Princess auto 2.3 GPM @ 2, 600 PSI GAS PRESSURE WASHER User Manual

User Manual

8384281V2.0

2.3 GPM @ 2,600 PSI

GAS PRESSURE WASHER

Please read and understand all instructions before use.

Retain this manual for future reference.

3

For technical questions call: 1-800-665-8685

8384281V2.0

2.3 GPM @ 2,600 PSI

GAS PRESSURE WASHER

SPECIFICATIONS

Engine Displacement

208 cc

Pump

Axial Pump with Aluminum Head

Flow Rate

2.3 gallons per min.

Pressure Rating

2,600 pounds per square inch

Hose

1/4 in. x 25 ft

3 Nozzle Tips

Detergent System

Detergent injector with siphon hose

Frame

Powder coated heavy duty

INTRODUCTION

This Pressure Washer is designed to remove dirt and mould from house siding, decks, garage floors, brick patios,

and cement walkways. This unit can be used to clean cars, motorcycles, boats, RV’s, outdoor furniture, lawn

equipment, and grills.

SAFETY

IMPORTANT SAFETY PRECAUTIONS

WARNING! The warnings, cautions and instructions discussed in this instruction manual cannot cover all

possible conditions and situations that may occur. It must be understood by the operator that common sense

and caution are factors which cannot be built into this product, but must be supplied by the operator.

WARNING! Read and understand all instructions before using this tool. Keep this manual for the safety warnings

and precautions, operating, inspection and maintenance instructions. When using this tool, basic precautions

should always be followed to reduce the risk of personal injury and/or damage to the equipment. Note that when

this manual refers to a part number, it refers to the parts list included. Before allowing someone else to use this

tool, make sure they are aware of all safety information.

WORK AREA

• Operate in a safe work environment. Keep your work area clean and well lit. Do not use in the presence of

flammable gases or liquids.

• Keep anyone not wearing appropriate safety equipment away from the work area. Distraction can cause you

to lose control.

• Do not operate power tools in an unsafe environment such as explosive atmospheres, flammable liquids,

gases and dust. A spark created by a power tool may ignite the fumes or dust.

2.3 GPM @ 2,600 PSI GAS PRESSURE WASHER

4

For technical questions call: 1-800-665-8685

8384281V 2.0

PERSONAL SAFETY

WARNING! Water pressure produced by this unit can cut through skin and tissue leading to serious injury and

possible amputation.

• Dress properly, wear protective equipment. Use breathing, ear, eye, face, foot, hand and head protection.

Always wear ANSI approved impact safety goggles, which must provide both frontal and side protection.

Always wear a mask when spraying. Protect your hands with suitable gloves. Wear a full face shield. Protect

your head from falling objects by wearing a hard hat. Wear an ANSI approved dust mask or respirator when

working around metal, wood and chemical dusts and mists. Wear ANSI approved earplugs. Protective,

electrically non-conductive clothes and non-skid footwear are recommended when working. Wear steel toed

boots to prevent injury from falling objects.

• Use indirect vented safety goggles designed for wet conditions to protect eyes from injury.

• Do not over reach; keep proper footing and balance at all times. Proper footing and balance enables better

control of the tool in unexpected situations.

• Keep any articles of clothing, jewellery, hair etc. away from moving parts. These can be caught in moving

parts, resulting in damage to the tool and/or serious injury.

• Stay alert, watch what you are doing and use your common sense. Do not operate any machine or tool when

you are tired, under the influence of drugs, alcohol or medications.

• Use clamps or other practical ways to secure and support the work piece to a stable platform. Holding the

work piece by hand or against your body is unstable and may lead to loss of control.

• Do not allow the spray to strike you and do not spray toward people, animals, or any electrical source.

• Do not touch movable parts or accessories while the power source is still connected.

• Remove adjusting tools such as wrenches or keys before turning the tool on. A wrench or key left attached

to a rotating part will fly off and may cause personal injury.

VIBRATION PRECAUTIONS

This tool vibrates during use. Repeated or long-term exposure to vibration may cause temporary or permanent

physical injury, particularly to the hands, arms and shoulders.

