Administrator’s Manual

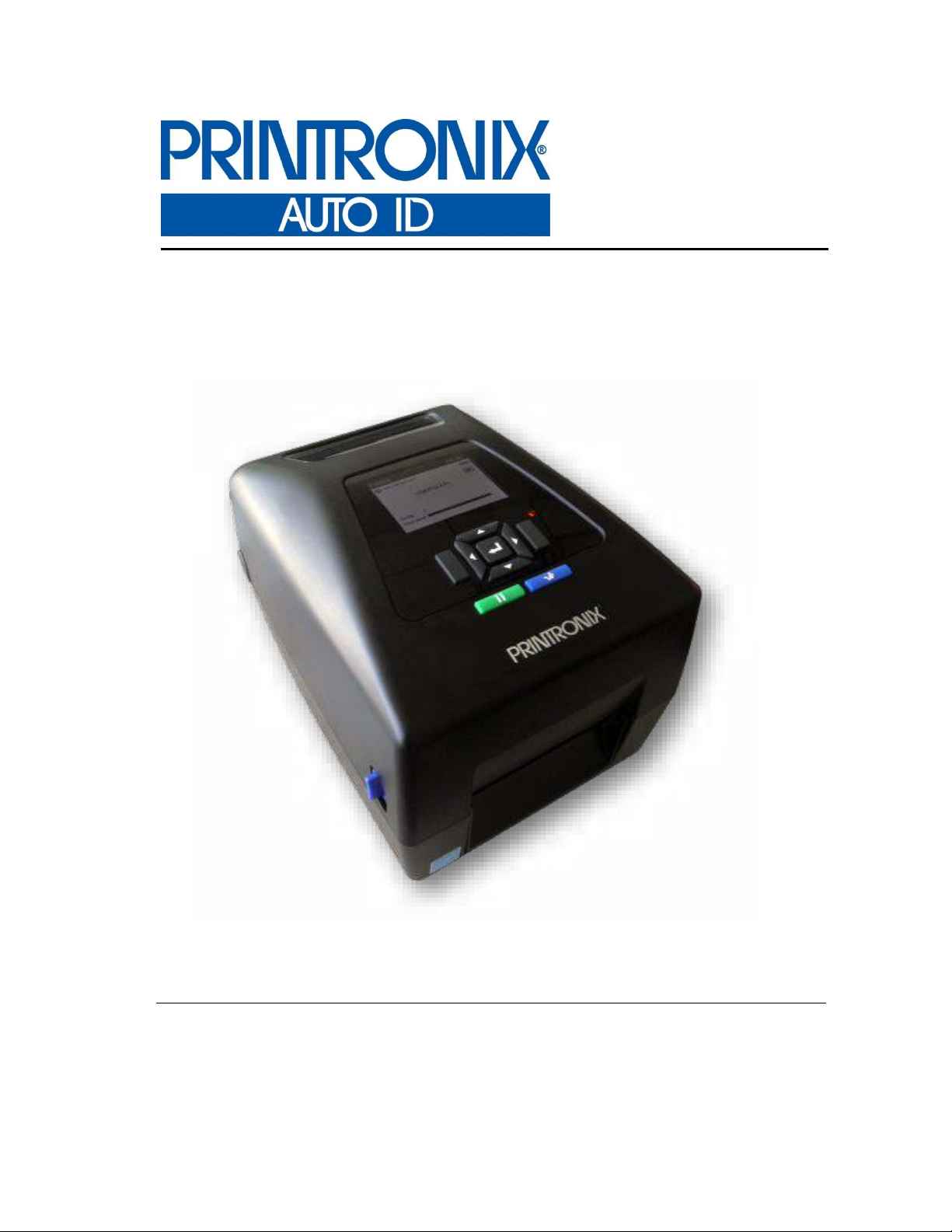

T800

Thermal Printers

Printronix Auto ID makes no representations or warranties of any kind regarding this

not limited to, implied warranties of merchantability

shall not be held responsible for errors contained herein or any omissions from this material or for any

damages, whether direct, indirect, incidental or consequential, in connection with the furnishing,

distribution, performance or use of this material. The

without notice.

This document contains proprietary information protected by copyright. No

reproduced, copied, translated or incorporated

manual, graphic,

ID.

COPYRIGHT © 2018 PRINTRONIX AUTO ID TECHNOLOGY, INC. All rights reserved.

electronic, mechanical or otherwise, without the prior written consent of Printronix Auto

and fitness for a particular purpose. Printronix Auto ID

information in this manual is subject to change

part of this document may be

in any other material in any form or by any means, whether

material, including, but

Trademark Acknowledgements

Printronix, IGP, Auto Label Mapping, LinePrinter Plus, PGL, and PrintNet are registered trademarks of

Printronix, Inc.

T800, T8000, and T6000 are trademarks of Printronix Auto ID Technology, Inc.

Code V is a trademark of QMS, Inc.

QMS is a registered trademark of Quality Micro Systems, Inc.

IBM is registered trademark of International Business Machines Corp.

MS-DOS and Windows are registered trademarks of Microsoft Corporation.

EIA is a registered service mark of Electronic Industries Association.

ZPL, ZPL II, and Zebra are registered trademarks of Zebra Technologies Corporation.

TEC is a registered trademark of the Toshiba TEC Corporation.

Intermec is a registered trademark of the Intermec Technologies Corporation.

SATO is a registered trademark of SATO America, Inc.

DPL is a trademark and Datamax is a registered trademark of Datamax Technologies Corporation.

IER is a registered trademark of IER Siège

Monarch is a registered trademark of Paxar Corporation.

SD, SDHC and SDXC are trademarks or registered trademarks of SD-3C, LLC in the United States, other

countries or both. Also, miniSD, microSD, miniSDHC, microSDHC, microSDXC, smartSD, smartSDHC,

SDIO and miniSDIO are all trademarks or registered trademarks of SD-3C, LLC in the United States,

other countries or both.

Page | 2

Regulatory Compliance

EN 55032:2015

EN 55024

EN 60950-1

This is a class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

FCC part 15B, Class A

ICES-003, Class A

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment.

Operation is subject to the following two conditions: (1) This device may cause

harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the manufacturer’s instruction manual, may

cause harmful interference with radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case you will be

required to correct the interference at your own expense.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conform à la norme NMB-003 du Canada.

AS/NZS CISPR 32, Class A

K 60950-1, KN 32 / KN 35

이 기기는 업무용(A 급) 전자파적합기기로서 판매자 또는 사용자는 이 점을

주의하시기 바라며, 가정외의 지역에서 사용하는 것을 목적으로 합니다.

GB 4943.1

GB/T9254, Class A

GB 17625.1

此为 A 级产品,在生活环境中,该产品可能会造成无线电干扰,

在这种情况下,可能需要用户对干扰采取切实可行的措施。

Energy Star for Imaging Equipment Version 2.0

The menu setting System > Energy Star > Pwr Saver Time is default 5 minutes and

can be modified by user if desired.

IS 13252(Part 1)/

IEC 60950-1

Page | 3

UL 60950-1

CAN/CSA-C22.2 No. 62368-1

NOM-019

CNS 13438

CNS 14336-1

CNS 15663

TP TC 004

TP TC 020

Important safety instructions:

1. Read all of these instructions and keep them for later use.

2. Follow all warnings and instructions on the product.

3. Disconnect the power plug from the AC outlet before cleaning or if fault happened.

Do not use liquid or aerosol cleaners. Using a damp cloth is suitable for cleaning.

4. The mains socket shall be installed near the equipment and easily accessible.

5. The unit must be protected against moisture.

6. Ensure the stability when installing the device, Tipping or dropping could cause damage.

7. Make sure to follow the correct power rating and power type indicated on marking label provided by

manufacture.

8. Please refer to user manual for maximum operation ambient temperature.

WARNING:

Hazardous moving parts, keep fingers and other body parts away.

CAUTION:

(For equipment with RTC (CR2032) battery or rechargeable battery pack)

Risk of explosion if battery is replaced by an incorrect type.

Dispose of used batteries according to the Instructions as below.

1. DO NOT throw the battery in fire.

2. DO NOT short circuit the contacts.

3. DO NOT disassemble the battery.

4. DO NOT throw the battery in municipal waste.

5. The symbol of the crossed out wheeled bin indicates that the battery should not be placed in municipal

waste.

Caution: The printhead may be hot and could cause severe burns. Allow the printhead to cool.

CAUTION:

Any changes or modifications not expressly approved by the grantee of this device could void the user's

authority to operate the equipment.

Page | 4

Frequency Band

Country

Remark

5150-5350MHz

Azerbaijan

No license needed if used

indoor and power not

exceeding 30mW

5470-5725MHz

Below statement are for product with optional RF function.

CE Statement:

This equipment complies with EU radiation exposure limits set forth for an uncontrolled environment. This

equipment should be installed and operated with minimum distance 20 cm between the radiator & your

body.

All operational modes:

2.4GHz: 802.11b, 802.11g, 802.11n (HT20), 802.11n (HT40)

5GHz: 802.11a, 802.11ac.

The frequency, mode and the maximum transmitted power in EU are listed below:

2400 MHz – 2483.5 MHz: 19.88 dBm (EIRP)(Wi-Fi)

5150 MHz – 5250 MHz: 17.51 dBm (EIRP)(Wi-Fi)

2402 MHz – 2480 MHz: 6.02 dBm (EIRP)(Bluetooth)

Requirements in

AT/BE/BG/CZ/DK/EE/FR/DE/IS/IE/IT/EL/ES/CY/LV/LI/LT/LU/HU/MT/NL/NO/PL/PT/RO/SI/SK/TR/FI/SE/C

H/UK/HR. 5150MHz~5350MHz is for indoor use only.

5150-5350MHz for Only indoor use

5470-5725MHz for indoor/outdoor use

Restrictions In AZE

National restrictions information is provided below

Hereby, PRINTRONIX Auto ID Technology Co., Ltd. declares that the radio equipment type [Wi-Fi] IEEE

802.11 a/b/g/n/ac is in compliance with Directive 2014/53/EU

The full text of the EU declaration of conformity is available at the following internet address:

http://printronixautoid.com/declarations-of-conformity/

Canada, Industry Canada (IC) Notices

This Class A digital apparatus complies with Canadian ICES-003 and RSS-210.

Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this

device must accept any interference, including interference that may cause undesired operation of the

device.

Canada, avis de l'Industry Canada (IC)

Cet appareil numérique de classe B est conforme aux normes canadiennes ICES-003 et RSS-210.

Son fonctionnement est soumis aux deux conditions suivantes : (1) cet appareil ne doit pas causer

d'interférence et (2) cet appareil doit accepter toute interférence, notamment les interférences qui peuvent

affecter son fonctionnement.

