction to installing a Prior PureFocus850. Please note that instructions for specic

microscopes and parts may vary. Consult Prior Scientic if you are unsure.

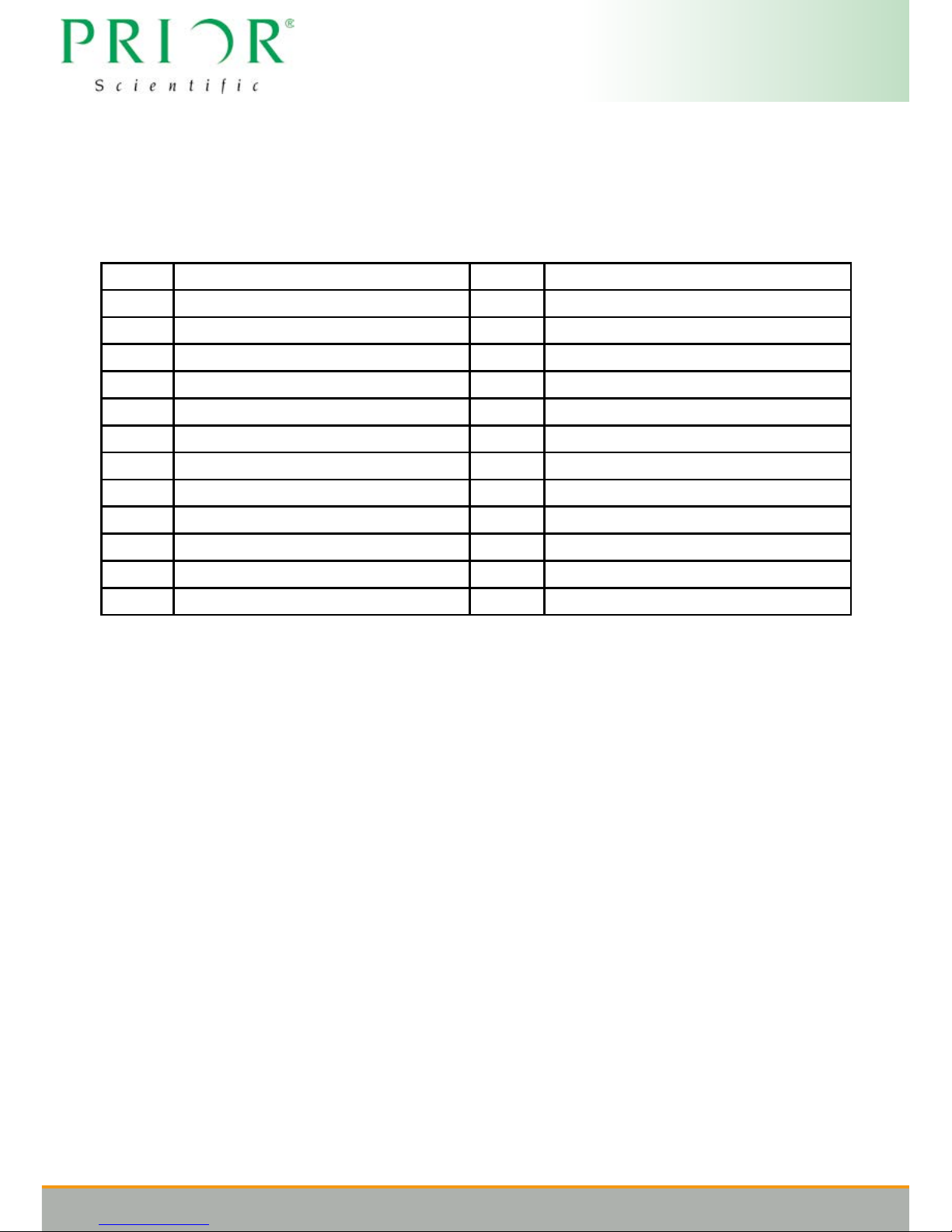

PF850 PureFocus Controller, Head, Cables & PSU LF523 Lower Dovetail Flange Olympus BX60

PF100 PureFocus controller LF320 Flange Set (Nikon 150)

