4411-0139

Issue 4

September 11, 2014

4411-0139

Revision History

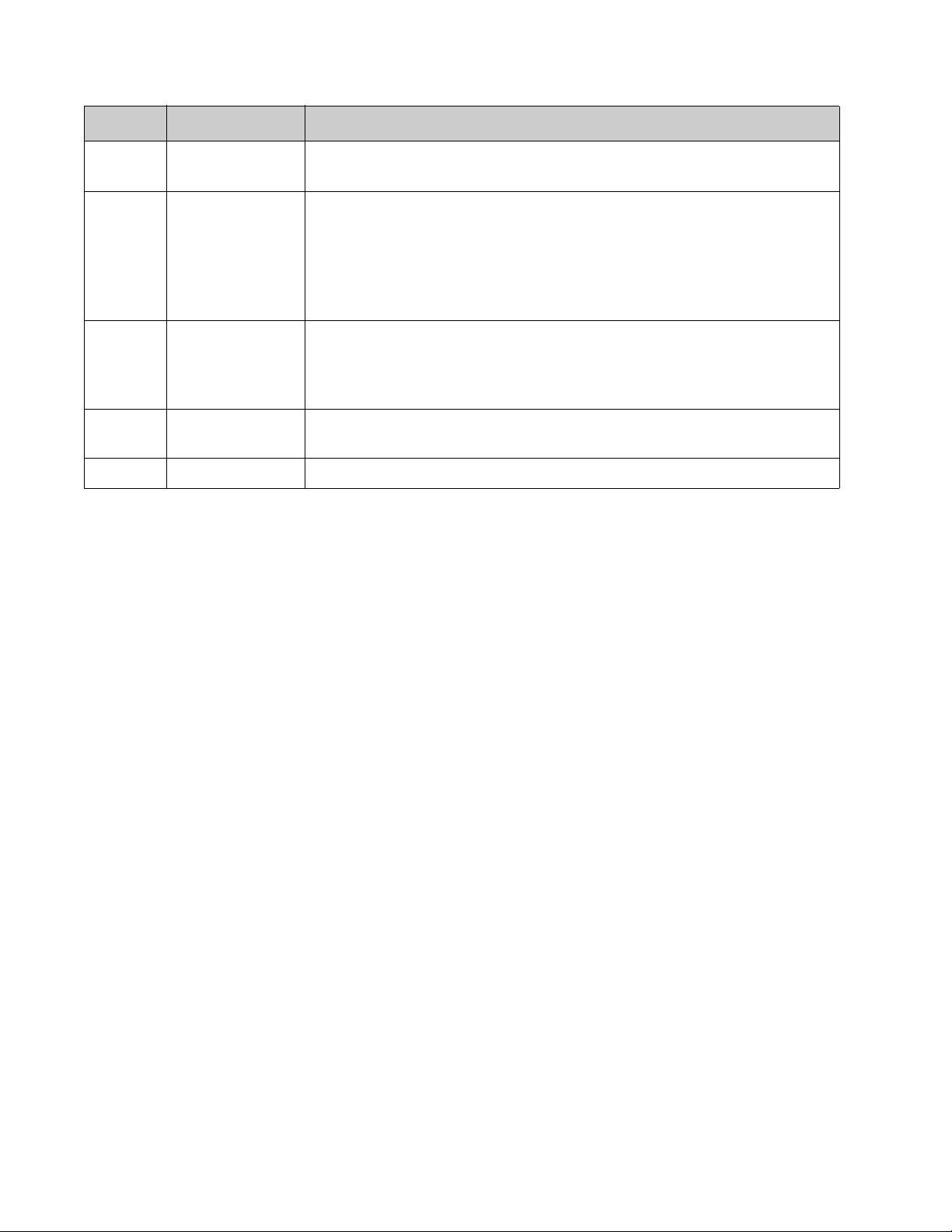

Issue Date List of Changes

4 September 11, 2014 Issue 4 of this document incorporates the following changes:

• Added information about the 1024EM and 1024EM(B) cameras.

3 October 11, 2013 Issue 3 of this document incorporates the following changes:

• Added Section 13.3.3.3, Custom, which details the use of custom RF gating

in LightField for PI-MAX4: 1024i-RF systems;

• Added PI-MAX4: 2048f information;

• Updated Appendix A, Technical Specifications;

• Added Section A.5, CCD Specifications.

2 July 24, 2013 Issue 2 of this document incorporates the following changes:

• Added Chapter 14, PI-MAX4: EM Family, and other EM-supporting

information throughout the document;

• Updated the Declarations of Conformity.

1.B February 11, 2013 Issue 1.B of this document incorporates the following changes:

• Editorial, graphic, and global nomenclature updates.

1.A February 27, 2012 This is the initial release of this document

Copyright 2012-2015 Princeton Instruments, a division of Roper Scientific, Inc.

All rights reserved. No part of this publication may be reproduced by any means without the written permission of Princeton Instruments, a division of

Roper Scientific, Inc. (“Princeton Instruments”.)

Printed in the United States of America.

Pentium is a registered trademark of Intel Corporation.

PVCAM is a registered trademark of Photometrics, Ltd. Corporation

Scientific Imaging ToolKit and SITK are trademarks of R Cubed Software Consultants, LLC.

IntelliCal, PICam, SuperSYNCHRO, and SyncMASTER are trademarks and IsoPlane, LightField, and PI-MAX are registered trademarks of Roper

Scientific, Inc.

Windows and Windows Vista are registered trademarks of Microsoft Corporation in the United States and/or other countries.

The information in this publication is believed to be accurate as of the publication release date. However, Princeton Instruments does not assume any

responsibility for any consequences including any damages resulting from the use thereof. The information contained herein is subject to change without

notice. Revision of this publication may be issued to incorporate such change.

3660 Quakerbridge Rd

Trenton, NJ 08619

TEL: 800-874-9789 / 609-587-9797

FAX: 609-587-1970

Table of Contents

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Chapter 1: Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.1 PI-MAX4 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1.2 Summary of PI-MAX4 Data Acquisition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

1.3 Safety Related Symbols Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

1.4 Grounding and Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

1.4.1 Intensifier Modes and Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

1.4.2 Audible Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

1.4.3 High Intensity Light Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

1.5 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

1.6 Cleaning and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

1.6.1 Cleaning the Camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

1.6.2 Cleaning Optical Surfaces – Protective Window . . . . . . . . . . . . . . . . . . .26

1.6.3 Flushing and Refilling the CCD Chamber . . . . . . . . . . . . . . . . . . . . . . . .26

1.7 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

1.8 About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

1.8.1 Conventions Used in this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

1.8.2 Manual Organization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Chapter 2: System Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.1 System Configuration Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Chapter 3: System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.1 Dangers and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.2 Unpacking the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.3 Checking the Equipment and Parts Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.4 General System Requirements and Information. . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.4.1 Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.4.2 Power Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.4.3 Host Computer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.4.3.1 WinX Host Computer Requirements . . . . . . . . . . . . . . . . . . .36

3.4.3.2 LightField Host Computer Requirements. . . . . . . . . . . . . . . .37

3.5 Mounting the Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.5.1 Imaging Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.5.2 Spectroscopy Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.6 Application Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.6.1 WinX Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.6.2 LightField Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.7 Connect the Circulator [Liquid-Cooled Cameras Only]. . . . . . . . . . . . . . . . . . . . . .42

3.8 Configure Default Camera System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

3.8.1 WinX (Versions 2.5.25.X or higher). . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

3.8.2 LightField . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

4PI-MAX

®

4 System Manual Issue 4

Chapter 4: First Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1 Required Equipment and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2 Cable Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3 Before Turning on the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.4 Turning on the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.5 LightField First Light Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.5.1 Assumptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.5.2 Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.5.3 Parameter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.5.4 Acquiring Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.5.5 Focusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.6 WinX First Light Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.6.1 Assumptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.6.2 Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.6.3 Configuring the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.6.4 Initial Data Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.6.5 Focusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Chapter 5: Gate Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.1 Data Acquisition Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.2 WinX System On/Off Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.3 Pre-Exposure Removal of Accumulated Charge . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.3.1 Dark Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.3.2 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.4 Phosphor Decay Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.5 Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5.1 Cooling Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5.2 Necessary Cooling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.5.3 Setting the Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.6 Exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.6.1 Exposure with an Image Intensifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.6.1.1 Exposure Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.6.2 Saturation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.7 Background Subtraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.8 Readout of the Array. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.8.1 Interline CCD Readout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.8.2 Full-Frame CCD Readout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.8.3 Binned Readout (Hardware Binning) . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.8.3.1 CCD Type and Readout Port(s) . . . . . . . . . . . . . . . . . . . . . . 77

