Page 1

Heated Landing Shelf

Prince Castle Model No. STB-36BF, & 48BF Series

This equipment chapter is to be placed in the

Miscellaneous Section of your Equipment Manual

MANUFACTURED BY

PRINCE CASTLE INC.

355 EAST KEHOE BLVD

CAROL STREAM, IL 60188 USA

PHONE 1-630-462-8800

TOLL FREE NUMBER

1-800-323-2930

FAX: 1-630-462-1460

WARRANTY .........................................................................................................................................................Page 1

INTRODUCTION..................................................................................................................................................Page 2

PARTS IDENTIFICATION ................................................................................................................................... Page 2-6

EXPLODED VIEW ................................................................................................................................................ Page 2-6

EQUIPMENT SET-UP AND CLOSE PROCEDURES......................................................................................Page 7

ORDERING PARTS.............................................................................................................................................Page 8

TROUBLESHOOTING GUIDE ...........................................................................................................................Page 9

WIRING INFORMATION..................................................................................................................................... Pag e 11

LIMITED WARRANTY

This Product is warranted to be free from defects in material and/or workmanship for a period of two (2) years

from date of original installation not to exceed 30 months from date of shipment from our factory. Any part or

component (with the exception of light bulbs) which proves to be faulty in material and or workmanship

within the warranty period will be replaced or repaired without cost to the customer for parts or labor. (At the

option of Prince Castle, Inc.)This warranty covers on-location service (i.e.,trip charges and or mileage). Travel

mileage is limited to 100 miles (200 Kilometers) round trip(one trip per warranty) from an authorized service

agency or its sub-service agency.

This warranty is subject to the following exceptions/conditions:

1. Any use of Non-Genuine Prince Castle Spare Parts voids this warranty.

2. All labor shall be performed during regular working hours. Overtime premium will not be covered

3. Damage caused by carelessness, neglect, and/or abuse (e.g., using wrong current, dropping, tampering

with or altering electrical components, or improper cleaning) is not covered. Equipment damaged in

shipment, by fire, flood or an act of God.

This Manual is for the Exclusive use of Licensees and Employees of McDonald's Systems, Inc.

2001McDonald's Corporation

All Rights Reserved

Printed In November 1996

EM 44

Misc 44

Part No. 536-527

Printed in the

United States of America

Page 2

INTRODUCTION

The Heated Landing Shelf comes with adjustable lane

dividers that can be realigned for existing or new products. The Heated Landing Shelf holds up to a 72 sandwich capacity with 12 product lanes for Model No.

STB-36, or up to a 96 sandwich capacity with 16

product lanes for Model No. STB-48. Adjustable upper

and lower heaters maintain correct temperatures at

various locations.

