11/2002

625-242

OPERATOR’S

MANUAL

PRINCETON PIGGY BACK OPERATOR’S MANUAL

PIGGY BACK®PB50/PB65

You must read and understand this

manual before operating the forklift.

Keep this manual with the forklift.

NEED HELP

?

If you have a question on the operation of

this unit...

Or

If you have a problem on this or any other

Princeton product...

Contact your local dealer.

A comprehensive dealer listing is

available at www.piggy-back.com

Or call

Princeton Delivery Systems

1-800-331-5851

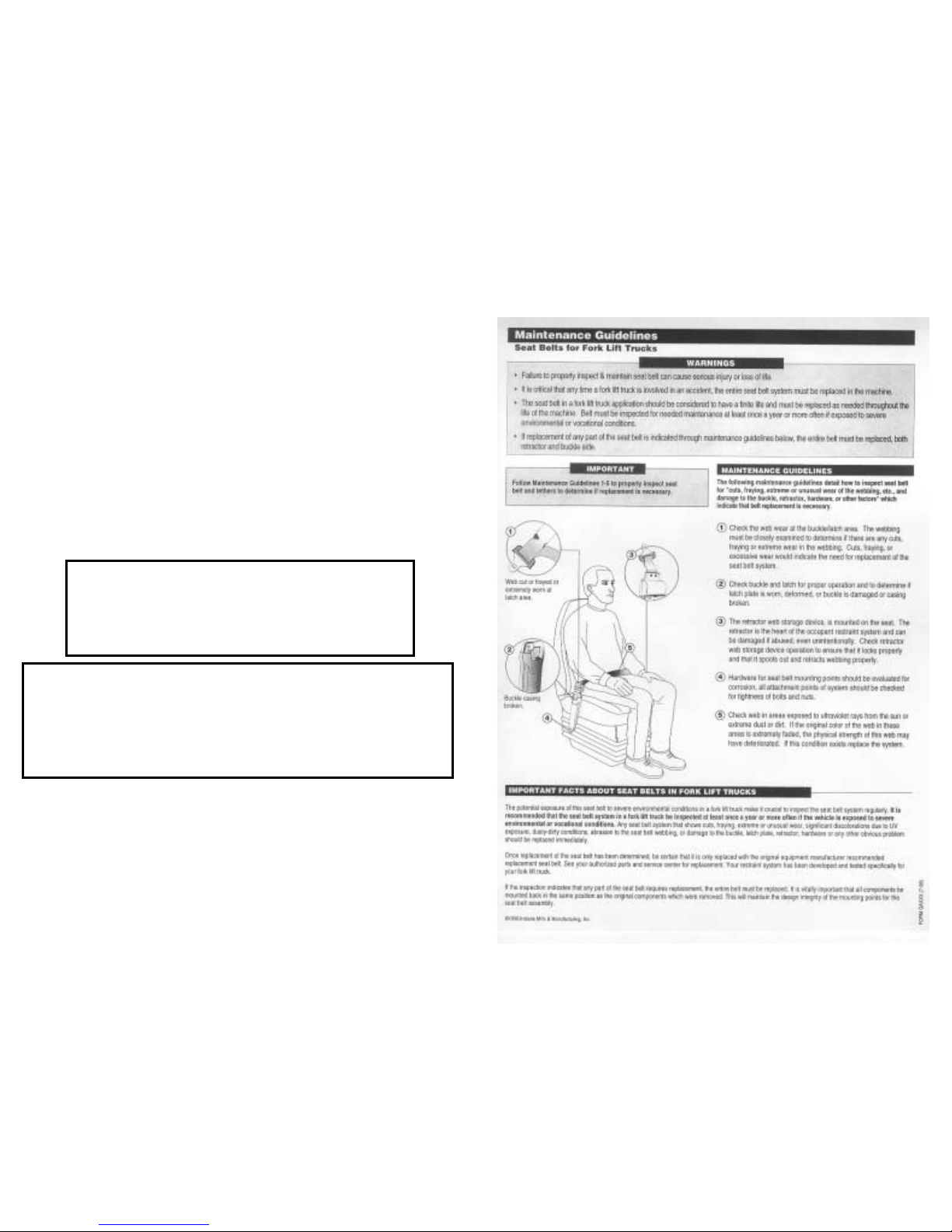

11 Seat Belt Safety Supplement

TRUCK DATA

Model No. _____________________________________

Serial No______________________________________

Weight (empty)_________________________________

Rated Capacity_________________________________

Gross Weight (loaded with Rated Load) _____________

Notice: The information in this manual was in effect at

the time of printing. Princeton Delivery Systems reserves

the right to make improvements and changes in specifications or designs without incurring obligation. Please

check with your Princeton dealer for possible updates or

revisions.

Copyright© 2002 Princeton Delivery Systems Inc. All rights reserved.

CALIFORNIA

PROPOSITION 65 WARNING

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm.

CALIFORNIA

PROPOSITION 65 WARNING

Battery posts, terminals and related accessories contain lead and

lead compounds, chemicals known to the State of California to

cause cancer, birth defects, and other reproductive harm.

Wash hands after handling.

54

10 Specifications

KUBOTAENGINE: (See Kubota engine manual)

CAUTION: Do not use ether or starting fluid. Severe non-warrantable

engine damage will occur.

FUEL: Diesel fuel must not be mixed with gasoline, kerosene, or alcohol.

*Above 32 Degrees. #2D should be used.

*Below 32 Degrees. either #1D or a mix of #1D and #2D

may be used.

ENGINE OIL: Use only CC/CD/CE rating API index oil in your diesel

engine.

*CF is the highest rating and is highly recommended.

*Change the engine oil type according to the ambient

temperature.

above 77 F. (25 C.) SAE30 or SAE10W30

SAE10W40

32 F. (0 C.) to 77 F. (25 C.) SAE20 or SAE10W30

SAE10W40

below 32 F. (0 C.) SAE10 or SAE10W30

SAE10W40

COLD WEATHER START: When the ambient temperature is below 50 F

(10 C), pre-heating is needed. The Kubota engine is equipped with quick

glow plugs. Automatic preheating is made for about 6 to 10 seconds

when starter switch key is turned to preheating position.

