Page 1

Operation

Manual

Product Identification

The 630-ROM4 Romar Pasta Cooker automates fresh

cooking and dispensing of individual servings of dry

pasta. At the touch of a button, a pasta hopper

dispenses an individual portion of dry pasta, then uses

pressure, water and steam to rapidly cook the pasta to

perfection every time in about 3 minutes per serving.

This product is warranted to be free from defects in material and/or

workmanship for a period of one (1) year from date of original

installation, not to exceed 30 months from date of shipment from

our factory. Any component which proves to be faulty in material

and/or workmanship will be replaced or repaired (at the option of

Prince Castle, Inc.) without cost to the customer for parts or labor.

This warranty covers on location service (i.e., trip charges and/or

mileage). Travel mileage is limited to 100 miles (200 kilometers)

round trip (one trip warranty) from an authorized service agency or

its sub-service agency.

This warranty is subject to the following exceptions/conditions:

•

Use of any non-genuine Prince Castle parts voids this warranty.

•

All labor shall be performed during regular work hours.

Overtime premium will be charged to the buyer.

•

Damage caused by carelessness, neglect, and/or abuse (e.g.,

dropping, tampering or altering parts, equipment damaged in

shipment, by fire, flood or an act of God) is not covered under

this warranty.

Romar Pasta Cooker

630-ROM4

TABLE OF CONTENTS LIMITED WARRANTY

Product Identification ........................................... 1

Safety Information ............................................... 2

Important!........................................................... 2

Installation ......................................................... 2

General Preparation & Operation ........................... 3

Cooking Pasta..................................................... 7

Periodic Maintenance & Cleaning........................... 7

SPECIFICATIONS

•

Power Voltage.........................................................................240 VAC

•

Power Amps........................................................................... 27 Amps

•

Phase................................................................................................... 3

•

Frequency ...............................................................................50/60 Hz

•

Boiler Controller Power ............................................................24VAC

•

Control Power...........................................................................24 VAC

•

Max Pressure ............................................................................100 PSI

•

Working Pressure...................................................................... 80 PSI

355 East Kehoe Blvd. • Carol Stream, IL 60118

Phone: 630-462-8800 • Toll Free: 1-800-PCASTLE

Fax: 630-462-1460 • www.PrinceCastle.com

630-500 Printed in USA 0404 © 2004

Page 2

Romar Pasta Cooker

630-ROM4

Safety Information Important!

WARNING!

Indicates information important to the proper operation of

the unit. Failure to observe may result in damage to the

equipment and/or severe bodily injury or death.

CAUTION!

Indicates information important to the operation of the

unit. Failure to observe may result in damage to the

equipment.

Installation

Pre-Installation General Setup

Prince Castle reserves the right to change specifications

and product design without notice. Such revisions do

not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously

purchased equipment.

Pre-installation is the responsibility of the user and should be

completed prior to the shipment of the unit to the location.

•

Floor drain sink located no further than 10 ft. from the

intended location of the unit.

•

Electrical hookup box located no further than 5 ft. from the

intended location of the unit. The box should provide three

phase, 240 V protected with a three-phase 30-A breaker. All

terminals should be rated for gauge number 10-4 wire (L1-L2L3-Ground).

•

Dedicated water outlet with manual shut off valve no further

than 7 ft. from the intended location of the unit. The water

pressure should be at least 50 psi. The manual shut-off valve

output has to accommodate ¾ in. NPT Hose connector.

•

Supporting counter with the minimum suggested dimensions

of 24 in. high, 28 in. deep, and 44 in. wide. The counter must be

capable of withstanding 340 lbs (weight of unit).

Plumbing Connections

It is highly recommended that a licensed plumber install all

plumbing connections.

All pre-installation and installation work must be in compliance

with national and local plumbing codes and health department

requirements.

•

For standard water installation, connect per local plumbing

codes.

•

The drainage from the unit to the floor sink is achieved by

gravity only. Make sure that the 1” white PVC tubing is directed

downwards preventing any back-flow to the unit. Most local

Health Departments require you to terminate the drainage tube

4 in. above the highest point of the floor-sink.

