Page 1

4411-0039-CE

Version 6.C

April 18, 2006

*4411-0039-CE*

Page 2

©Copy

3660 Quakerbridge Rd

Trenton, NJ 08619

TEL: 800-874-9789 / 609-587-9797

FAX: 609-587-1970

right 2003-2006 division of Roper Scientific, Inc. Princeton Instruments, a

All rights reserved. No part of this publication

permission of Princeton Instruments, a division of Roper Scientific, Inc. ("Princeton Instruments").

Printed in the United States of America.

IPLab is a trademark of Scanalytics, Inc.

Macintosh is a registered trademark of Apple Computer, Inc.

Microsoft, Windows, and Windows NT are registered tradem

Pentium is a registered trademark of Intel Corporation.

PVCAM is a registered trademark of Photometrics, Ltd.

Radio Shack is a registered trademark of TRS Quality, Inc.

TAXI is a registered trademark of AMD Corporation

The information in this publication is believed to be accurate as of the publication release date. However,

Princeton Instrum

resulting from the use thereof. The information contained herein is subject to change without notice.

Revision of this publication may be issued to incorporate such change.

ents does not assume any responsibility for any consequences including any damages

may be reproduced by any means without the written

arks of Microsoft Corporation.

Page 3

Table of Contents

Chapter 1 Introduction........................................................................................ 9

Introduction......................................................................................................................... 9

MicroMAX System Components ....................................................................................... 9

About this Manual ............................................................................................................ 12

Environmental Conditions ................................................................................................ 13

Grounding and Safety ....................................................................................................... 13

Precautions........................................................................................................................ 14

Repairs .............................................................................................................................. 14

Cleaning............................................................................................................................ 14

Princeton Instruments Customer Service.......................................................................... 14

Chapter 2 System Component Descriptions.................................................. 15

MicroMAX Camera.......................................................................................................... 15

ST-133 Controller ............................................................................................................. 18

Cables................................................................................................................................ 23

Interface Card ................................................................................................................... 23

Application Software ........................................................................................................ 23

User Manuals ....................................................................................................................24

Chapter 3 Installation Overview....................................................................... 25

Chapter 4 System Setup................................................................................... 27

Unpacking the System ...................................................................................................... 27

Checking the Equipment and Parts Inventory .................................................................. 27

System Requirements........................................................................................................ 28

Verifying Controller Voltage Setting................................................................................ 29

Installing the Application Software .................................................................................. 30

Setting up the Communication Interface .......................................................................... 30

Mounting the Camera ....................................................................................................... 34

Selecting the Shutter Setting............................................................................................. 39

Connecting the Interface (Controller-Computer) Cable ................................................... 39

Connecting the Detector-Controller Cable ....................................................................... 40

Entering the Default Camera System Parameters into WinX (WinView/32,

WinSpec/32, or WinXTest/32)..................................................................................... 40

Chapter 5 Operation.......................................................................................... 43

Introduction....................................................................................................................... 43

EMF and Xenon or Hg Arc Lamps................................................................................... 44

USB 2.0 System On/Off Sequences.................................................................................. 44

Imaging Field of View...................................................................................................... 45

RS-170 or CCIR Video..................................................................................................... 45

First Light (Imaging) ........................................................................................................ 47

First Light (Spectroscopy) ................................................................................................ 52

Exposure and Signal ......................................................................................................... 55

Readout .............................................................................................................................60

Digitization .......................................................................................................................71

iii

Page 4

iv MicroMAX System User Manual Version 6.C

Chapter 6 Advanced Topics............................................................................. 73

Introduction....................................................................................................................... 73

Standard Timing Modes.................................................................................................... 74

Frame Transfer Operation................................................................................................. 78

Interline Operation............................................................................................................ 80

Fast and Safe Speed Modes ..............................................................................................83

TTL Control...................................................................................................................... 85

Kinetics Mode...................................................................................................................89

Chapter 7 MicroMAX DIF Camera (Double Image Feature)........................... 93

Introduction....................................................................................................................... 93

Timing Modes................................................................................................................... 94

Tips and Tricks ...............................................................................................................100

Chapter 8 Virtual Chip Mode .......................................................................... 103

Chapter 9 Troubleshooting ............................................................................ 111

Introduction..................................................................................................................... 111

Baseline Signal Suddenly Changes................................................................................. 112

Camera Stops Working................................................................................................... 112

Camera1 (or similar name) in Camera Name field ......................................................... 112

Changing the ST-133's Line Voltage and Fuses............................................................. 113

Controller Is Not Responding ......................................................................................... 114

Cooling Troubleshooting ................................................................................................ 114

Data Loss or Serial Violation.......................................................................................... 115

Data Overrun Due to Hardware Conflict message.......................................................... 116

Data Overrun Has Occurred message ............................................................................. 116

Demo is only Choice on Hardware Wizard:Interface dialog (Versions 2.5.19.0

and earlier)................................................................................................................ 117

Demo, High Speed PCI, and PCI(Timer) are Choices on Hardware

Wizard:Interface dialog (Versions 2.5.19.0 and earlier) .......................................... 118

Detector Temperature, Acquire, and Focus are Grayed Out (Versions 2.5.19.0

and earlier)................................................................................................................ 120

Error Creating Controller message ................................................................................. 121

Error Occurs at Computer Powerup................................................................................ 121

No CCD Named in the Hardware Wizard:CCD dialog (Versions 2.5.19.0 and

earlier) ...................................................................................................................... 124

Program Error message................................................................................................... 124

Removing/Installing a Plug-In Module .......................................................................... 125

Securing the Detector-Controller Cable Slide Latch ...................................................... 127

Serial violations have occurred. Check interface cable. ................................................. 128

Shutter Malfunctions....................................................................................................... 128

Appendix A Specifications............................................................................. 129

CCD Arrays .................................................................................................................... 129

Temperature Control....................................................................................................... 130

Cooling ........................................................................................................................... 130

Mounting......................................................................................................................... 130

Shutters ........................................................................................................................... 131

Inputs .............................................................................................................................. 131

Outputs............................................................................................................................ 131

Page 5

Table of Contents v

Programmable Interface.................................................................................................. 132

A/D Converter................................................................................................................. 132

Computer Requirements ................................................................................................. 132

Miscellaneous ................................................................................................................. 132

Appendix B Outline Drawings........................................................................ 133

Detectors ......................................................................................................................... 133

ST-133B Controller ........................................................................................................139

ST-133A Controller ........................................................................................................ 139

Appendix C Repumping the Vacuum............................................................ 141

Introduction..................................................................................................................... 141

Requirements .................................................................................................................. 141

Vacuum Pumpdown Procedure....................................................................................... 142

Appendix D Spectrometer Adapters ............................................................. 145

Acton (NTE with or without shutter).............................................................................. 146

Chromex 250 IS (NTE with or without shutter) ............................................................. 147

ISA HR 320 (NTE with or without shutter).................................................................... 148

ISA HR 640 (NTE with or without shutter).................................................................... 149

JY TRIAX family (NTE without shutter)....................................................................... 150

SPEX 270M (NTE with or without shutter) ................................................................... 151

SPEX 500M (NTE with or without shutter) ................................................................... 152

SPEX TripleMate (NTE with or without shutter)........................................................... 153

Appendix E USB 2.0 Limitations.................................................................... 155

Declarations of Conformity ............................................................................ 157

Warranty & Service ......................................................................................... 161

Limited Warranty............................................................................................................ 161

Contact Information........................................................................................................ 164

Index ................................................................................................................. 165

Page 6

vi MicroMAX System User Manual Version 6.C

Figures

Figure 1. MicroMAX Cameras and Controller.................................................................. 9

Figure 2. Power Switch Location (ST-133A and ST-133B)........................................... 18

