Page 1

R

Page 2

Page 3

P/N 704766–001, Rev C

R

Page 4

Communication Notices

Federal Communications Commission (FCC) Statement:

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user

will be required to correct the interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order

to meet FCC emission limits. Printronixr is not responsible for any radio or

television interference caused by using other than recommended cables and

connectors or by unauthorized changes or modifications to this equipment.

Unauthorized changes or modifications could void the user’s authority to

operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Canadian Department of Communications Compliance Statement:

This Class A digital apparatus meets all requirements of the Canadian

Interference–Causing Equipment Regulations.

Avis de conformité aux normes du ministère des Communications du

Canada:

Cet appareil numérique de la classe A respecte toutes les exigences du

Règlement sur le matériel brouilleur du Canada.

European Union (EC) Electromagnetic Compatibility Directives:

This product is in conformity with the protection requirements of EC Council

Directive 89/336/EEC on the approximation of the laws of the Member

States relating to electromagnetic compatibility. Printronixr cannot accept

responsibility for any failure to satisfy the protection requirements resulting

from a non-recommended modification of the product, including the fitting

of non-Printronixr option cards.

Page 5

Dieses Gerät ist berechtigt in Übereinstimmung mit dem deutschen EMVG

vom 9.Nov.92 das EG–Konformitätszeichen zu furhren.

Properly shielded and grounded cables and connectors must be used in order

to reduce the potential for causing interference to radio and TV

communication and to other electrical or electronic equipment.

This product has been tested and found to comply with limits for Class A

Information Technology Equipment according to CISPR 22/European

Standard EN 55022. The limits for Class A equipment were derived for

commercial and industrial environments to provide reasonable protection

against interference with licensed communication equipment.

Warning: This is a Class A product. In a domestic environment this product

may cause radio interference in which case the user may be required to take

adequate measures.

Dieses Gerät erfüllt die Bedingungen der EN 55022 Klasse A. Für diese

Klasse von Geräten gilt folgende Bestimmung nach dem EMVG:

Geräte dürfen an Orten, für die sie nicht ausreichend entstört sind, nur mit

besonderer Genehmigung des Bundesminesters für Post und

Telekommunikation oder des Bundesamtes für Post und Telekommunikation

betrieben werden. Die Genehmigung wird erteilt, wenn keine

elektromagnetischen Störungen zu erwarten sind.

(Auszug aus dem EMVG vom 9.Nov.92, Para.3, Abs.4)

Hinweis: Dieses Genehmigungsverfahren ist von der Deutschen Bundespost

noch nicht veröffentlict worden.

Printronix, Inc. makes no representations or warranties of any kind regarding

this material, including, but not limited to, implied warranties of

merchantability and fitness for a particular purpose. Printronix, Inc. shall not

be held responsible for errors contained herein or any omissions from this

material or for any damages, whether direct, indirect, incidental or

consequential, in connection with the furnishing, distribution, performance or

use of this material. The information in this manual is subject to change

without notice.

This document contains proprietary information protected by copyright. No

part of this document may be reproduced, copied, translated or incorporated

in any other material in any form or by any means, whether manual, graphic,

electronic, mechanical or otherwise, without the prior written consent of

Printronix, Inc. All rights reserved.

Page 6

Trademark Acknowledgements

Postscript is a trademark of Adobe Systems, Inc.

IBM is a registered trademark of International Business Machines

Corporation.

HP is a registered trademark, and PCL is a trademark of Hewlett-Packard

Company.

Centronics is a registered trademark of Genicom Corporation.

Dataproducts is a registered trademark of Hitachi.

Epson is a registered trademark of Epson Seiko Corporation.

IGP, LinePrinter Plus, and Printronix are registered trademarks, and

DuraFusion, LaserLine, PGL, PSA, and Ribbon Minder are trademarks of

Printronix, Inc.

Magnum and QMS are registered trademarks, and Code V is a trademark of

Quality Micro Systems, Inc.

Microsoft, GW-BASIC, MS, and MS-DOS are registered trademarks, and

QuickBASIC, QBASIC, and Windows are trademarks of Microsoft

Corporation.

This product uses Intellifont Scalable typefaces and Intellifont technology.

Intellifont is a registered trademark of Agfa Division, Miles Incorporated

(Agfa).

CG, Garth Graphic, Intellifont, and Type Director are registered trademarks,

and Shannon and CG Triumvirate are trademarks of Agfa Division, Miles

Incorporated (Agfa). CG Bodoni, CG Century Schoolbook, CG Goudy Old

Style, CG Melliza, Microstyle, CG Omega, and CG Palacio are products of

Agfa Corporation. CG Times, based on Times New Roman under license

from The Monotype Corporation Plc is a product of Agfa.

Univers is a registered trademark of Linotype AG and/or its subsidiaries.

Letraset is a registered trademark, and Aachen, Revue and University Roman

are trademarks of Esselte Pendaflex Corporation.

Futura is a registered trademark of Fundición Tipográfica Neufville, S.A.

Page 7

ITC Avant Garde Gothic, ITC Benguiat, ITC Bookman, ITC Century, ITC

Cheltenham, ITC Clearface, ITC Galliard, ITC Korinna, ITC Lubalin Graph,

ITC Souvenir, ITC Tiepolo, ITC Zapf Chancery, and ITC Zapf Dingbats are

registered trademarks of International Typeface Corporation.

Albertus, Gill Sans, and Times New Roman are registered trademarks, and

Monotype Baskerville is a trademark of The Monotype Corporation Plc,

registered in the U.S. Pat. and TM office and elsewhere.

Hiroshige and Marigold are trademarks of AlphaOmega Typography, Inc.

COPYRIGHT 1996, 2000, PRINTRONIX, INC.

