Page 1

SOLID STATE DIGITAL ENERGY SAVING TOASTER

PRINCE CASTLE MODEL NO. 411-SD SERIES

This equipment chapter is to be placed in the

toasters section of your Equipment Manual.

MANUFACTURED FOR

MCDONALD’S®

BY

PRINCE CASTLE INC.

355 KEHOE BLVD.

CAROL STREAM, IL. 60188 USA

PHONE 1-630-462-8800

TOLL FREE NUMBER

1-800-323-2930

FAX:1-630-462-1460

WARRANTY .............................................................................................................................................................................................. Page 1

SIDE VIEW ................................................................................................................................................................................................ Page 2

FRONT VIEW............................................................................................................................................................................................ Page 3

REAR VIEW .............................................................................................................................................................................................. Page 3

INTERNAL VIEW ..................................................................................................................................................................................... Page 4

EQUIPMENT SET-UP.............................................................................................................................................................................. Page 5

PROGRAMMING ...................................................................................................................................................................................... Page 6

CLEANING ................................................................................................................................................................................................ Page 8

TROUBLESHOOTING ............................................................................................................................................................................. Page 8

DI AGNOSTIC TROUBLESHOOTING ....................................................................................................................................................... Page 9-11

TRANSLATIONS (FRENCH, GERMAN, SPANISH, ITALIAN) ......................................................................................................... Page 12-39

WIRING DIAGRAM .................................................................................................................................................................................. Page 40

LIMITED WARRANTY

This product is warranted to be free from defects in material and/or workmanship for a period of (2) years

from date of original installation not to exceed 30 months from date of shipment from our factory. Printed

circuit boards and platen are warranted for a period of (3) years from date of original installation not to

exceed 42 months from date of shipment from our factory. Any part or component which proves to be

faulty in material and/or workmanship within the warranty period will be replaced or repaired without cost

to the customer for parts or labor. (At the option of Prince Castle, Inc.)

This warranty is subject to the following exceptions/conditions:

Any use of Non-genuine Prince Castle spare parts voids this warranty, and all work must be per-

formed by an authorized Prince Castle Service Agent.

All labor should be performed during regular working hours. Overtime premium will not be covered.

Travel charges are limited to 100 miles (200 km) round trip, 2 hours travel time, one trip per repair.

Damage caused by carelessness, neglect, and/or abuse (e.g., using wrong current, dropping, tam-

pering with or altering electrical components, or improper cleaning) is not covered.

Equipment damaged in shipment, by fire, flood or an act of God.

This manual is for the exclusive use of licensees and employees of McDonald’s Systems, Inc.