PF301 PureFocus controller OEM LF526 Upper Dovetail Flange Nikon Optiphot 150

PF185 PureFocus Head LF527 Lower Dovetail Flange Nikon Optiphot 150

PF209 Sample Set Up Slide LF312 Flange Set (Leica LB)

PF300 PureFocus Setup Camera Jig LF532 Upper Dovetail Flange Leica DM4000

PF200 PureFocus Alignment Target Type 1 LF533 Lower Dovetail Flange Leica DM4000

PF201 PureFocus Alignment Target Type 2 LF341 Autofocus Flanges (Zeiss Axioskop 2/40)

PF202 IX73 PureFocus Mounting Kit LF534 Upper Dovetail Flange Zeiss AxiosKop 2 / 40

PF203 IX71 PureFocus Mounting Kit LF535 Lower Dovetail Flange Zeiss AxiosKop 2 / 40

LF335 Flange Set (Olympus BX) PF208 IX73 Basic PureFocus Mounting Kit

LF522 Upper Dovetail Flange Olympus BX60 PF400 Connecting Cable

W3045 USB Cable

If for whatever reason you fail to recieve all the items you require please contact techsupport2@prior.com,

where a member of sta will happily help with your issue.

Please note you will have to download the GUI from the prior.com website.

Downloads are free and additional infomation is available on our website on how to use the GUI.

More to PRIOR than meets the eye

For more information visit www.prior.com

5

1. PF system

In your shipment you should recieve:

PF head

PF controller

Connecting cable

Power supply

USB cable

Stepper motor (optional)

Piezo BNC cable (optional)

Dovetail kit (optional)

Inverted microscope kit (optional)

2. Alignment kit

Alignment target

IR alignment camera

3. Setup slide

Set up mirror

Sample for life science

Sample for material

science

The sample for life science consists of a thin specimen permanently mounted under a standard #1.5

coverslip.

The sample for material science consists of a a bare piece of stainless steel.