1. Anyone using vibrating tools regularly or for an extended period should first be examined by a doctor and

then have regular medical check ups to ensure medical problems are not being caused by or worsened from

tool use. Pregnant women or people who have impaired blood circulation to the hands, past hand injuries,

nervous system disorders, diabetes or Raynaud’s Disease should not use this tool. If you feel any medical

symptoms related to vibrations (such as tingling, numbness, and white or blue fingers), seek medical

attention as soon as possible.

2. Do not smoke during use. Nicotine reduces the blood flow to the hands and fingers, increasing the risk of

vibration-related injury.

3. Wear suitable gloves to reduce the vibration effects on the user.

4. Use tools with the lowest amount of vibration when there is a choice between different processes.

5. Do not use for extended periods. Take frequent breaks when using this tool.

6. Let the tool do the work. Grip the tool as lightly as possible (while still keeping safe control of it).

7. To reduce vibrations, maintain tool as explained in this manual. If abnormal vibrations occur, stop using this

tool immediately.

2.3 GPM @ 2,600 PSI GAS PRESSURE WASHER

5

For technical questions call: 1-800-665-8685

8384281 V 2.0

SPECIFIC SAFETY PRECAUTIONS

WARNING! Only use this unit as it is intended or serious injury or death could result.

WARNING! To reduce the risk of injection, injury or possible amputation, never direct water pressure towards

people or pets.

WARNING! Pressure washer can create slippery surfaces.

WARNING! Keep engine away from flammable objects and other hazardous materials.

WARNING! Starter cord recoils rapidly pulling arm towards the engine faster than you can let go which could

result in injury.

WARNING! Only use detergents or soaps that are safe to be used with pressure washers. Chemicals which are

caustic, such as acids or bleach, can result in serious injury, property damage, damage to the pressure

washer, or death.

• Keep the unit away from children and pets.

• Do not point the spray gun at other people, animals, plants, or fragile objects such as glass.

• Do not leave the spray gun unattended while the unit is running.

• Make sure the spray gun, nozzle, and accessories are attached correctly.

• Never attempt to repair the high pressure hose, always replace.

• Never attempt to repair leaks with sealant, always replace O-rings or seals.

• Never attempt to connect or disconnect the hose from the pump or spray the gun while the system

is pressurized.

• Always release the water pressure from the unit every time you stop the engine.

• Operate pressure washer from a stable surface as recoil form the spray gun could cause you to loose

your balance.

• Use extreme caution if operating the pressure washer from a ladder, scaffolding or uneven surface.

• Use both hands to control the spray gun to control the recoil.

• Do not over-extend yourself. Maintain proper balance at all times.

• Do not operate indoors or in a confined space preventing dangerous carbon monoxide gas from dissipating.

Keep the exhaust from this unit from entering a confined area through windows, doors, vents, or other

openings. Carbon monoxide gas is a poisonous, odourless gas that can cause fainting, sickness, seizures, or

death. When working in areas where vapours could be inhaled, use a respirator mask according to all of

its instructions.

• The fuel and its vapours used to power this unit are highly flammable and could explode resulting in serious

injury or death.

• Never overfill fuel tank. If fuel spills, move the unit at least 30 ft away from the spillage area and wipe up any

remaining fuel on the unit before starting the engine.

• Never operate or store this unit near an open flame, heat, or any other ignition source.

• Keep engine free of grass, leaves, or grease which are flammable.

• Before adding or draining fuel, unit should be turned off for at least 2 minutes to cool before removing fuel

cap. If unit has been running the fuel cap is under pressure, remove slowly.

• Do not tip the unit when operating or transporting. This will cause fuel to spill.

• When transporting the unit, disconnect the spark plug wire and make sure the fuel tank is empty with the

fuel shutoff valve turned to the off position. Secure the unit so it cannot tip over.

• Always relieve pressure from the spray gun before pulling the starter cord, including every failed attempt to

start the engine.

• To avoid recoil, pull the starter cord slowly until resistance is felt, then pull rapidly.