Start: Your unit is equipped with an (externally switched) Syncro-Start

Solenoid (Model 1753ES/1751ES).

Caution: Multiple start attempts and excessive engine cranking

could cause damage to the solenoid. Therefore, it is our

recommendation that engine cranking (pull-in coil energized) be

limited to three (3) 30 second attempts with a cool down period

120 seconds (two minutes) between each cranking attempt. After

three (3) cranking attempts, the solenoid must be allowed to cool

down to ambient temperatures before making further cranking

attempts.

53

Introduction

Your PIGGY BACK Delivery System was bought knowing it will give long

and useful service. To get the value built into it a small amount of time

and expense is needed to learn safe, productive operation, and to do

regular inspections and service.

This manual will tell you how to safely operate, inspect, and maintain

your PIGGY BACK forklift. Keep it with the forklift as a ready reference.

As with the use of all heavy machinery, failure to carefully follow these

instructions and use common sense may result in serious injury.

If you have questions about operating, maintaining, or obtaining parts for

your forklift; contact your Princeton dealer. They are always glad to help.

Table of Contents

Section

Page

Introduction 2

To Forklift Owners 3

To Forklift Operators 4

How To Use This Manual 5

Safety Signal Words 6

Service Position--Engine Off 7

Service Position--Engine Running 7

Jacking And Blocking 8

1 General Safety Practices 9

2 Operating Safety Rules And Practices 11

3 Forklift Description 13

4 Starting 16

5 Operation 18

6 Transport 34

7 Moving ADisabled Forklift 42

8 Inspection 43

9 Lubrication 46

10 Specifications 49

11 Seat Belt Safety Supplement 54

10 Specifications

ENGINE OIL: Lube oils are differentiated according to their effi-

ciency and quality grade. Commonly used are the API

Specifications.

Approved Oils:

Non-turbocharged Engines API-Specific

CC/SE CC/SF

CD/SE CD/SF

VISCOSITY: Because the viscosity of the lube oil is greatly influenced by the temperature, the choice of SAE-grade should be

governed by the ambient temperature at the engine site. Optimum

operating behavior will be attained if you use the chart below.

COLD WEATHER START: The Deutz engine is equipped with a

cold weather starting aid called “Glow Plugs”. When the temperature is below 40 F, you should use the pre-heat option. To pre-heat

the engine, turn the key to the “on” position until the pre-heat light

goes out. Then turn the key to the “start” position “the right”. If the

engine does not start, wait 1 minute before pre-heating the engine

again.

IMPORTANT: DO NOT OVERCRANK THE ENGINE

52

To Forklift Owners

ASME B56.1 and B56.6 are the standards for forklift operation,

rules and safety, maintenance, safe operation, training and supervision. You should read this manual and make it available to your

operators and their supervisors. You can get it from the American

Society of Mechanical Engineers, 345 East 47th Street, United

Engineering Center, New York, NY 10017.

ASME B56.1 and B56.6 are a key part of forklift safety. However,

making forklift operation safe involves other areas and responsibilities. The forklift owner is responsible to ensure their operators

have adequate training in operating the forklift. This training

includes, but should not be limited to, classroom and hands-on

training. Forklift safety involves the forklift itself, the environment it

works in, and the people who come in contact with it. Consider

your entire operation when addressing forklift safety.

The operator’s manual is not a training manual. It is a guide to

help trained and authorized operators safely operate their forklift

by showing the proper procedures. This manual combined with

adequate operator training will help reduce situations that may

cause an accident.

Operators must be trained and qualified to operate a forklift before

actually operating one.

Forklift training and operator awareness of the forklift work area

will help ensure a safe workplace for all your employees.

3

To Forklift Operators

Operators must become familiar with all forklift controls, procedures, and work areas. Understand what this forklift can do and its

limits. Understand and practice all safety rules.

Before driving a forklift, the user must inspect it completely to

insure safe operation. This is a requirement of OSHA, ANSI, and

ASME.

The operator is also responsible for understanding the environment the forklift is being operated in. Knowing how to operate the

forklift within their working environment is very important to overall

forklift safety.

Operate your forklift safely; careful driving is your responsibility.

Know your forklift’s capabilities and limits. Follow all instructions in

this manual.

4

10 Specifications

DEUTZ ENGINE: See Deutz engine manual)

CAUTION: Do not use ether or starting fluid. Severe non-warrantable engine damage will occur.

FUEL: Always use branded grades of diesel fuel having a sulfur

content of below 0.5%. In the case of higher sulfur content, the

periods between oil changes must be shortened.

The following fuel specifications are approved:

DIN 51 601

NATO Codes F54, F75 and F76

BS 2869: A1 and A2 (in case of A2, note sulfur content)

ASTM D 975-81 : 1-D and 2-D

VV-F-800a: DF-A, DF-1 and DF-2

WINTER-GRADE FUEL: At temperatures as low as -15 C (+5 F)

to -20 C (-4 F), kerosene should be mixed with the diesel fuel. The

necessary percentages for admixing are seen in the diagram

below.

51

10 Specifications

SPECIFICATIONS-FLUID CAPACITIES:

(All measurements listed below are completely empty/dry.)

HYDRAULIC OIL 17 US GALLONS

FUEL 8 US GALLONS

ENGINE OIL- DEUTZ 3FL1011 6.4 QUARTS

ENGINE OIL- DEUTZ 4FL1011 11.0 QUARTS

ENGINE OIL- KUBOTA 2003T 7.5 QUARTS

Fluids should be checked before starting, then run the

PIGGY BACK for 1 minute, shut engine off and re-check.

50

How To Use This Manual

The illustrations and explanations in this manual will help you

improve your skill and knowledge as a professional forklift operator

while taking full advantage of the capabilities and safety features

of your forklift.