PF head

PF controller

Connecting

cable

Power

Supply

USB cable

Version issue No. - 1.7

6

Section 4

Introduction

4.1 Working principle

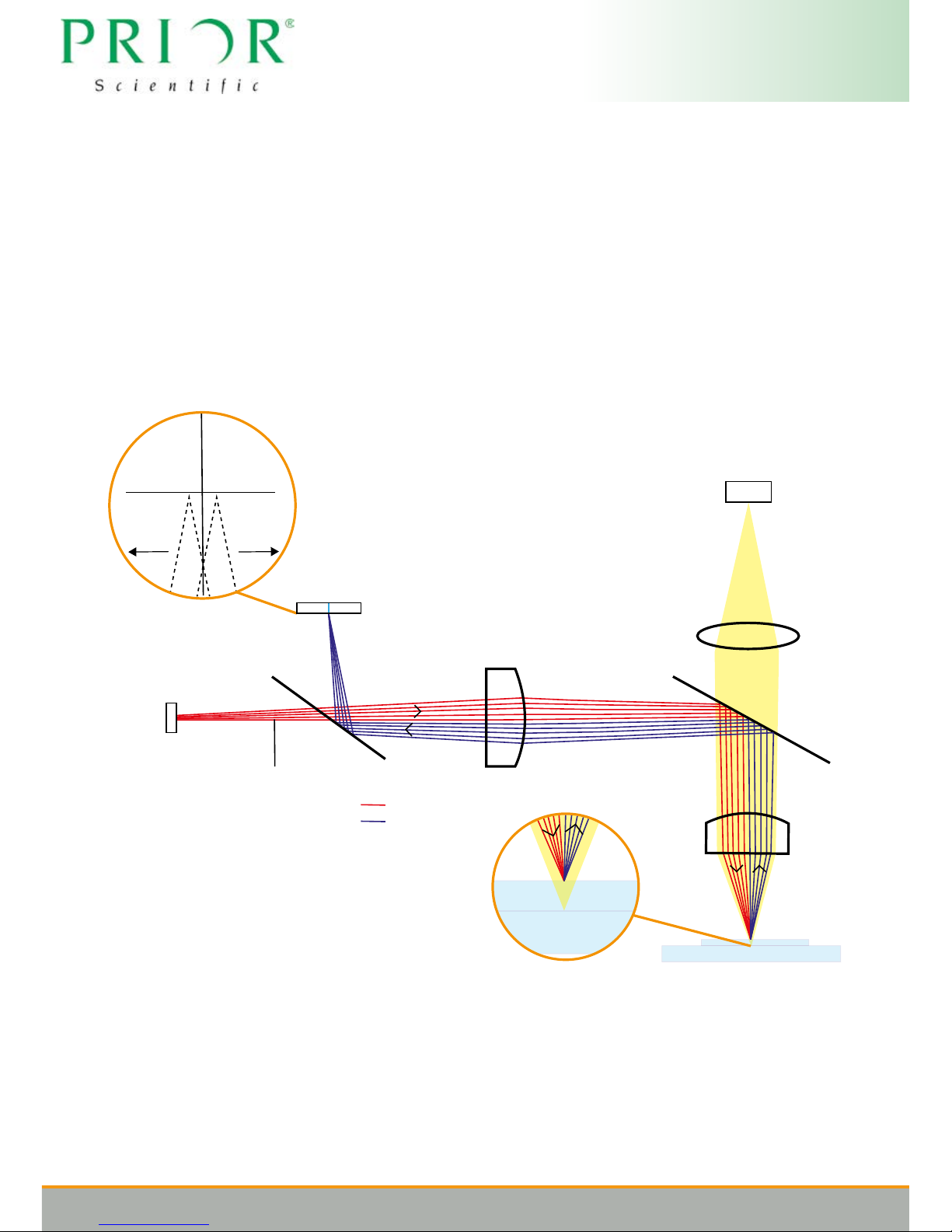

The Pure Focus operates using a sensor with mutiple pixels. Half the aperture of a collimated laser

beam is blocked via a knife edge and directed into the back of the microscope objective. The laser

light is focussed to a line on a reective surface at the sample and then reected back through the

objective and directed towards the sensor forming a corresponding line on the sensor at the centre

point. Due to half the aperture of the laser being blocked, motion of the reective sample up or down

causes this line to move either left or right on the sensor, giving information to automatically control the

focus of the microscope and keep the sample in focus.

Knife Blade

Beamsplitter

Laser Diode Source

Adjustable

Collimating Lens

Line Sensor

Dichroic Mirror

Objective Lens

Sample

Incident Beam

Reflected Beam

Out of focus Out of focus

Tube

Lens

Camera / eye piece

Due to the nature of the line sensor there is freedom to choose what range of pixels either side of the

centre point are used in calculating a focus error signal. This allows the rejection of reections from

spurious reective surfaces and oers great exibility when dealing with various dierent samples.

