Page 1

15 Discovery Way, Acton, MA 01720

Phone: (978)263-3584, Fax: (978)263-5086

Web Site:

www.piacton.com

Operating Instructions

Princeton Instruments Model VM-502

0.2 Meter Vacuum Monochromator

VM-502 s/n: Rev. 5.0

SD3 s/n:

Page 2

PRINCETON INSTRUMENTS CORPORATION

VM-502

Operating Instructions

CONTENTS

Section I. General Description ................................................................................................1

1.1 Description.......................................................................................................................1

1.2 Specifications...................................................................................................................1

Section II. Instrument Setup....................................................................................................3

2.1 General Description: ........................................................................................................ 3

2.2 Unpacking and Inspection: ..............................................................................................3

2.3 Removal of Protective Cover and Shipping Ties:.............................................................3

2.4 Pumping System Mounting:.............................................................................................4

2.5 SD3 Connections:............................................................................................................4

2.6 Software Installation: .......................................................................................................6

2.7 System Operation ............................................................................................................7

Section III. Instrument Operation............................................................................................8

3.1 Bilateral Slit Assemblies: .................................................................................................8

3.2 Fixed Width Slit Assemblies: (optional)............................................................................8

3.3 Grating and Holder Assembly:.........................................................................................8

3.4 Air Inlet Valve: (optional).................................................................................................9

3.5 Movable Diverter Mirror: (optional) .................................................................................9

3.6 Slit Chamber Isolation Valves: (optional) ........................................................................9

3.7 Slit Chamber Air Inlet Valves: (optional) ........................................................................10

3.8 Slit Chamber Roughing Valves: (optional) .....................................................................10

Section IV. Controlling the VM-502 with the SD3 SpectraDrive Controller .......................11

4.1 Description..................................................................................................................... 11

4.2 Controlling the VM-502 Monochromator with Acton Software......... ............................... 11

4.3 Controlling the VM-502 Monochromator with User-Generated Software or LabVIEW...11

4.4 Controlling the VM-502 Monochromator at the Command Level ...................................11

Section V. Care of the Instrument......................................................................................... 16

5.1 Main Chamber (Instrument)...........................................................................................16

5.2 Bilateral Slits..................................................................................................................16

5.3 Scanning Mechanism ....................................................................................................16

5.4 Optical Surfaces ............................................................................................................16

Appendix A. Drawings and Schematics............................................................................... 17

VM-502 Pictorial................................................................................................................... 18

Pumping Port Size ...............................................................................................................19

Schematic (SpectraDrive Units only).................................................................................... 20

Page 3

Section I. General Description

1.1 Description

The Princeton Instruments Model VM-502 is a nominal 0.2 meter vacuum scanning

monochromator, with an optimum wavelength range in the vacuum ultraviolet region.

However, with other gratings and coatings, the instrument is useful from the extreme UV to

the infrared.

The Model VM-502 is designed to use an aberration-corrected concave holographic grating,

which provides and aperture ratio of f/4.5.

The Model VM-502 is set up as specified in the conventional “V” configuration (Model VM-502V), in a straight through configuration (Model VM-502-S), or a combination of both

(Model VM-502).

1.2 Specifications

Specifications are with standard 1200 G/mm gratings unless otherwise noted.

Focal Length: Nominal 0.2 meters

Optical System: Aberration-corrected concave holographic grating

Aperture Ratio: Nominal f/4.5

Reciprocal Linear Dispersion: Nominally 4.0 nm/mm, with 1200 G/mm grating in the first

order

Wavelength Range: Mechanical scanning range is zero order to 546.1 nm, with a 1200

G/mm grating. Low wavelength limit is dependent upon light source and detector; typically

less than 30 nm

Grating Coating: Standard coating is Princeton Instruments #1200 VUV Aluminum and MgF2,

with reflectance of 80% typical at 121.6 nm. Iridium coatings are optional for the extreme UV,

and are supplied if specified

Grating Holder: The grating holder is kinematically mounted in the instrument, allowing

gratings to be interchanged without requiring realignment. Each grating holder contains the

classical grating adjustments for initial alignment of the grating to the instrument

Scanning Mechanism: A sine drive mechanism provides a linear wavelength change with the

rotation of a precision lead screw. A Model SD3 controller is provided for scanning drive

control using a computer (customer provided).

Slits: Standard bilateral slits are supplied and are adjustable from 5 micrometers to 3

millimeters. A precision micrometer provides for slit adjustment under vacuum conditions, and

is graduated in 10 micrometer increments. The slit height is adjustable from 0 to 20 mm.

