Page 1

HEATED LANDING SHELFS

PRINCE CASTLE MODEL NO. STB-11 & STB-22 SERIES

This equipment chapter is to be placed in the

Miscellaneous Section of your Equipment Manual

MANUFACTURED BY

PRINCE CASTLE INC.

355 E KEHOE BLVD

CAROL STREAM, IL 60188 USA

PHONE 1-630-462-8800

TOLL FREE NUMBER

1-800-323-2930

FAX: 1(630)462-1460

TABLE OF CONTENTS

WARRANTY ............................................................................................................................................ Page 1

INTRODUCTION .................................................................................................................................... Page 2

PARTS IDENTIFICATION ..................................................................................................................... Page 2

EXPLODED VIEW .................................................................................................................................. Page 3

EQUIPMENT SET-UP AND CLOSE PROCEDURES........................................................................ Page 4

ORDERING PARTS AND SERVICE .................................................................................................... Page 4

TROUBLESHOOTING ........................................................................................................................... Page 5

TRANSLATIONS (FRENCH, GERMAN, SPANISH, ITALIAN) ........................................................... Page 6-13

WIRING DIAGRAMS .............................................................................................................................. Page 14-16

MODEL NO. STB-11

MODEL NO. STB-22

LIMITED WARRANTY

This product is warranted to be free from defects in material and/or workmanship for a period of (2)

years from date of original installation not to exceed 30 months from date of shipment from our factory.

Printed circuit boards and platen are warranted for a period of (3) years from date of original installation

not to exceed 42 months from date of shipment from our factory. Any part or component which proves

to be faulty in material and/or workmanship within the warranty period will be replaced or repaired

without cost to the customer for parts or labor. (At the option of Prince Castle, Inc.)

This warranty is subject to the following exceptions/conditions:

z This warranty covers on location service (i.e., trip charges and or mileage). Travel mileage is

limited to 100 miles (200 kilometers) round trip (one trip per warranty) from an authorized Service

Agency or it's sub-service agency. All labor must be performed during regular working hours. Overtime premium will not be covered.

z Any use of non-genuine Prince Castle replacement spare parts voids this warranty.

z Damage caused by carelessness, neglect, and/or abuse (e.g., using wrong current, dropping , tam-

pering with or altering electrical components, or improper cleaning) is not covered.

z Equipment damaged in shipment, by fire, flood or an act of God.

This manual is for the exclusive use of licensees and employees of McDonald's Systems, Inc.

©1998 McDonald's Corporation

All Rights Reserved

Printed March

Part No. 536-507

EM 41

The United States of America

Printed in

Page 2

INTRODUCTION

The Heated Landing Shelfs are designed for special venues where space is at a premium.The STB-11 holds up

to 16 sandwiches on one shelf.The STB-22 holds up to 32 sandwiches on two shelves.

Adjustable lane dividers can be realigned for existing or new products. The Shelfs have adjustable heaters to

maintain correct temperatures at various locations. Plastic Trays are used for Regular Hamburgers and Regular

Cheeseburgers only.