2.3 GPM @ 2,600 PSI GAS PRESSURE WASHER

6

For technical questions call: 1-800-665-8685

8384281V 2.0

• Avoid contacting hot areas of this unit. Use caution around the muffler and other engine parts as they can be

very hot. Allow hot components to cool before touching.

• Do not bypass any safety device. Moving parts are covered with guards. Make sure all protective covers are

in place.

• Inspect hoses and connections making sure they are secure before starting the engine.

• Use only recommended accessories to avoid damage to this unit.

• Never carry this unit or make adjustments on it while it is running.

• Spray from this unit has extreme pressure and can ricochet back splashing water or propelling objects

at eyes.

• Never substitute eye protection with dry condition goggles.

TOOL USE AND CARE

• Use the correct tool for the work. The proper tool will do the work faster and safer.

• Do not use the tool if the On/Off switch is not working. Operating a tool that cannot be controlled by you is

dangerous and must be repaired before use.

• Always turn the unit off before storing the tool, making adjustments or adding/replacing accessories. This

simple prevention will reduce the risk of accidental starting the tool.

• Store the tool in a secure place out of reach of children. A secure storage location will prevent the

unauthorized use by untrained users.

• Properly maintain tools. Keep all tools clean. Remove contaminants from the tool and keep clean. Check for

broken parts or binding of moving parts before use. If damaged, have the tool serviced before use. Prevent

accidents caused by poorly maintained tools.

• Use only accessories recommended for your model. Accessories suitable for one tool may become

hazardous when used on another tool.

LUBRICATION

1. It is important that the tool be properly lubricated. Without proper lubrication the tool will not work properly

and parts will wear prematurely. Avoid over-lubricating the tool.

2. Use the proper lubricant to lubricate parts only as necessary. Use only recommended lubricants. Substitutes

may harm the rubber compounds in the tool’s O-rings and other rubber parts.

3. Lubricate before storing. In the event that it becomes necessary to store the tool for an extended period of

time (overnight, weekend, etc.,) it should receive a generous amount of lubrication at that time.

WARNING! NEVER use WD-40 to clean or lubricate your tool. WD-40 is a solvent that will break down the

internal grease and cause the tool to seize up.

CHANGING THE PUMP OIL

• Check engine oil level often. The first oil change should occur after the first 50 hours of use. Subsequent oil

changes should occur after every 500 hours of use.

• Engine oil will drain better if engine is still warm but not hot. To change oil, turn off engine. Place an oil pan

on the ground to catch the oil. Remove oil plug and tilt machine back and to the side to empty out oil from

the crankcase. Once oil is completely drained, reinsert oil plug and return the machine to a level position.

UNPACKING

• Remove the high pressure hose from the box.

• Once the high pressure hose has been removed, carefully open the product by cutting down the sides

of the box.

• Remove the product, parts, and all accessories. Make sure all items listed on the packing list are included.

• Inspect the parts carefully to make sure the tool was not damaged while shipping.

• Do not discard the packaging material until you have carefully inspected and satisfactorily operated the tool.

2.3 GPM @ 2,600 PSI GAS PRESSURE WASHER

7

For technical questions call: 1-800-665-8685

8384281 V 2.0

WARNING! If any part is missing, do not operate the tool until the missing parts are replaced. Failure to do so

could result in serious personal injury.

PACKING LIST

• Pressure Washer

• Operator’s Manual

• Handlebar with Fastening Hardware

• Spray Gun

• Extension Wand with Quick Connect Fitting

• High Pressure Hose

• Siphon Tube

• Spray Nozzles (x4): 0°, 15°, 25°, 40° and Soap Nozzle

• Drainable Detergent Tank

• Wheel (x2)

• Axle (x1)

• Cotter Pin (x2)

• 4-Cycle Engine Oil (SAE10W-30)