The manual is designed to be easy to read and find information

in.The sections are numbered. The page numbers are on the bottom leading edge of each page. The Table of Contents lists the

sections and their beginning page number.

This manual is meant to be permanently attached to your

forklift as a reference. If the manual gets lost or damaged call

your Princeton dealer, they are waiting to help.

5

Safety Signal Words

Know these safety signal words and remember their meaning.

CAUTION

Is a reminder of safety practices, that if not followed, may lead to

personal injury.

WARNING

Is used when a hazard exists which can result in injury or death if

proper precautions are not taken.

DANGER

Is used when extreme hazard exists which will result in death

or serious injury if proper precautions are not taken.

6

10 Specifications

49

109” (PB50)

114“ (PB65)

9 Lubrication

LUBRICANT KEY

(1) Lithium base multipurpose grease

(2) Air filter P/N 505-141, 505-142

(3)Hydraulic Fluid, Texaco Rando

HD46 (or equal).

(4) See engine manual

(5) Hydraulic Filter P/N 207-104

(6) Engine Oil Filter-see engine parts

manual

(7)SAE 10W30

(8)Fuel Filter P/N 504-598

(9) Motor Oil 30W-40W or chain lube

RECOMMENDED LUBRICA

TION

(A) 8-10 hours or daily

(B) 25-50 hours or monthly

(C) 150 hours or every 6 months

48

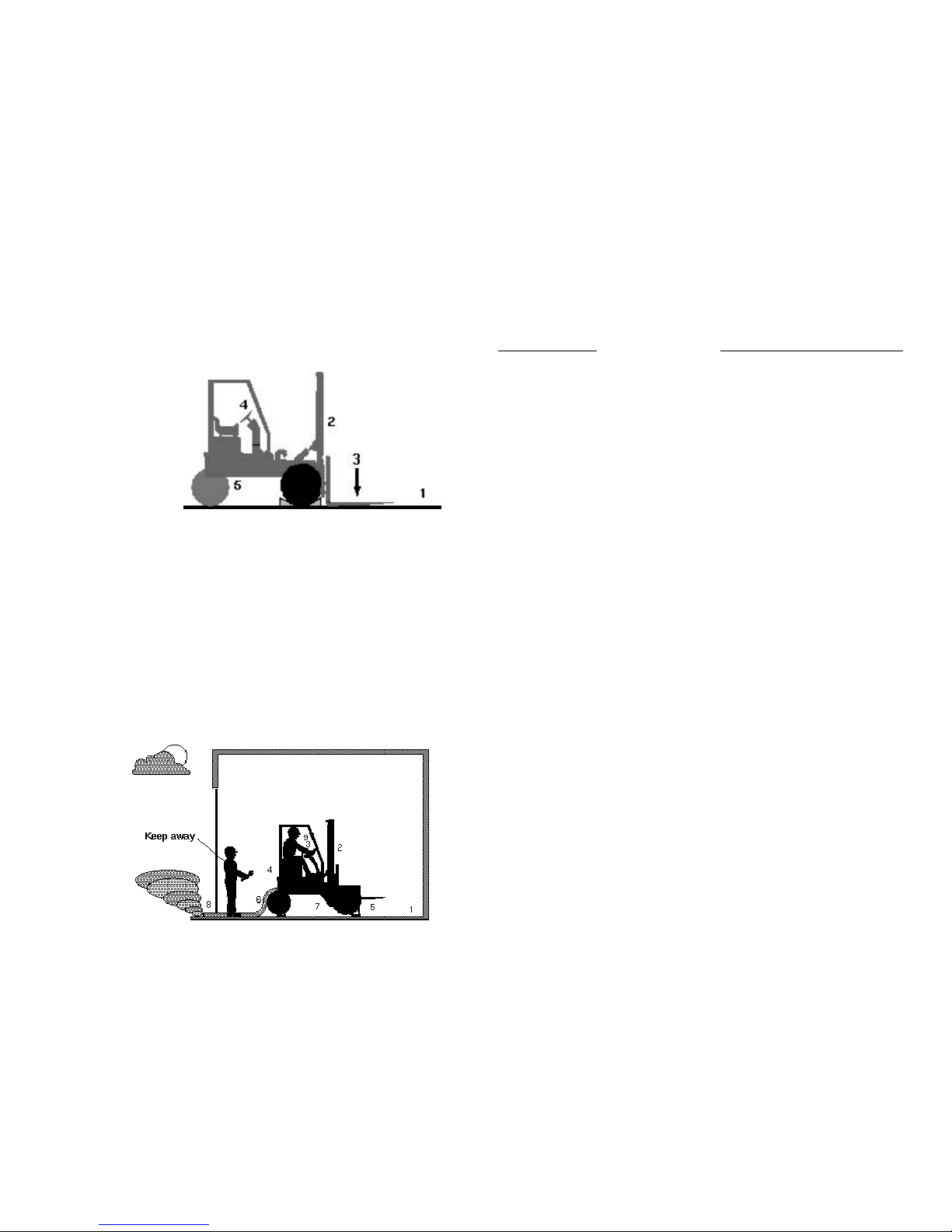

Service Position--Engine Off

1. Park forklift on flat level surface.

2. Tilt mast to vertical position.

3. Lower forks to floor.

4. Shut engine off.

5. Chock drive wheels.

Service Position--Engine Running

1. Park forklift on flat level surface.

2. Tilt mast to vertical position.

3. Set parking brake.

4. Shut engine off.

5. Chock drive wheels.

6. Raise rear of vehicle and block -- see jacking and blocking

section.

7. Raise front of vehicle and block -- see jacking and blocking

section.

8. Connect hose to exhaust -- do not run engine in closed area

without venting.

9. Operator must remain in seat while engine is running.

7

IMPORTANT INFORMATION ON THE FILTRATION

OF YOUR PB SERIES

Your PB Series unit is equipped with a “suction boost” filter. This filter

provides superior protection to the drive circuit. It is equipped with a

dash mounted notification light that indicates if the filter needs changed.

