Page 1

R

Page 2

Page 3

705815–001, Rev A

R

Page 4

US and CANADA Radio Interference Note

Note: This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission limits. The

manufacturer is not responsible for any radio or television interference caused by using other than recommended

cables and connectors or by unauthorized changes or modifications to this equipment. Unauthorized changes or

modifications could void the user’s authority to operate the equipment.

The input/output (I/O) cable must be shielded for the printer to comply with FCC rules and regulations Part 15

governing the radiation limits for Class “A” equipment.

This Class A digital apparatus meets all requirements of the Canadian Interference–Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

Printronix, Inc. makes no representations or warranties of any kind regarding this material, including, but not limited

to, implied warranties of merchantability and fitness for a particular purpose. Printronix, Inc. shall not be held

responsible for errors contained herein or any omissions from this material or for any damages, whether direct,

indirect, incidental or consequential, in connection with the furnishing, distribution, performance or use of this material.

The information in this manual is subject to change without notice.

This document contains proprietary information protected by copyright. No part of this document may be reproduced,

copied, translated or incorporated in any other material in any form or by any means, whether manual, graphic,

electronic, mechanical or otherwise, without the prior written consent of Printronix, Inc.

All rights reserved.

Trademark Acknowledgments

Compatibility Software Copyright 1989 Phoenix Technologies Ltd., All Rights Reserved.

Printronix is a registered trademark of Printronix, Incorporated.

IGP is a registered trademark of Printronix, Inc.

LinePrinter Plus is a trademark of Printronix, Inc.

PostScript is a registered trademark of Adobe Systems.

PhoenixPage PCL 5 is a registered trademark of Phoenix Technologies Ltd.

HP is a registered trademark of Hewlett–Packard Company.

PCL is a trademark of Hewlett–Packard Company.

Code V is a trademark of QMS, Inc.

QMS is a registered trademark of Quality Micro Systems, Inc.

17500 Cartwright Road, P.O. Box 19559

Irvine, California 92713

Telephone (714) 863–1900 FAX (714) 660–8682

Technical Support (714)

COPYRIGHT 1995, 1996, 1997 PRINTRONIX, INC.

221–2686

Page 5

Table of Contents

1

2

Introduction

About This Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Locate Information 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings and Special Information 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Printer 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Features 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emulations 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Options 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fonts and Forms 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Laser Printer Technology 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up the Printer

Safety Precautions 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check the Power Requirements 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select a Site 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpack the Printer 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Setup 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Developer Unit 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Add the Starter Toner 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Ozone Filter 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Waste Toner Container 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Fuser Cleaner Felt 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the OPC Drum Unit 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Paper 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Emulation Boot Diskette 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Connections 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check for Interference 2–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transporting the Printer 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short Distance Transport 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Long Distance Transport 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 6

3

Configuring the Printer

Overview 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Printer Settings 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving a Configuration 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying a Configuration 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing a Configuration 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Factory Settings 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Menus 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Control Menu 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Width 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Length 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horiz. Image Shift 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vert. Image Shift 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reprint on Fault 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Control Menu 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuser Temperature 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Energy Timeout 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics Menu 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Print 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Life Data 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk Management Menu 3–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Configuration 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Save Configuration 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Configuration 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delete Configuration 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power–up Configuration 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protect Configurations 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode (Emulation) Menu 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impact Printer 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCL5 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IGP/PGL 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IGP/VGL 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 7

CTHI 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IPDS 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance/Miscellaneous Menu 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Panel Key Sound 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power–up State 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hex Dump Mode 3–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTX–Setup Option 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Language 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host Interface Menu 3–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Centronics Interface Parameters 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dataproducts Interface Parameters 3–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Interface Parameters 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Font Memory Menu 3–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Character Memory 3–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Cache Memory 3–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Maximum Cache Size 3–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Cached Characters 3–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Fonts Loaded 3–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Font Weight 3–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Information Menu 3–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Memory 3–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics and Troubleshooting

Printer Diagnostics 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Off–Line Diagnostics 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On–Line Diagnostics 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the Printer Test 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hex Dumps 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Messages 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Calls 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fatal Error Messages 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 8

Appendices

Appendix A: Specifications

Appendix B: Host I/O Interfaces

Appendix C: Media Requirements

Appendix D: Disk Space Savings

Glossary

Index

iv

Page 9

1

Chapter Contents

Introduction

About This Manual 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Locate Information 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings and Special Information 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Printer 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Features 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emulations 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Options 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fonts and Forms 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Laser Printer Technology 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

1–1

Page 10

About This Manual

This manual is divided into chapters that contain all the information required to

use the printer.

Chapter 1: Introduction. General information about the manual and the printer,

safety precautions, and component locations.

Chapter 2: Setting Up the Printer. Procedures for installing the printer and its

components.

Chapter 3: Configuring the Printer. Configuration menus, options, and

outlines as well as factory default settings.

Chapter 4: Diagnostics and Troubleshooting. Diagnostics and procedures for

clearing paper jams, cleaning the printer, and interpreting the displayed error

messages.

Appendix A: Specifications

Appendix B: Host I/O Interfaces

Appendix C: Media Requirements

Appendix D: Disk Space Savings

How to Locate Information

You can locate specific procedures and information three ways:

• Use the Table of Contents at the front of the manual.

• Use the Chapter Contents list on the first page of each chapter.

• Use the Index at the back of the manual.

1–2

Introduction

Page 11

Warnings and Special Information

For your safety and to protect valuable equipment, it is very important that you

read and comply with all information highlighted under special headings:

WARNING

Conditions that could harm you as well as damage the equipment.

CAUTION

Conditions that could damage the printer or related equipment.

IMPORTANT

Information vital to proper operation of the printer.

NOTE: Information and helpful tips about printer operation.

Conventions

Throughout this manual, switches and possible switch settings or positions are

printed in UPPERCASE type.

In most cases, messages displayed in the LCD are shown in the following format:

In some cases, display messages may be shown in UPPERCASE type,

surrounded by quotation marks.

OFFLINE

PAPER CONTROL

Introduction

1–3

Page 12

The Printer

The printer is a programmable, non–impact printer. The printing technique is a

plain paper electrophotographic process, which uses a laser diode. Printer

emulations and font software load into the printer via diskettes.

1–4

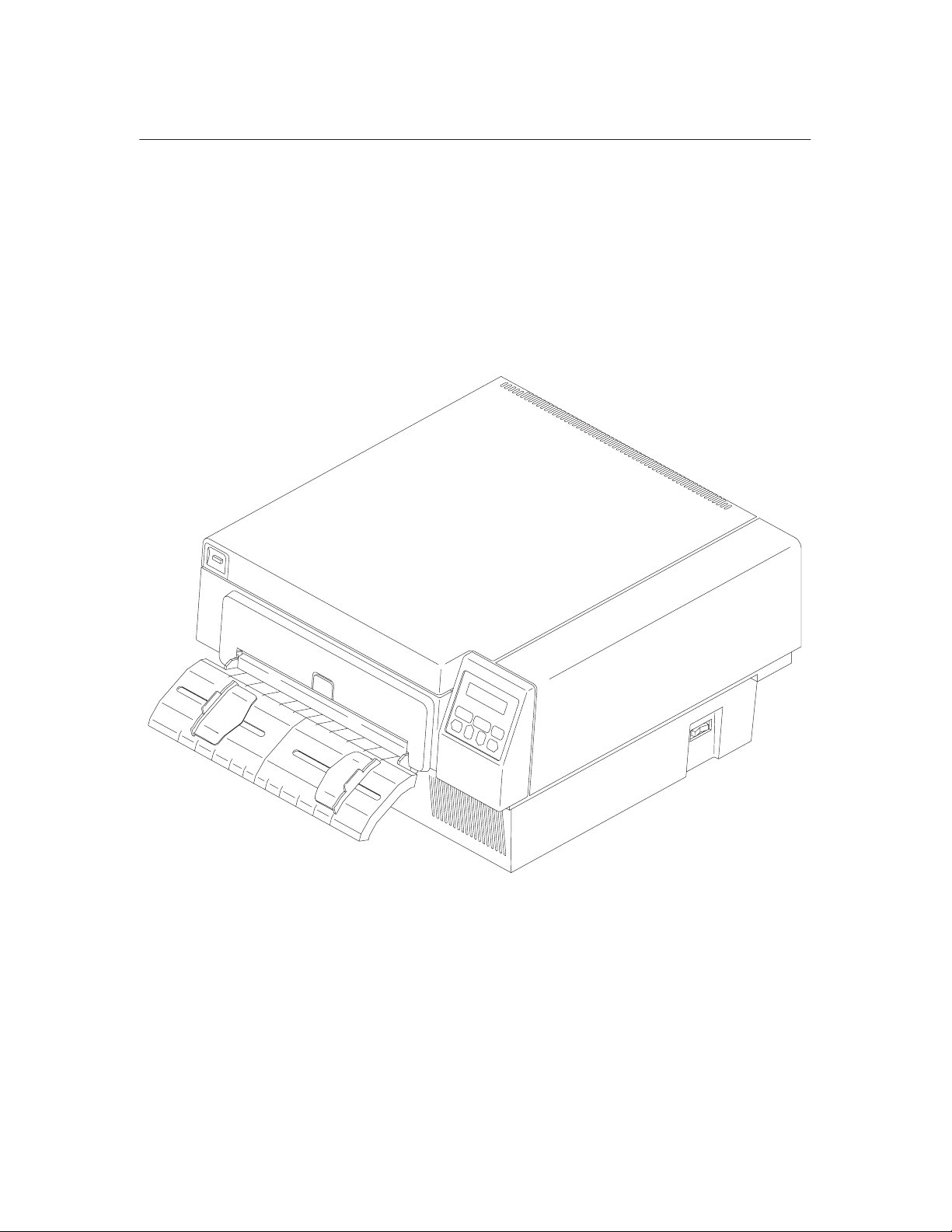

Figure 1–1. The Printer

Introduction

Page 13

Printer Features

The printer prints up to 24 pages per minute on an 8.5 x 11 inch page and

produces a 300 x 300 dots–per–inch (dpi) resolution on a continuous length

printable area. (See Appendix A for printer specifications.)