This unit is completely pre-wired and thoroughly tested prior to

shipment. All wiring and hookups shall be done without

opening the unit.

•

Place unit on the counter. The counter must be designed to fit

the size and support the weight of the unit.

•

The unit must be level to insure proper function. To level the

unit, use only the adjustable leveling feet (no shims or foreign

objects).

•

EPH require a minimum height of 4 in. between the counter

and the unit.

•

When connecting the steam generator blow-down outlet,

ensure that the valve (provided by Prince Castle) is reachable

(arms length) from the front of the unit. The connecting “black

pipe” must be installed behind the unit and below the counter,

away from easy reach. The blow-down piping must be

secured all the way to the floor sink.

•

Do NOT reduce the blow-down outlet from its original size.

Depending on local regulations, you may be required to

install a second check valve or pressure reducing backflow preventive device.

Printed in USA 0404 © 2004 2 630-500

Page 3

Electrical Connections

WARNING!

SHOCK/DAMAGE HAZARD! No internal access is needed

when wiring this unit. Substitution and/or modification of

components and/or wiring system may void all warranties.

Such practice may lead to dangerous operating conditions.

It is highly recommended that a licensed electrician install all

electrical connections.

All pre-installation and installation work must be in compliance

with national and local electrical codes.

•

Power wiring must be installed in accordance with local and

National Electric Code (N.E.C.) or Canadian electric code

requirements.

General Preparation & Operation

Preparation of Pasta

Romar Pasta Cooker

630-ROM4

•

Before conducting field power connection, check to be sure

that the field power conditions match with power

requirements and rating specified on the unit nameplate on

the back panel.

•

As indicated in the Pre-Installation requirements, the user

must provide a circuit breaker between the main power

source and the unit. (Refer to nameplate for rating.)

•

The unit is wired and tested by the factory to operate only

with a single phase power configuration with one ground for

main load and circuit control.

•

To avoid severe electrical shock, provide grounding in

accordance with N.E.C. requirements.

•

When all the above steps are completed, place both hoppers

on the rails and connect them.