2002 McDonald’s Corporation Printed in the

All Rights Reserved United States of America

Part No. 411-543 Rev. C

Page 2

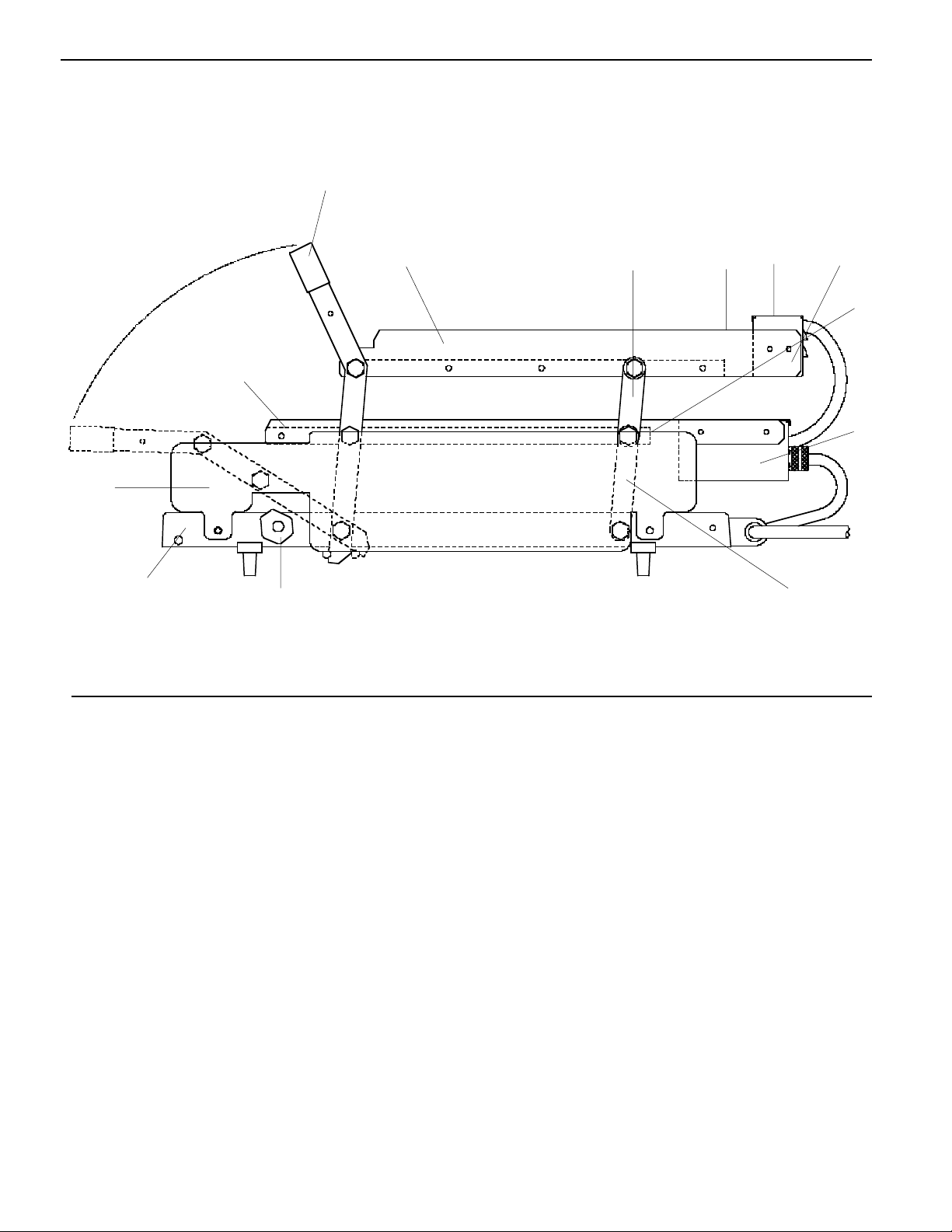

SIDE VIEW

12

1

23456

7

13

8

11

PARTS LIST

10

ITEM PART NUMBER DESCRIPTION

1 411-149S Handle and Lever Assy.

2 411-441 Right Hand Upper Bun Fence

411-440 Left Hand Upper Bun Fence

3 411-461S Upper Rear Lever Assy.

4 411-378 Upper Rear Bun Fence

5 411-31 Upper Cover

6 411-283 Upper Chassis

7 411-381 Lower Rear Bun Fence

8 411-741 Lower Chassis

9 411-459S Lower Rear Lever Assy.