Features of the printer include:

• Continuous fanfold paper or forms handling

• Supports a wide variety of form lengths

• User–replaceable developer kit, toner kit, and organic photoconductor

(OPC) drum kit

• Two–line, 16–character alphanumeric display that provides operating and

error messages

• Diskette drive which is used to load and store preset configurations,

printer emulations and fonts from a diskette

• Second diskette drive which stores fonts (optional)

• Serial or parallel interface

• Coax or twinax interface (optional)

• Ethernet LAN interface (optional)

Introduction

1–5

Page 14

Emulations

The printer comes with HPr Laserjet PCL5r, IPDS, or the Printronix

LinePrinter Plust emulation. The LinePrinter Plus emulation includes the

following printer protocols:

• Printronix P–Series

• Printronix P–Series XQ

• Serial Matrix

• Proprinter III XL

• Epson FX–1050

LinePrinter Plus emulation provides portrait and landscape image orientation.

Automatic 1–up, 2–up, 4–up, and gray bar overprinting are also provided. The

emulation offers proportional (scalable) fonts and multi–up form definition

capability as well.

Optional emulations are also available on diskette. Refer to Appendix A for a list

of optional emulations. Refer to the Programmer’s Reference Manual or

Operator’s Guide supplied with each emulation diskette for specific information.

Hardware Options

Ask your printer representative about these options which can enhance your

printer’s versatility:

• Paper stacker with printer stand

The paper stacker provides for properly stacked paper from the beginning to

completion of the print job. The stacker will hold an entire box of media.

• Memory expansion (4 meg and 16 meg increments)

The L1024 has 8 meg of memory factory installed. Memory expansion modules

are available in increments of either 4 or 16 meg. Using these modules, printer

memory can be expanded to 40 meg.

• Second Floppy Disk Drive

A second floppy disk drive can be installed, as disk drive B.

1–6

Introduction

Page 15

• LAN connection

A hardware option is available for proper connection of the printer to a LAN.

• Coax/Twinax connection

A hardware option is available for proper connection of the printer for

Coax/Twinax operation.

• Optional fonts

Optional printer fonts can be purchased and loaded into the printer using a

diskette.

Fonts and Forms

The printer provides a variety of resident fonts. The available fonts are dependent

the emulation used. For example, the Printronix LinePrinter Plus emulation

provides Letter Gothic, Courier, OCR–A, and OCR–B as standard fonts sets.

Additional fonts can be loaded from the host computer or from optional font

diskettes into printer memory. Once loaded, these additional fonts are accessed in

the same way as the resident fonts. Printer languages that support downloaded

fonts will not retain these fonts in memory when the printer is powered off.

Forms may be stored together with fonts. The storage space for forms and fonts

depends on memory availability and diskette space. Different fonts and forms

may be used depending on the emulation installed.

Introduction

1–7

Page 16

General Laser Printer Technology

The operation of a laser printer is somewhat different than that of an impact

printer. They produce an entire page at once, compared to line printers, which

produce complete character lines.

NOTE: If the software application fails to give a form feed at the end of the

data, and the data does not exceed the selected lines per page

setting, the page will not print. Rather, it will remain in memory.

The laser printer has two basic functional parts: the engine and the controller.

The engine is responsible for the mechanical aspects of producing the page. The

controller controls the printer and is responsible for electronic data

manipulations.

NOTE: Laser printers can not print to the physical edge of the paper. If the

document image runs to the edge of the paper, portions of the image

may be lost.

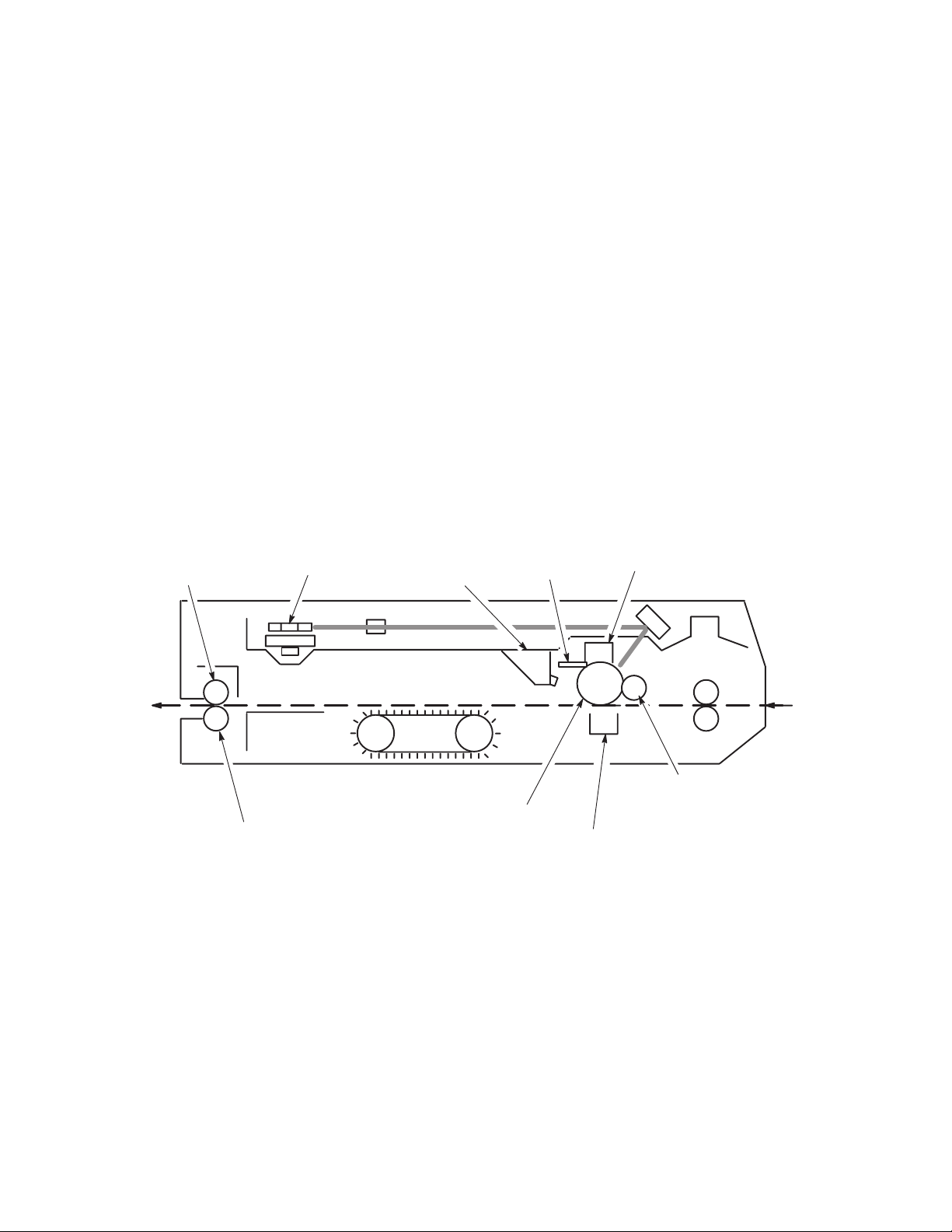

The electrophotographic printing process, shown in Figure 1–2, consists of the

following steps:

1. Charging: The charge corona is a thin wire electrode that extends

across the width of the media. This electrode places a high–voltage

electrostatic charge on the organic photoconductor (OPC) drum.

2. Imaging: Based on data received from the host computer, a bit–mapped

image of the page is generated in random access memory (RAM) on the

controller (not shown).

3. Exposing: The laser scanning unit (LSU) exposes areas of the OPC

which are to be imaged (i.e., black). This forms a latent image of the

bit–mapped data. This image is made up of charged and uncharged

areas.

4. Developing: The latent image areas of the OPC attract toner from the

developer unit to form the developed image on the OPC drum. Since the

charged areas of the drum have the same charge as the toner, they repel

the toner.

1–8

Introduction

Page 17

5. Transferring: Another thin wire electrode, the transfer corona, puts a

high electrostatic charge on the paper. This charge attracts the toner,

transferring the toner from the OPC drum to the paper.

6. Fusing: Heat and pressure rollers fuse the transferred image to the

paper.

7. Cleaning: As the OPC drum continues to turn, erase lamps remove all

residual electrostatic charge from the OPC. The cleaning unit then

removes unused toner from the OPC.

Paper

Exit

Heat

Roller

Pressure

Roller

Laser

Scanning

Unit

Erase

Lamps

Cleaning

Unit

OPC

.

Transfer

Corona

.

Charge

Corona

Paper

Entry

Developer

Unit

Introduction

Figure 1–2. The Printing Process

1–9

Page 18

1–10

Introduction

Page 19

2

Chapter Contents

Setting Up the Printer

Safety Precautions 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check the Power Requirements 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select a Site 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpack the Printer 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Setup 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Developer Unit 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Add the Starter Toner 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Ozone Filter 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Waste Toner Container 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Fuser Cleaner Felt 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the OPC Drum Unit 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Paper 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Emulation Boot Diskette 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Connections 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check for Interference 2–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transporting the Printer 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short Distance Transport 2–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Long Distance Transport 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–1Setting Up the Printer

Page 20

Safety Precautions

The use of controls or adjustments or the performance of procedures

other than those specified in this manual may result in exposure to

hazardous radiation.