OPERATION

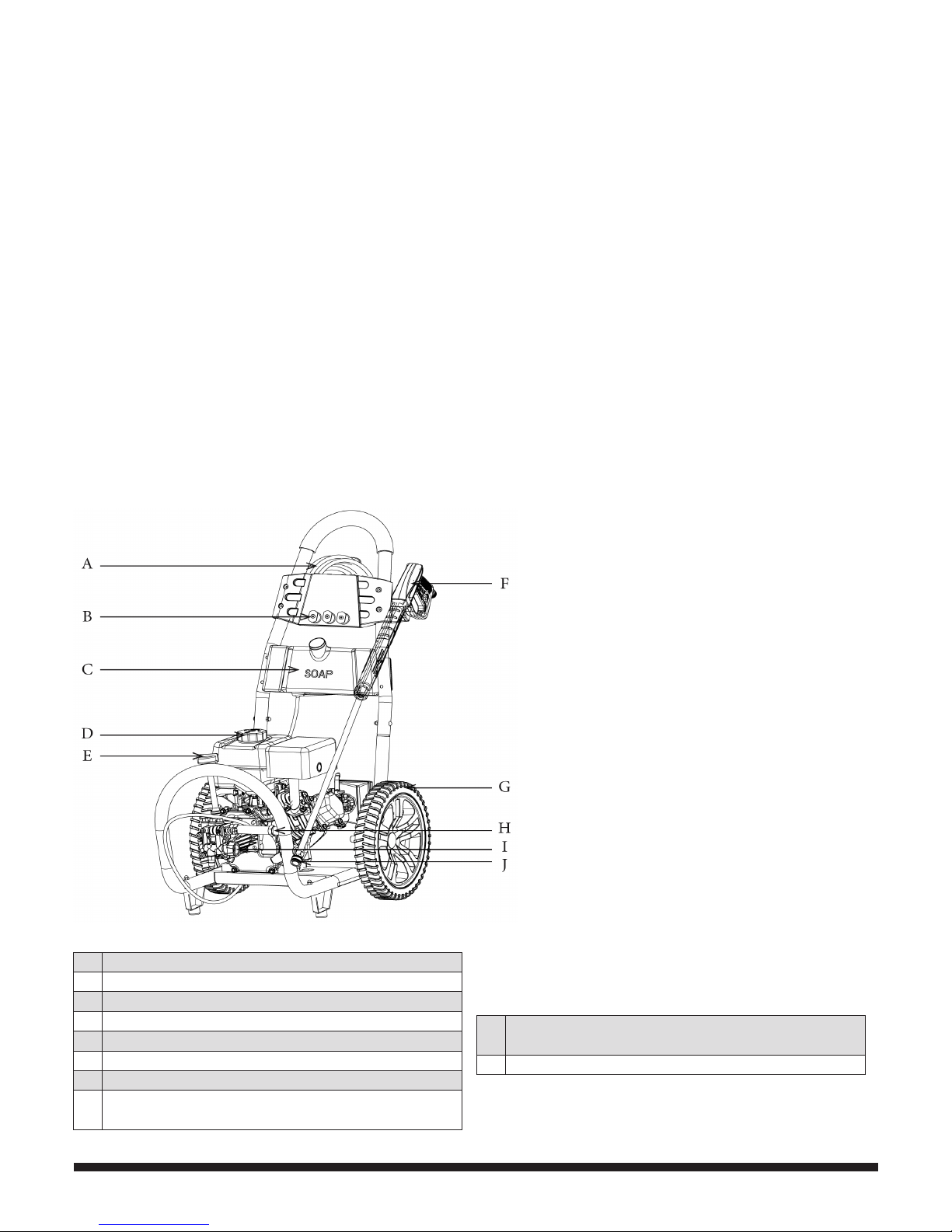

PARTS IDENTIFICATION

A High Pressure Hose – Extends 25 ft

B Spray Tips – Store 3 Spray Tips Here

C Soap Tank – Fill Pressure Washer Safe Detergent Here

D Fuel Tank – Check and Fill with Unleaded Fuel Here

E Oil Fill / Dipstick – Fill Oil Here

F Spray Gun – Used to Apply Water. Includes lock and trigger

G Foam Filled Tires – Tires Never Need Air

H

High Pressure Connection – Connection for

High Pressure Hose

I

Garden Hose Connection – Connect Male End of the Garden

Hose Here

J Nozzle Quick Connect – Connection for all Three Spray Tips

2.3 GPM @ 2,600 PSI GAS PRESSURE WASHER

8

For technical questions call: 1-800-665-8685

8384281V 2.0

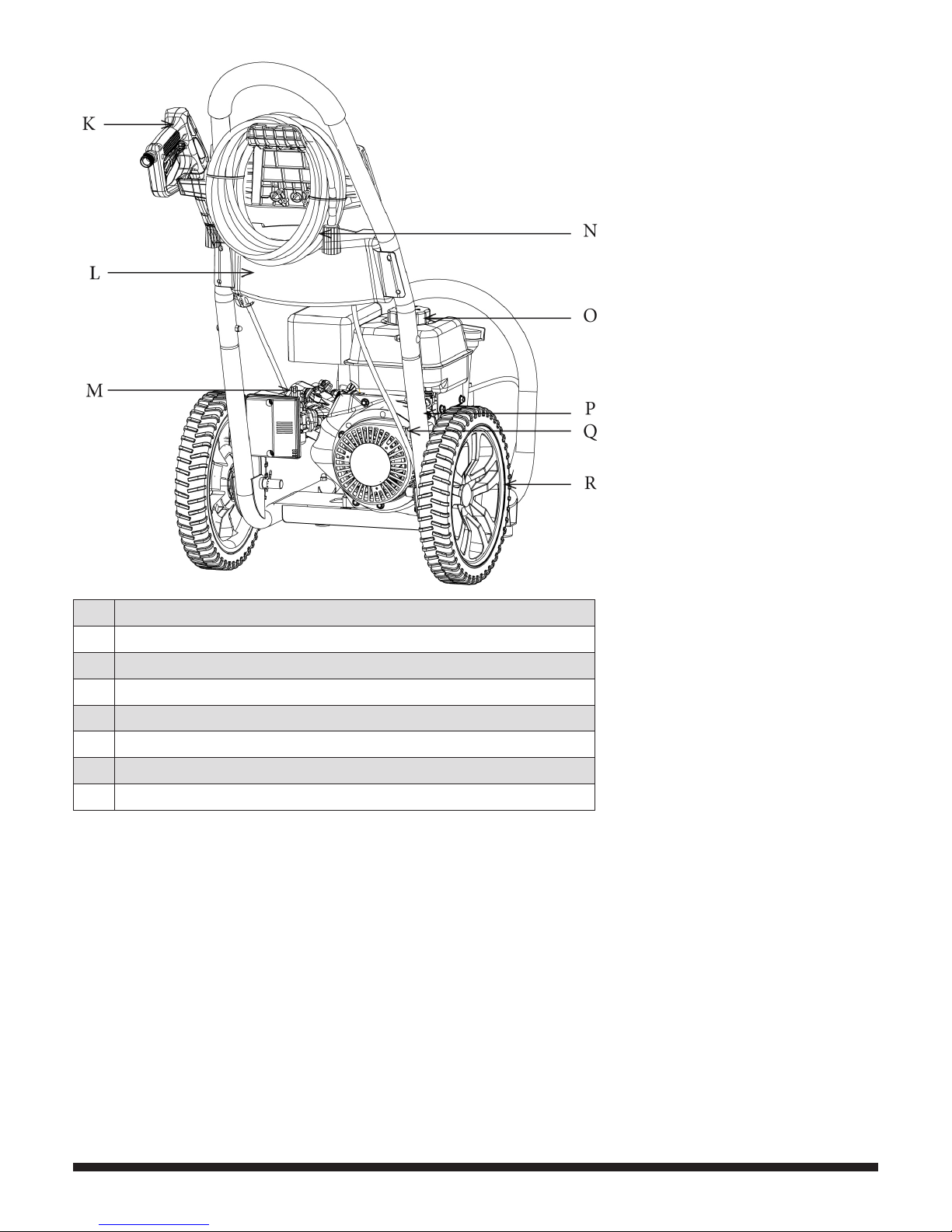

K Spray Gun – Used to Apply Water. Includes Lock and Trigger

L Soap Tank – Fill Pressure Washer Safe Detergent Here

M Choke – Use When Starting a Cold Engine

N High Pressure Hose – Extends 25 ft