10 411-137 Right Hand Stop Block

411-138 Left Hand Stop Block

11 411-2S Base

12 411-444 Side Panel, Right Hand

411-445 Side Panel, Left Hand

13 411-379 Right Hand Lower Bun Fence

411-380 Left Hand Lower Bun Fence

Not Shown 411-114 Safety Latch

Not Shown 411-744 Bun Board

9

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

2

Page 3

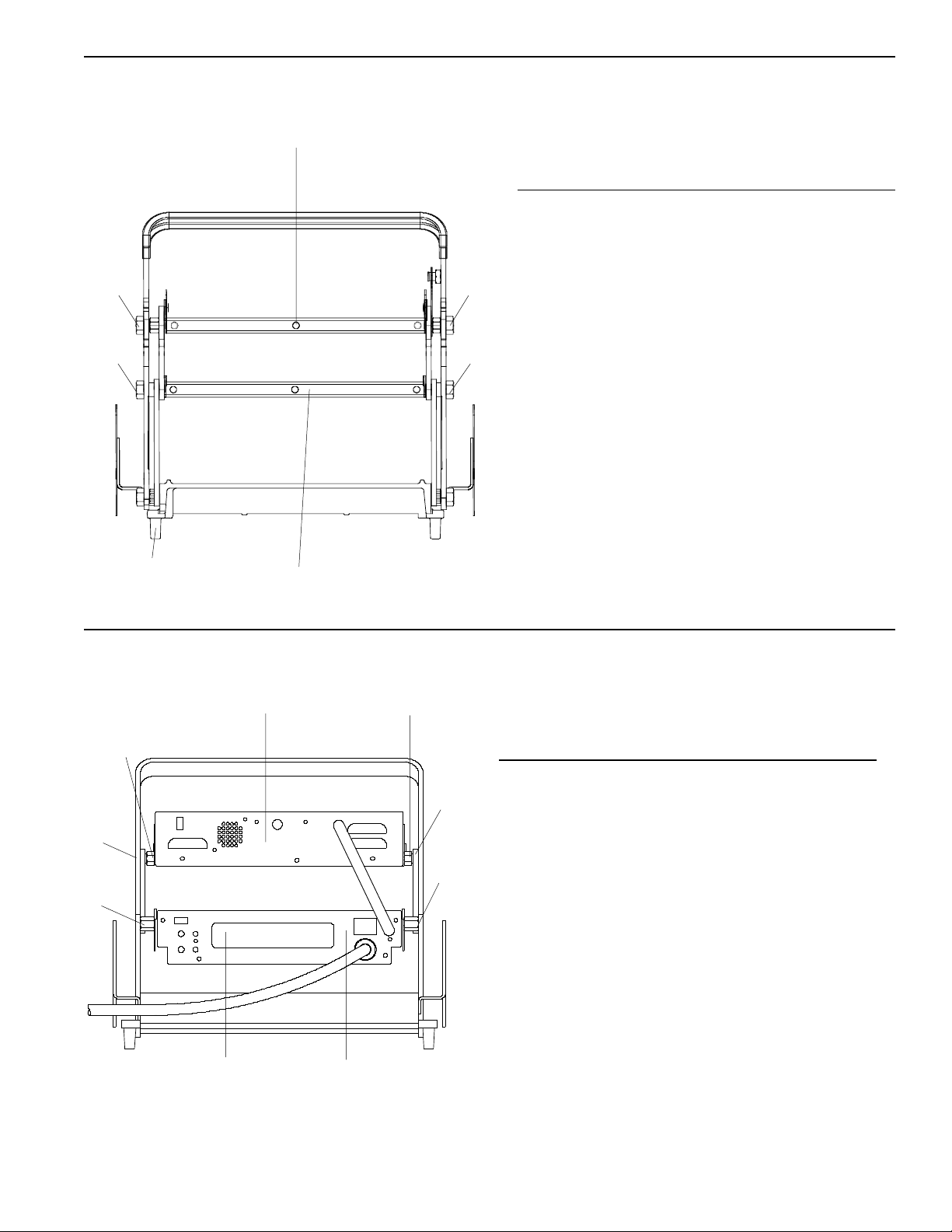

FRONT VIEW

1

PARTS LIST

2

3

5

REAR VIEW

2

3

4

1

2

ITEM PART NUMBER DESCRIPTION

1 411-483S Upper Platen 230V

411-6S Upper Platen 120V

2 411-60 Front Upper

Platen Stud

3 411-60 Front Lower

Platen Stud

4 411-486S Lower Platen 230V

411-8S Lower Platen 120V

5 89-959S Foot (Pkg. of 4)

