Page 1

OPERATING

INSTRUCTIONS

TABLE OF CONTENTS PAGE

Universal Toaster

Model No. 411-SL Series

Installation..................................................................... 2

Operating ....................................................................... 4

Troubleshooting ............................................................ 5

Self-Diagnostic Troubleshooting ................................. 6

Non-scheduled Maintenance ....................................... 7

Parts List..................................................................... 10

Exploded View ............................................................ 11

Wiring Diagram ........................................................... 12

LIMITED WARRANTYLIMITED WARRANTY

LIMITED WARRANTY

LIMITED WARRANTYLIMITED WARRANTY

This product is warranted to be free from defects in

material and/or workmanship for a period of two (2)

year from date of original installation, not to exceed

30 months from date of shipment from our factory.

Any component which proves to be faulty in material

and/or workmanship will be replaced or repaired (at

the option of Prince Castle, Inc.) without cost to the

customer for parts or labor.

This warranty is subject to the following exceptions/

conditions:

Prince Castle's Universal Batch Bun Toaster caramelizes

up to 12 regular 4" (10.16 cm)buns at one time. Perfectly

toasts two and three-part buns by allowing operators to

adjust time and temperature selections. Constructed of

durable stainless steel and aluminum, the 411-SL toaster

features a self-diagnostic trouble shooting system and

solid state controls and both audio and visual alarms.

Two nickel-plated platens offer precise temperature

control with superior and consistent toasting results. A

stainless steel bun board makes bun removal easy.

PRODUCT SPECIFICATION

Dimensions

Height Open: 15” (38.1 cm)

Height Closed: 7” (17.7 cm)

Width: 16-1/4” (41.2 cm)

Length Open: 35-1/4” (89.5 cm)

Length Closed: 31-1/2” (80.0 cm)

! Use of non-genuine Prince Castle Parts voids

this warranty.

! This equipment is portable; charges for on-loca-

tion service (e.g., trip charges, mileage) are not

included in the provisions of this warranty.

! All labor shall be performed during regular work

hours. Overtime premium will be charged to the

buyer.

! All problems due to operation at voltages other

than specified on toaster nameplates.

! This product must be serviced by a Prince Castle

Authorized Service Center or a Prince Castle

Factory Service Technician. Failure to do so

may void this warranty.

! Damage caused by carelessness, neglect, and/

or abuse (e.g., dropping, tampering or altering

parts), equipment damaged in shipment, by fire,

flood or an act of God is not covered under this

warranty.

Printed in December 1997

Prince Castle Inc.

355 East Kehoe Blvd. ! Carol Stream, IL 60188

Tel: (630) 462-8800 ! Fax: (630) 462-1460

Toll Free: 1-800-PCASTLE

411-506

Page 2

INSTALLATION

1. After you have removed the toaster from the carton,

inspect the unit for signs of damage. If there is

damage to the unit:

figure 3

! Notify carrier within 24 hours after delivery.

! Save carton and packing materials for inspection

purposes.

! Contact the Prince Castle Customer Sales

Department at 1-800-722-7853 to arrange for

a replacement to be sent.

2. Verify that all parts have been received.

3. If you find a part missing call 1-800-722-7853 and

ask for the Customer Sales Department. If you

have a question with operation ask for the Service

Department.

4. Toaster must be cold before Teflon release sheets

can be installed.

IMPORTANT: Toaster must be locked in the open

position by engaging the safety latch so toaster cannot

be closed before installing the Teflon release sheet.