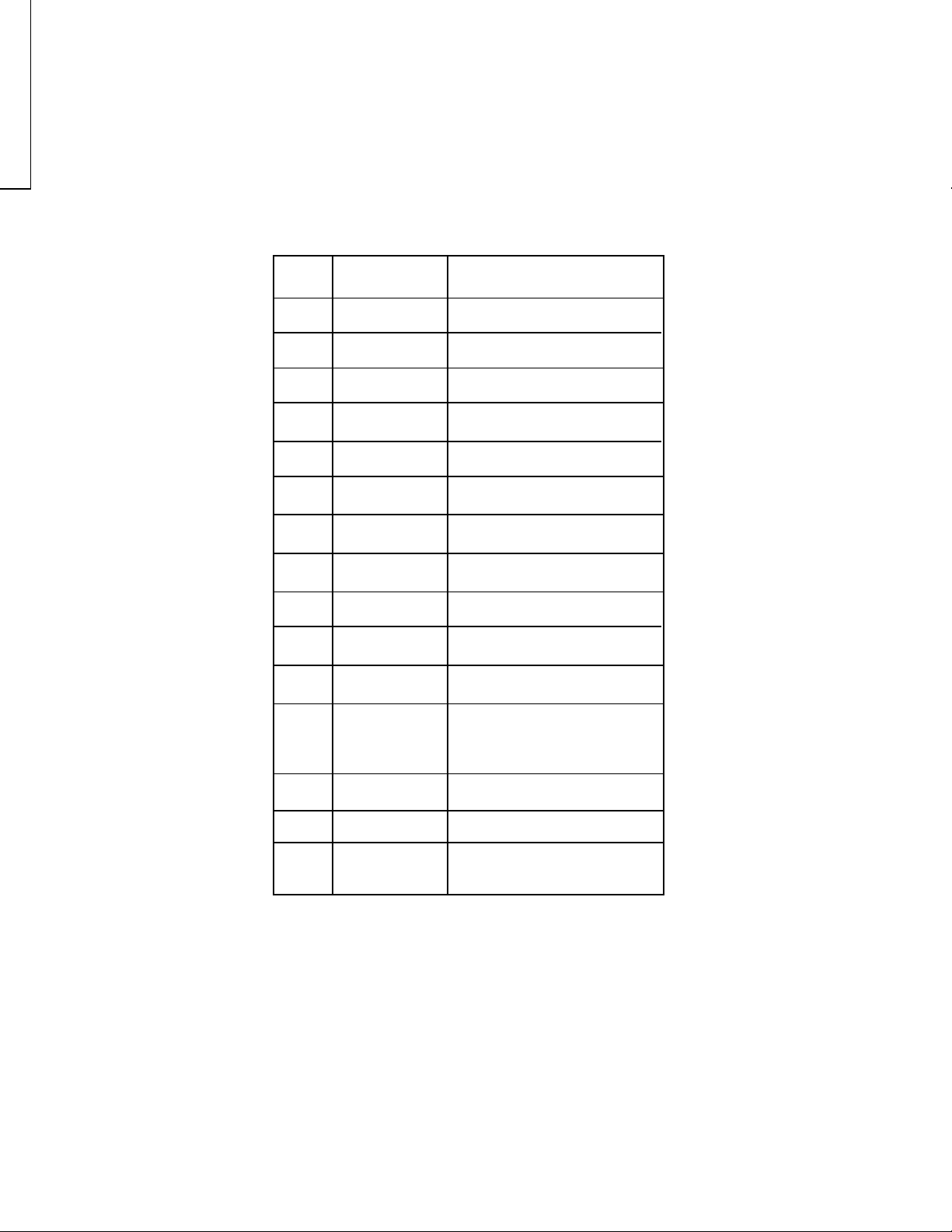

PARTS IDENTIFICATION LIST

ITEM PART NO. DESCRIPTION

2

3

4

5

6

7

8

9

10

11

12

13

536-23

536-17

65-037S

76-640

73-015

536-33

536-9S

411-133s

89-156

213-257S

78-166S

72-207S

72-200-11

72-234S

Lane Divider

Wire Rack

Solid State Relay

Slotted Binder Head Screw

Hex Nut

Potentiometer Door

P.C. Board Assy

Potentiometer Assy.

Spacer

Pilot Light

Rocker Switch

Power Cord (STB-22)

Power Cord (STB-11)

Power Cord (CE)

14

15 z

536-31

536-45S

z NOT

SHOWN

Control Panel Assy.