2

PARTS LIST

3

3

4

4

6

2000 McDonald’s Corporation Part No. 411-543 Rev C. Printed in the

All Rights Reserved United States of America

5

ITEM PART NUMBER DESCRIPTION

1 411-712 Upper Faceplate

2 411-57 Platen Spacer

3 411-147 Rear Upper

Platen Stud

4 411-61 Rear Lower

Platen Stud

5 411-705 Lower Faceplate

6 411-707 Overlay

3

Page 4

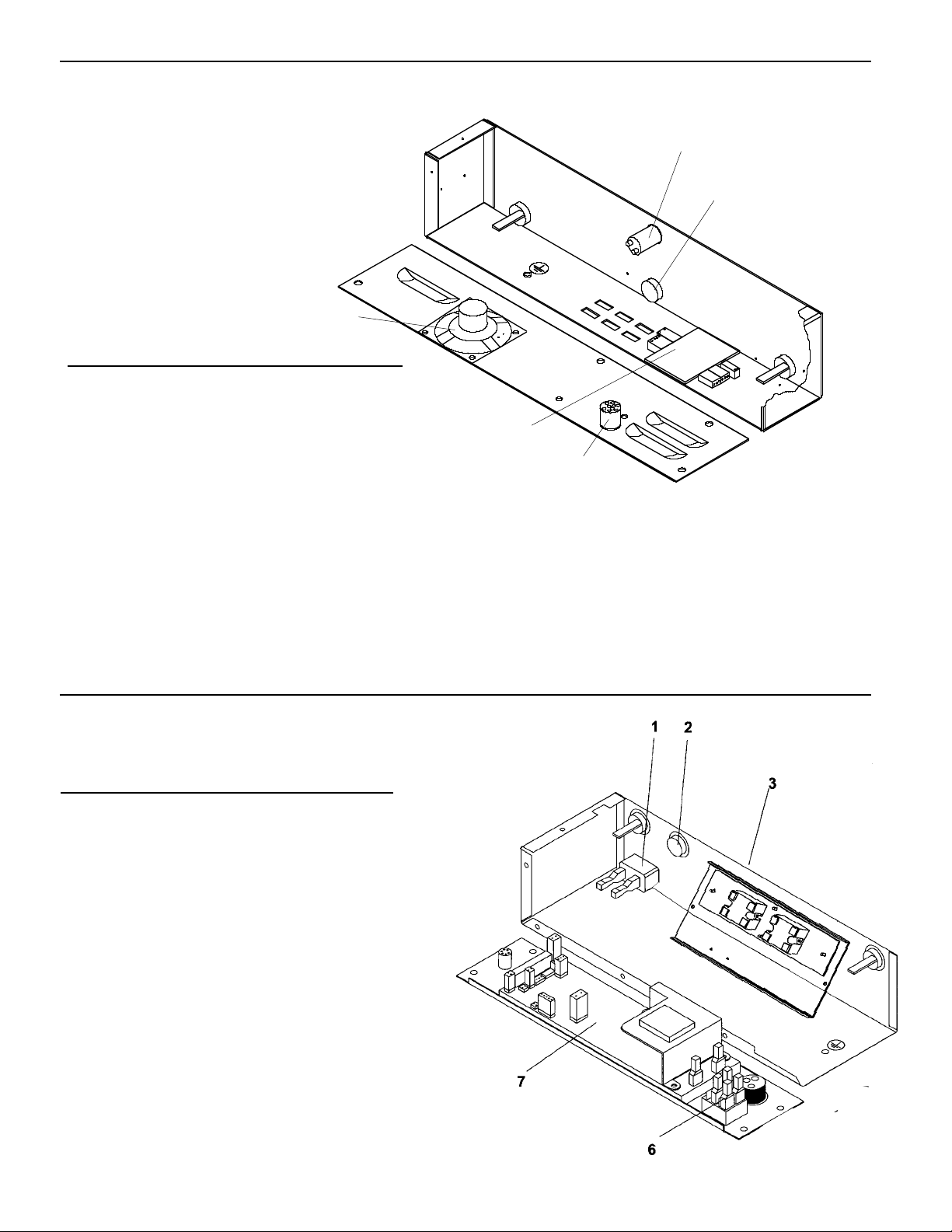

INTERNAL VIEW UPPER CONTROL BOX