NCC

警語:

經型式認證合格之低功率射頻電機,非經許可,公司、商號或使用者均不得擅自變更頻率、加大功率或變更

原設計之特性及功能。(即低功率電波輻射性電機管理辦法第十二條)

低功率射頻電機之使用不得影響飛航安全及干擾合法通信;經發現有干擾現象時,應立即停用,並改善至無

干擾時方得繼續使用。

Page | 5

前項合法通信,指依電信法規定作業之無線電通信。低功率射頻電機須忍受合法通信或工業、科學及醫療用

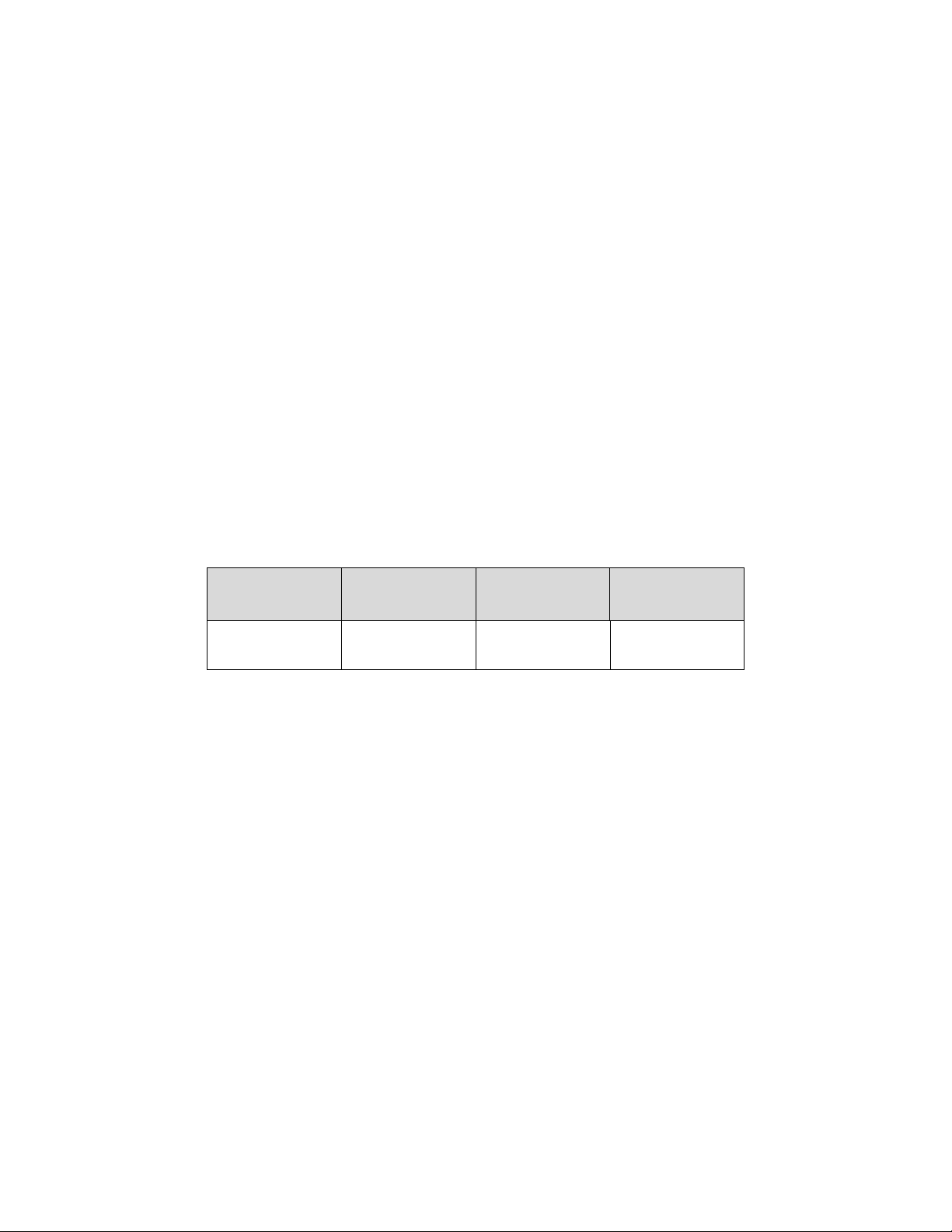

單元 Unit

限用物質及其化學符號

Restricted substances and its chemical symbols

鉛Lead

(Pb)

汞Mercury

(Hg)

鎘

Cadmium

(Cd)

六價鉻

Hexavalent

chromium

(Cr+6)

多溴聯苯

Polybrominated

biphenyls

(PBB)

多溴二苯醚

Polybrominated

diphenyl ethers

(PBDE)

內外塑膠件

○ ○ ○ ○ ○

○

內外鐵件

○ ○ ○ ○ ○

○

滾輪

○ ○ ○ ○ ○

○

電路板組件

- ○ ○ ○ ○

○

晶片電阻

- ○ ○ ○ ○

○

積層陶瓷表

面黏著電容

○ ○ ○ ○ ○

○

集成電路-IC

○ ○ ○ ○ ○

○

電源供應器

○ ○ ○ ○ ○

○

印字頭

○ ○ ○ ○ ○

○

馬達

- ○ ○ ○ ○

○

插座

○ ○ ○ ○ ○

○

線材

○ ○ ○ ○ ○

○

備考 1.〝超出 0.1 wt %〞及〝超出 0.01 wt %〞係指限用物質之百分比含量超出百分比含量基準值。

Note 1:“Exceeding 0.1 wt %” and “exceeding 0.01 wt %” indicate that the percentage content of the restricted substance exceeds the reference

percentage value of presence condition.

備考 2.〝○〞係指該項限用物質之百分比含量未超出百分比含量基準值。

Note 2:“○” indicates that the percentage content of the restricted substance does not exceed the percentage of reference value of presence.

備考 3.〝-〞係指該項限用物質為排除項目。

Note 3:The “−” indicates that the restricted substance corresponds to the exemption.

電波輻射性電機設備之干擾。(即低功率電波輻射性電機管理辦法第十四條)

BSMI Class A

這是甲類的資訊產品,在居住的環境使用中時,可能會造成射頻 干擾,在這種情況下,使用者會被要求採

取某些適當的對策。

限用物質含有情況標示聲明

警語:

Page | 6

Warnings and Special Information

For your safety and to protect valuable equipment, read and comply with all information highlighted under

special headings:

WARNING Conditions that could harm you and damage the equipment.

WARNING Achten Sie auf folgendes, um keine Personen in Gefahr zubringen bzw. das

Gerät zu beschädigen.

WARNING Condiciones que pueden causar daños a personas y equipos.

WARNING Conditions à respecter pour éviter tout danger corporel et dommage matériel.

WARNING Condizioni che possono arrecare danni alle persone e alle apparecchiature.

CAUTION

Conditions that could damage the printer or related equipment.

IMPORTANT Information vital to proper operation of the printer.

NOTE: Information and helpful tips about printer operation.

Important Safety Instructions

1. Read all of these instructions and keep them for later use.

2. Follow all warnings and instructions on the product.

3. Disconnect the power plug from the AC outlet before cleaning or if a fault occurs.

4. Do not use liquid or aerosol cleaners. Using a damp cloth is suitable for cleaning printer surfaces.

5. The mains socket shall be installed near the equipment and easily accessible.

6. The unit must be protected against moisture.

7. Ensure the stability when installing the device. Tipping or dropping could cause damage.

8. Make sure to follow the correct power rating and power type indicated on marking label provided by

manufacturer.

9. Please refer to user manual for maximum operation ambient temperature.

WARNING Hazardous moving parts, keep fingers and other body parts away.

CAUTION Risk of explosion if RTC battery is replaced by an incorrect type. Dispose of used

batteries according to the Instructions listed below.

6. DO NOT throw the battery in fire.

7. DO NOT short circuit the contacts.

8. DO NOT disassemble the battery.

9. DO NOT throw the battery in municipal waste.

10. The symbol of the crossed out wheeled bin indicates that the battery should not be

placed in municipal waste.

CAUTION The printhead may be hot and could cause severe burns. Allow the printhead to

cool before servicing.

Page | 7

Manual Conventions

• Operator panel keys are printed in uppercase letters.

Example: Press the PAUSE key and then press ENTER.

• Operator panel keys are often shown by their symbol or icon (located on the control panel directly

above the key).

Example: Press the key for ENTER.

• Operator panel menu settings are often shown by their full location that includes the ICON name,

submenu, and then menu, each separated with a ‘>’ sign.

Example: Change the Media > Image > Label Length menu.

• Control panel LCD messages are printed in uppercase letters inside quotation marks ( “ ” ).

Example: When “OFFLINE” appears on the control panel LCD, you may release the PAUSE key.

• Key combinations are indicated by the + (plus) symbol.

Example: Press + means Press the Up key and the Down key at the same time.

Page | 8

Table of Contents

Trademark Acknowledgements ........................................................................... 2

Regulatory Compliance ....................................................................................... 3

Warnings and Special Information ...................................................................... 7

Important Safety Instructions ............................................................................... 7

Manual Conventions ............................................................................................ 8

1 Introduction .................................................................. 17

The T800 Family of Printers .............................................................................. 17

Standard Features ............................................................................................. 17

Optional Features .............................................................................................. 18

2 Operation ..................................................................... 19

Controls and Indicators...................................................................................... 19

Power Switch .............................................................................................. 19

Control Panel .............................................................................................. 19

Operating Modes ............................................................................................... 20

Online Screen .................................................................................................... 21

Offline (Home) Screen ....................................................................................... 22

Wizard .............................................................................................. 22

Settings .............................................................................................. 23

Calibrate .............................................................................................. 25

Fault ..................................................................................................... 25

Job in Process ............................................................................................ 25

Media Handling Modes ...................................................................................... 26

Setting Up the Printer ........................................................................................ 26

Loading Ribbon ........................................................................................... 28

Loading Media ............................................................................................ 30

Loading External Media .............................................................................. 33

Positioning the Media Sensors ................................................................... 34

Sensing Different Media Types ................................................................... 36

Media with No Label Length Indicators ........................................................ 37

Media with Underside Horizontal Black Marks ............................................... 37

Media with Gaps, Notches or Holes ........................................................... 37

Media with Gaps ......................................................................................... 37

Calibrating the Media Sensors .................................................................... 37

Running Auto Calibrate ............................................................................... 38

Running Media Profile ................................................................................. 39

Gap Sensing ............................................................................................... 40

Page | 9

Running Manual Calibrate .......................................................................... 40

Label Peel-Off (Optional) ................................................................................... 42

Loading Media Using Peel-Off Mode .......................................................... 42

Configuring the Printer Menu ...................................................................... 43

Media Cutter (Optional) ..................................................................................... 44

Loading Media Using Cutter Mode ............................................................. 44

Configuring the Printer Menu ...................................................................... 44

Printing Adjustments .......................................................................................... 45

Printhead Burn Line Adjustment ................................................................. 45

Cleaning ............................................................................................................ 46