This light is additional information for the operator and is not a

substitute for filter changes during PM’s.

This light will normally illuminate* under three circumstances.

1) During cold weather operation, the light may illuminate until

the hydraulic oil warms. This generally takes 1 to 3 minutes of

operation.

2) During high-speed multi-function operation, the light may

illuminate temporarily.

3) If the light remains on at any other time the filter should be

changed.

*An illuminated light does not mean the filter is by-passing but indicates

contaminates in the hydraulic system.

A “break-in” filter change is recommended in the first 5-10 hours of

operation.

Jacking and Blocking

WARNING

Avoid the risk of injury or death.

Use jack stands when working

on raised truck.

Front Jacking

With forklift in Service Position

Engine Off:

1.Use a hydraulic jack of 5 ton

capacity minimum.

2.Position front jacks under

stabilizer feet.

3.Position jack stands under

carriage.

4.Slowly lower forklift onto

stands.

Rear Jacking

With forklift in Service

Position Engine Off:

1.Use a hydraulic jack of 5 ton

capacity minimum.

2.Position jack under frame at

rear.

3.Position jack stand under

frame.

4.Slowly lower forklift onto

stands.

WARNING

Avoid hydraulic line damage.

Do not jack or block forklift

frame near hydraulic lines.

8

C

C

9 Lubrication

47

Grease Fitting, top of tilt

cylinder-1, B

Mast Chains-9, B

Grease Fitting, bottom of tilt

cylinder-1, B

Grease Fitting, Side Shift

Cylinder-1, B

Side Shift Blocks-1, B

Side Shift Blocks-1, B

1 General Safety Practices

DO

*Safeguard pedestrians at all times.

*Be sure everyone is clear of rear swing area.

*Use caution around pedestrian doorways, where they may step into

path of travel.

*Operate forklift safely.

DO NOT

*Start or operate unless you are in the driver position.

*Put any part of body into mast, or between mast and forklift.

*Put body within reach of mechanism or attachments.

*Drive forklift with anyone standing in front.

*Allow anyone to stand or walk under elevated part of forklift.

*Permit passengers.

*Hit overhead installations such as lights, wiring , pipes, sprinklers,

etc...

*Leave forklift unattended.

CHANGES TO THE FORKLIFT

*Affecting capacity or operation, must have manufacturer’s prior written

approval.

*Involving rebuild, replacement parts, and repair must meet the manufacturer’s set criteria and guidelines.

INSPECTION

*Daily or each shift.

STOPPING DISTANCE

*Operator must always have enough room to safely stop the forklift in

any given situation.

STABILITY changed by:

*Operator judgement.

*Improper operation.

*Faulty maintenance.

*Grade.

*Ground and floor conditions.

*Fast turns.

*Cutting corners.

9 Lubrication

Hyd. Return Filter-5, C (Left)

Fuel Filter-8, C (Right)

Tire Pressure-Check A

Chain Sheave-1, B

46

Air Cleaner-2, C

Hydraulic Oil- Check A

Diesel Fuel-Check A

Engine Oil-Check A

9

1 General Safety Rules

LOAD BACKREST

*If the load causes hazard, equip forklift with a vertical load backrest extension.

FUEL

*Fuel handling and storage must be done following ANSI/NFPA 505 and

ANSI/NFPA30.

HAZARDOUS CONDITIONS

*Operating in hazardous conditions is the responsibility of the user.

AISLES AND OBSTRUCTIONS

*Path of operation and ramps must be marked and clearly visible.

LIGHTS

*Where needed, forklift must have lights.

ENGINE EXHAUST

*Forklift must be used in a well ventilated area.

SOUND

*Consideration should be given to the sound exposure of personnel in the work

area.

DROP OFFS

*Keep safe distance from the edge of ramps and platforms.

TRAILER CREEP

*When driving on and off trucks or trailers apply trailer brakes and chock the

wheels.

*Do not mount or dismount the forklift from a semi-trailer which is not coupled to

a tractor.

*Forklifts mounted to uncoupled semi-trailers may need supports to prevent

upending.

LIFTING PEOPLE

*Do not use this forklift to lift people; it is not designed for it.

*Equipment specifically designed to raise people is available.

OPERATINGENVIRONMENT

*Avoid areas near excavations and embankments.

*Watch out for low electric lines, tree branches, and other obstacles.

SEATBELT

*Always wear the provided seat belt when operating the forklift.

10

8 Inspection

*Mast

Push lift control away from you, forks should move down. As the control is

pushed more, the forks should move faster. Report any sticking or jerking.

Pull lift control toward you, forks should move up. As the control is pulled more,

the forks should move faster. Report any sticking or jerking.

Push tilt control away from you, mast should tilt forward. As the control is

pushed more, the mast should tilt faster. Report any sticking or jerking.

Pull tilt control toward you, mast should tilt backward. As the control is pulled

more, the mast should tilt faster. Report any sticking or jerking.

Push carriage control away from you, mast should move forward. As the control

is pushed more, the mast should move faster. Report any sticking or jerking.

Pull carriage control toward you, mast should move backward. As the control is

pulled more, the mast should move faster. Report any sticking or jerking.

Push side shifter control away from you, mast should move left. As the control is

pushed more, the mast should move faster. Report any sticking or jerking.

Pull side shifter control toward you, mast should move right. As the control is

pulled more, the mast should move faster. Report any sticking or jerking.

Push stabilizer control away from you, stabilizer should move down. As the control is pushed more, the stabilizer should move faster. Report any sticking or

jerking.

Pull stabilizer control toward you, stabilizers should retract. As the control is

pulled more, the stabilizers should move faster. Report any sticking or jerking.

If forklift is unsafe or in need of repair, do not use it until it is returned to a safe

operating condition.

During use, if forklift becomes unsafe in any way, stop using. Do not use it until

is is returned to a safe operating condition.

