Page 1

15 Discovery Way, Acton, MA 01720

Phone: (978)263-3584, Fax: (978)263-5086

Web Site:

www.piacton.com

Operating Instructions

Acton SP-750i

0.750 Meter Focal Length Triple Grating

Imaging Monochromator / Spectrograph

750i Manual V1098.1

Page 2

Acton SP-750i

Operating Instructions

CONTENTS: Page

I. Brief Introduction and SP-750i Description 2

II. Specifications 3

III. SP-750i Setup

A. Unpacking Note 4

B. Connecting the SP-750i to the Optional 749 4

Remote Scan Controller, or to a Computer

C. Cables and Connections for SP-750i 5

D. Mounting Accessories 6

E. Mounting Focal Plane Detectors 7

F. Slit Width Adjustment for 716 Bilateral Slits and 715 Fixed

Slit Assemblies 8 - 9

IV. SP-750i Operation

A. Initialization 10

B. Operating the SP-750i Using the Model 750-749

Remote Scan Controller 10 - 14

C. Operating the SP-750i Using a Computer 15 - 19

D. Focusing and Aligning CCD Array Detectors 19

E. Changing from Monochromator to Spectrograph Operation 20

V. Appendices and Schematic Drawings

A. Alternate Start-Up Parameters 21

B. Cable Connection Diagrams 22

C. Standard Slit Assembly Drawing 23

D. Accessories List and Ordering Information 24 - 29

E. Certification and Warranty Information 30

F. Drawing No. 8450-750-50, titled “SP-750i” 31

1

Page 3

I: Brief Introduction and SP-750i Description

Brief Introduction:

This instruction manual is intended to assist you in set-up and operation of your new SP-750i

monochromator/spectrograph. Even if you are an experienced user of spectroscopic equipment, we suggest

that you follow the manual (at least initially) to insure proper setup and operation. If you have any

questions about the information contained in this manual, please feel free to contact the Princeton

Instruments customer service department.

SP-750i Description:

The SP-750i is a 750mm focal length monochromator/spectrograph. It features an astigmatism-corrected

optical system, triple indexable gratings and triple grating turret. The SP-750i includes a direct digital

grating scan mechanism with full wavelength scanning capabilities, plus built-in RS232 and IEEE488

computer interfaces.

2

Page 4

II: SP-750i Specifications

NOTE: Each SP-750i is operated for at least 15 minutes prior to

calibration to insure optimum stability. End users should

follow this practice if their application calls for optimum

stability & reproducibility.

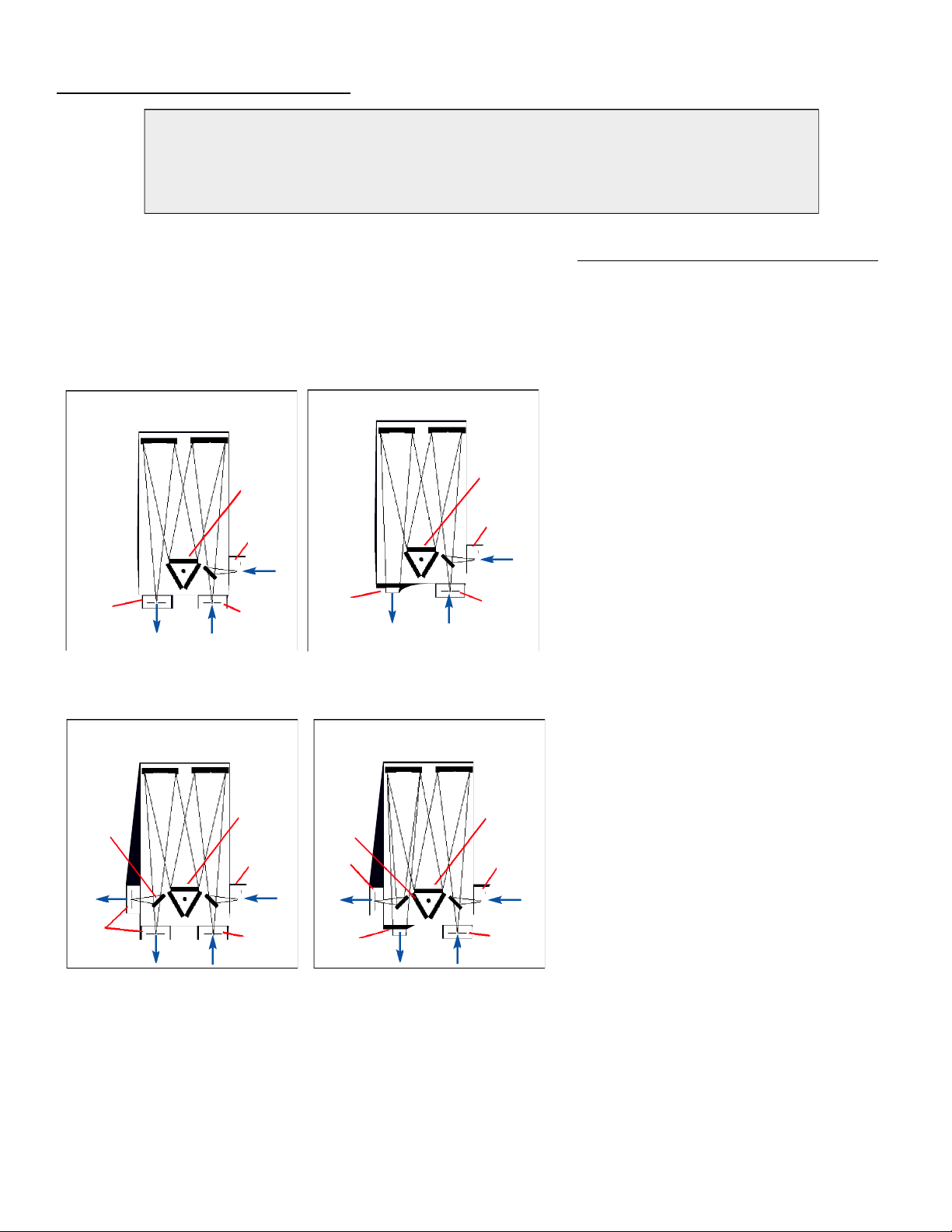

Every SP-750i monochromator or spectrograph

includes a triple grating turret for 1, 2, or 3 gratings,

an imaging optical system, 32-bit microprocessor

controlled scanning, built-in RS232 and IEEE488

interfaces, and micrometer controlled entrance slit

(optional second entrance slit available).

Model SP-555 Monochromator

Triple

Grating

Turret

Entrance

Slit

Exit

Slit

Includes 90° optical path, and micrometer

adjustable entrance and exit slits.

Optional

Entrance

Slit

Model SP-557

Dual Exit Port Monochromator

Motorized

Mirror

Two

Exit

Slits

Includes micrometer controlled dual exit

slits (90 & 180°), and motorized mirror for

rapid, computer controlled exit slit selection.

Triple

Grating

Turret

Entrance

Slit

Optional

Entrance

Slit

Model SP-556 Spectrograph

CCD

Port

Includes 90° optical path, large 14mm X

27mm focal plane, plus sliding tube CCD

adapter with focus-stop.

Model SP-558

Monochromator/Spectrograph

Motorized

Mirror

Exit

Slit

CCD

Port

Includes dual exit ports; one exit slit and

one sliding tube CCD adapter with motorized mirror for rapid, computer controlled

exit port selection.

Triple

Grating

Turret

Entrance

Slit

Optional

Entrance

Slit

Triple

Grating

Turret

Entrance

Slit

Optional

Entrance

Slit

Specifications (1200g/mm Grating)

Focal length: 750mm

Aperture Ratio: f/6.5 (68x68mm gratings)

Optical Design: Imaging Czerny-Turner with

original polished aspheric mirrors

Optical Paths: 90° standard, 180° and

multi-port optional

Scan Range: 0 to 1400nm mechanical

range

Operating Range: 185nm to the far infrared

with available gratings and accessories

Resolution: 0.05nm at 435.8nm

Dispersion: 1.7nm/mm (nominal)

Accuracy: ±0.2nm

Repeatability: ±0.05nm

Drive Step Size: 0.0025nm (nominal)

Focal Plane Size: 27mm wide x 14mm high

CCD Focus Arrangement: Exclusive o-ring

sealed sliding tube with unique 3-point focus

stop/fine focus adjustment mechanism.

Detector Coverage: ~42.5nm across a 1.0”

wide focal plane (~85nm: 600g/mm grating)

Standard Slits: Micrometer adjustable from

10µm to 3mm wide. Slit heights: 4 & 14mm

Grating Mount: Triple grating turret for 1, 2,

or 3 gratings.