Die Nichtbeachtung der in diesem Handbuch dargelegten Punkte sowie

die Verwendung anderer Kontroll– oder Steuereinrichtungen kann dazu

führen, daß gefährliche Strahlung abgegeben wird.

L’utilisation de commandes et réglages ou l’exécution de procédures

autres que celles spécifiées dans ce manuel peuvent entraîner une

exposition à des radiations dangereuses.

WARNING

WARNUNG

ATTENTION

Be aware of components in the printer that are potentially hazardous or easily

damaged. For example, the fuser unit becomes very hot under normal operating

conditions, and several components use high voltage.

Observe the following precautions to ensure personal safety and proper

installation and operation of the printer.

• Read all instructions.

• Save these instructions for later reference and use.

• Follow all warnings and instructions printed in this manual and marked

on the printer.

• Keep combustible materials away from the printer.

• Provide adequate ventilation.

• Never push objects of any kind through the cabinet slots. They may

contact dangerous voltage points or other hazards. Injury to the operator,

damage to the printer, or fire could result.

• Never spill liquid of any kind on or in the printer. Use only cleaning

agents and methods indicated in this manual.

2–2 Setting Up the Printer

Page 21

• Make sure nothing rests on the power cord. Do not locate the power cord

where people will walk on it. Do not place the power cord under any

carpet.

• Do not lean or place heavy objects on top of the printer.

For additional requirements, refer to Appendix A.

Check the Power Requirements

WARNING

Do not connect the printer to the power source until instructed to do so

and until all shipping restraints have been removed.

WARNUNG

Den Drucker nur unter Anleitung an die Stromquelle anschließen, und

erst dann, wenn alle Versandmaterialien entfernt worden sind.

ATTENTION

A moins d’en avoir recu l’ordre, ne pas brancher l’imprimante avant

d’en avoir ôté tout le matériel d’emballage.

The printer must be connected to an acceptable AC power source; otherwise, the

printer will not operate properly and may be damaged. The rear side panel label

identifies the correct power source for the printer: either 100 to 120 VAC, 60 Hz

or 220 to 240 VAC, 50 Hz.

The power source must be properly grounded. Since large power fluctuations can

cause the printer to malfunction, it should be connected to a “noise–free” power

source, not subject to surges or noise generated by motors, lighting, or air

conditioning equipment on the same circuit. To allow for an adequate power

cable run, the printer should be placed no more than eight feet (2.5 meters) from

the power outlet.

2–3Setting Up the Printer

Page 22

Select a Site

When selecting the location for the printer, consider the following power

requirements, interface requirements, and environmental factors:

• A proper power source must be available. (Complete power requirements

are specified in the “Check Power Requirements” section on page 2–3.)

• The location must be within the maximum cable length specifications for

the host computer interface.

• The temperature range should be +50°F to +90°F, with no sudden

changes in temperature or humidity. The printer should be positioned

away from any air drafts from heating or air conditioning ducts.

• Insure that the room provides adequate ventilation. The minimum room

volume is 1000 cubic feet and must provide, at a minimum, one fresh air

exchange every two hours.

• The location should provide enough space for maintenance and

replacement of consumables (toner, developer, paper, etc.). Refer to

Figure 2–1.

• The printer should not be exposed to direct sunlight or hot lighting

equipment. This may cause an abnormal temperature rise in the printer

and adversely affect its operation. If necessary, shade or screen the

printer from such exposure.

• Avoid exposing the printer to any corrosive gases or vapors.

• Avoid installing the printer in an area subject to heavy vibrations.

For additional environmental requirements, refer to the Introduction chapter and

to Appendix A.

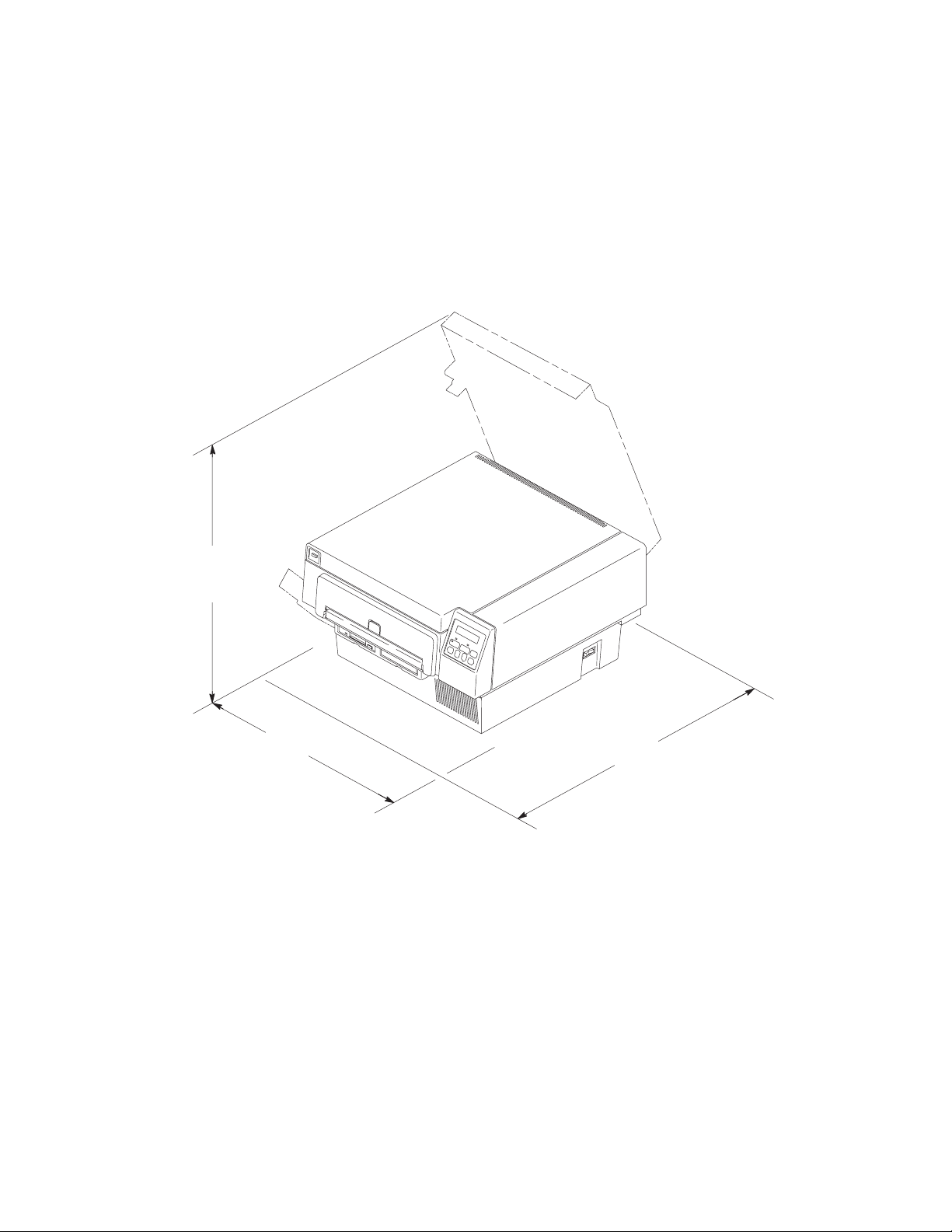

Figure 2–1 illustrates spatial site requirements for the printer. The dimensions are

listed in inches and include the requirements with the top and front covers open.

NOTE: The actual printer dimensions are shown in Figure 2–1. When

installing the printer at your site, allow an additional 6 inches

clearance behind the printer for connection of interface and power

cables.