More to PRIOR than meets the eye

For more information visit www.prior.com

7

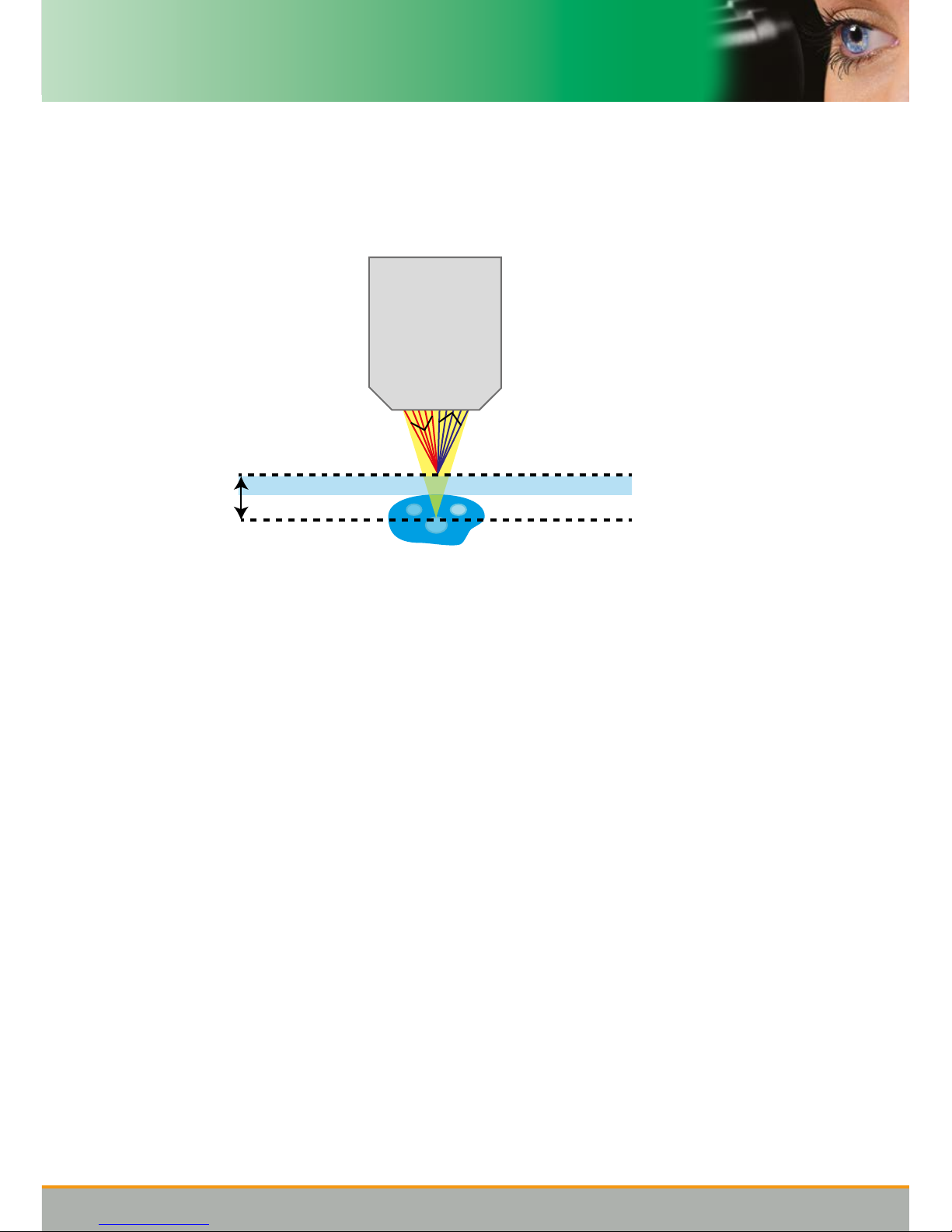

The addition of adjustable laser collimation also allows the reective surface, used by PureFocus

for holding focus, to be located at a dierent plane to the microscopes imaging plane, where the

specimen resides. This allows for continuously variable osets to be added. This is especially useful

when dealing with biological samples where the specimen will reside under a coverslip, which has a

reective top surface.

Offset

Reflective plane

Imaging plane

20x/0.75

To form a focus error signal rstly the system sums the pixel values to the left and right of a dened

centre pixel on the sensor, these summations are named A and B respectively. The number of

pixels that are summed either side of the centre to generate A and B can be chosen. The command

PINHOLE allows the centre point and width to be set. The sensor has 1500 pixels so the maximum

possible width is 750 pixels, for a centre point in the exact centre of the sensor at pixel 750.

The position signal is then computed as

POS = (A-B)/(A+B)

which is a signal that nominally swings between -1 and +1. A target value is subtracted from the

position signal to form an error signal

ERROR = TARGET - POS = TARGET - (A-B)/(A+B)

This signal is fed into a PID controller and the output of this controller is sent to either the Prior stepper

motor or to an analogue voltage for driving an external piezo controller.

PureFocus also computes two further values from the line sensor, C and D, which aid in operation.

C is simply the value of the centre pixel. D is the summation of pixels across an arbitrary section of

the sensor, which is settable to any range of pixels. This D value is useful for detecting if the system

is focussed to the correct interface when working with samples that contain more than one reective

surface.

Version issue No. - 1.7

8

4.2 Sample types

PureFocus works with a variety of dierent samples:

Permanently mounted slides

These are specimens that are xed in a mounting media usually with refractive index matched to the

glass coverslip (n≈1.5). When working with dry objectives with such samples a reective signal is

only available from the outside of the coverslip. It is recommended to work with #1.5 coverslips with

PureFocus.