Interchangeable Grating Turrets: Optional

Grating Change Time: Less than 20 seconds

Grating Drive System: 32-bit microprocessor

controlled direct digital scanning (DDS)

system.

Scan Linearity: The SP-750i scans

linear with respect to wavelength

Size: 21” long (534mm)

11” wide (280mm)

8” high (203mm)

4.875” (123.8mm) optical axis height

Weight: 40 lbs (18kg)

Tested and conforms to European CE

Standards

3

Page 5

III. SP-750i Setup

Section III-A: Unpacking and Inspection

Carefully unpack and examine the SP-750i and any accessories purchased.

Note: Report any damage immediately to the carrier and to

Princeton Instruments, and save all packing materials.

Section III-B: Connecting the SP-750i Monochromator/Spectrograph to the

Optional Model 750-749 Remote Scan Controller or Computer

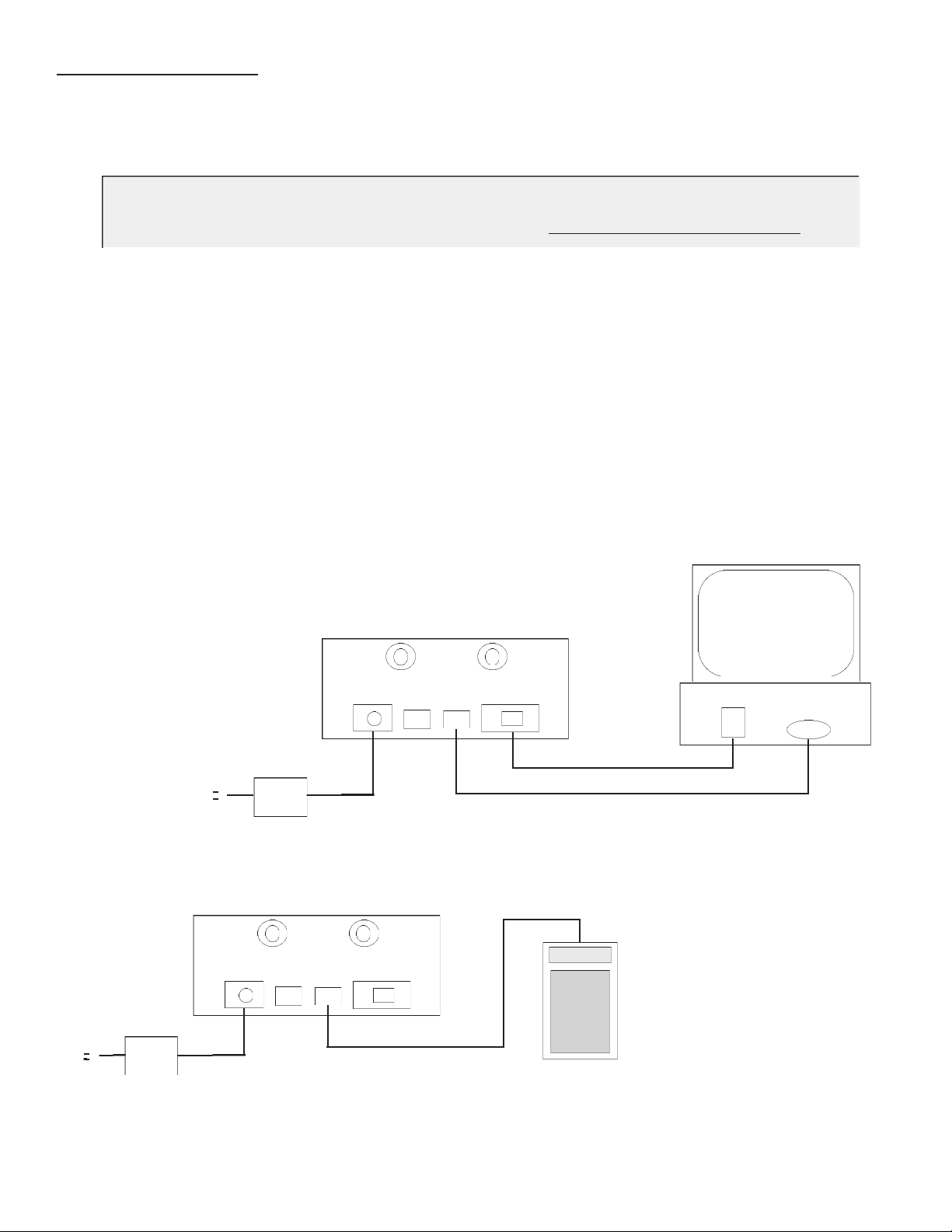

The SP-750i is designed for operation by computer using RS232 or IEEE488, or by using the optional

Model 750-749 Remote Scan Controller. Either method of control enables wavelength scanning

at a pre-set linear scan rate, change of scanning speeds, grating selection, rapid GOTO wavelength

positioning, change of grating turrets if available, and “jog” wavelength positioning. Figure 1 below shows

the cable connections necessary for operation from a computer through the COM ports or with a GPIB

controller card. Figure 2 below shows the cable connections necessary for operation of the SP-750i

with the optional Model 750-749 remote scan controller. Refer to the Monochromator Control

Software for Windows for operation with a computer. Refer to Section IV-B for details on operation with the

Model 750-749 remote scan controller.

SP-750i Cable Connections:

Optional 750-749 Remote Scan Controller, RS232, or IEEE488

SP-750i Computer

FIGURE 1

Control from Computer

GPIB

power

POWER

SUPPLY

SP-750i

RS232

power

RS232

GPIB

GPIB Controller

COM Port*

FIGURE 2

Control from Optional

750-749 Remote Scan

Controller

*COM 1

or

COM 2

POWER

SUPPLY

750-749

4

Page 6

Section III-C: Cables and Connections for SP-750i

Princeton Instruments offers the following computer cables as options:

CC-499-1 IBM PC or XT compatible

25 pin female ( DB25S) connector to 9 pin male connector ( DB9P).

CC-499-2 IBM AT or compatible

9 pin female ( DB9S) connector to 9 pin male connector ( DB9P).

CC-499-3 Computer terminal type

25 pin male ( DB25S) connector to 9 pin male connector ( DB9P).

CC-499-4 9-pin cable for Macintosh computer

CC-499-5 IEEE488 cable, 4 meters long

The cable CC-499-2 is included with the SP-750i. The other cables are optional. If none of these

cables are compatible with your system, consult Princeton Instruments for a custom cable. If you have

facilities for constructing a custom cable, use the RS232 pin arrangement shown in Table 1, or the

IEEE-488 pin arrangement shown in Table 2. See also Appendix B.

Table 1: RS232 Computer Interface Pin Arrangement:

pin # description

1 open

2 RD data from SP-750i to computer

3 TD data from computer to SP-750i

4 open

5 ground

6 open

7 RTS connect these two pins together

8 CTS

9 Open

A terminal or RS232 computer port must be set up as follows: 9600 baud, 8 data bits, no parity, 1 start bit,

1 stop bit.