2–4 Setting Up the Printer

Page 23

23 inches

19 inches

25 inches

Figure 2–1. Clearance Requirements

2–5Setting Up the Printer

Page 24

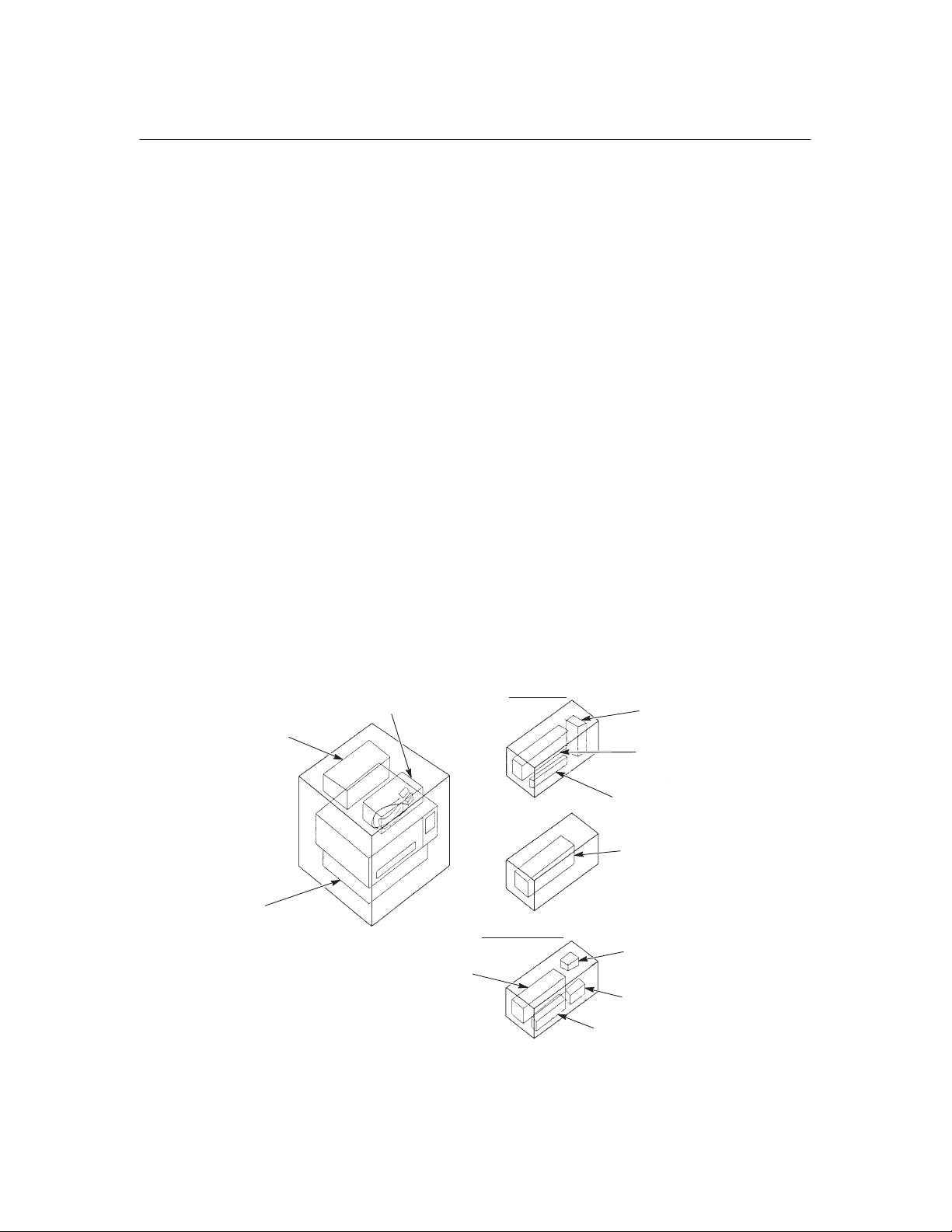

Unpack the Printer

The printer is shipped in two cartons. The carton containing the consumables

ship set is placed on top of the printer carton. The printer carton is shown in

Figure 2–2 with all of the contents. The consumables ship set; which is made up

of the toner kit, OPC cartridge, and developer kit, is shipped in its own carton

(not shown in Figure 2–2), as shown in the figure below.

NOTE: Save the printer shipping materials in case they are needed to

transport the printer to a new location.

NOTE: The material in the toner kit is recyclable. Save the toner box and

packaging materials for recycling. A recycling shipping label, with

instructions attached, is provided.

The OPC unit must be kept in its protective bag whenever the unit is not

housed in the printer.

CAUTION

Carefully open each carton and examine contents for indication of damage during

transport. Use care when lifting the printer from the shipping carton.

Emulation Diskettes,

Documentation, etc.

Printer

Power Cable and

Front Paper Guide

Developer Unit

Toner Kit:

Developer kit:

W

aste Container (2)

T

oner Bottle (2)

Cleaner Felt (2)

OPC Unit

Ozone Filter

Cleaning Kit

Starter T

oner

Figure 2–2. Unpacking the Printer

2–6 Setting Up the Printer

Page 25

Initial Setup

To prepare the printer for operation, install the consumables that are packaged in

consumable kits within the consumable ship set box. They are:

• Developer unit (Developer Kit)

• Starter Toner (Developer Kit)

• Ozone filter (Developer Kit)

• Waste toner container (Toner Kit)

• Fuser cleaner felt (Toner Kit)

• OPC drum unit

NOTE: The material in the toner kit is recyclable. Save the toner box and

To install the consumables, perform the following procedures in the order

presented.

packaging materials for recycling. A recycling shipping label is

provided with instructions attached.

2–7Setting Up the Printer

Page 26

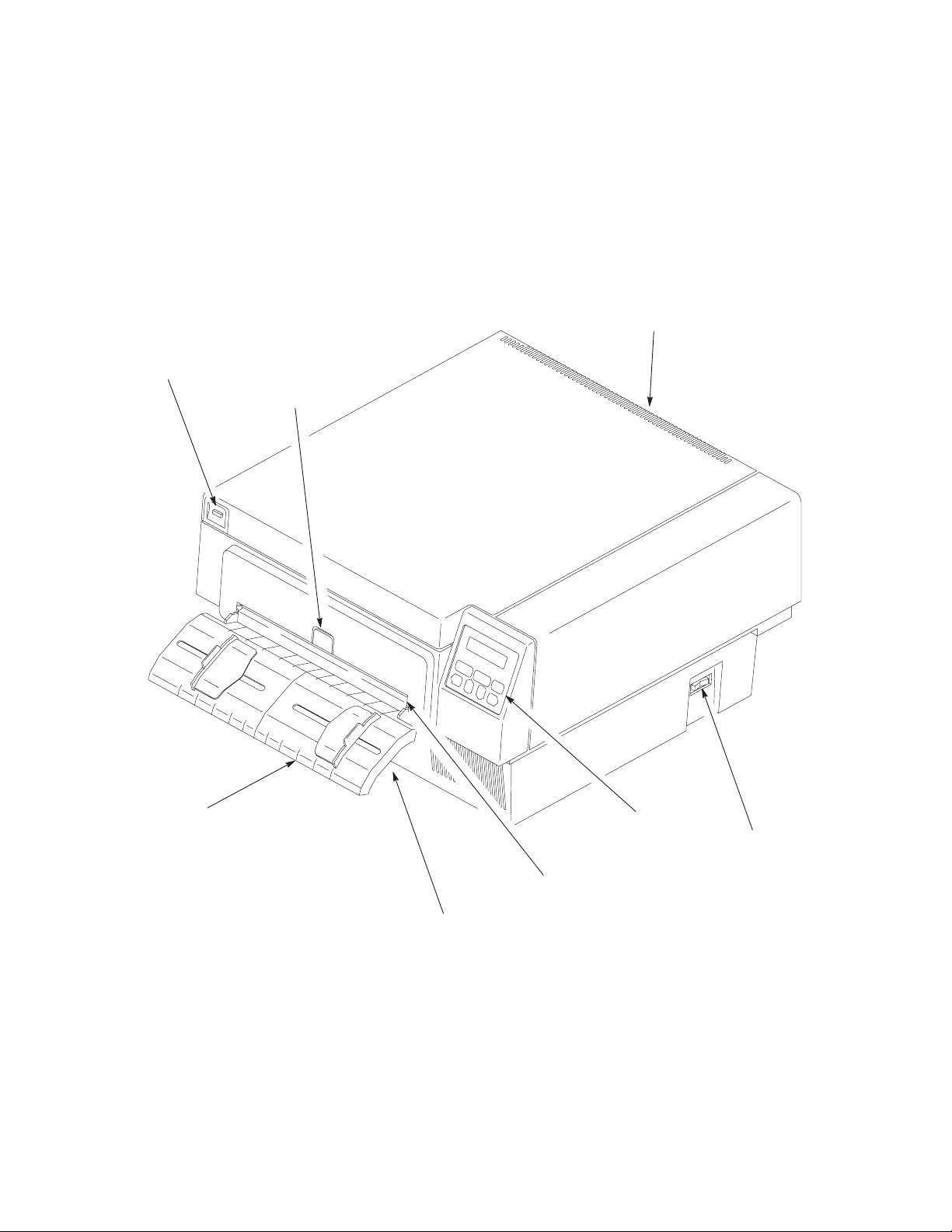

Exit Paper Guide

(not shown)

Top Cover Latch

Paper Tension

Release

Input Paper Guide

Paper Entry

Disk Drive(s)

(not shown under

paper guide)