Do not make repairs or adjustments, unless you are authorized to do so.

DOUBLE REACH (Optional)

1) Ensure the cylinder operates smoothly and that it slows at the end of

extension and retraction.

2) Inspect the cylinder and hoses for leaks and wear.

3) Inspect the bearings for breakage and that they turn freely.

45

2 Operators Safety Rules and Practices

OPERATORS RESPONSIBILITY

*Safe operation is the responsibility of the operator.

*Read and understand operator’s manual.

*Know all functions of controls and instruments.

*Be alert to other personnel and hazardous conditions.

*Be alert to unusual or special operating conditions and safety precautions.

*In hazardous areas, use only forklifts approved for those areas.

*Always where the provided seat belt when operating forklift.

OPERATORS MUST BE TRAINED AND UNDERSTAND

*Equipment operation.

*Control locations and functions, and what problems will occur when handled

improperly.

*Traveling.

*Loading.

*Mechanical limits.

*Center of gravity.

*Stability.

*Operating conditions.

*Nameplate information.

*Warning signs.

TRAVELING

*Obey all traffic rules and speed limits.

*Keep to the right.

*Always keep your forklift under control and stay a safe distance, based on

speed, from other vehicles.

*Operate at speed that allows stopping in a safe manner.

*Yield to pedestrians and emergency vehicles.

*Be alert to blind spots, and other locations where vision is not clear.

*Be sure you have a clear view of your path of travel.

*When load obstructs view of forward travel, travel backward.

*Cross railroad tracks at an angle, do not park closer than 6 ft.

*Go up and down grades slowly and carefully, tilt forks back.

*Avoid turning on grades, ramps or inclines.

*Stopping distances going down grades will be longer.

*Slow down and allow enough room at the bottom of grades to stop.

*Travel with forks raised, only far enough to clear road surface, and tilted back.

8 Inspection

*Fuel

Do not use open flame to check fuel level. When refueling, stop engine.

Replace fuel cap before starting engine. If spillage happens, be sure it has all

been absorbed or evaporated before starting engine.

*Engine oil

Check and fill, following manufacturers instruction.

*Hydraulic oil

Check and fill, if needed, with recommended hydraulic

oil.

*Lights

If forklift has lights, they must be in good condition and work.

*Mast chains

Check mast chains for damage or missing parts.

*Brakes

When the engine is off the brakes will engage.

DOUBLE REACH (Optional)

1) Ensure the scissor cylinder lock nut is tight. (FIG 1)

2) Ensure the stop bolts are properly contacting the ITA board. (FIG 2)

3) Inspect the scissor assembly for structural cracking.

INSPECTION WITH ENGINE RUNNING

Do this inspection in a large, open area (away from people, walls, ceil-

ings, and other equipment).

*Travel

Bring forklift to a complete stop before changing direction.

*Neutral position

When motion pedal is in neutral, drive wheels will not turn.

*Travel control

Push motion pedal away from you. The forklift should move forward.

As the pedal is pushed more, the the forklift should move faster.

Pull motion pedal toward you. The forklift should move backward. As the pedal

is pulled more, the the forklift should move faster.

44

11

Jam

Nut

FIG 1

Contact

FIG 2

2 Operators Safety Rules and Practices

TRAVELING (cont.)

*Starts, stops, turns and directional changes must be made smoothly to prevent

load shift and overturn.

*No horse play or stunt driving.

LOAD HANDLING

*Only handle loads that are stable, safely arranged, and within forklift capacity.

*Fork length must be within 2/3rds of load length.

*Tilt back only enough to stabilize load.

*Be careful when tilting stacked or high loads.

*Do not tilt forward when elevated except to deposit load.

BEFORE LEAVING OPERATOR’S POSITION

*Bring forklift to a complete stop.

*Do not block the way of fire equipment, fire aisles, or stairways.

*Be sure directional controls are in neutral.

*Full lower forks.

*Set parking brake.

*Turn ignition off and remove key.

ACCIDENTS

*Report all accidents , including personnel, equipment, or building structures.

SLOPES

*Use caution when driving on slopes. Avoid turning on slopes, if possible, and

use extreme caution on grades, ramps or inclines; normally travel straight up

and down.

*Elevation of load should also be avoided on sloped surfaces.

12

8 Inspection

INSPECTION WITH ENGINE OFF

Do this inspection with the forklift in a safe parked position.

*Warning and safety devices

Push horn button, horn must sound loud and clear. If forklift has other warning

devices (flashing lights, etc..), they must work.

*Frame

Look at the condition of the frame. Report cracked or broken frame members.

*Tires

Check tire pressure. Tires must be inflated to recommended pressure. Inspect

wheel fasteners. All fasteners must be in place and tight. Look at the condition

of the wheels and tires. Report worn, cracked or leaking tires.

*Lift control

Must work freely and return to neutral when released.

*Side shift control

Must work freely and return to neutral when released.

*Carriage control

Must work freely and return to neutral when released.

*Stabilizer control

Must work freely and return to neutral when released.

*Tilt control

Must work freely and return to neutral when released.

*Steering wheel

Must be in good condition and work freely.

*Forks

Must be in good condition and in good alignment. Report any cracks or breaks.

*Fuel system

Inspect fuel lines and fittings for leaks. Do not use open flame to inspect fuel

system.

43

7 Moving A Disabled Forklift

RELEASING BRAKE

THIS MACHINE HAS A BRAKE

IN THE FRONT MOTORS.

To release drive hub brake,

remove cap on the inside of the

hydraulic motor. Screw in a

12mm x 1.75mm x 35mm hex

head bolt with a washer larger

than the hole diameter. Tighten

the bolt to release the brake.

Reverse procedure to make

brakes work after towing and

repairs are completed.

Remove the bolt and install the

cap before operating the PIGGY

BACK. Drive hub will not operate

unless the bolt is removed.

TOWING FORKLIFT

Fasten a chain or cable to tow vehicle around fork bar of forklift. Cable

or chain must have capacity to pull 3 tons.