Page 8

Page 9

Volume 1

Table of Contents

1

Introduction

English:

General Safety Precautions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Safety Precautions 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Label Locations 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deutsch:

Allgemeine Sicherheitsvorkehrungen 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sicherheitsvorkehrungen beim Installieren 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Anbringungsorte der Sicherheitsetiketten 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Manual 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Locate Information 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notices and Special Information 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switches and Display Messages 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documents 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Features 1–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Table of Contents

Setup

Power Requirements 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select a Site 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpack and Level the Printer 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connect the Cables 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Signal Cables 2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Consumables 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 10

3

Consumables

Install Consumables (Initial Printer Setup) 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Photoreceptor Drum 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Add the Developer 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Developing Unit 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Toner Cartridge 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading Fanfold Paper 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading Cut–sheet Paper 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Cassette Paper Size 3–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Diskettes 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Power Supply Voltage 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Consumables 3–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Photoreceptor Drum 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Developer 3–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Developing Unit 3–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Replacing the Toner Cartridge 3–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Waste Toner Bottle 3–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scheduled Maintenance

General Cleaning 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Quality Problems 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Tools 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Level Page Counts 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About the Page Counter Software 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Schedule 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Schedule 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning inside the Front Cover 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Transport Unit 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Paper Feed Section 4–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Photoreceptor Drum 4–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Main Charger 4–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Pre–charger and Transfer/Separator Charger 4–25. . . . . . . . . . . . . . . . . . . . .

ii

Table of Contents

Page 11

Cleaning the Selfoc Lens (LED Print Head) 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Discharge LED 4–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Fuser Unit Cover Glass and Lamp Filter 4–31. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Developing Unit / Replacing Developer 4–34. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Pickup Rollers 4–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Reverse Rollers 4–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Flash Power Supply Filter 4–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

Principles of Operation

Printing System Descriptions 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Printing Process 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How Images are Processed 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Mapping 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Recovery 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Photoconduction Section 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discharge 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Charging 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exposure 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Developing Section 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Developing Unit 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Principles of Developing 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer/Separation Section 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Separation 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fixing Section 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preheating 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash Fixing 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Section 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre–cleaning Charging 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drum Cleaning 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

iii

Page 12

Paper Feed, Transport, and Output Sections 5–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Detection 5–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Loading 5–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Transport 5–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Output 5–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Parking 5–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive System Descriptions 5–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drum Drive 5–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Developing Roller Drive 5–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Unit Feed Roller Drive 5–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gate Drive 5–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Unit Drive 5–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tractor Drive 5–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Perforation Cutter Drive 5–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Separation Claw Drive 5–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cut–sheet Paper Feed Section Drive 5–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control System Descriptions 5–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Transport System Monitoring 5–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Rotation Control 5–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drum Surface Potential Control 5–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Toner Density Control 5–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remaining Toner Level Monitoring 5–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waste Toner Monitoring 5–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Temperature Monitoring 5–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuser Temperature Monitoring 5–55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Developing Bias Adjustment 5–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Sequences 5–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronics Initialization 5–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Initialization 5–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Operations 5–64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Operations 5–74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

Table of Contents

Page 13

6

Electrical and Wire Data

System Configuration 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interconnect diagram 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensors/Actuators connected to MPU Board 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensors/Actuators connected to I/O Board 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input / Output Signals 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MPU Board Input/Output Signals 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Board Input/Output Signals 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Board Input/Output Signals 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Interface 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O board 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Array Unit 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash Power Supply 6–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Developing Unit 6–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High–voltage Power Supply Unit 6–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Explanation of Circuits According to Function 6–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drum Surface Potential Control Circuit 6–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Developing Bias Control Circuit 6–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Toner Density Control Circuit 6–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drum Motor Control Circuit 6–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tractor Motor Control Circuit 6–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Unit Feed Motor Control Circuit 6–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Elevator Motor Control Circuit 6–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cutter Motor Control Circuit 6–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 6–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Power Supply Unit For Flash 6–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

v

Page 14

7

Troubleshooting

Overview 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jam Detection Sensors 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Components 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Views 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front View with Cover Removed 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear View with Cover Removed 7–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Unit Locations 7–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Block Diagram 7–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Control Menu 7–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Diagram 7–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Surface Volts 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bias Volts 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Time 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cut–sheet X Adj. and Cut–sheet Y Adj. 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan–fold X Adj. and Fan–fold Y Adj. 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset Toner Full 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan–fold Paper Jams 7–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper jam near the tractor 7–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper jam near the paper output section 7–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cut–sheet Paper Jams 7–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper jam at the back of the paper cassette 7–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper jam in the transport input section 7–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper jam in the transport output section 7–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper jam in the face–up or face–down paper path 7–24. . . . . . . . . . . . . . . . . . . . . . . .

Error Message Table 7–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

01 – Front Cover Open 7–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

02 – Paper Empty (fan–fold paper): Upon Power–on 7–32. . . . . . . . . . . . . . . . . . . . . . . . .

02 – Paper Empty (fan–fold paper): When Loading/Beginning Print 7–33. . . . . . . . . . . . .

03 – Paper Jam at Drum (B) 7–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

04 – Paper Jam at Fuser (C): Transport Section 7–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Table of Contents

Page 15

05 – Paper Jam at Fuser (D): Paper Output Section 7–37. . . . . . . . . . . . . . . . . . . . . . . . . . .

07 – Scuff Lever Open 7–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

08 – Cut–sheet Path Open 7–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

09 – Transport Motor Fail (complete stop) 7–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0A – Cutter Fail (front) 7–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0B – Cutter Fail (rear) 7–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0C – Transfer Platform Fail (upper) 7–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0D – Transfer Platform Fail (lower) 7–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 – Paper Jam at Drum (B) 7–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 – Paper Jam at Fuser (C) 7–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 – Paper Jam at Exit (D): Straight Output (face–up) 7–51. . . . . . . . . . . . . . . . . . . . . . . .