5.8.3.2 LightField and Partial Frame ROI Binning. . . . . . . . . . . . . . 80

5.9 Software Binning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.10 Controller Gain {Analog Gain} . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.11 Digitization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.12 Logic Out Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.13 WinX Experiment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.13.1 Main Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.13.2 Timing Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table of Contents 5

5.14 LightField Experiment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

5.14.1 Common Acquisition Settings Expander . . . . . . . . . . . . . . . . . . . . . . . . .90

5.14.2 Region of Interest Expander . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

5.14.3 Trigger Expander . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

5.14.4 SuperSYNCHRO Timing Expander . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Chapter 6: LightField and Gated Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.1 Gating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

6.2 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

6.2.1 Intensifier Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

6.2.2 Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

6.3 Timing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

6.4 Micro-Channel Plate (MCP) Bracket Pulsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

6.4.1 Bracket Pulsing in LIF Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . .99

6.4.2 Bracket Pulsing in Nanosecond Pump Probe Experiments . . . . . . . . . . .99

6.4.3 Limitations of Bracket Pulse Gating. . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

6.4.4 Impact of Bracket Pulsing on Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

6.4.5 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

6.5 Experiments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

6.5.1 Swept Gate Experiment [Fixed Width, Variable Delay] . . . . . . . . . . . .103

6.5.1.1 Experiment Supplies the Master Clock . . . . . . . . . . . . . . . .103

6.5.1.2 SyncMASTER1 Supplies the Master Clock. . . . . . . . . . . . .112

6.5.2 Single Shot Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

6.5.3 Swept Gate Experiment [Variable Width, Variable Delay] . . . . . . . . . .117

6.5.4 Static Gate Experiment [Fixed Width, Fixed Delay] . . . . . . . . . . . . . . .117

Chapter 7: WinX and Gated Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7.1 Gating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

7.2 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

7.2.1 Intensifier Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

7.2.2 Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

7.3 Timing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

7.4 Micro-Channel Plate (MCP) Bracket Pulsing . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

7.4.1 Bracket Pulsing in LIF Measurements . . . . . . . . . . . . . . . . . . . . . . . . . .123

7.4.2 Bracket Pulsing in Nanosecond Pump Probe Experiments . . . . . . . . . .124

7.4.3 Limitations of Bracket Pulse Gating. . . . . . . . . . . . . . . . . . . . . . . . . . . .124

7.4.4 Impact of Bracket Pulsing on Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

7.4.5 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

7.5 Experiments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

7.5.1 Swept Gate Experiment [Fixed Width, Variable Delay] . . . . . . . . . . . .127

7.5.1.1 Experiment Supplies the Master Clock . . . . . . . . . . . . . . . .127

7.5.1.2 SyncMASTER1 Supplies the Master Clock. . . . . . . . . . . . .141

7.5.2 Single Shot Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

7.5.3 Swept Gate Experiment [Variable Width, Variable Delay] . . . . . . . . . .146

7.5.4 Static Gate Experiment [Fixed Width, Fixed Delay] . . . . . . . . . . . . . . .146

Chapter 8: Timing Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

8.1 Pulse Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

8.1.1 Supported Timing Generator Trigger Modes . . . . . . . . . . . . . . . . . . . . .148

8.2 Single Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

8.2.1 Supported Timing Generator Trigger Modes . . . . . . . . . . . . . . . . . . . . .149

6PI-MAX

®

4 System Manual Issue 4

Chapter 9: LightField and Dual Image Feature . . . . . . . . . . . . . . . . . . . . . . . 151

9.1 Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

9.2 Interline CCD Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

9.3 Trigger Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

9.3.1 Trigger Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

9.3.2 Trigger Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

9.3.2.1 Internal Trigger Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

9.3.2.2 External Trigger Source . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

9.4 Configure a Single Trigger DIF Experiment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

9.4.1 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

9.4.2 Software Configuration and Operation . . . . . . . . . . . . . . . . . . . . . . . . . 156

9.5 Configure a Dual Trigger DIF Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

9.5.1 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

9.5.2 Software Setup and Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

9.6 Tips and Tricks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Chapter 10: WinX and Dual Image Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

10.1 Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

10.2 Interline CCD Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

10.3 Timing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

10.4 Configure a Single Trigger DIF Experiment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

10.4.1 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

10.4.2 Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

10.4.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

10.5 Configure a Dual Trigger DIF Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

10.5.1 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

10.5.2 Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

10.5.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

10.6 Tips and Tricks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Chapter 11: MCP Gating Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

11.1 Setup and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

11.2 Gain Variation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

11.3 Fluorescence Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

11.4 Cabling for MCP Gated Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Chapter 12: Picosecond Gating Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

12.1 Activating Picosecond Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

12.2 Gain and Gate Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

12.3 MONITOR Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

12.4 Repetition Rate Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

12.5 Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

12.6 Methods for Finding a Short Optical Pulse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Table of Contents 7

Chapter 13: PI-MAX4: 1024i-RF and RF Modulation . . . . . . . . . . . . . . . . . . . 183

13.1 Basics of RF Modulation on Intensified CCDs . . . . . . . . . . . . . . . . . . . . . . . . . . .183

13.2 Advantages of PI-MAX4: 1024i-RF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

13.3 RF Experiment Design in LightField . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

13.3.1 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

13.3.2 Trigger Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

13.3.3 Gating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

13.3.3.1 Repetitive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

13.3.3.2 Sequential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

13.3.3.3 Custom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

13.3.4 Phase Modulation Sorting Add-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

13.4 PI-MAX4: 1024i-RF Rear Panel Information . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

13.4.1 PI-MAX4: 1024i-RF Power Supply Rear Panel Information. . . . . . . . .202

13.5 RF Modulator Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Chapter 14: PI-MAX4: EM Family . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

14.1 Electron Multiplication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

14.1.1 Enabling EM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

14.1.2 EM Gain Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

14.1.2.1 Optimal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

14.1.2.2 Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

14.2 Kinetics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

14.2.1 Masking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

14.2.2 Trigger Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

14.2.3 Image/Frame Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

14.2.4 Data Readout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

14.2.5 Binning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

14.2.5.1 File Storage Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . .218

14.2.6 Configuring Kinetics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

14.2.7 Cleaning the CCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

14.2.8 Configuring a Kinetics Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

14.2.8.1 Configuring the Software Parameters: . . . . . . . . . . . . . . . . .222

14.3 Photon Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .223

14.3.1 Configuring Photon Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .224

14.4 High Speed Camera Add-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .225

14.4.1 Configuring the High Speed Camera . . . . . . . . . . . . . . . . . . . . . . . . . . .226

Chapter 15: Tips and Tricks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

15.1 Overexposure Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

15.2 Signal Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

15.2.1 Time Budgets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

15.2.2 Measuring Coincidence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .231

15.2.3 Adjusting the Signal Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .232

15.2.4 Optimizing the Gate Width and Delay . . . . . . . . . . . . . . . . . . . . . . . . . .232

15.3 Lasers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233

15.3.1 Free Running Lasers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233

15.3.2 Triggered Lasers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233

15.3.3 Jitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .234

15.4 Inhibiting the Pulser During Readout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .234

8PI-MAX

®

4 System Manual Issue 4

15.5 Lens Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

15.5.1 Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

15.5.2 Depth of Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

15.6 Baseline Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

15.7 Temperature Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

15.8 Intensifier Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Chapter 16: Component Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

16.1 Mount Adapters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

16.2 Switches, Connectors, and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

16.2.1 AUX I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

16.2.2 AUX Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

16.2.3 AUX Power [PI-MAX4: 1024i-RF only] . . . . . . . . . . . . . . . . . . . . . . . 239

16.2.4 Coolant Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

16.2.5 Error LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

16.2.6 Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

16.2.7 Gig-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

16.2.8 I.I.T. PWR On/Off Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

16.2.9 Logic Out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

16.2.10 Mon RF Out [PI-MAX4: 1024i-RF only] . . . . . . . . . . . . . . . . . . . . . . . 241

16.2.11 Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

16.2.12 Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

16.2.13 Ready Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

16.2.14 Thermoelectric Cooler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

16.2.15 Trigger In. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

16.2.16 User RF Out [PI-MAX4: 1024i-RF only] . . . . . . . . . . . . . . . . . . . . . . . 242

16.3 Gig-E Ethernet Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

16.4 Extender Bracket Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

16.5 CoolCUBE

16.6 Spectrograph (Option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

16.7 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

16.8 Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

16.9 Application Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

16.10 User Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Coolant Circulator (Option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