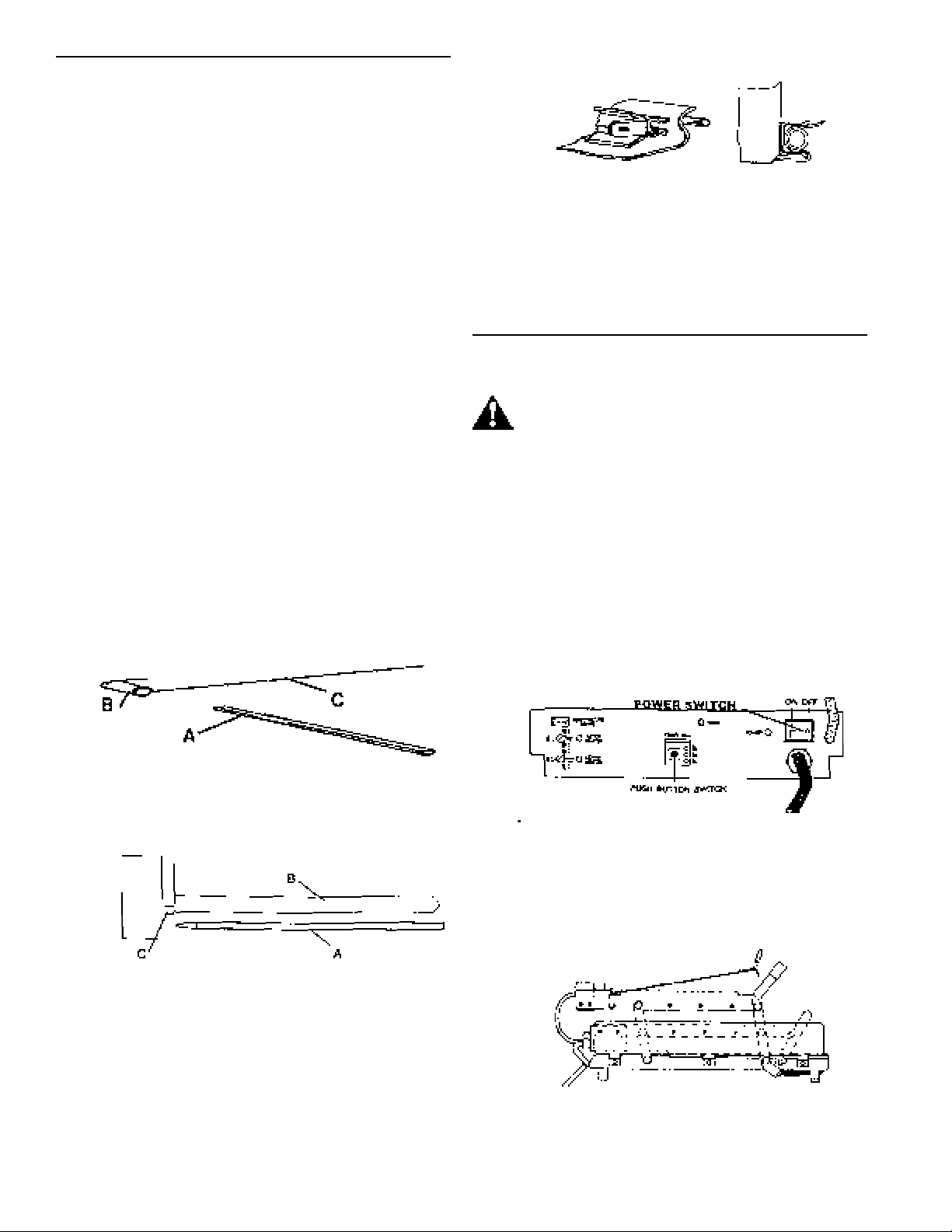

5. Install the stretcher bar (A) into the loop (B) of each

release sheet (C). See figure 1.

figure 1

IMPORTANT: The release sheet should be tight to the

bottom of the platen. If not, remove round bar and

repeat step 5.

9. Repeat steps 3-6 to install the release sheet on

upper platen.

OPERATION

CAUTION: Before plugging in, make sure

toaster power switch is in the OFF position.

1. Insert the power cord into an ANSI 125/250 volt, 3

pole 4 wire grounding outlet. The receptacle should

be a type NEMA #L14-20R. For European units the

receptacle should be a MENNEKES #316 P6 1302.

IMPORTANT: This should be a dedicated outlet. No

other equipment should be operating on this line (i.e.

fryers, refrigerators, cash registers, etc.).

2. Place the power switch in the ON position.

See figure 4.

6. Slide release sheet (A) to rear of bottom platen (B)

and attach to hooks (C). See figure 2.

figure 2

IMPORTANT: Slots in the stretcher bar are to face the

front of the toaster.

7. Pull the release sheet tight against the bottom of

the platen and spring retainer on the front of the

platen.

8. Push round bar and release sheet into the spring

retainer. See figure 3.

figure 4

3. Platens must be in the “UP” position while the

toaster warms up so that the timer is not activated.