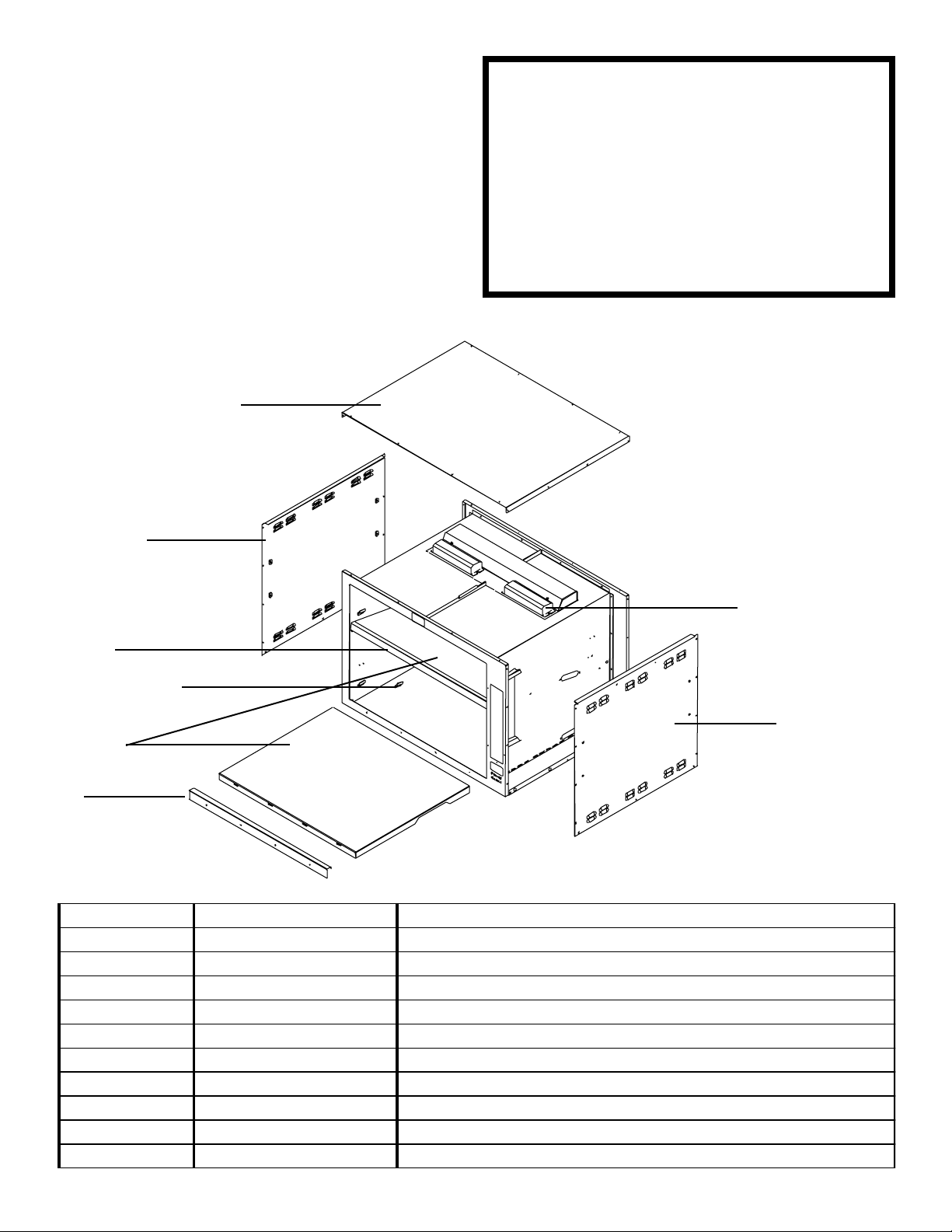

STB-36BF EXPLODED VIEW

5

This unit utilizes Radiant Energy to maintain

food temperature. The Racks, Sides, Top, and

Internal Air Temperature of the unit will remain

relatively cool while in operation. The only parts

of the unit with a Hot Surface are the Black

Decks which contain the Radiant Heat Source.

Please refer to this Operating Manual for Calibration. Check the Actual Food Temperature or

Surface Temperature of the Black Decks with

an appropriate thermometer. Measuring the Air

Temperature IS NOT an indication of the Food

Temperature.

4

3

2

7

1

Item Part # Description

1 536-104 Lower Face

2 536-199S Bracket w/Screws (pkg of 4)

3 536-420 Upper Face

4 536-139 Side Panel

5 536-120 Top Cover

6 536-601S Ballast (240 Volt)

7 536-127S Heater Assy

* 536-443 Lamp Guard (Not Shown)

* 72-200-16 Line Cord (Not Shown)

* 88-633-3S Florescent Lamp (Not Shown)