II

Chapter 17: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

17.1 Alarm Sounds Repetitively . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

17.2 Alarm Sounds Sporadically. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

17.3 Baseline Signal Suddenly Changes by > 1000 ADU . . . . . . . . . . . . . . . . . . . . . . 248

17.4 Camera Is Not Responding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

17.5 Camera Stops Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

17.6 Camera1 (or similar name) in Camera Name field . . . . . . . . . . . . . . . . . . . . . . . . 249

17.7 Cooling Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

17.7.1 Temperature Lock Cannot be Achieved or Maintained. . . . . . . . . . . . . 250

17.8 Data Loss or Serial Violation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

17.9 Error Occurs at Computer Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

17.10 Ethernet Network is Not Accessible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

17.10.1 LightField Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

17.10.2 WinX Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

17.11 Excessive Readout Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

17.12 Gating Pulse Artifact Strings Displayed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Table of Contents 9

Appendix A: Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

A.1 Mechanical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

A.2 Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

A.3 Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

A.4 Intensifier Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

A.5 CCD Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

A.6 AUX I/O Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .258

A.6.1 AUX I/O Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

A.7 CoolCUBE

Circulator Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .261

II

Appendix B: Outline Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

B.1 PI-MAX4: 1024i/1024f/2048f/1024x256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .263

B.2 PI-MAX4: 512 EM/512 EM(B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

B.3 PI-MAX4 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .269

B.4 PI-MAX4: 1024i-RF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .270

B.5 PI-MAX4: 1024i-RF Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

B.6 CoolCUBE

Circulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .274

II

Appendix C: WinX/LightField Cross Reference . . . . . . . . . . . . . . . . . . . . . . . . 275

C.1 WinX-to-LightField Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .275

C.2 LightField to WinX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .277

Appendix D: Extender Bracket Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Appendix E: C- and F-Mount Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

E.1 C-Mount Lens Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

E.1.1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

E.1.2 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

E.2 F-Mount Lens Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .282

E.2.1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .282

E.2.2 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .282

E.3 Camera Orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .283

E.4 Focusing C- and F-Mount Lenses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .283

Appendix F: Spectrograph Mount Information . . . . . . . . . . . . . . . . . . . . . . . . 285

F.1 Mount PI-MAX4 to an Acton SpectraPro Series Spectrograph . . . . . . . . . . . . . . .285

F.1.1 Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .285

F.1.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .285

F.2 Mount a PI-MAX4 to an IsoPlane SCT-320 Spectrograph . . . . . . . . . . . . . . . . . .287

F.2.1 Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .287

F.2.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .287

F.3 Spectrograph-Camera Rotational Alignment and Focusing. . . . . . . . . . . . . . . . . .288

F.3.1 Aligning and Focusing an Acton SpectraPro Series Spectrograph. . . . .288

F.3.2 Align and Focus an IsoPlane SCT-320 Spectrograph. . . . . . . . . . . . . . .290

10 PI-MAX® 4 System Manual Issue 4

Appendix G: Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

G.1 Accessory Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

G.2 Adapter Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

G.3 Quick Start Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

G.4 Standard C-, F-, and Spectroscopy-Mount Adapters . . . . . . . . . . . . . . . . . . . . . . 294

G.5 Spectroscopy-Mount for IVUV and NVUV Cameras . . . . . . . . . . . . . . . . . . . . . 295

G.5.1 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

G.6 Optical Distance from Mounting Face to Image Plane . . . . . . . . . . . . . . . . . . . . . 297

Appendix H: Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Warranty & Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Limited Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Basic Limited One (1) Year Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Limited One (1) Year Warranty on Refurbished or Discontinued Products. . . 309

XP Vacuum Chamber Limited Lifetime Warranty . . . . . . . . . . . . . . . . . . . . . . 309

Sealed Chamber Integrity Limited 12 Month Warranty . . . . . . . . . . . . . . . . . . 310

Vacuum Integrity Limited 12 Month Warranty . . . . . . . . . . . . . . . . . . . . . . . . 310

Image Intensifier Detector Limited One Year Warranty. . . . . . . . . . . . . . . . . . 310

X-Ray Detector Limited One Year Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Software Limited Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Owner's Manual and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Your Responsibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Contact Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

List of Figures

Figure 1-1: Typical PI-MAX4 System Components . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 1-2: Major Components of the Intensifier-CCD . . . . . . . . . . . . . . . . . . . . . . 21

Figure 2-1: Typical PI-MAX4 System Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 2-2: Typical PI-MAX4: 1024i-RF System Diagram . . . . . . . . . . . . . . . . . . . 31

Figure 3-1: Typical WinView/32 Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 3-2: Typical LightField InstallShield Wizard Dialog . . . . . . . . . . . . . . . . . . 41

Figure 3-3: Typical CoolCUBE

Figure 3-4: Typical WinX Camera Detection Wizard Dialog . . . . . . . . . . . . . . . . . 44

Figure 4-1: LightField Desktop: Available Devices. . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 4-2: Camera Icon in Experiment Devices Area . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 4-3: LightField Desktop View Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 4-4: Typical SuperSYNCHRO Timing Expander . . . . . . . . . . . . . . . . . . . . . 53

Figure 4-5: LightField View Area Displaying an Acquired Image . . . . . . . . . . . . . 54

Figure 4-6: Typical WinX Pulsers Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 4-7: Typical SuperSYNCHRO Dialog: Trigger In Tab. . . . . . . . . . . . . . . . . 56

Figure 4-8: Typical SuperSYNCHRO Dialog: Gating Tab . . . . . . . . . . . . . . . . . . . 56

Figure 4-9: Typical Repetitive Gating Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 4-10: Typical Experiment Setup Dialog: Main Tab . . . . . . . . . . . . . . . . . . . . 58

Figure 4-11: Typical Experiment Setup Dialog: ADC Tab . . . . . . . . . . . . . . . . . . . . 58

Figure 4-12: Typical Experiment Setup Dialog: ROI Setup Tab . . . . . . . . . . . . . . . . 59

Figure 4-13: Sample Acquired Test Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 5-1: Block Diagram: Signal Path in a Standard PI-MAX4 System. . . . . . . . 62

Circulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

II

List of Figures 11

Figure 5-2: Clean Cycles in Internal Trigger Mode of Operation . . . . . . . . . . . . . . .64

Figure 5-3: WinX: Phosphor Decay Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Figure 5-4: LightField: Phosphor Decay Delay Parameters. . . . . . . . . . . . . . . . . . . .66

Figure 5-5: Interline CCD Readout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Figure 5-6: Step 1: Non-Overlapped, Early Exposure . . . . . . . . . . . . . . . . . . . . . . . .72

Figure 5-7: Step 2: Non-Overlapped, Early Readout . . . . . . . . . . . . . . . . . . . . . . . . .72

Figure 5-8: Step 3: Non-Overlapped, Transfer to Output Node. . . . . . . . . . . . . . . . .73

Figure 5-9: Step 4: Non-Overlapped, End of Readout. . . . . . . . . . . . . . . . . . . . . . . .73

Figure 5-10: Full Frame CCD Readout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Figure 5-11: Dual Port Readout: 2 × 2 Binning of Interline CCD . . . . . . . . . . . . . . . .77

Figure 5-12: Dual Port Readout: LightField Setting, 2x2 Binning, Interline CCD . . .78

Figure 5-13: Single Port Readout: 2 × 2 Binning of Full Frame CCD. . . . . . . . . . . . .78

Figure 5-14: Experiment Setup: ROI Configuration Dialog . . . . . . . . . . . . . . . . . . . .79

Figure 5-15: Typical Edit Regions of Interest Window . . . . . . . . . . . . . . . . . . . . . . . .80

Figure 5-16: Single Port Readout: Partial Frame, 2×2 Binning, Interline CCD . . . . .81

Figure 5-17: Dual Port Readout: LightField Settings, 5×3 Binning, Interline CCD . .82

Figure 5-18: Typical PI-MAX4 Hardware Setup Dialog . . . . . . . . . . . . . . . . . . . . . . .84

Figure 5-19: Timing Diagram: Shutter {Shutter Open}, Read Out {Reading Out},

Acquiring {Acquiring} . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Figure 5-20: Typical Experiment Setup Dialog: Main Tab . . . . . . . . . . . . . . . . . . . . .86

Figure 5-21: Typical Experiment Setup Dialog: Timing Tab . . . . . . . . . . . . . . . . . . .87

Figure 5-22: Fast Mode/Slow Mode Flow Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Figure 5-23: Typical Common Acquisition Settings Expander . . . . . . . . . . . . . . . . . .90

Figure 5-24: Typical Region of Interest Expander. . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Figure 5-25: Typical Trigger Expander: Internal Trigger Source Parameters . . . . . . .92

Figure 5-26: Typical Trigger Expander: External Trigger Source Parameters . . . . . .92