Exterior Cleaning ........................................................................................ 46

Interior Cleaning .......................................................................................... 46

Cleaning the Printhead, Platen Roller, Media Sensors/Damper ................. 46

Printhead Cleaning ..................................................................................... 46

Platen Roller Cleaning ................................................................................ 47

Media Sensor Cleaning ............................................................................... 47

Cutter Option Cleaning ............................................................................... 48

3 Printer Settings ............................................................ 49

Overview ............................................................................................................ 49

Setting Printer Configuration Parameters .................................................... 49

Saving a Configuration

Auto Save Configuration ............................................................................. 52

Naming Configurations ............................................................................... 52

Loading a Configuration .............................................................................. 53

Specifying a Power-Up Configuration ......................................................... 54

Modifying a Saved Configuration ................................................................ 54

Viewing the Current Configuration .............................................................. 54

Printing a Configuration .............................................................................. 54

Settings Organization

Quick Setup ........................................................................................ 56

Menu Items ................................................................................................. 56

Entering Safe Mode .................................................................................... 57

Exiting Safe Mode ....................................................................................... 57

Forgot the Password ................................................................................... 58

Media

Intro: Label Length ...................................................................................... 59

Intro: Clip Page ........................................................................................... 59

.................................................................................................... 59

.................................................................... 51

........................................................................ 55

Page | 10

Media > Image ............................................................................................ 60

Media > Speed ............................................................................................ 66

Media > Handling ........................................................................................ 67

Media > Ribbon ........................................................................................... 72

Media > TOF ............................................................................................... 72

Media > Fault .............................................................................................. 74

Media > Auto Label Map ............................................................................. 75

Auto Label Map Examples .......................................................................... 76

Example 1: Simple Case ............................................................................. 76

Example 2: Uneven Number Case .............................................................. 77

Example 3: Past Maximum File Width ......................................................... 78

Example 4: Blank Label Case ..................................................................... 78

Sensors ................................................................................................ 79

Intro: Sensor Types ..................................................................................... 79

Sensors > Control ....................................................................................... 79

Sensors > Calibrate .................................................................................... 81

Sensors > Diagnostics ................................................................................ 87

System

Host IO

Network ............................................................................................ 113

System > Control ........................................................................................ 88

System > Energy Star ................................................................................. 91

System > Flash File View ........................................................................... 91

System > Flash File Edit ............................................................................. 91

System > SD File View ............................................................................... 93

System > SD File Edit ................................................................................. 93

System > USB File View ............................................................................. 95

System > USB File Edit............................................................................... 95

System > Printer Mgmt ............................................................................... 96

System > Date ............................................................................................ 99

Host IO > Control ...................................................................................... 101

Host IO > USB Port ................................................................................... 101

Host IO > Serial Port ................................................................................. 103

Network > Control ..................................................................................... 113

Network > Ethernet ................................................................................... 115

Network > WLAN ...................................................................................... 118

Network > WLAN Params ......................................................................... 120

............................................................................................... 88

.......................................................................................... 101

Page | 11

Network > WLAN EAP .............................................................................. 127

Application

LP+, PGL, VGL Character Sets ................................................................ 129

Application > Control ................................................................................. 133

Application > PGL Setup ........................................................................... 138

Application > LP+ SETUP ......................................................................... 149

Application > P-SERIES Setup ................................................................. 154

Application > P-SERIES XQ Setup ........................................................... 160

Application > Serial Matrix Setup .............................................................. 164

Application > Proprinter Setup .................................................................. 168

Application > Epson FX Setup .................................................................. 171

Application > Fonts ................................................................................... 176

Configs .............................................................................................. 178

Configs > Control ...................................................................................... 178

Configs > Custom ..................................................................................... 179

Tools

Tools > Print Tests .................................................................................... 181

Tools > Diagnostics................................................................................... 182

Tools > Statistics ....................................................................................... 183

Tools > About ............................................................................................ 184

................................................................................................. 181

..................................................................................... 129

Page | 12

RFID .................................................................................................. 186

4 Downloading Firmware .............................................. 187

Firmware File Types (.prg) and (.exe) ............................................................. 188

Web Page Download ....................................................................................... 189

Windows Driver Download .............................................................................. 191

Automatic Download (.exe) ............................................................................. 192

Manual Two-Key Download Sequence ........................................................... 193

Manual Three-Key Download Sequence......................................................... 194

Sending Firmware in Download Mode ............................................................ 194

Sending Firmware via Ethernet (LPR) ...................................................... 195

Sending Firmware via USB ....................................................................... 195

Sending Firmware via Serial ..................................................................... 196

Downloading Files to the Main File System .................................................... 197

Filename Extensions Not Shown in Menus ..................................................... 197

File Properties Not Shown in Menus ............................................................... 198

Web Page Download ....................................................................................... 198

PTX_SETUP Download................................................................................... 200

Manual Two-Key Download ............................................................................ 200

Downloading Files to the SD Card .................................................................. 201

Using TrueType Fonts ..................................................................................... 201

Downloading TrueType Fonts ................................................................... 201

PGL Emulation .......................................................................................... 201

Adding a Header/Manual Two-Key Download .......................................... 202

Header for SD Card ................................................................................... 203

Labeling Applications ................................................................................ 203

Select and Print Downloaded TrueType Fonts ......................................... 203

To Print ASCII Characters ........................................................................ 203

To Print All Characters .............................................................................. 203

Demo Facility ................................................................................................... 203

Downloading a Demo File ......................................................................... 203

Configuring the Printer to Run a Demo File .................................................... 204

Starting a Demo File ................................................................................. 204

Pausing a Demo File ................................................................................. 204

Stopping a Demo File ............................................................................... 204

Deleting a Demo File ................................................................................ 204

WLAN Radio Firmware Upgrade ..................................................................... 205

Firmware Download Methods ................................................................... 205

Firmware File Types (.fls) and (.exe) ........................................................ 205

Web Page Download ................................................................................ 206

Windows Driver Download ........................................................................ 207

Automatic Download (.exe) ....................................................................... 207

Manual Two-Key Download Sequence ..................................................... 207

Page | 13

5 Diagnostics and Troubleshooting ............................... 208

Printer Tests ...................................................................................................... 208

Troubleshooting Common Situations ................................................................. 208

Interfacing ................................................................................................. 208

Hex Dump Mode ....................................................................................... 208

Controlling Print Quality ............................................................................ 209

Replacing the Printhead assembly ........................................................... 211

Restore the Printer to Operation ............................................................... 213

Diagnostics for Fatal Error ........................................................................ 213

Solving Other Printer Problems ................................................................ 214

Printer Alarms ........................................................................................... 222

Fault Messages ......................................................................................... 222

Operator-Correctable Fault Messages ..................................................... 222

Fault Messages Requiring Field Service Attention ................................... 222

Fatal Messages Requiring Firmware Upgrade or Diagnostics ................. 222

A Specifications ............................................................ 232

Print Method .............................................................................................. 232

Media ........................................................................................................ 233

Ribbon ....................................................................................................... 235

Indicators and Switches ............................................................................ 235

Memory ..................................................................................................... 236

Media Cutter Option .................................................................................. 236

Host Interfaces .......................................................................................... 237

Power ........................................................................................................ 237

Environmental ........................................................................................... 238

Physical ..................................................................................................... 238

Acoustic Specifications ............................................................................. 238

B Printer Options ........................................................... 239

Media Handling Accessories ........................................................................... 239

Media Cutter.............................................................................................. 239

Peel Dispenser .......................................................................................... 239

Hardware Options ............................................................................................ 239

RFID .......................................................................................................... 239

Interface Options ............................................................................................. 239

Wireless NIC (802.11 a/b/g/n/ac/b/g/n wireless) ....................................... 239

Bluetooth 4.2 ............................................................................................. 239

Software Options ............................................................................................. 240

Premium Asian Fonts ................................................................................ 240

Quick Change Memory Cartridge ............................................................. 240

Supplies ........................................................................................................... 240

Manuals ........................................................................................................... 240

Page | 14

C Media Cutter Installation

Preparing the Printer ....................................................................................... 241

Installing the Media Cutter ............................................................................... 241

D Peel-off Module Installation

Preparing the Printer ....................................................................................... 244

Installing the Peel-off Module .......................................................................... 244

................................................ 241

............................................ 244

E Loading WLAN Certificates ........................................ 247

Overview .......................................................................................................... 247

Loading Wifi Certificate file(s) from Windows .................................................. 247

Loading Wifi Certificate file(s) from Linux ........................................................ 247

Loading Wifi Certificate file(s) from Webpage ................................................. 248

F PTX_SETUP Commands ........................................... 250

Overview .......................................................................................................... 250

The PTX_SETUP Commands ........................................................................... 250

General Commands .................................................................................. 250

Summary of the CONFIG Command ........................................................ 255

Operation of the FILE_IO Command ........................................................ 255

Thermal Commands ................................................................................. 255

G Quick Change Memory Card (QCMC) ....................... 258

Overview .......................................................................................................... 258

Installing the QCMC ........................................................................................ 259

Saving the Printer’s Configuration to the QCMC ............................................. 259

Copying the QCMC “Snapshot” Image to a Second Printer

Updating the QCMC Image

Erasing the QCMC Image

................................................................................... 263

...................................................................................... 263

........................................... 261

H Custom Configuration Module (CCM) ........................ 265

Overview .......................................................................................................... 265

Creating a CCM ............................................................................................... 265

Using CCM To Configure A Printer ................................................................. 266

I Customer Support ...................................................... 268

Printronix Customer Support Center ............................................................... 268

Corporate Offices ............................................................................................ 269

J Glossary .................................................................... 270

K Communication Notices and Warranties .................... 275

Communication

European Union Conformity...................................................................... 277

Industry Canada Compliance Statement .................................................. 277

Statement of CISPR 32 Compliance ........................................................ 277

German Conformity Statement ................................................................. 278

Korea ......................................................................................................... 278

China ......................................................................................................... 279

Software License Agreement .......................................................................... 280

eCos .......................................................................................................... 281

Open SSL.................................................................................................. 282

OpenSSL License ..................................................................................... 282

Original SSLeay License ........................................................................... 283

WPA Supplicant License ........................................................................... 284

Brian Gladman AES Library ...................................................................... 284

Google Font Open Sans ........................................................................... 285

Cousine Font ............................................................................................. 285

Limited Software Product Warranty ................................................................. 286

Remedy ..................................................................................................... 286

Disclaimer of Warranties and Limitation of Remedies .............................. 286

Statements

................................................................................ 276

Page | 15

Termination of License Agreement ........................................................... 286

U.S. Government Restricted Rights .......................................................... 286

Acknowledgement of Terms and Conditions ............................................ 287

Warranty Information ....................................................................................... 288

PRINTER WARRANTY ............................................................................. 288

THERMAL PRINTHEAD ........................................................................... 288

SUPPLIES................................................................................................. 288

ON-SITE MAINTENANCE SERVICE ....................................................... 288

Page | 16

Version

Max Print

Speed (ips)

Printing

Density

Max Print

Width

T820

8

203

4.1

T830

6

300

4.1

1 Introduction

The T800 Family of Printers

NOTE: The terms “T800” and “printer” refer to both the T820 (203 DPI) and T830 (300 DPI) models.