An operator must be seated on forklift.

42

3 Forklift Description

13

REAR DOLLY

HYDRAULIC FILTER

FUEL FILTER

ST ABILIZER PAD AND ARM

7-PIN WIRING CONNECTOR

MOTION PEDAL

TAIL LIGHTS

SEAT BELT

(With Integrated Brake Interlock)

3 Forklift Description

ACCELERATOR PEDAL BATTERY

DASH AND CONTROLS

MOUNTING HOOK

14

WHEEL MOTOR AND TIRE

MAST

6 Transport-EASY HITCH

Lower the PIGGY BACK

to the ground.

Tilt the top of the mast

forward to lower the rear

tire.

Drive the PIGGY BACK

straight back to pull the

forks from the fork supports.

41

6 Transport-EASY HITCH

Tilt the top of the mast

fully to the rear to raise

the rear tire of the PIGGY

BACK..

Raise the PIGGY BACK

until the hooks clear the

pins.

Extend the carriage 4-6

inches.

40

3 Forklift Description

15

WARNING

LIGHTS:

(left to right)

TOP:

Engine Temp.

Oil Pressure

Alternator

BOTTOM:

Blank

Blank

Filter Indicator

KEY SWITCH:

LEFT-OFF

RIGHT ONE POSITION-

ACCESSORY

RIGHT TWO POSITIONS-

PREHEAT

RIGHT THREE POSITIONS-

START

HORN

BUTTON

WORK

LIGHTS

3WDTRAC-LOC

SWITCH,

see pg. 19.

PARKING BRAKE:

UP-ON

DOWN-OFF

RE-SETABLE

CIRCUIT

BREAKERS

FUEL

GAUGE

4 Starting

BEFORE STARTING be sure

*Forward and reverse control (motion pedal) is in neutral.

*Seat belt is fastened.

*Operator Inspection is done.

COLD START (Deutz)

*Turn key to the right and hold on pre-heat for several seconds.

*Turn the key to the right and start engine.

*When the engine starts release ignition switch.

*If the engine fails to start, turn off ignition switch and repeat the

above.

COLD START (Kubota)

*Turn key to the right and hold on pre-heat for several seconds.

*Pre-heat engine several times in colder climates.

*Turn the key to the right and start engine.

*When the engine starts release ignition switch.

*If the engine fails to start, turn off ignition switch and repeat the

above.

WARM START

*Turn the key to the right and start engine.

*When the engine starts release ignition switch.

16

6 Transport-EASY HITCH

Dismounting the PIGGY

BACK from the transport vehicle.

Disconnect the safety

chains.

Disconnect the 7-pin electrical connector.

Remove the lynch pins

and pull out the hitch

pins.

Fasten your seat belt.

Start the PIGGY BACK.

39

4 Starting

JUMP START

WARNING

Failure to follow the these rules will cause serious injury or death.

BATTERIES PRODUCE EXPLOSIVE GASES.

*Keep sparks, flames, and cigarettes away from battery.

*Do not let tools or other metal touch positive (+) battery post.

*Remove all jewelry, rings, watches, etc.

CONNECT BOOSTER CABLES IN THE FOLLOWING ORDER

*Connect one Positive (+) red end of booster cable to Positive (+) post

on each battery.

*Connect second Negative (-) black end of booster cable to Negative (-)

post of starting battery and the other end to stalled vehicle engine block

or frame.

*Be sure everyone is away from both vehicles.

*Cables must be clear of all moving parts.

*Start engine of starting vehicle. Wait a few minutes.

*Start engine of stalled vehicle.

*If vehicle does not start after cranking for ten seconds, STOP PROCEDURE. More than ten seconds seldom starts the engine unless some

mechanical adjustments are made.

*After vehicle starts, remove Negative (-) black booster from engine or

frame ground. Then remove the other end from the starting battery.

*Remove Positive (+) black booster cable from stalled battery, then from

starting battery.

6 Transport-EASY HITCH

Install the hitch pins and

attach lynch pins.

Connect the safety chains.

Connect the 7-pin electrical

connector.

Before driving the transport vehicle

Check the function of the

tail, turn and stop lights.

Check the safety chains to

see if they are latched.

Check the hitch and lynch

pins on top of the hooks for

proper installation.

38

Note:

Your unit may be equipped with an automatic tilting device. It is

activated when the transporting vehicle’s lights are activated.

17

6 Transport-EASY HITCH

Retract the carriage to pull

the PIGGY BACK toward

the transport vehicle.

When the carriage is fully

retracted, lower the PIGGY

BACK until the hooks are

fully seated on the pins. Do

not power down.

Note

: If tires do not

contact tire pads

before hooks are

fully seated, tire

pads may be

incorrectly installed.

Shut off the PIGGY BACK.

Push the tilt lever forward

to “relax” the PIGGY BACK

tires onto the front tire

pads.

Note

: If unit does not

correctly contact the

two position tire

pads, then correctly

remount the tire

pads.

37

5 Operation

MOTION PEDAL

WARNING

UNEXPECTED FORKLIFT MOVEMENT

Avoid the risk of injury, follow this rule.

Do not casually rest foot on motion pedal.

Motion pedal controls speed and direction of travel.

IMPORTANT NOTE:

Your unit may be equipped with a seat belt/brake interlock. The seat belt

must be fastened to release parking brake. you must come to a complete stop before unlatching your seat belt to avoid a potential forward tip

or premature brake wear.

REMEMBER

Forklift will not respond to motion pedal until parking brake is released.

Forward

Push front of motion pedal

down and forklift will move forward. The more it is pushed

the faster the forklift will go.

Reverse

Push rear of motion pedal down

and forklift will move backward.

The more it is pushed the faster

the forklift will go.

Neutral Position

When the motion pedal is in

the center, the forklift will be in

the neutral position and should

not move.

18

6 Transport-EASY HITCH

Drive the PIGGY BACK

forward until the forks are

in the fork supports, tilting

the mast forward as you

drive to make sure the

forks are under the front

fork tube.