1

Page 4

If specified, standard fixed width slits 1m high are supplied to customer’s specified width.

Movable Diverter Mirror (optional): A movable diverter mirror is provided to divert the beam

from the V slit position to the straight through position. A knob in the instrument cover allows

the mirror to be moved under vacuum conditions

Slit Chamber Isolation Valve (optional): Vacuum valves are provided to isolate the slit

chambers form the main instrument chamber. Ports (1/8 NPT) are provided in the slit

chambers for gauge and roughing accessories

Air Inlet Valve (optional): An air inlet valve is located in the instrument housing to vent the

instrument to atmospheric pressure.

2

Page 5

Section II.

Instrument

2.1 General Description:

The instrument is shipped completely assembled, tested and ready for immediate installation. If

the instrument is to be stored before use, contact Princeton Instruments for storage instructions.

For shipping purposes, some optical components are covered, and mechanical components

are tied or placed in specific positions. The following procedure is recommended to prepare

the instrument for use.

2.2 Unpacking and Inspection:

Carefully unpack and examine both the VM-502 monochromator and the scan controller

unit. If there is any indication of physical damage, report the condition immediately to

the carrier and Princeton Instruments. Save all packing material.

2.3 Removal of Protective Cover and Shipping Ties:

To remove the protective cover on the optical component and the shipping tie, the instrument

must be vented and the cover removed. This should be done only by personnel familiar with

optical surfaces and instrumentation.

Setup

1. Locate the air inlet valve in the instrument housing. Remove the protective cap.

Connect the air inlet valve to a dry nitrogen tank if possible. Open the air inlet valve

slowly by rotating the handle until it is in line with the valve body.

2. Remove the instrument cover by rotating the two cover knobs until they are loose, and

lift off the cover.

--------------------------------------------------------------------------------------------------------------------CAUTION: THE OPTICAL SURFACE IS NOW EXPOSED--DO NOT TOUCH, TALK, OR

BREATHE OVER THE OPTICAL SURFACES!

---------------------------------------------------------------------------------------------------------------------

3. If the instrument is equipped with a movable diverter mirror, it is held in position with

rubber bands for shipment. Locate the rubber bands holding the movable diverter

mirror in position; cut and remove these rubber bands.

4. A protective cover is attached to the grating mask with rubber bands. Verify that all

rubber bands are removed from the chamber. Remove the shipping grating cover.

NOTE: Save this cover to protect the grating if interchanging gratings.

5. Replace the instrument cover after checking the o-ring and mating surface for

cleanliness.

NOTE: If the instrument has a movable diverter mirror, make sure that the diverter

mirror and the control knob on the cover align before replacing the instrument cover.

Refer to Section 3.5 for more information

6. Close the air inlet valve by rotating the handle 90º to the valve body.

3

Page 6

2.4 Pumping System Mounting:

The instrument is now ready for mounting to a pumping system. The VM-502 and Pumping

Port Size drawings (pages 18 and 19, respectively) show the location and dimensions of a

pumping port in the instrument base. The instrument may be supported by the pumping port or

by the three pads provided.

--------------------------------------------------------------------------------------------------------------------------CAUTION: DO NOT APPLY EXCESS PRESSURE BETWEEN THE PUMPING PORT AND

THE THREE PADS PROVIDED ON THE BASE OF THE INSTRUMENT!

---------------------------------------------------------------------------------------------------------------------------