The T800 series consists of a family of high quality, desktop direct thermal and thermal transfer printers

specifically designed for printing labels and tags from multiple environments:

• Windows

• Unix/Linux

• MS-DOS

• SAP/ERP (PGL-based SAP device type)

The T800 series is comprised of the products detailed in Table 1.

®

®

Table 1. The T800 Series

Standard Features

• Thermal Transfer and Direct Thermal Printing

• High Resolution Printhead: 203dpi or 300dpi for sharp graphics and text.

• Sensors: Fixed media Gap, adjustable Black Mark sensor, Head Open, Ribbon End sensors

• User Interface: 3.5” color LCD screen, with 9 button keyboard

• 128MB DDR3 memory (fixed).

• 128MB NAND Flash memory (fixed).

• Auto Label Mapping®: For compatibility with programs written for Printronix line matrix printers.

• Bar Codes: Supports multiple types of 1-D and 2-D bar codes.

• Download: Fonts, forms, and graphics to printer memory.

• Emulations:

o Printronix PGL® for text, barcodes, graphics, lines, and boxes.

o Printronix LinePrinter Plus® (LP+) for direct compatibility with Printronix P-Series printers,

Epson FX-1050, Proprinter IIIXL, and Serial Matrix Printers.

o Printronix VGL. Emulates the QMS Code V™ Version II programming language.

17

o ZGL interpreter for legacy ZPL (Zebra®) applications

o TGL interpreter for legacy TEC (TEC®) applications

o IGL interpreter for legacy IPL (Intermec®) applications

o STGL interpreter for legacy SPL (SATO®) applications

o DGL interpreter for legacy DPL™ (Datamax®) applications

o IEGL interpreter for legacy IER-520® (IER®) applications

o MGL interpreter for legacy MPCL II® (Monarch®) applications

o EGL interpreter for Eltron® applications

• Serial RS-232: DB9 connector

• USB 2.0 Universal Serial Bus

• Network Interface Port: This interface allows you to attach the printer to a LAN (Local Area

Network). The port is visible on the back panel. The Ethernet port is a 10/100Base and supports

data transfer rates up to 100 Mbps. The PrintNet Enterprise Suite (PNE) remote management

software can be downloaded from

• Real Time Clock (RTC): The RTC has an internal battery. The clock keeps track of the year,

month, day, hour, minute and second values. It will continue to operate when the printer is off.

Graphic languages can use the RTC values to program fields in labels to indicate the date and/or

time.

http://www.printronixautoid.com.

• Resident Fonts (Standard Firmware): Letter Gothic Bold (#93779), Courier Bold (#93952), CG

Triumvirate Bold Condensed (#92250), OCR-A (#90993), OCR-B (#91409), CG Triumvirate

(#92244), CG Triumvirate Bold (#92248), and CG Times New Roman (#92500).

• Mini SD memory card slot: Supports SD cards from 4 to 32 GB.

Optional Features

Ask your authorized representative about the following enhancement options:

• Peel Dispenser: Peels off labels one at a time before printing the next label. Liner is ejected to

front of printer.

• Media Cutter: Automatically cuts printed media when the media exits the printer.

• RFID MP2 Encoder: The RFID (Radio Frequency Identification) UHF encoder reads and writes

information to smart labels (with embedded RFID tags) with a pitch typically two to six inches.

These labels are used on shipping cartons and pallets. Not available as a field installed option

(factory only).

• Premium Asian Fonts: A selection of three different purchasable Asian fonts can be provided

(one font per SD card). These Asian fonts include Hanzi GB, Kanji SJIS, and Hangul. They are

available for use when the SD card is installed.

• QCMC (Quick Change Memory Card): The QCMC SD card provides the ability to duplicate an

entire printer’s firmware, saved configurations, and custom files quickly through the printer’s

control panel with a user friendly interface.

• Bluetooth 4.2: The BT 4.2 adapter provides wireless communications protocol designed for low

power usage, within a short range. Not available as a field installed option (factory only).

• Wireless Network: This card provides wireless 802.11a/b/g/n/ac/b/g/n connectivity without

expensive cabling and reconfigurations required from a wired network. Wi-Fi Alliance certified.

PNE is standard with this option. Not available as a field installed option (factory only).

For more information about printer options, see Appendix B page 239.

18

Navigation / Enter

Status LED

RIGHT SOFT key

FEED Key

LEFT SOFT key

PAUSET key

2 Operation

Controls and Indicators

Power Switch

The power switch is located on the bottom back left panel of the printer. To apply

the | (ON) position. When you first power on the

on the color LCD control panel.

To remove power, place the power switch in the O (OFF) position.

printer, an initialization sequence will immediately appear

Control Panel

The control panel is located on the top of the printer and includes a Status LED, QVGA color display,

PAUSE key, FEED key, LEFT SOFT key, RIGHT SOFT key, and navigation keys (buttons) with the

ENTER button in the center. These are described in the following

tables.

power, place the switch in

The QVGA (quarter VGA) screen is a 320 x 240 pixel color display (non-touch). It is comprised of a Header

that shows the printer state and location with the User Interface (UI), the general display area, and a footer

used to show the purpose of the LEFT and RIGHT SOFT keys (when available).

The status LED indicates when the

• LED is on solid: ONLINE and Ready to Print.

• LED is off: OFFLINE and not accepting data.

• LED is flashing: Fault Indicator.

printer is ONLINE, OFFLINE, or when there is a fault condition:

19

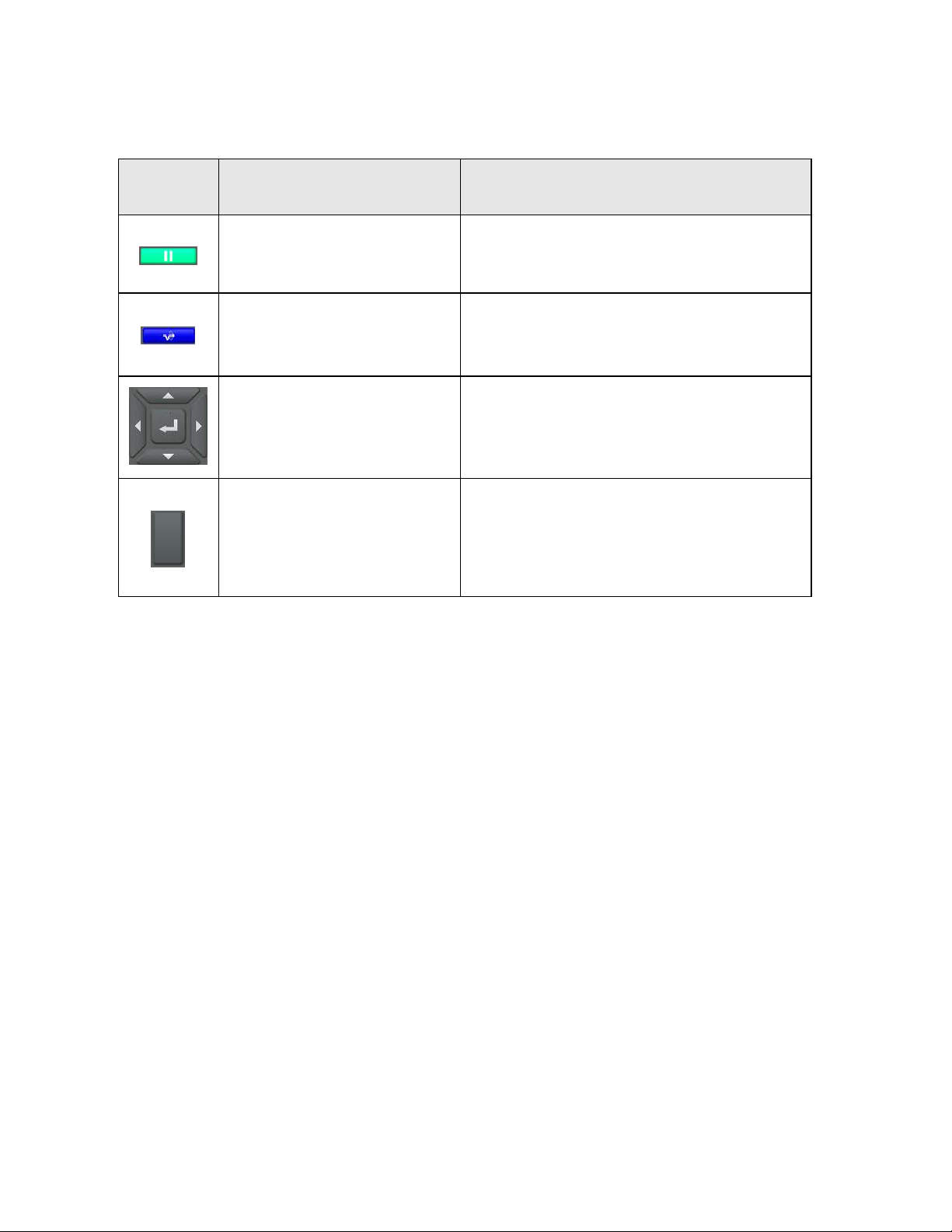

Button

Description

Functionality

PAUSE Key

Toggles the printer between

ONLINE and OFFLINE Modes.

When ONLINE, sets printer to OFFLINE Mode

and the UI to the Home Screen.

When OFFLINE, puts the printer back ONLINE.

FEED Key

Advances the media one label length. When

ONLINE, the menu System Control > Feed Key

Online must be enabled for this key to function.

Navigational Keys

The navigational menus consist

of up, down, left, and right keys

with a

ENTER button in the

center for selection.

Used to select icons, menu selection, and

navigation in the UI.

Soft Keys

There is a LEFT and RIGHT

SOFT key on the sides of the

navigational menus. The labels

on the footer of the UI will

explain their function.

Check the labels on the footer of the UI screen.

The meaning of the soft keys will vary.

NOTE: The printer is shipped with the ENTER button locked. To unlock, press the UP+DOWN arrow keys

simultaneously until you see the message “ENTER SWITCH UNLOCKED”.

Operating Modes

The operating mode can be selected through the control panel keys or can result from routine operations

such as powering on the printer.

Online: In ONLINE mode, the printer can receive and print data sent from the

key toggles the printer between the ONLINE and

Offline (Home): When the printer goes OFFLINE, the Status LED is off and the UI is in Home Screen. From the

Home Screen, the user has three different icons to choose from: 1) Wizard, 2) Settings, and 3) Calibrate. The

green highlighted icon is the current selection. Pressing the PAUSE key toggles the printer from

Screen to ONLINE mode.