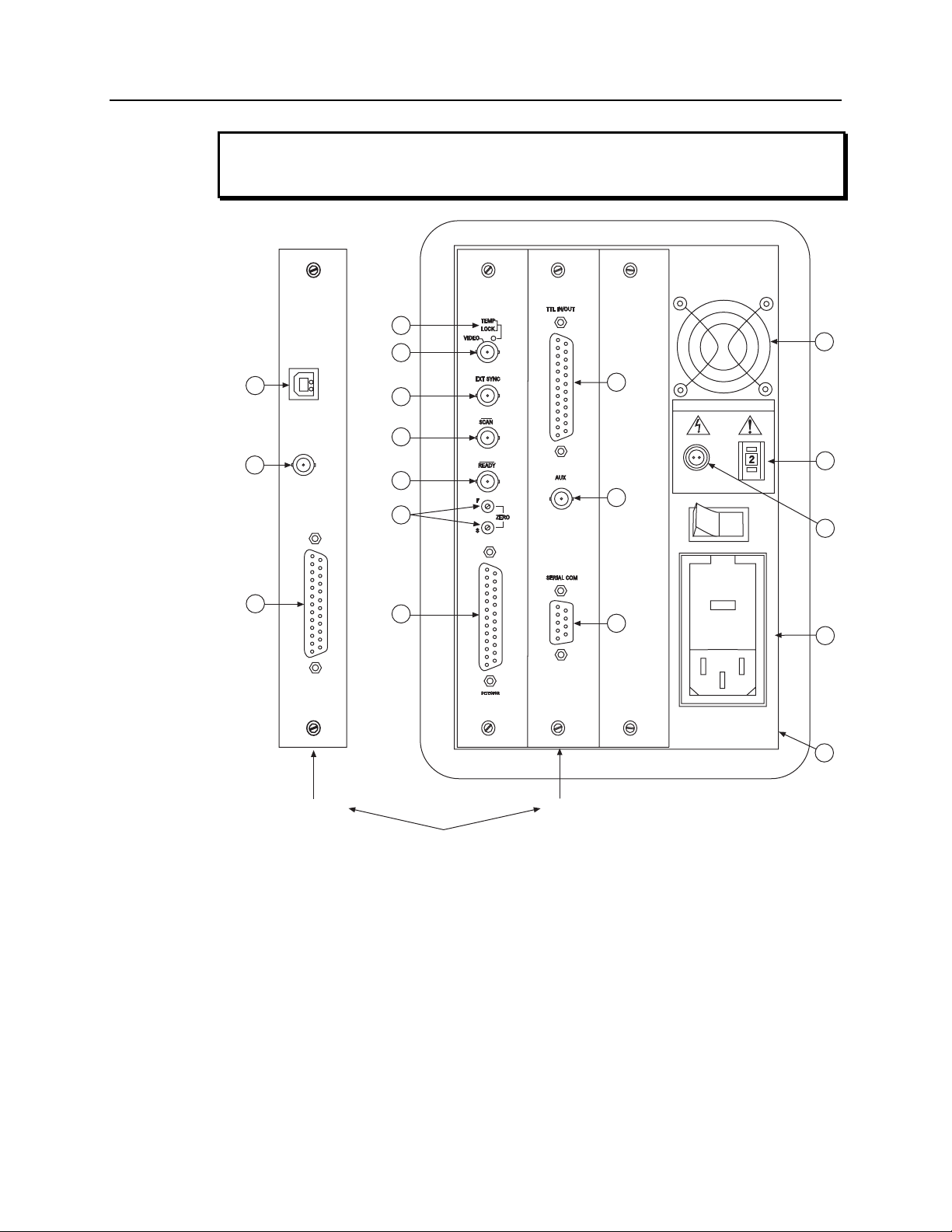

Figure 3. ST-133 Rear Panel Callouts............................................................................. 19

Figure 4. Shutter Compensation Times ........................................................................... 22

Figure 5. Standard System Diagram ................................................................................ 26

Figure 6. Controller Power Input Module........................................................................ 29

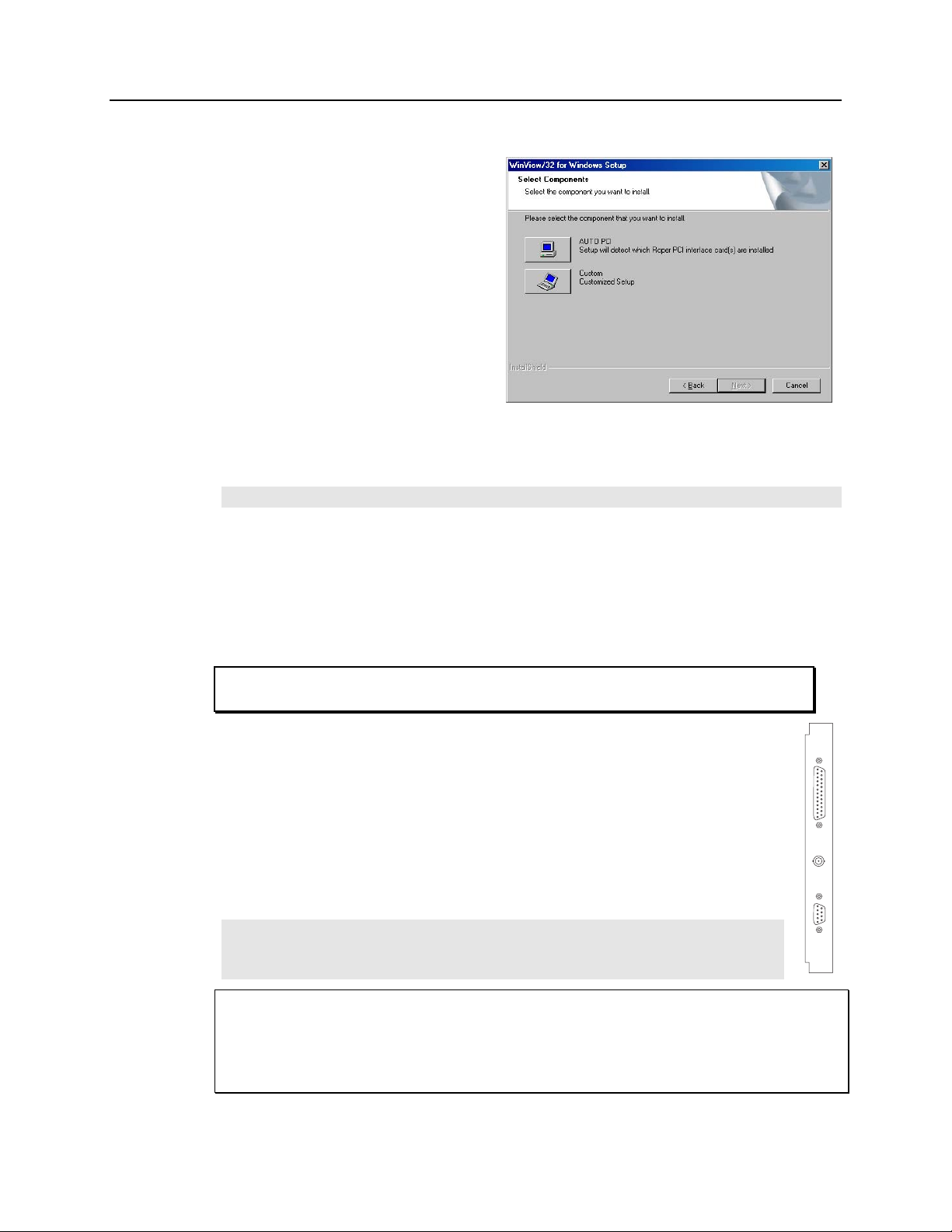

Figure 7. WinView Installation: Interface Card Driver Selection ................................... 30

Figure 8. Bottom Clamps................................................................................................. 37

Figure 9. Bottom Clamp secured to Relay Lens .............................................................. 38

Figure 10. Shutter Setting for 25 mm Internal Shutter .................................................... 39

Figure 11. Camera Detection Wizard - Welcome dialog box.......................................... 41

Figure 12. RSConfig dialog box ...................................................................................... 41

Figure 13. Hardware Setup wizard: PVCAM dialog box ................................................ 42

Figure 14. Block Diagram of Light Path in System........................................................ 43

Figure 15. Imaging Field of View.................................................................................... 45

Figure 16. Monitor Display of CCD Image Center Area................................................. 46

Figure 17. Standard System Connection Diagram........................................................... 47

Figure 18. F-mount Focus Adjustment ............................................................................51

Figure 19. CCD Exposure with Shutter Compensation ................................................... 57

Figure 20. WinView/WinSpec Detector Temperature dialog box.................................. 58

Figure 21. Full Frame at Full Resolution......................................................................... 61

Figure 22. Frame Transfer Readout ................................................................................. 63

Figure 23. Overlapped Mode Exposure and Readout...................................................... 65

Figure 24. Non-Overlapped Mode Exposure and Readout.............................................. 66

Figure 25. 2 × 2 Binning for Full Frame CCD ................................................................ 68

Figure 26. 2 × 2 Binning for Interline CCD .................................................................... 69

Figure 27. Timing tab page.............................................................................................. 73

Figure 28. Free Run Timing Chart (part of the chart in Figure 40) ................................. 74

Figure 29. Free Run Timing Diagram.............................................................................. 75

Figure 30. Showing Shutter "Preopen" & "Normal" Modes in External Sync Operation76

Figure 31. External Sync Timing Diagram (- edge trigger)............................................. 76

Figure 32. Continuous Cleans Flowchart......................................................................... 77

Figure 33. Continuous Cleans Timing Diagram .............................................................. 78

Figure 34. Frame Transfer where tw1 + t

Figure 35. Frame Transfer where tw1 + t

Figure 36. Frame Transfer where Pulse arrives after Readout......................................... 80

Figure 37. Overlapped Mode where tw1 + t

Figure 38. Overlapped Mode where tw1 + t

Figure 39. Overlapped Mode where Pulse arrives after Readout ....................................82

Figure 40. Chart of Safe and Fast Mode Operation ......................................................... 84

Figure 41. TTL In/Out Connector.................................................................................... 87

Figure 42. TTL Diagnostics dialog box........................................................................... 87

Figure 43. Kinetics Readout ............................................................................................ 89

Figure 44. Hardware Setup dialog box ............................................................................ 90

Figure 45. Experiment Setup dialog box ......................................................................... 90

Figure 46. Free Run Timing Diagram.............................................................................. 91

Figure 47. Single Trigger Timing Diagram ..................................................................... 91

Figure 48. Multiple Trigger Timing Diagram.................................................................. 92

+ tc < tR................................................... 79

exp

+ tc > tR................................................... 79

exp

+ tc < tR............................................... 82

exp

+ tc > tR..................................................... 82

exp

Page 7

Table of Contents vii

Figure 49. Free Run Mode Timing Diagram ................................................................... 95