Figure 5-27: SuperSYNCHRO Timing Expander . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Figure 6-1: Timing Diagram: MCP Bracket Pulsing . . . . . . . . . . . . . . . . . . . . . . . . .98

Figure 6-2: Timing Diagram: MCP Bracket Pulsing . . . . . . . . . . . . . . . . . . . . . . . .101

Figure 6-3: Typical PI-MAX4 Experiments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Figure 6-4: Block/Timing Diagram: Swept Gate Experiment . . . . . . . . . . . . . . . . .104

Figure 6-5: Typical Sensor Cleaning Fly-out Pane . . . . . . . . . . . . . . . . . . . . . . . . .104

Figure 6-6: Typical Spectrometer Expanders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Figure 6-7: Typical Region of Interest Expander: Full Sensor . . . . . . . . . . . . . . . .105

Figure 6-8: Typical Common Acquisition Settings Expander . . . . . . . . . . . . . . . . .106

Figure 6-9: Typical Analog to Digital Conversion Expander . . . . . . . . . . . . . . . . .106

Figure 6-10: Typical Trigger Expander . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Figure 6-11: Typical Region of Interest Expander: Full Sensor Binned . . . . . . . . . .108

Figure 6-12: Trigger Expander: External Trigger Source Configuration. . . . . . . . . .108

Figure 6-13: Typical SuperSYNCHRO Timing Expander. . . . . . . . . . . . . . . . . . . . .109

Figure 6-14: Typical SuperSYNCHRO Timing: SyncMASTER On. . . . . . . . . . . . .110

Figure 6-15: Typical Experiment Results: Frame Cross Section . . . . . . . . . . . . . . . .111

Figure 6-16: Block Diagram: SyncMASTER1 as Master Clock . . . . . . . . . . . . . . . .112

Figure 6-17: Timing Diagram: SyncMASTER1 as Master Clock . . . . . . . . . . . . . . .112

Figure 6-18: Block Diagram: Single Shot Experiment . . . . . . . . . . . . . . . . . . . . . . .113

Figure 6-19: Cleaning Cycles, Cleaning and Skipping Expander . . . . . . . . . . . . . . .114

Figure 6-20: Common Acquisition Settings Expander: Intensifier Gain . . . . . . . . . .114

Figure 6-21: Typical Repetitive Gating Setup: 100 ns Width, 25 ns Delay. . . . . . . .115

Figure 6-22: Single Shot Result: Fluorescence Spot, Width = 100 ns,

Delay = 10 ns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

12 PI-MAX® 4 System Manual Issue 4

Figure 6-23: Single Shot Result: Fluorescence Spot, Width = 100 ns,

Delay = 10 ns, Binned Vertically. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Figure 6-24: Repetitive Gating Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 7-1: Timing Diagram: MCP Bracket Pulsing . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 7-2: Timing Diagram: MCP Bracket Pulsing . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 7-3: Typical PI-MAX4 Experiments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 7-4: Block/Timing Diagram: Swept Gate Experiment . . . . . . . . . . . . . . . . 128

Figure 7-5: Typical Hardware Setup Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Figure 7-6: Typical WinSpec/32 Installation Sequence: Acton 300I

Spectrograph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Figure 7-7: Typical Move Spectrograph Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 7-8: Typical Experiment Setup Dialog: Main Tab . . . . . . . . . . . . . . . . . . . 131

Figure 7-9: Typical Experiment Setup Dialog: Timing Tab. . . . . . . . . . . . . . . . . . 132

Figure 7-10: Typical Experiment Setup Dialog: ADC Tab . . . . . . . . . . . . . . . . . . . 133

Figure 7-11: Typical Experiment Setup Dialog: ROI Tab . . . . . . . . . . . . . . . . . . . . 133

Figure 7-12: Typical WinX Pulsers Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 7-13: Typical SuperSYNCHRO Dialog: Trigger In Tab. . . . . . . . . . . . . . . . 134

Figure 7-14: Typical WinX Pulsers Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 7-15: Typical SuperSYNCHRO Dialog: Trigger In Tab. . . . . . . . . . . . . . . . 135

Figure 7-16: Typical SuperSYNCHRO Dialog: Gating Tab . . . . . . . . . . . . . . . . . . 136

Figure 7-17: Typical Sequential Gating Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 7-18: Typical View Width/Delay Sequence Dialog . . . . . . . . . . . . . . . . . . . 137

Figure 7-19: Typical SuperSYNCHRO Dialog: Trigger Out Tab . . . . . . . . . . . . . . 138

Figure 7-20: Experiment Setup: Timing Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 7-21: Experiment Setup: Main Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 7-22: Typical Experiment Results Shown in 3-D . . . . . . . . . . . . . . . . . . . . . 140

Figure 7-23: Block Diagram: SyncMASTER1 as Master Clock . . . . . . . . . . . . . . . 141

Figure 7-24: Timing Diagram: SyncMASTER1 as Master Clock . . . . . . . . . . . . . . 141

Figure 7-25: Block Diagram: Single Shot Experiment . . . . . . . . . . . . . . . . . . . . . . . 142

Figure 7-26: Hardware Setup Dialog: Cleans/Skips Tab . . . . . . . . . . . . . . . . . . . . . 143

Figure 7-27: Experiment Setup Dialog: Main Tab . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 7-28: Typical Repetitive Gating Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 7-29: Single Shot Result: Fluorescence Spot, Width = 100 ns,

Delay = 10 ns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Figure 7-30: Single Shot Result: Fluorescence Spot, Width = 100 ns,

Delay = 10 ns, Binned Vertically. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Figure 7-31: Repetitive Gating Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 8-1: Timing Diagram: Pulse Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Figure 8-2: Timing Diagram: Trigger Per Pulse. . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Figure 8-3: Timing Diagrams: Three Repetition Sequence . . . . . . . . . . . . . . . . . . 148

Figure 8-4: Timing Diagram: 3 Repetition Sequence, Trigger per Pulse . . . . . . . . 149

Figure 9-1: Readout Expander . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Figure 9-2: Common Acquisition Settings Expander. . . . . . . . . . . . . . . . . . . . . . . 152

Figure 9-3: Trigger Expander . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Figure 9-4: SuperSYNCHRO Timing Expander: DIF Operation. . . . . . . . . . . . . . 154

Figure 9-5: Block Diagram: DIF Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Figure 9-6: Timing Diagram: DIF Operation, Single Trigger . . . . . . . . . . . . . . . . 156

Figure 9-7: Block Diagram: DIF Experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Figure 9-8: Timing Diagram: DIF Operation, Dual Trigger. . . . . . . . . . . . . . . . . . 158

Figure 10-1: Block Diagram: DIF Experiment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

List of Figures 13

Figure 10-2: Timing Diagram: DIF Operation, Single Trigger . . . . . . . . . . . . . . . . .163

Figure 10-3: WinX Hardware Setup Dialog: Controller/Camera Tab . . . . . . . . . . . .164

Figure 10-4: WinX Experiment Setup Dialog: Main Tab . . . . . . . . . . . . . . . . . . . . .164

Figure 10-5: WinX Experiment Setup Dialog: Timing Tab. . . . . . . . . . . . . . . . . . . .165

Figure 10-6: WinX Pulsers Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

Figure 10-7: WinX SuperSYNCHRO Dialog: Gating Tab . . . . . . . . . . . . . . . . . . . .166

Figure 10-8: WinX DIF Gating Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

Figure 10-9: WinX SuperSYNCHRO Dialog: Trigger In Tab. . . . . . . . . . . . . . . . . .167

Figure 10-10: WinX SuperSYNCHRO Dialog: Trigger Out Tab . . . . . . . . . . . . . . . .167

Figure 10-11: Block Diagram: DIF Experiment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Figure 10-12: Timing Diagram: DIF Operation, Dual Trigger . . . . . . . . . . . . . . . . . .169

Figure 10-13: WinX Hardware Setup Dialog: Controller/Camera Tab . . . . . . . . . . . .169

Figure 10-14: WinX Experiment Setup Dialog: Main Tab . . . . . . . . . . . . . . . . . . . . .170

Figure 10-15: WinX Experiment Setup Dialog: Timing Tab. . . . . . . . . . . . . . . . . . . .171

Figure 10-16: WinX Pulsers Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

Figure 10-17: WinX SuperSYNCHRO Dialog: Gating Tab . . . . . . . . . . . . . . . . . . . .172

Figure 10-18: WinX DIF Gating Setup Dialog: Dual Trigger . . . . . . . . . . . . . . . . . . .172

Figure 10-19: WinX SuperSYNCHRO Dialog: Trigger In Tab. . . . . . . . . . . . . . . . . .173

Figure 10-20: WinX SuperSYNCHRO Dialog: Trigger Out Tab . . . . . . . . . . . . . . . .173