2.5 SD3 Connections:

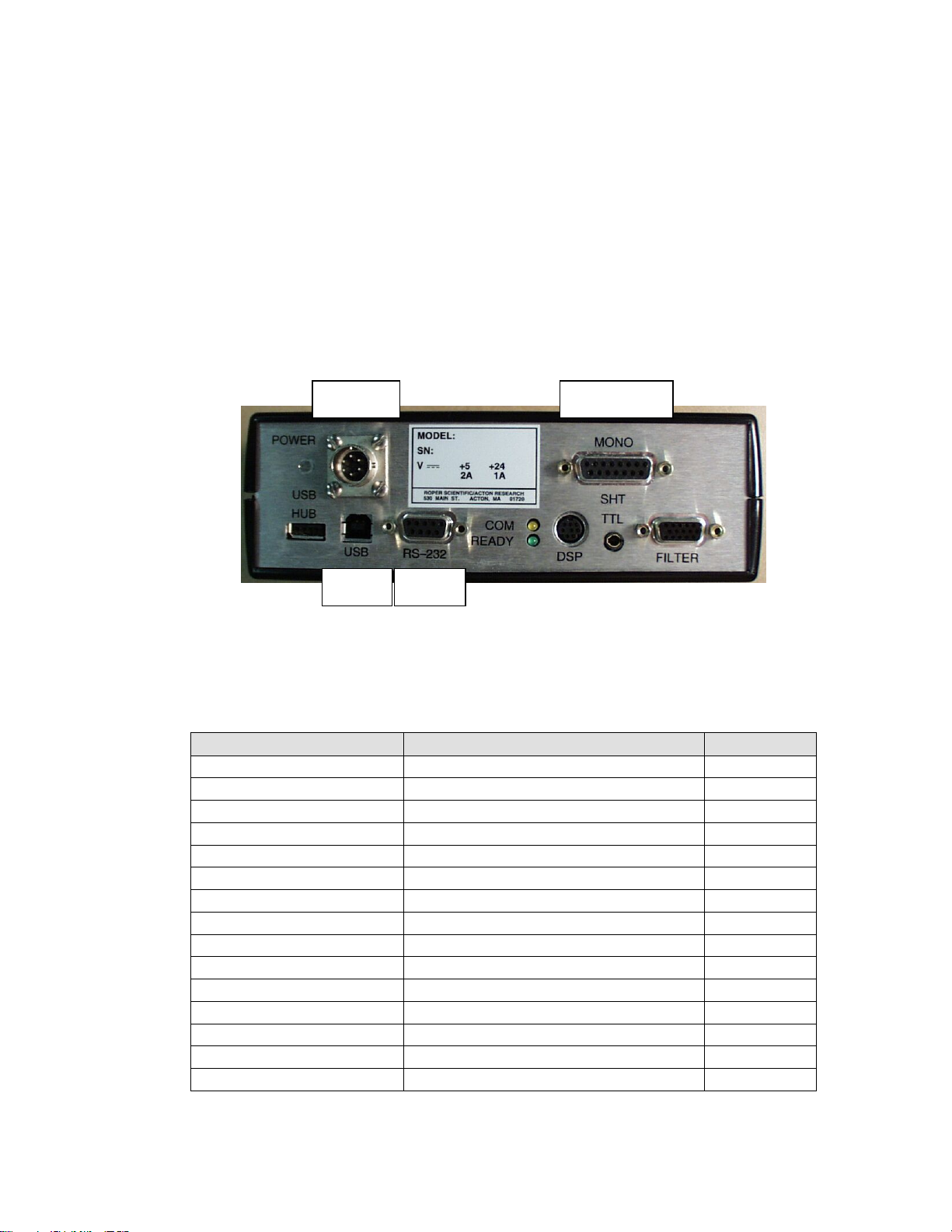

The figure below shows the cable connections necessary for operation from a computer

through the RS-232 or USB port.

Power

Connection

USB

Interface

RS-232

Interface

Monochromator

Connection

1. Locate the SD3 controller, two interconnecting cables, the power supply and power

cable.

2. Connect the motor drive cable between the 15 pin D connector (J1) on the

monochromator and the 15 pin D connector (MONO) on the SD3-502.

Pin #-Monochromator Description Pin #-SD3

1 Motor – A1 1

2 Motor – A2 2

3 Motor – B1 3

4 Motor – B2 4

5 Open 5

6 Shield–(Controller Only) 6

7 Interrupt Module +5V 7

8 Interrupt Module GND 8

9 Interrupt Module 1 LED K 9

10 Interrupt Module 2 LED K 10

11 Interrupt Module 1 LED A 11

12 Interrupt Module 1 OUT WORM 12

13 Interrupt Module 2 LED A 13

14 Interrupt Module 2 OUT MOTOR 14

15 Open

4

Table 1: J1 - Motor Drive Connector at Monochromator and SD3-502

Page 7

3. Make sure that power supply is switched OFF and connect it to POWER connector on

the SD3. Connect the line cord provided with the SD3 to the power supply and the AC

line. The power supply will operate with line voltages between 100 and 250 volts AC

50/60 Hz and provides +5 volts DC for the SD3 control logic and +24 volts DC for the

motor drives.