Settings: When Settings is chosen from the Home Screen, the user has access to the printer menus by

navigating icons and traversing menu lists. Configurations can be saved using the Configs icon or by use of

the Auto-Save feature when returning ONLINE.

Wizard: When Wizard is chosen from the Home Screen, the user can perform different areas of printer setup

with the help of detailed explanations, references to online videos, and other material. On the first power-cycle,

the user will automatically be taken into the Printer Setup Wizard.

Fault: In fault mode, a fault condition exists that must be cleared before

LED indicator flashes, and the UI shows the Fault screen.

Before normal printing can continue, the fault must be corrected, the message cleared by pressing the

PAUSE key, and the printer placed ONLINE.

OFFLINE modes. The Status LED indicator is on.

host. Pressing the PAUSE

Home

printing can continue. The Status

20

Item

Description

1

The full model name includes the printer width and DPI.

2

The Network Printer Name can be set via telnet, SNMP, or the webpage

and is used with Ethernet or WLAN features.

3

The Ethernet IP address is displayed if the IP address is set (non-zero).

4

The active IGP Emulation and the active Host IO (based on last job).

5

This area is reserved for messages such as receiving data, batch

counters, and job status.

6

The RFID icon will show when the RFID option is installed and active. If

installed but not active it will be shown as grey and disabled.

7

The last loaded configuration is referred to as the “Active Config”.

8

The print head gauge is used to show how much of the print head has

been used in relationship to the warranty.

9

The ribbon gauge is used when a ribbon is installed (thermal transfer).

10

The WLAN IP address is displayed if the IP address is set (non-zero).

There is also a signal strength indicator next to the WLAN address.

11

The WLAN signal strength is displayed in dBm

Online Screen

When the printer is ONLINE and ready to receive data, the ONLINE screen is shown. By default, this will

be the first screen the user sees after the power-up process has completed. In order to demonstrate the

full features of the ONLINE Screen, the following options are assumed:

• Model T820 (203 DPI)

• Network is installed and IP is set

• Wi-Fi is installed and IP is set

• The printer has a Network Printer Name

• The Media > Handling > Print Mode is set to Transfer (ribbons).

• RFID is installed and enabled

• The Active Configuration has been saved under a custom name “Warehouse”

• The menu option under System > Control > Batch Counter is enabled.

The illustration above has labels associated with each of the ONLINE screen features which are described

in the table below. Notice there are differences for the wired Ethernet and wireless ONLINE screens.

21

Item

Description

12

The WLAN active channel

13

The WLAN SSID

If there is a warning that needs to be displayed while ONLINE, a popup message will come onto the

screen. For example, entering Power-Saver mode, Print Head Hot, etc.

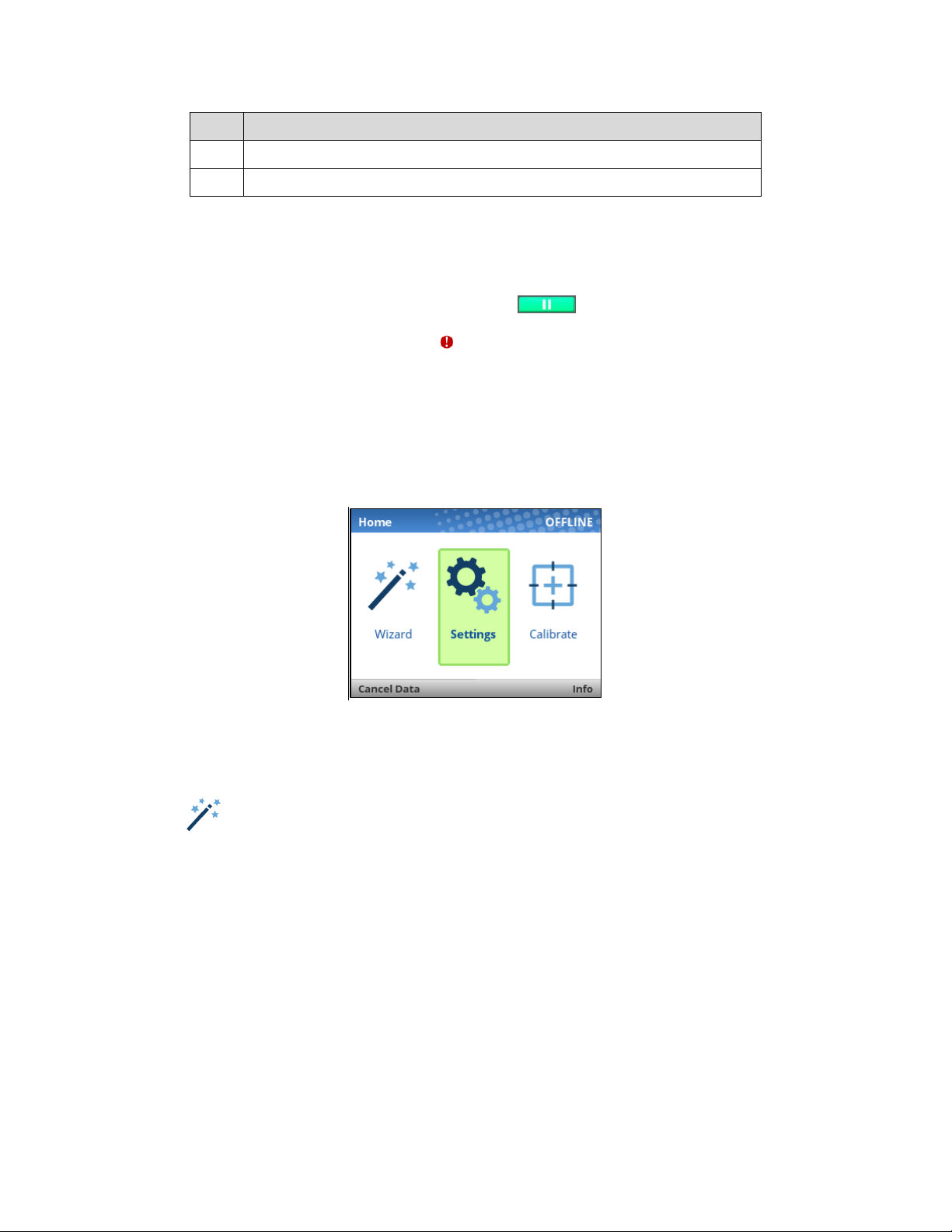

Offline (Home) Screen

When the printer is taken OFFLINE using the PAUSE Key , the UI will show the Home screen.

The Home screen will be the first screen seen by the user when transitioning from ONLINE to OFFLINE.

The right corner of the header may include the symbol in case there are faults in the system not yet

cleared.

Using the navigational keys, the user can move among three options:

• Wizard – Provides Setup Instruction, Web Resources, and other links to the Printronix website via QR

barcodes for Product Support.

• Settings – Provides access to the printer menu system for configuration.

• Calibrate – Makes Calibration convenient and easy to perform when media or ribbon are installed.

There are also functions for the LEFT and RIGHT SOFT keys. The LEFT SOFT key “Cancel Data” is

present if there is data within the buffer and the setting System > Control > Cancel Operation is enabled.

The RIGHT SOFT key labeled “Info” will show the current configuration as text on the UI and the user can

scroll through the data and/or print if desired.

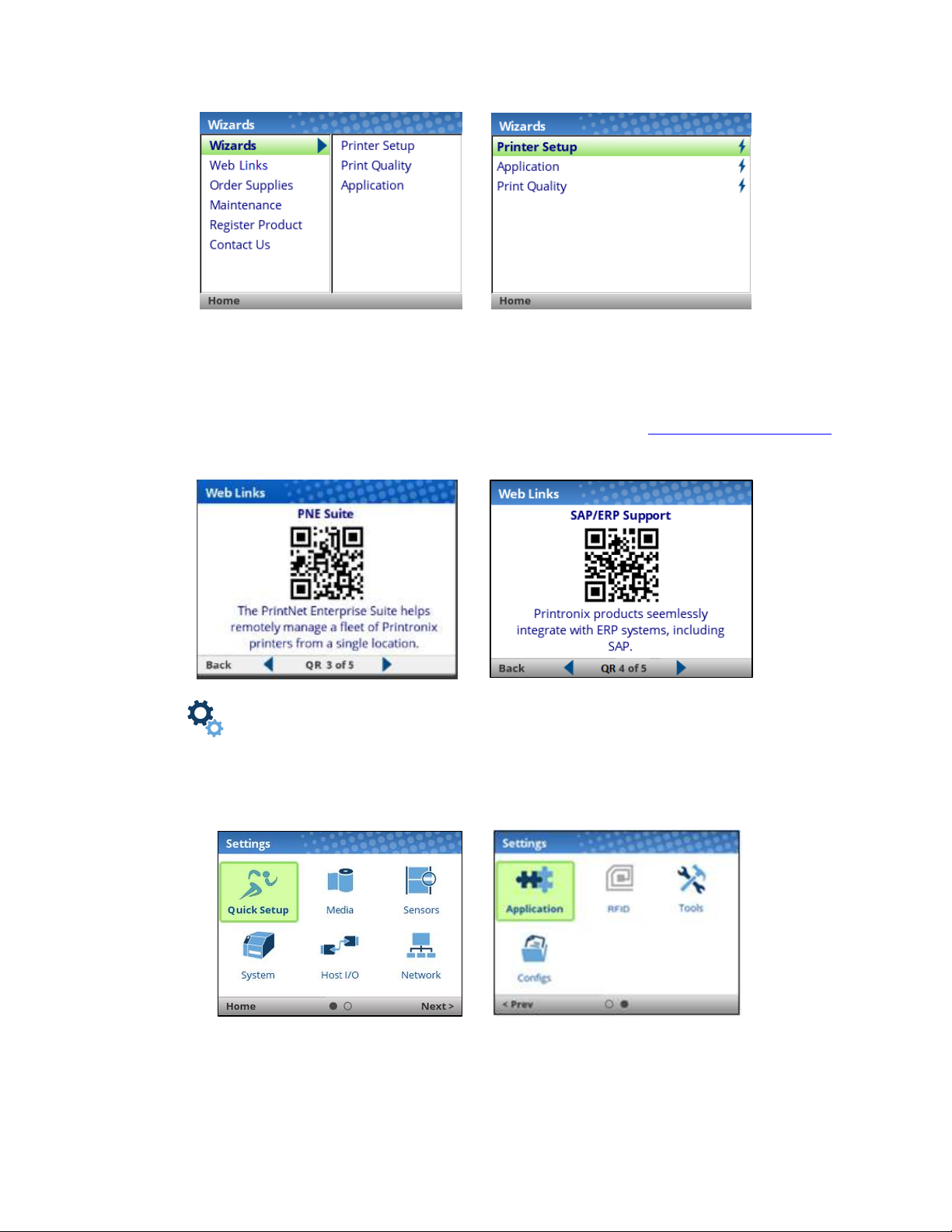

Wizard

The Wizard has several resources available as shown in the next figures. The greatest benefit of the

Wizard is the first subcategory “Wizards”. By highlighting this category (green) and pressing ENTER or the

RIGHT ARROW key, the user can then select the Wizard of choice to run:

• Printer Setup will help the user choose the proper display language, install ribbon & media, set media

and sensor options, calibrate, and run a test pattern to verify the product is working properly.