5

PARTS LIST

1

2

ITEM PART NUMBER DESCRIPTION

1 213-257S Bun Done Light

2 411-700S Upper Probe

3 411-740 Interconnect Cable

4 411-14S Interconnect Board

5 213-229S Speaker

INTERNAL VIEW LOWER CONTROL BOX

PARTS LIST

ITEM PART NUMBER DESCRIPTION

4

3

1 65-058S Relay, Lower & Upper

2 411-700S Probe

3 72-301S Power Cord 220-230V

72-274 Power Cord 120V

4 78-166S Rocker Switch

5 411-427-05S Control PCB 220-230V

411-601S Control PCB 120V

2000 McDonald’s Corporation Part No. 411-543 Rev C

All Rights Reserved

4

United States of America

Printed in the

Page 5

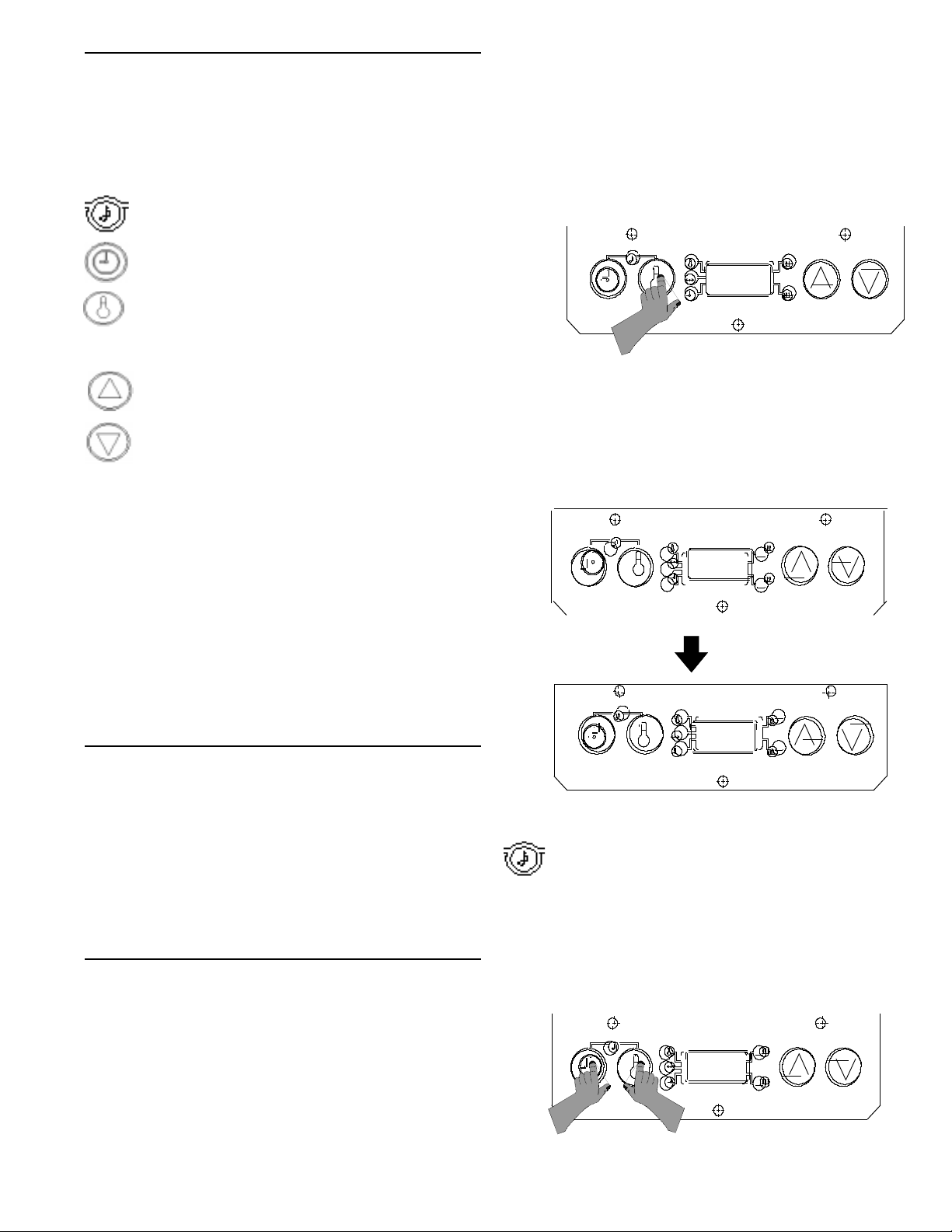

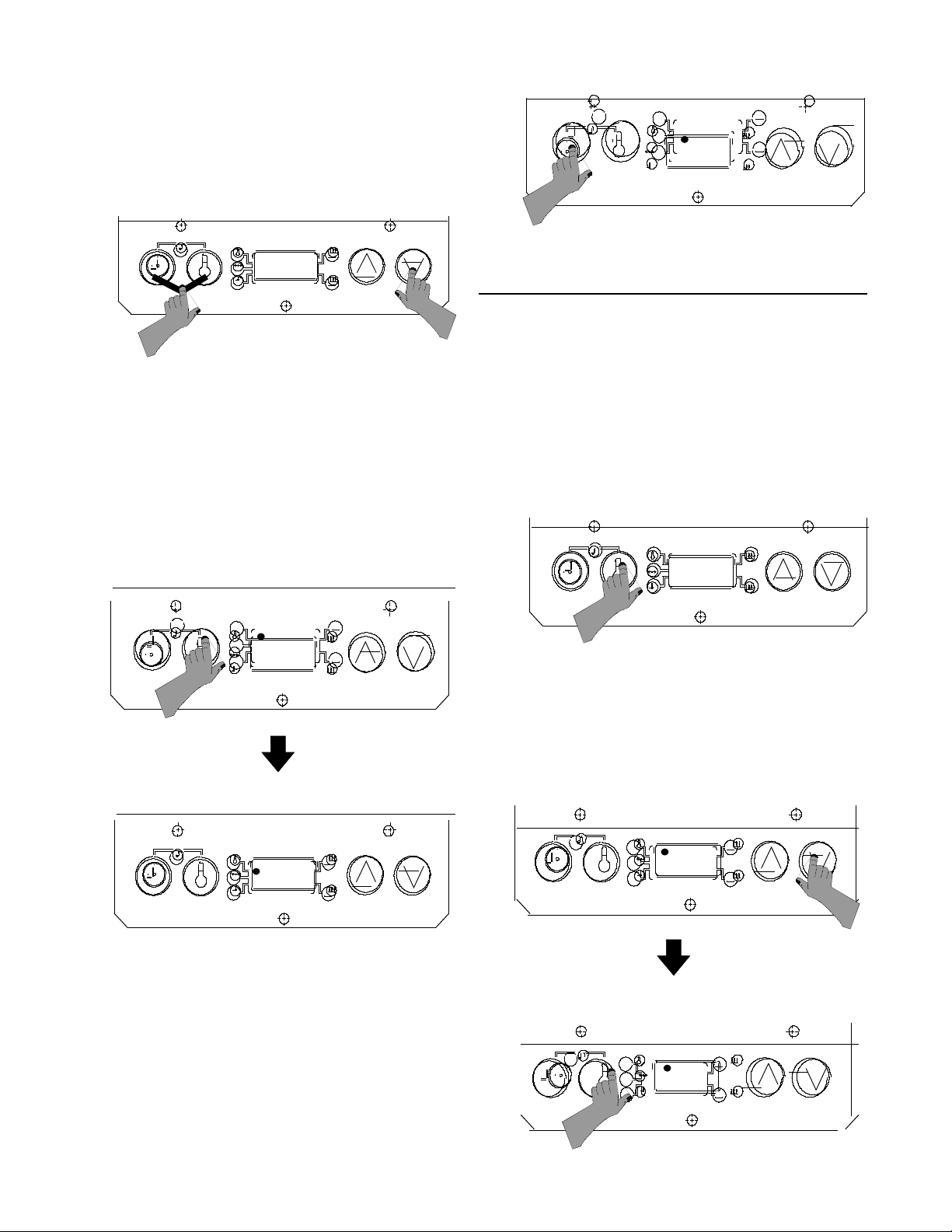

SYMBOLS & TERMS

C - - A Toaster is set on Celsius.

F - - A Toaster is set on Fahrenheit.

A L - Alarm Level setting 1-4.

operating temperature.