13 – Paper Jam at Exit (D): Cut–sheet Face–down Output 7–52. . . . . . . . . . . . . . . . . . . . .

14 – Tractor Speed Too High 7–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 – Tractor Speed Too Low 7–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 – Paper Jam at Entrance (A) 7–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17 – High Voltage Fail 7–57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 – Drum Motor Fail (complete stop) 7–59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 – Surface Voltage Too High 7–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1A – Surface Voltage Too Low 7–63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1B – Paper Jam at Entrance (A) 7–65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1E – Fuser Supply Fail 7–66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1F – Fuser Failure 7–68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 – Fuser Lamp Overheat 7–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26 – No Cleaning Unit 7–73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28 – Waste Toner Full 7–74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29 – No Waste Toner Box 7–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2A – Toner Empty 7–76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2B – Toner Density Too High 7–78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2C – Toner Density Too Low 7–78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32 – LED Head Overheat 7–80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

vii

Page 16

8

Engine Checker

Overview 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Engine Checker 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Control Panel 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Menu 8–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device Check Menu 8–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting a Mode/Item/Device 8–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading Device Status (input device check) 8–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driving/Stopping a Device (output device check) 8–14. . . . . . . . . . . . . . . . . . . . . . . . .

Volume Adjustment Menu 8–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Surface Potential 8–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Eraser Lamp 8–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drum Motor 8–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Feed Motor 8–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

Tractor Motor 8–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Toner Density 8–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Operation Menu 8–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan–fold Paper 8–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cut–sheet Paper 8–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Operation Menu 8–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading and Changing Data 8–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Board Adjustments

MPU Board Adjustment 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Feed Motor 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting NVRAM Values 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Vacuum Fan 9–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Pre–heating Lamp 9–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Board Adjustment 9–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Drum Motor 9–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Tractor Motor 9–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Table of Contents

Page 17

Adjusting the Drum Surface Potential Sensor – Procedure 1 9–11. . . . . . . . . . . . . . . .

Adjusting the Drum Surface Potential Sensor – Procedure 2 9–15. . . . . . . . . . . . . . . .

Adjusting the Eraser Lamp Input Voltage 9–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Toner/Developer Density Sensor 9–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Rotary and Dip Switches 9–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Confirming I/O Board Operation 9–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Confirming the Developing Bias Voltage Control Circuit 9–19. . . . . . . . . . . . . . . . . . .

Confirming the Main Charger Current Control Circuit 9–20. . . . . . . . . . . . . . . . . . . .

Confirming the Sleeve Motor Operation 9–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Confirming the Magroll Motor Operation 9–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Confirming the Toner Supply Clutch Operation 9–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Confirming the Head Cooling Fan Operation 9–22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Confirming the Head Blower Fan Operation 9–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Confirming the Drum Counter Operation 9–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Power Supply Board 9–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

Table of Contents

ix

Page 18

Volume 2

Table of Contents

10

Replacement Procedures

Overview 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Covers 10–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Cover 10–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Cover 10–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Top Cover 10–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stand Cover 10–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inside the Front Cover 10–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waste Toner Recovery Unit 10–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Developing Unit 10–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Toner Cartridge 10–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Photoreceptor Drum and Peripheral Equipment 10–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuser Unit 10–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer/Transport Unit 10–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inside the Rear Cover 10–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MPU Board and I/O Board 10–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Power Supply Board 10–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motors 10–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fans 10–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoids 10–59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Miscellaneous 10–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Under the Top Cover 10–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Array Unit 10–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High–voltage Power Supply Unit 10–73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cutter Unit 10–74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensors/Switches 10–77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gates 10–82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Behind the Stand Cover 10–83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Smoke Filter 10–83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

Table of Contents

Page 19

Flash Power Supply Unit 10–85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capacitors 10–89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other 10–92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tractor Removal 10–92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tractor Adjustment Procedure 10–94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Back–Feed Sensor 10–98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Near–End Sensor 10–98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel 10–99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Module 10–100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Rear Cover 10–101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motherboard 10–103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 10–105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling Fan 10–107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Floppy Disk Drives 10–109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

B

Specifications

Replacement Schedule A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Intervals A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Specifications A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Specifications A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host Interface A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emulations A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Characteristics A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Requirements A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Regulations A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electromagnetic Interference A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Characteristics and Environment A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Metric Conversion Tables

Table of Contents

xi

Page 20

C

Illustrated Parts List

Overview C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Tools C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List by Description C–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front View of Printer C–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Front Cover Assembly Open C–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Developer Assembly C–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Miscellaneous Details C–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Assembly & Photoreceptor Drum C–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Assembly C–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuser Assembly C–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base, WT Assembly (Waste Toner) C–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Back View of Printer C–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Back View of Printer, Closup C–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cut Sheet Output Assembly C–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Array C–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cut Sheet Feeder Assembly C–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front View, Left Side C–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Board C–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PNE Sensor Assembly (Paper Near–End Sensor Assembly) C–60. . . . . . . . . . . . . . . . . . . .

Controller Module Assembly C–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head Blower Fan Assembly C–68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Developer Drive Assembly C–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Details C–72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filter Assembly Box C–76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Blower Assembly C–78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply For Flash Lamp C–80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Miscellaneous Details C–82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P/S EU Assembly (Main Power Supply Assembly) C–84. . . . . . . . . . . . . . . . . . . . . . . . . . .

MPU PC Board C–86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Back View, Left Side C–88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drum Shaft Assembly & Belts C–94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Duct Flash Assembly C–96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xii

Table of Contents

Page 21

Bracket FU Connect Assembly (Fuser Unit Assembly) C–98. . . . . . . . . . . . . . . . . . . . . . . .