Figure 11-1: Timing Diagram: Normal Gated Operation. . . . . . . . . . . . . . . . . . . . . .175

Figure 11-2: Timing Diagram: MCP Bracket Pulsing Operation. . . . . . . . . . . . . . . .175

Figure 11-3: Timing Diagram: MCP Gated Operation for Gen II Intensifiers . . . . .176

Figure 11-4: QE Curves: Gen II Intensifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

Figure 11-5: Block Diagram: MCP Gated Operation Cabling . . . . . . . . . . . . . . . . . .177

Figure 11-6: Timing Diagram: MCP Gated Operation . . . . . . . . . . . . . . . . . . . . . . .178

Figure 13-1: System Diagram: RF Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Figure 13-2: SuperSYNCHRO Timing Expander: Repetitive Gating Mode. . . . . . .187

Figure 13-3: SuperSYNCHRO Timing Expander: Sequential Gating Mode. . . . . . .188

Figure 13-4: SuperSYNCHRO Timing Expander: Custom Gating Mode . . . . . . . . .190

Figure 13-5: Typical Edit Custom Phase Modulations Window . . . . . . . . . . . . . . . .191

Figure 13-6: Add a Single Modulation Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

Figure 13-7: Add Phase Sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

Figure 13-8: Typical Modulation Phase Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

Figure 13-9: Typical Modulation Phase Curve with Points Shuffled . . . . . . . . . . . .195

Figure 13-10: Typical Manage Add-ins Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

Figure 13-11: Typical Phase Modulation Sorting Add-in . . . . . . . . . . . . . . . . . . . . . .198

Figure 13-12: Typical Phase Modulation Sorting Add-in Button: Data Toolbar. . . . .198

Figure 13-13: Typical Sort Phases Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

Figure 13-14: Typical Sort Phases Dialog: SPE File Specified . . . . . . . . . . . . . . . . . .199

Figure 13-15: PI-MAX4: 1024i-RF Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Figure 13-16: PI-MAX4: 1024i-RF Power Supply Rear Panel . . . . . . . . . . . . . . . . . .202

Figure 14-1: Block Diagram: EMCCD with Dual Output Registers . . . . . . . . . . . . .206

Figure 14-2: Typical emICCD Hardware Stackup . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Figure 14-3: Enabling Electron Multiplication . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Figure 14-4: Typical emICCD Gain Configuration Field . . . . . . . . . . . . . . . . . . . . .208

Figure 14-5: Typical Intensifier Gain Configuration Fields. . . . . . . . . . . . . . . . . . . .209

Figure 14-6: Typical EM Gain Configuration Field. . . . . . . . . . . . . . . . . . . . . . . . . .209

Figure 14-7: Typical EM Gain Configuration Display for EM Gain > 100. . . . . . . .210

Figure 14-8: Configuring Readout Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

Figure 14-9: Typical Full-Frame and Frame Transfer CCDs, Kinetics Masking . . .212

14 PI-MAX® 4 System Manual Issue 4

Figure 14-13: File Storage Convention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Figure 14-14: Configuring Readout Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Figure 14-15: Configuring Trigger Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Figure 14-16: Block Diagram: Typical Kinetics Experiment. . . . . . . . . . . . . . . . . . . 221

Figure 14-17: Typical Common Acquisition Settings Expander . . . . . . . . . . . . . . . . 224

Figure 14-18: Typical Thresholding and Clipping Configuration Parameters . . . . . . 224

Figure 14-19: Typical High Speed Camera Expander . . . . . . . . . . . . . . . . . . . . . . . . 225

Figure 14-20: Typical High Speed Camera Spectroscopy Settings . . . . . . . . . . . . . . 226

Figure 14-21: Typical High Speed Camera Imaging Settings . . . . . . . . . . . . . . . . . . 226

Figure 14-22: Typical Previous and Current Frame Rate Information . . . . . . . . . . . . 226

Figure 14-23: Typical Configuration Options: Time Stamping, Frame Tracking . . . 227

Figure 16-1: PI-MAX4 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Figure 16-2: PI-MAX4: 1024i-RF Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Figure 17-1: Camera1 in Camera Name Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Figure 17-2: Editing Camera Name in Notepad . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Figure 17-3: Updated Hardware Setup Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Figure 17-4: eBUS Driver Installation Tool Dialog for LightField . . . . . . . . . . . . . 252

Figure 17-5: eBUS Driver Installation Tool Dialog for WinX . . . . . . . . . . . . . . . . . 253

Figure 17-6: Typical Diagonal Line of Gating Pulse Artifacts. . . . . . . . . . . . . . . . . 254

Figure A-1: AUX I/O Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Figure A-2: AUX I/O Interface Cable (Part Number 6050-0660). . . . . . . . . . . . . . 260

Figure D-1: Extender Bracket Kit Mounted to a PI-MAX4 . . . . . . . . . . . . . . . . . . 279

Figure E-1: F-Mount (Nikon) Lens Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Figure G-1: Magnetic Screwdriver with Reversible Flat and Phillips Bit. . . . . . . . 293

Figure G-2: Standard PI-MAX4 Mount Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Figure G-3: Standard, IVUV, and NVUV Spectroscopy Mounts . . . . . . . . . . . . . . 295

Figure G-4: Positioning the 2.739” (ID) O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Figure G-5: Positioning the 2.614” (ID) O-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