Heater

2

Page 3

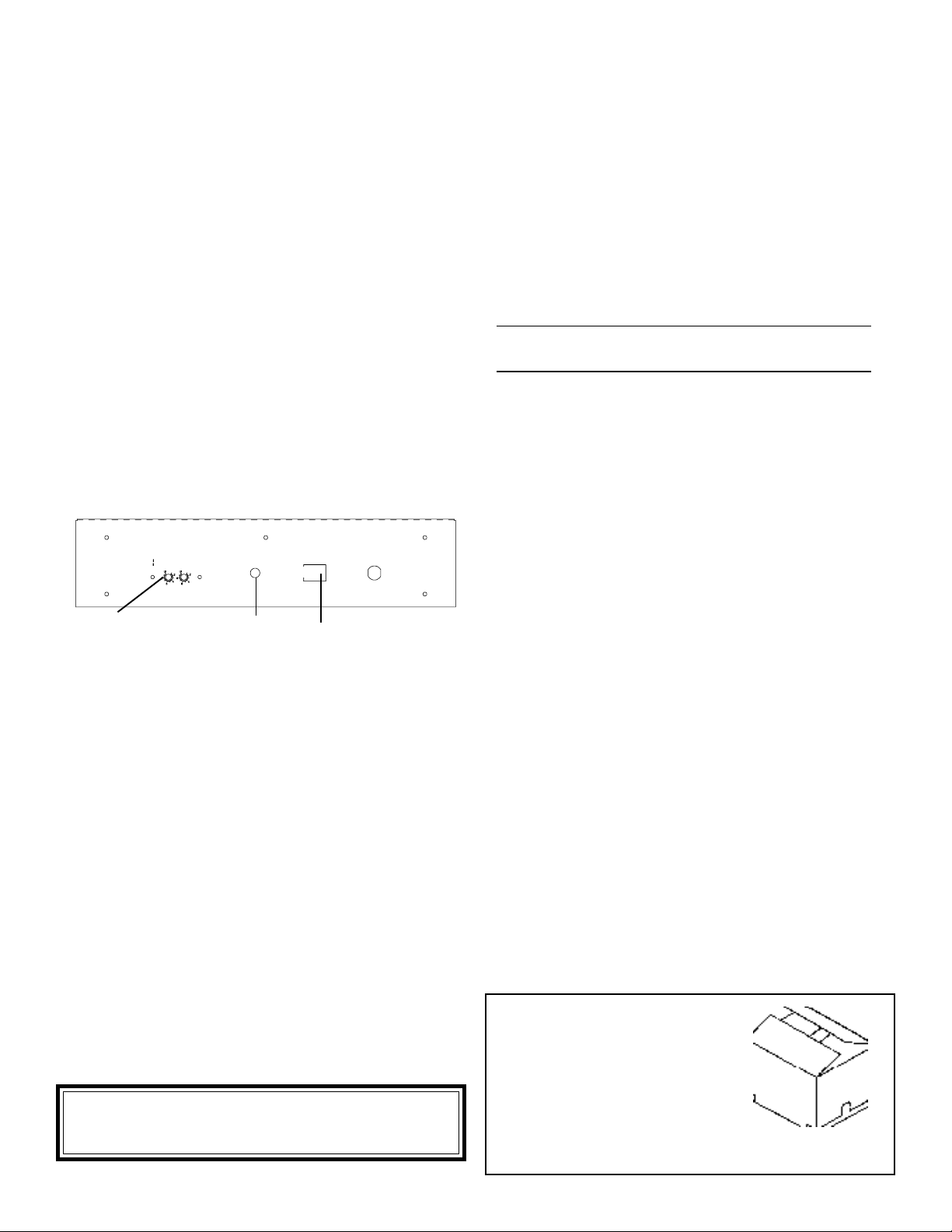

Set - up

EQUIPMENT SET-UP AND

CLOSE PROCEDURES

ORDERING / SERVICE INFORMATION

PARTS

1. Place Heated Landing Shelf on counter.

2. Insert the 6 FT Power Cord W/ NEMA 15-P Plug into

a 120 Volt, grounded outlet. NOTE: International

units come with a 6 FT Power Cord with no Plug

attached. International units should be attached to a

220 Volt, 50/60 Hertz, Single Phase Outlet.

NOTE: This should be a dedicated outlet. No other

equipment should be operating on this line (i.e.

fryers, refrigerators, cash registers, etc.)

3. Turn Power Switch (A) "ON". The Amber Power

Light (B) will turn on. Allow 20 minutes for warm-up.

FRONT CONTROL PANEL

CAUTION - HOT CAUTION - HOT

LOWER

UPPER

HEATER

HEATER

NOTE: STB-11 has

POWER

ON

B

OFF

ON

A

(1) Adjustment Potentiometer

1. WHERE AND HOW TO ORDER REPLACEMENT

PARTS.