Back of Printer, Left Side C–101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation/Maintenance Tools C–108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D

Optional Cut Sheet Feeder

Physical Description D–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Feed Cassette D–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup and Connection D–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Principles D–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive principle D–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cassette principle D–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control principles D–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper level / Lower level paper size detector sensor D–11. . . . . . . . . . . . . . . . . . . . . .

Paper feed cassettes D–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper level / lower level paper empty sensor (PES1 / PES2) D–13. . . . . . . . . . . . . . . .

Cut sheet feed sensor (PFS), paper register sensor D–13. . . . . . . . . . . . . . . . . . . . . . . .

Paper timing sensor (PTS) D–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cut sheet pick up motor encoder (PME) D–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cut sheet feed motor encoder (FME) D–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper guide interlock switch (ICIL) D–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detection Errors D–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper level cassette section error D–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lower level cassette section error D–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer unit error D–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit sequencer section errors D–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Operation D–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cut Sheet Output Unit D–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Description D–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup and Connection D–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Principles D–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

xiii

Page 22

E

Optional Power Paper Stacker

Physical Description E–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup and Connection E–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Principles E–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Feed roller and transfer belt E–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Swinger E–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assisting Arm E–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Elevator Table E–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Principles E–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Unit Paper Sensor (PMS) E–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jam sensor (PPS) E–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper surface sensor 1/2 (PSS1/2) E–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stacker full sensor (SFS), Elevator down sensor (EDS) E–21. . . . . . . . . . . . . . . . . . . .

Stacker motor encoder (SME), Elevator motor encoder (EME) E–23. . . . . . . . . . . . . .

Swinger position sensor (SPS), Assisting arm position sensor (APS1) E–24. . . . . . . . .

Elevator Upper limit / Lower limit switches (LIMT1 / LIMT2) E–25. . . . . . . . . . . . . .

Safety sensors 1/2 (SS1/2) E–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Elevator keys (ESWA / ESWS / ESWD) E–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detection Errors E–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator call status error E–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serviceman call status error E–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Operation E–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Belt Removal Procedures E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Stacker Cover E–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inside the Left Frame E–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inside the Right Frame E–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Swinger Belts E–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Perforation Beater Belts E–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Elevator Belt E–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stacker Motor E–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xiv

Table of Contents

Page 23

F

Host I/O Interfaces

Overview F–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Considerations F–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Centronics Parallel Interface F–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Centronics Interface Connector Pin Assignments F–6. . . . . . . . . . . . . . . . . . . . . . . . .

Centronics Parallel Interface Signals F–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Centronics Parallel Interface Configuration F–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dataproducts Parallel Interface F–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dataproducts Interface Connector Pin Assignments F–9. . . . . . . . . . . . . . . . . . . . . . .

Dataproducts Parallel Interface Signals F–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dataproducts Parallel Interface Configuration F–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Termination Resistors F–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232 Serial Interface F–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232 Interface Connector Pin Assignments F–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232 Serial Interface Signals F–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

RS–232 Serial Interface Configuration F–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–422 Serial Interface F–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–422 Interface Connector Pin Assignments F–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–422 Serial Interface Signals F–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–422 Serial Interface Configuration F–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

xv

Page 24

xvi

Table of Contents

Page 25

1

Chapter Contents

English:

General Safety Precautions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Safety Precautions 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Label Locations 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deutsch:

Allgemeine Sicherheitsvorkehrungen 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sicherheitsvorkehrungen beim Installieren 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Anbringungsorte der Sicherheitsetiketten 1–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

About This Manual 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Locate Information 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Notices and Special Information 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switches and Display Messages 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documents 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Features 1–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–1Introduction

Page 26

General Safety Precautions

This chapter provides safety information for technicians who are installing and

maintaining L5000 Series printers. Installation, initial setup, testing and

maintenance should be performed only by a factory-trained service representative.

The

printer r

The

printer must be connected to a 30 Amp, 250 V

power

switch does

cord to shut off all power to the printer.

When handling the printer, observe the following precautions to avoid accidents and

ensure safe operation:

• Follow all safety notices and instructions printed in this manual and indicated on

the printer.

• Remove packaging materials carefully, and save them for possible future use. If

the printer is powered on without removing all internal tape and packing, the

printer may be damaged.

elies on pr

not shut off all power to the printer

CAUTION

otective devices in the building installation for pr

outlet. The operator

. Y

ou must unplug the power

-accessible

otection.

• Keep combustible materials away from the printer. Dispose of used toner

properly, as it is flammable.

• Be aware of components in the printer that are potentially hazardous or easily

damaged. For example, the fuser unit becomes very hot under normal operating

conditions, and several components use high voltage.

If it is necessary to remove the fuser section after operating the printer, take care

not to touch its metal portions or cover glass.

• Do not touch the following parts, as high voltages are present:

Corona power supply

Flash lamp power supply

• Do not touch the photoreceptor drum surface, due to the hazardous nature of the

material; it is also easily damaged.

• Do not touch the developer roller assembly.

• Do not touch the xenon and halogen lamps or fuser cover glass, as fingerprints on

lamps will absorb heat and cause them to break.

• Do not place magnetically sensitive items near the developer roller assembly, as

it is magnetized.

• Do not place the toner near vinyl material, as the toner melts vinyl chloride.

1–2 Introduction

Page 27

• Before servicing the printer, disconnect its power plug from the power outlet.

• When performing operational checkout with the printer turned ON, use extreme

caution not to let your clothing or hair get caught in the rotating mechanisms.

• Do not block or obstruct any cabinet ventilation slots.

• Make sure that no foreign matter enters the printer, as injury to personnel,

equipment malfunction, or fire may result.

• Do not spill any kind of liquid on the printer. If the printer surface is soiled, use

only cleaning agents and methods approved by the manufacturer.

• Do not lean on or place heavy objects on top of the printer.