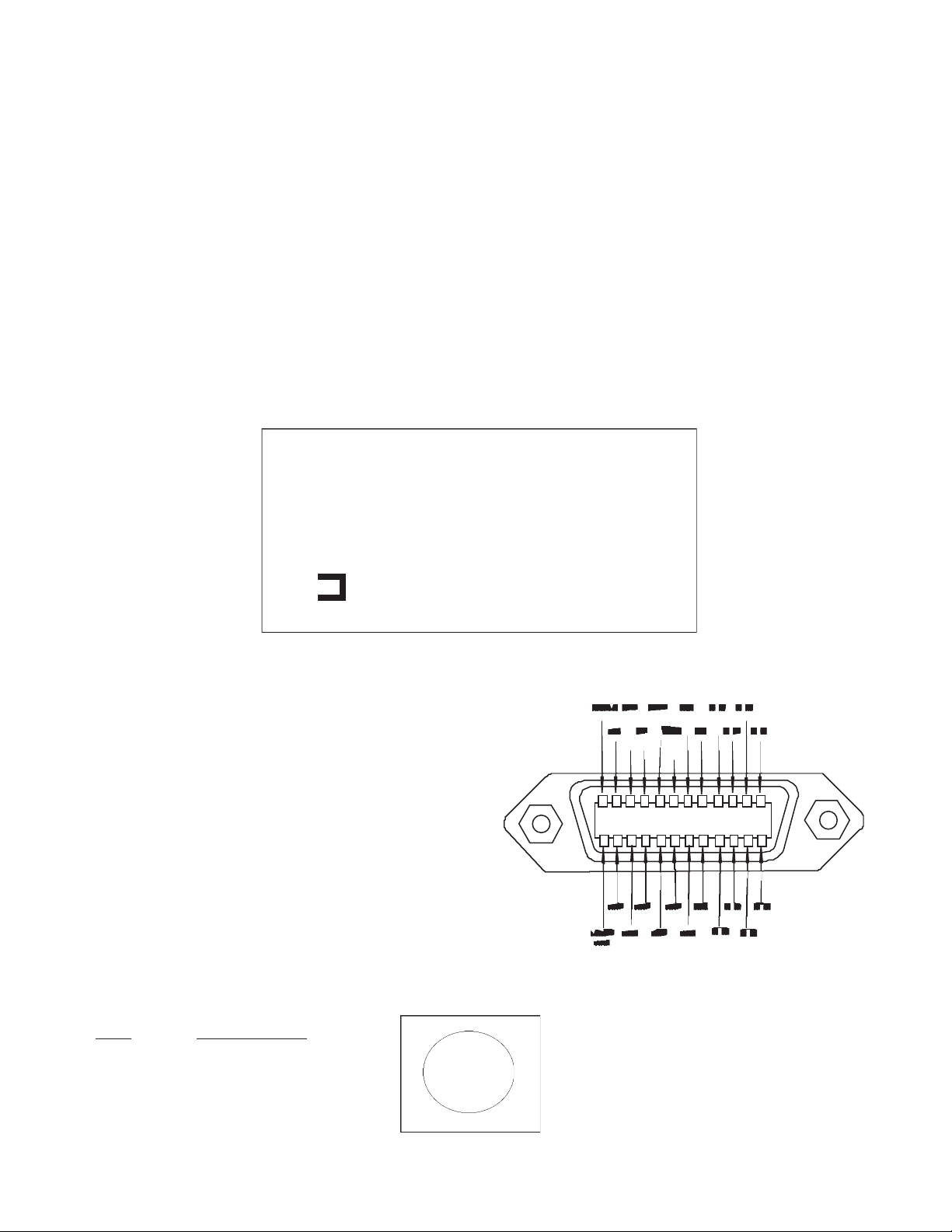

Table 2: IEEE488 Computer Interface

Pin Arrangement:

Table 3: Power Input Pin Arrangement:

PIN# DESCRIPTION

1 +5V

2 GND

3 GND

4 +24V

#2

#3

#1

#4

5

Page 7

Section III-D: Mounting Accessories to the SP-750i Slit Assemblies

All Acton accessories come with their own set of instructions for proper mounting and operation. The

instructions below are only general information. Please refer to the individual instructions for detailed

information.

Accessories: The full range of Acton SP accessories mount directly to the SP-750i slit assemblies.

A drawing of the standard slit assemblies can be found in the Appendices Section to assist you

in mounting accessories. To mount an accessory to the slit, the general procedure is as follows:

1. Place the accessory directly against the face of the slit body. Light sources normally mount

on the entrance slit, detectors on the exit slit. Other accessories such as fiber bundles

normally mount on the entrance slit, but are also compatible with the exit slit.

2. Using four (4) 8-32 screws normally provided with the accessory, secure the accessory to the

slit body.

Light sources fitted with light collection/focusing optics are normally factory aligned to the standard slit.

Note: In some instances with light sources, there is limited access to the

bottom two screw holes. In this case, Princeton Instruments provides

special slotted holes in the light source housing to facilitate mounting

of the source to the slit.

Section III-E: Detector Mounting Instructions: Mounting Focal Plane Detectors to

the SP-750i Spectrograph

The standard mounting flange for CCDs and diode arrays accommodates detectors with two different bolt

circles. There are three (3) equally spaced 10-32 tapped holes on a 3.60” bolt circle, and three (3) equally

spaced holes on a 3.88” bolt circle designed to accept 10-32 button head screws. A set of special

cross-shaped baffles are mounted in the array detector mounting flange to define the focal plane area and

reduce potential stray light. This unique baffle shape permits mounting of many different array detectors.

To mount an array detector to the SP-750i, use the following procedure:

1. The array detector mounting flange is attached to a sliding tube, which fits inside a unique

split camp arrangement.

2. Loosen the split clamp and gently slide the array detector mounting flange all the way out of

the SP-750i housing. Make sure that the sliding tube and o-ring are kept clean.

NOTE: At this point it is very important to check the focal plane distance

of the array detector. This is the distance from the front mounting

surface of the array detector to the actual CCD or diode array

element. Because array detector focal distances vary, the correct

distance is crucial in order to determine if a spacer is required for

proper focus. This spacer is provided with spectrographs. If the

detector focal plane distance falls between .67” and 1.00”, then no

spacer is required.

6

Page 8

3. Position the array detector mounting flange against the array detector, and match the hole

patterns. When correctly positioned, the baffles should be square to the array detector. If it

does not align properly, contact Princeton Instruments.

4. Fasten the array detector mounting flange to the detector, then carefully slide this assembly

back into the SP-750i housing.

5. Tighten the #10-32 set screw on the top of the front plate first, and then tighten the one on

the side.

Refer to Section IV-D for focusing reprocedures for array detectors.

7

Page 9

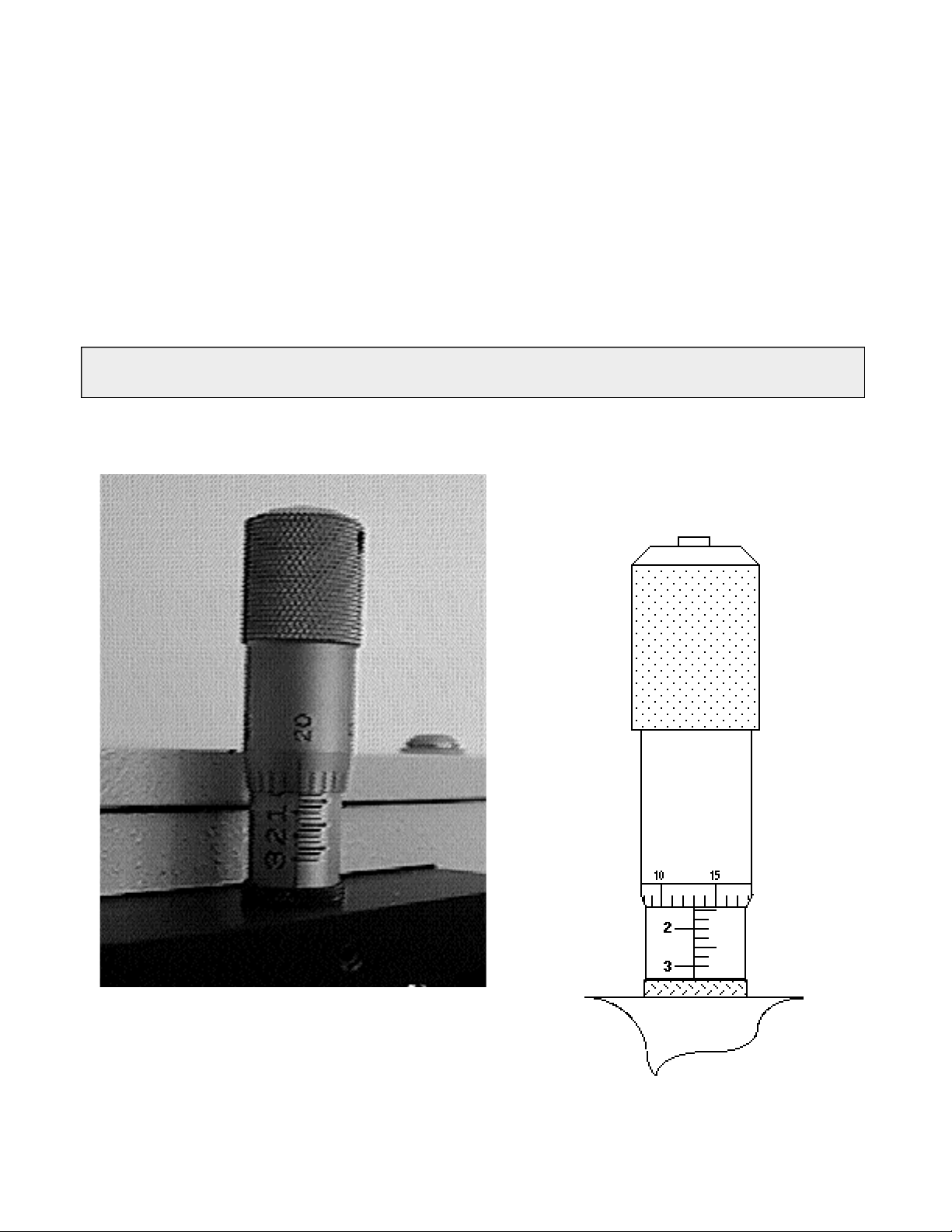

Section III-F: Slit Width Adjustments in the Model 716 Bilateral Slits

The slit width of each bilateral slit assembly (716 type) is adjustable from 0.010 millimeters to 3

millimeters (10 to 3,000 µm) by a micrometer located on the top of the slit housing. The micrometer

knob is graduated in 0.010 millimeter (10 µm) increments.