6

4

2

Page 3

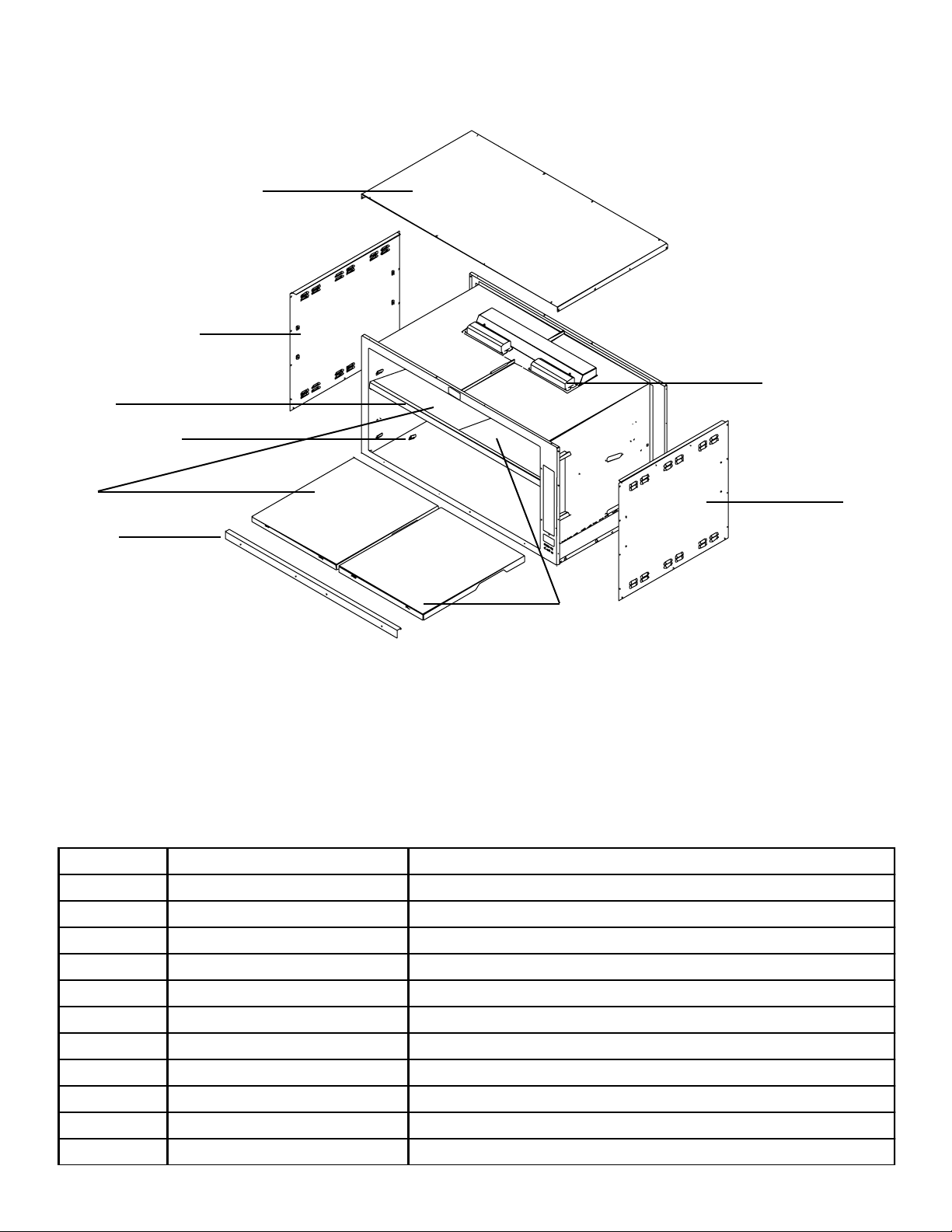

STB-48BF EXPLODED VIEW

5

4

6

3

2

7

1

8

3

Item Part # Description

1 536-150 Lower Face

2 536-199S Bracket w/Screws (pkg of 4)

3 536-414 Upper Face

4 536-139 Side Panel

5 536-148 Top Cover

6 536-601S Ballast (240 Volt)

7 536-172S Heater Assy. (Left Side)

8 536-255S Heater Assy (Right Side)

* 536-443 Lamp Guard (Not Shown)

* 72-200-16S Line Cord (Not Shown)

* 88-633-3S Florescent Lamp (Not Shown)