Before loading the pasta into the unit, the long-cut

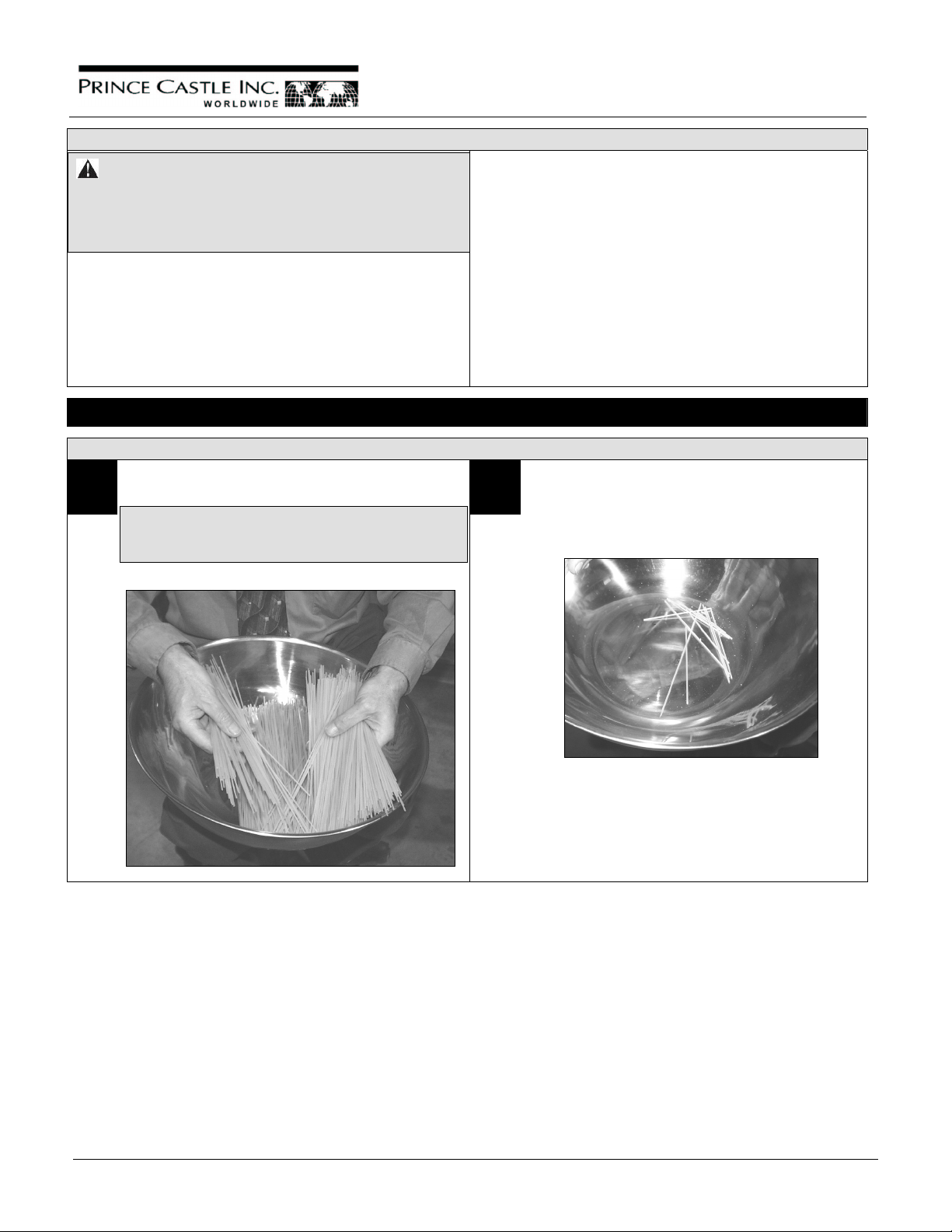

1 2

pasta must be “feathered” by hand.

Ensure that your hands are clean before handling

pasta.

Place long-cut pasta into a large bowl.

Procedure Complete

A. Gently lift the pasta (as shown on left), letting it

fall between your hands back into the bowl.

B. Repeat feathering several times, as necessary.

The broken, unusable pieces that remain in the bottom

of the bowl may be discarded.

The feathered long-cut pasta is now ready to be

cooked.

630-500 3 Printed in USA 0404 © 2004

Page 4

Romar Pasta Cooker

630-ROM4

Pasta Dispensers

1 2

The Pasta Dispenser assembly is composed of

three removable parts: one hopper, one hopper

cover and one loading box. No tools are needed to

assemble these parts.

The Pasta Dispenser is a precision machine and

should be handled with care.

Lift the cover from the Pasta Dispenser assembly and

slide the cover down inside the loading box as shown.

Loading

Box

Cover

A. Fill loading box with approx. 1 lb. of long-cut

pasta.

B. Fill hoper with up to 14 lbs. of the same long-cut

pasta.

Use only pasta recommended by Prince Castle.

Using other types of pasta or food may cause

severe damage and void all warranties and

maintenance contracts.

Loading

Box

Loading

Box

A. Remove the loading box cover, allowing pasta to

3 4

fall into the hopper.

B. Place loading box cover firmly on top of loading

box.

The long-cut Pasta Dispenser is now ready for use.

It is recommended that you keep the hopper

supplied with at least two pounds of pasta at all

times.

Loading

Box

Cover

Hopper

Fill each of the two short-cut past dispensers with up

to 14 lbs. of pasta.

The short-cut Pasta Dispensers are now ready for use.

Procedure Complete

Printed in USA 0404 © 2004 4 630-500

Page 5

Romar Pasta Cooker

Pasta Guides/Funnels

630-ROM4

Push the dispensers to the back position, then place

1 2

the four funnels into the holes located on top of the

unit.

Funnels

Procedure Complete

Retract the dispensers to their normal positions.

For proper operation of the unit, ensure that all

the Pasta Dispensers are securely in place in

the slots on top of the unit.

Trays & Strainers

The trays come already positioned. However, these may be

removed for cleaning. When returning the tray to its position,

ensure that it is snug and secure.