Each clockwise revolution of the micrometer knob increases the slit width 0.25 millimeters (250 µm). For

maximum reproducibility, the slit width should be set in a clockwise direction (increasing slit widths)

each time it is changed. Refer to the drawing below.

The micrometer knob should not be rotated below a reading of 0.00 or above 3.00. A micrometer setting

of less than 0.010 millimeters (10 µm) should not be used, because a stop is provided to prevent the slit

jaws from contacting each other.

Note: Damage May Be Done If Slit Jaws Are Opened Wider Than 3.0mm.

Slit Width Setting:

200 Micrometers (0.200mm)

Slit Width Setting:

1380 Micrometers (1.38mm)

8

Page 10

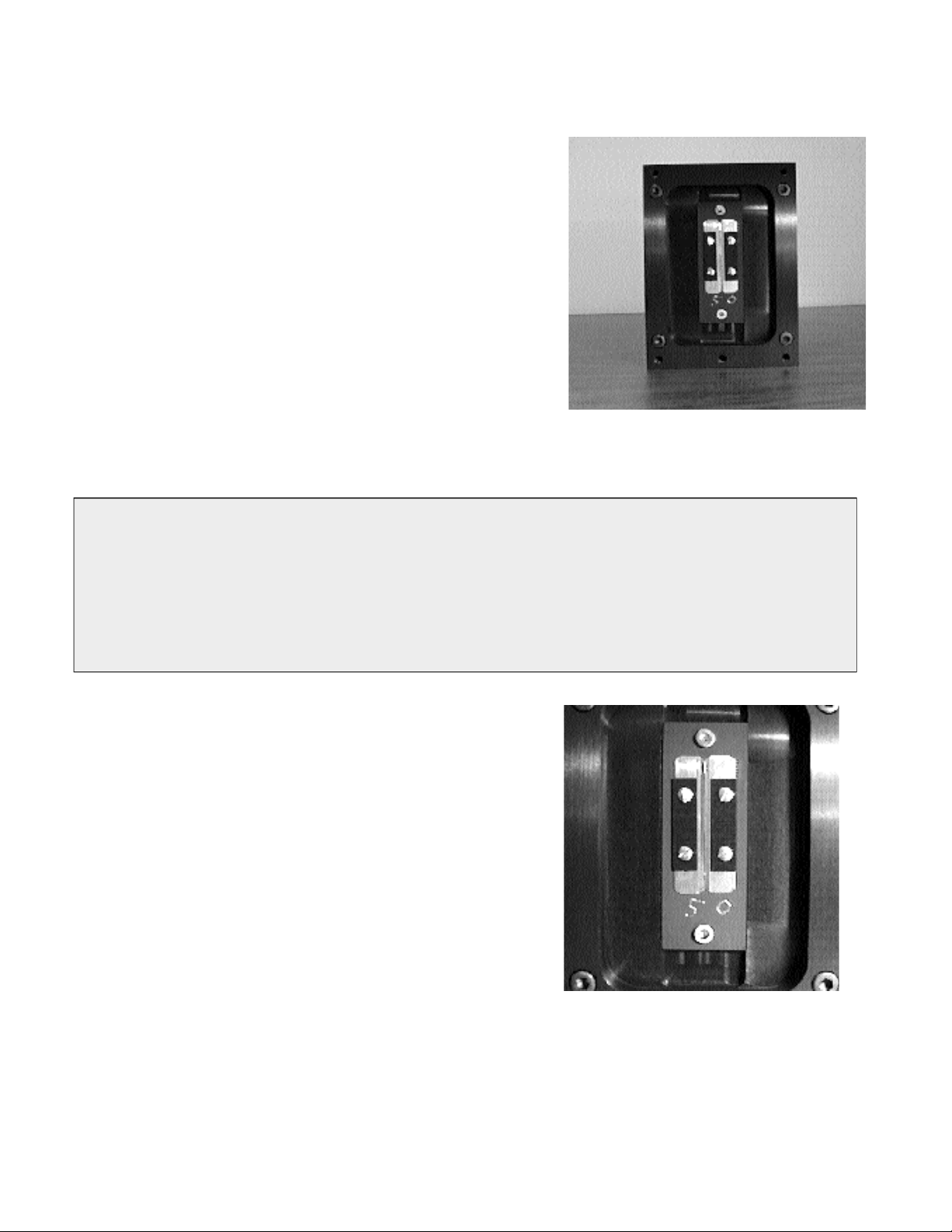

Section III-F Continued: Interchanging Fixed Width Slit Plates in the

Model 715 Fixed Slit Assemblies:

If your SP-750i was purchased with the Model 715 type

fixed slit assemblies, the following procedure should be

used in order to change slit widths. First, at least one

additional fixed slit plate, Model 715-4-XX or 715-14-XX,

must be available to permit changing widths in the 715 type

slit assemblies.

Changing Fixed Slit Plates in the 750-715-1

and 750-715-2 Assemblies:

1. Remove any accessories from the slit body.

2. Using an allen wrench, loosen the two slit plate screws

which hold the slit plate to the slit body. Remove the slit

plate without contacting the slit blades. Store the

removed slit plate in a clean, dry area.

Standard Model 715 Fixed Slit

Assembly

NOTE: Optical Axis Position

Note: Align the new slit plate to the SP-750i optical axis by

orienting it so that the slit width label is upright and readable.

When correctly mounted, the slits are off-centered height-wise,

slightly above the center of the slit body. See the slit assembly

drawing in the appendices section for details, or pictures on this

page for reference.

3. Place the new slit plate in the slit body and secure

it in position using the slit plate screws. The cone

shaped holes in the slit plate are designed to align

the slits to the optical system.

4. The slit width has now been changed.

Fixed Width Slit Plate

Note Orientation for Correct Installation

9

Page 11

IV: SP-750i Operation

Section IV-A: Initialization

When power is turned ON to the SP-750i, it initializes to a wavelength of 0.0nm for grating number 1.

If the power is switched OFF and then ON again to the SP-750i, it will re-initialize. Initialization gives

the system a reference, or starting position to keep track of wavelength position, grating location, and

other parameters. Alternative start-up parameters can be programmed if the factory defaults are not

suitable (See Appendix A).

Section IV-B: Using the Optional Model 750-749 Remote Scan Controller

The Model 750-749 is a Remote Scan Controller (referred to as “controller” for the remainder of this manual)

for the SP-750i Monochromator/Spectrographs. Functions include scanning of wavelengths, GOTO

for rapidly moving the monochromator to a specific center wavelength, grating selection, and interchanging

of grating turrets. It consists of an H-P Model HP 48G Graphics Calculator with RS232 interface, and

Acton-written scan control software. The controller is programmed with all the instrument scan functions

displayed as convenient menu items, with simple keystrokes enabling any of the scan

functions to be performed.

The controller is connected to the SP-750i through the standard RS232 port with the cable provided.

It is designed to send commands and receive information about the specific SP-750i it is attached to,

therefore a single controller can be used with many different instruments (one at a time, however).

When the power is switched OFF and then ON again to the SP-750i and the controller, the SP-750i

will re-initialize. If the controller power is switched OFF then ON again, and the SP-750i power is left

ON, then the controller will return to the last menu selected.

Battery Power Management Feature:

If the controller is not used for a few minutes, the LCD screen will turn off to save

battery power. If this happens, simply press the ON button to return to the menu you

were using.

Operation of the Controller with the SP-750i:

With the controller connected to the SP-750i, turn the power ON to both components. After the

SP-750i initializes, the following menu should be displayed:

{ HOME }

4:

3:

2:

1:

SP300

UTILIT

If the above menu does not appear (for example, if the controller was operated in the calculator mode),

press the RIGHT FUNCTION KEY (➦), followed by the LIBRARY key, then select SP300. When the above

menu is displayed, press the white key below the SP300 function to begin operation (see Appendices Section

for use of the "UTILIT” functions). The following menu will be shown:

10

Page 12

Acton

SP-300

Wavelength= 0.0nm

Scan to 0.0nm

Rate= 100.0 nm/min

Grating #1 1200 g/mm

Main Menu

Jog Incr 1.00nm

GOTO SCAN SPEED GRAT TURR QUIT

All functions of the SP-750i are accessed while the controller displays the Main Menu.