4

4

Page 4

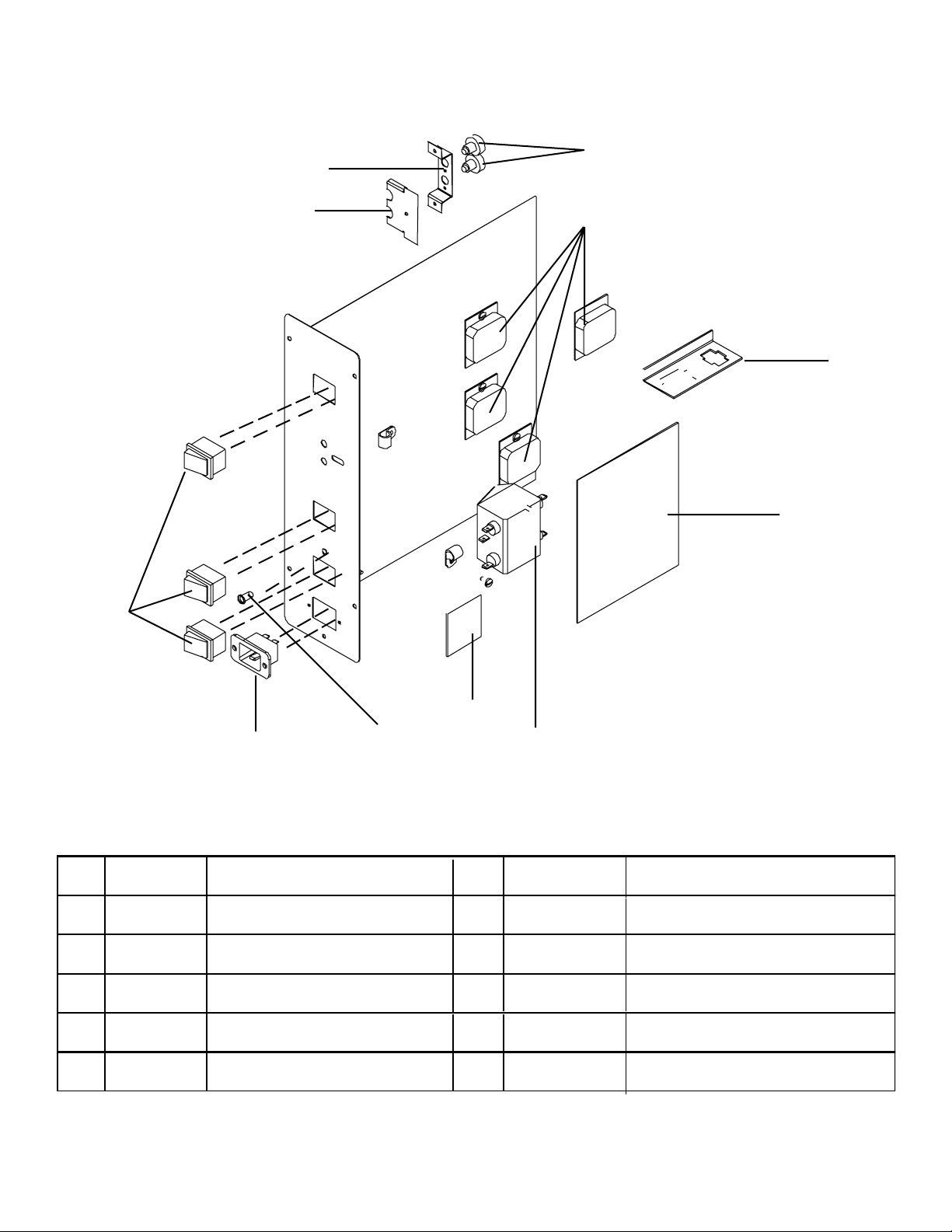

10

STB-36BF Control Box

9

11

8

7

6

1

3

2

ItemPart #

Description

1 78-184S Lighted Rocker Switch

2

3

4 65-037S

5 421-208S

536-348S

536-197S

Status Light

Control P.C. Board Assy.