Warm-up takes 30 minutes. See figure 5.

figure 5

2

Page 3

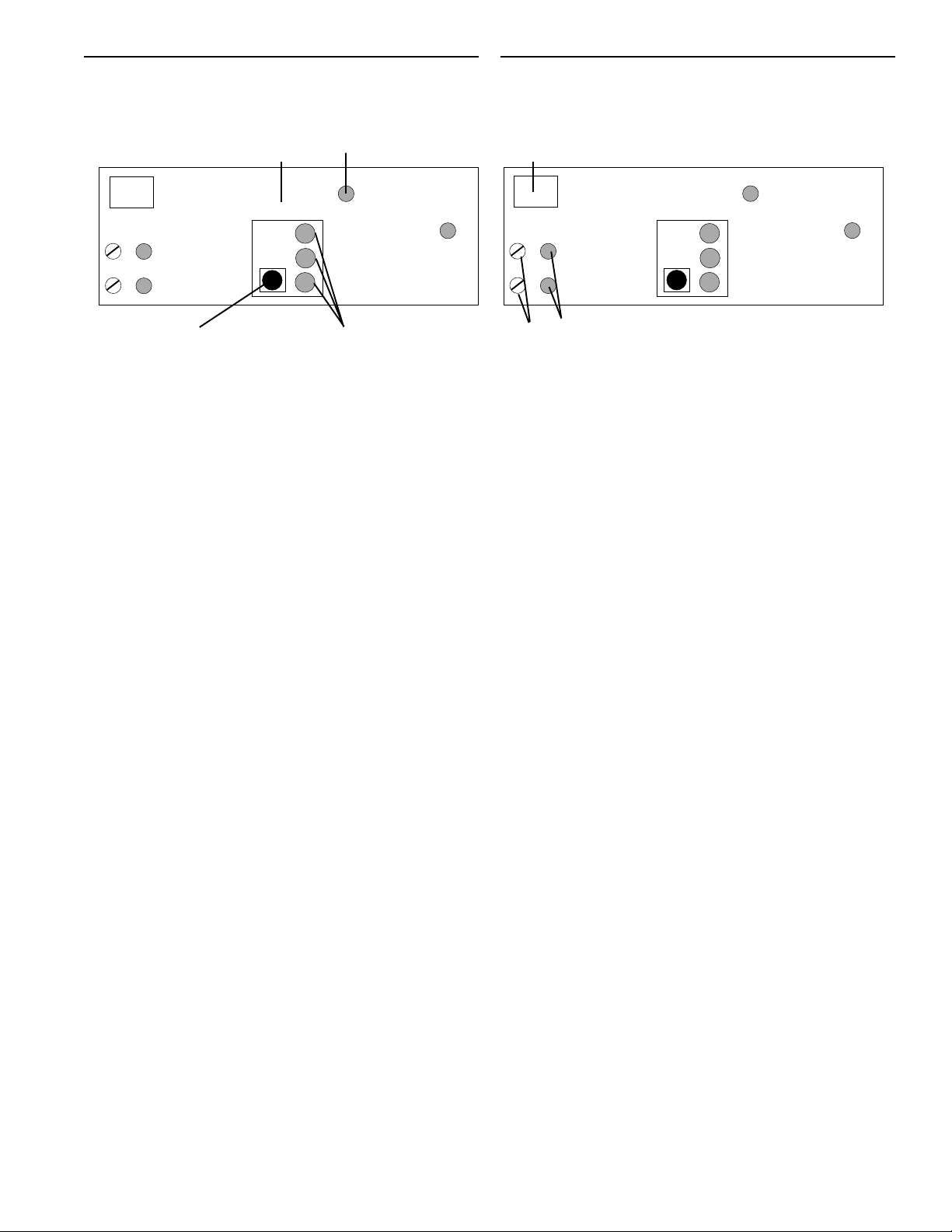

SETTING TOAST TIMES (See figure 6.)

SETTING TOAST TEMPERATURES

(See figure 7.)

figure 6

D

TIMER

55 Sec

45 Sec

35 Sec

B

POWER

TEMPERATURE

PROBE

TIMER ADJ

UPPER

HEATER

LOWER

HEATER

C

A

The toaster is preset at the factory for a 35 second

toasting time and a 420° F toasting temperature on

both platens. Temperature settings using commercial

bakery buns are:

35 seconds 420° F

45 seconds 410 ° F

55 seconds 400° F

Settings may have to be adjusted because sugar within

the product being toasted may vary from bakery to

bakery.

1. On the lower control box panel, locate and lift the

sliding door marked TIMER ADJ (A). Behind the

door are three red LED’s (B) each denoting a bun

toasting time setting of either 35 sec, 45 sec or 55

sec.

IMPORTANT: There should be only one time setting

light on.

2. Behind the TIMER ADJ (A) door there is a small

PUSH BUTTON SWITCH (C). The bun toasting

time can be set or changed whenever the toasting

cycle is NOT active (i.e. when the red timer light

(D) is not lit).

3. Press and hold the TIMER ADJ (A) button in for 5

seconds until an audio alarm sounds. At this point

the next bun toasting time light will turn on. Release and press the TIMER ADJ (A) button until the

desired bun toasting time for your product is

selected.