• Do not look directly at the flash lamp.

• Turn off the power immediately if the printer emits an unusual noise or smell.

• Lifting and removing the top cover from the main body requires two people (one

person for the paper feed side, the other person for the paper output side).

1–3Introduction

Page 28

Setup Safety Precautions

When installing the printer, observe the following setup precautions:

Printer

• Do not operate the printer in a room that is not properly ventilated. The room

should be at least 1,000 cubic feet with complete air exchange every two hours.

• Make sure nothing rests on the power cord. Do not locate the power cord where

people will walk on it. Do not place the power cord under any carpet.

• Do not splash water onto the printer. This causes deterioration of internal

insulation, and creates a dangerous condition.

• Do not place drinking cups or other objects on the printer.

• Do not jostle the printer.

• Do not let any metallic pieces (e.g., paper clips or staples) fall into the printer.

• Do not turn off the power while the printer is printing.

• Do not open the top cover while the printer is printing. This may cause a paper

jam.

• Do not clean the printer while it is printing.

• Do not use any flammable spray near the printer.

Consumables

• Never stock the printer consumables –

• Keep all consumables packed until they are to be used.

• Read the installation instructions provided with each consumable.

Near an open flame

Where they may be exposed to direct sunlight

In an area that is hot and humid

In an area that is dusty and dirty

(See page A–8 in Appendix A, Specifications.)

1–4 Introduction

Page 29

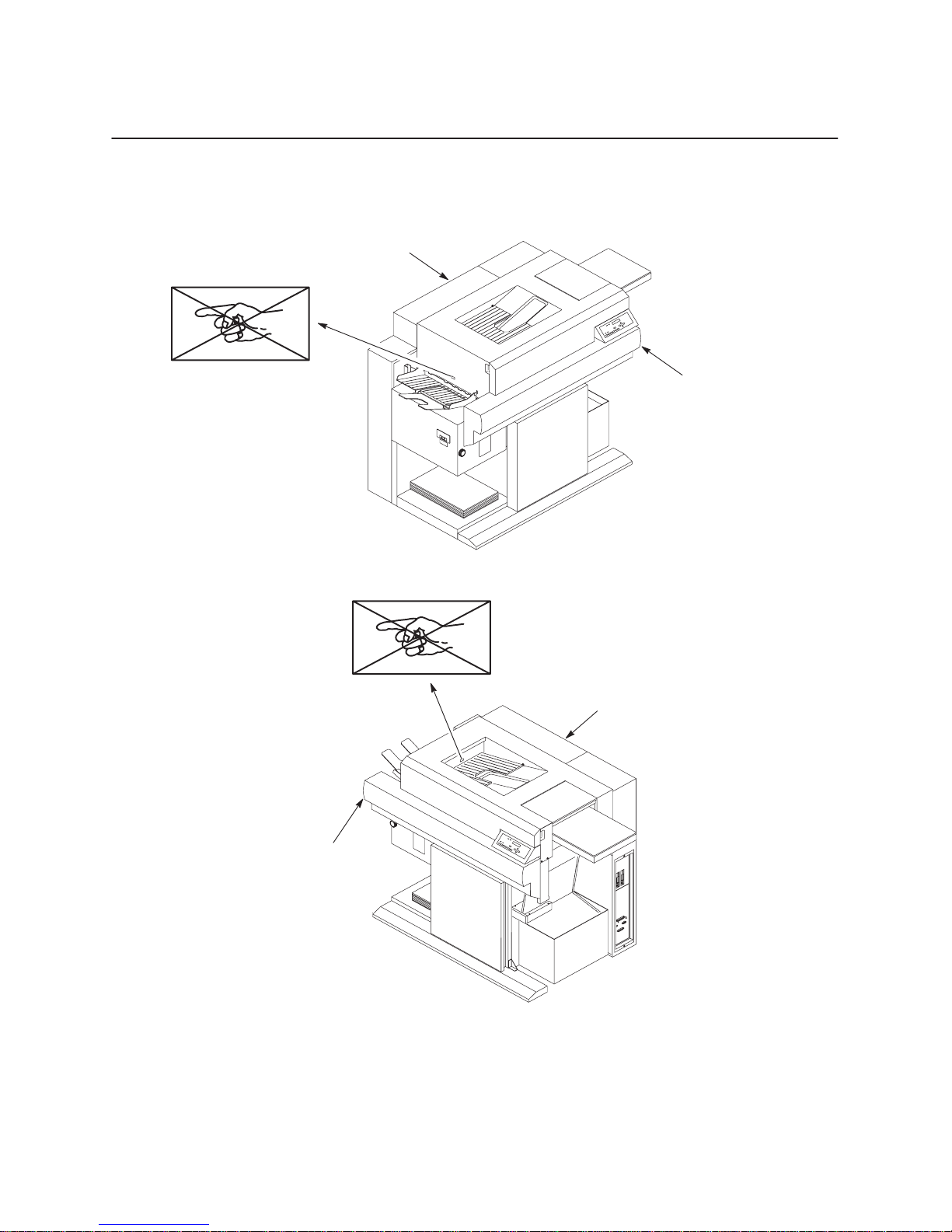

Safety Label Locations

Rear cover

Front upper cover

Front upper cover

Rear cover

Figure 1–1. Safety Labels

1–5Introduction

Page 30

DANGER

Keep your hands away from

tractors while printing.

Printer emits bright light while

printing. Do not stare into

tractor area while printing.

Figure 1–2. Safety Label – Paper Input Side

1–6 Introduction

Page 31

High voltage on

chargers while printing.

DANGER

Hot surface.

Do not touch.

DANGER HOT

Do not touch fuser

unit cover glass.

Figure 1–3. Safety Labels – Front View with Cover Removed

DANGER

1–7Introduction

Page 32

1–8 Introduction

DANGER

Hot surface and hot air.