Relay

P.C. Board Assy. 10 88-612

4

5

Item

Part #

6 536-317

7 536-33

8

411-133S

9

536-359

Description

Potentiometer Bracket

Potentiometer Door

Potentiometer

Connector Bracket

Line Filter

3

Page 5

STB-48BF Control Box

9

10

8

7

6

5

1

2

3

4

Item Part # Description Item Part Description

1 78-184S Lighted Rocker Switch 6 65-037S Relay

2 536-348S Status Light Assy. 7 411-133S Potentiometer

3 88-626 Filter 8 536-317 Potentiometer Bracket

4 536-241 Connector Bracket 9 536-33 Potentiometer Door

5 536-197S Control P.C.Board Assy. 10 421-208S P.C. Board

5

Page 6

STB-36BF & STB-48BF Heated Landing Shelf

Accessories

3

2

4

5

Item Part # Description

1 536-218 Lane Divider

2 536-213 Wire Rack (FHB-36)

536-214 Wire Rack (FHB-48)

3 536-131 Time Card Storage Rack (FHB-36)

536-167 Time Card Storage Rack (FHB-48)

4 536-391QS Time Card Kit

5 536-132 Time Card Return Rack

6 536-411 Left Side Tray Bracket

7 536-412 Right Side Tray Bracket

* 536-410 Center Tray Bracket (FHB-48 Only) (Not Shown)

8 536-421 Tray Rod (FHB-36)

536-413 Tray Rod (FHB-48)

6

1

* Individual replacement time cards are available in packages of three. Contact Prince

Castle or a local Prince Castle Service Agent.

6

Page 7

EQUIPMENT SET-UP AND

CLOSE PROCEDURES

1. Place Heated Landing Shelf on counter and seal it

completely with a food approved sealant.

2. Insert Power Cord into a proper voltage receptacle

NOTE: This should be a dedicated outlet. No other

equipment should be operating on this line (i.e. fryers,

refrigerators, cash registers, etc.)

3. Snap in Wire Racks with lip toward counter. The

Lower Rack can be set at an angle by setting the rear

(Kitchen Side) Part of the racks in the upper brackets

located on the sides of lower shelves. The upper rack

adjustment is located in the front (Counter Side).

4. Attach Air Baffles By Sliding the two hooks located

on the air baffle over the top (restaurant side) of the wire

rack. Note: The rack in the upper compartment should

be positioned at a downward angle by setting the restaurant side of the wire rack in the lower rack brackets

located on the sides of the bin. The lower compartment

rack may be positioned at either a horizontal or angled

position.

5. Lane Dividers can be easily lifted out and moved to

accommodate different size products.

7. Loosen the two Phillips Head screws (A) on both sides of

the bin. NOTE: The screws only need to be loosened 2-3

turns DO NOT REMOVE. (See Figure 1)

8. Place key hole slots (B) on the time card rack over the

loosened screws and tighten. (See Figure 1)

9. The Time Card Return Rack can be mounted on either side

of the Heated Landing Shelf.

10. Loosen two Phillips Head screws (A) one on top and one

on bottom so the rack sits at an angle on side of the bin.

NOTE: The screws only need to be loosened 2-3 turns DO

NOT REMOVE. (See Figure 2)

11. Place key hole slot s (B) on the time card return rack over

the loosened screws and tighten. (See Figure 2)

A

B

<

Tilt Down Toward Kitchen Side

6. The Time Card Storage Rack will be mounted on the top of

the landing shelf on the kitchen side.

B

O O O O

A

FIGURE 1

FIGURE 2

12. Turn on the Lighted Rocker Switch marked MAIN

POWER.

Upper Heating

Shelf

Lighted

Rocker

Switch

Temperature

Controls

Lower Heating

Shelf

Lighted

Rocker

Switch

Status

Light

7

Main

Power

Lighted

Rocker

Switch

Page 8

13. Turn on the lighted rocker switches marked UPPER

HEATER and LOWER HEATER. The lights and heaters

will come on for both shelves and the unit will begin to

heat up. Allow 30 minutes for warm-up.