4. Activate toaster timing cycle by pulling the handle/

lever assembly forward and down. After selected

time (35, 45, or 55 seconds) has elapsed the

audible alert will sound and the “bun ready light”

will come on.

figure 7

A

TEMPERATURE

PROBE

UPPER

HEATER

LOWER

HEATER

C

B

TIMER ADJ

TIMER

55 Sec

45 Sec

35 Sec

POWER

To properly calibrate and set cooking temperatures

the following tools are required:

! “K” Type Pyrometer

! Thermo - Electric Patch Cord #SF001-250

! Flat Blade Screwdriver

1. Locate the two yellow–colored temperature probe

jacks (A) on the upper and lower control boxes.

2. Plug one end of the Patch Cord into the temperature probe jack (A) of either the upper or lower

control box depending on which platen you are

calibrating first. Plug the other end of the patch

cord into the “K” type pyrometer.

3. Directly beneath the temperature probe jack (A) on

the lower control box are the two platen temperature control potentiometers (B), labeled upper adj

and lower adj for upper platen and lower platen.

Next to each temperature control potentiometer is a

yellow indicating light (C) (upper header and lower

heater). These indicating lights will be lit when

power is being supplied to the corresponding

platen. Thus these lights will cycle on/off as the

corresponding platen temperature is being controlled.

4. To set a temperature use the flat blade screwdriver

to turn the temperature control potentiometer (B).

Turning the pot clockwise will increase the platen

temperature counterclockwise to decrease.

5. Observe the potentiometers temperature display

and note the temperature at the point when the

Yellow heater indicator light (C) of the corresponding platen turns off. This temperature is considered

the calibration temperature.

IMPORTANT: Toasting temperatures will vary by bread

product so your calibrated temperature may vary for

different products.