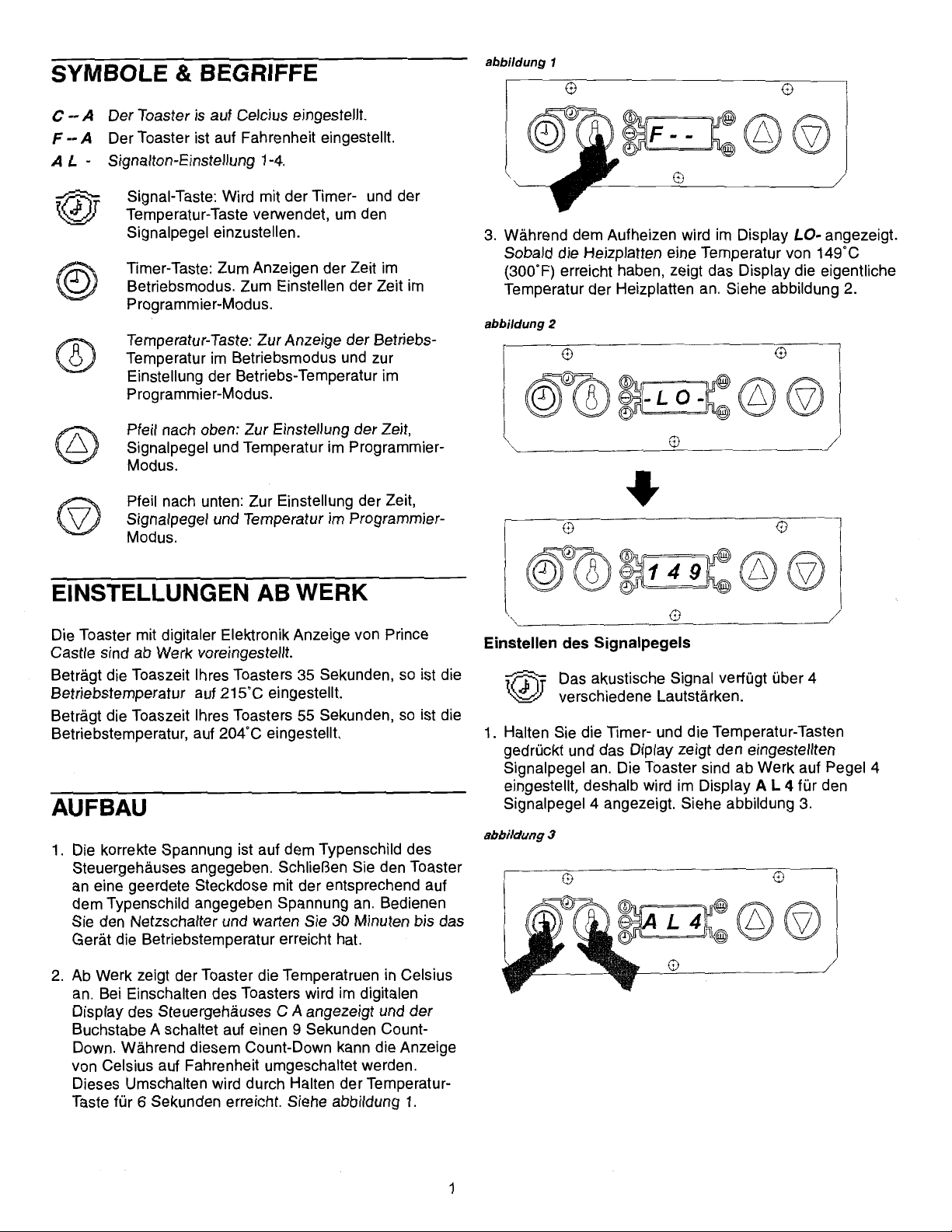

2. The toaster is factory-set to display temperatures

reading in Celsius. When the toaster is turned on,

the digital display on the control box will read C--A

for Celsius, and the “A” will begin to count down 9

seconds. During this countdown, you can change

the temperature display from Celsius to Fahrenheit

Sound Button: Used with timer button

and temperature button to set alarm

level.

Timer Button: Used to view time in run

mode. Used to set time in program mode.

Temperature Button: Used to view set

point temperature in run mode, and used

to set the set point temperature in

program mode.

Up Arrow: Used to set time, sound and

temperature in program mode.

Down Arrow: Used to set time, sound,

and temperature in program mode.

ENERGY SAVING MODE

To conserve energy during non-toasting periods,

pull the toaster handle down, so that the timing

cycle activates. When the audio alarm goes off,

indicating that the toasting time is complete, DO

NOT pull the handle up. Allow the audio alarm to

sound until the alarm shuts off, the display will

alternately flash “Stand” and “By”, indicating the

toaster is in the energy savings mode. The toaster

platens will continue to maintain the programmed

operating temperature, raising the toaster handle

will put the toaster back into the operation mode.

figure 1

F - -

readings. To change temperature display, press

and hold the temperature button for six seconds.

See figure 1.