Figure 50. Setup using to Trigger an Event....................................................... 95

Figure 51. Timing for Experiment Setup shown in Figure 50......................................... 95

Figure 52. Timing Diagram for Typical IEC Measurement ............................................ 97

Figure 53. Setup for IEC Experiment with Two Lasers .................................................. 97

Figure 54. Timing Diagram for IEC Experiment with Two Lasers................................. 97

Figure 55. Another Hardware Setup for an IEC Measurement........................................ 98

Figure 56. EEC Timing Example with Exposure Time in Software Set to t

Figure 57. ESABI Timing Example: Image Exposure time = t

Figure 58. Virtual Chip Functional Diagram................................................................. 103

Figure 59. System Diagram ...........................................................................................105

Figure 60. Virtual Chip dialog box................................................................................ 108

Figure 61. Camera1 in Camera Name Field................................................................... 112

Figure 62. Power Input Module..................................................................................... 113

Figure 63. Fuse Holder .................................................................................................. 113

Figure 64. Data Overrun Due to Hardware Conflict dialog box.................................... 116

Figure 65. Hardware Wizard: Interface dialog box ....................................................... 117

Figure 66. RSConfig dialog box .................................................................................... 117

Figure 67. Hardware Wizard: PVCAM dialog box .......................................................118

Figure 68. Hardware Wizard: Interface dialog box ....................................................... 118

Figure 69. RSConfig dialog box: Two Camera Styles .................................................. 119

Figure 70. Hardware Wizard: PVCAM dialog box .......................................................119

Figure 71. RSConfig dialog box: Two Camera Styles .................................................. 120

Figure 72. Error Creating Controller dialog box ........................................................... 121

Figure 73. Hardware Wizard: Detector/Camera/CCD dialog box ................................. 124

Figure 74. Program Error dialog box............................................................................. 124

Figure 75. Module Installation....................................................................................... 125

Figure 76. Serial Violations Have Occurred dialog box................................................ 128

Figure 77. Rectangular Camera Head: C-Mount ........................................................... 133

Figure 78. Rectangular Camera Head: F-Mount............................................................ 134

Figure 79. Rectangular Camera Head: Spectroscopy Mount with Shutter .................... 135

Figure 80. Rectangular Camera Head: Spectroscopy Mount without Shutter ............... 136

Figure 81. 1 MHz and 100kHz/1MHz Round Head Camera: C-Mount Adapter and

Shutter..................................................................................................................... 137

Figure 82. 1 MHz Round Head Camera: F-Mount Adapter .......................................... 138

Figure 83. ST-133B Controller Dimensions.................................................................. 139

Figure 84. ST-133A Controller Dimensions.................................................................. 139

Figure 85. Vacuum Connector Required for Pumping .................................................. 142

Figure 86. Removing the Back Panel ............................................................................ 142

Figure 87. Attaching the Vacuum Connector ................................................................ 143

Figure 88. Opening the Camera to the Vacuum System................................................ 143

set in software ....... 100

exp

............. 99

exp

Tables

Table 1. ST-133 Shutter Drive Selection.........................................................................

Table 2. PCI Driver Files and Locations ......................................................................... 31

Table 3. USB Driver Files and Locations........................................................................ 34

Table 4. Bottom Clamps for Different Microscopes........................................................ 37

Table 5. ST-133 Shutter Setting Selection....................................................................... 39

Table 6. Approximate Readout Time for the Full-Frame CCD Array............................. 62

21

Page 8

viii MicroMAX System User Manual Version 6.C

Table 7. Approximate Readout Time for the Frame-Transfer CCD Array...................... 63

Table 8. Approximate Readout Time for the Interline CCD Arrays................................ 67

Table 9. Readout Rates for PI 1300 × 1030 Array at 1 MHz .......................................... 67

Table 10. Well Capacity for some CCD Arrays .............................................................. 70

Table 11. Detector Timing Modes ................................................................................... 74

Table 12. Bit Values with Decimal Equivalents: 1 = High 0 = Low .............................. 86

Table 13. TTL In/Out Connector Pinout.......................................................................... 87

Table 14. MicroMAX:512BFT: Virtual Chip Size, Exposure Time, and Frames per

Second..................................................................................................................... 104

Table 15. I/O Address & Interrupt Assignments before Installing Serial Card ............. 122

Table 16. I/O Address & Interrupt Assignments after Installing Serial Card................ 122

Table 17. MicroMAX Model and CCD Types Cross Reference ................................... 129

Table 18. Shutter Compensation Times......................................................................... 131

Table 19. Features Supported under USB 2.0................................................................ 156

Page 9

Chapter 1 Introduction

Introduction

The Princeton Instruments MicroMAX system is a high-speed, low-noise CCD camera

system designed for demanding imaging applications and is an optimal system for use in

fluorescence microscopy applications such as high-resolution immunofluorescence, FISH

or GFP imaging. The MicroMAX system incorporates a compact camera head, cooled

CCD, advanced exposure-control timing, video output, and sophisticated readout

capabilities.

Among the advantages of the MicroMAX concept are the range of CCD arrays available

and the built-in video output m

interline CCDs to provide true 12-bit images at a readout rate of up to 5 million pixels per

second or with a variety of front or back-illuminated CCDs to provide true 16-bit images.

The built-in video output mode simplifies setup and focusing on the microscope. The

combination of the MicroMAX system with one of a variety of specialty software

packages results in a powerful digital imaging system that can meet most experimental

needs.

Note: "WinView/32" and "WinView" are used throughout this manual when referring to

the application software. Unless otherwise indicated, the information associated with

these terms also applies to Princeton Instruments' WinSpec/32 spectroscopy software.

ode. The system can be configured with a variety of

MicroMAX System Components

Overview

The MicroMAX imaging system consists of a

camera (either a round head or a rectangular

head depending on application), controller,

digital interface card, a computer, cables,

manuals, and application software. Together,

these components allow you to acquire

quantitative digital data under very low light

imaging conditions. Each component is

optimized for its specific function. In

operation, data acquired by the

camera is routed to the controller and from there to the computer for processing and

display. A composite video output allows immediate viewing of the acquired images on a

separate monitor. The application software (for example, Princeton Instruments

WinView/32) allows the computer to control both the system configuration and data

acquisition.

9

Figure 1. MicroMAX Cameras and

Controller

Page 10

10 MicroMAX System User Manual Version 6.C

Camera

Introduction: The function of the camera is to collect very low intensity light and

convert the energy into a quantitative, electronic signal (photo-electrons) over a two

dimensional space. To do this, light from the subject is focused onto a CCD array, which

accumulates photoelectrons for the exposure time. At the end of the exposure time, the

image thus formed is read out. The accumulated charge on each cell of the array is

transferred out of the CCD array, amplified, and sent to the controller as an analog signal,

where it is digitized prior to transfer to the computer.

The camera is highly integrated, containing the shutter (if applicable) and thermoelectric

cooler with optional forced-air supplem

Surface mount electronic technology is used wherever possible, giving a compact

package with uncompromising performance.

Depending on your application, the camera included in your MicroMAX system will be

either a com

pact round camera head or a high performance, cooled, rectangular camera

head. The round head features interline CCDs; its small size ensures that the camera can

be mounted on virtually any microscope port, including those found on inverted

microscopes. The rectangular head features back-illuminated CCDs with frame transfer

readout.

ental cooling in a single, shielded housing.

At the heart of the camera is the CCD array centered on the optic axis. Available form

ats

include the:

• EEV CCD57-10, 512×512, 13×13µm pixels for the MicroMAX:512BFT

• EEV CCD47-10, 1024×1024, 13×13µm pixels for the MicroMAX:1024B

• Sony ICX075, 782×582, 8.3× 8.3µm pixels for the MicroMAX:782Yand the

MicroMAX:782YHS systems

• Sony ICX061,1300×1030, 6.7× 6.7µm pixels for the MicroMAX:1300Y, the

MicroMAX:1300YHS, and MicroMAX:1300YHS-DIF systems

A special clocking mode to minimize background signal is supported. See the Princeton

Instruments brochures and data sheets for detailed specifications.

Cooling System: MicroMAX cam

eras have a multi-stage Peltier type cooler that is

thermally coupled to the CCD surface. Heat is sequentially transferred through the Peltier

stages and from there to the outer shell of the camera via a heat transfer block. This

cooling system allows the camera to maintain CCD temperature of typically -15°C for

round cameras head and -45°C for rectangular camera heads. Cameras equipped with a

fan assembly can reach lower CCD temperatures for reduced thermal noise and extended

exposure times.

Low Noise Readout: In order to achieve a low-noise readout of the CCD, several

design features have been im

plemented. These include cooling the preamplifier on the

CCD, isolating circuits to prevent electronic crosstalk and minimizing the path lengths of

critical electronic circuits. The net result of these design features is the lowest available

readout noise at the highest speed possible for these CCDs.

Controller

Data Conversion: The controller accepts the analog data and converts it to digital data

using specially designed, low-noise electronics supporting scientific grade 12- or 16-bit

Analog to Digital (A/D) converters.

Page 11

Chapter 1 Introduction 11

The standard MicroMAX Controller enables both high-speed and high-precision readout

capabilities. It can collect 16-bit images at a readout rate of up to 1 million pixels per

second (1 MHz) in the high-speed mode or at 100 thousand pixels per second (100 kHz)

in the optional precision mode (16-bit). Switching between the two modes is under

software control for total experiment automation.