6. Remove the patch cord from the toaster temperature.

3

Page 4

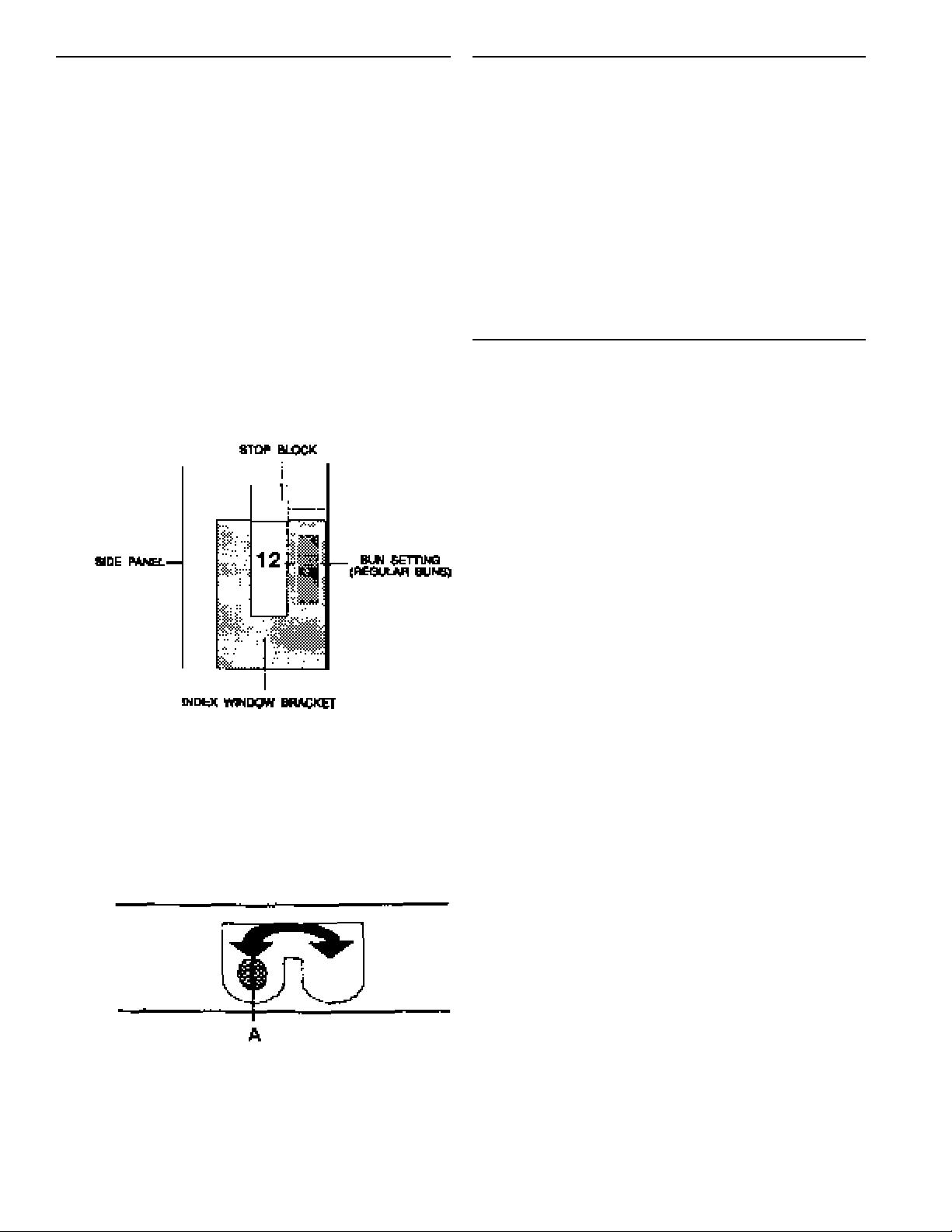

SETTING STOP BLOCKS (See figures 8 & 9.)

The stop blocks allow toasting different sizes, cuts and

brands of bread product. There are (6) combination

stop block settings in 1/16” increments. The overall

range is 3/4” to 1-1/4”. The stop block settings allow a

better crush when toasting different styles of buns.

1. Ensure stop blocks are on the correct setting

before operating toaster. There are (6) stop block

combinations available.

2. To change a stop block setting, depress the right

stop block to disengage locking pin and turn in

either direction to the desired setting.

3. View the stop block setting selected through the

index window bracket which is located over each

stop block. See figure 8.

CENTER OPENING ADJUSTMENT

To adjust the opening between the upper and lower

platens, loosen the two screws holding the adjustment plate on each side of the lower platen. There

are 11 adjustments. The middle adjustment is 1/2 ” .

Each adjustment moves the opening 1/16”. Moving

the adjustment plate to the left increases the opening, moving it to the right decreases the opening.

The center adjustment should be used when toasting different cuts of bread.

OPERATION

figure 8

4. Locate the selector lever (A) on the front of the

toaster frame and move the lever left or right to

allow you to switch back and forth between the

combination setting selected on the stop block.

See figure 9.

After selecting a cooking time and temperature, and

setting the stop blocks and the center adjustment

plate you are ready to begin toasting buns.

1. Using the bun spatula place the crowns face up.

2. Using the other bun spatula place the heels cut

face down.

3. Lift the bun board on the upper platen up and insert

the spatula with the heels on it.

4. Lower bun board down on top of heels and spatula

slide spatula out leaving heels on platen with bun

board on top.

5. Insert spatula with crowns on it into he center

section or lower section of toaster.

6. Pull toaster handle forward to move platen on top of

crowns, the timer will automatically activate and

the red timer light will come on.

7. When the audio alarm sounds and the bun done

light comes on, immediately push handle back to

release crowns from platen. Remove spatula with

crowns from toaster.

figure 9

8. Lift bun board on upper platen and slide the spatula

in under the heels and remove

4

Page 5

REMOVAL & CLEANING OF

RELEASE SHEETS

2. Rinse release sheets using clean running water

and wipe the sheets dry in one direction only

using a clean damp grill cloth until all residue is

removed. Do not fold or crease (air dry).

TO REMOVE:

1. Toaster must be cold before release sheets can

be removed.

CAUTION: Before removing release

sheets the toaster platen must be locked

in its open position by engaging the

“safety latch”.

2. Remove release sheets by removing the round

bar from the spring clip on the front of platens

and then remove the stretcher bar from rear

hooks.

3. Remove stretcher bar from release sheets.

TO CLEAN:

1. Lightly scrub the release sheet on both sides

using a damp clean towel. Keep sheet flat while

cleaning to ensure no wrinkles or creases are

put into sheet.

IMPORTANT: Do not use green pads to scrub

release sheets.

3. Rinse release sheets using clean running water

and wipe the sheets dry in one direction only

using a clean damp grill cloth. Keep wiping until

all residue is removed.

CLEANING

CAUTION: Before unplugging power cord

make sure the toaster power switch is

turned OFF.

1. Unplug toaster power cord from outlet.

2. Allow toaster to cool.

3. Follow cleaning instructions.

IMPORTANT: Always lock platens in open position

using the safety latch before cleaning or relocating

toaster to a different location.

IMPORTANT: When cleaning do not pour water on

the platen. This may cause an electrical hazard and

cause serious damage to the sensitive solid state

circuitry in this toaster.