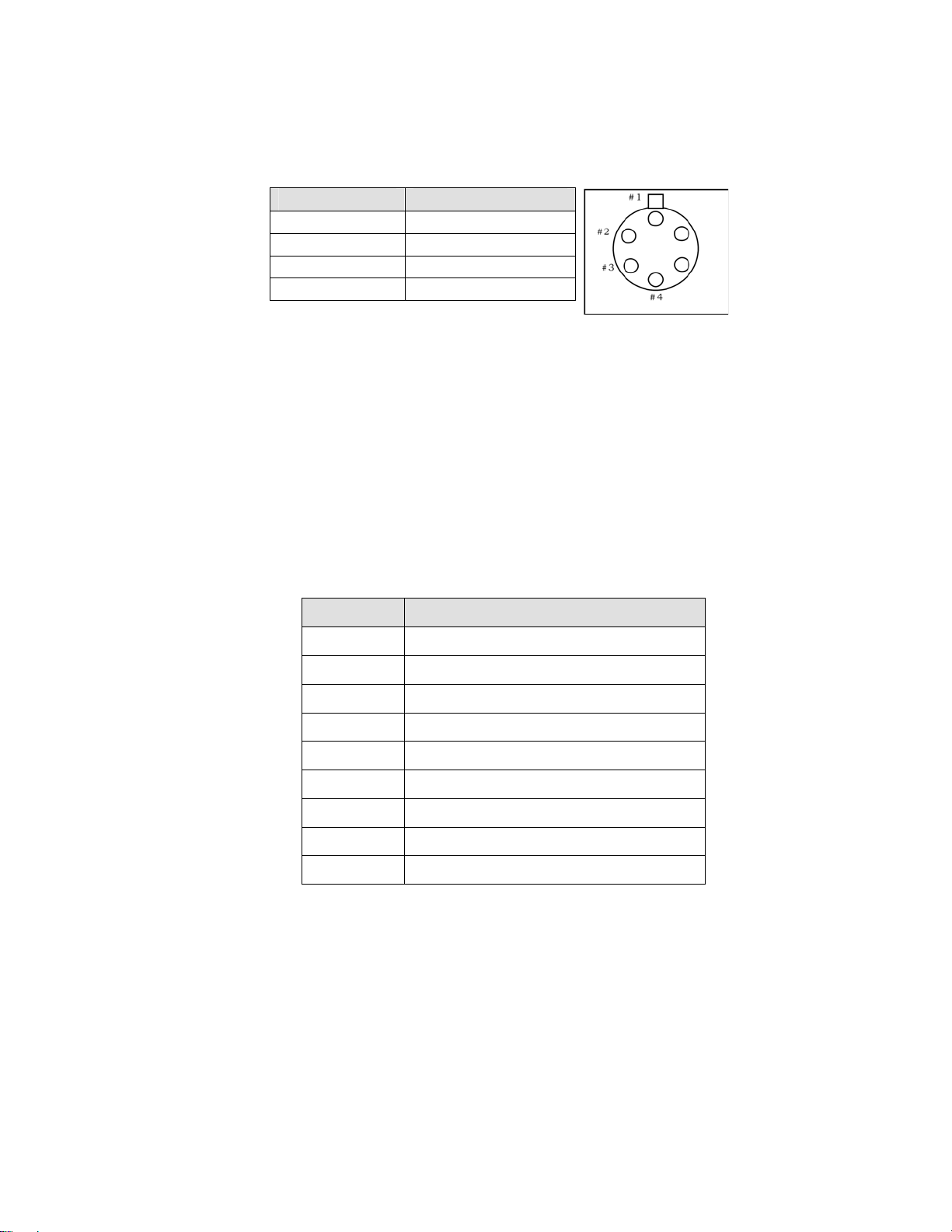

Pin # Description

1 +5V

2 GND

3 GND

4 +24V

Table 2: Power Input Pin Arrangement:

4. Connect the SD3 to a computer.

Computer: Use one of the two-supplied computer cables:

RS-232 IBM PC or compatible 9-pin female (DB9S) connector to 9-pin male

connector ( DB9P).

USB USB Cable Type A to Type B.

NOTE: If neither of these cables is compatible with your system, consult Princeton

Instruments for a custom cable. If you have facilities for constructing a custom cable,

use the RS232 pin arrangement shown in Table 3.

Pin # Description

1 open

2 RD data from SD3 to computer

3 TD data from computer to SD3

4 open

5 ground

6 open

7 RTS

8 CTS

9 open

Table 3: RS232 Computer Interface Pin Arrangement:

5. For RS232 communication, set up the terminal or RS232 computer port as follows:

9600 baud, 8 data bits, no parity, 1 start bit, 1 stop bit.

5

Page 8

2.6 Software Installation:

Each VM-502 monochromator ships with the Actono Monochromator Control Software CD

CD. If you have not purchased Princeton Instruments' SpectraSense or WinSpec/32 software,

use this CD to install the Monochromator Control Software on your computer. The following

instructions briefly describe the installation process. For greater detail, refer to the

Monochromator Control Software manual on the CD.