If the specimen is high contrast (such as a stained section) as you scan over the slide, the level

of scattered/reected light from the inside of the coverslip where the specimen resides can vary

signicantly. In such cases it is benecial to position the knife edge `past-centre’ so more than half of

the laser line is blocked. This can be achieved by turning the knife edge screw (4) one additional turn

anticlockwise.

When working with water immersion objectives with such samples, a weaker reective signal is still

available from the outside of the coverslip. However, when working with oil immersion objectives

with such samples no reective signal will be available to work with. In these scenarios it may still be

possible to use a very weak reective signal from one of the interfaces to hold focus

Specimens in aqueous solution

These are specimens that sit on the inside face of a vessel or coverslip in a solution usually with

refractive index similar to water (n≈1.3). When working with dry objectives with such samples a strong

reective signal is available from the outside the coverslip/vessel and a weak reective signal is

available from the inside of the coverslip/vessel.

By default PureFocus works with the strong outside signal, however it does have capability in certain

conditions to work with the inside signal (See Operation - Section 6). It is recommended to work

with #1.5 coverslips/glass bottoms with PureFocus, although performance is possible with higher

thicknesses depending on the objective being used.

When working with water immersion objectives with such samples, reective signals are still available

from the outside and inside of the coverslip/vessel. However, when working with oil immersion

objectives with such samples there is only a reective signal from the inside of the coverslip/vessel.

Purely reective samples

For samples such as thick glasses, mirrors, metals and silicone wafers there will be a strong isolated

reection signal available.

Other samples with multiple reective layers

In a similar manner to biological samples, some industrial samples may consist of dierent layers

of reective material/coating, one example being an LCD panel. Depending on the thicknesses and

reectivities involved PureFocus may also be compatible with these samples

More to PRIOR than meets the eye

For more information visit www.prior.com

9

4.3 Types of microscope system

PureFocus works on a range of dierent microscopes which use innity corrected optics. The

PureFocus head sits in the innity space of the optical path between the objective and tube lens.