Tilt the top of the mast fully

to the rear to raise the rear

tire.

Raise the PIGGY BACK

until the hooks are above

the pins.

36

5 Operation

3WD AND TRAC-LOC SWITCH

Three Wheel Drive (3WD)

With the switch in the lower position, the

forklift will be in 3WD and power is

applied to all three wheels.

3WD IS THE NORMAL OPERATING

MODE.

Trac-Loc

Rock switch toward mast and the rear

wheel will be in locked in.

Use Trac-Loc in slippery conditions.

Continuous Trac-Loc usage adds

heat to hydraulic drive system and

inhibits vehicle turning. Use TracLoc only when necessary.

19

2 POSITION SWITCH

UP TRAC-LOC

DOWN 3WD

Important Note:

Disengage Trac-Loc before

starting the PIGGY BACK or

damage to the Hydraulic

System may occur.

5 Operation

STEERING WHEEL

20

Left

Turning steering wheel left when

you want to turn left. The forklift

responds quicker, the more the

more the wheel is turned.

Right

Turning steering wheel right when

you want to turn right. The forklift

responds quicker, the more the

more the wheel is turned.

6 Transport-EASY HITCH

Mounting the PIGGY BACK to the transport vehicle.

Fasten your seat belt.

Start the PIGGY BACK.

Raise the forks to the level

of the fork support tubes.

Extend the carriage 4-6

inches.

35

6 Transport-EASY HITCH

34

EASY HITCH MOUNTING SYSTEM

OPERATORS INSTRUCTIONS

The Easy Hitch mounting system for the Princeton PIGGY

BACK Material Handler consists of the following components:

Safety Chains

7-Pin Electrical Connector

Fork Support Tubes

Front Tire Pads

Hitch Pins with Lynch Pin Attached

Support Pins mounted to the Transport Vehicle

Hooks Mounted to the PIGGY BACK

5 Operation

LIFT CONTROL

21

Up

Push lift control away

from you, the forks will

move down. As the

control is pushed

more, the forks will

move down faster.

Neutral

When lift control is

in neutral, the forks

will not move.

Down

Pull lift control to you,

the forks will move up.

As the control is pulled

more, the forks will

move up faster.

5 Operation

TILT CONTROL

22

Down

Push tilt control away

from you, the forks

will tilt forward. As

the control is pushed

more, the mast will

tilt faster.

Neutral

When tilt control is

in neutral, the mast

will not move.

Up

Pull tilt control to you,

the mast will tilt backward. As the control is

pulled more, the mast

will tilt faster.

5 Operation

SAFETY SIGNS

33

Motion Pedal

NEVER put your body

between the horizontal

carriage and dash.

STAY away from pedestrians

at all times.

NEVER put your body between

the forklift and the mast.

DO NOT place foot under the

stabilizer pad .

KEEP YOUR HANDS AWAY

from chains at all times

PINCHPOINT-keep hands

and feet away at all times.

P.N. 604-218

5 Operation

SAFETY SIGNS

32

MAIN WARNING

DO NOT stand on or below

the forks.

NO RIDERS

STEERING CYLINDERkeep hands, arms and

body away from cylinder at all times

5 Operation

SIDE SHIFTER CONTROL (OPTIONAL)

Left

Push side shifter

control away from

you, the forks will

move left. As the

control is pushed

more, the forks will

move faster.

Right

Pull side shifter control to you, the forks

will move right. As the

control is pulled more,

the forks will move

faster.

23

Neutral

When control is in

neutral, the side

shifter will not

move.

5 Operation

SCISSOR CONTROL (OPTIONAL)

Out

Push scissor control away from you,

the forks will move

forward. As the control is pushed more,

the forks will move

faster.

Neutral

When scissor control is

in neutral, the forks will

not move.

Back

Pull scissor control to

you, the forks will move

backward. As the control is pulled more, the

forks will move faster.

24

5 Operation

Go up and down grades slowly and carefully. The mast must be extended and

as low as possible when climbing grades. Grades that are approaching the forklift’s capability limits should be climbed in reverse with the mast fully retracted.

Extreme care must be taken in these cases. Avoid turning on grades, ramps,

or inclines. Stopping distance going down grades will be longer. Slow down and

allow enough room at bottom of grades to stop.

Travel with forks raised only far enough to clear road surface and tilted back.

Starts, stops, turns, and directional changes must be made smoothly to prevent

overturn.

Operators must always be aware of any obstacles that may interfere with forklift

travel. These objects include: ground obstacles, ceilings, ceiling fixtures, and

objects interfering with the forklift travel path.

DEPOSITING LOAD-MAST RETRACTED

To deposit load after being moved into correct position, tilt mast forward to ver-

tical position and lower load.

Adjust fork height and tilt mast forward as needed for smooth fork removal from

load.

Carefully back away and clear forks from the load.

Raise forks for travel and tilt mast back.

DEPOSITING LOAD-MAST EXTENDED

To deposit load after being moved into correct position, tilt mast forward to vertical position and put stabilizers down. Extend mast and lower load.

Adjust fork height and tilt mast forward as needed for smooth fork removal from

load.

Carefully retract mast all the way from the load.

Raise stabilizers and back away from the load.

Raise forks for travel and tilt mast back.

31

5 Operation

Raise load to travelling height and tilt fully back. Never tilt mast forward past

horizontal when loaded.

PICKING UP LOAD-MAST EXTENDED

Forks must be spaced as far apart as the load being carried allows. Both forks

should be the same distance from the center of the mast. Be sure the fork lock

pin fits securely into a locking notch.

Handle only stable loads within the forklift’s rated capacity as shown on the

capacity sign. Always center load on forks.

Do not handle loads higher then the load backrest or its extension, unless load

is secured and will not fall backward.

Use lift and tilt controls, adjust the forks to correct height and angle for engaging

load.

Move forward until the forklift is almost touching load. Put stabilizers down.