Control Panel

Power Switch

Figure 2–3. Front and Right Side View of Printer

2–8 Setting Up the Printer

Page 27

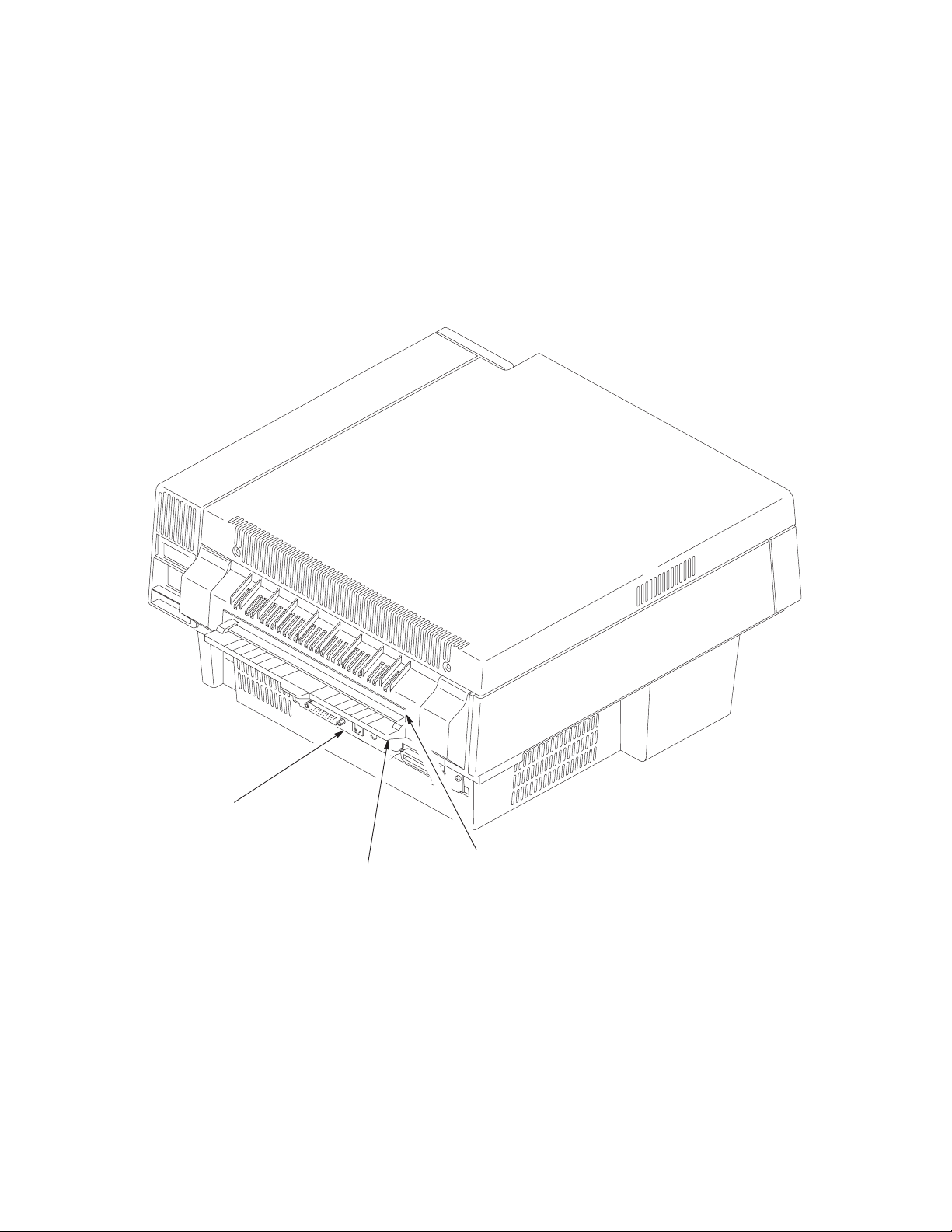

I/O Panel

Paper Exit

Exit Paper Guide

Figure 2–4. Rear and Left Side View of Printer

2–9Setting Up the Printer

Page 28

Install the Developer Unit

Perform this procedure only if this is the initial installation and no toner

has been added to the developing unit. Otherwise, fill the toner hopper

with toner from the toner bottle.

Refer to Figure 2–5 and perform the following steps:

1. Raise the top of the printer by firmly pressing the button on the left of

the front panel.

2. Remove the new developer unit from its foil package.

3. Slide the developer unit along the plastic rails on either side of the printer

until the developer unit is in position.

4. Lock the developer unit in place by pushing the two green lock–down

clamps down until they click.

CAUTION

Lock–down Clamps

Developer Unit

Figure 2–5. Installing the Developer Unit

2–10 Setting Up the Printer

Page 29

Add the Starter Toner

For the initial installation, use the starter toner bottle from the

developer kit. Do not use the toner bottles in the toner kit, which consists

of two toner bottles, two fuser cleaner felts, and two waste toner

containers.

After adding the starter toner, do not add toner from the toner kit until

the printer displays a toner low message. Starter toner will provide

approximately 200 pages of print at 5%.

Toner is light and easily becomes air–borne and can contaminate the printer. Be

careful not to stain your hands, clothes, or the interior of the printer with toner.

NOTE: If toner is spilled, use a toner vacuum to clean up the loose toner.

Do not use water to clean the toner from the printer. Any toner

remaining on clothes can be removed with a cloth dampened in cold

water. Never use hot water to remove toner from clothes or skin.

Use care when handling toner.

IMPORTANT

When the toner is low, the printer will stop and the LCD will show “03 ADD

TONER AND CHK WASTE BOTTLE.”

NOTE: Do not turn off the printer during a print job to add toner; otherwise,

all unprinted data will be lost. Once the toner is added, press ON

LINE to continue printing.

Refer to Figure 2–6 and perform these steps:

1. Open the starter toner bottle from the developer kit, and attach the

spout.

2. Carefully open the developer unit cover.

3. Carefully pour the starter toner into the developer unit. Make sure to

spread the toner evenly from side to side.

2–11Setting Up the Printer

Page 30

IMPORTANT

Do not squeeze the toner bottle as you pour the toner. Doing so could

cause the loose toner to be blown out of the hopper and contaminate the

printer and soil hands and clothes.

If the toner bottle does not empty completely, gently tap the end of the

bottle while holding it over the hopper.

4. Close the developer unit cover. Press the cover until you hear a “click”

which indicates that the developer unit is closed completely.

5. Clean up any toner that may have spilled during this process using one

of the moist towels that come with the cleaning kit inside the developer

kit.

NOTE: Some software stops communicating with the printer if the printer is

off line for more than two minutes. In this case, you may need to

restart your print job.

Starter Toner Bottle

(with spout attached)

Developer Unit Cover

(shown in the open position)

Figure 2–6. Filling the Toner Cartridge

2–12 Setting Up the Printer

Page 31

Install the Ozone Filter

Refer to Figure 2–7 and perform the following steps:

1. Remove the ozone filter from the plastic bag.

2. Holding the ozone filter by its tab, place the ozone filter into the slot on

the inside of the front of the printer.

Figure 2–7. Installing the Ozone Filter

Ozone Filter

2–13Setting Up the Printer

Page 32

Install the Waste Toner Container

NOTE: The OPC drum unit must be removed before placing the waste toner

container into its opening.

Refer to Figure 2–8 and perform these steps:

The OPC drum unit is light sensitive. Install it within five minutes.

When removing the drum unit from the foil bag, do not touch the

surface of the drum unit. Fingerprints and scratches can damage the

drum surface and cause poor print quality. Do not rotate the drum unit

manually. Forced rotation will cause an incorrect count for the life of the

drum unit and may cause poor print quality.

1. If installed, remove the OPC unit by lifting it carefully out of the printer

and place it on a flat surface.

2. Remove one of the waste toner containers from the toner kit box.

CAUTION

NOTE: If the green cap is placed on the filling hole, it cannot be removed,

in which case the waste toner container should be discarded.

3. Make sure that the green cap is on the cap holder rather than on the

filling hole of the new waste toner container.

NOTE: The waste toner container must be properly seated in the printer or

the printer will display an error message when the printer cover is

closed.

4. Install the waste toner container in the printer as shown in Figure 2–8.

2–14 Setting Up the Printer

Page 33

Waste Toner

Container

Figure 2–8. Installing the Waste Toner Cartridge

2–15Setting Up the Printer

Page 34

Install the Fuser Cleaner Felt

Refer to Figure 2–9 and perform these steps:

1. Remove one of the fuser cleaner felts from the toner kit box

2. Remove the fuser cleaner felt from its plastic wrapping.

3. Lift the cleaner felt cover on the fuser unit. If the cleaner felt cover

comes off, simply slide the shafts into the appropriate openings in the

fuser unit.

4. Carefully slide the fuser cleaner felt into the opening on the top of the

fuser unit.

5. Close the cleaner felt cover.

Fuser Cleaner Felt

Fuser Cleaner

Felt Cover (shown

in the open position)

Figure 2–9. Installing the Fuser Cleaner Unit

2–16 Setting Up the Printer

Page 35

Install the OPC Drum Unit

The OPC drum unit is light sensitive. Install it within five minutes.

When removing the drum unit from the foil bag, do not touch the

surface of the drum unit. Fingerprints and scratches can damage the

drum surface and cause poor print quality. Do not rotate the drum unit

manually. Forced rotation will cause an incorrect count for the life of the

drum unit and may cause poor print quality.