Avoid contact.

Figure 1–4. Safety Label – Rear Cover

Page 33

DANGER

Keep your hands away from

stacker while printing.

Figure 1–5. Safety Label – Power Paper Stacker (output side)

1–9Introduction

Page 34

DANGER

HIGH VOLTAGE

Do not touch charger

power supply below this

plate.

1–10 Introduction

DANGER HIGH VOLTAGE

Do not touch the varistor on left.

Figure 1–6. Safety Labels – Rear View

Page 35

Allgemeine Sicherheitsvorkehrungen

Dieses Kapitel enthält Sicherheitsinformation für die richtige Installation und

Wartung der L5000 Drucker-Serie. Installation, anfängliches Aufstellen und

Wartung sollten nur von einem durch den Hersteller ausgebildeten

Servicefachmann vorgenommen werden.

VORSICHT

Der Schutz des Druckers beruht auf integrierten Schutzeinrichtungen. Der

Drucker muß an eine 30 A, 250 V Steckdose angeschlossen werden.

Der für den Bediener zugängliche Netzschalter unterbricht die Stromzufuhr

zum Drucker nur teilweise. Das Netzkabel muß ganz herausgezogen sein, um die

Stromzufuhr zum Drucker zu unterbrechen.

Beim Bedienen des Druckers beachten Sie bitte genau die folgenden

Sicherheitsvorkehrungen, um Unfälle zu vermeiden und den sicheren Betrieb des

Druckers zu gewährleisten:

• Befolgen Sie alle Sicherheitshinweise und Anweisungen, die in diesem

Handbuch angeführt oder auf dem Drucker angebracht sind.

• Entfernen Sie das Verpackungsmaterial sorgfältig, und bewahren Sie es für eine

spätere Wiederverwendung auf. Der Drucker könnte beim Einschalten beschädigt

werden, falls Klebebänder und Verpackungsmaterial nicht vollständig vom

Drucker entfernt wurden.

• Halten Sie brennbare Materialien vom Drucker fern. Entsorgen Sie gebrauchten

Toner vorschriftsgemäß. Er ist brennbar.

• Gehen Sie mit den Druckerbestandteilen, die eventuell gefährlich sind oder leicht

beschädigt werden, vorsichtig um. Die Fixiereinheit wird beispielsweise unter

normalen Betriebsbedingungen extrem heiß, und verschiedene Bestandteile

stehen unter hoher Spannung.

Sollte es notwendig sein, dden Bereich der Fixiereinheit nach dem Betrieb des

Druckers zu entfernen, berühren Sie bitte nicht die Metallteile und/oder die

Glasabdeckung.

• Die folgenden Teile nicht berühren, da Sie unter Starkstrom stehen:

Corona Netzteil

Blitzlampennetzteil

• Nicht die Oberfläche der Photorezeptortrommel berühren, da das Material

gesundheitsgefährdend und auch leicht empfindlich ist.

1–11Introduction

Page 36

• Die Entwicklerwalzeinheit nicht berühren.

• Die Xenon- und Halogenlampen sowie die Glasabdeckung des Fixierers nicht

berühren, da Fingerabdrücke Hitze anziehen und die Lampen dadurch platzen.

• Halten Sie magnetisch empfindliche Gegenstände von der Entwicklerwalzeinheit

fern, da sie magnetisiert ist.

• Den Toner nicht in der Nähe von Vinylmaterialien abstellen, da der Toner

Vinylchlorid schmilzt.

• Vor Wartungsarbeiten am Drucker oder bei Einstellungsänderungen den Stecker

immer erst aus der Dose ziehen.

• Wenn Sie den Betrieb des Druckers prüfen wollen, während er angestellt ist,

achten Sie besonders sorgfältig darauf, daß Kleidungsstücke oder Haare nicht in

den Rotationsmechanismus geraten.

• Achten Sie darauf, daß die Gehäuseventilationsschlitze nicht blockiert oder

verstopft sind.

• Achten Sie darauf, daß keine Fremdkörper in den Drucker gelangen. Dies kann

zu Verletzungen des Personals, zu einer Betriebsstörung oder einem Brand

führen.

• Halten Sie jegliche Art von Flüssigkeit vom Drucker fern. Sollte die Oberfläche

des Druckers beschmutzt werden, benutzen Sie nur vom Hersteller empfohlene

Reinigungsmittel und -methoden.

• Lehnen Sie sich nicht auf den Drucker und stellen Sie keine schweren

Gegenstände darauf.

• Schauen Sie nicht direkt in das Blitzlicht.

• Gibt der Drucker ungewühnliche Geräusche oder Gerüche von sich, unterbrechen

Sie sofort die Stromzufuhr.

• Das Heben oder Entfernen der oberen Abdeckung vom Hauptkörper sollte von

zwei Personen vorgenommen werden. (Eine Person auf der Papierzufuhrseite, die

andere auf Papierausgabeseite).

1–12 Introduction

Page 37

Sicherheitsvorkehrungen beim Installieren

Beachten Sie bitte beim Installieren des Druckers die folgenden

Vorsichtsmaßnahmen:

Drucker

• Der Drucker darf nur in einem Raum mit ausreichender Ventialtion eingesetzt

werden. Dieser Raum sollte mindestens 28 Kubikmeter groß sein und

Frischluftzufuhr sollte alle zwei Stunden erfolgen.

• Sorgen Sie dafür, daß keine Gegenstände auf dem Netzkabel abgestellt werden.

Verlegen Sie das Netzkabel so, daß niemand darauf treten kann und daß es nicht

unter einem Teppich liegt.

• Lassen Sie kein Wasser auf den Drucker kommen. Dies kann die interne

Isolierung beschädigen und dadurch einen Gefahrenzustand verursachen.