Modular Design: In addition to containing the power supplies, the controller contains

the analog and digital electronics, scan contro

I/O connectors, all mounted on user-accessible plug-in modules. The design is highly

modularized for flexibility and convenient servicing.

l and exposure timing hardware, and system

Flexible Readout: There is provision for extrem

Readout modes supported include full resolution, simultaneous multiple subimages, and

nonuniform binning. Single or multiple software-defined regions of interest can also be

tested without having to digitize all the pixels of the array

High Speed Data Transfer: Data is transferred directly to the host computer memory

via a high-speed serial link. A proprietary

controller directly into the host computer RAM using Direct Memory Access (DMA).

The DMA transfer process ensures that the data arrives at sufficiently high speed to

prevent data loss from the controller. Since the data transfer rate is much higher than the

output rate from the A/D, the latter becomes the data acquisition rate-limiting factor.

Once the digital data is in RAM, the image acquisition program can transfer the image

into its own working RAM for viewing and further processing.

Note: A frame buffer with standard composite video, either RS-170 (EIA) or CCIR,

whichever was ordered, is also provided.

Interface card places the data from the

ely flexible readout of the CCD.

Applications

With its small size, fully integrated design, cooled CCD and temperature control,

advanced exposure control timing, and sophisticated readout capabilities, the MicroMAX

system is well suited to both general macro imaging and microscopy applications.

Page 12

12 MicroMAX System User Manual Version 6.C

About this Manual

Manual Organization

This manual provides the user with all the information needed to install a MicroMAX

camera and place it in operation. Topics covered include a detailed description of the

camera, installation, cleaning, specifications and more.

Notes:

1. The general identifier "ST-133" is used for both the ST-133A Controller and the

ST-133B Controller. Where there is a difference, the specific identifier is used.

2. "WinX" is a generic term for WinView, WinSpec, and WinXTest application

software.

Chapter 1,

details the structure of this manual; and documents environmental, storage, and

cleaning requirements.

Chapter 2, System Component Descriptions provides descriptions of each

sy

Chapter 1, Installation Overview cross-references sy

relevant manuals and/or manual pages. It also contains system layout diagrams.

Chapter 4, System Setup provides detailed directions for interconnecting the

sy

Chapter 5, Operation discusses num

vacuum degradation, and sensitivity to damage from EMF spikes generated by

Xenon or Hg arc lamps. Includes step-by-step directions for verifying system

operation.

Chapter 6, Advanced Topics discusses standard tim

External Sync, and Continuous Cleans), frame transfer operation, interline

operation, Fast and Safe speed modes, TTL control, and Kinetics mode.

Chapter 7, MicroMAX DIF Camera (Double Image Feature) describes DIF

(Dual Im

Chapter 8, Virtual Chip Mode describes how to set up and use the Virtual Chip

option, a special fast-acquisition technique.

Introduction briefly describes the MicroMAX family of cameras;

stem component.

stem setup actions with

stem components.

ber of topics, including temperature control,

ing modes (Free Run,

age Feature) camera and its operation.

Chapter 9, Troubleshooting provides courses of action to take if y

have problems with your system.

Appendix A, Specifications includes controller and camera specifications.

Appendix B, Outline Drawings includes outline drawings of the MicroMAX

eras and the ST-133A and ST-133B Controllers.

cam

Appendix C, Repumping the Vacuum explains how to restore the 1 MHz or

100kHz/1MHz round head cam

time.

Appendix D, Spectrometer Adapters provides m

spectrometer adapters available for MicroMAX rectangular head (NTE) cameras.

era's vacuum if that vacuum has deteriorated over

ounting instructions for the

ou should

Page 13

Chapter 1 Introduction 13

Appendix E, USB 2.0 Limitations covers the currently known limitations

associated with operating under the USB 2.0 interface.

Declarations of Conformity contains the Declaration of Conform

(includes 100 kHz/1MHz) MicroMAX systems.

Warranty and Service provides warranty and customer support contact

inform

ation.

Safety Related Symbols Used in This Manual

Caution! The use of this symbol on equipment indicates that one or more

nearby

items should not be operated without first consulting the manual. The

same symbol appears in the manual adjacent to the text that discusses the

hardware item(s) in question.

Caution! Risk of electric shock! The use of this sy

indicates that one or more nearby items pose an electric shock hazard and

should be regarded as potentially dangerous. This same symbol appears in the

manual adjacent to the text that discusses the hardware item(s) in question.

Environmental Conditions

• Storage temperature: < 55°C

• Operating environm

• Relative hum

ent: 0°C to 30°C

idity: ≤50%, non-condensing.

ity for 1 MHz

mbol on equipment

Grounding and Safety

The apparatus described in this manual is of the Class I category as defined in IEC

Publication 348 (Safety Requirements for Electronic Measuring Apparatus). It is

designed for indoor operation only. Before turning on the controller, the ground prong of

the power cord plug must be properly connected to the ground connector of the wall

outlet. The wall outlet must have a third prong, or must be properly connected to an

adapter that complies with these safety requirements.

WARNING

WARNING

If the equipment is damaged, the protective grounding could be disconnected. Do not use

damaged equipment until its safety has been verified by authorized personnel.

Disconnecting the protective earth terminal, inside or outside the apparatus, or any

tampering with its operation is also prohibited.

Inspect the supplied power cord. If it is not compatible with the power socket, replace the

cord with one that has suitable connectors on both ends.

Replacement power cords or power plugs must have the same polarity as that of the

original ones to avoid hazard due to electrical shock.

Page 14

14 MicroMAX System User Manual Version 6.C

Precautions

To prevent permanently damaging the system, please observe the following precautions:

• Always switch off and unplug the ST-133 Controller before changing your system

configuration in any way.

• Never remove the camera’s front window, as it is necessary to maintain vacuum (or

to maintain a dry nitrogen environment).

• The CCD array is very sensitive to static electricity. Touching the CCD can destroy

it. Operations requiring contact with the device can only be performed at the factory.

• Never operate the camera cooled without proper evacuation or backfill. This could

damage the CCD!

• Never connect or disconnect any cable while the MicroMAX system is powered on.

Reconnecting a charged cable may damage the CCD.

• Never prevent the free flow of air through the equipment by blocking the air vents.

Repairs

Cleaning

WARNING!

Repairs must be done by Princeton Instruments. If your system hardware needs repair,

contact Princeton Instruments Customer Service. Please save the original packing

material so you can safely ship the system to another location or return it for repairs.

Turn off all power to the equipment and secure all covers before cleaning the units.

Otherwise, damage to the equipment or personal injury could occur.

Camera and Controller

Although there is no periodic maintenance that must be performed on the camera or the

ST-133 Controller, you may clean these components from time to time by wiping them

down with a clean damp cloth. This operation should only be done on the external

surfaces and with all covers secured. In dampening the cloth, use clean water only. No

soap, solvents or abrasives should be used. Not only are they not required, but they could

damage the finish of the surfaces on which they are used.

Optical Surfaces

Optical surfaces may need to be cleaned due to the accumulation of atmospheric dust. We

advise that the drag-wipe technique be used. This involves dragging a clean cellulose

lens tissue dampened with clean anhydrous methanol over the optical surface to be

cleaned. Do not allow any other material to touch the optical surfaces.

Princeton Instruments Customer Service

Refer to the contact information located on page 164 of this manual.

Page 15

Chapter 2 System Component Descriptions

MicroMAX Camera

CCD Array: MicroMAX offers a choice of CCD technologies to improve quantum

efficiency (QE) and blue/green sensitivity. Arrays are available in full-frame, interline,

and frame-transfer formats. Thinned, back-illuminated devices have a higher QE across

the entire visible spectrum and far superior sensitivity in the blue/ green region than

front-illuminated CCDs. The MicroMAX combines back-illumination technology with

frame-transfer readout to provide high sensitivity with nonshuttered operation. Interlinetransfer CCDs contain alternate columns of imaging and storage cells.

Because the charge on each image pixel never has to transfer m

transfer can be made very quickly without smearing. By attaching microlenses to an

interline-transfer CCD, incident light is directed to the photosensitive areas of the sensor.

As a result, lens-on-chip formats dramatically improve the QE in the blue/green region of

the spectrum while still allowing fast imaging. Since no shutter is required, high-speed

gating and faster focus are possible.

CCD Chamber: The vacuum

contamination as well as insulates it from the warmer air in the camera body. The

inherent low humidity prevents condensation on the cooled surface of the array. The

thermal barrier provided by the vacuum isolates the window from the cooled CCD, keeps

the window from cooling below the dewpoint, and thereby prevents condensation on the

outside of the window.

MicroMAX cameras are normally shipped with a vacuum level of ~10 mTorr or better.

Because this vacuum

components, round head MicroMAX cameras are designed with a built-in vacuum port

that can be used to restore the vacuum to its original level. Instructions for repumping the

vacuum are provided in Appendix C.

Window: The cam

quartz window is integral to the vacuum chamber. By having only one window, the

MicroMAX camera reduces the chance of image degradation due to multiple reflections,

stray light, and interference patterns that may occur with a multiple-window design.

may deteriorate over time due to outgassing of electrical

era has one window in the optical path. The high-quality optical

-sealed CCD chamber protects the CCD from

ore than one row, the

Thermoelectric Cooler: While the CCD accum

electrons, generating dark current. Cooling the CCD enhances the low-light sensitivity by

reducing thermally generated charge. With forced-air assistance the MicroMAX camera’s

thermoelectric cooler is capable of cooling the CCD to -35°C with ±0.04°C stability at

temperature lock.