Extend forks into load. Be sure forks do not extend beyond load, getting caught

on other loads or materials.

If forks are longer than load, move tips partially under load without extending

beyond the load. Raise load to clear floor. Back out, set the load down and position correctly on forks.

Raise load by tilting mast back just far enough to lift load from floor.

Raise load to travelling height and tilt fully back. Never tilt mast forward past

horizontal when loaded.

Retract mast and lift stabilizers.

TRAVELING LOADED

Keep load against the load backrest. Loads out on the fork ends make the forklift less stable and more likely to overturn.

Obey all traffic rules and speed limits. Always keep your forklift under control

and at a safe distance, based on speed, from other vehicles.

Be sure you have a clear view of your path of travel. Be alert to blind spots, and

other locations where vision is not clear. When load obstructs view, travel backwards.

30

5 Operation

CARRIAGE CONTROL

25

Out

Push carriage control away from you,

the mast will move

forward. As the control is pushed more,

the mast will move

faster.

Neutral

When control is in

neutral, the mast

will not move.

Back

Pull carriage control to

you, the mast will

move backward. As

the control is pulled

more, the forks will

move faster.

5 Operation

STABILIZER CONTROL

26

Down

Push stabilizer control

away from you, the

stabilizers will move

down. As the control is

pushed more, the stabilizers will move

faster.

Neutral

When stabilizer

control is in neutral,

the stabilizers will

not move.

Up

Pull stabilizer control

to you, the stabilizers

will retract. As the

control is pulled more,

the stabilizers will

retract faster.

5 Operation

TRAVELING EMPTY

Obey all traffic rules and speed limits. Always keep your forklift under control

and at a safe distance, based on speed, from other vehicles.

Be sure you have a clear view of your path of travel. Be alert to blind spots, and

other locations where vision is not clear.

Go up and down grades slowly and carefully. The mast must be extended and

as low as possible when climbing grades. Grades that are approaching the forklift’s capability limits should be climbed in reverse with the mast fully retracted.

Extreme care must be taken in these cases. Avoid turning on grades, ramps,

or inclines. Stopping distance going down grades will be longer. Slow down and

allow enough room at bottom of grades to stop.

Travel with forks raised only far enough to clear road surface and tilted back.

Starts, stops, turns, and directional changes must be made smoothly to prevent

overturn.

Operators must always be aware of any obstacles, trees, electrical wires, and

objects interfering with forklift travel path.

PICKING UP LOAD-MAST RETRACTED

Forks must be spaced as far apart as the load being carried allows. Both forks

should be the same distance from the center of the mast. Be sure the fork lock

pin fits securely into a locking notch.

Handle only stable loads within the forklift’s rated capacity as shown on the

capacity sign. Always center load on forks.

Do not handle loads higher then the load backrest or its extension, unless load

is secured and will not fall backward.

Use lift and tilt controls, adjust the forks to correct height and angle for engaging

load.

Move forward until the forks are squarely and completely under load. Be sure

forks do not extend beyond load, getting caught on other loads or materials. If

forks are longer than load, move tips partially under load without extending

beyond the load. Raise load to clear floor. Back out, set the load down and position correctly on forks.

Raise load by tilting mast back just far enough to lift load from floor.

29

5 Operation

DOUBLE REACH (Optional)

5 Operation

LOAD ARMS (Optional)

The Load Arm Option is used

when the forklift is carrying long

loads such as lumber, drywall,

and other building materials.

LOWERING ARMS

To lower the Load Arms into operating position, pull the spring pin

out of the hole on mounting hook

and lower the arm onto the front

support. Make sure pin end is

below the load surface or dimpling of load arm and load will

occur.

RAISING ARMS

To raise Load Arms, lift the arm

until spring pin snaps into detent

hole on mounting hook.

MOUNTING

Load Arms are to be in the raised

position when the forklift is

mounted on an EASY HITCH

Mounting. Safety chains will run

through the holes in the Load

Arms.

27 28

The first stage of reach is the standard moving mast and the second stage of

the reach is a scissor mechanism.

This option has been ordered by the owner of the PIGGY BACK Delivery

System for the following uses.

1) It allows a 4000 lb.* load on a truck or trailer to be unloaded from one side.

2) It allows a 2500 lb.* load to be placed in an area with low overhead clearance.

3) It allows a 2500 lb.* load to be placed across a small open area.

(See restrictions below)

GENERAL

It is recommended that the scissor is only operated as a second stage reach. This

means that it is the last reach extended and the first retracted when utilizing the double

reach feature. The unit has two extend levers the tall one operates the mast movement,

the short one operates the scissor (FIG 3). The utilization of the scissor reach for unloading may require a spotter to watch the other side of the truck or trailer for pedestrian or

vehicle traffic.

FREE LIFTING (LOAD FULLY EXTENDED)

The rated capacity for this option is 2500 lbs. when the unit is free standing, with stabilizers down, on reasonably firm terrain. This means that a 2500 lb. load that is 48” wide

can be fully extended out when the stabilizers are engaged. This would be a typical low

overhead clearance or an across open area drop.

WARNING: Exceeding this capaci-

ty will result in a forward tip.

ONE SIDE TRUCK UNLOADING

When unloading from one side of the truck you can get a lift capacity of up to 4000 lbs.

This is achieved by placing the mast of the unit up against the truck or trailer. There are

special bars welded to the mast (FIG 4) that allows free operation of the mast when the

unit is against the truck. To unload the truck or trailer, you will 1) drive up to it while raising your forks, 2) engage your stabilizers, 3) extend your mast until it contacts the truck

or trailer, 4) extended your scissor reach, 5) lift your load 1” to 2”(FIG 5), 6) fully retract

your scissor reach, 7) fully retract your mast, 8) raise your stabilizers, 9) back away from

the truck or trailer and lower your load to the carrying height.

Rub Bar

Contact

FIG 3

FIG 4

Scissor

Control

Mast

Control

FIG 5

1” to 2”

Loading...

Loading...