To order replacement parts. Look on the back of

the price list for your local Prince Castle Service

Center, or call Prince Castle at 1-800-323-2930

and we will help you.

Then call your local Prince Castle Service Center.

Fill in name and number here.

INTERNATIONAL

Contact your kitchen Equipment Supplier or designated

repair facility for parts and service.

2. PARTS RETURNS

Should the need ever arise to return parts to your

Center for credit, it is necessary that you:

Obtain authorization from your Service Center

for such return;

All warranty situations should be handled by your

Service Center.

3. PRICES

4. Snap in Wire Racks with lip to counter.

5. Place all other products on the wire rack.

6. Refer to your operation and procedure manual for

correct holding times.

Close Procedures

Caution: Before unplugging power cord make sure

Power Switch is in "OFF" position.

1. Unplug Heated Landing Shelf From outlet.

2. Allow unit to cool down.(About 15 Minutes)

3. Wipe down with a damp cloth.

.

CAUTION: When cleaning do not pour water on

the heaters. This may cause an electrical hazard

and damage to the sensitive solid state circuitry.

A. All prices are F.O.B. Prince Castle Service

Center or F.O.B. factory, Carol Stream Illinois.

B. All prices are subject to change without notice.

These prices are exclusive of all sales taxes or any

special taxes which may be levied by federal, state,

or city governments.

Parts price lists are sent to the U.S.A. restaurants

once a year, which indicates the prices available

from your local Center.

4. TERMS

Net 30 days.

INSPECT

CARTON

Remove product from carton...

if damaged:

Notify Carrier

Save caton and packing material

Contact Prince Castle Customer Sales for replace-

ment.

4

Page 4

EXPLODED VIEW

NOTE: The one and two shelf Transfer Bins have the same internal parts.

3

Page 5

TROUBLESHOOTING GUIDE

In the event that the shelve(s) do not heat, first determine that power has not been interrupted to the Heated

Landing Shelf . This can easily be confirmed by the "POWER ON" light on the control panel. Assuming that the

unit has power, determine whether or not the temperature adjustments are at their proper settings.

To fully diagnose the Heated Landing Shelf further, it will be necessary to access the control compartment. To

accomplish this, first unplug the power cord, remove the four (4) corner screws and the top center screw on the

cover, and slide the drawer out. The cover must be lifted over the lip of the chassis before the drawer can be

pulled out. Replug the power cord. Turn the Heated Landing Shelf on.

CAUTION: HAZARDOUS VOLTAGE PRESENT WITHIN CONTROL COMPARTMENT. Do not touch any

connector or Printed Circuit Board while the Heated Landing Shelf is plugged in.

Note the four red LEDS on the printed circuit board under the letters "UPR" (meaning upper) and "LWR" (meaning

lower). The upper two LEDs indicate that the circuitry is telling the Heater Control Relays to turn on ("RLY SIG").

The lower LEDs indicate that the Heater Control Relays are on ("RLY ON").

PROBLEM CAUSE

"RLY SIG" LED does not turn on,

even when temperature setting is

increased.

"RLY SIG" LED is on, but "RLY ON"

LED is off.

"RLY SIG" and "RLY ON" LEDs are

both on but no heat.

Too much heat. "RLY SIG" and

"RLY ON" LEDs stay on even when

temperature setting is decreased.

Temperature Adjust disconnected

1.

from circuit board.

Inoperable Circuit Board.

2.

InoperableTemperature Adjust Con-

3.

trol.

Temperature Sensor Wire Discon-

4.

nected at Circuit Board.

Temperature Sensor Wire Discon-

5.

nected within cabinet.

"RLY CONTROL" connector loose.

1.

"RLY DIAGN" connector loose.

2.

Loose connection on Heater

3.

Control Relay.

Inoperable Heater Control Relay.

4.

Loose connection in heater

1.

harness within cabinet.

Inoperable Heater.

2.

Inoperable Temperature Adjust

1.

Control.

Inoperable Circuit Board.

2.

SOLUTION

1.

Reconnect Temperature Adjust to

Circuit Board.

2.