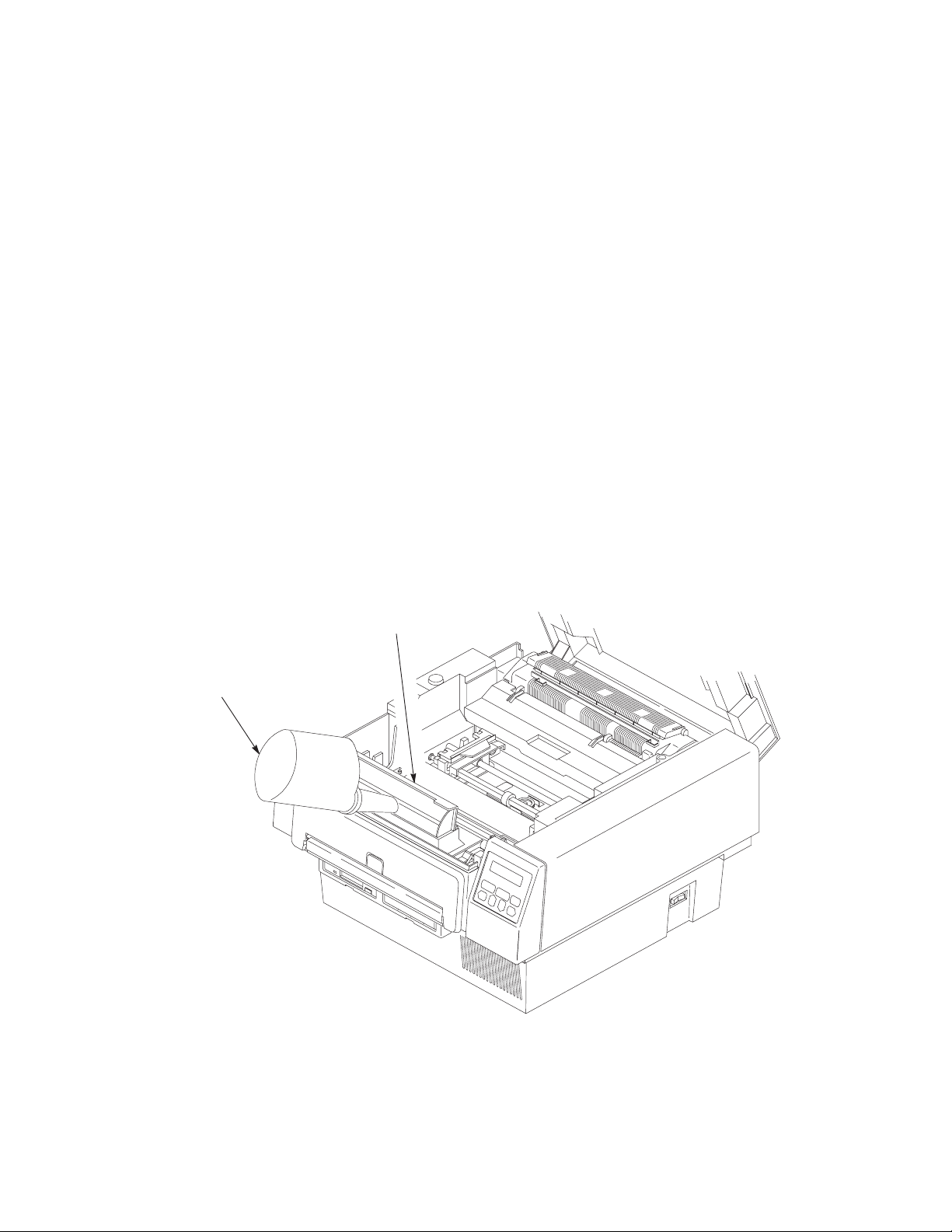

Refer to Figure 2–10 and perform these steps:

1. Remove the OPC drum unit from its foil bag.

NOTE: Save the foil bag and insert the OPC drum unit into the bag

whenever the printer cover is open for more than five minutes.

2. Insert the drum unit behind the developer unit. The OPC drum unit will

slide into place easily.

CAUTION

NOTE: The drum unit does not lock into place; it rests behind the developer

unit.

3. Close the printer cover.

OPC Drum Unit

Figure 2–10. Installing the OPC Drum Unit

2–17Setting Up the Printer

Page 36

Load Paper

NOTE: Before loading paper, make sure the Paper Length and Paper Width

Refer to Figure 2–11 and perform the following steps:

1. Raise the top of the printer by firmly pressing the top cover latch on the

2. Insert paper into the front of the printer. Press the tension release as

3. Open the tractor gates on the tractor unit, place the paper on the pins,

4. Unlock the tractors by pushing up the tractor locks.

5. Adjust the width of the tractors so that the paper is tight.

options are set properly in the Paper Control configuration menu.

Refer to the Configuring the Printer chapter, page 3–17, for details.

left side of the front panel.

required to insert the paper.

and close the tractor gates.

6. Lock the tractor unit by pushing down on the tractor locks.

7. To ensure that the printer will start at the top of a page, check the

following:

The leading edge of the paper should be straight; not torn, crooked, or curled.

The leading edge of the paper should not extend beyond the tractors. This allows

the printer to set the top of form accurately and automatically at the leading edge

of the paper.

8. Close the top cover of the printer.

NOTE: Repeat the paper loading procedure whenever top of form must be

reset (e.g., after clearing a paper jam, loading new paper, etc.). For

details on clearing paper jams, refer to the Diagnostics and

Troubleshooting chapter.

2–18 Setting Up the Printer

Page 37

Top Cover Latch

Tension Release

Tractor Gate

Paper Entrance

Tractor Pins

Tractor Locks

Figure 2–11. Loading Paper

2–19Setting Up the Printer

Page 38

Install the Emulation Boot Diskette

Diskette Drive “A”

Eject Button

Write

Protection

Tab

Figure 2–12. Installing the Diskette

1. Make sure the power switch on the printer is turned off.

CAUTION

Do not bend or touch exposed areas of the diskette. Keep the diskette

away from magnetic fields. Do not store in especially cold (50

(120

° F) areas.

° F) or hot

2. Remove the emulation boot diskette from its shipping container. Contact

your vendor if the diskette is missing.

3. Make sure the diskette is not write–protected. The tab must be closed.

4. Insert the emulation boot diskette into drive A until it snaps into place.

5. If you are installing a font diskette, insert the diskette into drive B.

Make sure this diskette is not write–protected. (The tab must be closed

as shown in Figure 2–12.)

NOTE: The printer comes standard with one floppy disk drive. Certain

optional software emulations, require two floppy disk drives. For

software emulations requiring two floppy disks, insert the program

disk into the Drive A and the fonts disk into Drive B.

2–20 Setting Up the Printer

Page 39

Cable Connections

Now the printer can be connected to power and to your system. To connect the

cables, refer to Figure 2–13 and perform the steps listed below.

To prevent injury to yourself or damage to the printer, make sure the

printer is connected to a proper power source.

Um Personenschäden oder eine Beschädigung des Druckers zu

verhindern, sicherstellen, daß der Drucker an eine geeignete

Stromquelle angeschlossen ist.

S’assurer que l’imprimante est branchée afin d’éviter tout risque de

blessures corporelles ou de dommages à l’imprimante.

1. Verify that the site line voltage is the same as the voltage specified in

“Check the Power Requirements” section, page 2–3.

WARNING

WARNUNG

ATTENTION

2. Make sure the printer power switch is set to 0 (OFF).

3. Connect the power cord (supplied with the printer) to the AC power

connector on the printer.

NOTE: To avoid possible electrical interference, separate the AC power

cord and the interface cable.

4. Connect the opposite end of the power cord to the AC line receptacle.

5. Connect the interface cable to the appropriate printer interface connector

and to the host computer. The printer supports a variety of standard and

optional interfaces:

• Centronics parallel

• Dataproducts parallel (requires optional cable adapter)

• RS–232 and RS–422 serial

• Coax/Twinax (option)

• Local Area Network (option)

2–21Setting Up the Printer

Page 40

NOTE: RS–422 can be enabled or disabled via a menu option on the control

panel under the host interface selection. Make sure this selection is

properly made for your application.

NOTE: The printer must be properly configured for the appropriate

interface. Refer to the Configuring the Printer chapter for more

information.

AC Plug

RS–232/422 Port

Coax/Twinax Connector

Diagnostic Test Port

Centronics Parallel Port or

Dataproducts Port (with adapter)

Figure 2–13. Cable Connections

2–22 Setting Up the Printer

Page 41

Check for Interference

The printer should be used only with FCC, VDE, or CE certified computing

devices. If the printer is installed within 10 feet of audio or video equipment,

interference may occur. Determine if there is interference by turning the printer

ON and OFF and checking the audio and video equipment for noise spikes. If

interference occurs, perform the following:

1. Relocate the printer or the electronic device affected by the interference,

including the antenna, if applicable.

2. Ensure that the printer and electronic device are on separate power

circuits or install AC line filters.

3. Ensure that the wall outlets are properly grounded.

If these steps do not resolve the problem, refer to the Federal Communications

Commission Booklet, “How to Identify and Resolve Radio – TV Interference

Problems” (stock number: 004–000–00345–4), available through the U.S.

Government Printing Office, Washington, D.C. 20402.

2–23Setting Up the Printer

Page 42

Transporting the Printer

Take precautions to prevent damage to the printer during transport. If a move

requires trucking, use the original packaging materials.

Short Distance Transport

1. Turn off the printer and unplug the power cord from the wall outlet.

2. Remove the paper.

3. Remove all external communication and interconnection cables (AC

line cord, coax cable, any optional attachment cards, etc.) from the

printer.

4. Before you remove the developer unit, place several sheets of paper in

front of the printer and on a work surface that you will set the developer

on. Do this in case any toner spills.

5. Remove the developer unit. (It is a good idea to have a toner vacuum

handy when performing this step.)

6. Place the developer unit in a sealable plastic bag.

7. Temporarily remove the OPC drum in order to remove the waste toner

container.

NOTE: The waste toner container is recyclable. A recycling shipping label

is provided, with instructions attached, in the toner box.

8. Place the green cap on the filler hole of the waste toner container and

remove it from the printer and package it for recycling.

9. Install the OPC Drum in the printer.

CAUTION

Do not touch exposed areas of or bend the diskette. Keep the diskette

away from magnetic fields. Do not store in especially cold (50

(120

°F) areas.

10. Remove the diskette from the disk drive and place it in a protective

cover.

°F) or hot

11. Always carry the printer and developer unit upright.

2–24 Setting Up the Printer

Page 43

Long Distance Transport

1. Pack all connecting cables in a plastic bag.

2. Place the developer unit in appropriate packaging for recycling. It is not

practical to move the developer unit over long distances.

3. Using a towel and a toner vacuum, remove residual toner from inside

the printer.

Failure to secure the pressure roller for shipment can cause permanent

damage to the printer.

The fuser must be cool before proceeding further.

4. Secure the fuser pressure roller (lower roller) to prevent it from

bouncing during shipment. Insert the original foam pad between the

fuser rollers.

CAUTION

NOTE: If the original foam pad is not available for use, use bubble wrap or

other foam packing material to secure the lower fuser roller.

NOTE: Replacement packaging material can be procured from your

authorized representative.