TROUBLESHOOTING CHART

CAUTION: Service is to be performed by

qualified service personnel.

CAUTION: Use extreme caustion during

electrical ciruit tests. Live circuits will be

exposed.

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Platen Has excessive movement. Platen attachment bolts loose. Tighten bolts.

Audio Alarm works, no amber Light burned out. Replace amber colored bun done

colored bun light. light.

No audio alarm or amber colored Speaker defective. Replace speaker.

bun done light. Opto sensor board defective. Replace opto sensor board.

Buns being crushed. Stop blocks not adjusted properly Adjust stop blocks.

Buns cut improperly. Adjust stop block to (=) or (-).

Buns sticking to platen. Excessive heat. Calibrate toaster.

Built up carmelized sugar on platen. Clean platen (PM Card #17).

One platen not heating but no Corresponding probe inoperable. Replace probe.

diagnostic signals.

5

CAUTION: Inspection, testing and repair of

electrical equipment should be performed

only by qualified service personne. The unit

should be unplugged when servicing, except

when electrical tests are required.

Page 6

SELF-DIAGNOSTIC TROUBLESHOOTING CHART

Observe the (3) red indicator lights (A), and the (2)

LOWER CONTROL BOX FACEPLATE

yellow lights controlling the upper & lower heater

area (B). An audio alarm will sound, match the

lights in the malfunction section below to the toaster

TEMPERATURE

PROBE

malfunciton to identify the corrective action.

UPPER

Indicates red lights is on and flashing.

Indicates red lights is off.

Indicates red lights is off.

AREA B

HEATER

LOWER

HEATER

Yellow

Indicator

Lights

SELF-DIAGNOSTIC TROUBLESHOOTING CHART

For the five

malfunctions in

this column,

replace the 411261S Power

Board located in

the lower control

box.

UPPER

HEATER

LOWER

HEATER

UPPER

HEATER

LOWER

HEATER

TIMER ADJ

55 Sec

45 Sec

35 Sec

TIMER ADJ

55 Sec

45 Sec

35 Sec

Check the lower probe

connector at the main

P.C. Board. Replace

the 411-85S located in

the lower control box.

Check the upper probe

connection at the optosensor board located

in the upper control

box. Replace the 41185S located in the

upper control box.

TIMER ADJ

AREA A

UPPER

HEATER

LOWER

HEATER

UPPER

HEATER

LOWER

HEATER

TIMER

POWER

55 Sec

45 Sec

35 Sec

Red

Indicator

Lights

TIMER ADJ

55 Sec

45 Sec

35 Sec

TIMER ADJ

55 Sec

45 Sec

35 Sec

UPPER

HEATER

LOWER

HEATER

UPPER

HEATER

LOWER

HEATER

UPPER

HEATER

LOWER

HEATER

TIMER ADJ

TIMER ADJ

TIMER ADJ

55 Sec

45 Sec

35 Sec

55 Sec

45 Sec

35 Sec

55 Sec

45 Sec

35 Sec

Replace the No. 411262S Main P.C. board

located on the front

faceplate on the lower

control box.

If there is no timer or

heater lights on, but

the audio alarm is

sounding replace the

411-262S Main P.C.

Board.

If (3) timer lights are

flashing and an audio

alarm is sounding the

upper and lower

platens are over

heating. Turn the

toaster OFF and

disconnect the power

cord from receptacle.

UPPER

HEATER

LOWER

HEATER

UPPER

HEATER

LOWER

HEATER

UPPER

HEATER

LOWER

HEATER

TIMER ADJ

55 Sec

45 Sec

35 Sec

TIMER ADJ

55 Sec

45 Sec

35 Sec

TIMER ADJ

55 Sec

45 Sec

35 Sec

Then call the Prince Castle Service Department at 1-800323-2930 for assistance.

6

Page 7

NON-SCHEDULED MAINTENANCE

Model No. 411-14 Opto-Sensor P.C. Board

Tools Needed: 1/4” Flat blade screwdriver

Model No. 411-261S Power P.C. Board

Tools Needed: 1/4” Flat Blade Screwdriver

1. Disengage safety latch and lower toaster to toast

position. Using 1/4” flat blade screw driver remove

(2) screws (A) from cover (B) on the lower control

box, and remove cover. See figure 13.

1. With the toaster in the up position and the safety

latch in place use the flat blade screwdriver to

remove (7) screws (A) from the upper control box

and slowly lift up the back. See figure 10.

figure 10

2. Disconnect the (4) wire connectors (A) from the

P.C. Board (B). Using the flat blade screwdriver

remove (4) screws (C) holding the P.C. Board to

the standoffs (D) and carefully remove the P.C.