NOTE: The UPPER And LOWER shelves can be

operated as two seperate areas. During slow

periods one shelf may be used while the other

shelf is switched off.

14. Refer to the operations and training manual for

correct holding times.

CLOSE PROCEDURES

This appliance is not of water tight construction. Do not clean with a Water Jet / Jet Spray.

Do not immerse appliance in water.

CAUTION: Before unplugging Power Cord make sure all

Power Switches are in the "OFF" position.

1. Unplug Heated Landing Shelf.

2. Allow unit to cool down. (Approximately 15 minutes)

INSPECT CARTON

Remove product from carton.

If damaged:

X Notify carrier within 24 hours.

X Save carton and packing material.

X Prince Castle can assist with freight claims and

arranging for a replacement unit if field repair is

impossible, or if you find a part or parts missing In the

USA Contact Prince Castle at 1-800-323-2930 outside the USA contact your KES or your Local Distributor.

PARTS

1. Always refer to the Parts List in this manual. You

will then have a part number for reference when

ordering.

3. Wipe down with a damp cloth.

Caution: When cleaning do not pour water on

the heaters. This may cause an electrical hazard and damage to the sensitive solid state

circuitry. Do not use Grill Cleaner

2. All replacement parts should be purchased from

your local Prince Castle Service Center (see enclosed list). Outside the U.S.A contact your local

Prince Castle Distributor.

3. RETURNS: All inoperable warranty parts must

be returned to the Service Center.

8

Page 9

STB-36BF & STB-48BF P.C. Board Diagnostics

UPR1

LWR1

UPR2

LWR2

Status Light Diagnostic Troubleshooting

The main purpose of the Status Light is to signal the

operator that the Heated Landing Shelf is functioning

properly.

n Under normal conditions the Status Light will be a

steady green.

n Under a condition of malfunction, the Status Light

will flash red. At this point switch off either heater, if the

Status Light turns back to a steady green when you

turn off a particular heater the malfunction is related to

the switched off heater.

Control

Panel

NOTE: Never turn off the Main Power Switch when

experiencing a flashing red this will reset the Status

Light. A reset Status Light takes 20 minutes to warm

back up.

n The Status Light should never be off, amber/

yellow, or a steady red. Should this be the case, then

the electronics driving the Status Light itself has malfunctioned.

NOTE: Once you have determined which heater

compartment has malfunctioned, locate the diagnostic LED's on the P.C.Board. Follow the

Diagnostic Troubleshooting on page 9 of this

manual.

STATUS LIGHT

Diagnostic

LEDS

9

Page 10

STB-36BF & STB-48BF P.C. Board Diagnostics

LED Signal Corrective Action

Heater sensor leads are reversed. Locate the

Blinking Red

corresponding sensor leads and verify that the yellow

and red sensor wires are connected in the correct

position (YEL or RED). Reverse the leads if incorrect.

Locate corresponding sensor wires and make sure

Steady Red

leads are securely in the terminal and that there are no

broken wires. If all leads are secure and not broken

replace the associated heater assembly.

If there is no heat at all being generated replace the

heater assembly. If the shelf is heating, check for

Blinking Orange

loose wires in the relay diagnostic header. If wire

connections are good, replace the relay.

CAUTION: HIGH VOLTAGE PRESENT

If heater does not turn on, check quick connect at the

Steady Orange

relay. If connection is good, replace the relay.

CAUTION: HIGH VOLTAGE PRESENT

Upper 1&2 LED's or

Lower 1&2 LED's

Blink Red & Orange

The heater switch is in the off position. There

is a bad connection on the heater switch.

The heater switch is defective.

IMPORTANT SPECIAL TROUBLESHOOTING PROCEDURES

FOR STB-48BF FOOD HOLDING BIN ONLY

If the FHB-48 fails to heat and the lights do not turn on, determine that the unit is receiving electrical power. Check

line cord connections, check that the FHB-48 Power Switches are in the "ON" position (they should be glowing

when in the "ON" position), and lastly check the store's circuit breakers. Follow the Troubleshooting procedures

below.