• Keine Trinkgefäße oder andere Objekte auf dem Printer abstellen.

• Rütteln Sie nicht an dem Drucker.

• Lassen Sie keine Metallstücke (z.B. Büro- oder Heftklammern) in den Drucker

fallen.

• Drehen Sie während des Druckens nicht den Strom ab.

• Öffnen Sie während des Druckens nicht die Abdeckplatte. Dies kann einen

Papierstau zur Folge haben.

• Reinigen Sie den Drucker nicht während des Druckens.

• Benutzen Sie keine feuergefährlichen Sprays in der Nähe des Druckers.

Verbrauchsmaterialien

• Lagern Sie niemals Verbrauchsmaterialien für den Drucker -

in der Nähe einer offenen Flamme

wo sie direktem Sonnenlicht ausgesetzt sind

in einer heißen und feuchten Umgebung

an einem staubigen und schmutzigen Platz

(Siehe Seite A–8 im Anhang A. Angaben.)

• Lassen Sie alle Verbrauchsmaterialien bis zu ihrem Gebrauch in der Verpackung.

• Lesen Sie alle Installationsanweisungen, die mit jedem Verbrauchsgut geliefert

werden.

1–13Introduction

Page 38

Anbringungsorte der Sicherheitsetiketten

Rückseite

Vorderseite

Vorderseite

Abbildung 1–1. Sicherheitsetiketten

Rückseite

1–14 Introduction

Page 39

GEFAHR

Während des Druckvorgangs

Traktoren nicht anfassen.

Drucker emittiert während des

Druckvorgangs helles Licht.

Nicht in den Traktorbereich

schauen.

Abbildung 1–2. Sicherheitsetikette - Seite der Papiereingabe

1–15Introduction

Page 40

GEFAHR

Lader stehen während

des Druckvorgangs

unter hoher Spannung.

GEFAHR

Heiße Oberfläche.

Nicht berühren.

GEFAHR - HEISS

Abdeckglas der

Fixiereinheit

nicht anfassen.

Abbildung 1–3. Sicherheitsetiketten - Vorderansicht bei entfernter Abdeckung

1–16 Introduction

Page 41

Abbildung 1–4. Sicherheitsetikette - Hintere Abdeckung

GEFAHR

Heiße Oberfläche und

heiße Luft. Kontakt

vermeiden.

1–17Introduction

Page 42

VORSICHT

Während des Druckvorgangs

Hände von der automatischen

Papierausgabe fernhalten.

Abbildung 1–5. Sicherheitsetikette - Seite der automatischen Papierausgabe

1–18 Introduction

Page 43

GEFAHR

HOCHSPANNUNG

Netzteil des Laders

unterhalb dieser Platte

nicht berühren.

Abbildung 1–6. Sicherheitsetiketten – Rückansicht

GEFAHR HOCHSPANNUNG

Varistor links nicht berühren.

1–19Introduction

Page 44

About This Manual

This manual explains how to and repair the L5000 Series printers at the field service

level of maintenance. It covers alignments and adjustments, preventive and corrective

maintenance, basic troubleshooting, and principles of operation.

This manual does not explain how to configure or operate the printer. That

information is in the User’s Manual, which supplements this manual.

How to Locate Information

This manual consists of two volumes that are designed so that you can find the

information you need to maintain and repair the printer. You can locate maintenance

information in three ways:

• Use the Table of Contents at the front of Volume 1 and Volume 2.

• Use the Chapter Contents on the first page of each chapter.

• Use the Index at the end of Volume 1 and Volume 2.

Read the entire procedure before beginning any maintenance task. Gather all required

tools and make sure you understand all dangers, cautions, and notes before you begin

working on the printer.

Safety Notices and Special Information

For your safety and to protect valuable equipment, it is very important that you read

and comply with all information highlighted under the following special headings:

DANGER, CAUTION, IMPORTANT, and NOTE. Safety notices that include

conditions that could harm you are written in English and German. (See also the

safety topics in English and German at the beginning of this chapter.)

DANGER

A danger notice calls attention to a condition that could harm you.

CAUTION

A caution notice calls attention to a condition that could harm you or damage

the printer.

1–20 Introduction

Page 45

An important notice provides information that is vital to proper operation of the

printer.

NOTE: A note provides information considered important enough to emphasize.

Switches and Display Messages

In this manual, switches and indicators that are labeled on the printer appear in

uppercase letters.

Control panel display messages also appear in uppercase letters.

Example: “Press the CLEAR switch to take the printer to the OFFLINE READY

state.”

Related Documents

IMPORTANT

For additional information about printer configuration and operation, and optional

interfaces, refer to the following documents:

• L5024 Multifunction Printer User’s Manual (P/N 703718-001)

• L5031 Multifunction Printer User’s Manual (P/N 704765-001)

• Impact Printer Emulation User’s Manual (P/N 703272-001)

• IGP/PGL User’s Manual (P/N 702610-001)

• IGP/VGL User’s Manual (P/N 702611-001)