1. Locate your Monochromator Control Software CD.

2. Exit any programs you are running to avoid conflicts during the installation.

3. Insert the CD. Windows should automatically detect the autostart program and begin

the installation process. If it does not, click on the Start button and go up to Run. Click

on the Browse button, find the directory that contains Autorun.exe, and then click on

Open. Click on OK.

4. Install Acton Control.

5. After the installation is complete, restart your computer.

If you have received SpectraSense and are planning to use it to control the system, the

following instructions briefly describe the software installation process. For greater detail, refer

to the SpectraSense manual on the CD.

1. Locate the SpectraSense Software CD (it is not necessary to install the Monochromator

Control Software since it has been incorporated into the SpectraSense software).

2. Exit any programs you are running to avoid conflicts during the installation.

3. Place the SpectraSense CD-ROM in the drive. Click on the Start button, go up to Run.

Click on the Browse button and find the drive and directory that contains Autorun.exe.

Click on Autorun.exe and then Open. Click on OK.

4. An installation panel will appear. Click on the install button that is appropriate for your

operating system.

5. Follow the directions on the screen to complete the installation.

6. After the installation is complete, restart your computer.

If you will be using Princeton Instruments WinSpec/32 software, the following instructions

briefly describe the software installation process. For greater detail, refer to the WinSpec

and the Monochromator Control Software manuals.

1. Locate your WinSpec/32 CD and your Monochromator Control Software CD.

2. To avoid conflicts during the installation, exit any programs you are running.

3. Insert the WinSpec/32 CD. Windows should detect the autostart program and begin the

installation process.

4. Click on the program you want to install. In most cases, this will be WinSpec/32.

5. When asked, choose “AutoPCI” as the communications type.

6. After the installation is complete, restart your computer.

7. After restart, insert the Mono Control Software CD and install the monochromator

control software.

8. After the installation is complete, restart the computer.

6

Page 9

2.7 System Operation

It is important that the VM-502 be connected to the computer and be initialized before the

controlling software is started.

If the VM-502 is part of a system that includes a Princeton Instruments SpectraHub

Detector Interface and a single point detector such as a PMT or a Silicon Diode detector,

then the entire system will be controlled through the Princeton Instruments SpectraSense

software. The software automatically detects the VM-502 and sets up all necessary

parameters for its operation.

If the VM-502 is part of a system that includes a Princeton Instruments CCD camera,

the system is then controlled either through SpectraSense software mentioned above

or through Princeton Instruments WinSpec software. If using WinSpec, you must set

up the Spectrograph parameters by selecting AM505 in "Define Spectrograph" and by

setting the focal length to 200 mm, the included angle to 64 degrees and the detector

angle to 32.5 degrees in calibration. Follow the instructions in the WinSpec manual for

CCD calibration.

Now that you have completed the hardware and software installations, refer to

Instrument Operation

for information about operating, adjusting, or changing various VM-502

Section III.

hardware assemblies and components. See Section IV. Controlling the VM-502 with the SD3

SpectraDrive Controller

and the Monochromator Control Software for software-control

information. For additional information about maintaining the VM-502, see Section V Care of

the Instrument

.

7

Page 10

3.1 Bilateral Slit Assemblies:

Section III.

Instrument

Operation

1. Slit

2. Slit

3. Optional Adapters are available for use with Princeton Instruments CCD Cameras. Cameras

Width: The slit width of each bilateral slit assembly is adjustable from 0.005 millimeters

to 3 millimeters (5 to 3,000 micrometers) by a micrometer knob located on the slit housing.

The micrometer knob is graduated in 0.01 millimeter (10 micrometer) increments.

One counterclockwise revolution of the micrometer knob increases the slit width 0.25

millimeters (250 micrometers). For maximum reproducibility, the slit width should be set in

a counterclockwise direction (increasing slit widths) each time it is changed.

The micrometer knob should not be rotated below a reading 0.00 or above a reading of

3.00. A micrometer setting of less than 0.005 millimeters (5 micrometers) cannot be used,

because a stop is provided to prevent the slit jaws from touching each other.

Height: The slit height is controlled by a pair of horizontal baffles located in the slit

housing, and must be set up prior to mounting a pair of graduated blocks, located in the slit

housing. The graduations on the blocks are 1 mm apart, with the center graduation being

the widest. To adjust the baffles, loosen the screws at each end of the horizontal baffles,

loosen the screws at each end of the horizontal baffle and set the baffles to 1/2 the total

desired slit height above and below the center graduation.

are available that will allow operation down to the VM-502 lower wavelength limit of 3 0 nm.