A. Insert the four drainage strainers into the trays.

B. Place the serving strainers inside the drainage strainers.

For sanitary purposes, remove and wash the trays and all

strainers thoroughly before first time use.

Wash trays and all strainers frequently to prevent starch

accumulation.

Switching the Unit On

1 2

Ensure that all the previous steps were executed

properly before proceeding!

A. Visually and manually check that the Blow-Down

valve is closed.

B. Check that water supply line is fully opened.

Serving

Tray

Verify that the on/off switch on the back of the unit is

in ON position.

When unit is switched on, a beep sounds for two

seconds. This switch should remain on at all times

except when the unit is undergoing maintenance or

repair.

All the cooking chambers are sanitized for 60

secs. at 280°F each time the machine is switched

on.

Drainage

Strainer

Strainer

630-500 5 Printed in USA 0404 © 2004

Page 6

Romar Pasta Cooker

g

630-ROM4

On the back of the unit, turn the power button to the

3 4

ON position.

Power button

The power button lights up and the unit proceeds

through its start-up process.

The boiler begins to fill. The boiler is completely filled

when the water level has filled the Sight Glass halfway.

Sight

Glass

4

CAUTION!

DAMAGE HAZARD! While the steam generator is

heating and the sanitizing process is in progress,

the blue I/O button blinks. Do NOT push any

buttons until the process is complete.

When the blue I/O button light is steady and the

four green Serving buttons flash several times

and remain off, the entire process is complete.

CAUTION!

BURN HAZARD! Hot steam and hot water passes

through the unit. Keep hands and objects clear of

unit until numbered green lights no longer flash.

Hold the blue I/O button for approx. 3 secs.

Blue I/O

button

WARNING!

EXPLOSION/DAMAGE/INJURY HAZZARD! The

Sight Glass indicator should NEVER rise above the

¾ full position! If so, immediately shut down the

unit and call for repair.

WARNING!

EXPLOSION/DAMAGE/INJURY HAZZARD! Do NOT

turn either of the two red-handled Sigh Glass turnvalves. These are used by authorized service

personnel ONLY.

When the steam pressure reaches 80 psi, the gates are

5

actuated and the chambers are sanitized.

The four numbered green Serving button lights begin to

flash.

When the green Serving button lights remain steady,

the unit is ready for use.

Procedure Complete

Yellow

Clean

button

The button light blinks until the water pressure gauge

on the front of the unit indicates the water has reached

the proper level (80 psi).

Pressure

e

Gau

Numbered Green

Serving buttons

Printed in USA 0404 © 2004 6 630-500

Page 7

Romar Pasta Cooker

630-ROM4

Cooking Pasta

To begin the cooking cycle, press any of the dimmed

1 2

green Serving button(s).

The loaded dry pasta drops into the unit and begins to

cook.

When finished, the cooked pasta drops into the serving

strainer to be rinsed. The green Serving button light

flashes.

While the cook cycle is in progress, the green light

on the Serving button is lit. This indicates that the

cooking chamber is in use and cannot be used to

start another cook cycle until the green light has

turned off.

Procedure Complete

Periodic Maintenance & Cleaning

Daily Maintenance

A. Throughout the day, check the water level

1 2

Procedure Complete

frequently.

B. Check for any leaks from the Sight Glass. If leaks

are found, tighten the Sight Glass fixture nuts or

replace the Sight Glass and gaskets if necessary.

When the rinsing is complete, the unit beeps and the

green light stops flashing and dims.

The pasta is now ready to be served.

To turn the unit off at the end of the day, press and hold

3

the blue I/O button for about 3 secs.

The blue I/O button light dims.

The unit shuts down.

At the end of each day, perform the Daily Blow-Down

procedure (see Daily Blow-Down Procedure in the

Maintenance & Troubleshooting manual).

Also, clean the unit thoroughly (see Daily or Weekly

Cleanup below).

Daily Blow-Down Procedure

IMPORTANT!

It is extremely important to fully understand and perform

these maintenance procedures. This procedure should be

performed with caution, preferably at the end of the

workday. For the first few days, only TWO blow-downs per

day are recommended to clean the inside of the boiler.