5. Use original packing material if available. Otherwise, use sufficient

shock–absorbing packaging material.

6. Secure the top and front covers to keep them from opening.

7. At the new site, install a new developer unit and waste toner container.

2–25Setting Up the Printer

Page 44

2–26 Setting Up the Printer

Page 45

3

Chapter Contents

Configuring the Printer

Overview 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Printer Settings 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving a Configuration 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modifying a Configuration 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing a Configuration 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Factory Settings 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Menus 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Control Menu 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Width 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Length 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horiz. Image Shift 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vert. Image Shift 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reprint on Fault 3–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Control Menu 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuser Temperature 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Energy Timeout 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics Menu 3–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1Configuring the Printer

Page 46

Test Print 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Life Data 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk Management Menu 3–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Configuration 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Save Configuration 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Configuration 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delete Configuration 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power–up Configuration 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protect Configurations 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode (Emulation) Menu 3–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impact Printer 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCL5 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IGP/PGL 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IGP/VGL 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CTHI 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IPDS 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance/Miscellaneous Menu 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Panel Key Sound 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power–up State 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hex Dump Mode 3–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTX–Setup Option 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Language 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host Interface Menu 3–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 Configuring the Printer

Page 47

Centronics Interface Parameters 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dataproducts Interface Parameters 3–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Interface Parameters 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Font Memory Menu 3–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Character Memory 3–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Cache Memory 3–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Cache Size 3–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Cached Characters 3–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Fonts Loaded 3–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Font Weight 3–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Information Menu 3–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Memory 3–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3Configuring the Printer

Page 48

Overview

The configuration process is matching the printer operating characteristics to

those of the host computer.

This chapter explains how to use the control panel to change individual settings

and save them as a customized configuration.

Figure 3–1 shows an overview of the configuration menu. The next pages

describe how to move within the menu, change configuration settings, and save

and print configurations. This is the menu structure for the LinePrinter Plus

emulation. (Menu options are explained beginning on page 3–16.)

Paper

Control

Page 3–17 Page 3–23

Image Width

Paper Length

Hor Image Shift

Vert Image Shift

Reprint on Fault

Mode Maint / Misc

Page 3–26 Page 3–29 Page 3–32 Page 3–44

Impact Printer Panel Key Sound

Printer

Control

Page 3–19 Page 3–21

Fuser Temperature

Energy Timeout

Alarm

Power–up State

Hex Dump Mode

PTX–SETUP Option

Display Language

Diagnostics

Test Print

Engine Life Data

Host

Interface

Centronics*

Dataproducts

Serial

Twinax*

Coax

Max Char Memory

Max Cache Memory

Max Cache Size

Max Cached Char

Max Fonts Loaded

Font Weight

Drive B Fonts

Installed Fonts

Disk

Management

Load Config.

Save Config.

Print Config.

Delete Config.

Power–up Config.

Protect Configs.

Font

Memory

System

Info.

Page 3–48

System Memory

Note:

If the T

factory

default. If T

is the default.

winax interface is supportedT

winax is not supported, Centronics

winax is the

Figure 3–1. The Configuration Menu

3–4 Configuring the Printer

Page 49

Changing Printer Settings

Changing printer settings, such as paper length, emulation, and host I/O interface,

is referred to as configuring. You configure the printer using the control panel.

1. Make sure the printer is offline. If ONLINE is lit, press ON LINE.

OFFLINE

PAPER CONTROL

2. Press NEXT or PREV to cycle through these menus:

Paper Control

Printer Control

Diagnostics

Disk Management

Mode

Maint./Misc.

Host Interface

Font Memory

System Info.

3. When the desired menu is displayed, press DOWN to access the

available options or submenus for that menu.

4. Press NEXT or PREV to scroll through the values.

5. Press ENTER to select a value. An asterisk is displayed next to the

selected value.

NOTE: The ENTER switch must be unlocked to change printer settings.

The default at power–up is the “LOCKED” state. If the ENTER

switch has been locked, you must unlock it before the printer will

accept the new parameter setting. Press UP and DOWN

simultaneously to toggle between lock and unlock. When ENTER is

unlocked, the display will momentarily flash:

ENTER SWITCH

UNLOCKED

3–5Configuring the Printer

Page 50

6. If there are more values you want to change, use the UP, DOWN, NEXT

and PREV switches to access the value and press ENTER to select it.

7. At any time, you may press UP to return to the options one level higher.

8. At any time, you may also press ON LINE to save your changes

temporarily, exit the configuration menu, and place the printer online.

9. Once you have finished selecting all of your options, you can save your

configuration for later access. Save the configuration as described on

page 3–7, if desired.

IMPORTANT

If you do not save your configuration, all of the new values will be lost

when you turn off the printer. (Refer to “Disk Management Menu” on

page 3–23.)

3–6 Configuring the Printer

Page 51

Saving a Configuration

You can save up to eight different configurations to meet unique print job

requirements.

For example:

Config. 0: Factory Default (This cannot be altered. See page 3–14.)

Config. 1: Selects RS–232 Serial Interface

Config. 2: Selects Dataproducts Parallel Interface

The configurations are saved and stored on diskette for later use. These

configurations, including the factory default, will not be affected when the printer

power is turned off. If you do not save your configuration before you turn off the

printer, the current configuration will be lost.

Selects Image Width of 4 inches

Selects Paper Length of 24 inches

Selects Image Shift of 1 inch, etc.

Selects Image Width of 8 inches

Selects Paper Length of 11 inches

Selects Image Shift of 3/20 inch, etc.

NOTE: If the “Protect Configs.” option is enabled, the new configuration

will not be saved unless the existing configuration has been deleted.

Refer to page 3–25 for details.

Follow these steps to save a new configuration:

1. Press ON LINE to take the printer offline.

OFFLINE

PAPER CONTROL

2. Press NEXT or PREV until the following is displayed:

OFFLINE

DISK MANAGEMENT

3. Press DOWN.

3–7Configuring the Printer

Page 52

4. Press NEXT or PREV until the following is displayed:

DISK MANAGEMENT

Save Config.

5. Press DOWN.

6. Press NEXT or PREV to cycle through the options (1–8).

NOTE: Configuration “0” does not appear in this list. It is the default

configuration and can not be altered.

NOTE: If the “Protect Configs.” option is not enabled, the number

configuration selected will be erased in order to write the current

configuration. Make sure the number selected is empty or no longer

required before making this selection.

7. When the desired number is displayed, press ENTER to select it.

If the configuration number has been previously saved and the “Protect

Configs.” option is enabled, the following error message is displayed

briefly:

CFG FILE EXISTS

DELETE FIRST

If the configuration number has not been previously saved or the

“Protect Configs.” option is disabled, the JOB IN PROCESS light

flashes and the following is displayed briefly:

STANDBY

. . .

The following is displayed to indicate the configuration is being saved:

Save Config.

(selected number) *

3–8 Configuring the Printer

Page 53

8. It is recommended you print the configuration and store it in a safe place

for future reference. Refer to page 3–13 for details on printing the

configuration.

NOTE: If you want to make these new configuration parameters active at

printer power–up, make sure you select this configuration as the

“power–up config” (page 3–25).

3–9Configuring the Printer

Page 54

Modifying a Configuration

You can change a saved configuration by “writing” over it. For example, you can

modify Config. 1, shown below. Suppose you want to keep all settings except the

interface type (e.g., you want to change RS–232 to Centronics). It is necessary to

load a configuration, make the desired changes, delete the current “copy” of the

configuration, and save the current machine configuration (in this example,

configuration 1 with the desired changes) as the newly modified configuration.

Config. 1: Selects RS–232 Serial Interface

Selects Image Width of 4 inches

Selects Paper Length of 24 inches

Selects Image Shift of 1 inch, etc.

1. Load the configuration to be changed (for example, Config. 1).

a. Press ON LINE to take the printer offline.

OFFLINE

PAPER CONTROL

b. Press NEXT or PREV until the following is displayed:

OFFLINE

DISK MANAGEMENT

c. Press DOWN.

d. Press NEXT or PREV until the following is displayed:

DISK MANAGEMENT

Load Config.

e. Press DOWN.

f. Press NEXT or PREV to cycle through the options (0–8).

NOTE: Configuration “0” is the factory default configuration and cannot be

altered.

3–10 Configuring the Printer

Page 55

g. When the desired number is displayed, press ENTER to make

the selection. The JOB IN PROCESS light flashes and the

following is displayed briefly:

STANDBY

. . .

The following is displayed to indicate the configuration is being

loaded:

Load Config.

(selected number) *

2. Move through the menu and change all the desired values. (In this

example, you would change the interface type value from Serial to

Centronics.)

3. Press ENTER to save each new value. An asterisk is displayed next to

the selected value.

4. Before saving the modified configuration, you must delete the original.

a. Press ON LINE to take the printer offline.

OFFLINE

PAPER CONTROL

b. Press NEXT or PREV until the following is displayed:

OFFLINE

DISK MANAGEMENT

c. Press DOWN.

d. Press NEXT or PREV until the following is displayed:

DISK MANAGEMENT

Delete Config.

3–11Configuring the Printer

Page 56

e. Press DOWN.

f. Press NEXT or PREV to cycle through the options (1–8).

When the desired number is displayed (e.g., 1), press ENTER

to select it. The JOB IN PROCESS light flashes and the

following is displayed briefly:

STANDBY

. . .

Then, the following is displayed to indicate the configuration is

being deleted:

Delete Config.

1 *

5. Save the new configuration as described on page 3–7. Make sure you

select the same number (e.g., Config. 1) when saving the modified

configuration. The new configuration replaces the existing one.