• Print Quality helps the user adjust the printer mechanically, and set Print Speed and Intensity of the

printer. A test printout helps the user in making the choices.

• Application helps the user setup the menu configuration particular to their label or application coming

from the host system.

22

→

When a Wizard has been completed (all steps executed until the end), the user is required to save their

configurations per usual procedure (see Configuration). The exception to this is the first time the printer is

powered up; in this case, the user is automatically taken into the Printer Setup Wizard and the

configuration is automatically saved to Config 1 when completed.

The Wizard also has support available in the form of QR barcodes for the other categories such as “Web

Links”, “Order Supplies”, etc. These QR barcodes provide links to the website www.PrintronixAutoID.com

to view online videos, manuals, drivers, including places where they can order supplies and register their

product.

→

Settings

The Settings section of the menu represents the heart of the OFFLINE process in which users will peruse

the full menu set, edit menus, run diagnostics, and save configurations. The Settings section begins with

two pages of ICONs that can be selected using the navigational keys and the ENTER button.

NOTE: The printer is shipped with the ENTER button locked. To unlock, press the UP+DOWN arrow keys

simultaneously until you see the message “ENTER SWITCH UNLOCKED”.

23

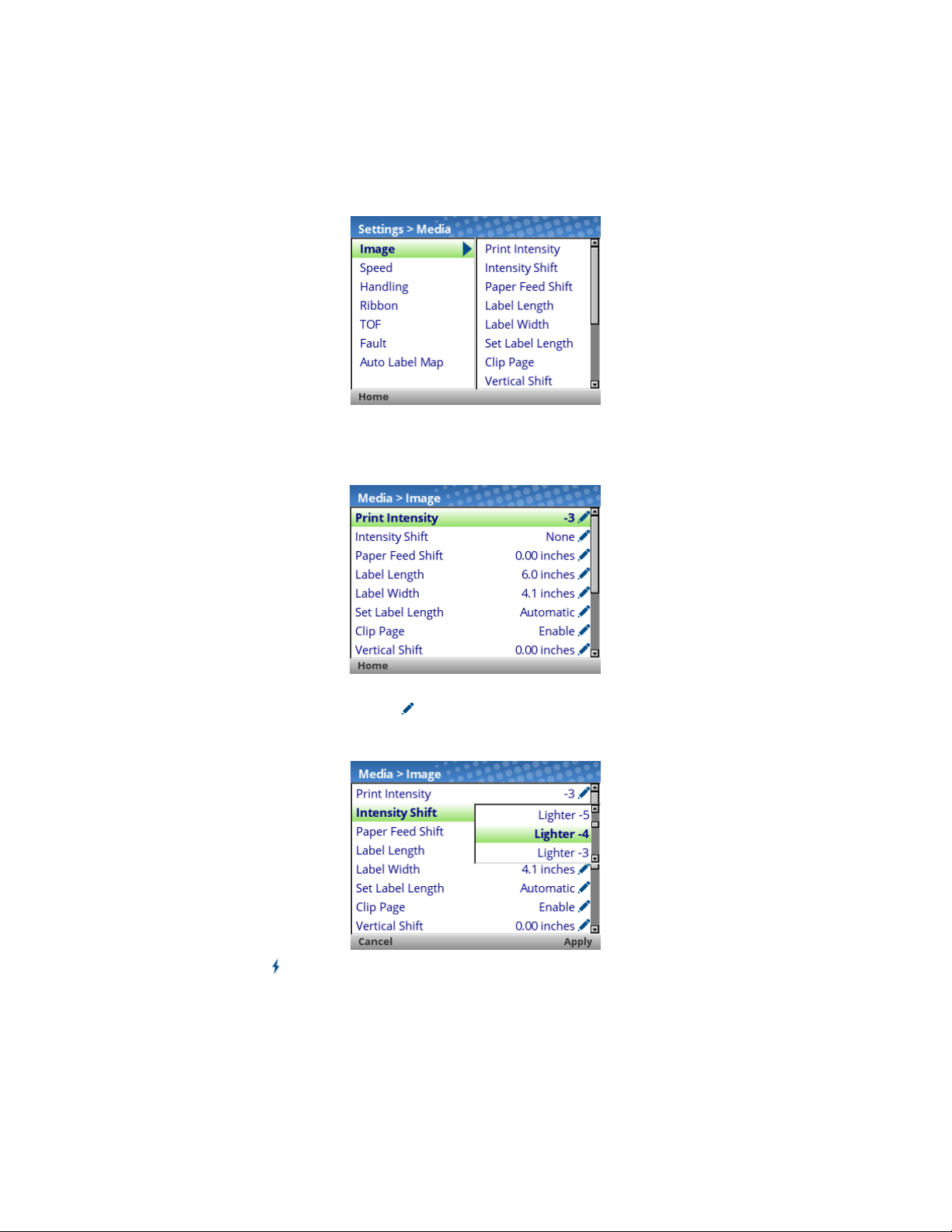

When an ICON is selected, the user moves into the View Level in which the screen is divided with the

submenus on the left and the menu subsections on the right. As they traverse the submenus using the

up/down arrow keys, the menu subsections on the right change so that users can quickly see the menu

contents.

To view the full contents of a particular subsection or edit their menus, the user can either press ENTER or

use the RIGHT ARROW key to get into the Edit Level. Conversely, the user can hit the LEFT ARROW key

to return to the previous screen.

When in the Edit Level, the user can scroll the menus and their values using the up/down arrow keys. The

user can edit any menu that has the icon by pressing the ENTER key, changing the value, and

confirming their change using the “Apply” soft key on the right. There is also a “Cancel” soft key on the left,

if the user does not want to accept the change.

If the menu has a bolt icon, this is an executable menu and pressing the ENTER key will result in a

particular action (e.g., running a print test, clearing statistics). If the menu does not have any icon, then it is

a read-only menu and pressing ENTER key will not have any effect.

24

Calibrate

Calibration must be performed whenever new media or ribbon is installed or any configuration parameter

that affects sensors is modified. Selecting this shortcut ICON and pressing the ENTER key will activate the

Auto-Calibrate function, also available in Sensors > Calibrate > Auto Calibrate.

Fault

When faults occur, the user will be notified with the following screen on the display. The red color is used

to make a clear indication that the printer needs attention.

Users can follow the simple instructions shown in the screen or request additional help with the faults by

using the RIGHT SOFT key “Fault Help” if available. When Fault Help is selected, the user will be provided

a set of screens to help them through the process. However, Fault Help is only offered for faults that are

complex or require several steps with the printer mechanism.

The user can also choose via the LEFT SOFT key to go the “Home” screen, then to the Settings or

Wizard sections to adjust menu values (e.g., change media parameters, load Configs, etc.).

NOTE: The icon will be shown in the upper right corner as a reminder there is a fault that needs to

be cleared. Even when the user has completed all the steps necessary, the icon may continue

to be shown. Some faults are self-clearing in the OFFLINE state while other faults are cleared

only when returning ONLINE. If any fault was not successfully cleared, the Fault screen shown

above will reappear when the user attempts to return ONLINE.

Job in Process

There is no dedicated LED or status indicator for Job in Process. Users will know the printer is receiving

data instead via messages in the circled portion of the ONLINE screen as shown below.

When the printer is in ONLINE mode and data is being received and being processed, the message “Job

in Process” will be shown in the message area. After the job has been printed the message will go away. If

the user is printing in batch mode and the option System > Control > Batch Counter is enabled, the page

count will have priority over the ‘Job in Process’ message.

25

When the printer is in OFFLINE mode and in the Home screen, the LEFT SOFT key will be labeled “Cancel

Data” if there is Data in Buffer when the printer is taken OFFLINE. If there is no Data in Buffer, then the LEFT

SOFT key label will not show anything. In order for the Cancel Data operation to be available, the menu

System > Control > Cancel Operation must be enabled.

Media Handling Modes

Before you load media, you must decide which media handling mode to use:

• Continuous. Prints on the media and sends it out the front of the printer.

• Tear-Off Strip. Prints on the media and sends it out the front until the

positions the trailing edge of the last label over the tear bar for removal.

• Peel-Off. When the optional internal peel-off rewinder is installed, the printer

die-cut labels from the liner without user assistance. A

remind you to remove the label before the next one can be printed. For more information, see

Label Peel-Off.

• Cut. When the optional media cutter is installed, the printer automatically

label is printed or can cut the media after a

Active IGP Emulation cut

Once you have decided on the mode, configure the printer.

command.

specified number of labels have been printed using the

“Remove Label” message will display to

print buffer is empty. It then

prints and peels

cuts media after each

Setting Up the Printer

This section describes the procedures for loading various types of ribbon and media.

The term “media” in this manual refers to all the different kinds of paper, label, or tag stock material that

can be printed on by the printer. Your thermal printer can print on continuous paper, adhesive backed

labels, or non-adhesive tags packaged in roll or fanfold form.

For clarity, all operator touch points are blue in color.

IMPORTANT For best result, use only genuine Printronix supplies. See “Supplies and

CAUTION

Accessories”.

Do not wear rings or other metallic objects while servicing any interior area of

the printer.

CAUTION DO NOT TOUCH the printhead or the electronic components under the pivoting

deck. The discharge of electrostatic energy that accumulates on the surface of

the human body or other surfaces can damage or destroy the printhead or

electronic components used in this device.

CAUTION Do not close the pivoting deck without label stock installed between the

printhead and the platen, because debris on the platen may damage the

printhead.

IMPORTANT Adhesive backed labels that DO NOT lay flat on the liner can jam the printer.

This can cause the label to peel off the liner. The exposed edges can stick to the

label guides and rollers inside the printer.

If you run out of labels while printing, do not turn off the printer while reloading

labels, because you can lose data.

26

27

Note: Please follow the direction when

installing the ribbon spindle.

Loading Ribbon

For direct thermal media (no ribbon required), go to “Loading Media” section.

IMPORTANT Clean the printhead, platen roller, and media sensors every time you change the

ribbon. See Cleaning the Printhead, Platen Roller, Media Sensors/Damper.