Cooling is accomplished by mounting the CCD on a cold finger, which in turn is seated

on a therm

stages to the camera body where the heat is then radiated via a fins and removed by

15

oelectric (Peltier-effect) cooler, and then transferring heat through the Peltier

ulates charge, thermal activity releases

Page 16

16 MicroMAX System User Manual Version 6.C

forced air. CCD temperature is controlled and monitored by via the host computer and

the ST-133 Controller.

Shutter: Rectangular head cam

A shutter drive signal is available at the Remote shutter connector on the rear of the

ST-133 Controller or on the rear of the cam

Electronics: The camera electronics enclosure contains the preamplifier and array

driver board. This design keeps all signal leads to the pream

and also provides complete RF shielding.

Speed of data acquisition and dynamic range is determ

converter used (binning on the array is also a factor). MicroMAX cameras are available

with 100 kHz (16-bit A/D), 100 kHz /1 MHz (16-bit A/D), 1 MHz (12-bit A/D), or

1 MHz (16-bit A/D). The dual 16-bit digitizers give you the choice of the 100 kHz A/D

for the better signal-to-noise ratio or the 1 MHz, 16-bit A/D for increased data acquisition

speed.

Connectors: Power, control signals, and data are transm

MicroMAX camera via the 25-pin D connector located on the rear of the 1 MHz or

100kHz/1 MHz camera. The cables and connectors are keyed so that they cannot be

connected incorrectly.

Lens Mount Housing: At the front of the cam

mount or F-mount. The C-mount employs a standard size thread to make the connection

while an F-mount uses a tongue and groove type mechanism to secure the lens or

microscope adapter to the camera. The details of the housing will vary depending on the

type of mount.

eras are available with an internal 25 mm shutter.

era.

plifier as short as possible

ined primarily by the A/D

itted between the ST-133 and the

era is the lens mount housing, either C-

Caution

Note: C-mount cameras are shipped with a dust cover lens installed. Although this lens

is capable of providing surprisingly good images, its throughput is low and the image

quality is not as good as can be obtained with a high-quality camera lens. Users should

replace the dust-cover lens with their own high-quality laboratory lens before making

measurements.

If you have a camera with a UV scintillator coated CCD, protect it from excessive

exposure to UV radiation. This radiation slowly bleaches the scintillator, reducing

sensitivity.

Mounting Holes: The round head camera has four ¼″ x 20 UNC threaded holes on the

camera body at 90° intervals. These holes are provided for flexibility in mounting the

camera to your system optics. The rectangular head camera can be ordered with an

optional tripod mount kit.

Fan: Depending on the cam

camera's back panel. Its purpose is:

• to rem

• to cool the electronics.

An internal Peltier device directly cools the cold finger on which the CCD is m

The heat produced by the Peltier device is then removed by the air drawn into the camera

by the internal fan and exhausted through the back panel. The fan is always in operation

and air cooling of both the Peltier and the internal electronics takes place continuously.

ove heat from the Peltier device that cools the CCD array

era, there may be an internal fan located inside or on the

ounted.

Page 17

Chapter 2 System Component Descriptions 17

The fan is designed for low-vibration and does not adversely affect the image. For the fan

to function properly, free circulation must be maintained between the rear of the camera

and the laboratory atmosphere.

WARNING

Shutter: In imaging applications an adapter is m

either C-mount or F-mount, is mounted to the adapter. An F-mount adapter and a

C-mount adapter differ not only in their lens-mounting provisions, but also in depth

because the focal plane of F-mount lenses is deeper than that of C-mount lenses.

Nevertheless, rectangular head cameras can be ordered with an internal 25 mm shutter

and the appropriate lens mount adapter already installed.

Shutter Life: Note that shutters are m

on the order of a million cycles, although some individual shutters may last a good deal

longer. How long a shutter lasts in terms of experimental time will, of course, be strongly

dependent on the operating parameters. High repetition rates and short exposure times

will rapidly increase the number of shutter cycles and decrease the time when the shutter

will have to be replaced. Possible shutter problems include complete failure, in which the

shutter no longer operates at all, or the shutter may stick open or closed causing

overexposed or smeared images. It may even happen that one leaf of the shutter will

break and no longer actuate.

Shutter replacement is usually done at the factory. If you find that the shutter on your

cam

era is malfunctioning, contact the factory to arrange for a shutter-replacement repair.

Disconnecting or connecting the shutter cable to the camera while the controller is on can

destroy the shutter or the shutter drive circuitry. Always power off the controller before

adjusting the shutter cable.

echanical devices with a finite lifetime, typically

ounted to the camera and then the lens,

Page 18

18 MicroMAX System User Manual Version 6.C

ST-133 Controller

Electronics: The Model ST-133 is a compact, high performance CCD Camera

Controller for operation with Princeton Instruments cameras. Designed for high speed

and high performance image acquisition, the ST-133 offers data transfer at speeds up to 5

Megapixel per second, standard video output for focusing and alignment. A variety of

A/D converters are available to meet different speed and resolution requirements.

In addition to containing the power supply, the controller contains the analog and digital

electronics, scan control and exposure timing hardware, and controller I/O connectors, all

mounted on user-accessible plug-in modules. This highly modularized design gives

flexibility and allows for convenient servicing.

WARNING

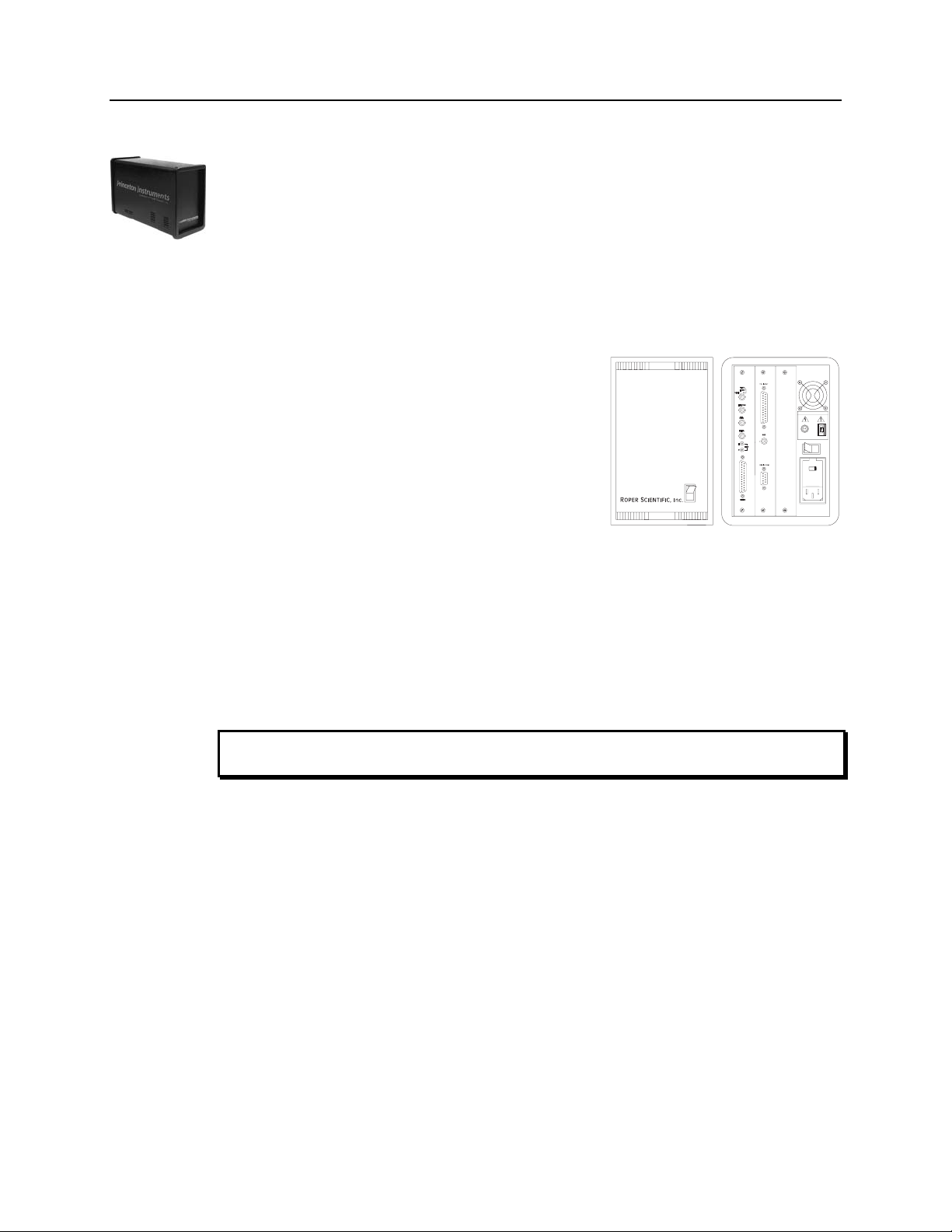

POWER Switch and Indicator: The power s

witch

location (see Figure 2) and characteristics depend on the

version of ST-133 Controller that was shipped with y

system. In some versions, the power switch is on the

front and has an integral indicator LED that lights

whenever the ST-133 is powered. In other versions, the

power switch is located on the back of the ST-133 and

does not include an indicator LED.

our

SHUTTER CONTROL

REMOTE

l

~

|

O

120Vac

LEFT: FUSES: RIGHT:

0.75A - T 100 - 120V

1.25 A - T 220 - 240 V

50-60Hz 420 W MAX

Rear Panel Connectors: There are three controller

board slots. Two are occupied by

the plug-in cards that

provide various controller functions. The third,

Figure 2. Power Switch Location

(ST-133A and ST-133B)

covered with a blank panel, is reserved for future development. The left-most plug-in

card is the Analog/Control module. Adjacent to it is the Interface Control module. Both

modules align with top and bottom tracks and mate with a passive back-plane via a 64pin DIN connector. For proper operation, the location of the modules should not be

changed. Each board is secured by two screws that also ground each module’s front

panel. Removing and inserting boards is described in Chapter 9, pages

125-126.