Replace Circuit Board.

3.

Replace Temperature Adjust Control.

4.

Check Sensor Wire Connection on

Circuit Board.

5.

Check Sensor Wire Connection inside Cabinet.

1.

Check Connector for tightness.

2.

Check Connecter for tightness.

3.

Check Connection To Relay.

4.

Replace Heater Control Relay.

1.

Check all Heater Harness Connections.

2.

Replace Heater.

1.

Replace Temperature Adjust Control.

2.

Replace Circuit Board.

Too much heat. "RLY SIG" LED is

off but "RLY ON led is on.

Heated Landing Shelf is heating

okay, but no "POWER ON" light.

No heat. "POWER ON" light, "RLY

SIG", and "RLY ON" LEDs are off.

Heated Landing Shelf is plugged in

and turned on.

Inoperable Heater.

3.

Inoperable Heater Control Relay.

1.

"PWR LIGHT" connector loose.

1.

Inoperable "POWER ON" light.

2.

Tripped circuit breaker in store.

1.

"PWR SWITCH" connector loose.

2.

Connections at Power Switch loose.

3.

Inoperable Circuit Board.

4.

Inoperable Power Switch.

5.

6.

Inoperable Power Cord.

5

3.

Replace Heater.

1.

Replace Heater Control Relay.

1.

Check "PWR LIGHT" Connection.

2.

Replace "POWER ON' light.

1.

Check Circuit Breaker in store.

2.

Check "PWR SWITCH" Connection.

3.

Check Power Switch Connection.

4.

Replace Circuit Board.

5.

Replace Power Switch.

6.

Replace Power Cord.

Page 6

CARD NO.

HEATED LANDING SHELF

Planned Maintenance System

Maintenance Requirement Card (MRC)

Temperature & Calibration of STB-22& STB-11

The Heated Landing Shelf leaves the factory with the plate temperature set at 225-230 F. ( 107-110

C.)Readings with the Surface Probe should be taken at the surface of the heaters 2" to the right of the

center screw on top and bottom (SEE FIGURE BELOW). NOTE: Because the location of the Heated

Landing Shelf may vary from restaurant to restaurant there may be a need to adjust the

temperature setting due to climate control conditions in that location.

○○○

HEATER

SURFACE

2"

○○○

CENTER

SCREW

oo

72

The following "Water Test" is intended for use only when the integrity of the Heated Landing Shelf is

questioned by regulatory agencies, ie; health department, etc.

MATERIALS REQUIRED:

1ea. 8oz. paper(CAUTION: Do not use "Waxed Paper Cup) or styrofoam coffee cup with lid (lid may

be plastic)

1ea. "K" type thermometer and probe, or a conventional bulb type thermometer capable of reading in the

100-200 F. range (35-100 C.)

PRODUCT SIMULATION:

Place 4 tablespoons (1/4 cup) of water in the paper cup. Use hot water, or microwave until the temperature

of the water measures 155-160 F. (68 - 71 C.)Immediately place the lid on the cup and place the cup

anywhere on the wire rack in the Transfer Bin.

WARNING: DO NOT place any object under the cup (paper, plastic, foil, cardboard, etc...) to help

"balance the cup" on the rack.

After 10 minutes, place the cup on the counter, immediately insert thermometer end (or needle probe) thru

a small (1/4" max.) hole in the lid, and record the temperature of the water. If the temperature is between

140-150 F (60 - 65 C.) the unit is operating as intended. If the temperature of the bin is too high or too

low it can be adjusted by turning the adjustment potentiometer located behind the access door on the front

of the transfer bin.

NOTE: To raise access door loosen the screw in between the two heater pots,(NOTE: on STB-11

screw above single Pot) then raise up exposing the adjustment potentiometer(s) .

o

o

o

o

o

o

Turning the pot clockwise will adjust the temperature up, turning it counter clockwise will adjust it down.

Each small mark will cause about a 5 Degree adjustment in temperature.

Page 7

WIRING DIAGRAM

6

Page 8

WIRING DIAGRAM

(STB-11)

6

Page 9

WIRING DIAGRAM

(STB-22)

7

Loading...

Loading...