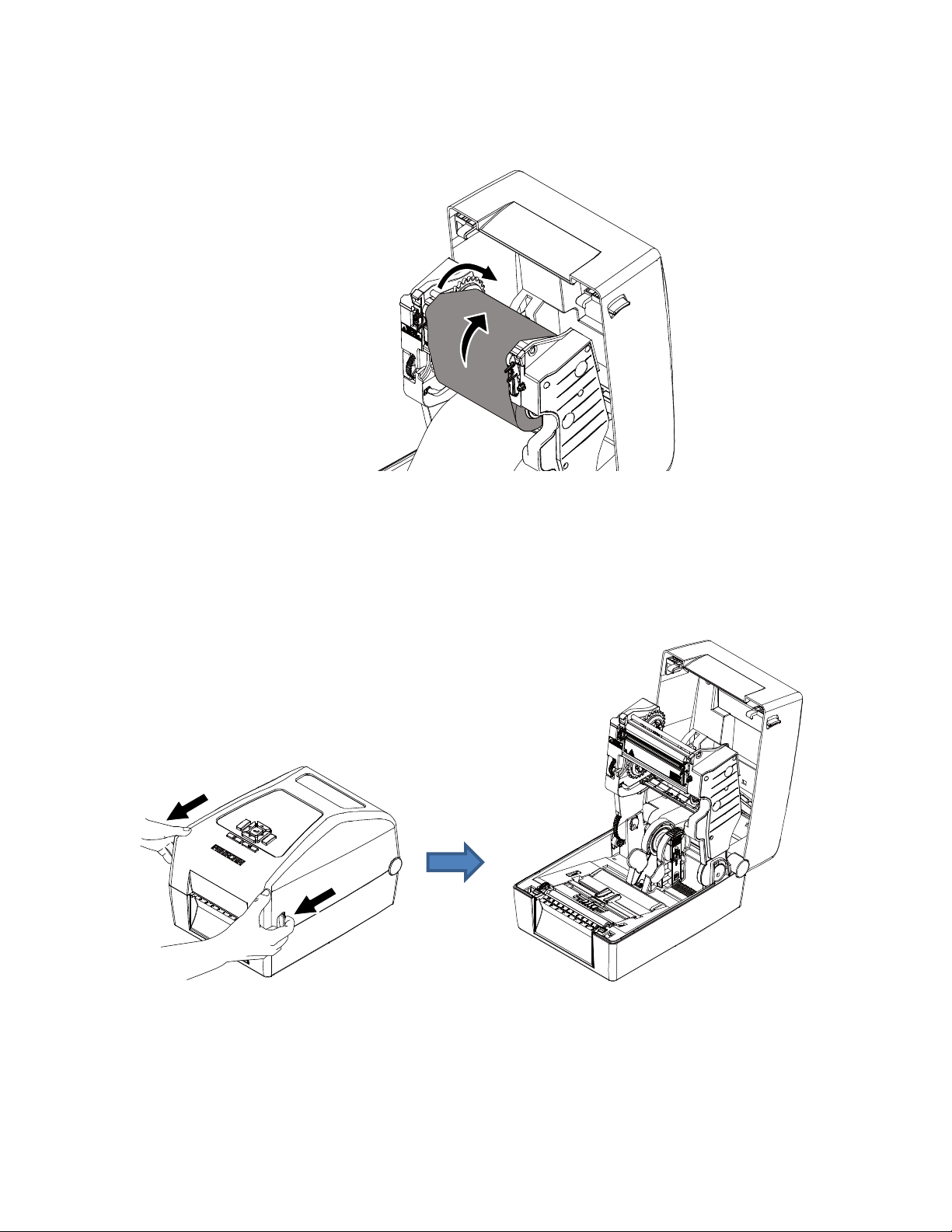

1. Open the printer top cover by pulling the blue levers, located on each side, toward the front of the

printer, then lift the top cover.

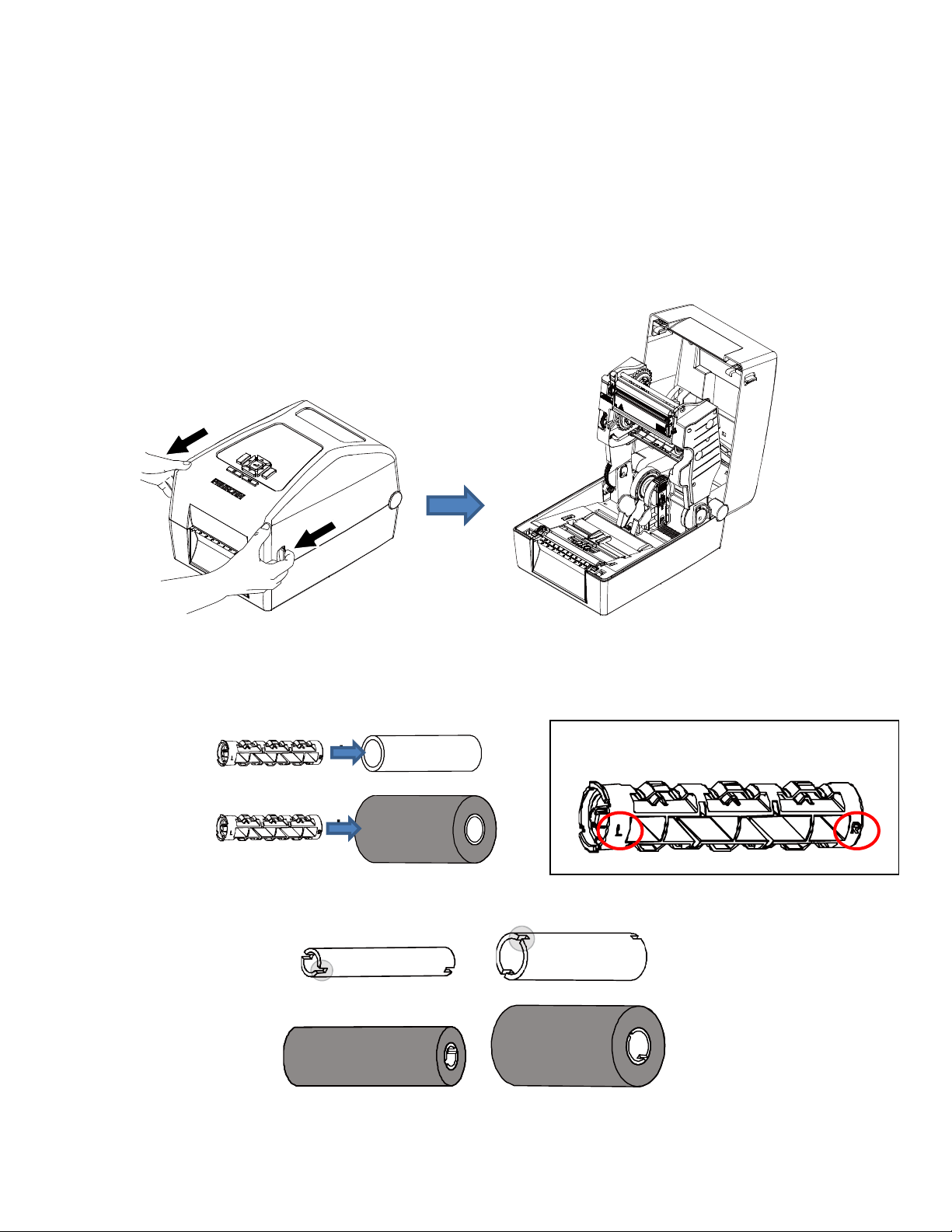

2. T800 supports 3 kinds of paper core for ribbon.

▪ For 1 inch paper core without notches, please insert the ribbon spindles into the paper core and

ribbon.

▪ For 1 inch & 0.5 inch paper core with notches, do not need to install the ribbon spindles.

28

Note: Please insert the right side of spindle

first. Then, insert the left side to the

hole at the left side of the blue hub.

Ribbon

Paper core for rewinding

the used ribbon

3. Install the paper core and ribbon to the hubs. For 0.5 or 1 inch paper roll with notches on both sides,

please insert them at the hubs directly.

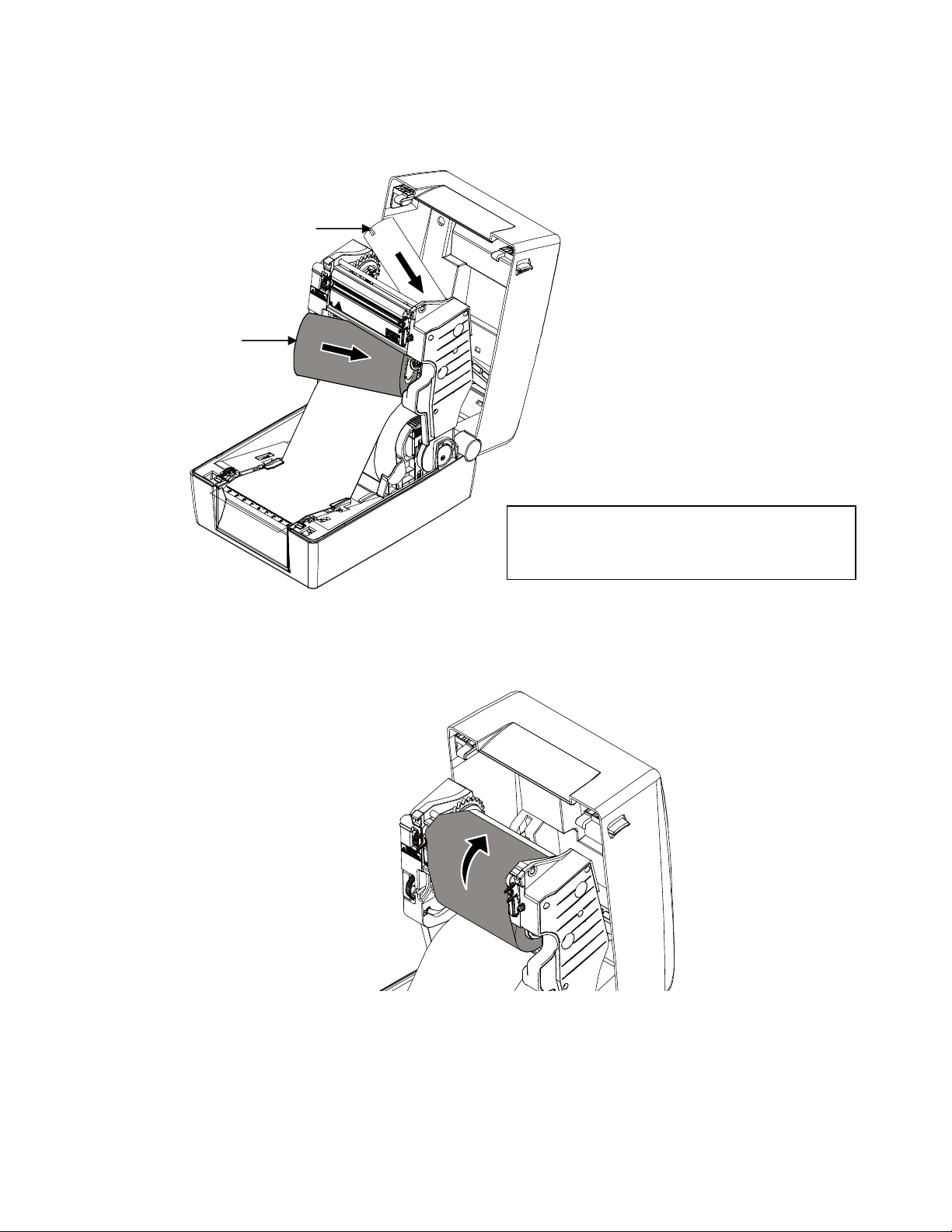

4. Pull the leader of the ribbon through the print head and stick the leader of the ribbon onto the ribbon

rewind paper core.