SOLUTIONCAUSEPROBLEM

1. Unit appears to be "DEAD"

and it has been determined that

power is reaching the unit.

2. Both Lights on a shelf are out

but the shelf is heating. (Associated Diagnostic LED's are cycling on (Green) and off).

1. Inoperable Line Cord.

2. Inoperable Main Power Switch.

3. Unit has overheated and High Limit

Switch has tripped.

1. Inoperable Light Bulbs.

2. Lamp Fuse has Opened.

1. Replace Line Cord.

2. Replace Switch.

3. Reset High Limit Switch. NOTE:

High Limit Is Located inside the

Control Box on the bottom of the

unit.

1. Replace Bulbs.

2. Ensure Lamp Circuit is not

shorted and replace appropriate

lamp fuse.

10

Page 11

CARD NO.

HEATED LANDING SHELF

72

Planned Maintenance System

Maintenance Requirement Card (MRC)

Temperature & Calibration of STB Series Heated Landing Shelf

The Heated Landing Shelf leaves the factory with the plate temperature set at 225°- 230°F (107°- 110°C) for

Models STB-22 & STB-11 and 235°- 240°F (113°- 116°C) for Models STB-36 & STB-48. Readings with the

Surface Probe should be taken at the surface of the heaters 2" to the right of the center circle marking on top and

bottom (See Figure Below). NOTE: Because the location of the Heated Landing Shelf may vary from

restaurant to restaurant there may be need to adjust the temperature setting due to climate control

conditions in that location.

○○○

Heater

Surface

2"

○○○

Center

Circle Marking

(View Facing Control

Panel)

The following "Water Test" is intended for use only when the integrity of the Heated Landing Shelf is questioned

by regulatory agencies, ie; health department, etc.

MATERIALS REQUIRED:

1 ea. 8 oz paper (CAUTION: Do not use Waxed Paper Cup) or styrofoam coffee cup with lid (lid may be plastic).

1 ea. "K" type thermometer and probe, or a conventional bulb type thermometer capable of reading in the

100°-200°F Range (35°-100°C).

PRODUCT SIMULATION:

Place 4 tablespoons (1/4 cup) (60cc) of water in the paper cup. Use hot water, or microwave until the temperature

of the water measures 155°-160°F (68°-71°C) Immediately place the lid on the cup and place the cup anywhere

on the wire rack in the Heated Landing Shelf.

WARNING: DO NOT place any object under the cup (paper, plastic, foil, cardboard, etc...) to help "balance the cup"

on the rack.

After 10 minutes, place the cup on the counter, immediately insert thermometer end (or needle probe) thru a small

(1/4" max) hole in the lid, and record the temperature of the water. If the temperature is between 140°-150°F

(60°-65° C) the unit is operating as intended. If the temperature of the Heated Landing Shelf is too high or too low

it can be adjusted by turning the adjustment potentiometer located behind the access door on the control panel.

NOTE: On STB-11& STB-22 To raise the access door, loosen the screw between the two heater pots, then

raise the door to expose the adjustment potentiometers.

On STB-36 & STB-48 Loosen the screw to the right of the temperature controls and slide it to the right

exposing the adjustment potentiometers.

Turning the pot clockwise will adjust the temperature up, turning it counter clockwise will adjust it down. Each small

mark will cause about a 5 degree adjustment in temperature.

Page 12

STB-36BF SERIES WIRING DIAGRAM

STB-48BF SERIES WIRING DIAGRAM

11

Page 13

WIRING DIAGRAM AND INSTALLATION

MODELS STB-36AFJ ONLY

TO HARD WIRE UNIT REMOVE THE UPPER COVER EXPOSING THE CONTROL DRAWER.

FOLLOW THE INSTRUCTIONS BELOW USING THE WIRING DIAGRAM ABOVE.

8

Loading...

Loading...