Board. See figure 11.

figure 11

figure 13

2. Carefully disconnect the wire connectors (A)

from the board, using the 1/4” flat blade screwdriver remove the (3) wire connections (B) from

the terminal black (C). See figure 14.

figure 14

3. Using the 1/4” flat blade screwdriver remove the

(2) screws and washers (A) that hold the power

board to the standoffs from the top of the power

board. Slide the P.C. Board out of the (2) rear

mounting brackets (B) and lift out of the control

box. See figure 15.

3. To install replacement Opto-Sensor P.C. Board

reverse steps 1 and 2. When reconnecting the

(4) wire connectors the RED connector goes into

PROBE slot on board, the 3 prong white connector goes into the done light slot on the board, the

2 pronged white connector goes into the speaker

slot on the board and the six prong maroon

connector goes into the main P.C. Board slot on

the board. Make sure all connections are tight.

See figure 12.

figure 12

figure 15

4. Reverse steps 1-3 to install the replacement

board. Be sure all wire connections are tight

and properly located.

7

Page 8

Model No. 411-262S Main P.C. Board

Model No. 411-85S Probe Assembly

Tools Needed: 1/4” Flat Blade Screwdriver

1. Disengage safety latch and lower toaster to toast

position. Using 1/4” flat blade screwdriver

remove (2) screws (A) from cover (B) on lower

control box, and remove cover. See figure 16.

figure 16

2. Using the 1/4” flat blade screwdriver remove (2)

screws (A) from the front of the lower control box

and carefully pull back faceplate exposing main

P.C. Board. See figure 17.

figure 17

Tools Needed: 3/16” Flateblade Screwdriver

1/4” Flatblade Screwdriver

Nut Driver 8-32

1. Using the 1/4” flat blade screwdriver remove (7)

screws (A) that secure the cover tot he control

box. See figure 20.

figure 20

2. Using a 3/16” flateblade screwdriver loosen the

(2) screws (A) that attach probe wires to the

yellow mini-jack (B) and remove the (2) wires

from this connection. See figure 21.

A

3. Disconnect the (5) wire connectors (A) from the

board. See figure 18.

figure 18

A

A

4. Using the 1/4” flat blade screwdriver remove the

(5) screws (A) from the front of the faceplate

which holds the board to the faceplate, and

remove the old board. See figure 19.

figure 19

figure 21

3. Unplug wire connector (A) from the probe (B) to

the printed circuit board (C). See figure 22.

figure 22

A

A

5. To install the new P.C. Board reverse steps 1-4.

Make sure all wire connections are tight.

8

Page 9

4. Using a nut driver remove nut (A) which secures probe

bracket (B) to screw (C) on the control box.

See figure 23.

figure 23

5. Remove probe bracket (A) and carefully slide probe (B)

out of the platen tube. Discard old probe assembly.

See figure 24.

figure 24

B

Model No. 78-166S Power Switch

Tools needed: 1/4” Flat Blade Screwdriver.

1. Lower toaster to toast position. Using 1/4” Flat

Blade Screwdriver remove (2) screws (A) from

the lower control box and lift off cover. See

figure 25.

figure 25

2. Disconnect (4) wire connections (A) from the

power switch (B). See figure 26.

figure 26

6. Install new probe by reversing steps 2 through 5. For

probe replacement in the lower control box follow these

same instructions.

3. Remove power switch by squeezing bezel clips

on switch (A) and pushing switch (B) out of the

control box. See figure 27.

figure 27

4. To install new power switch reverse steps 1-3.

Make sure all wire connections are

tight and on the right posts.

Top Left = Brown Wires

Bottom Left = Black Wire

Top Right = Double Black Wire

Bottom Right = Double Red Wire

9

Page 10

PARTS LIST

ITEM PART NO. DESCRIPTION

1 411-2S Base

2 89-959S Rubber Foot

3 411-243 Rear Lever Assy.

7 411-200 Safety Latch

8 411-238 Front Lever Assy.

9 411-118 Safety Latch Pin

10 411-8S Lower Platen

411-26S Lower Platen (220 Volt)

11 411-42 Lower Rear Bun Fence

12 411-44 Lower Left Hand Bun Fence

13 411-43 Lower Right Hand Bun Fence

14 411-70 Platen Tube

15 411-6S Upper Platen

411-24S Upper Platen (220 Volt)

16 411-254 Upper Rear Bun Fence

17 411-234 Upper Left Hand Bun Fence

18 411-223 Upper Right Hand Bun Fence

19 411-86 Spring Rod

20 81-013 Extension Spring

21 411-146 Guide Rod (Shaft)

22 411-108 Lever Block

23 89-925 Plunger Spring

24 411-107 Lever

25 411-117 Cover Plate

26 411-230 Left Hand Stop Block

27 411-231 Right Hand Stop Block

28 411-127 Index Window

29 411-123 Bun Tray Stop

30 411-256 Right Side Panel Assy.