Note: When entering a number for GOTO, SCAN or SPEED, the controller

will accept an integer or a number to the nearest tenth of a

nanometer (nm). If you enter a number with hundredths or lower, it

rounds up to the nearest tenth nanometer.

GOTO Menu:

Press the white key below the GOTO command. The following menu will appear (with a flashing arrow next

to the Enter Wavelength line):

{ HOME } PRG

Go To:

Enter Wavelength

Key in the desired wavelength (in nm) and then push the <ENTER> key (ex: 500 <ENTER>). The

SP-750i will then race at the maximum motor speed to the selected wavelength and display this

interim menu.

Acton

SP-300

Wavelength= 234.5nm

Scan to 500.0nm

Rate= 100.0 nm/min

GOTO Interim Menu

11

Page 13

After the GOTO command is completed, the Main Menu will appear again showing the new center

wavelength (in a monochromator this is the wavelength at the exit slit, in a spectrograph it is the center of

the focal plane).

Acton

SP-300

Wavelength= 500.0nm

Scan to 500.0nm

Rate= 100.0 nm/min

Grating #1 1200g/mm

Main Menu

Jog Incr 1.00nm

GOTO SCAN SPEED GRAT TURR QUIT

SCAN Menu:

SCAN moves the SP-750i to a desired wavelength at a pre-set scanning rate in nanometers per minute.

To use the SCAN menu function, press the white key under the SCAN command while in the Main

Menu. The following menu will appear (with a flashing arrow after Enter wavelength):

{ HOME }

Scan to:

SCAN Menu

Enter Wavelength

As with GOTO, key in the desired wavelength (in nm) followed by <ENTER>. The SP-750i will scan

to the selected wavelength at the preset scanning rate. To change the scanning rate, see the SPEED

(Scanning Rate) instructions following this section. The controller will continue to update the wavelength

display as scanning takes place. When the scanning is complete, the controller returns to the Main Menu

with updated information:

Acton

SP-300

Wavelength= 100.0nm

Scan to 100.0nm

Rate= 100.0 nm/min

Grating #1 1200g/mm

Jog Incr 1.00nm

Main Menu

GOTO SCAN SPEED GRAT TURR QUIT

12

Page 14

SPEED (Scanning Rate) Menu:

To change the wavelength scanning speed of the SP-750i, press the white key below the SPEED

function in the Main Menu. The following menu will be displayed (with a flashing arrow after Enter speed):

{ HOME } PRG

SCAN Menu

Enter speed

Key in the desired scanning speed in nm/min then press <ENTER> (ex: 200.0 <ENTER>). If you enter a

wavelength above the maximum scanning speed for a specific grating, the SP-750i and controller will

default to the maximum scanning speed allowed for the specific grating. The controller will return to

the Main Menu with updated scan speed, as shown in the menu below:

Acton

SP-300

Wavelength= 100.0nm

Scan to 100.0nm

Rate= 200.0 nm/min

Main Menu

Grating #1 1200g/mm

Jog Incr 1.00nm

GOTO SCAN SPEED GRAT TURR QUIT

GRAT (Grating Change) Menu:

Use the GRAT menu to index a desired grating into the operating position (only if there is more than one

grating installed in your SP-750i). From the Main Menu, press the white key below the GRAT command.

This will display a menu that shows the available gratings for the turret currently installed, with

a dot (■) indicating the grating currently in operating position. For example:

Grating:

■

1 1200g/mm BLZ=500nm

GRAT Menu

2 300g/mm BLZ=500nm

3 150g/mm BLZ=500nm

QUIT321

This menu shows that Grating #1 (1200g/mm, blazed at 500nm) is in the operating position. To select

grating #2, press the white button under the number 2 on the display. During the 20 seconds required for

a grating change, the controller displays “Changing Grating”. When the change is complete, the dot (■)

appears next to the #2 grating. To return back to the Main Menu, press the white key below the QUIT

function. The Main Menu will now display the new grating.

13

Page 15

TURR (Turret Change) Menu:

The SP-750i comes with a triple grating turret which accepts 1, 2 or 3 gratings. If more than 3

gratings are required, optional interchangeable turrets are available. If your SP-750i has been

purchased with more than one turret (up to three turrets are possible for a total of nine gratings), you must

input the appropriate turret number using the TURR menu each time a turret is changed. For example, if

you switch from turret #1 to turret #2, use the TURR Menu to let the software know you made the change.

This enables the SP-750i and controller to scan correctly and provide correct wavelength display.

To select the Turret Change Menu from the Main Menu, press the white key below TURR on the controller

display. The TURR menu displays, with a dot (■), which grating turret is currently installed in the

SP-750i, along with available turrets. A display of “Not Inst” means that no gratings have been installed

in the specified turret position. For example, the following menu shows that turret #1 is installed with

Grating #1 (1200g/mm) and Grating #2 (300g/mm). It also shows that turret #2 is available, and that

#3 is not installed. To input the correct turret information, press the white key below the numbers 1, 2, or

3 (in this case, nothing will happen if you select turret 3).

Turret:

Grat #1 Grat #2 Grat #3

■ 1 1200g/mm 300g/mm 150g/mm

TURR Menu

2 600g/mm 150g/mm 75g/mm

3 Not Inst Not Inst Not Inst

1 2 3 QUIT

Press the key below the QUIT function to return to the Main Menu.

JOG Instructions:

The controller for the SP-750i allows the user to change wavelengths without accessing GOTO or

SCAN, and without keying in a destination wavelength. This function is useful for rapidly scanning from

one wavelength region to another, searching for the peak of a line, or accurately positioning a source image

on an array detector. This function is called JOG, and it can be accessed at any time that the other

functions (GOTO, SCAN, etc.) are not in operation. The controller has four direction keys marked with

arrow indicators (▲ ,▼, , and ). JOG operates by moving the SP-750i in wavelength increments

ranging from 0.1nm to 1000nm, and also in “single motor step” increments. Pressing the UP arrow ( )

increases the JOG increment a factor of 10 each time it is pressed, while the DOWN arrow ( ▼ ) decreases

the increment a factor of 10. To access the single motor step JOG, press the DOWN arrow ( ▼ ) until the

increment setting decreases below 0.1nm.

JOG direction is controlled by the arrow keys marked ( and ). To JOG to increasing wavelengths (by

the increment chosen), press the ( ) key. To JOG to decreasing wavelengths, press the ( ) key. If you

press either key more than once, the SP-750i will move the preset JOG increment multiplied by the

number of times the key is pressed. The maximum wavelength possible depends on the grating in the

operating position (1400nm maximum with a 1200g/mm grating, 2800nm maximum with a 600g/mm

grating, etc.). The minimum wavelength possible is -10nm for all gratings.

14

Page 16

Section IV-C: Operating the SP-750i Using a Computer

The Acton SP-750i Monochromator can be controlled from an RS232 terminal or computer using

RS232 or IEEE488. The same command set, listed below, is used for both RS232 and IEEE488.

Commands can be sent as single commands or grouped in strings of commands. All commands are single

words (contain no spaces) and all commands in a string are separated by at least one space. Parameters, if

needed, precede the command and are separated from the command by at least one space (e.g. 546.7

GOTO).

For RS232 operation, the port set-up is 9600 baud, 8 data bits, 1 stop bit and no parity. All commands or

strings of commands must be terminated with a carriage return (0D hex). The SP-750i responds to a

command when the command has been completed by returning the characters OK followed by carriage

return and line feed (hex ASCII sequence 20 6F 6B 0D 0A). The default condition is to echo each character

that is sent to the SP-750i.

When using the IEEE488 (or GPIB) interface, the default device address is 11. The device address can be

set to any value from 1 to 30 using the command SET-ID. The command ?ID is used to read back the IEEE

address. Each command or string of commands must be terminated with a carriage return (0D hex). When

sending a command or string of commands, it is important to wait for the monochromator to complete the

processing of that command string before sending another command. This is accomplished by checking the

status byte. The monochromator controls bits in the IEEE488 status byte which can be read from the

IEEE488 controller. The command for reading this status byte will be unique to your IEEE controller.

For example, with National Instrument controllers, the command is IBRSP. With CEC controllers, the

command is SPOLL.

IEEE488 Status Byte Bits:

Bit 0 0 = command is being processed

1 = SP-750i ready for another command

Bit 1 0 = no errors

1 = SP-750i detected an error in the command

Bit 7 0 = no response or response has been read

1 = SP-750i generated a response which is now ready to be sent

Note that with some fast computers, it is necessary to add a few milliseconds delay in your program after

sending a command and before checking the status byte to allow time for the status byte to be updated.