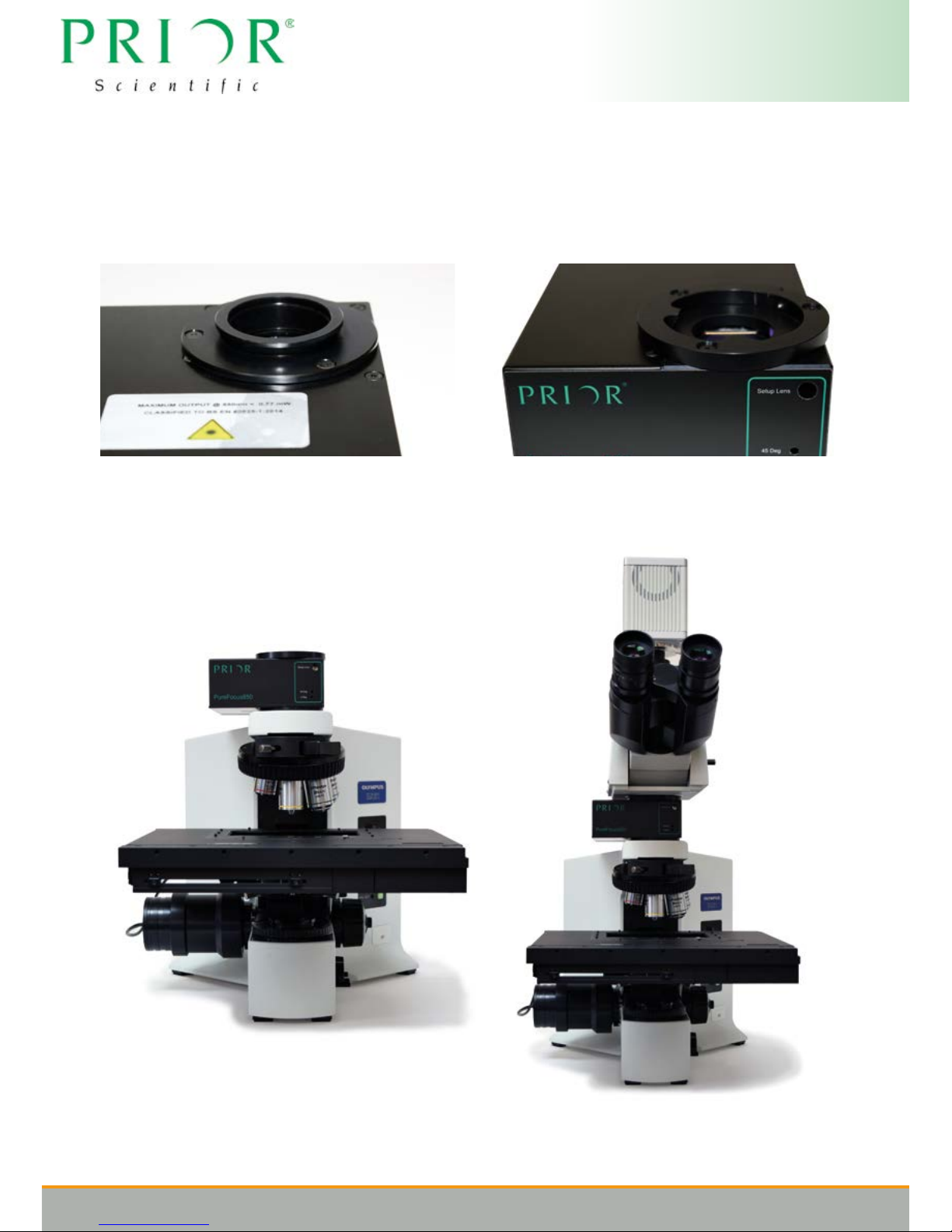

Inverted microscopes

On inverted microscopes where the objective moves and the sample is xed the PureFocus head

sits directly behind the objective nosepiece moving with the objective nosepiece as it changes focus

height, this is achieved using an mounting kit for the particular microscope being used.

Upright microscopes

On upright microscopes where the objective is xed and the sample moves the PureFocus head

can sit at any position in the innity space of the optical path, remaining xed to the body of the

microscope using a dovetail kit for the particular microscope being used.

Transmitted light/brighteld illumination

When working with transmitted light illumination, PureFocus could be susceptible to illumination light

reaching its sensor. In this case it is better to set the illumination light source to the lowest brightness

that still gives an acceptable image at the camera/eye pieces.

Reected light/epi illumination and uorescence

For reected light illumination and uorescent applications it is benecial to position the PureFocus

head below beam splitters and uorescence lter cubes which could attenuate or prevent the 850nm

PureFocus light reaching the sample

Phase contrast and DIC

PureFocus can work with a range of phase contrast objectives. The polarisation optics in DIC

microscopes must be positioned after the PureFocus head to be compatible.

Version issue No. - 1.7

10

Section 5

Installation

5.1 Installing the head

Install the microscope dovetail kit onto the PureFocus head unit. For information on installation for

inverted microscopes please contact a Prior representative.

Mount the PureFocus head unit onto the microscope between the objectives and tube lens, in the

ininity space (there are multiple places it could be mounted in the innity space depending on the

microscope).