1–21Introduction

Page 46

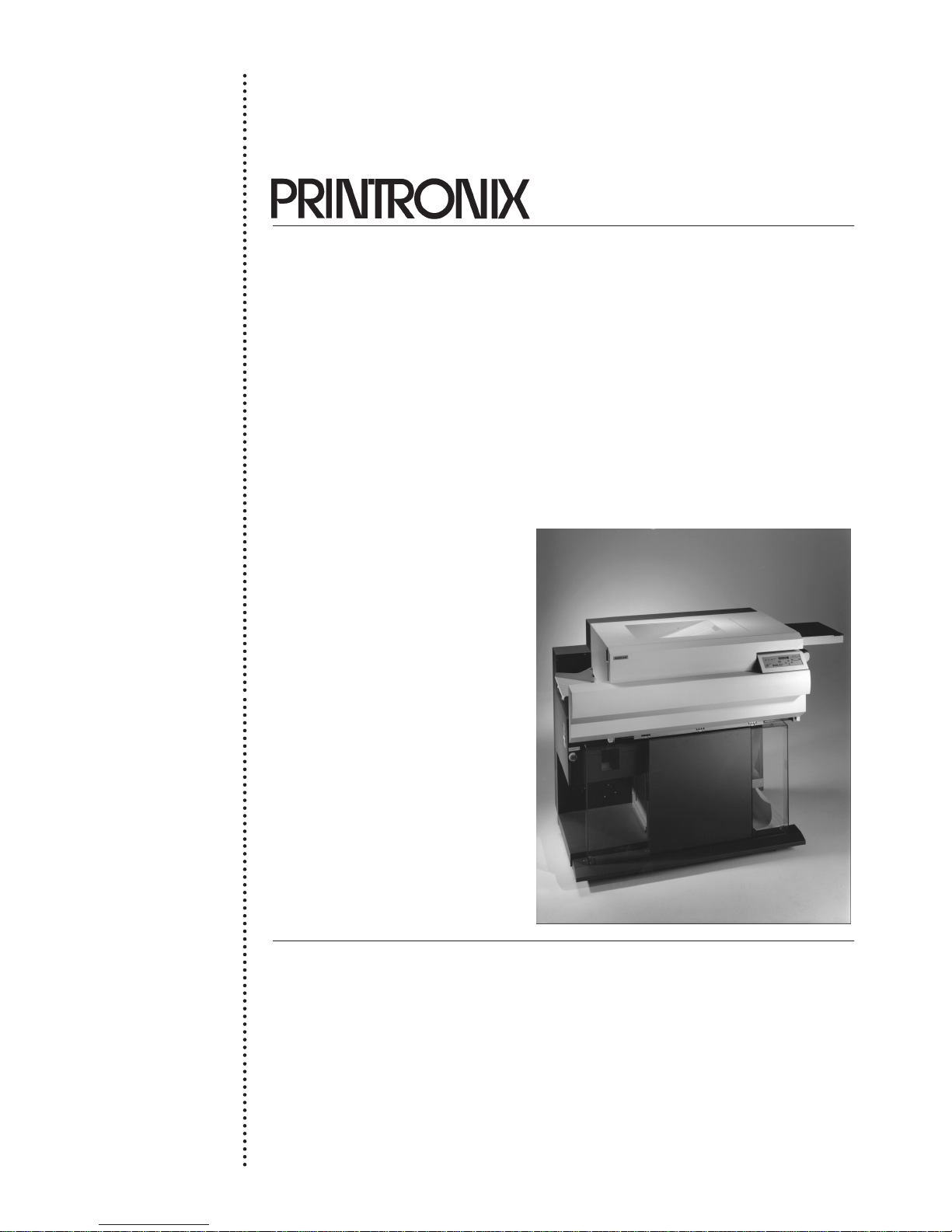

Printer Features

The L5000 Series printer provides the following standard features:

• Non-impact/electrophotographic page printer

The printer is a non-impact page printer that employs the same

electrophotographic system as regular copiers. It meets the needs of users who

wish to produce high-quality prints rapidly and quietly.

• High performance-to-cost ratio

Print speed is 31 pages per minute on continuous 8.5-inch x 11.0-inch forms

(long edge fed), and 24 pages per minute on 8.5-inch x 11.0-inch forms in the

optional cut sheet mode. The low hardware and consumable costs offer higher

cost efficiency than existing competing brands.

• LED exposure system for enhanced printing resolution

Exposure LEDs are arranged at a density equivalent to the printing resolution

(300 dpi standard), and exposure is executed one dot row at a time.

• Two-component developer used for high print quality assurance

The two-component developer contains a synthetic carrier that is resin coated to

weaken its magnetism. This assures that the toner properly adheres to the

Photoreceptor drum surface, depending on the strength of electric and magnetic

fields generated between the photoreceptor drum and developer roller surfaces.

• Supports a wide variety of paper sizes

Either continuous forms or cut-sheet paper can be used. The maximum width of

fan-fold paper that can be used is 16 inches, and various cut-sheet paper sizes up

to ledger size are applicable. The built-in automatic paper parking mechanism

enables switching to the cut-sheet paper mode while fan-fold paper is set in

position.

• Flash fixing system, which works on most paper types

A xenon (Xe) lamp-based, non-contact, flash toner fixing system is employed,

enabling printing on various types of special paper such as mailing and other

adhesive labels. Further, the use of a very simple paper transport system permits

printing onto thick paper having weights up to 44 lb. bond or 125 lb. tag and

label stock.

1–22 Introduction

Page 47

• Small-size and low acoustic noise

Although a flash fixing system is employed, an advanced acoustic noise

reduction feature is incorporated that reduces the acoustic noise emission to a

level that is comparable to that of a thermal roller fixing type laser printer.

Further, the printer size is minimized to permit effective office space utilization.

• PrintronixR System Architecture (PSAt)

The controller is compatible with all requirements of the PSA system. This

means that all PSA compatible emulations (IGP/PGL, IGP/VGL, Lineprinter

Plus, HP PCL5, etc.) can be accommodated, and are configured by exchanging

floppy disks.

• Wide Selection of Host Interfaces

A wide variety of host interfaces are provided. Serial RS-232/422, Centronics

parallel, and Dataproducts parallel (requires optional cable adapter) are standard,

with IBM Coax and Twinax available as options. A serial diagnostic port is also a

standard feature.

• Suitable for wide applications

User needs were analyzed to make the printer capable of satisfying a wide variety

of applications. For example, it can serve as a high-speed, high-quality line

printer, graphics printer, or bar-code printer.

1–23Introduction

Page 48

1–24 Introduction

Page 49

2

Chapter Contents