To minimize the risk of equipment damage, a module should never be removed or

installed when the system is powered.

The Analog/Control Module, which should always be located in the left-most slot,

provides the following functions.

• Pixel A/D conversion • Tim

• CCD scan control • Tem

ing and synchronization of readouts

perature control

• Exposure control • Video output control

SETTING

O

~

3.50A - T

~

1.80A - T

The Interface Control Module, which should alway

provides the following functions.

• TTL In/Out Program

• Com

munications Control (TAXI or USB 2.0 protocol)

mable Interface

s be located in the center slot,

Page 19

Chapter 2 System Component Descriptions 19

WARNING

Always turn the power off at the Controller before connecting or disconnecting any cable

that interconnects the camera and controller or serious damage to the CCD may result.

This damage is NOT covered by the manufacturer’s warranty.

1

11

12

13

14

16

USB 2.0

2

8

3

SHUTTER CONTROL

4

9

AUX

5

REMOTE

SETTING

9

TTL

IN/OUT

8

6

7

10

l

120Vac

O

~

USB 2.0

Interface Control Module

Figure 3. ST-133 Rear Panel Callouts

TAXI

LEFT: FUSES: RIGHT:

0.75A - T 100 - 120V

1.25 A - T 220 - 240 V

50-60Hz 420 W MAX

~

3.50A - T

~

1.80A - T

15

Page 20

20 MicroMAX System User Manual Version 6.C

The descriptions of the rear panel connectors are keyed to the accompanying figure.

Depending on your system, either the TAXI or the USB 2.0 Interface Control Module will be

installed in the second from the left slot (as you face the rear of the ST-133). In

TAXI m

odule is shown in that position.

Figure 3, the

# Feature

1. Temperature Lock LED: Indicates that the temperature control loop has locked and that

the temperature of the CCD array will be stable to within ± 0.05°C.

2. Video/Aux Output: Composite video output is provided at this connector; if labeled Aux,

this output is reserved for future use. The Video output amplitude is 1 V pk-pk and the

source impedance is 75 Ω. Either RS-170 (EIA) or CCIR standard video can be provided

and must be specified when the system is ordered. The video should be connected to the

monitor via 75 Ω coaxial cable and it must be terminated into 75 Ω.

Note that video output is not currently supported under USB 2.0.

3. External Sync Input: TTL input that has a 10 kΩ pullup resistor. Allows data acquisition

and readout to be synchronized with external events. Through software, positive or negative

(default) triggering can be selected.

4. Output WinX/32 (ver. 2.4 and higher) software-selectable NOT SCAN or

SHUTTER signal. Default is SHUTTER. NOT SCAN reports when the controller is

finished reading out the CCD array. NOT SCAN is high when the CCD array is not being

scanned, then drops low when readout begins, returning to high when the process is

finished. The second signal, SHUTTER, reports when the shutter is opened and can be

used to synchronize external shutters. SHUTTER is low when the shutter is closed and

goes high when the shutter is activated, dropping low again after the shutter closes. See

Figure 4 for timing diagram.

5. Output: Initially HIGH. After a Start Acquisition command, this output changes

state on completion of the array cleaning cycles that precede the first exposure. Initially

high, it goes low to mark the beginning of the first exposure. In free run operation it

remains low until the system is halted. If a specific number of frames have been

programmed, it remains low until all have been taken, then returns high.

6. Zero Adjustment: (1 MHz and 100kHz/1 MHz systems) Control the offset values of the

Fast (F) and Slow (S) A/D converters; if potentiometers are not present, bias may be

software-settable. Preadjusted at factory. The offset is a voltage that is added to the signal to

bring the A/D output to a non-zero value, typically 50-100 counts. This offset value

ensures that all the true variation in the signal can really be seen and not lost below the A/D

“0” value. Since the offset is added to the signal, these counts only minimally reduce the

range of the signal from 4095 to a value in the range of 50-100 counts lower. Adjusting a

potentiometer clockwise increases the counts while rotating it counterclockwise decreases

the counts. If potentiometers are not present, bias may be software-settable.

CAUTION: Do not adjust the offset values to zero, or some low-level data will be missed.

7. Detector Connector: (1MHz and 1 MHz/100kHz systems) Transmits control information

to the camera and receives data back from the camera via the Detector-Controller cable.

8. TTL In/Out: User-programmable interface with eight input bits and eight output bits that

can be written to or polled for additional control or functionality. Output is not currently

supported under USB 2.0. See Chapter 6.

9. AUX Output: Reserved for future use.

Page 21

Chapter 2 System Component Descriptions 21

# Feature

10. Serial COM Connector: Provides two-way serial communication between the controller and

the host computer. Uses TAXI protocol. Contact the factory if an application requires use of

the optional fiber-optic data link to increase the maximum allowable distance between the

camera and the computer.

11. Fan: Cools the controller electronics. Runs continuously when the controller is turned on. Do

not block the side vents or the fan exhaust port.

12. Shutter Setting Selector: Sets the shutter hold voltage. Dial is correctly set at the factory

for the camera’s internal shutter if one is present. Refer to Table 1 for setting selection.

13. Remote Shutter Connector: Provides shutter-hold pulses for a 25 mm Princeton

Instruments-supplied external shutter (typically an entrance slit shutter).

WARNING:

connector. To avoid shock hazard, the Controller power should be OFF when connecting

or disconnecting a remote shutter.

Dangerous live potentials are present at the Remote Shutter Power

WARNING: If t

not be used to drive a second external shutter. This configuration will result in under-

powering both shutters and may cause damage to the system In a system which requires

both an internal and an external shutter, use the Shutter signal (provided at the

connector when selected by an internal jumper or by software parameter selection) to

control the external shutter. Suitable driver electronics will additionally be required.

Contact the factory Technical Support Dept. for information.

14. Power Input Module: Contains the powercord socket and two fuses. Depending on the

ST-133 version, the power switch may be located directly above the power module.

15. Fuse/Voltage Label: Displays the controller’s power and fuse requirements. This label

may appear above the power module.

16. USB 2.0 Connector: Provides two-way serial communication between the controller and the

host computer. Uses USB 2.0 protocol.

he camera has an internal shutter, then the Shutter Power connector should

WARNING

: Dangerous live potentials are present at the Remote Shutter Power

connector. To avoid shock hazard, the Controller power should be OFF when connecting

or disconnecting a remote shutter.

Shutter Setting* Shutter Type

1 25 mm Princeton Instruments supplied External shutter

(typically an Entrance slit shutter)

2 25 mm Princeton Instruments Internal shutter

4 35 mm Princeton Instruments Internal shutter (requires

70 V Shutter option), supplied with rectangular head

camera having 1300 × 1340 CCD

5 40 mm Princeton Instruments Internal shutter

* Shutter settings 0, 3, and 6-9 are unused and are reserved for future use.