NOTE: In most optical systems, resolution deteriorates with increasing slit height;

therefore, if maximum resolution is required, slits of one to four millimeters should be used.

3.2 Fixed Width Slit Assemblies: (optional)

Slit apertures 1 cm high and with a fixed width are provided. The width of each slit is marked

on each fixed slit assembly. The fixed slit assemblies are removable from the slit housing and

are precisely aligned to a master slit for each interchange and precise alignment.

3.3 Grating and Holder Assembly:

The grating holder assembly is kinematically mounted onto a rotary table in the instrument

vacuum chamber. Therefore, after initial alignment, the assembly can be removed and

replaced without alignment.

To remove the grating holder assembly from the instrument, the following procedure is

recommended:

1. Make sure that the instrument is at atmospheric pressure.

2. Remove the instrument cover by rotating the two cover knobs counterclockwise until the

screws are loose. Remove the cover.

---------------------------------------------------------------------------------------------------------------------

CAUTION: THE GRATING IS NOW EXPOSED--DO NOT TOUCH, TALK, OR

BREATHE ON THE GRATING!

---------------------------------------------------------------------------------------------------------------------

8

Page 11

3. Place the shipping grating cover supplied over the face of the grating. Loosen the one

8-32 clamp screw in the base of the grating assembly and remove the

complete grating holder assembly.

Reverse the procedure when reinstalling the grating assembly.

NOTE: To ensure proper positioning, make sure that the grating assembly is properly seated

before tightening the 8-32 clamp screw. The clamp screw should be tightened the same

torque to ensure proper positioning.

-----------------------------------------------------------------------------------------------------------------------------CAUTION: If the instrument has a movable diverter mirror, make sure that the diverter mirror

and the control knob on the cover align before replacing the instrument cover. Refer to

Section 3.5 for more information.

------------------------------------------------------------------------------------------------------------------------------

3.4 Air Inlet Valve: (optional)

An air inlet valve is supplied to bring the main instrument chamber to atmospheric pressure,

and is located in the instrument housing. The valve is open when the handle is in line with the

valve body, and closed when the handle is at 90º to the valve body.

--------------------------------------------------------------------------------------------------------CAUTION: Make sure that the vacuum system is in the proper mode

before opening air inlet valve!

---------------------------------------------------------------------------------------------------------

3.5 Movable Diverter Mirror: (optional)

A movable diverter mirror diverts the beam from the “V” slit position to the straight through slit

position. A knob on the instrument cover indexes the mirror to either the “S” or “V” position.

The “V” position, positions the mirror out of the beam, and the “S” position diverts the beam to

the straight through slit position. To change the mirror position, gently rotate the knob to the

desired “S” or “V” position; a click will be heard and felt when the mirror indexes into position.

NOTE: When the instrument cover is replaced, make sure that the diverter mirror and its

control knob are set to the same “S” or “V” position for proper engagement of the mirror and

knob control arm.

3.6 Slit Chamber Isolation Valves: (optional)

Vacuum valves are located in the slit housing to isolate the slit chamber from the main

instrument chamber. A valve control knob is located on the top of each slit housing. The valve

is open when the knob is in line with the optical beam and closed when the knob is in line with

the silver dot on the slit housing. (approximately 80 degrees to the beam).

--------------------------------------------------------------------------------------------------------------------CAUTION: Never vent the main instrument chamber with the slit chamber isolation valves

closed. Never open the slit chamber isolation valve with the main instrument chamber under

vacuum and the slit chambers at atmospheric pressure. When the main instrument chamber is

under vacuum, the slit chambers must be evacuated to 200 Torr or less before the slit

chamber isolation valves can be opened.

---------------------------------------------------------------------------------------------------------------------

9

Page 12

3.7 Slit Chamber Air Inlet Valves: (optional)

An air inlet valve is supplied to bring the slit chamber to atmospheric pressure and is located

on the side of the slit housing. The valve is open when the handle is in line with the valve

body, and closed when the handle is 90 degrees to the valve body.

--------------------------------------------------------------------------------------------------------------------CAUTION: Make sure that the isolation valve is closed

before opening slit chamber air inlet valve!

---------------------------------------------------------------------------------------------------------------------

3.8 Slit Chamber Roughing Valves: (optional)

A slit chamber roughing valve is supplied for connection to an auxiliary mechanical pump for

rough pumping of the slit chamber. The valve is open when the handle is in line with the valve

body, and closed when the handle is 90 degrees to the valve body.

---------------------------------------------------------------------------------------------------------------------

CAUTION: Make sure that the isolation valve and the air inlet valve are closed

before opening roughing valve!