31 411-41 Strain Relief Bracket

32 66-015 Strain Relief Bushing

33 72-126S Power Cord

34 411-257 Left Side Panel Assy.

40 411-77 Lower Chassis

41 411-80 Lower Face Plate Assy.

42 411-32 Potentiometer Bracket

43 411-133S Lower Potentiometer Assy.

44 411-132S Upper Potentiometer Assy.

46 411-261S Power P.C. Board

47 89-924 Standoff

48 77-058 Barrier Strip

49 411-85S Probe Assy.

50 213-166 Probe Retainer

51 411-31 Chassis Cover

52 411-262S Main P.C. Board

53 88-497 Mini-Jack

54 71-117 Clear Lens

55 78-166S Power Switch

56 411-69S Interconnect Cable

411-109S Interconnect Cable (220 Volt)

57 66-027 Aluminum Stain Relief

66-062 Strain Relief (220 Volt)

58 411-83 Cable Cord Bracket

59 89-938 Loop Steel Clamp

60 411-33 Door Plate

61 411-34 Door Guard

62 88-573 Cable Clamp

63 89-921 Nylon Spacer

65 411-72 Upper Chassis Assy.

66 411-74 Upper Face Plate

67 213-229 Speaker Assy.

68 482-18 Speaker Grease Seal

69 411-14S Sensor P.C. Board

70 213-257 Done Light Assy.

71 411-140 Insulator

A 411-59 Base Stud 5/16-18

411-113 Base Spacer

73-167 Self Locking Hex Nut 5/16-18

B 411-60 Lower Rear Platen Stud

411-57 Lower Platen Spacer

C 411-60 Upper Platen Stud

411-241 Safety latch Spacer

D 411-60 Upper Platen Stud

411-221 Upper Platen Spacer

E 76-218 Slotted Binder Head Screw 1/4-20

F 411-60 Lower Front Lever Platen Stud

411-57 Upper Platen Spacer

H 76-179 Slotted Binder Head Screw 10-18

J 76-382 Hex Head Screw 1/4 -20 x 3/8

K 76-343 Set Screw 10-32 x 3/4

L 68-039 Roll Pin

M 76-600 Slotted Flat Head Screw 10-24 x 1

73-008 Self Lock Hex Nut 10-32

N 76-040 Slotted Binder Head Screw 10-32

P 76-043 Slotted Binder Head Screw 8-32

R 76-095 Slotted Binder Head Screw 6-32

S 76-095 Slotted Binder Head Screw 6-32

79-002 Intl. Tooth Washer #6

T 76-044 Slotted Binder Head Screw 8-32

73-021 Hex Nut 8-32

U 76-095 Slotted Binder Head Screw 6-32

79-033 Split Lock Washer #6

73-031 Self Locking Hex Nut

V 76-043 Slotted Binder Head Screw 8-32

79-031 Split Lock Washer #8

73-021 Hex Nut 8-32

W 76-043 Slotted Binder Head Screw 8-32

79-143 Flat Washer

73-013 Self Locking Hex Nut

X 920-184 Hex Nut

79-144 Washer

Y 76-043 Slotted Binder Head Screw 8-32

73-013 Self Locking Hex Nut

AA 76-043 Slotted Binder Head Screw 8-32

73-013 Self Locking Hex Nut

BB 76-064 Slotted Binder Head Screw 8-32

73-021 Hex Nut 8-32

CC 76-043 Slotted Binder Head Screw

73-021 Hex Nut

DD 76-051 Slotted Binder Head Screw 6-32

73-015 Self Locking Hex Nut 6-32

EE 76-300 Slotted Pan Head Screw

72 411-233 Upper Bracket

Page 11

73 411-234 Upper Bracket

74 411-240 Front Bracket

75 212-622 Front Bracket

76 411-227 Platen Bracket

EXPLODED VIEW

77 411-228 Platen Bracket

78 411-239 Front Bracket

79 411-242 Teflon Holder

80 212-331 Platen Plate

UPPER CHASSIS ASSEMBLY

LOWER CHASSIS ASSEMBLY

Page 12

WIRING DIAGRAM

12

Loading...

Loading...