Table 1. ST-133 Shutter Drive Selection

Page 22

22 MicroMAX System User Manual Version 6.C

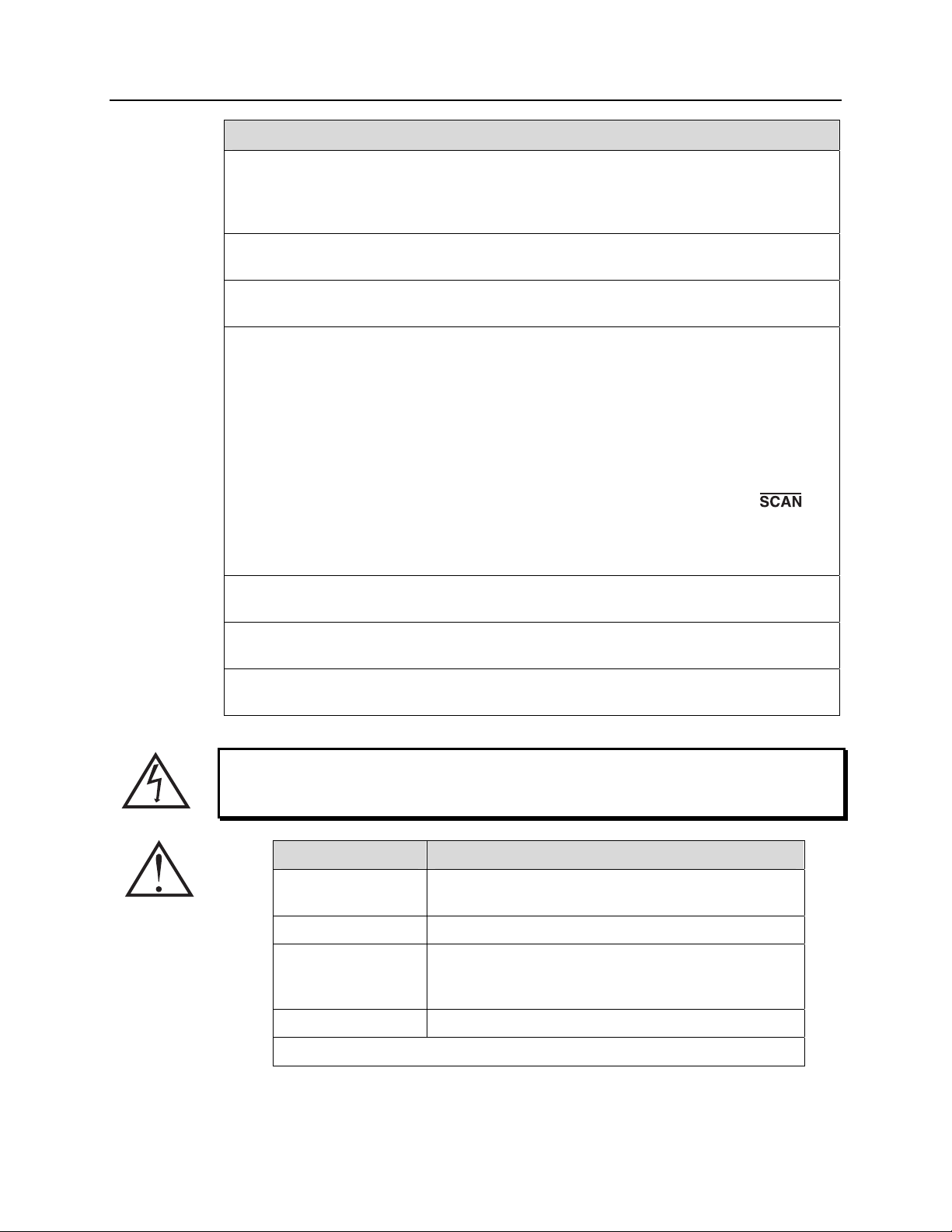

WARNING

Selecting the wrong shutter setting will result in improper functioning of the shutter and

may cause premature shutter failure.

t

exp

Shutter

t

NOTSCAN

t

c

t

= Exposure Time

exp

t

= Readout Time

R

t

= Shutter Compensation Time

c

Shutter Type Compensation Time

NONE 200 nsec

Electronic 6.0 msec

Remote (Roper Scientific 23 mm, External, 8.0 msec

typically a slit shutter)

Small (Roper Scientific 25 mm, Internal) 8.0 msec

Large (Roper Scientific 35/40 mm, External) 28.0 msec

Figure 4. Shutter Compensation Times

R

Page 23

Chapter 2 System Component Descriptions 23

Cables

Detector-Controller: 1 MHz or 100kHz/1MHz systems. The standard 10' cable

(6050-0321) has DB-25 Male connectors with

cable interconnects the Detector connector on the rear of the ST-133 with the

Detector connector on the back of the MicroMAX camera. The Detector-Controller

cable is also available in 6', 15', 20', and 30' lengths.

Interface Cable: Depending on the system configuration, either a TAXI or a USB

cable will be shipped.

slide-latch locking hardware. This

Interface Card

PCI Card: This interface card is required when the system interface uses the TAXI

protocol rather than USB 2.0. The PCI card plugs-into the host computer's

motherboard and provides the serial communication interface between the host

computer and the ST-133. Through WinView/32, the card can be used in either

Speed PCI

interrupt-driven and can give higher performance in some situations.

allows data transfer to be controlled by a polling timer.

USB 2.0 Card: This interface card is required when the system interface uses the

USB 2.0 protocol rather the TAXI protocol and the computer does not have native

USB 2.0 support. The USB 2.0 card plugs-into the host computer's motherboard and

provides the communication interface between the host computer and the ST-133.

The USB 2.0 PCI card (70USB90011) by Orange Micro is recommended for desktop

computers; the SIIG, Inc. USB 2.0 PC Card, Model US2246 is recommended for

laptop computers. See

more information.

TAXI: The standard 25' (7.6 m) cable (6050-0148-CE) has DB-9 Male

connectors with screw-down locking hardware. The TAXI (Serial

munication) cable interconnects the "Serial Com" connector on the rear of

com

the ST-133 with the PCI card installed in the host computer. In addition to the

standard length, this cable is available in 10', 50', 100', and 165' lengths. Also

available are fiber optic adapters with fiber optic cables in 100, 300, and 1000

meter lengths.

USB 2.0: The standard 16.4'

that interconnect the "USB 2.0" connector on the rear of the ST-133 with a

USB card installed in the host computer.

or PCI(Timer) mode. High Speed PCI allows data transfer to be

www.orangemicro.com

(5 m) cable (6050-0494) has USB connectors

High

PCI(Timer)

or www.siig.com, respectively, for

Application Software

The Princeton Instruments WinView/32 software package provides comprehensive image

acquisition, display, processing, and archiving functions so you can perform complete data

acquisition and analysis without having to rely upon third-party software. WinView/32

provides reliable control over all Roper Scientific detectors, regardless of array format

and architecture, via an exclusive universal programming interface (PVCAM

WinView/32 also features snap-ins and macro record functions to permit easy user

customization of any function or sequence.

®

).

Page 24

24 MicroMAX System User Manual Version 6.C

PVCAM is the standard software interface for cooled CCD cameras from Roper

Scientific. It is a library of functions that can be used to control and acquire data from the

camera when a custom application is being written. For example, in the case of Windows,

PVCAM is a dynamic link library (DLL). Also, it should be understood that PVCAM is

solely for camera control and image acquisition, not for image processing. PVCAM

places acquired images into a buffer, where they can then be manipulated using either

custom written code or by extensions to other commercially available image processing

packages.

User Manuals

MicroMAX System User Manual: This manual describes how to install and use the

MicroMAX system components.

WinView/32 User Manual: This manual describes how to install and use the

WinView/32 application program. A PDF version of this manual is provided on the

installation CD. Additional information is available in the program's on-line help.

Page 25

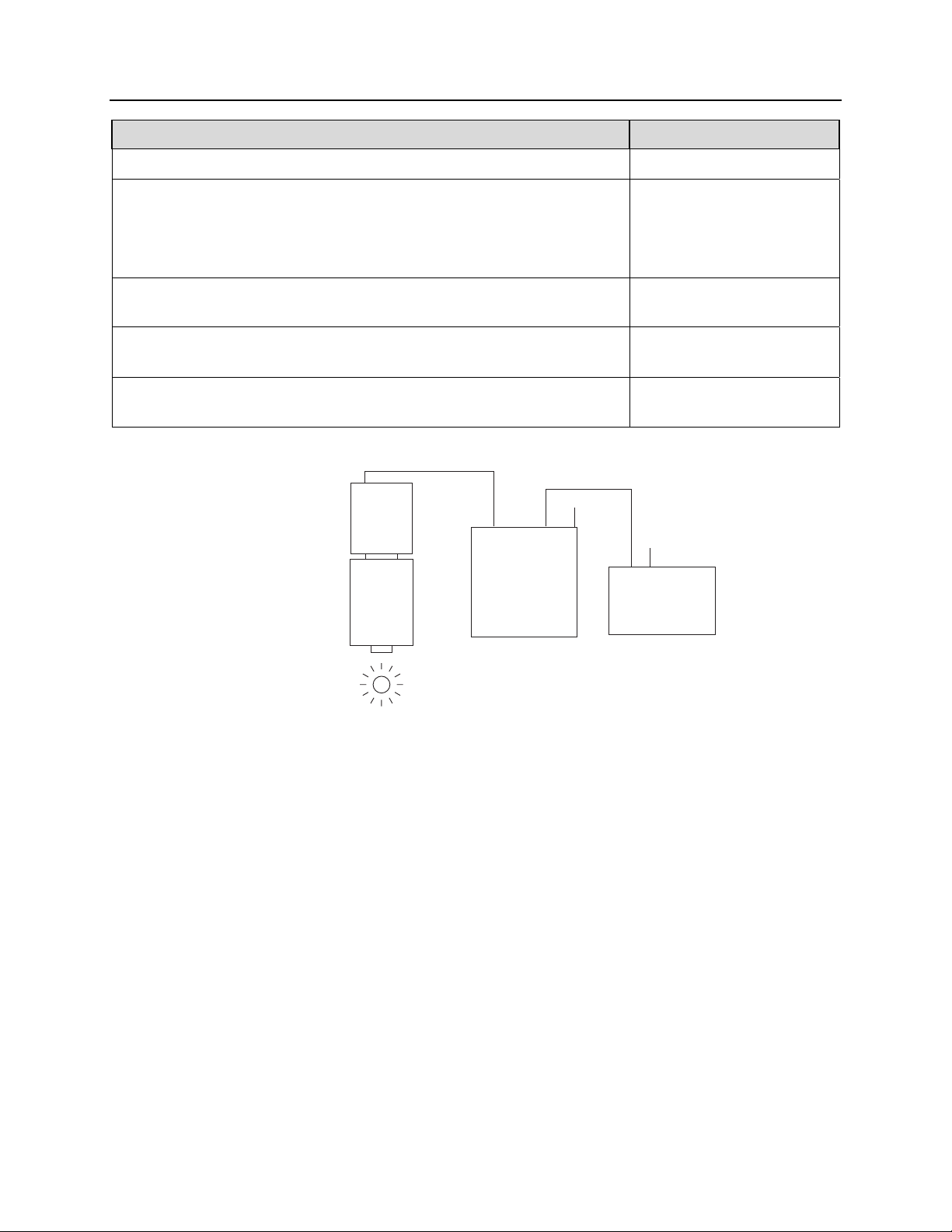

Chapter 3 Installation Overview

The list and diagrams below briefly describe the sequence of actions required to

hookup your system and prepare to gather data. Refer to the indicated references

for more detailed information. This list assumes that the application software is

Princeton Instruments WinView/32.