---------------------------------------------------------------------------------------------------------------------

10

Page 13

Section IV.

Controlling

4.1 Description

The Princeton Instruments SD3 SpectraDrive Controller is used with the Acton

VM Monochromators in conjunction with Acton Monochromator Control

Software to provide the electronic drive for wavelength positioning, diverter mirror control and

filter positioning. The SD3 also provides the link between the monochromator and the

computer. Both USB and RS-232 are supplied as standard interfaces.

4.2 Controlling the VM-502 Monochromator with Acton Software

The Monochromator Control Software is normally installed in the directory C:\Program

Files\Acton. This directory contains the subdirectory Bin. The Bin directory contains the

executable code. There will normally be a Acton icon on the desktop that can be used

for starting the software. If this icon is not on the desktop, go to the Acton Bin directory

and start the software. When the Monochromator Control software loads, there is a main

screen with selections for operating the monochromator and various setup functions. Click on

the Operation box and a screen will come up which allows for basic control of the

monochromator wavelength. All functions of this software are described in the Monochromator

Control Software manual supplied on the Monochromator Control Software install CD.

4.3 Controlling the VM-502 Monochromator with User-Generated Software or LabVIEW

the VM-502 with the SD3 SpectraDrive Controller

The Monochromator Control Software install disk contains a folder named Acton_SDK.

This folder contains DLLs with example code in Delphi, Visual Basic, C++ and LabVIEW as

well as a folder with examples for use of the COM interface.

4.4 Controlling the VM-502 Monochromator at the Command Level

Although it requires more programming on the user’s part, the SD3 can also be controlled with

direct commands through its USB port or RS-232 port. The same command set, listed below,

is used for both RS232 and USB.

Commands can be sent as single commands or grouped in strings of commands. All

commands are single words (contain no spaces) and all commands in a string are separated

by at least one space. Parameters, if needed, precede the command and are separated from

the command by at least one space (e.g. 546.7 GOTO).

For RS232 operation, the port setup is 9600 baud, 8 data bits, 1 stop bit and no parity. A

convenient tool for trying out this mode of operation is the program HyperTerminal supplied

with the Windows operating system. The USB port with the driver supplied also shows up as

and is treated like a com port – although a very fast one. All commands or strings of

commands must be terminated with a carriage return (0D hex). The SD3 responds to a

command when the command has been completed by returning the characters OK followed by

carriage return and line feed (hex ASCII sequence 20 6F 6B 0D 0A). The default condition is to

echo each character that is sent to the SD3 with the RS-232 interface and to not echo the

commands when using the USB interface. When sending a command or string of commands,

it is important to wait for the SD3 to complete the processing of that command string before

sending another command.

11

Page 14

Monochromator Wavelength Movement Commands

GOTO

Goes to a destination wavelength at maximum motor speed. Accepts

destination wavelength in nm as a floating point number with up to 4

digits after the decimal point or whole number wavelength with no

decimal point.

<GOTO>

NM

<NM>

>NM

?NM

MONO-?DONE

MONO-STOP

Same as GOTO (For compatibility with software written for previous Acton

models.)

Goes to a destination wavelength at constant nm/min rate specified by

last NM/MIN command. Accepts destination wavelength in nm as a

floating point number with up to 4 digits after the decimal point or

whole number wavelength with no decimal point.

Same as NM (For compatibility with software written for previous Acton

models.)

Similar to NM except it returns control to user immediately rather than

waiting for Completion of monochromator wavelength move. Can be

used with? NM or MONO-?DONE below. This command must be

terminated with MONO-STOP listed below. NOTE: Use the NM

command when communication with the monochromator during the

scan is not required.

Returns present wavelength in nm to 0.01 nm resolution with units nm

appended. e.g. ?NM 300.00 nm

Used with >NM command to determine if monochromator has reached

the destination. Returns 0 if move is not complete, 1 if move is

complete.

Stops the monochromator wavelength move after use of the >NM

command.

NM/MIN

Sets constant scan rate in nm/min to 0.01 nm/min resolution. e.g. 10.0

NM/MIN

?NM/MIN

Returns present scan rate in nm/min to 0.01 nm/min resolution with

units nm/min appended. e.g. ?NM/MIN 100.00 nm/min

Grating Control Commands:

NOTE: These Grating Control Commands are used for all Acton series Monochromators. The

VM-502 has a limited selection of concave gratings. When manually changing gratings, it is

necessary to also select the grating number in Monochromator Control software,

SpectraSense, or WinSpec to allow the correct grating parameters to be used.

GRATING

Recalls parameters for the specified grating from non-volatile memory.