A daily blow-down is essential maintenance for a steam

generator. It lengthens the life of the boiler and prevents boiler

malfunction due to scale build-up.

The following blow-down procedure removes most sediment.

However, a manual clean-out must also be performed

periodically, depending on local water conditions, but no less

than once every six months (see 3-6 Month Maintenance in the

Maintenance & Troubleshooting manual).

IMPORTANT!

Do NOT use distilled water to operate the boiler.

Do NOT use any boiler cleaning components.

CAUTION!

EXPLOSION/BURN/INJURY HAZZARD! The boiler is under

high pressure and high temperature. Never leave the boiler

unattended while performing the blow-down procedure.

Always wear protective gloves and goggles to prevent

injuries.

IMPORTANT!

Before beginning the blow-down procedure, ensure that the

blow-down line is properly connected to a blow-down tank

or drain line for safe discharge purposes. If blowing down

into a receptacle, allow pressure to decrease to 5-10 psi

before opening Blow-Down Valve.

IMPORTANT!

Discharge only to a blow-down tank or to a safe discharge.

If blowing down into a receptacle, allow pressure to

decrease to 10 psi before opening blow-down valve.

630-500 7 Printed in USA 0404 © 2004

Page 8

Romar Pasta Cooker

630-ROM4

A. Press and hold the blue I/O button for about 3 secs.

1 2

The I/O button light dims.

IMPORTANT!

The blow-down valve must be opened SLOWLY, not

in one fast stroke.

B. On the back of the unit, open the Blow-Down Valve

lever (see figure) SLOWLY by turning the handle

until the valve is fully opened for approx. 3 secs.,

then turn the handle back to the starting position to

close.

C. Keep repeating this process until the water level

indicator reaches the bottom of the Sight Glass.

Blow-down

Valve Lever

If the Blow-Down Valve is connected to blowdown tank of drainage system, you can perform

the blow-down at operating pressure (80 psi). If

blowing down into a container or receptacle, wait

until the pressure drops to 10 psi.

A. When the discharge is complete and the boiler is

drained, ensure that the blow-down valve is closed

completely.

B. Press and hold the blue I/O button for about 3

secs. to turn the unit on.

C. Fill the boiler with water.

Procedure Complete

Daily or Weekly Clean-Up

1

IMPORTANT!

This process is semi-automatic and must be

followed exactly. Frequency of this procedure

depends upon frequency of usage. Failure to

comply with this procedure may void the unit

warranty.

Remove the four funnels from the top of the unit.

Press and hold the blue I/O button for approx. 6 secs.

2 3

to turn the unit off.

The I/O button light dims.

IMPORTANT!

Use a standard long-handle 3.5 scrub brush head and mild

detergent only. No other cleaning tools or detergents other

than those supplied by Prince Castle may be used. Do NOT

use any boiler cleaning components.

This clean-up procedure is the last procedure to be

performed at the end of the day.

Press the yellow Clean button.

The Clean button light flashes for approx. one minute

as the unit prepares the chambers for manual

cleaning.

A beep sounds and the Clean button light becomes

steady, indicating that the chambers are ready to be

cleaned.

Printed in USA 0404 © 2004 8 630-500

Page 9

Romar Pasta Cooker

630-ROM4

Use a standard long-handle 3.5 in. scrub brush head

4 5

and mild detergent to clean each of the four chambers

and break away any residue.

Clean chambers by introducing the scrubber through

the top of the chamber.

Chamber

w/o funnel

(top view)

A. When finished, ensure that all foreign objects are

6 7

removed from the chambers.

B. Replace the funnels.

Funnels

Press the yellow Clean button to start the automated

cleaning cycle.

The top gates automatically close.

The chambers are flushed and rinsed, and the bottoms

gates are closed.

When the cleaning cycle is finished (approx. 30 secs.),

the unit automatically shuts down.

Slide the three dispensers forward to their normal

position. Ensure that they are secure in their

appropriate slots as shown.

Procedure Complete

630-500 9 Printed in USA 0404 © 2004

Loading...

Loading...