More to PRIOR than meets the eye

For more information visit www.prior.com

11

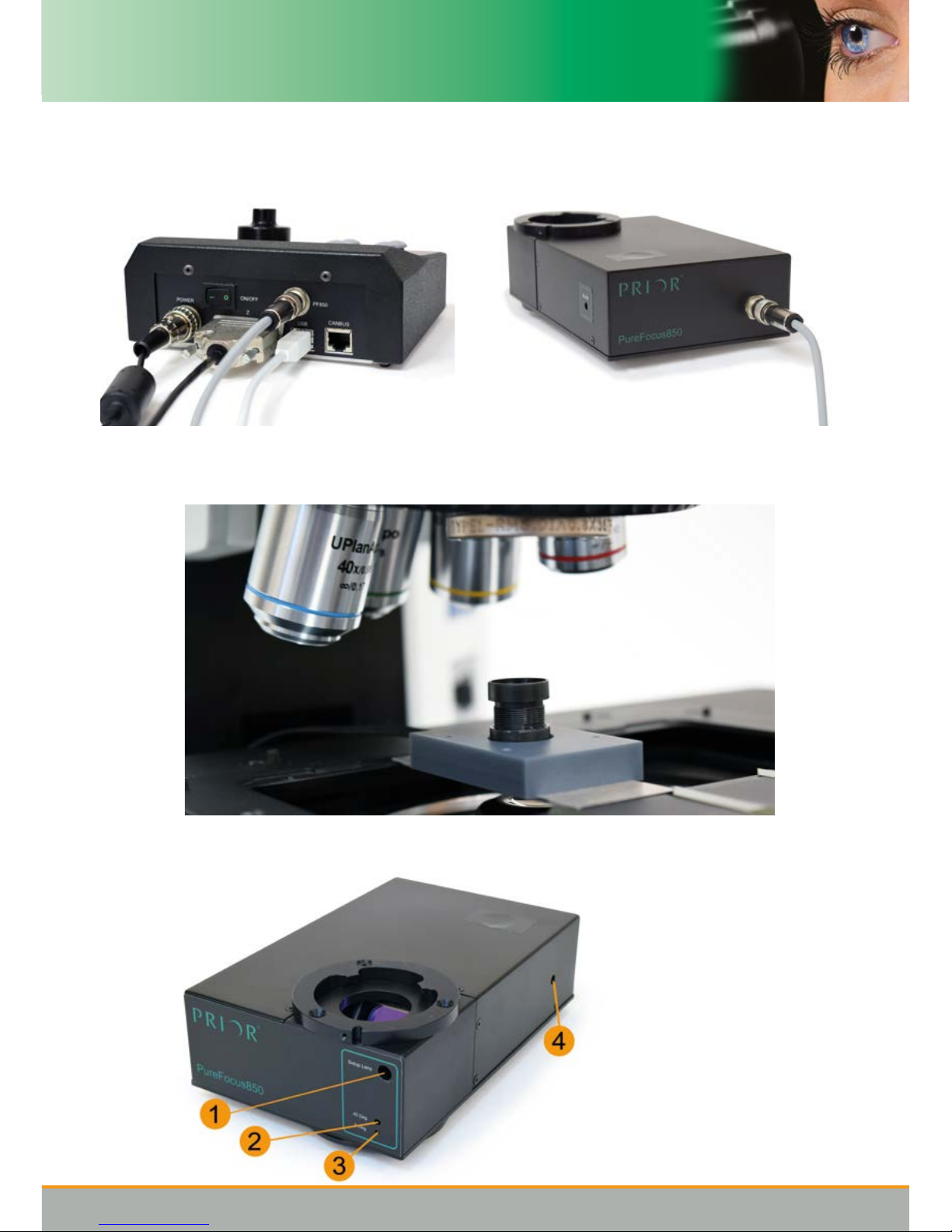

5.2 Initalizing the head

1. Connect cables

2. Insert IR alignment target into nosepiece and mount the setup camera onto the microscope

stage

3. Turn Allen screw labelled Blade (4) clockwise to the limit to remove knife edge from beam path

4. Turn on the control box and run the PureFocus850.exe Graphical User Interface (GUI)*

*Please note you will have to

download the GUI from the

prior.com website.

Downloads are free and

additional infomation is

available on our website on

how to use the GUI.

1. Setup Lens adjustment

2. Dichroic adjustment

(Nominal 45°)

3. Dichroic adjustment

(Nominal 0°)

4. Blade adjustment

Version issue No. - 1.7

12

5. Reset the PureFocus (Settings > Factory Reset) to ensure all settings are at factory defaults

6. Set laser power to 4000 (Laser > Set Power , value 4000)

7. In the main GUI, set the oset lens (Oset>Goto Limit)

8. Place the Camera alignment tool on the stage and move the IR alignment nosepiece target into

position. Using the camera software, camera.exe* check that the camera is focused onto the

front surface of the IR target. Adjust the camera focus lens if required.