O Fuel Tank – Check and Fill with Unleaded Fuel Here

P Engine Switch – Turns the Pressure Washer On and Off

Q Pull Cord – Used to Start the Engine

R Foam Filled Tires – Tires Never Need Air

2.3 GPM @ 2,600 PSI GAS PRESSURE WASHER

9

For technical questions call: 1-800-665-8685

8384281 V 2.0

INSTALLATION

ATTACHING THE WHEEL ASSEMBLY

1. Parts needed – 2 wheels, axle pins, and 2 cotter pins.

2. Remove the cotter pins from the wheel axle pins.

3. Slide the wheel axle pin through the hole located in the centre

of the wheel.

4. Raise or tilt the pressure washer so you can slide the

wheel axle pin into the wheel mounting hole located

on the side of the frame.

5. Secure the wheel assembly by reinserting a cotter pin through

the hole at the end of the wheel axle and pressing until it locks

into place.

6. Repeat the process on the other side of the pressure washer

to install the second wheel.

INSTALLING THE HANDLE

1. Install the upper frame (handle) onto the lower frame by

sliding the handle over the two upright tubes on the lower

frame and pressing down firmly until seated.

2. Align the upper and lower frame carriage bolt holes and

install 2 carriage bolts and 2 acorn nuts provided.

3. Tighten with a wrench until the upper frame tube begins to

crush slightly, securing the nut and the tubing.

ADDING / CHECKING ENGINE OIL

WARNING! Oil must be added to the unit prior to the first use.

1. Place the pressure washer on a level surface.

2. Unscrew the oil cap / dipstick by turning it counter clockwise.

3. Carefully add between 900 to 1,000 ml (33 to 33 oz)

of 4-Cycle engine oil (SAE10W-30) to the reservoir to where

the oil reaches the upper level of the oil filler neck.

4. Replace the oil cap / dipstick by turning it clockwise until it is

tightened.

5. To check the oil, set the pressure washer on a level surface,

wipe the dipstick clean, and then reinsert the dipstickwithout re-threading.

FIG. 2

FIG. 1

2.3 GPM @ 2,600 PSI GAS PRESSURE WASHER

10

For technical questions call: 1-800-665-8685

8384281V 2.0

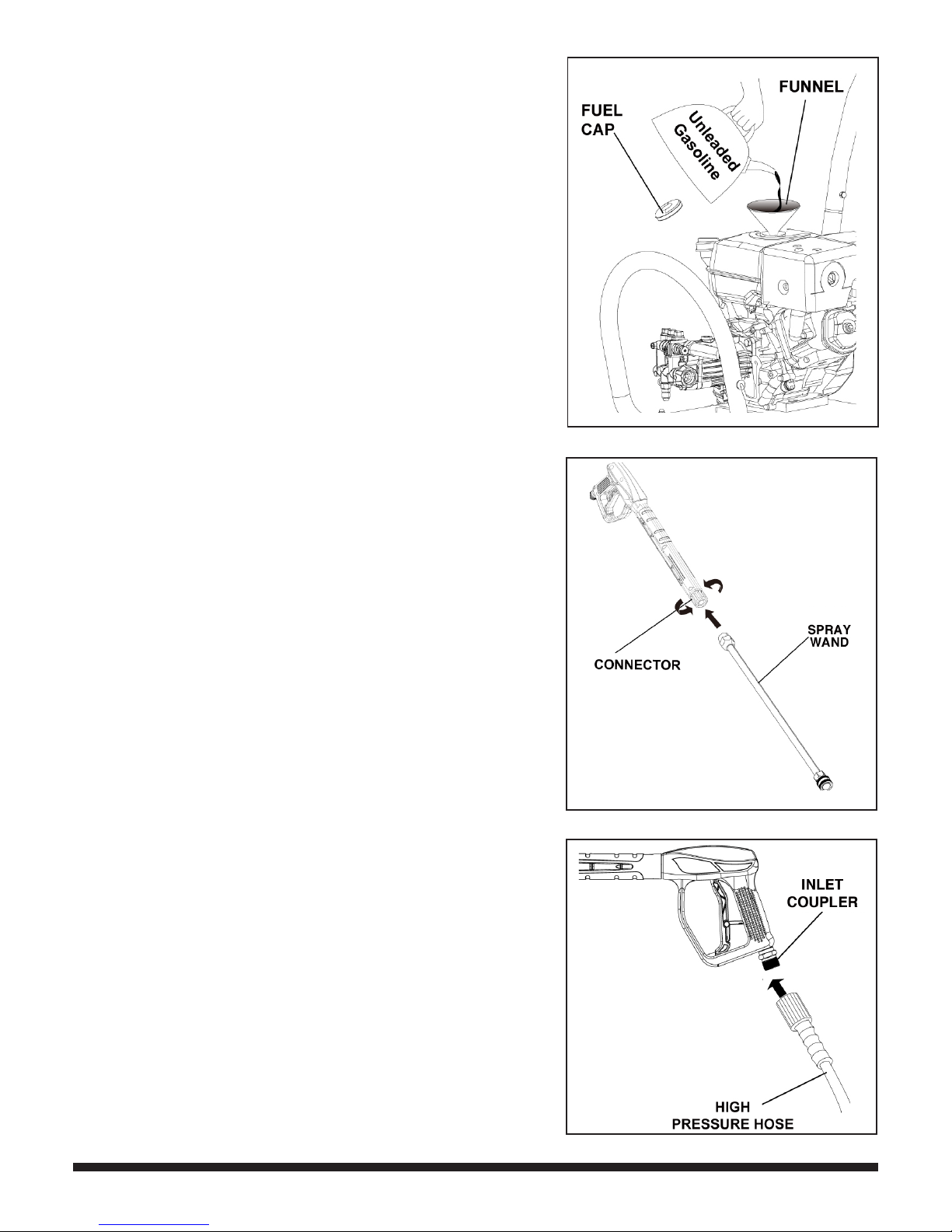

ADDING FUEL

1. Set the pressure washer on a clean and level surface

in an area that is well ventilated.

2. Remove the fuel cap.

3. Insert a funnel into the fuel tank and carefully pour

gasoline into the tank until the fuel level reaches

1-1/2 in. below the top of the neck.

ATTACHING THE SPRAY GUN

1. Screw the spray waned and the trigger handle together until

they are secure.

2. Insert the inlet coupler of the spray hose into the threaded

fitting on the high pressure spray gun and thread the black nut

on by turning it clockwise until it is hand tight.

FIG. 3

FIG. 3

FIG. 4

2.3 GPM @ 2,600 PSI GAS PRESSURE WASHER

11

For technical questions call: 1-800-665-8685

8384281 V 2.0

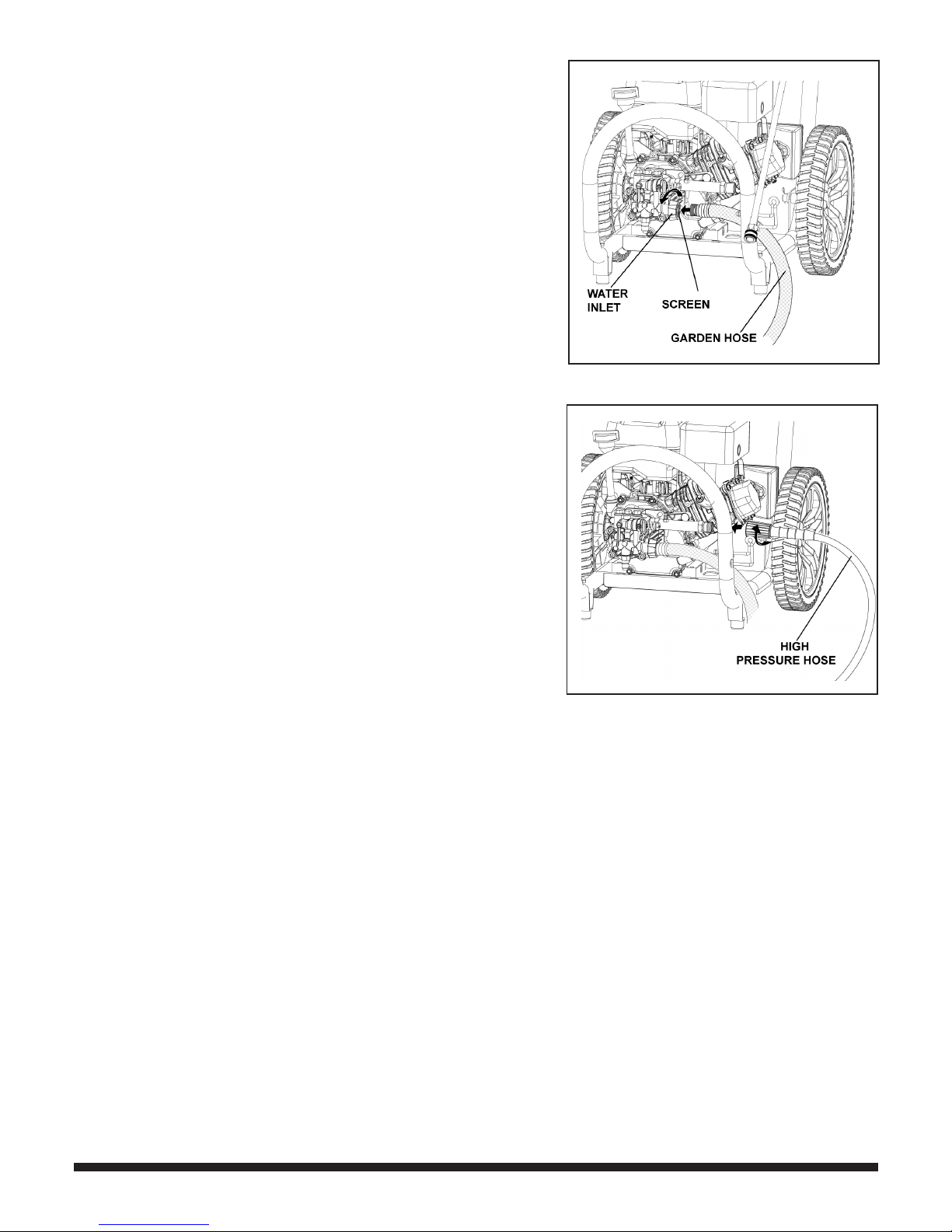

CONNECTING A GARDEN HOSE TO

THE PRESSURE WASHER

1. Run water through the hose for 30 to 60 seconds to flush any

debris from the hose.

2. Inspect the inlet screen and remove any debris.

3. Connect the garden hose to the water inlet and tighten by hand.

There must be a minimum of 10 ft of unrestricted hose

between the pressure washer and the faucet or shut off valve.

4. Turn on the water.

5. Purge the systems’ pump of air by releasing the safety and

squeezing the trigger of the spray gun.

CONNECTING THE HIGH PRESSURE HOSE

TO THE PUMP

1. Attach the end of the high pressure hose to the high pressure

outlet on the pump.

2. Follow the same procedure with the opposite end to attach the

high pressure hose to the spray wand.

3. Pull back on the quick connect collar to attach the spray tips.

4. Once the nozzle is inserted, press and hold it while you release

the collar. Releasing the collar should lock the tip in place.

WARNING! An unlocked tip may cause injury or damage. Verify that

the tip is locked by tugging on the tip before attempting to spray.

OPERATION

PRE-OPERATION CHECK LIST

• Read and understand this operator manual in its entirety before operating this pressure washer.

• Check the oil level and add oil to the proper level if low.

• Check the fuel level and add fuel if needed.

• Check the connections of the handle and all hoses to make sure they are secure.

• Check all hoses for kinks and damage.

• Check the flow of the water supply and make sure it is adequate.

WARNING! Do not run the pressure washer with a damaged hose. Do not run the pressure washer without first

connecting and turning on the water supply or damage to the pressure washer could result. Failure to follow

these instructions will void the product warranty.

FIG. 6

FIG. 7

Loading...

Loading...