Monochromator Wavelength Movement Commands:

GOTO Goes to a destination wavelength at maximum motor speed. Accepts destination

wavelength in nm as a floating point number with up to 3 digits after the decimal

point or whole number wavelength with no decimal point.

<GOTO> Same as GOTO (For compatibility with software written for previous Acton SP

models.)

NM Goes to a destination wavelength at constant nm/min rate specified by last NM/MIN

command. Accepts destination wavelength in nm as a floating point number with up

to 3 digits after the decimal point or whole number wavelength with no decimal point.

<NM> Same as NM (For compatibility with software written for previous Acton SP models.)

15

Page 17

Monochromator Wavelength Movement Commands (cont.) :

>NM Similar to NM except it returns control to user immediately rather than waiting for

completion of monochromator wavelength move. Can be used with ?NM or

MONO-?DONE below. This command must be terminated with MONO-STOP listed

below. NOTE: Use the NM command when communication with the monochromator

during the scan is not required.

?NM Returns present wavelength in nm to 0.01nm resolution with units nm appended.

E.G. ?NM 300.00 nm

MONO-?DONE Used with >NM command to determine if monochromator has reached the destination.

Returns 0 if move is not complete, 1 if move is complete.

MONO-STOP Stops the monochromator wavelength move after use of the >NM command.

NM/MIN Returns present scan rate in nm/min to 0.01 nm/min resolution with units nm/min

appended.

E.G. ?NM/MIN 100.00 nm/min

Grating Control Commands:

GRATING Places specified grating in position to the wavelength of the wavelength on the present

grating. Up to nine (9) gratings are allowed on three (3) turrets. This command takes

a grating number from 1 - 9. IMPORTANT NOTE: This command assumes that the

correct turret is specified by the TURRET command. For example, using grating

numbers 1, 4 and 7 will place the first grating on the installed turret into that position

and call up the parameters for the grating number specified.

?GRATING Returns the number of gratings presently being used numbered 1 - 9.

?GRATINGS Returns the list of installed gratings with position groove density and blaze.

The present grating is specified with an arrow.

TURRET Specifies the presently installed turret or the turret to be installed.

E.G. If installing the second turret, issue the command 2 TURRET to insure using

the correct parameters.

?TURRET Returns the correctly installed turret numbered 1 - 3.

The following command is used for grating installation by Acton part#:

INSTALL Installs new grating parameters into the non-volatile memory of the Acton SP

monochromator. Uses the part # of the grating to specify the parameters.

E.G. 1-120-500 5 INSTALL places a 1200 g/mm grating blazed at 500nm into the

second grating position on turret #2.

16

Page 18

Grating Control Commands (cont.) :

The following commands are used for grating installation by grating parameters:

SELECT-GRATING Specifies the grating number to be installed 1 - 9.

G/MM Specifies groove density of grating to be installed in g/mm.

E.G. 1200 G/MM

BLAZE Specifies the blaze wavelength and units of the grating to be installed with 7

characters of the user’s choice. Unlike other commands, this command is issued

before the parameters. After the command is issued, the SP-750i responds with

“ “ . Seven characters are then entered (these may be numbers, letters,

spaces or special characters).

UNINSTALL Used to remove a grating and its parameters from the SP-750i non-volatile memory.

Diverter Control Commands:

EXIT-MIRROR Designates the exit diverter mirror to receive the diverter control commands. This

command is for Acton SP monochromators that can accept two diverter mirrors.

The SP-750i monochromators will accept this command but it is not required in these

monochromators.

ENT-MIRROR Designates the entrance diverter mirror to receive the diverter control commands.

This command is for Acton SP monochromators that can accept two diverter

mirrors. The SP-750i monochromators will not accept this command.

FRONT Moves the designated diverter mirror to position the beam to the front port position.

SIDE Moves the designated diverter mirror to position the beam to the side port position.

?MIRROR Returns the position of the designated diverter mirror with the responses “front” and

“side”.

?MIR Returns the position of the designated diverter mirror with the responses 0 for front

and 1 for side.

Slit Width Control Commands:

FRONT-EXIT-SLIT Designates front exit slit to receive slit control commands. NOTE: The designation

remains in effect until changed by another slit designator. This command does not

have to be repeated until the designated slit is changed.

SIDE-EXIT-SLIT Designates side exit slit to receive slit control commands.

FRONT-ENT-SLIT Designates front entrance slit to receive slit control commands.

SIDE-ENT-SLIT Designates side entrance slit to receive slit control commands.

MICRONS Sets the slit width for the designated slit in the range of 10 to 3000 microns to

1 micron resolution.

?MICRONS Returns the slit width setting in microns to the nearest 1 micron.

17

Page 19

GRATING CALIBRATION COMMANDS:

INIT-OFFSET Sets the offset value for the designated grating. Default values are 0 for gratings 1, 4

and 7; 1536000 for gratings 2, 5 and 8; and 3072000 for gratings 3, 6, and 9. The

limits on the settings are +/- 2500 for a 1200 g/mm grating. This corresponds to an

error of greater than +/- 5nm for a 1200 g/mm grating. The limits are adjusted for

grating groove density, e.g. error for a 600 g/mm grating is +/- 5000. The grating

density designator used with this command is grating# - 1.

E.G. 3072056. 8 INIT-OFFSET for setting offset on grating #9 - 3rd grating on

turret #3.

NOTE: This command requires a decimal point after the offset value.

INIT-SP750-OFFSET Same as INIT-OFFSET above except no decimal point is used after the offset value.

E.G. 3072056 8 INIT-SP750-OFFSET

INIT-GADJUST Sets grating adjustment value for the designated grating. Default values are 10000 for

all gratings. The limits on the parameter for this command are +/- 1000 for all

gratings. The grating designator used with this command is the grating # - 1.

E.G. 9993 1 INIT-GADJUST for setting gadjust on the second grating of turret #1.

NOTE: This command is to maintain compatibility with previous Acton SP

applications. For new applications, use the INIT-SP750-GADJUST command below.

INIT-SP750-GADJUSTSets grating adjustment value for the designated grating. Default values are 1000000

for all gratings. The limits on the parameter for this command are +/-100000 for all

gratings. The grating designator used with this command is the grating# - 1.

E.G. 999322 4 INIT-SP300-GADJUST for setting gadjust on the second grating of

turret #2.

MONO-EESTATUS Returns setup and grating calibration parameters for all gratings.

RESTORE FACTORY

SETTINGS Returns all parameters including grating calibration parameters to the original factory

calibrated settings. NOTE: This command will overwrite any calibration parameters

set by the user.

MONO-RESET Initializes monochromator. Necessary after using INIT-OFFSET,

INIT-GADJUST or INIT-SP750-GADJUST.

HELLO Same as MONO-RESET. Used to maintain compatibility with existing applications.

MODEL Returns model number of Acton SP monochromator.

E.G. MODEL SP-558

SERIAL Returns serial number of Acton SP monochromator. Format is 7 digits with the first

3 digits being the model #.

E.G. SERIAL 3060232

The following are the Start-Up parameters and their default values:

Default Values:

TURRET #1

GRATING #1

WAVELENGTH 0.0 nm

SCAN SPEED 100.0 nm/min

18

Page 20

INIT-GRATING Selects which of the three gratings on the installed turret the monochromator will go to

after finding 0.0 nm on the first grating of the installed turret.

E.G. 2 INIT-GRATING selects the second grating as the default. Accepts values 1 - 9.

INIT-WAVELENGTH Sets an initial wavelength for the monochromator after initialization.

E.G. 435.84 INIT-WAVELENGTH

INIT-SRATE Sets an initial scan rate for the monochromator.

E.G. 500.0 INIT-SRATE

Section IV-D: Focusing and Alignment of Array Detectors

With a CCD or diode array properly mounted to the SP-750i, use the following procedure to align and

focus the system.

1. Mount a light source such as a mercury pen-ray type to the entrance slit of the

SP-750i. Princeton Instruments offers a standard mercury lamp, Model MS-416, designed

for this purpose. Any light source with line output can be used. If there are no “line” sources

available, it is possible to use a broadband source such as a tungsten-halogen lamp for the

alignment. If this is the case, use only a wavelength setting of 0.0nm for alignment purposes.

2. Turn the power ON and move the spectrograph to a wavelength of 435.8nm if using a

mercury lamp, or 0.0nm for a broadband source, or another wavelength corresponding to a

spectrum produced by a different ”line” source.

3. With the array detector operating, check the image of the light source if running in an

imaging mode with a CCD. Otherwise check the line intensity and shape.