List of Tables 15

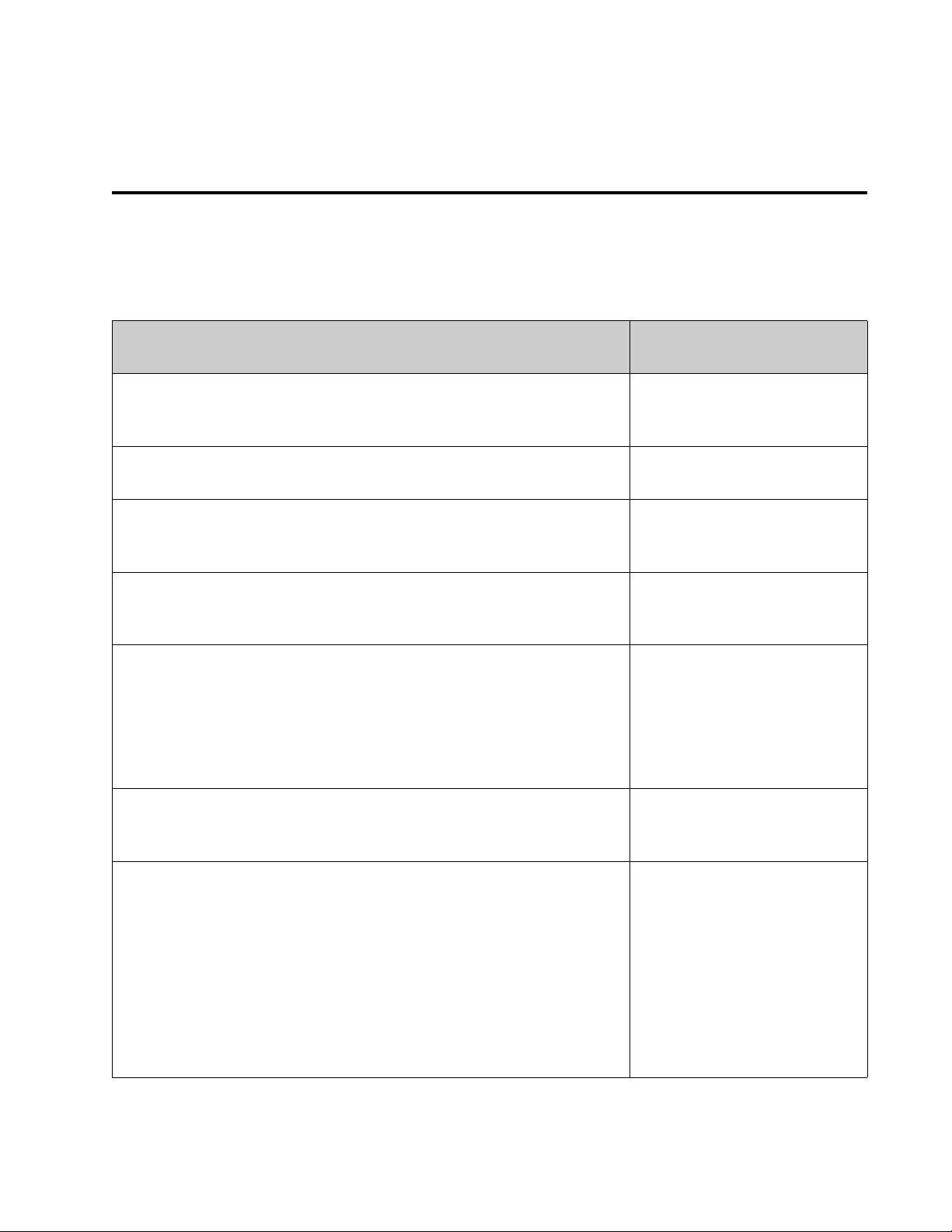

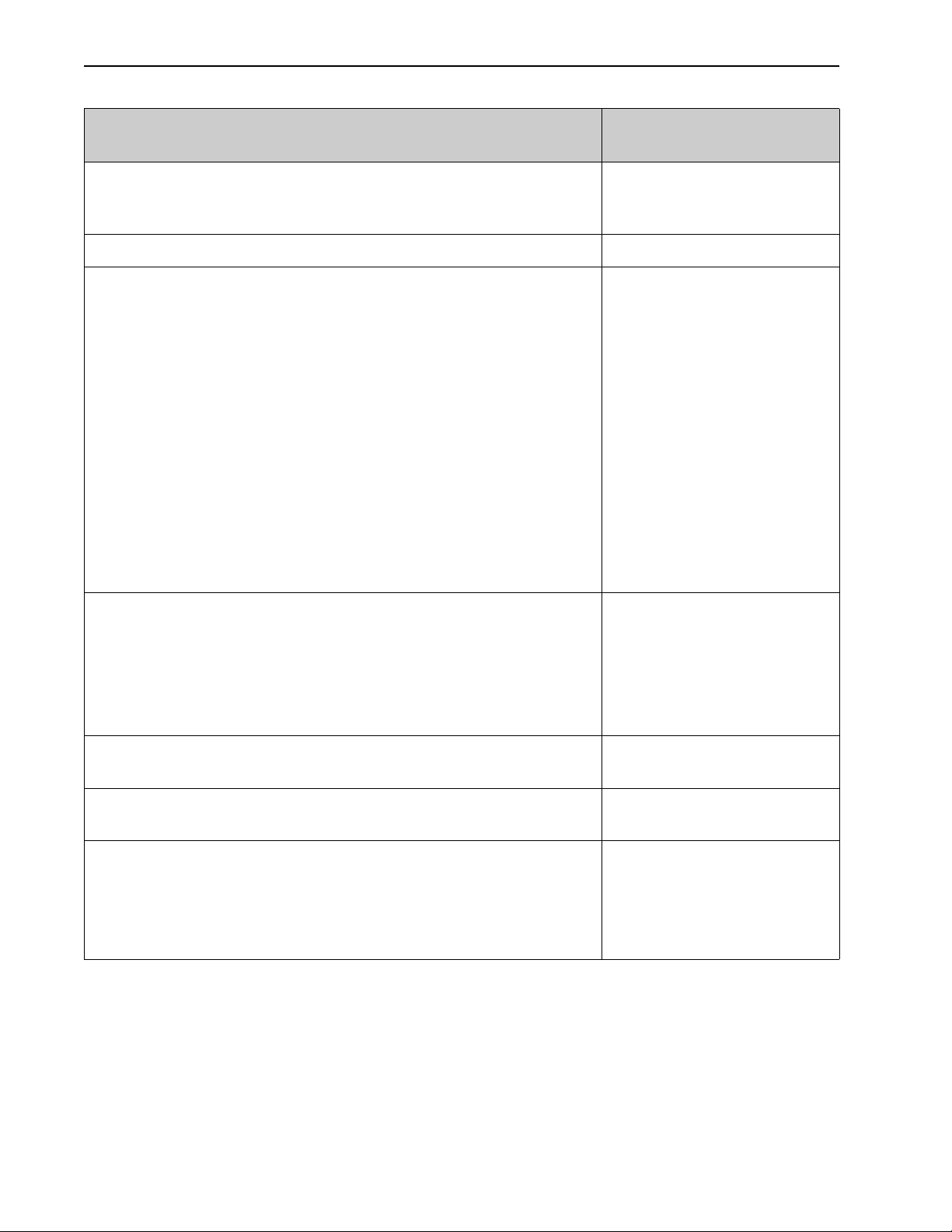

List of Tables

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Table 2-1: PI-MAX4 System Installation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . .29

Table 6-1: Internal Sync Information for Gated Operation. . . . . . . . . . . . . . . . . . . . .97

Table 6-2: Single Shot Experiment Time Budget . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Table 7-1: Internal Sync Information for Gated Operation. . . . . . . . . . . . . . . . . . . .122

Table 7-2: Single Shot Experiment Time Budget . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Table 12-1: Typical Picosecond Gating Information: PI-MAX4:1024i . . . . . . . . . . .180

Table 13-1: Phase Sweep Information for Sweep > 360° . . . . . . . . . . . . . . . . . . . . . .193

Table 13-2: PI-MAX4: 1024i-RF Connectors, Indicators, and Switches . . . . . . . . . .201

Table 13-3: PI-MAX4: 1024i-RF Power Supply Connectors, Indicators, and

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Table 14-1: Mask/Window Sizes for 16 x 16 CCD, Full Frame . . . . . . . . . . . . . . . . .212

Table 17-1: Issues with Recommended Troubleshooting Procedures. . . . . . . . . . . . .247

Table A-1: Input Power Specifications: External PI-MAX4 Power Supply . . . . . . .255

Table A-2: PI-MAX4 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . .256

Table A-3: CCD Array Specifications for Electron Multiplied PI-MAX4

Detectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

Table A-4: CCD Array Specifications for non-EM PI-MAX4 Detectors . . . . . . . . .257

Table A-5: AUX I/O Interface TTL Signal Specifications . . . . . . . . . . . . . . . . . . . .258

Table A-6: AUX I/O Connector Pinout and Signal Descriptions. . . . . . . . . . . . . . . .258

Table A-7: AUX I/O Interface Cable Pinout and Signal Information . . . . . . . . . . . .260

Table C-1: WinX-to-LightField Cross Reference . . . . . . . . . . . . . . . . . . . . . . . . . . .275

Table C-2: LightField-to-WinX Cross Reference . . . . . . . . . . . . . . . . . . . . . . . . . . .277

Table G-1: Adapter Kit Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .293

16 PI-MAX® 4 System Manual Issue 4

This page is intentionally blank.

Warnings and Cautions

WARNING!

NOTE:

CAUTION!

!

When biased ON, intensified CCD cameras, such as the PI-MAX®4

can be irreparably damaged if continuously exposed to light levels

higher than twice the A/D saturation level. Therefore, it is critical that

conditions not be created which could result in damage to the

intensifier. Although intensified cameras are less prone to damage from

background light when operated in gated mode, they are at significant

risk to damage from high-intensity light sources such as a laser.

High-intensity sources can damage the intensifier before protection

circuits have time to respond, or even cause spot damage without the

protection circuits acting at all. If a sustained alarm indication occurs

when the controller is turned on, either completely cover the intensifier

to reduce the light to halt the overload condition, or further reduce the

laboratory illumination until safe operating conditions have been

established.

Alarm

To reduce the risk of camera damage, the PI-MAX4 camera is equipped with an audible alarm

in the camera head, activated when the intensity of light falling on the image intensifier

exceeds a preset threshold. While the alarm is sounding, the photocathode is disabled.

Immediately switch the I.I.T. switch (on the back of the PI-MAX4) to the OFF position.

Cover the camera window and only switch the I.I.T. switch to ON after the illumination level

has been lowered. If the alarm sounds continuously even when the illumination level is

adequately low, shut the system down and contact the factory for guidance.

It is normal for the alarm to sound briefly when the system is first

turned on.

Discontinue operation and contact the factory immediately if

sporadic or continuous unwarranted alarms continue. They may

be an indication of intensifier damage or another condition which

may require immediate attention.

17

18 PI-MAX® 4 System Manual Issue 4

This page is intentionally blank.

Chapter 1: Introduction

4411-0137_0001

The Princeton Instruments PI-MAX®4 Intensified CCD camera is designed for general

macro-imaging and microscopy imaging applications. It is ideal for applications involving

ultra low light measurements, or measurements of transient effects. PI-MAX4 uses a

proximity-focused micro-channel plate (MCP) image intensifier (Gen II and Filmless Gen

III intensifiers available) fiber-optically coupled to a CCD array. The fastest intensifiers can

be gated in as little as 3 ns or less (option board allows gating to <500 ns) with an

exceptionally high on/off light-transmission ratio. The CCD array provides a low noise,

high dynamic range readout device that can be scanned at a variety of pixel rates. A number

of different arrays are available to match the PI-MAX4 to the widest possible range of

experimental requirements. In operation, data acquired by the camera is routed to the

computer for processing and display. The computer controls both the system configuration

and data acquisition via software, of which Princeton Instruments LightField

WinView/32 are examples.