Up to nine (9) gratings are allowed. This command takes a grating

number from 1 - 9. e.g. 3 GRATING

?GRATING

?GRATINGS

Returns the number of the grating presently being used numbered 1-9.

Returns the list of installed gratings with position, groove density and

blaze. The present grating is specified with an arrow.

12

Page 15

The following command is used for grating installation by Acton part #:

INSTALL

Installs new grating parameters into the non-volatile memory of the

monochromator. Uses the part # of the grating to specify the

parameters.

e.g. 1-120-500 5 INSTALL places a 1200 g/mm grating blazed at

500 nm into the second grating position on #5.

The following commands are used for grating installation by grating parameters:

SELECT-GRATING

G/MM

Specifies the grating number to be installed 1 - 9.

Specifies groove density of grating to be installed in g/mm.

e.g. 1200 G/MM

BLAZE

Specifies the blaze wavelength and units of the grating to be installed

with 7 characters of the user’s choice. Unlike other commands, this

command is issued before the parameters. After the command is

issued, the SD3 responds with “ “ . Seven characters are then entered

(these may be numbers, letters, spaces or special characters).

UNINSTALL

Used to remove a grating and its parameters from the SD3 non-volatile

memory e.g. 3 UNINSTALL

13

Page 16

Calibration Commands:

INIT-OFFSET

Sets the offset value for the designated grating. Default

values are 25600 for all gratings. The grating designator

used with this command is grating# - 1.

e.g. 25590. 0 INIT-OFFSET for setting offset on grating #1.

NOTE: This command requires a decimal point after the

offset value.

For the new parameters of this command to take effect, the

monochromator must be initialized with the MONO-RESET

command or by turning the power off and back on.

INIT-GADJUST

MONO-EESTATUS

RESTORE

FACTORY

SETTINGS

MONO-RESET

Sets grating adjustment value for the designated grating.

Default values are 10000 for all gratings. The limits on the

parameter for this command are +/- 1000 for all gratings.

The grating designator used with this command is the

grating # - 1.

e.g. 9993 1 INIT-GADJUST for setting gadjust on the

second grating.

NOTE: No decimal point is used with this command. For the

new parameters of this command to take effect, the

monochromator must be initialized with the MONO-RESET

command or by turning the power off and back on.

Returns setup and grating calibration parameters for all

gratings.

Returns all parameters including grating calibration

parameters to the original factory calibrated settings.

NOTE: This command will overwrite any calibration

parameters set by the user.

Initializes the monochromator. Necessary after using INIT-

OFFSET or INIT-GADJUST.

HELLO

MODEL

SERIAL

14

Same as MONO-RESET. Used to maintain compatibility

with existing applications.

Returns model number of the monochromator.

e.g. MODEL VM-502

Returns serial number of the monochromator.

e.g. SERIAL 37480263

Page 17

The following are the Start-Up parameters and their default values:

Default Values:

GRATING #1

WAVELENGTH 0.0 nm

SCAN SPEED

INIT-

WAVELENGTH

INIT-SRATE

200.0 nm/min

Sets an initial wavelength for the SD3 after initialization.

e.g. 435.84 INIT-WAVELENGTH

Sets an initial scan rate for the SD3.

e.g. 200.0 INIT-SRATE

15

Page 18

Section V.

Care

5.1 Main Chamber (Instrument)

The main chamber should be kept sealed at all times, and under vacuum if possible. Only

vacuum-compatible material should be exposed to the vacuum of the instrument. When

operating the instrument in the vacuum ultraviolet region, the vacuum should be better than 5 x

-5

10

Torr.

5.2 Bilateral Slits

The knife edges that form the slit aperture are mounted on Ball Slides and therefore require no

lubrication. Nothing should contact the slit jaws directly; the slides are spring-loaded to

prevent damage, thus their positions can be changed if they are contacted directly.

5.3 Scanning Mechanism

The precision drive screw is located in the instrument base and should be lubricated every 6

months with the oil supplied.

5.4 Optical Surfaces

of the Instrument

The optical surfaces are extremely delicate and can be permanently damaged by mechanical

contact with anything. Do not touch, talk or breathe over the optical surfaces. After long

periods of use, the optical surfaces become contaminated and therefore have a drastically

reduced efficiency. Princeton Instruments can generally re-coat the optical components and

obtain their original efficiency, depending of course on the condition of the surfaces. Please

contact Princeton Instruments directly if you believe the optical surfaces are contaminated

or damaged.

16

Page 19

Appendix A.

Drawings

and Schematics

17

Page 20

Page 21

Page 22

Loading...

Loading...