6. Print a copy of this newest configuration and store it in a safe place.

Refer to page 3–13 for details.

NOTE: If you want to make these new configuration parameters active at

printer power–up, make sure you select this configuration as the

“power–up config” (page 3–25).

3–12 Configuring the Printer

Page 57

Printing a Configuration

It is recommended that you print and store your configurations for future

reference. The printout provides a list of the parameters you set when you created

this configuration.

To print a configuration:

1. Press ON LINE to take the printer offline.

OFFLINE

PAPER CONTROL

2. Press NEXT or PREV until the following is displayed:

OFFLINE

DISK MANAGEMENT

3. Press DOWN.

4. Press NEXT or PREV until the following is displayed:

DISK MANAGEMENT

Print Config.

5. Press DOWN.

6. Press NEXT or PREV to cycle through the following printout options:

Current

Factory (this is 0)

Power–up

All

1–8 customized configurations

7. When the desired option is displayed, press ENTER. The JOB IN

PROCESS light flashes and the printer prints the specified configuration.

3–13Configuring the Printer

Page 58

Factory Settings

Table 3–1 lists the the factory default settings (i.e., Config. 0). These values are

available for loading at any time, and are maintained in the printer until a new

configuration is loaded.

Paper Control

Image Width

Paper Length

Hor Image Shift

Vert Image Shift

Reprint on Fault

Table 3–1. Factory Settings

8.2 inches

1

1.0 inches

3/20 inches

0/100 inches

Enabled

Mode

Impact Printer

PCL5 (optional)

IGP/PGL (optional)

IGP/VGL (optional)

CTHI (optional)

IPDS (optional)

Maint / Misc

Panel Key Sound

Alarm

Power–up State

Hex Dump Mode

PTX_SETUP Option

SETUP PARSE

SETUP SFCC

Display Language

Host Interface

Centronics

Data Bit 8

Paper Inst Line

Data Polarity

Strobe Polarity

Output Polarity

Paper Instruction Polarity

Strobe Filter

Fast Busy

Trailing Edge

Impact Printer

(Refer to the Impact Printer

User’s Manual for defaults.)

On

On

Online

Disable

Enable

21h

English

Twinax or Centronics

Enable

Disable

Standard

Standard

Standard

Standard

Enable

Enable

Enable

3–14 Configuring the Printer

Page 59

Dataproducts

Data Bit 8

Paper Instruction Line

Data Polarity

Strobe Polarity

Output Polarity

Paper Instruction Polarity

Strobe Filter

Trailing Edge

Serial

Host Protocol

Baud Rate

Data Bits

Stop Bits

Parity

DTR Function

RTS Function

DTR Polarity

RTS Polarity

Buffer Size

Number of Buffers

FIFO Trigger

Diagnostic

Series 1 Poll

Series 1 Delay

Series 1 Idle

RS–422 Input

Enable

Disable

Standard

Standard

Standard

Standard

Enable

Enable

None

9600 baud

8 bits

1 bit

None

On/Offline and Buffer

On/Offline and Buffer

Normal

Normal

8192 bytes

2 buffers

14 bytes

None

0

0+ Msec

Disable

Disable

Font Memory

Maximum Character Memory

Maximum Cache Memory

Maximum Cache Size

Maximum Cached Characters

Maximum Fonts Loaded

Font Weight

Standard Characters

Bold Characters

Extra Bold Characters

300 KBytes

200 KBytes

900 characters

1 KBytes

5 fonts

168

218

259

3–15Configuring the Printer

Page 60

Configuration Menus

The printer provides the following “main level” configuration menus:

• Paper Control

• Printer Control

• Diagnostics

• Disk Management

• Mode (Emulation)

• Maintenance/Miscellaneous

• Host Interface

• Font Memory

• System Information

The following pages show the configuration menus and describe the options.

3–16 Configuring the Printer

Page 61

Paper Control Menu

Paper Control

Image Width

0.5 inches

1.0 inches

1.5 inches

2.0 inches

2.5 inches

.

.

.

8.0 inches

8.2 inches *

Paper Length

Inch Select *

Length in

Inches

3.0 inches

.

.

.

1

1.0 inches *

.

.

.

33.0 inches

6 LPI Select

Length in

6 LPI

18 lines

.

.

.

66 lines *

.

.

.

198 lines

8 LPI Select

Length in

8 LPI

24 lines

25 lines

26 lines

.

.

.

88 lines *

.

.

.

264 lines

Hor Image Shift

–20/20 inches

–19/20 inches

–18/20 inches

*

*

0/20 inches

1/20 inches

2/20 inches

3/20 inches *

4/20 inches

*

*

*

20/20 inches

V

ert Image Shift

–100/100 inches

–99/100 inches

–98/100 inches

*

*

0/100 inches *

1/100 inches

2/100 inches

3/100 inches

4/100 inches

*

*

100/100 inches

Reprint on

Fault

Enable *

Disable

Figure 3–2. Paper Control Menu

Press UP, DOWN, NEXT

to view options.

Press ENTER to select an option.

Press ON LINE at any time to exit

configuration (will save changes until

printer is turned of

* = Factory Default

, and PREV

f).

3–17Configuring the Printer

Page 62

Image Width

This option specifies the width of the image to be printed. The allowable range is

0.5 to 8.2 inches. The factory default value is 8.2 inches.

NOTE: If the paper width is less than 8.2 inches, you must set this

Paper Length

This option specifies the vertical perf–to–perf distance of the continuous–form

paper (i.e., the physical form length). The paper length may be specified in three

different units:

Inches: 3.0 to 33.0 inches, in 1/2–inch increments (default: 11”)

6 LPI: 6 to 198 lines, in 1–line increments (default: 66 lines)

8 LPI: 8 to 264 lines, in 1–line increments (default: 88 lines)

The printer can move paper in 1/6 or 1/8 inch increments. Therefore, the printer

will always move paper the exact distance specified from this option.

parameter for proper positioning of the image on the paper.

Horizontal Image Shift

This option specifies the amount to shift an image to the right for precise

positioning on the page. The actual width of the image is not affected by this

parameter. The allowable range is 0.0 to 1.0 inch, in 1/20–inch increments. The

factory default is 3/20 inch.

Vertical Image Shift

This option specifies the amount to shift an image down for precise positioning

on the page. The actual length of the image is not affected by this parameter. The

allowable range is 0.0 to 1.0 inch, in 1/100–inch increments. The factory default

is 0/100 inch.

Reprint on Fault

The printer stops processing of a print image when the printer experiences a fault

condition. Enable the reprint on fault option so the printer will process the entire

image page that was being printed when the fault occurred. This option verifies

that a printer fault will not interfere with the printing of an entire document.

3–18 Configuring the Printer

Page 63

Printer Control Menu

Printer Control

Fuser

Temperature

Normal *

–5 degrees C

–10 degrees C

–15 degrees C

–20 degrees C

Energy

Timeout

1 minute

5 minutes *

10 minutes

30 minutes

Disabled

Press UP, DOWN, NEXT

to view options.

Press ENTER to select an option.

Press ON LINE at any time to exit

configuration (will save changes until

printer is turned of

* = Factory Default

Figure 3–3. Printer Control Menu

, and PREV

f).

3–19Configuring the Printer

Page 64

Fuser Temperature

The fuser temperature option allows you to reduce the normal temperature of the

fuser by up to –20 C in 5 degree increments. This reduction can be required due

to the print media. For example, thinner material may curl or waffle at high

temperatures and adhesive material on label material may melt. It is necessary to

lower fuser temperature in such cases.

The selections on the control panel are:

Normal (this is the default selection)

–5 degrees C

–10 degrees C

–15 degrees C

–20 degrees C

Energy Timeout

The energy timeout option provides the ability to select the length of time before

the printer goes into the energy saving mode. From the energy saving mode, the

printer will require warm up time to bring the fuser to the configured

temperature. Energy is saved by turning off heater power to the fuser.

The timeout selections are:

1 minutes

5 minutes (this is the default selection)

10 minutes

30 minutes

Disabled

3–20 Configuring the Printer

Page 65

Diagnostics Menu

Diagnostics

T

est Print

T

est Pattern

Lines *

Grid

Checkerboard

All Gray

All Black

No. of Pages

1 *

2

5

10

Continuous

Start

Test

Engine Life

Data

Engine Pages

Drum Pages

Power Of

f Count

Press UP, DOWN, NEXT

to view options.

Press ENTER to select an option.

Press ON LINE at any time to exit

configuration (will save changes until

printer is turned of

* = Factory Default

Figure 3–4. Printer Control Menu

, and PREV

f).

3–21Configuring the Printer

Page 66

Test Print

The test print option allows you to print different user specified test patterns for a

user specified number of pages. The test print can be used to identify the source

of printer image problems.

The factory default for the test pattern is lines and the default for number of

pages is 1. The selections for these options are:

Test Pattern

• Lines *

• Grid

• Checkerboard

• All Gray

• All Black

Number of Pages

• 1*

• 2

• 5

• 10

• Continuous

Press Enter

Engine Life Data

Engine life data provides you with information concerning page count and

power off count. This data is used by the controller to determine the proper time

to replace consumables. The power off count is used to identify the proper time

to replace the EPROM. The specific information provided on the control panel is:

Engine Pages

Drum Pages

Power Off Count

3–22 Configuring the Printer

Page 67

Disk Management Menu

Disk

Management

Load Config

0 *

1

2

3

4

5

6

7

8

Protect

Configs

Save Config

1 *

2

3

4

5

6

7

8

Print Config

Current *

Factory

Power–up

All

1