Except where specifically noted, the information within this system manual pertains to the

following camera systems:

•

PI-MAX4: 512EM • PI-MAX4: 1024EM(B) • PI-MAX4: 1024i-RF

• PI-MAX4: 512EM(B) • PI-MAX4: 1024 x 256 • PI-MAX4: 1024f

• PI-MAX4: 512EM • PI-MAX4: 1024i • PI-MAX4: 2048F

a. May also be referred to as PI-MAX4-RF within this manual.

®

and

a

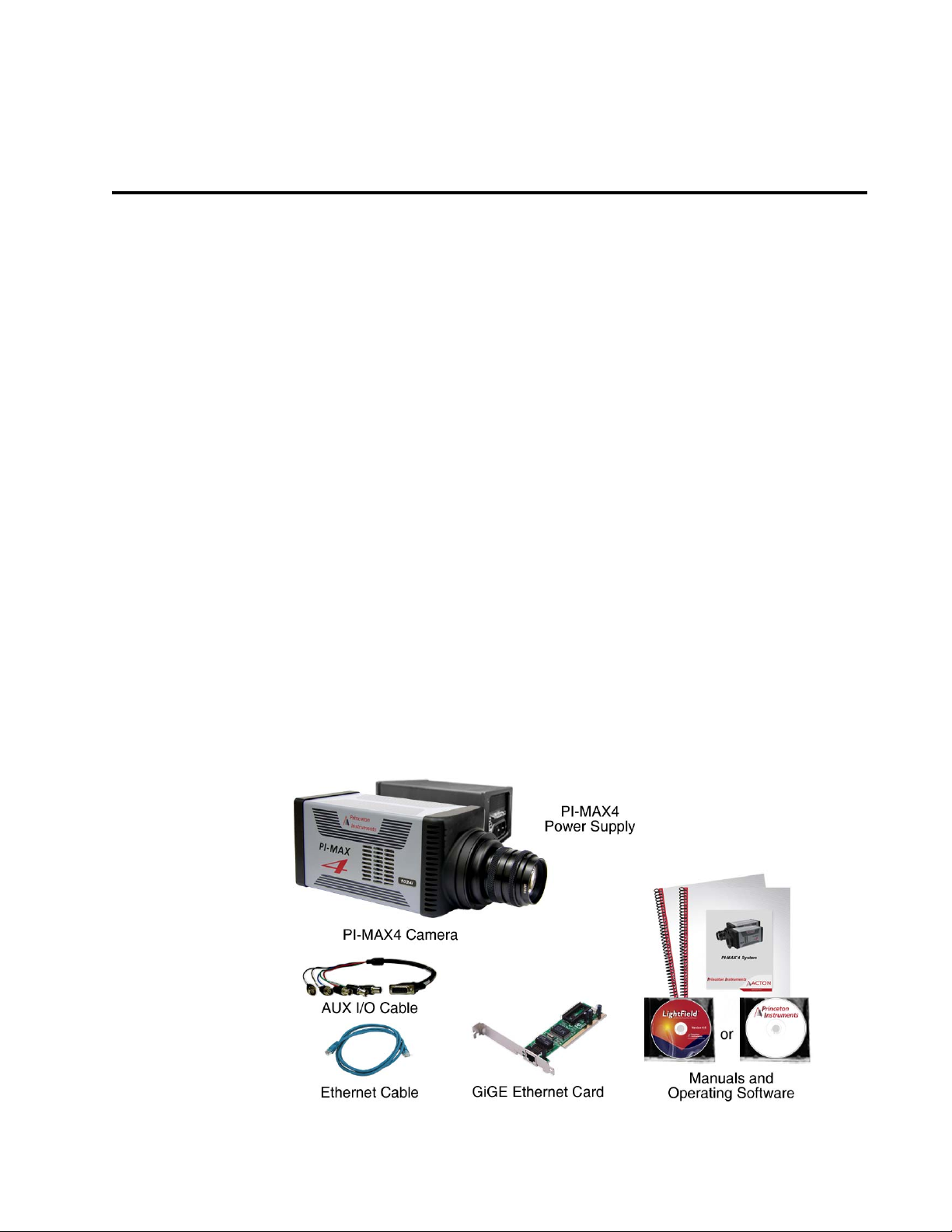

1.1 PI-MAX4 System Components

All PI-MAX4 systems consist of standard hardware and software as well as the appropriate

interface hardware for your computer system. Figure 1-1 illustrates the set of typical system

components included with all PI-MAX4 systems.

Figure 1-1: Typical PI-MAX4 System Components

19

20 PI-MAX® 4 System Manual Issue 4

The following items are standard with all PI-MAX4 systems:

•Camera

The PI-MAX4 camera houses the CCD and intensifier and it supplies all of the high

voltages needed to operate the intensifier (refer to Chapter 3, System Setup, for

more information.)

Cooling within the camera is performed by a cooling fan and a multi-stage Peltier

cooler that is thermally coupled to the CCD (liquid coolant circulation can also be

used for the PI-MAX4 camera.) Photocathode cooling to reduce equivalent

background illumination (EBI) can be achieved via a chilled dry nitrogen source.

C-, F-, and Spectroscopy-mount adapters are supplied (one of which is

factory-installed.)

The camera can be operated in one of the following two modes:

— Safe Mode

In Safe mode, the photocathode is gated off.

— Gate Mode.

In Gate mode, the photocathode is biased on only during the time each gate

pulse is applied.

The PI-MAX4 contains the analog and digital electronics, scan control and

exposure timing hardware, and controller I/O connectors. Readout modes supported

include full resolution, simultaneous multiple sub-images, and non-uniform

binning. Single or multiple software-defined regions of interest can also be tested

without having to digitize all the pixels of the array. Flexible exposure, set through

software, is also fully supported.

The PI-MAX4 contains two High Speed analog-to-digital converters. The effective

digitization rate is software-selectable. After the data is converted, it is transferred

directly from the camera to the host computer memory via the high speed interface

cable.

•Cable

AUX I/O Cable: 6050-0660, female DB26 to 5 BNC.

• Computer Interface

Standard Ethernet Cable: 6050-0621, 5 meter. Other lengths up to 100 m are

available.

User-provided GigE interface card. (Intel Pro1000 recommended)

• Tubing

Clear PVC tubing, 3’, 5/32” OD, 1/32” wall (McMaster-Carr 5006K42) for dry

nitrogen cooling of photocathode.

• Manuals

PI-MAX4 System manual and optional application software manual.

• Optional Application Software

Princeton Instruments' WinView/32 or WinSpec/32.

—

— Princeton Instruments’ LightField.

Chapter 1 Introduction 21

Electr

Intensifier Gated On

Input Window

CCD Array

Fiberoptic Bundle

on Flow

Input Window

-200 V

0 V

600 V - 900 V

6 kV

Electrical Connection Rings

Photocathode

Microchannel Plate (MCP)

: - +

Incident Light

Phosphor (Fluorescent Screen)