Action Reference

1. If the system components have not already been unpacked, unpack

them and inspect their carton(s) and the system components for intransit damage. Store the packing materials.

2. Verify that all system components have been received. Chapter 4 System Setup,

3. If the components show no signs of damage, verify that the

appropriate voltage settings have been selected for the Controller.

4. If WinView/32 software is not already installed in the host

computer, install it. In addition to installing the WinView/32

software, this operation will load all of the interface card drivers.

5. If the appropriate interface card is not already installed in the host

computer, shut down the computer and install the interface card.

6. Depending on the application, attach a lens to the camera, mount the

camera to a microscope, or mount the camera to a spectrometer.

7. With the Controller and computer power turned OFF, connect the

interface cable (TAXI or USB) to the Controller and the interface

card in the host computer. Then tighten down the locking hardware.

8. With the Controller power turned OFF, make the camera-to-

controller connections to the back of the Controller. Secure the

latch(es) to lock the cable connection(s).

Chapter 4 System Setup,

27

page

27

page

Chapter 4 System Setup,

29

page

Chapter 4 System Setup,

30

page

WinView/32 manual

Chapter 4 System Setup,

30 or page 32

page

Chapter 4 System Setup,

34, 35, or 38

page

Chapter 4 System Setup,

39

page

Chapter 4 System Setup,

40

page

9. With the Controller power turned OFF, make the camera-to-

controller connections to the back of the Camera. Secure the

latch(es) to lock the cable connection(s).

10. With the Controller power turned OFF, connect the Controller

power cable to the rear of the controller and to the power source.

11. If using a microscope Xenon or an Hg arc lamp, turn it on before

turning on the controller and host computer.

12. Turn the Controller ON.

25

Chapter 4 System Setup,

40

page

Chapter 5 Operation,

44

page

Page 26

26 MicroMAX System User Manual Version 6.C

Action Reference

13. Turn on the computer and begin running the WinX application. WinView/32 manual

14. Run the Camera Detection wizard or load the defaults from the

controller.

Chapter 5 Operation,

40, 48, or 53

page

WinView/32 or

WinSpec/32 m

anual

15. Set the target array temperature. Chapter 5 Operation,

48, 53, or 58

page

16. When the system reaches temperature lock, begin acquiring data in

focus mode.

Chapter 5 Operation,

50 or page 54

page

17. Adjust the focus for the image. Chapter 5 Operation,

50 or page 54

page

Detector-Controller

Camera

Microscope

Detector

Controller

Interface cable

(TAXI or USB 2.0)

110/220

Serial Com

or USB 2.0

110/220

Computer

EXPERIMENT

Figure 5. Standard System Diagram

Page 27

Chapter 4 System Setup

Unpacking the System

During the unpacking, check the system components for possible signs of shipping

damage. If there are any, notify Princeton Instruments and file a claim with the carrier. If

damage is not apparent but camera or controller specifications cannot be achieved,

internal damage may have occurred in shipment. Please save the original packing

materials so you can safely ship the camera system to another location or return it to

Princeton Instruments for repairs if necessary.

Checking the Equipment and Parts Inventory

Confirm that you have all of the equipment and parts required to set up the system. A

complete MicroMAX system consists of a camera, a controller, a computer and other

components as follows.

• Camera to Controller cable: D

this cable are available, one having an external shield and the other not. The shielded

version offers superior noise performance and is required by regulation in some

countries.

• Computer Interface Dependent Components:

• Controller-Computer Interface cable:

• TAX

• USB cable: Five (5) m

• Interface Card:

• TAXI:

• USB 2.0: Native on m

• Vacuum

necessary to refresh the vacuum for round camera heads. Contact the factory

Technical Support Dept. for information on refreshing the vacuum. See page

contact information.

I cable: 25 ft DB9 to DB9 cable (6050-0148-CE) is standard. Lengths

up to 165 ft (50 m) are available. Optional fiber-optic transducers can be

used to extend this distance to as much as 1000 meters or

High Speed PCI Interface board or

(Orange Micro 70USB90011 USB2.0 PCI is recommended for desktop

computers and the SIIG, Inc. USB 2.0 PC Card, Model US2246 is

recommended for laptop computers).

Pumpdown connector (2550-0181): This item is required if it becomes

B25 to DB25, 10 ft (6050-0321). Two versions of

eter cable (6050-0494) is standard.

otherboard or user-provided USB 2.0 Interface Card

164 for

• WinView/32 CD-ROM

• User Manual

27

Page 28

28 MicroMAX System User Manual Version 6.C

System Requirements

Power

Detector: The MicroMAX detector receives its power from the controller, which in turn

plugs into a source of AC power.

Caution

ST-133: The ST-133 Controller can operate from

any one of four different nominal line

voltages: 100, 120, 220, or 240 V AC. Refer to the Fuse/Voltage label on the

back of the ST-133 for fuse, voltage, and power consumption information.

The plug on the line cord supplied with the system

should be compatible with the linevoltage outlets in common use in the region to which the system is shipped. If the line

cord plug is incompatible, a compatible plug should be installed, taking care to maintain

the proper polarity to protect the equipment and assure user safety.

Host Computer

Note: Computers and operating systems all undergo frequent revision. The following

information is only intended to give an approximate indication of the computer

requirements. Please contact the factory to determine your specific needs.

Requirements for the host computer depend on the type of interface, TAXI or USB 2.0,

that will be used for com

requirements are a listed below according to protocol.

TAXI Protocol:

• AT-com

• Windows

patible computer with 200 MHz Pentium

®

2000, or Windows

munication between the ST-133 and the host computer. Those

®

II (or better).

95, Windows® 98SE, Windows® ME, Windows NT®, Windows®

®

XP operating system.

• High speed PCI serial card (or an unused PCI card slot). Com

puters purchased

from Princeton Instruments are shipped with the PCI card installed if High speed

PCI was ordered.

• Minim

um of 32 Mbytes of RAM for CCDs up to 1.4 million pixels. Collecting

multiple spectra at full frame or high speed may require 128 Mbytes or more of

RAM.

• CD-ROM drive.

• Hard disk with a m

inimum of 80 Mbytes available. A complete installation of the

program files takes about 17 Mbytes and the remainder is required for data

storage, depending on the number and size of images or spectra collected. Disk

level compression programs are not recommended.

• Super VGA m

onitor and graphics card supporting at least 256 colors with at least

1 Mbyte of memory. Memory requirement is dependent on desired display

resolution.

• IEEE-488 GPIB port (required by

DG535 Timing Generator, if present). May

also be required by Spectrograph.

• Two-button Microsoft com

patible serial mouse or Logitech three-button

serial/bus mouse.

Page 29

Chapter 4 System Setup 29

USB 2.0 Protocol:

• AT-com

better.

• Windows 2000 (with Service Pack 4), Windows XP (with Service Pack 1) or

later operating sy

• Native USB 2.0 support on the m

Micro 70USB90011 USB2.0 PCI is recommended for desktop; SIIG, Inc. USB

2.0 PC Card, Model US2246 for laptop)

• Minim

• CD-ROM drive.

• Hard disk with a m

program files takes about 17 Mbytes and the remainder is required for data

storage, depending on the number and size of images or spectra collected. Disk

level compression programs are not recommended.

• Super VGA m

1 Mbyte of memory. Memory requirement is dependent on desired display

resolution.

• IEEE-488 GPIB port (required by

also be required by Spectrograph.

• Two-button Microsoft com

serial/bus mouse.

patible computer with Pentium 3 or better processor and runs at 1 GHz or

stem.

other board or USB Interface Card (Orange

um of 256 Mb of RAM.

inimum of 80 Mbytes available. A complete installation of the

onitor and graphics card supporting at least 256 colors with at least

DG535 Timing Generator, if present). May

patible serial mouse or Logitech three-button

Verifying Controller Voltage Setting

The Power Module on the rear of the Controller contains the

voltage selector drum, fuses and the powercord connector. The

appropriate voltage setting is set at the factory and can be seen on

the back of the power module.

Each setting actually defines a range and the setting that is closest

to the actual line voltage should have been selected. The fuse and

power requirem

module. The correct fuses for the country where the ST-133 is to be

shipped are installed at the factory.

Note: On ST-133s, the voltage ranges and fuse ratings may be

printed above or below the power module (Figure 6).

To Check the Controller's Voltage Setting: