Page 1

Service

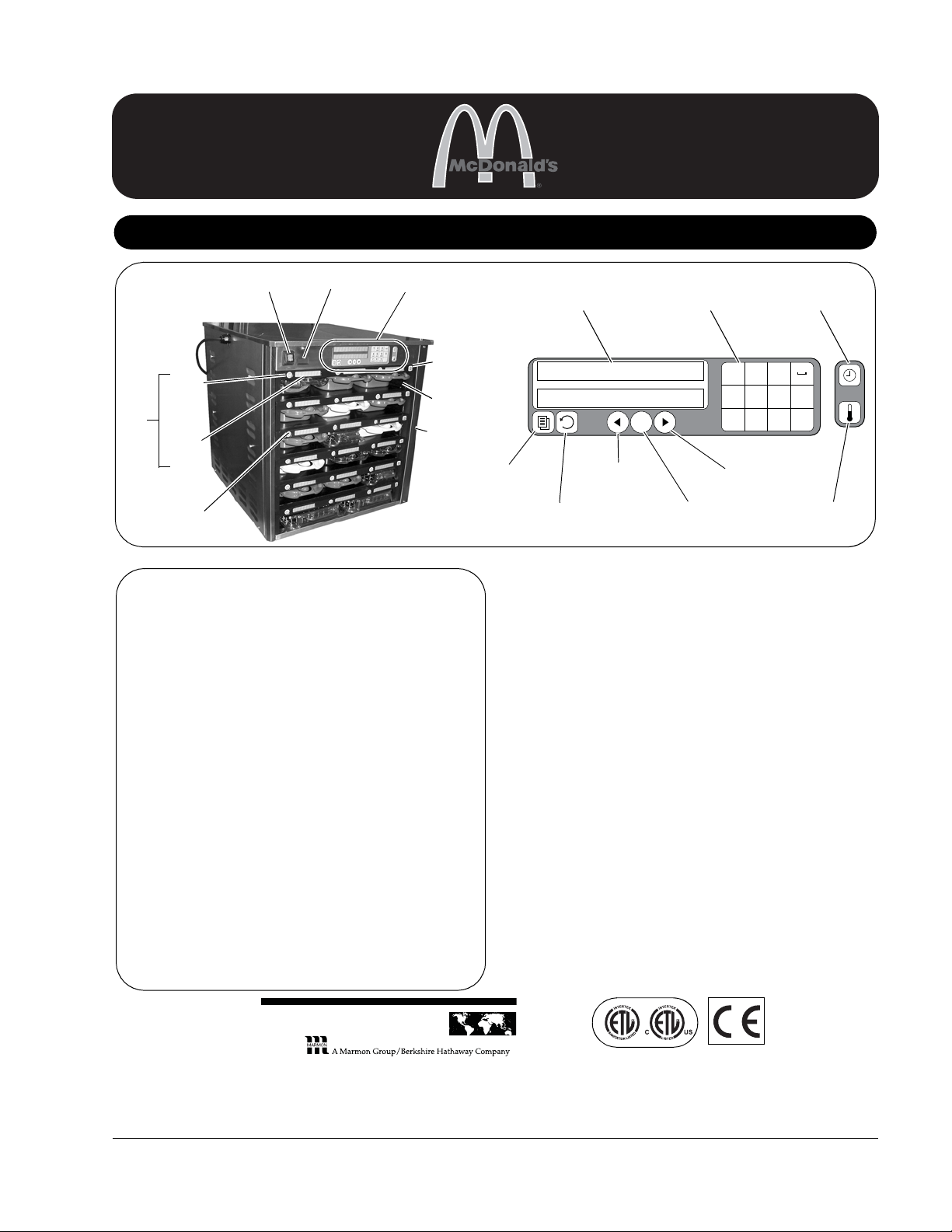

Product Identification

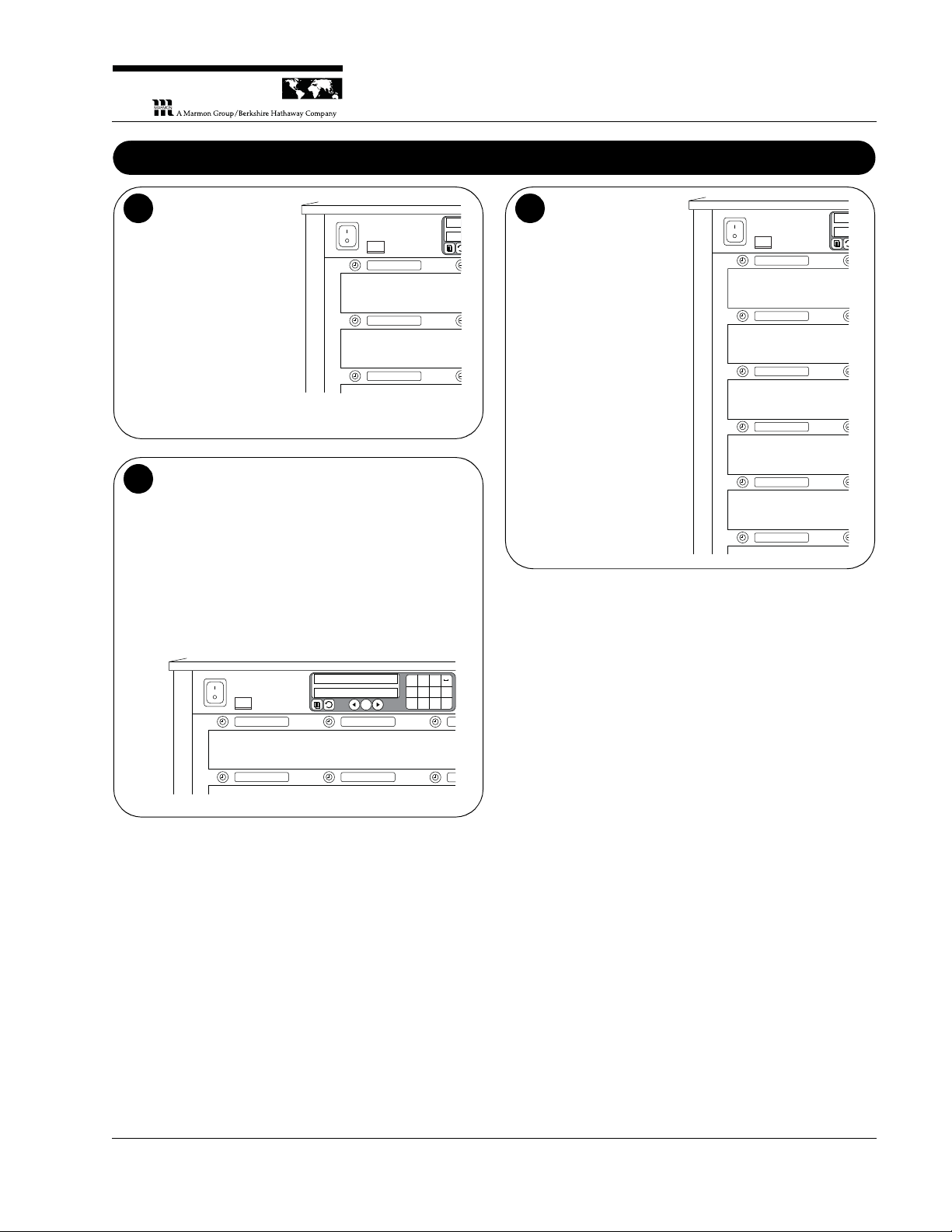

ON/OFF

Switch

Item

Timer

Button

Item

Display

Slot

Row Mode

Button

Master Control

(MCB)

Left

Button

Master

Display

Master

Keypad

Master

Timer

Button

Master

Temperature

Button

Right

Button

OK Select

Button

Back

Button

Program

Button

USB

Por t

Bezel

Right Front

Corner

IUC

TABLE OF CONTENTS

Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safe Service Practices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Serial Number Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Resetting Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Management Programming . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Accessing Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

System Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Service Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Removing/Replacing Bezels . . . . . . . . . . . . . . . . . . . . . . . . . 9

Removing/Replacing Heater Boards . . . . . . . . . . . . . . . . . . . 10

Removing/Replacing Distribution Board . . . . . . . . . . . . . . . . 11

Removing/Replacing Rows . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Replacing Heater Platen/Probe Assembly. . . . . . . . . . . . . . . 12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Exploded View and Parts List . . . . . . . . . . . . . . . . . . . . . . . . 16

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LIMITED WARRANTY

This product is warranted to be free from defects in material and/or

workmanship for a period of three (3) years from date of original

installation, not to exceed 42 months from date of shipment from our

factory. Any part or component which proves to be faulty in material and/

or workmanship within the warranty period will be replaced or repaired

(at the option of Prince Castle) without cost to the customer for parts or

labor, except as provided below.

This Limited Warranty is subject to the following exceptions/conditions:

• Use of any non-genuine Prince Castle parts voids this warranty. All

work must be performed by an authorized Prince Castle Service

Agent, except as provided herein.

• All covered labor shall be performed during regular work hours.

Overtime premium will not be covered.

• Travel charges are limited to 100 miles (200 kilometers) round trip; 2

hours travel time, one trip per repair.

• Damage caused by carelessness, neglect, and/or abuse (e.g., using

wrong current, dropping, tampering with or altering electrical

components, or improper cleaning) is not covered.

• Equipment damaged in shipment or by fire, flood or an act of God is

not covered.

• Damage to coated surfaces is not covered by this Limited Warranty.

• Labor for repair or replacement of the following parts is not covered by

this Limited Warranty:

Display Bar (IUC) part number 547-058S

Heater Board part number 547-221S

Prince Castle will provide replacement parts to customer so customer

can replace such parts if they are defective. Replacement instructions

are set out in the product’s Operations Manual.

PRINCE CASTLE SHALL NOT BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSSES, OR EXPENSES. THIS IS PRINCE

CASTLE’S ONLY WARRANTY. PRINCE CASTLE MAKES NO OTHER

WARRANTY, EXPRESS OR IMPLIED. ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND/OR FITNESS FOR ANY PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED AND EXCLUDED.

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

355 East Kehoe Blvd. • Carol Stream, IL 60188 USA

Telephone: 630-462-8800 • Toll Free: 1-800-PCASTLE

Fax: 630-462-1460 • www.princecastle.com

Universal Holding Cabinet

Manual

UHC6PT-22MCD

213

ABC DEF

2430

JKLGHI MNO

OK

879

TUVPQRS WXYZ

547-504-EN Printed in USA 01/11 © 2011

Page 2

Universal Holding Cabinet

Electrical Specifications

208-240V 50/60 Hz 2250-3450W

Safe Service Practices

NOTE: This service manual is intended for use by persons

having electrical and mechanical training and a level of

knowledge of these subjects considered acceptable in the

service trade. Prince Castle cannot be responsible, or assume

any liability, for injury or damage arising from the use of this

manual.

To avoid personal injury and /or property damage, it is

important that Safe Service Practices be observed, including

the following limited examples:

• Do not service the unit without first reading this manual.

• Do not attempt a repair if you have any doubt as to your

ability to complete it in a safe manner.

• Do not attempt to repair or replace any component unless all

power has been disconnected.

• Prior to returning the unit to service, ensure that:

– All electrical connections are correct and secure.

– All safety grounds are correctly and securely connected.

– All components are properly re-assembled.

Failure to disconnect power

from the unit before servicing

could result in severe bodily

injury or death. The ON/OFF

Switch does not disconnect

incoming power to the unit.

WARNING

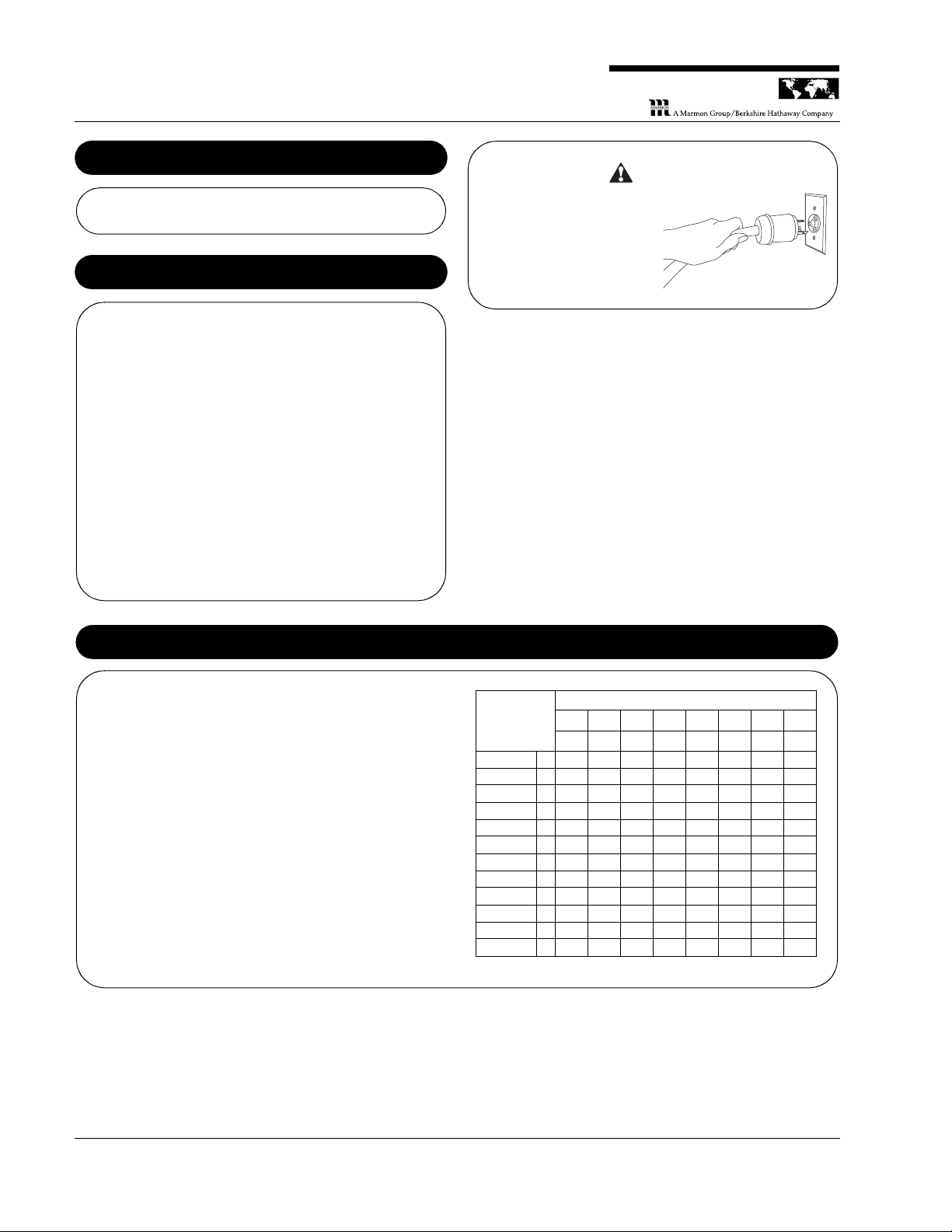

Serial Number Matrix

The manufacture date is encoded in the unit’s serial number.

The service bench installation date (used to determine warranty

coverage) is considered to be the end of the following month. For

example:

Serial Number: FE0000458

Manufacture Date: June 2010

Service Bench Installation Date: July 31, 2010

SERIAL NUMBER MATRIX

2009 2010 2011 2012 2013 2014 2015 2016

DEFGHJKL

January A AD AE AF AG AH AJ AK AL

February B BD BE BF BG BH BJ BK BL

March C CD CE CF CG CH CJ CK CL

April D DD DE DF DG DH DJ DK DL

May E ED EE EF EG EH EJ EK EL

June F FD FE FF FG FH FJ FK FL

July G GD GE GF GG GH GJ GK GL

August H HD HE HF HG HH HJ HK HL

September J JD JE JF JG JH JJ JK JL

October K KD KE KF KG KH KJ KK KL

November L LD LE LF LG LH LJ LK LL

December M MD ME MF MG MH MJ MK ML

UHC6PT-22MCD

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 01/11 © 2011 2 547-504-EN

Page 3

Universal Holding Cabinet

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

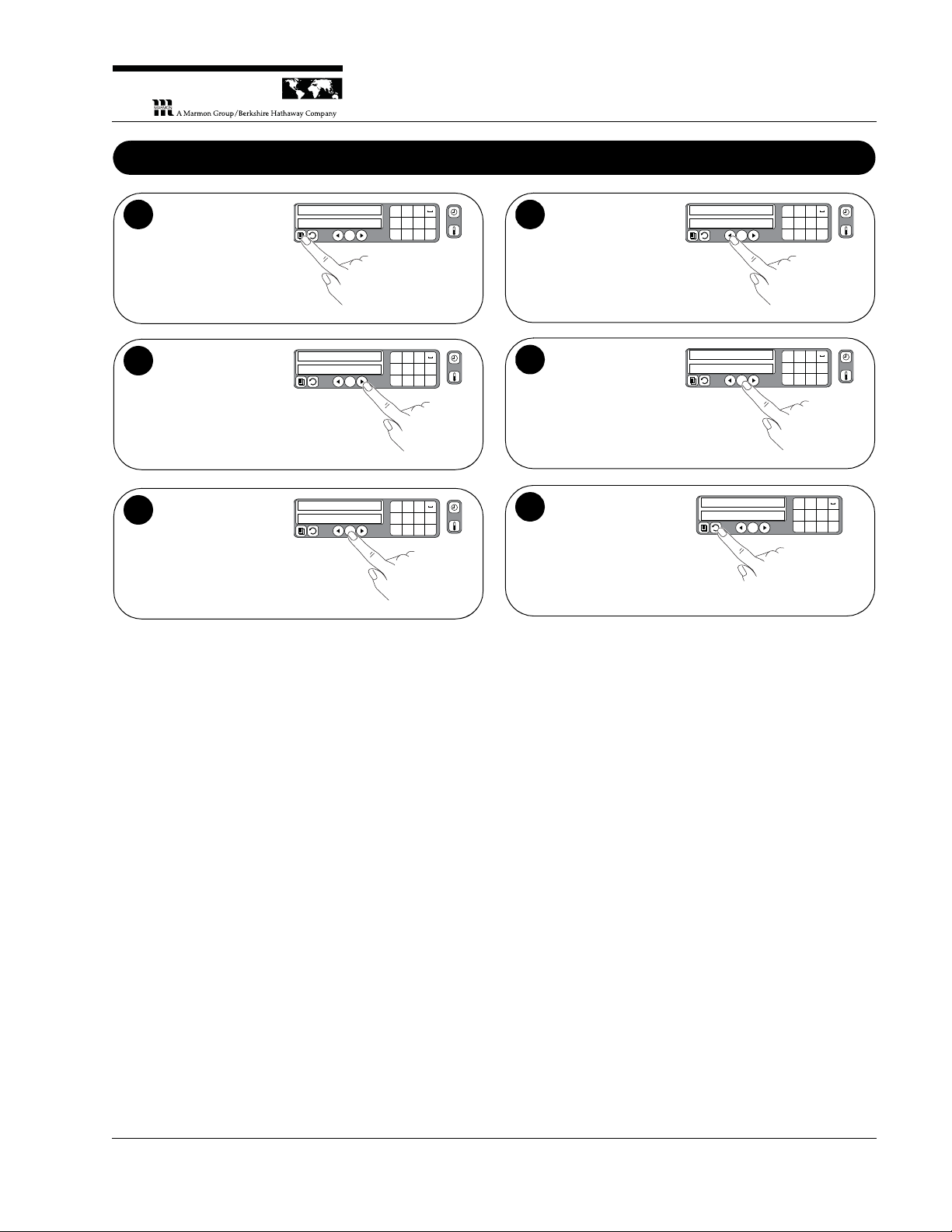

Resetting Factory Defaults

Press the Master

Program button and

enter 3550_9 on the

Keypad. The

maintenance menu

will appear and the

Master Display will

read TEST MODE.

OK

213

ABC DEF

2430

JKLGHI MNO

879

TUVPQRS WXYZ

test mode

press

1

Press the Right

button four times.

Press the Right

button on the Master

Display until CHG

SETTINGS appears

on the Master

Display.

OK

213

ABC DEF

2430

JKLGHI MNO

879

TUVPQRS WXYZ

chg settings

press

2

Press the OK Select

button.

OK

213

ABC DEF

2430

JKLGHI MNO

879

TUVPQRS WXYZ

chg settings

press

3

Press the Left

button one time.

Press the Left button

on the Master Display

until USE SYS DEFS

appears on the

Master Display.

OK

213

ABC DEF

2430

JKLGHI MNO

879

TUVPQRS WXYZ

use sys defs

press

4

Press the OK Select

button. SAVING

DONE will appear in

the Master Display.

OK

213

ABC DEF

2430

JKLGHI MNO

879

TUVPQRS WXYZ

saving done

5

Exit programming.

Press the back button

two times to exit

programming and

return to normal

operation.

OK

213

ABC DEF

2430

JKLGHI MNO

879

TUVPQRS WXYZ

CHG COMPLETE

6

UHC6PT-22MCD

547-504-EN 3 Printed in USA 01/11 © 2011

Page 4

Universal Holding Cabinet

Management Programming

Press the Master Program button. The Master

Display will request your password. NOTE: The

default password is “1955”.

1

Enter your password. Type your password in on the

keypad and press the OK Select button.

Programmable categories will appear in the rows of

Item Displays, reading from the left.

2

Choose a

programmable

category. Press the

lit Item Timer button

to the left of the

category you wish to

program. Follow the

instructions on the

Master Display to

navigate and

program the UHC.

Confirm selections by

pressing the OK

Select button.

Press the Back

button to retreat one

level of programming

(press several times

to exit programming).

3

The first

programmable

category is MODES.

Sets the entire UHC

to one of the different

daypart modes,

Breakfast, Change

Over, Regular,

Custom 1, Custom 2,

or Cleaning. Each of

the dayparts modes is

displayed. Press the

button next to the

desired daypart mode

and then press the

OK Select button on

the Master Control

Panel. Press the Back

button on the Master

Control Panel twice to

exit programming.

brkfst

CHG OVER

REG MENU

CUSTOM 1

CUSTOM 2

Mo

SE

4

The second

programmable

category is MENUS.

Sets which food

product is assigned to

each tray in each of

the daypart modes.

Press the button next

to the daypart mode

whose menu is to

change. The name of

the food product

currently assigned to

each tray position is

displayed. Pressing

the button next to the

desired tray position

cycles through the

available food

products that can be

assigned to the tray

position. When the

desired food product

is displayed, press

the OK Select button

on the Master Control

Panel. You can

change more than

one item before

confirming by

pressing OK Select.

NOTE: Be sure to

start with the left-most

Item Display in each

row, because

changing an item may

also make changes to

items to the right in

that row due to

temperature

restrictions.

brkfst

CHG OVER

REG MENU

CUSTOM 1

CUSTOM 2

Me

SE

bagel

fold egg

Mcgriddl

Mcgriddl

rnd egg

BR

SA

5

UHC6PT-22MCD

modes

menus

pr

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

program

CHG COMPLETE

Printed in USA 01/11 © 2011 4 547-504-EN

213

ABC DEF

2430

JKLGHI MNO

OK

OK

879

TUVPQRS WXYZ

213

ABC DEF

2430

JKLGHI MNO

879

TUVPQRS WXYZ

Page 5

Universal Holding Cabinet

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Management Programming (continued)

The third

programmable

category is ITEMS.

Press the button next

to the task to be

performed, add a

food product, change

a product’s

parameters, or delete

a food product from

the UHC’s product

library. You can set

the item’s Name, Top

Temperature, Bottom

Temperature, Hold

Time and CookNow Time.

6

The fourth programmable category is LOCALE.

Choose the language for the displays and whether

temperatures are reported in Fahrenheit or Celsius.

Press the button next to LANGUAGE and a list of

available languages appears. Press the button next to

the desired language and then the OK Select button.

Press the Back button twice to exit language selection

or additional times to exit programming.

Press the button next to DEGREES to select between

Celsius and Fahrenheit. Press the button next to the

desired temperature units and then the OK Select

button. Press the Back button twice to exit language

selection or additional times to exit programming.

7

The last

programmable

category is SOUND.

Choose how loud the

alarms are. There are

four sound levels plus

silent. Press the

button next to the

desired sound level

and the OK Select

button. Press the

Back button three

times to exit

programming.

8

UHC6PT-22MCD

add item

CHG item

del item

SE

it

curre

level 1

level 2

level 3

level 4

silent

so

SE

547-504-EN 5 Printed in USA 01/11 © 2011

locale

g

englishlanguage

fahrenhtdegrees

213

ABC DEF

2430

JKLGHI MNO

OK

879

TUVPQRS WXYZ

Page 6

Universal Holding Cabinet

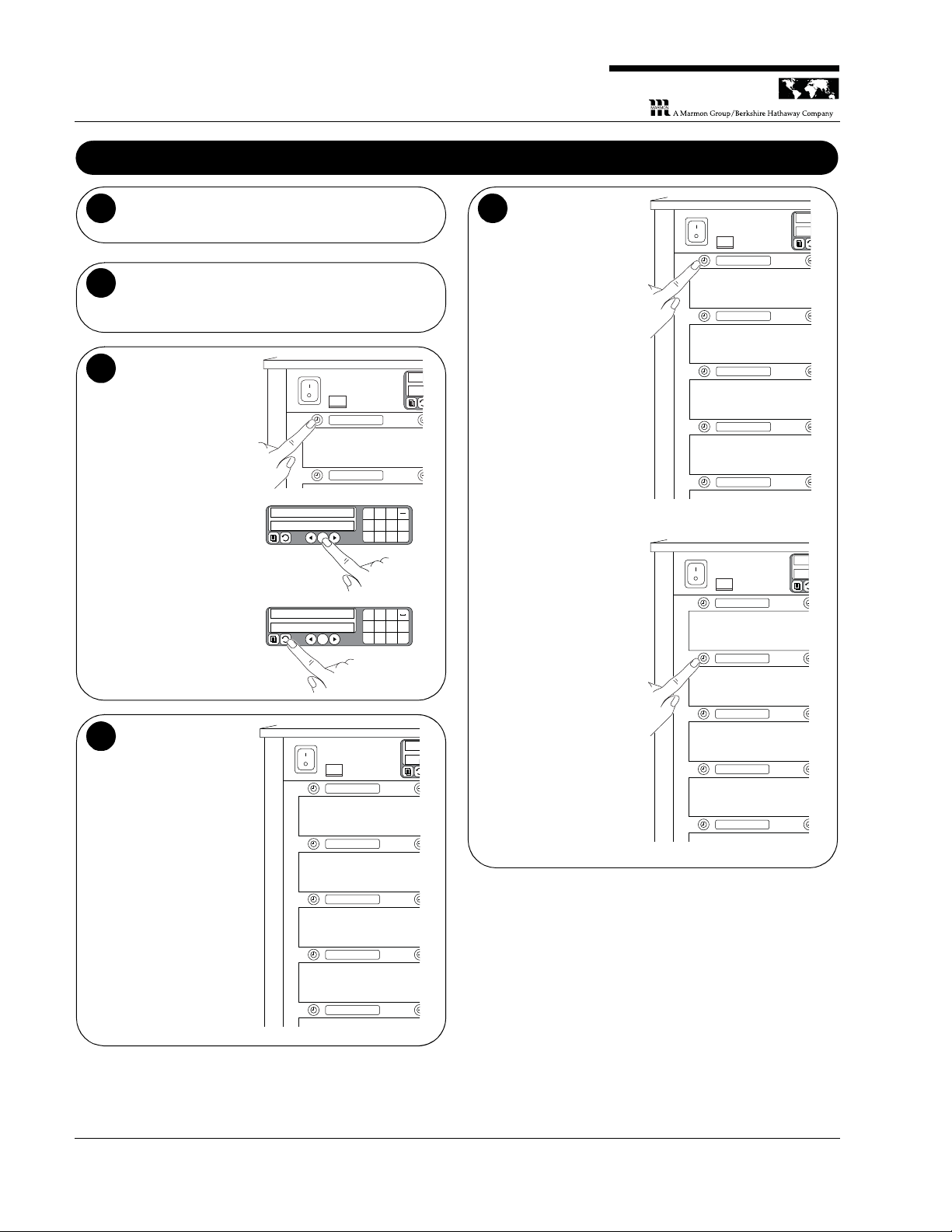

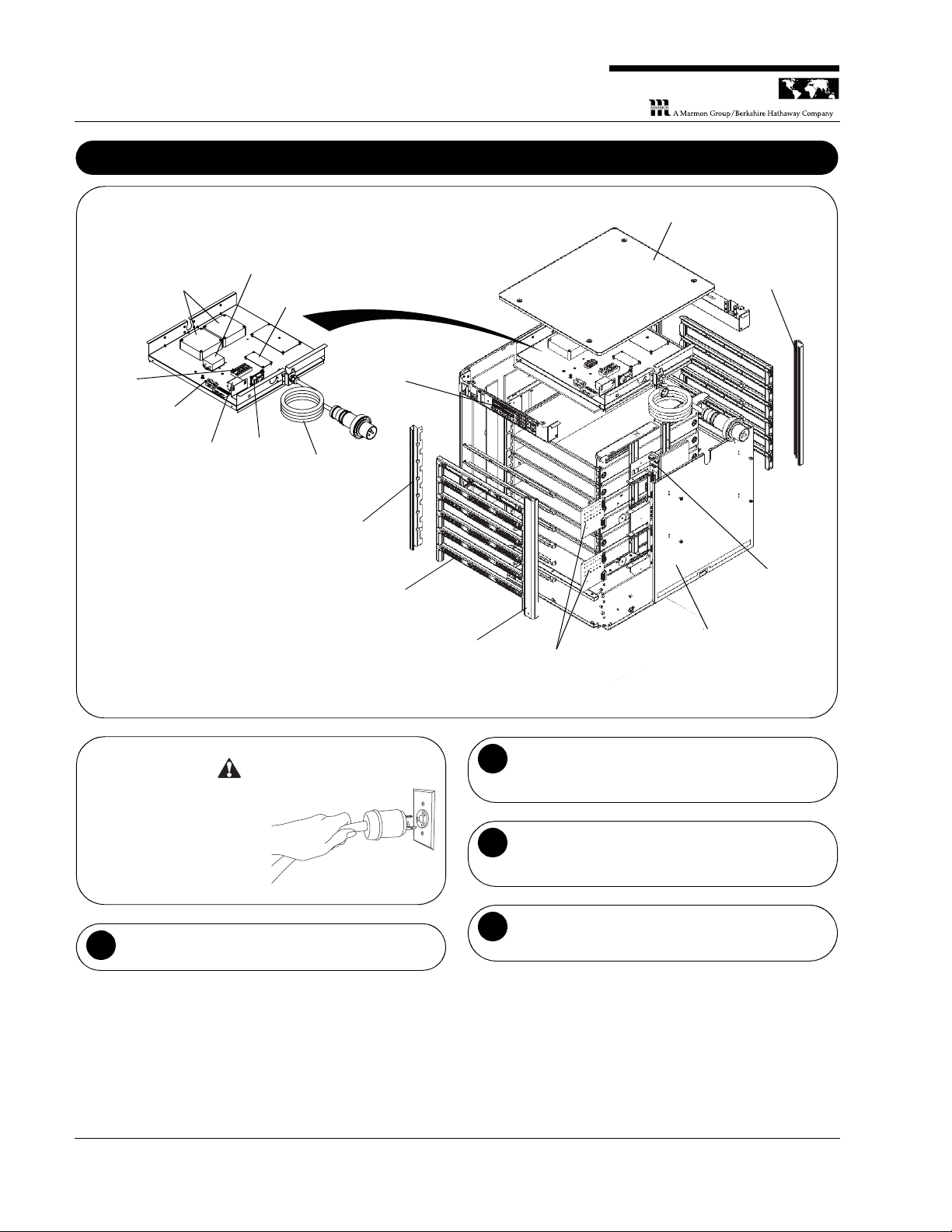

Accessing Components

Row Display

Board

Lid

Powe r

Supply

Fans

Filter

Rear Right

Corner

Front Right

Corner

Power

Cord

Speaker

Relay

Fuse Box

and Fuses

Ter minal

Block

Distribution

Board

Right Side

Panel

Heater

Boards

Front Left

Corner

Master

Display Board

Failure to disconnect power

from the unit before servicing

could result in severe bodily

injury or death. The ON/OFF

Switch does not disconnect

incoming power to the unit.

WARNING

Unplug the unit.

1

Remove the right front corner.

a. Remove the screw from the base of the corner.

b. Tilt the corner up and remove.

2

Remove the lid.

a. Remove the 4 screws on the top of the unit.

b. Lift the lid off of the unit.

3

Remove the right side panel.

a. Lift the panel up and remove.

4

UHC6PT-22MCD

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 01/11 © 2011 6 547-504-EN

Page 7

Universal Holding Cabinet

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

System Diagnostics

ENTER SYSTEM DIAGNOSTICS

a. Turn the ON/OFF switch on and wait for the Master

Display to show BRKFST MENU, then press the

Master Program button.

b. On the keypad enter 3550_9, then press the OK

Select button.

1

MASTER CONTROL BOARD DISPLAY TEST

a. Press the Right button 5 times until the Master

Display shows MCP DISPLAYS.

b. Press the OK Select button and all segments of

digit #1 on each row of the Master Display will turn

on.

c. Confirm all 14 segments of digit #1 are illuminated.

d. Press the Right button to check digit #2.

e. Continue until all 12 digits have been checked.

f. Press the Back button to exit this test.

2

MASTER CONTROL BOARD BUTTON LIGHT TEST

a. Press the Right button 1 time and the Master

Display shows MCP BTN LGTS.

b. Press the OK Select button and the Right button,

the OK Select button, the Left button, and the Back

button should light up.

c. Confirm these four buttons are illuminated.

d. Press the Back button to exit this test.

3

MASTER CONTROL BOARD BUTTON ACTUATION

TEST

a. Press the Right button 1 time and the Master

Display shows MCP BUTTONS.

b. Press the OK Select button.

c. Press every button (18 on front and 2 on back of

attic assembly), except the Back button, and watch

the Master Display to confirm that the pressed

button is recognized.

d. Press the Back button to exit this test.

4

IUC BUTTON LIGHT TEST

a. Press the Right button 1 time and the Master

Display shows IUC BTN LGTS.

b. Press the OK Select button and the Master Display

shows ALL OFF.

c. Press the Right button and the ring around all the

Item Timer buttons becomes dimly lit.

d. Press the Right button again and the ring around all

the Item Timer buttons gets brighter.

e. Press the Right button again and the lighted ring

around all the Item Timer buttons flashes on and off.

f. Press the Right button again and the flashing

lighted ring gets brighter.

g. Press the Back button to exit this test.

5

IUC BUTTON ACTUATION TEST

a. Press the Right button 1 time and the Master

Display shows IUC BTN PRSS.

b. Press the OK Select button.

c. Press the buttons on each of the 12 IUCs (total of

48 buttons) and confirm that the message on the

Master Display matches the switch name which is

in the IUC display next to the pressed switch.

d. Press the Back button to exit this test.

6

IUC DISPLAY TEST

a. Press the Right button 1 time and the Master

Display shows IUC DISPLAY1.

b. Press the OK Select button and all segments of

digit #1 light up on all the Item Displays of each IUC

(both front and back).

c. Confirm all 16 segments of digit #1 are illuminated.

d. Press the Right button to check digit #2.

e. Continue until all 8 digits have been checked.

f. Press the Back button to exit this test.

7

AUDIO TEST

a. Press the Right button 2 times and then the OK

Select button, and the Master Display shows

LEVEL 0.

b. Press the Right button 1 time and the Master

Display shows LEVEL 1.

c. Listen for an audible tone from the speaker.

d. Repeat for levels 2, 3, and 4 and the volume should

increase for each step.

e. Press the Back button to exit this test.

f. Press the Back button again to exit the system

diagnostic mode. Shortly, the Master Display will

show BRKFST MENU.

8

UHC6PT-22MCD

547-504-EN 7 Printed in USA 01/11 © 2011

Page 8

Universal Holding Cabinet

Service Tests

POWER SUPPLY TEST

a. Disconnect power and inspect all terminals and

connections for loose wires.

b. Reconnect power and check for 5V DC on output

pins of the power supply (orange wires = +V, black

wires = GND).

c. If 5V DC is not on the output pins of the power

supply, turn power off, disconnect the output

connector, turn power back on and check the

voltage between the same two pins as in the

previous step.

1

HEATER BOARD TEST

a. Disconnect power and ensure heater board

connectors are fully engaged with the receptacles

on the bus board.

b. Apply power and check for line voltage between

pins 1 and 2 on connector P3.

c. Check for 5V DC between pins 1 and 10 on

connector P2.

d. Check the operation of each triac on the heater

board by checking the voltage between the

following pins:

Triac Q1 = Pins 2 and 3

Triac Q3 = Pins 2 and 4

Triac Q6 = Pins 2 and 5

Triac Q9 = Pins 2 and 6

Triac Q11 = Pins 2 and 7

Triac Q13 = Pins 2 and 8

If the voltage reading switches between line voltage

and no voltage, the triac is working correctly. If the

voltage reading is steady at line voltage, the triac is

not turning on. If the voltage reading is very small,

the triac is turned on constantly.

2

DISPLAY TEST

a. Move a ribbon cable from a display that is working

to a failed display to determine if the failed display

is defective.

b. Reconnect all connections to original positions.

3

HEATER PLATEN TEST

a. Disconnect power and disconnect the heater

connector from the bus board.

b. Measure resistance between the two pins in

the heat connector. Resistance should be

190-220 ohms.

c. Incorrect resistance indicates a defective heater

platen.

4

UHC6PT-22MCD

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 01/11 © 2011 8 547-504-EN

Page 9

Universal Holding Cabinet

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Removing/Replacing Bezels

Unplug the unit.

1

Failure to disconnect power

from the unit before servicing

could result in severe bodily

injury or death. The ON/OFF

Switch does not disconnect

incoming power to the unit.

WARNING

Remove the screw. Remove the screw from the base

of the front right corner if the bezel to be removed is on

the front of the unit. If the bezel to be removed is on

the back of the unit (the side without the Master

Control), remove the screw from the base of the rear

right corner.

2

Tilt the corner up

and remove.

Right Front

Corner

3

Slide the bezel toward the open corner and then

pull outward. NOTE: The back side of the bezels

should be wiped with a damp, clean towel once every

three months.

4

If the bezel is being

replaced,

disconnect the

ribbon cable and

connect it to the

replacement bezel.

Hole in

Row

Ribbon

Cable

Bezel

5

To reassemble, align the three plastic protrusions

on the back of the bezel with the three holes in the

row and push inward.

6

Slide the bezel toward the closed corner. The bezel

should now line up with the other bezels at the open

corner.

7

Reassemble the corner.

8

UHC6PT-22MCD

547-504-EN 9 Printed in USA 01/11 © 2011

Page 10

Universal Holding Cabinet

Removing/Replacing Heater Boards

Unplug the unit.

1

Failure to disconnect power

from the unit before servicing

could result in severe bodily

injury or death. The ON/OFF

Switch does not disconnect

incoming power to the unit.

WARNING

Remove the right front corner.

2

Disconnect ribbon cables. Disconnect ribbon cables

that may interfere with forward movement of the heater

board being removed.

3

Lift both ejector

tabs on the

heater board to

disconnect it

from the bus

board.

Ejector Tabs

Heater

Board

4

Slide the heater board forward and out. Hold any

connections out of the way while sliding the heater

board so they don’t impede movement.

5

To reassemble, align the replacement heater

board. The top and bottom of the heater board must

be fit into the top and bottom grooves.

6

Slide the replacement heater board in and back.

Hold any connections out of the way while sliding the

heater board back in.

7

Reconnect the heater board to the bus board by

firmly pushing on the ejector tabs. Make sure the

board-to-board connectors are fully seated together.

8

Reconnect any disconnected ribbon cables.

9

Reassemble the unit.

10

UHC6PT-22MCD

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 01/11 © 2011 10 547-504-EN

Page 11

Universal Holding Cabinet

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Removing/Replacing Distribution Board

Unplug the unit.

1

Failure to disconnect power

from the unit before servicing

could result in severe bodily

injury or death. The ON/OFF

Switch does not disconnect

incoming power to the unit.

WARNING

Disassemble the

unit to access

the distribution

board. Remove

the right front

corner, lid and

right side panel

according to

Accessing

Components

section.

Distribution

Board

2

Label and disconnect connections. NOTE: Be sure

to label each of the 26 connections before

disconnecting.

3

Remove both heater boards from the bus board.

4

Remove screws. Remove and save the screws

holding the distribution board to the unit.

5

To reassemble, align the replacement distribution

board.

6

Replace the screws.

7

Reattach both heater boards to the bus board.

8

Reconnect connections. Using your labels as a

guide, reconnect the 26 connections.

9

Reassemble the unit.

10

UHC6PT-22MCD

547-504-EN 11 Printed in USA 01/11 © 2011

Page 12

Universal Holding Cabinet

Removing/Replacing Rows

Unplug the unit.

1

Failure to disconnect power

from the unit before servicing

could result in severe bodily

injury or death. The ON/OFF

Switch does not disconnect

incoming power to the unit.

WARNING

Disassemble the unit to access the faulty row.

Remove the lid, both side panels, and all four corner

pieces from the unit.

2

Label and

disconnect

connections.

NOTE: Be sure to

label each of the

wires before

disconnecting the

row wires from

the distribution

board.

Row

Bezel Attachment

Strip

Bezel

3

Access the faulty row. Remove the necessary

bezels and the two bezel attachment strips on the top

and bottom of the faulty row. Remove the four side

bolts securing the row to the unit.

4

Remove the faulty row. Carefully slide the row out of

the unit, feeding the attached wires through the row

opening.

5

Replace the row. Align the replacement row and the

unit. Carefully slide the insulation wrapped row into the

unit, routing the wires through to the back of the unit.

6

Replace the screws. Replace and secure the four

side bolts.

7

Reconnect connections. Using your labels as a

guide, reconnect the distribution board connections.

8

Reassemble the unit. Reattach the bezel attachment

strips, the bezels, the four corner pieces, both side

panels and the lid.

9

Replacing Heater Platen/Probe Assembly

Remove the row. Disassemble the unit and remove

the row according to Removing/Replacing Rows

section.

1

Access the

faulty heater

platen. Slide the

row from the

heater insulation

wrap. Remove

the four

setscrews

attaching the

faulty heater

platen to the

platen rail.

Heater

Platens

Insulation

Wrap

Setscrew

Platen

Rails

2

Remove the heater platen. Carefully slide the platen

out of the rail.

3

Replace the heater platen. Align the replacement

heater platen and the platen rail. Carefully slide the

platen into the rail. Replace and secure the four

setscrews. Neatly recover the row unit with the heater

insulation wrap.

4

Reassemble the unit. Replace the row and

reassemble the unit according to Removing/Replacing

Rows section.

5

UHC6PT-22MCD

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 01/11 © 2011 12 547-504-EN

Page 13

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Troubleshooting

MASTER DISPLAY MESSAGES

PROBLEM PROBABLE CAUSE SOLUTION

Left-most Item Display in affected

row reads: HI TEMP

Left-most Item Display in affected

row reads: LOW TEMP

Left-most Item Display in affected

row reads: CALL SERVICE

ROW TEMP TOO HIGH

and alarm sounds

Left-most Item Display in affected

row reads: CALL SERVICE

ROW TEMP TOO COOL and alarm

sounds

Left-most Item Display in affected

row reads: CALL SERVICE TEMP

SENSOR ERROR and alarm

sounds

Left-most Item Display in affected

row reads: CALL SERVICE RATE

OF RISE and alarm sounds

Master Display reads: CALL

SERVICE DISTRIBUTION BOARD

ERROR and alarm sounds

Master Display reads:CALL

SERVICE ROW DISPLAY BOARD

ERROR and alarm sounds

PROBLEM PROBABLE CAUSE SOLUTION

Unit will not turn on and fans don’t

run

While turned on, one display won’t

light

While turned on, all displays won’t

light

While turned on, one row will not

heat or heats improperly

Row is changing to a

temperature that is lower than

its current value.

Row is changing to a

temperature that is higher than

its current value.

Slot temperature is more than

10°F (6°C) above setpoint for

more than 15 minutes.

Slot temperature is more than

10°F (6°C) below setpoint for

more than 15 minutes.

There is a problem with the

temperature probe.

A row is taking longer than 30

minutes to reach minimum

temperature — there is a

problem with the temperature

probe or heater in row.

Heaters for 3 rows will not

operate — distribution board is

down.

One of the Item Displays is not

operating.

OTHER FAILURE CONDITIONS

There is an exterior power

supply problem.

There is a problem with the

ribbon cable or display.

There is an internal power

supply problem.

There is a problem with that

row’s heater board, heater

platen or probe.

Wait for temperature to change before using slot.

Wait for temperature to change before using slot.

• Using a stand-alone temperature meter, check the actual heater

platen temperature and compare it to the displayed

temperature.

• To make sure the heater is responding to the unit’s circuits,

press that row’s Row Mode button until OFF appears in the Item

Displays and press the OK Select button. Then press the Row

Mode button until an active mode appears and press OK Select.

• Heater platen may be defective — refer to Heater Platen Test.

• Inspect the probe’s ribbon cable connection.

• Replace probe — refer to Replacing Heater Platen/Probe

Assembly.

• Turn the ON/OFF switch off and on to clear any software

problem.

• To make sure the heater is responding to the unit’s circuits,

press that row’s Row Mode button until OFF appears in the Item

Displays and press the OK Select button. Then press the Row

Mode button until an active mode appears and press OK Select.

• Heater platen may be defective — refer to Heater Platen Test.

• Move a probe lead from a row that is working to this failed row

to determine if a probe is defective.

• Replace probe — refer to Replacing Heater Platen/Probe

Assembly.

• Turn the ON/OFF switch off and on to clear any software

problem.

• Inspect the board’s ribbon cable connections.

• Check for line voltage at the ON/OFF switch and the

transformer.

• Reset the circuit breaker.

• Inspect the display’s ribbon cable connection.

• Move a ribbon cable from a display that is working to this failed

display to determine if this display is defective.

• Check for 5V DC on output pins of the power supply — refer to

Power Supply Test.

• Make sure that leads and inputs are securely seated on the

heater boards.

•Perform Heater Board Test.

• Move power leads from a row that is working to this failed row to

determine if this heater is defective.

• Move a probe lead from a row that is working to this failed row

to determine if a probe is defective.

Universal Holding Cabinet

UHC6PT-22MCD

547-504-EN 13 Printed in USA 01/11 © 2011

Page 14

Universal Holding Cabinet

UHC6PT-22MCD

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

UHC IN STORE TROUBLESHOOTING

SYMPTOM RECOGNITION

Item Displays on a timer bar are blank and there is no error

message on the Master Display.

Parts of the displayed characters on a timer bar are

missing.

Parts of the displayed characters on a timer bar remain lit

all the time.

Pressing Item Timer button does not start product timer. A

Item Timer button does not light up when pressed. A

“ERROR” appears on a timer bar display when the unit is

turned on.

The displayed items are not correct but instead are a

duplicate of another timer bar.

Error message on Master Display says “CALL SERVICE

ROW DISPLAY BOARD ERROR xxx”.

Error message on affected timer bar display says “CALL

SERVICE ROW TEMP TOO COOL Rx” where x = row (1-

6).

Error message on affected timer bar display says “CALL

SERVICE ROW TEMP TOO HIGH Rx” where x = row (1-6).

Error message on affected timer bar display says “CALL

SERVICE RATE OF RISE Rx” where x = row (1-6).

Error message on affected timer bar display says “CALL

SERVICE TEMP SENSOR ERROR Rx zzz” where x = row

(1-6) and zzz = TOP or BOT.

UHC TROUBLESHOOTING TEST STEPS

A 1 Replace the display bar (see section on display bar

removal).

B 1 Turn off power to the UHC and remove the corner

cover of the affected side and check the connection

of the cable to the display bar. Turn power on and

check for proper operation. If error is not fixed,

continue with step 2.

2 Turn the power off and swap the connector of the

affected display bar and the working display bar

above or below and turn the power on. If the error

stays on the affected display bar REPLACE THE

DISPLAY BAR.

3 If the error shifts to the other display bar, call your

service agent.

C 1 Turn power off and remove the metal corner cover

(right side when looking at the front of the unit, left

side when looking from the back of the unit).

2 Turn the power switch off, wait 10 seconds, turn the

power switch on and in the right most display of each

display bar a position code should be briefly

displayed.

FR1 = top front row BR1 = top back row

FR2 = front row #2 BR2 = back row #2

FR3 = front row #3 BR3 = back row #3

FR4 = front row #4 BR4 = back row #4

FR5 = front row #5 BR5 = back row #5

FR6 = front row #6 BR6 = back row #6

3 Note which display bar displays the wrong position

code and slide it towards the end where the cable is

connected (right on front-side, left on back-side).

4 Slide the display bar with the same position code

towards the end where the cable is connected.

A

A

A

B

C

D

E

F

G

H

5 Swap the connectors between the two display bars.

6 Turn the power switch off, wait 10 seconds, turn the

power switch on.

7 If the display bar that showed the wrong position

code still shows the same code - Replace the display

bar.

8 If the same two display bars still show the same

position code - Call a service technician.

D 1 Turn power off and remove the metal corner cover

(right side when looking at the front of the unit, left

side when looking from the back of the unit).

2 Refer to the following position code list to determine

which display bar appears to have a problem.

FR1 = top front row BR1 = top back row

FR2 = front row #2 BR2 = back row #2

FR3 = front row #3 BR3 = back row #3

FR4 = front row #4 BR4 = back row #4

FR5 = front row #5 BR5 = back row #5

FR6 = front row #6 BR6 = back row #6

3 Slide the display bar identified in the error message

towards the end where the cable is connected.

4 Make sure the cable connector is fully connected

with the connector on the display bar.

5 If the connector was loose, turn the unit’s power

switch on, and continue this check if after 60

seconds the same message re-appears on the

master display.

6 Slide a display bar either directly above or below the

bar exhibiting the problem towards the end where

the cable is connected.

7 Swap the connectors between the two display bars.

8 Turn the power switch off, wait 10 seconds, turn the

power switch on and wait 60 seconds.

9 If the position code in the error message changes -

Replace the display bar identified in the original error

message.

10 If the position code in the error message remains the

same - Call a service technician.

E 1 Loosen the retaining screw at the bottom of the front

right corner cover of the unit, swing it up and remove

it.

2 Check that the red LEDs on both heater control

boards are blinking at about the same rate (NOTE:

during normal operation they will not always both be

on at the same time).

3 NOTE: Rows 1-3 are controlled by the upper heater

control board while rows 4-6 are controlled by the

lower heater control board.

If the LED on the heater control board associated

with the row displaying the error message is blinking

at a different rate from the other board, or not at all,

turn off the power switch and proceed to step 5.

4 If both LEDs are blinking correctly proceed to step

10.

Printed in USA 01/11 © 2011 14 547-504-EN

Page 15

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

5 Remove and reconnect the heater control board

whose LED is not blinking correctly (see section on

heater control board replacement). Turn on the

power switch, wait 15-20 seconds, and check if the

LED on the repositioned heater control board starts

to blink.

6 If the LED on this board is still not blinking turn off

the power switch and switch the two heater control

boards.

7 Turn on the power switch, wait 15-20 seconds, and

check the LEDs on the heater control boards.

8 If the LED is still not blinking correctly on the board in

question - Replace that heater control board.

9 If the LED starts blinking on the board in question but

has now stopped blinking on the other heater control

board - Call a service technician.

10 Remove and reconnect both heater control boards

(see section on heater control board replacement).

Turn on the power switch and wait approximately 20

minutes to see if the error appears again.

11 If the error message reappears check for a change in

airflow around the unit that may be cooling the

heaters.

12 If nothing around the unit has changed - Call a

service technician.

F 1 Press the Master Temperature button at the top of

the unit.

If the displayed temperature on the row that showed

the error message is above 210°F (99°C) check if a

batch of an item was put into the unit at a

temperature much higher than normal.

2 If all the product temperatures are normal - Call a

service technician.

G 1 Press the Master Temperature button at the top of

the unit.

2 If the displayed temperature on the row that showed

the error message is below 160°F (71°C) check for a

change in airflow around the unit that may be cooling

the heaters.

3 If nothing around the unit has changed - Call a

service technician.

H 1 Turn off the power and remove the right front corner

cover.

2 Switch the heater control boards and turn the power

on.

3 If the error message reappears on a different row -

Replace the heater control board associated with the

error.

4 If the error message reappears on the same row -

Call a service technician.

Universal Holding Cabinet

UHC6PT-22MCD

547-504-EN 15 Printed in USA 01/11 © 2011

Page 16

Universal Holding Cabinet

Exploded View and Parts List

ITEM PART NO. DESCRIPTION QTY

1 547-004 Right Wall Assembly 1

2 547-035 Base Assembly 1

3 547-007 Left Wall Assembly 1

4 547-123 Attic Electrical CE Assembly 1

5 547-033 MCU Assembly 1

6 547-014 Upper Rear Assembly 1

7 547-074 Left Cover Weldment 1

8 547-073 Right Cover Weldment 1

9 547-030 Card Guide Assembly 1

10 547-079 Card Guide (DIGIKEY #: SDC-400) 4

11 547-119 2

12 547-099 Front Left Corner 1

13 547-100 Back Left Corner 1

14 547-020 Lid 1

15 547-023 Front Right Corner 1

16 547-024 Rear Right Corner 1

17 547-103 Base Pad 1

18 547-090 Right Wall Insulation 2

19 547-089 Top and Bottom Insulation 1

20 547-091 Left Wall Insulation 1 1

21 547-095 Left Wall Insulation 2 2

22 547-096 Left Wall Insulation 3 1

23 547-017 Platen Rail 12

24 547-061 Heater Platen 12

25 547-048 Heater Insulation Wrap 6

26 76-900 Knurled Cup Setscrew (McM#:

93445A315 or Equivalent)

48

27 76-619 SCR, HXCP, SS 1/4-20 x 7/16* 1

28 76-908 XXX* 24

29 547-058 IUC Assembly 12

30 547-067 Hanger Bolt 8

31 073-008 Nut, Self-Lock, 10-32, Thin, SS* 8

32 547-223 Bus Board 1

33 547-221 Heater Board 2

34 88-790 Lug, Ground Bond #2-#14 GA* 1

35 076-864 Screw, PNPH, SS, 8-32 x 3/8* 44

36 76-902 #8-32 x 0.375 PHPS* 2

37 79-178 #8 Captive Washer* 2

38 547-080 Grommet (McMaster-Carr Part No.

5269T64 or Equivalent)

1

39 076-230 SCR, PHRD, SS, 8-32 x 3/8* 16

40 069-011 Rivet, Pop, Dome-Head, Open-End, SS,

1/8 x 0.265*

3

41 547-111 IUC Mount* 12

42 076-037 * 8

43 547-130 Bridge Bracket Connector Assembly* 1

44 069-011 Rivet, Pop, Dome-Head, Open-End, SS,

1/8 x 0.265*

4

45 76-910 XXX* 8

* Not Shown

ITEM PART NO. DESCRIPTION QTY

3

25

8

23

17

2

1

10

30

9

Heater Assembly

Exploded View

11

32

5

18

7

15

29

12

33

21

20

22

4

19

14

6

16

38

13

24

26

UHC6PT-22MCD

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Printed in USA 01/11 © 2011 16 547-504-EN

Page 17

Universal Holding Cabinet

P

RINC

E

C

A

STL

E

LLC

WORLDWIDE

Wiring Diagram

UHC6PT-22MCD

547-504-EN 17 Printed in USA 01/11 © 2011

Loading...

Loading...