4. Loosen the split clamp and slowly move the array detector IN or OUT until the sharpest image

or best focus is achieved.

5. Move the focus-stop screw until it just makes contact with the array detector mounting

flange. This enables you to rotate the detector without changing the focus position.

6. Rotate the detector until the light source image is vertical on the CCD, or until the best focus

is achieved if a diode array is used. Tighten the split clamp to secure the detector.

7. The SP-750i is now ready for operation.

19

Page 21

V. Appendices and Schematic Drawings

Appendix V-A: Selecting Alternate Start-Up Parameters

The following are the Start-Up parameters and their default values:

GRATING #1

WAVELENGTH 0.0 nm

SCAN SPEED 100.0 nm/min

Each of the above may be changed through the RS232 port or IEEE488 port using the following

commands. These values are stored in non-volatile memory and will be in effect after the next power-up.

INIT-GRATING Selects which of the two gratings on the installed turret the SP-750i will go to

after finding 0.0 nm on the first grating.

E.G. 2 INIT-GRATING selects the second grating as the default

INIT-WAVELENGTH Sets an initial wavelength for the SP-750i after initialization.

E.G. 435.84 INIT-WAVELENGTH Notice that two digits after the decimal point are

required

INIT-SRATE Sets an initial scan rate for the SP-750i.

E.G. 500.00 INIT-SRATE Notice that two digits after the decimal point are required

The following command is used to return all grating parameters and start-up parameters to the original

factory settings.

Note that any gratings installed at a later date (after initially receiving the SP-750i) will be erased

from memory using this “restore command”.

RESTORE-FACTORY-SETTINGS Returns all parameters, including grating calibration parameters, to the

original factory calibrated settings. NOTE: This command will overwrite

any calibration parameters set by the user.

20

Page 22

DB9P

MALE

SP-750i to PC-XT

or Terminal

1

6

2

7

3

8

4

9

5

1

6

2

7

3

8

4

9

5

1

6

2

7

3

8

4

9

5

PC-AT or Compatible

SP-750i to

1

2

15

3

16

4

1

5

1

6

7

2

8

2

9

22

10

DB9P

MALE

11

24

DB9P

MALE

1

6

2

7

3

8

4

9

5

1

2

3

4

5

6

7

8

Macintosh Computer

(Modem or Printer Port)

12

2

13

SP-750i to

8 PIN

MALE

21

Page 23

Appendix V-C:

Standard Slit Assemblies

22

Page 24

Appendix V-D: Accessories Listing

SP-750i Monochromators & Spectrographs

SP-755 SP-750i, 750mm Monochromator: Base instrument with 90˚ optical path,

direct digital wavelength drive, Autotrack™ electronics, built-in RS232 and IEEE488

computer compatibility and triple indexable grating mount with one triple grating turret.

Requires grating(s), entrance slit, exit slit, and a #750-749 remote scan controller or computer

for operation. Includes PC-based software for control of SP-750i.

SP-756 SP-750i, 750mm Spectrograph: Same as above, with an array detector mounting

flange mounted on the exit port, compatible with standard Princeton Instruments, EG&G

PARC, or Photometrics (Spectra 9000 type) array detectors.

SP-757 SP-750i, 750mm Dual Exit Port Monochromator: Same as SP-755, with a

micrometer controlled entrance slit, two micrometer controlled exit slits and a motorized exit

slit selection mirror. Provides 90° and 180° optical paths.

SP-758 SP-750i, 750mm Monochromator/SpectroGraph: Same as SP-755, with

micrometer controlled entrance and exit slits 180° apart, motorized exit port selection mirror

and a multichannel detector adapter flange on end port.

Remote Scan Controller

750-749 Remote Scan Controller with Software: Functions include scanning, change of scan

speeds, wavelength readout in nanometers, GOTO, and grating selection. Includes controller

(H-P Graphics Calculator with RS232 output port), 5 foot long connecting cable and

dedicated scan control software.

Assemblies: Bilaterally Adjustable and Fixed Width

SP-716-1 Bilaterally adjustable ENTRANCE slit assembly for SP-750i monochromator or

spectrograph. Micrometer adjustable widths from 10µm to 3mm. Supplied with

interchangeable 4.0mm and 14.0mm high baffles.

SP-716-2 Bilaterally adjustable EXIT slit assembly with adapter for SP-750i monochromator.

Micrometer adjustable widths from 10µm to 3mm. Supplied with interchangeable 4.0mm

and 14.0mm high baffles.

Triple Grating Turret

GT-483 Optional interchangeable triple grating turret for the SP-750i. Must be specified at

time of SP-750i manufacture. Includes second turret, requires gratings.

23

Page 25

Other Acton SP Monochromators & Spectrographs

SP-150-M SP-150, 150mm Monochromator with internal image correction with original

polished aspheric optics, interchangeable dual grating turret, exclusive SpectraDrive™

stepping motor scanning system with 32-bit microprocessor control, Rs232 and IEEE488

computer interfaces, micrometer controlled entrance and exit slits, 90° optical path and scan

control software for Windows. Gratings are required for operation.

SP-150-S SP-150, 150mm Spectrograph: Same as above with a standard multichannel

detector adapter flange on exit port. Provides a 90° optical path.

SP-305 SP-300i, 300mm Monochromator with micrometer adjustable entrance/exit slits,

90° optical path, internal image correction with original polished aspheric optics, a triple

grating turret, exclusive SpectraDrive™ stepping motor scanning system with 32-bit

microprocessor control, RS232 and IEEE488 computer interfaces, plus scan control software

for Windows. Computer with RS232 or IEEE488 and gratings are required for operation.

SP-306 SP-300i, 300mm Spectrograph: Same as above Model SP-305, except with

micrometer controlled entrance slit, 14mm X 27mm focal plane, sliding tube CCD

adapter with exclusive focus stop and standard multichannel detector adapter flange.

Provides a 90° optical path.

SP-307 SP-300i, 300mm Dual Exit Port Monochromator: Same as SP-305, except with

micrometer controlled entrance slit, two micrometer controlled exit slits and a motorized exit

port selection mirror. Provides 90° and 180° optical paths.

SP-308 SP-300i, 300mm Monochromator/Spectrograph: Same as SP-305, except with

micrometer controlled entrance and exit slits 180° apart, motorized port selection mirror and

multichannel detector adapter on 90° port.

DM-481-N Motorized Diverter Mirror for entrance port selection.

SP-555 SP-500i, 500mm Monochromator with a triple indexable grating turret, micrometer

controlled entrance and exit slits 180° apart, exclusive SpectraDrive™ stepping motor

scanning system, remote scan controller with RS232 computer interface (IEEE488 optional),

plus scan control software for Windows. Gratings are required for operation.

SP-556 SP-500i, 500mm Spectrograph: Same as above, with micrometer controlled

entrance slit and standard multichannel detector adapter flange on exit port. Provides a 90°

optical path.

SP-557 SP-500i,500mm Dual Exit Port Monochromator: Same as SP-555, with

micrometer controlled entrance slit, two micrometer controlled exit slits and a motorized exit

slit selection mirror. Provides a 90° and 180° optical path.

SP-558 SP-500i, 500mm Monochromator/Spectrograph: Same as SP-555, with

micrometer controlled entrance and exit slits 180° apart, exit port selection mirror

and a multichannel detector adapter flange on end port.

Light Sources

MS-416 Low Pressure Mercury Light Source with power supply and mounting flange for Acton SP

monochromators and spectrographs. Provides output at typical mercury wavelengths (line

output).

DS-421 30 Watt Deuterium Light Source with housing, power supply, mounting flange, and light

collection mirror. Provides output from 190 to 350nm.

24

Page 26

Light Sources (cont.)

TS-425 30 Watt Tungsten-Halogen Light Source with housing, power supply, mounting flange, and

light collection mirror. Provides output from 350nm to >2.0µm

TS-428 250 Watt Tungsten-Halogen Light Source with housing, AC power supply, mounting flange,

variable brightness control and light collection mirror. Provides output from 350nm to

>2.0µm.

TS-428-DC Same as TS-428 with Regulated DC Power Supply .

TDS-429 Dual Light Source with 30 watt deuterium & 30 watt tungsten-halogen lamps. Includes

housing with light collection mirror, mounting flange, and power supply. Provides combined

output from 190 to >2.0µm.

XS-432 75 Watt Xenon Light Source includes power supply, housing, mounting flange and light

collection mirror. Provides continuous spectral output from 190nm to 750nm and declining

continuum out to 2.6µm.

IS-434 Infrared Source for wavelength region 2.6-16 microns includes silicon carbide resistor,

housing, mounting flange, light collection mirror and power supply.