4411-0137_0001

1.2 Summary of PI-MAX4 Data Acquisition

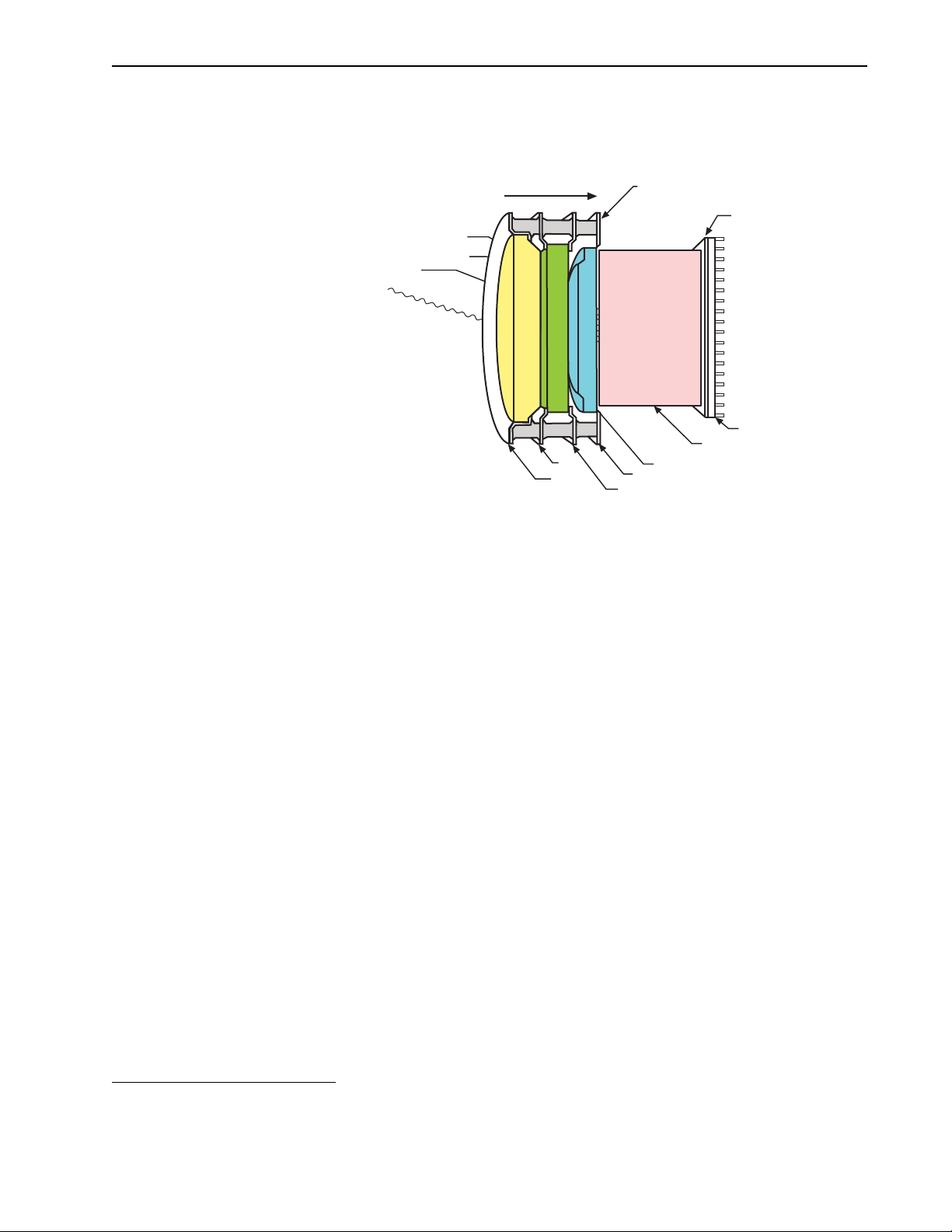

Figure 1-2 illustrates the major components that comprise an Intensifier-CCD.

Figure 1-2: Major Components of the Intensifier-CCD

In the PI-MAX4 camera, the input image is focused onto the photocathode of an image

intensifier tube. The tube electronically amplifies the image and outputs it, much brighter, as

gray-scaled green light. That light is then coupled to the CCD using a fused fiber-optic bundle

from the output of the image intensifier to the front side of the CCD. The image at the output

1

of the image intensifier is translated to the input of the CCD at the same size.

After being

detected by the CCD, the image is read out to the internal controller, where it is digitized, and

then transferred to the computer for processing via a high-speed data link.

The sequence below steps through the process by which photons are converted to data that

can be displayed on a computer monitor. For the sake of simplicity, triggers and gate pulses

are not mentioned and it is assumed that a high speed (GigE) serial interface card is installed

in the host computer. When reading through the sequence, keep in mind that electrons are

attracted to more positively charged surfaces and are repelled by more negatively charged

surfaces. This principal is used to control electron flow through the intensifier tube:

changing the photocathode voltage with respect to the voltage at the MCP input is used to

switch (gate) the intensifier on and off.

1. Incident photons pass through the intensifier input window, strike the photocathode, and

release electrons. See Figure 1-2.

2. Assuming that the intensifier is gated ON (the photocathode is more negative than the

MCP input,) these electrons will be attracted to the MCP input.

shutter in that gating the intensifier on allows the CCD to see light and gating the

intensifier off prevents the CCD from seeing light.

Since the voltage at the MCP output is much more positive, most of the electrons

3.

Gating acts like a

accelerate into the MCP channels and, if they hit the channel walls, will generate

additional electrons, resulting in electron gain.

increasing or decreasing the voltage at the MCP output.

The amount of gain is adjusted by

1. Units having a tapered fiber optic bundle may also be available. Contact the factory for information.

22 PI-MAX® 4 System Manual Issue 4

CAUTION!

!

WARNING! RISK OF ELECTRIC SHOCK!

4. When the electrons exit the channels they are further accelerated by a constant high

voltage (5-6 kV) and strike the phosphor coating on the fluorescent screen causing it to

release photons.

photon that struck the photocathode surface.

5.

The photons released by the coating are transferred to the surface of the CCD (via

Because of the MCP gain, there are now many photons for each

fiber-optic) and produce charge at the pixels they strike. Note that fiber-optic coupling

is not only the most efficient coupling possible, but lens-coupling effects such as

vignetting are eliminated.

6. Charge accumulates in the pixel wells until the intensifier is gated off (the photocathode

is more positive than the MCP input) and the phosphor decays.

7. At that point, the accumulated charge is shifted to the serial register where it is read out

to an on-chip amplifier that converts the charge to an analog voltage.

8. This voltage is input to the selected analog-to-digital (A/D) converter(s) where it is

digitally encoded. The conversion speed and the quality of the data are dependent on the

effective ADC rate.

9. The digitized information is transmitted from the camera through the Ethernet cable to

the interface card in the host computer where it is stored in RAM.

10. The application software retrieves the information from RAM, processes it, displays it,

and/or stores it to a file according to user-defined settings.

1.3 Safety Related Symbols Used in This Manual

The use of this symbol on equipment indicates that one or more

nearby items should not be operated without first consulting

the manual. The same symbol appears in the manual adjacent

to the text that discusses the hardware item(s) in question.

The use of this symbol on equipment indicates that one or more

nearby items pose an electric shock hazard and should be

regarded as potentially dangerous. This same symbol appears

in the manual adjacent to the text that discusses the hardware

item(s) in question.

Chapter 1 Introduction 23

WARNINGS!

WARNING! RISK OF ELECTRIC SHOCK!

WARNING!

1.4 Grounding and Safety

The PI-MAX4 and power supply are of Class I category as defined in IEC Publication 348

(Safety Requirements for Electronic Measuring Apparatus.) They are designed for indoor

operation only. Before turning on the power supply, the ground prong of the power cord

plug must be properly connected to the ground connector of the wall outlet. The wall outlet

must have a third prong, or must be properly connected to an adapter that complies with

these safety requirements.

1. If the PI-MAX4 camera system is used in a manner not specified

by Princeton Instruments, the protection provided by the

equipment may be impaired.

2. If the equipment is damaged, the protective grounding could be

disconnected. Do not use damaged equipment until its safety has

been verified by authorized personnel. tampering with its

operation is also prohibited.

Inspect the supplied power cord. If it is not compatible with the power socket, replace the

cord with one that has suitable connectors on both ends.

The PI-MAX4 has internal power supplies that generate

hazardous (and potentially lethal) voltages. It contains no

user-serviceable parts. Do not attempt to operate it with the

covers removed.

Replacement power cords or power plugs must have the same

polarity and power rating as that of the original ones to avoid hazard

due to electrical shock.

24 PI-MAX® 4 System Manual Issue 4

NOTE:

NOTE:

CAUTION!

!

1.4.1 Intensifier Modes and Safety

WinX Applications

The Experiment Setup

intensifier modes:

only for the time that each gate pulse is applied. As a result, the tolerance to room light is

higher in gated operation, but the risk of damaging overload from intense light sources such

as lasers remains. In fact, intense light sources in gated experiments can cause spot damage

that would be undetected by the alarm circuit. In

continuously biased OFF and the intensifier is as safe as it can be.

LightField

In LightField, you can enable or disable the intensifier on the

Settings

the photocathode is continuously biased OFF and the intensifier is as safe as it can be.

expander. When the intensifier is enabled, the camera can be gated; when disabled,

In order for gating to occur, the I.I.T. switch on the back of the

PI-MAX4 must also be in the ON position.

Main screen in WinX applications allows you to select one of two

Gate Mode or Safe Mode. In Gate Mode, the photocathode is biased on

Safe Mode, the photocathode is

Common Acquisition

1.4.2 Audible Alarm

To reduce the risk of camera damage, the PI-MAX4 camera is equipped with an audible

alarm in the camera, activated when the intensity of light falling on the image intensifier

exceeds a preset threshold. While the alarm is sounding, the photocathode is disabled.

Immediately switch the

the camera window and only switch the

been lowered. If the alarm sounds continuously even when the illumination level is