29

5. Turn the blue ribbon rewind hub until the ribbon plastic leader is thoroughly wound and the black

section of the ribbon covers the print head.

Loading Media

1. Open the printer top cover by pulling the blue levers , located on each side, toward the front of the

printer, then lift the top cover.

30

Media guide

Black mark

sensor

RFID antenna

slide (if equipped)

2. Separate and hold open the blue media holders.

3. Place the roll between the holders and close them onto the core.

4. Separate the blue media guides.

Note:

▪ For black mark media or media with notch or holes used to indicate label length, the blue Black

Mark sensor is moveable. Slide it to correct position for detecting.

▪ For RFID model, slide the blue antenna slide to the correct position.

31

5. Place the paper, printing side face up, through the media sensor and place the label leading edge onto

the platen roller. Move the blue media guides to fit the label width.

6. Press down on both sides of the top cover to close it gently.

7. Initiate Auto Calibrate via the Home Screen ICON , selecting this shortcut ICON and pressing the

ENTER key will activate the Auto-Calibrate function. Calibration may also be activated via the Sensors

menus within the Settings section (Sensors > Calibrate > Auto Calibrate).

Note: Calibration must be performed whenever new media or ribbon is installed or any configuration

parameter that affects the sensors is modified.

Your printer is equipped with media sensors that detect the top-of-form position on media with label length

indicators (gaps, notches, holes, or black marks). These sensors also detect when a Paper Out condition

exists.

32

Loading External Media

If using either an external media holder or folded labels, feed the media through the rear external label

entrance chute.

1. Open the printer top cover by pulling the blue levers, located on each side, toward the front of the

printer, then lift the top cover.

2. Separate and hold open the media holders.

3. Set the media holder lock switch to down to keep the media holders separated.

4. Feed the paper from rear external label entrance chute, printing side face up, through the media

sensor and place the label leading edge onto the platen roller. Move the media guides to fit the label

width.

5. Press down on both sides of the top cover to close it gently.

6. Initiate Auto Calibrate via the Home Screen ICON , selecting this shortcut ICON and pressing the

ENTER key will activate the Auto-Calibrate function or initiate calibration via the Sensors menus

33

Black Mark Sensor (Moveable/ Reflective)

Gap Sensor (Fixed/ Transmissive)

The black mark sensor position is moveable.

Move the triangular mark (

▽) directly into the

path of the black mark on the underside of the

media, or extraneous cut-out (notch or hole) to be

used for detection. Please make sure there is no

dark pre-printing or RFID tags that could cause

false black mark detection or paper out faults

within the path of the sensor.

The gap sensor is in a fixed position in the center,

covering an offset 4 mm to right or 7 mm to left

from center. The default is located in center of

offset 4 mm. Please make sure the media has no

vertical gap, rounded die-cut label corners or dark

pre-printing that could cause false gap detection

or paper out faults.

Gap sensor

(Transmitter)

Gap sensor (Receiver)

Black Mark sensor

(Transmitter &

Receiver)

within the Settings section (Sensors > Calibrate > Auto Calibrate).

Positioning the Media Sensors

Your printer is equipped with two media sensors that detect the top-of-form position on media with label

length indicators (gaps, notches, holes, or black marks). These sensors also detect when a Paper Out

condition exists. You may select via the Control Panel which sensor will be used, based on the type of

media to be printed.

34

Avoid Dark

Pre-printing

Extraneous

Cut-out

Vertical Gap and Rounded

Die-cut Label Corners

35

Sensing Different Media Types

The printer’s media sensors can detect the different types of label length

media types. This is accomplished by selecting

Sensors > Control > Gap/Mark Sensor menu or within the “Printer Setup” Wizard.

1. Press the PAUSE key to place the printer OFFLINE (Home Screen).

2. Find the Settings ICON and press ENTER.

3. Press the UP + DOWN ARROW keys together until “ENTER SWITCH UNLOCKED” displays.

4. Find the Sensors ICON and press ENTER.

5. Select the “Control” submenu and press ENTER.

6. Find the “Gap/Mark Sensor” option and press ENTER to edit this menu. Find the option that matches

the type of label length indicators on the installed media displays:

Disable. Select when using media with no label length indicators (no gaps, notches, holes, or black

marks) or when you want the printer to ignore all existing label length indicators on the installed media.

Mark. Select when using media that has horizontal black marks

liner or tag stock or when using media with notches or holes as label length

Gap. Select when using media with a liner space between die-cut

located on the topside of the label.

the correct sensor option: Gap, Mark, or Disable under

indicators on a large variety of

located on the underside of the label

indicators.

labels or has horizontal black marks

NOTE: When you select Disable, the length of each label is based on the

Length menu or the value

sent via host software.

NOTE: If the printer detects a false PAPER OUT message when you change

vice-versa, find the Home Screen and run Calibrate

or

7. Press ENTER to enable the displayed option or use the RIGHT SOFT key labeled “Apply”. An asterisk

.

(*) appears next to the selection

8. Press the PAUSE key or the LEFT SOFT key labeled “Home” to return to the Home Screen.

9. Review Media with Gaps

10.

1. Media with a horizontal liner space between die-cut labels or horizontal black marks located on the

upper side of the label liner.

2. Select “Gap” in the Sensors > Control > Gap/Mark Sensor menu.

3. Perform an Auto Calibrate. See Running Auto Calibrate on page 38.

11. Calibrating the Media Sensors on page 37. Perform the Auto Calibrate procedure per Running Auto

Calibrate on page 38.

Media > Image > Label

to Gap or Mark sensing

36

Sensors > Control > Gap/Mark Sensor

The available options specify the sensor type needed for detecting the

Top-of- Form position on media with label length indicators (gaps, notches,

holes, or black marks).

Disable

Select when using media with no label length

indicators (no gaps, notches, holes, or black marks), or

when you want the printer to ignore all existing label

length indicators on the installed media.

Mark

Select when using media that has horizontal black

marks located on the underside of the label liner or tag

stock. Also used for tag stock with notches, or holes

used as label length indicators.

Gap

Select when using media with a horizontal liner space

between die-cut labels or horizontal black marks

located on the upper side of the label liner.

Media with No Label Length Indicators

1. When using media without label length indicators (no gaps, notches,

want to ignore all existing length indicators,

the center of the media so it can detect when a

2. Select “Disable” in the Sensors > Control > Gap/Mark Sensor menu. See Section “Sensors > Control”.

3. Perform an Auto Calibrate.

place the triangle mark ▽ on the media sensor assembly in

Paper Out condition exists.

holes, or marks) or when you

Media with Underside Horizontal Black Marks

1. Position the triangle mark

located

2. Select “Mark” in the Sensors > Control > Gap/Mark Sensor menu.

3. Perform an Auto Calibrate.

on the underside of media.

▽ on the media sensor assembly in the center of the horizontal black marks

Media with Gaps, Notches or Holes

1. Position the triangle mark

in media.

2. Select “Mark” in the Sensors > Control > Gap/Mark Sensor menu.

3. Perform an Auto Calibrate. See Running Auto Calibrate on page 38.

▽ on the media sensor assembly in the path of the gaps, notches, or holes

Media with Gaps

4. Media with a horizontal liner space between die-cut labels or horizontal black marks located on the

upper side of the label liner.

5. Select “Gap” in the Sensors > Control > Gap/Mark Sensor menu.

6. Perform an Auto Calibrate. See Running Auto Calibrate on page 38.

37

Calibrating the Media Sensors

Due to manufacturing differences in media, the media sensors

the label and the liner or the label

a

label or display a fault message such as “GAP NOT DETECTED” or “PAPER OUT”.

Media sensor sensitivity and reliability can be improved by changing the

Thresh and/or Sensors > Control > Paper Out Thresh values. You can change

automatically by performing an Auto Calibrate or Manual Calibrate procedure from the Sensors >

Calibrate menu section. (The changes take effect immediately within the current configuration menu.)

Auto or Manual Calibrate is completed successfully when the displayed

matches that of the installed media. When

from the

selected, the Sensed Distance should match the length

leading edge of the next black

When you have completed Auto or Manual Calibrate, you can verify the new

the FEED key several times. Each time you

correct Top-of-Form

Once you confirm the correct values, save them to the desired configuration

printer.

trailing edge of one gap to the trailing edge of the next gap (or one label + one gap). When Mark is

position of the next label.

and the black mark. When this occurs, the printer may intermittently skip

Gap is selected, the Sensed Distance should match the length

mark.

press FEED, media advances one label and stops at the

may have difficulty differentiating between

Sensors > Control > Gap/Mark

these values manually or

Sensed Distance value correctly

from the leading edge of one black mark to the

values are correct by pressing

menu before powering off the

Running Auto Calibrate

You can initiate Auto Calibrate via the Home Screen ICON or via the Sensors menus within the

Settings section.

NOTE: Verify that the Gap/Mark Sensor option (Gap, Mark, or Disable) matches the installed media.

Check that the media sensors are horizontally positioned to permit

indicators. See Positioning the Media Sensors.

Make sure the Media > Image > Label Length value matches the physical length of the installed

media. Entering the

calibrate for long labels (so actual gaps, notches, and marks can be detected) and reduce the

amount of media advanced for short labels.

If you try to do an Auto Calibrate when Peel-Off Media Handling is

display “CANNOT CALIBRATE” error. Before you can do an Auto Calibrate, you must select

another media handling mode.

1. Press the PAUSE key to place the printer OFFLINE (Home Screen).

2. Select the Calibrate ICON and press the ENTER key.

3. Media advances until it can accurately detect the label length

Top-of-Form position. The Sensed

4. Auto Calibrate is successful when the Sensed Distance value correctly

media:

Gap/Mark Sensor = Gap:

length of one gap, notch, or hole.

Gap/Mark Sensor = Mark: The Sensed Distance value is the

of one black mark to the

Gap/Mark Sensor = Disable: Not applicable. If Gap/Mark Sensor is

Distance value will not be updated.

If “GAP NOT DETECTED” displays, run Auto Calibrate again.

correct length forces the printer to advance media far enough during

Distance value will then display for one second.

The Sensed Distance value is the physical length of one label plus the

physical distance from the leading edge

leading edge of the next black mark.

sensing of the label length

enabled, the LCD will

indicators and then stops at the

matches that of the installed