Detectors and Accessories

PD-438 Universal Photomultiplier Tube Housing for standard 1 1/8" side window photomultiplier

tubes. Requires side window PMT, and photometer/power supply for operation. Accepts Acton

tubes P1, P2 or P3 below, or customer specified 1 1/8” side window PMTs.

PD-439 Same as PD-438 above, also includes integrated light tight shutter.

P1 IP28 side window photomultiplier tube (or equivalent) for wavelength region 185-650nm.

Fits PD-438 or PD-439 housing.

P2 R928 side window photomultiplier tube (or equivalent) for wavelength region from

185-900nm. Fits PD-438 or PD-439 housing.

P3 R5108 side window photomultiplier tube (or equivalent) for wavelength region from

300-1100nm. Fits PD-438 or PD-439 housing.

ID-441 InGaAs Detector, includes pre-amplifier, uncooled version.

ID-441-C InGaAs Detector, includes pre-amplifier, cooled version, requires either Model 442-1 or

442-1A thermoelectric cooling for operation.

ID-442 Infrared Detection Assembly (PbS) with housing, power supply, and mounting flange for

SP-750i, for wavelength region from 1.1 - 2.9 microns. (Requires 442-2 preamplifier

or customer supplied pre-amplifier for operation).

442-1 Thermoelectric cooling for ID-441 or ID-442 detectors; includes direct temperature readout.

442-1 A Thermoelectric cooling for ID-441 or ID-442 detectors.

442-2 Preamplifier for ID-442 detection assembly.

ID-443 IR Detection Assembly (InSb) for 1.5 to 5.0 microns. Includes detector housing,

pre-amplifier, and Dewar.

25

Page 27

ID-444 MCT IR Detector ( Mercury Cadmium Telluride). Covers 2 - 15 µm, includes power supply,

LN2 Dewar and pre-amplifier.

SC-1 SpectraCard data acquisition system, 16-bit PC expansion card with Windows data

acquisition software.

Filter Wheels and Order Sorting Filter Assemblies

FA-448 Six Position Filter Wheel Assembly. Manual sample indexing, holds up to six samples, each

1.0” diameter.

FA-448-1 Order Sorting Filter Assembly. Includes 320nm, 590nm, 665nm, and 715nm filters

mounted in FA-448 filter wheel. Manual indexing of filters for elimination of unwanted second

order radiation.

FA-448-2 Motorized Six Position Filter Wheel Assembly, with stepping motor and FA-448-4

controller. Enables indexing via thumb wheel control, or by computer with RS232. Requires

computer with RS232 for computerized operation.

FA-448-3 Motorized Order Sorting Filter Assembly. Includes 320nm, 590nm, 665nm,and 715nm

filters mounted in FA-448-2 filter wheel. Enables computer controlled indexing of order

sorting filters for elimination of unwanted second order radiation. Requires computer with

RS232 for operation.

FA-448-4 Controller Only for FA-448 or 448-1 filter wheel assemblies. Retrofit kit which enables

changing the FA-448 or 448-1 from manual to computer controlled indexing. Requires

FA-448 type filter wheel and computer with RS232 for operation.

488-03 IEEE488 Interface option for Models FA-448-2, FA-448-3 and FA-448-4.

Software

SW-417 Data Acquisition Software Package: Acton data acquisition and scan control software with

graphical user interface. Functions include spectral data acquisition, reflectance,

transmittance, plus storage and printing of acquired data. Data saved in ASCII format.

Requires Acton SP monochromator with SpectraDrive (SD-748) scan system. PS-445 detector

system, PMT detector and a 486 or higher PC-computer with Windows operating system for

operation. Pentium highly recommended for optimum performance.

26

Page 28

Fiber Optic Light Guides: All Fiber optic light guides contain 19 fibers, 200µm diameter, arranged in

a line pattern at the slit end, and round at the source end.

LG-455-020-1 UV-VIS Fiber Optic Bundle 1.0 meter long, for 190nm to 1100nm. Requires mount.

LG-455-020-3 UV-VIS Fiber Optic Bundle 3.0 meter long, for 190nm to 1100nm. Requires mount.

LG-456-020-1 VIS-NIR Fiber Optic Bundle 1.0 meter long, for 400nm to 2200nm. Requires mount.

LG-456-020-1 VIS-NIR Fiber Optic Bundle 3.0 meter long, for 400nm to 2200nm. Requires mount.

FC-446-020 Slit mount with horizontal translation capability for 10mm diameter fiber optic bundle.

Connecting Cables

CC-499-1 Cable for IBM-PC or XT compatible computer. 25 pin female connector to 9 pin male connector.

CC-499-2 Cable for IBM-PC AT or compatible computer. 9 pin female connector to 9 pin male connector.

CC-499-3 Computer terminal type connector. 25 pin male connector to 9 pin male connector.

CC-499-4 9-pin cable for Macintosh computer.

CC-499-5 IEEE488 cable, 4 meters long.

If the above cables are not compatible with your system,

contact Princeton Instruments for a custom cable.

27

Page 29

Gratings for SP-750i

Grooves/mm

20 45µm 1-002-45

75 8µm 1-075-8

50 12µm 1-050-12

150 500nm 1-015-500

150 4µm 1-015-4

300 300nm 1-030-300

300 500nm 1-030-500

300 2µm 1-030-2

600 300nm 1-060-300

600 1µm 1-060-1

600 1.6µm 1-060-1.6

1200 300nm 1-120-300

1200 500nm 1-120-500

1200 750nm 1-120-750

1200 holographic† 1-120-HUV

1200 holographic†† 1-120-HVIS

1800 250nm 1-180-250

1800 500nm 1-180-500

2400 240nm 1-240-240

2400 holographic††† 1-240-H

3600 240nm 1-360-240

Blaze Part

Wavelength Number

NOTES:

† Blazed Holographic, 190-400nm

optimum range

†† Blazed Holographic, 450-

1400nm optimum range

††† Blazed Holographic, 190-400nm

optimum range

Gold coated optics are

available on request.

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Ordering Information

Telephone Orders MasterCard / VISA

Telephone orders may be placed between 7:30AM MasterCard & VISA accepted for purchases.

and 5:00PM EST. Written "Confirmations" are required

on all verbal orders. Written Orders

Telephone: (978) 263-3584 Submit all written orders to our mailing

address:

Fax Orders

Orders may be placed by fax with written confirmation. Princeton Instruments-Acton

Please include complete name and address with these orders 15 Discovery Way

FAX: (978) 263-5086 Acton, MA 01720

U.S.A.

Orders accepted subject to current pricing.

All orders FOB Princeton Instruments-Acton

or shipping charges & insurance added

separately.

• SpectraPro® is a registered trademark of Acton Research Corporation •

28

Page 30

Appendix V-E: Certification and Warranty

Certification

Princeton Instruments certifies that this instrument was thoroughly tested and

and found to meet the specifications furnished by Princeton Instruments when it

was shipped from the factory.

Warranty

Princeton Instruments instruments and accessories are warranted for a period of

one full year from date of delivery to be free from defects in material and to

conform to the specifications furnished by Princeton Instruments. The company's

obligation under this warranty is limited to servicing or adjusting an instrument

returned to the factory, prepaid, and to repairing or replacing at the factory any part

or parts thereof. All purchased items carry the original manufacturers warranty.

Princeton Instruments shall not be liable for consequential damages resulting

from accident, alteration, misuse, improper installation, operation on low or excessive

voltages or any use in violation of the operating instructions furnished by

Princeton Instruments.

If any defect appears within the warranty period, the purchaser shall promptly notify

Princeton Instruments. No material will be accepted for repair or replacement without

prior authorization from Princeton Instruments. Upon such authorization and in

accordance with instructions of Princeton Instruments, parts, materials or equipment

for which repair or replacement is requested shall be returned to Princeton Instruments

for examination, with shipping charges prepaid by the purchaser. Final determination

as to whether a product or part is actually defective rests with Princeton Instruments.

In such cases where necessary repairs are not covered by this warranty, an estimate

of repair charges will be submitted to the purchaser before servicing the equipment.

Princeton Instruments reserves the right to make changes or improvements

upon its products without imposing any obligations upon itself to install the same

upon its products previously manufactured.

This warranty is expressly in lieu of all other obligations or liabilities on the part of

Princeton Instruments, and Princeton Instruments neither assumes, nor authorizes

any other person to assume for them, other obligations or liability in connection with

the sale of equipment manufactured by Princeton Instruments

29

Page 31

Appendix V-F: Drawing No. 8450-750-50, titled “SP-750i”

1

Page 32

Loading...

Loading...