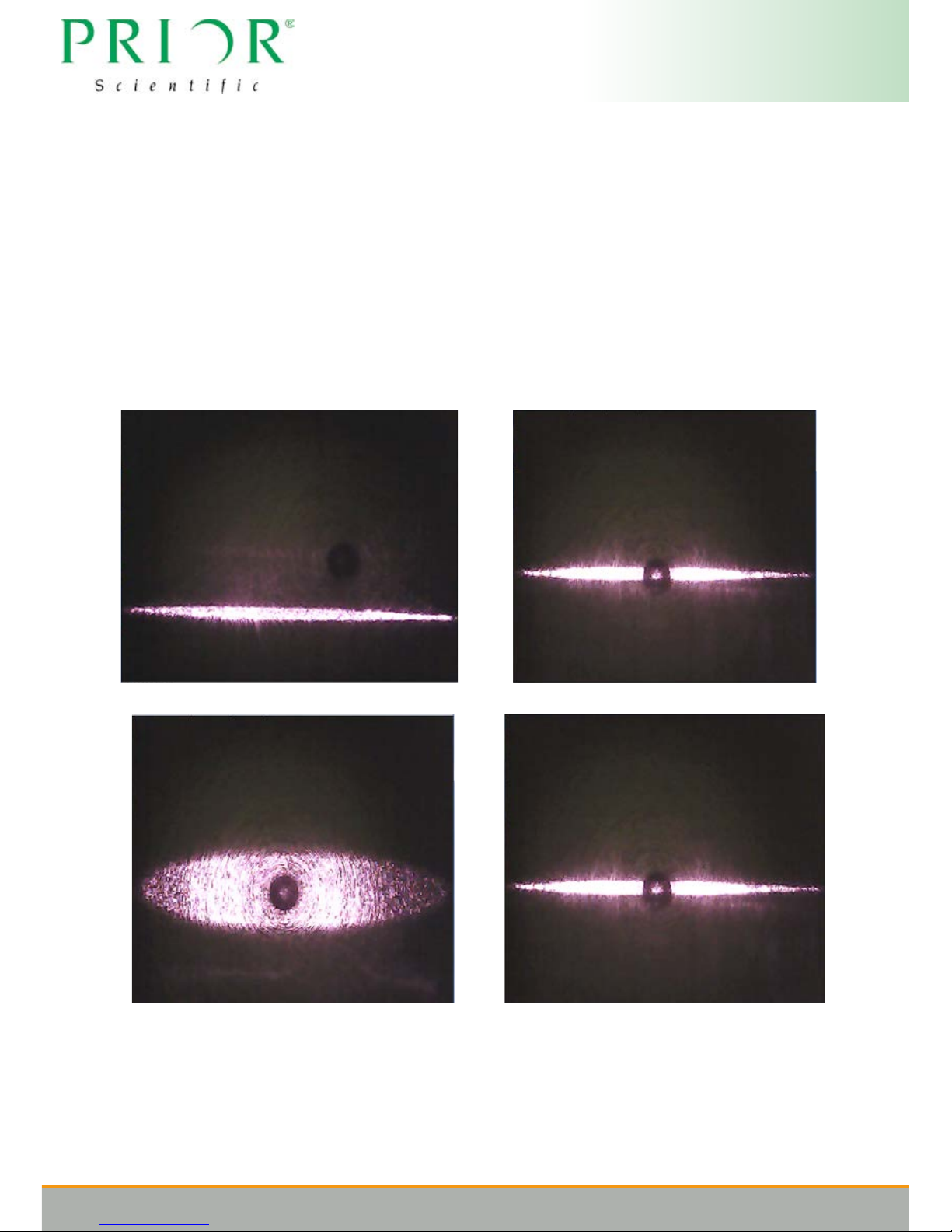

9. For some microscopes an adjustment of the oset may be required to get a good view of the

laser line across the camera eld of view, similar to the below images

10. Align the laser line with the centre of the target using the dichroic adjustment screws (2 and 3).

Please note that the laser line orientation may vary depending on the orientation of the camera

on the stage.

11. Adjust the setup lens screw (1) to get the sharpest line on the target:

12. Remove the alignment target and put a 10x objective in the nosepiece and position the objective

over the mirror section of the setup slide

13. Set Oset lens back to default position (Oset>Goto Factory Home)

14. Using your camera imaging software and PureFocus controller nob, or microscope manual

Bad Good

*camera.exe can be downloaded from the prior.com website along with the GUI software

Loading...

Loading...