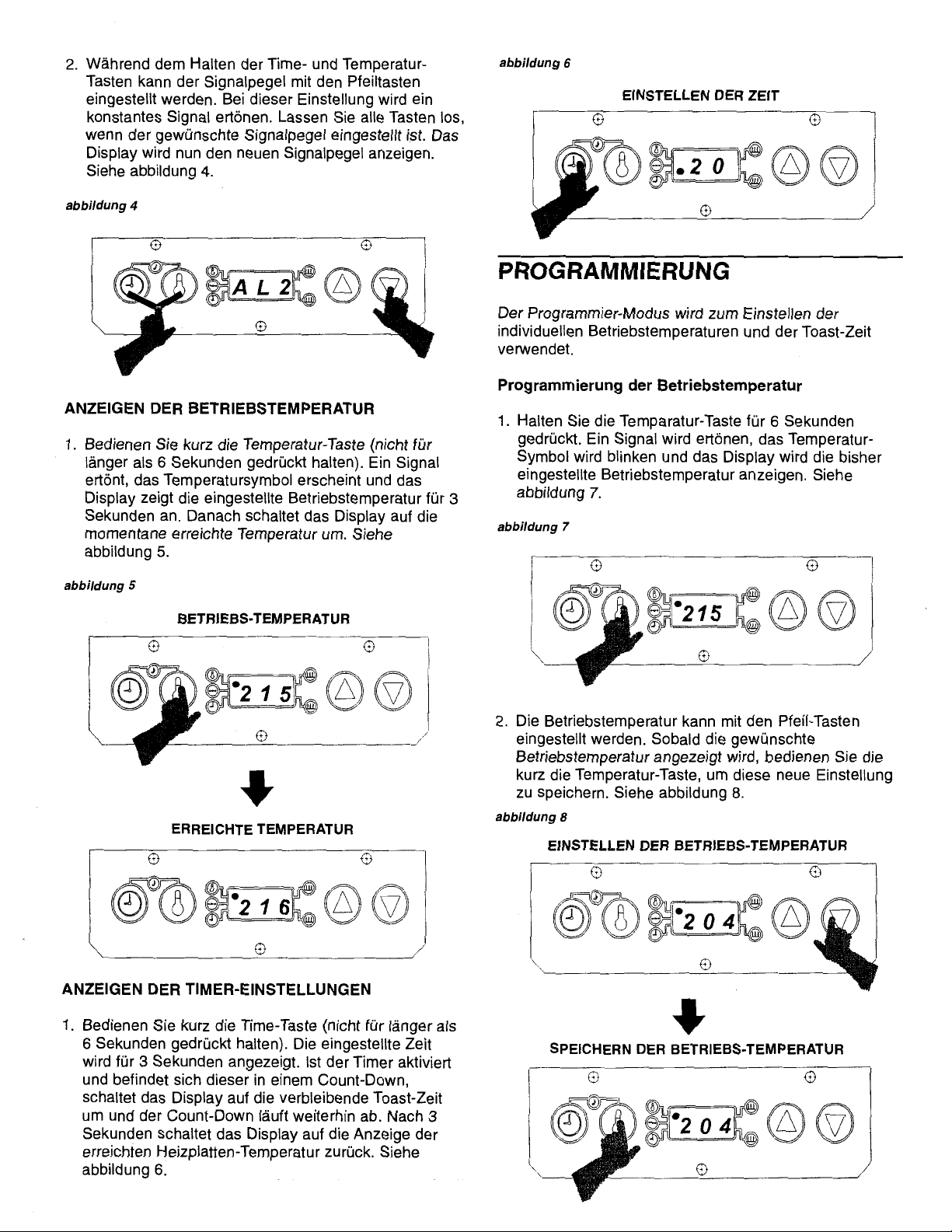

3. During the pre-heat cycle, the display will read -

L O -. When the platen temperature reaches

figure 2

- L O -

1 4 9

FACTORY PRE-SET

Prince Castle’s Solid State Digital Display toasters are

pre-set at the factory.

If your toaster model is set for a 35 second toast time,

then the temperature is pre-set and calibrated to

215°C.

If your toaster model is set for a 55 second toast time,

then the temperature is pre-set and calibrated to

204°C.

SET-UP

1. Refer to the nameplate on the control box for the

proper operating voltage. Connect the toaster to a

grounded receptacle that matches the nameplate

voltage information. Press the power switch to the

on position, allow the unit 30 minutes to reach

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

149°C (300° F), the display will begin to show

the actual platen temperatures throughout

the toasting cycles. See figure 2

Sound Level Adjustment

The audio alarm has four sound levels.

1. Press and hold the time button and temperature

buttons simultaneously. The display will show the

current sound level. The toasters are factory set at

level 4, and the display will read, A L 4 for Alarm

figure 3

A L 4

5

Page 6

Level 4. See figure 3.

2. While holding the time and temperature buttons,

press the up or down arrow buttons to adjust

the sound level. A continuous tone will sound.

Release all buttons when the desired sound

figure 4

figure 6

SET TIME

2 0

A L 2

level is reached. The display will show the

current sound level. See figure 4.

VIEW SET POINT TEMPERATURE

1. Press and release the temperature button. (Do not

hold for more than 6 seconds.) A beep will sound,

the temperature indicator will turn on, and the

display will show the set point temperature for

three seconds. The display will then change to

show the actual temperature. See figure 5.

figure 5

SET POINT TEMPERATURE

2 1 5

change to show actual platen temperature. See

figure 6.

PROGRAMMING

The programming modes are used for setting individual set point temperature, and setting toast times.

Programming the Set Point Temperature

1. Press and hold the temperature button for six

seconds. A beep will sound, the temperature

indicator light will blink, and the display will show

215

figure 7

the current set point temperature. See figure 7.

2. To change the set point temperature, use the up

or down arrow. Once the desired temperature is

figure 8

ACTUAL TEMPERATURE

ADJUST SET POINT TEMPERATURE

2 0 4

2 1 6

VIEW TIMER SETTING

1. Press and release the time button. (Do not

press the time button for more than 6 seconds.)

The set time will be displayed for three seconds. If the timer is activated and is in a countdown sequence, the time remaining will be

displayed, and will continue to countdown to

zero. After three seconds, the display will

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

6

STORE SET POINT TEMPERATURE

2 0 4

Page 7

displayed, press the temperature button to store

the new setting. See figure 8.

3. To cancel the set point programming mode at any

time, press and release the time button. The

figure 9

time is reached, press and release the time

button to store the new time. See figure 11.

3. To cancel the time set function at any time, press

and release the temperature button. The time indicator light will turn off, and the display will change to

figure 12

2 1 5

display will change to show the actual platen

temperature. See figure 9.

Programming Toast Times

1. Press and hold the time button for 6 seconds. A

beep will sound, and the time indicator light will

figure 10

5 5

blink. Release the time button to show the

current toast time. See figure 10.

2. Use the up and down arrow buttons to set your

desired toast time. The range is from 20 seconds to 1 minute, 30 seconds. When desired

figure 11

SETTING THE NEW TIME

2 1 5

show the actual platen temperature. See figure 12.

SETTING STOP BLOCKS

Stop blocks allow for proper crush when toasting

buns. The toaster leaves the factory with the stop

blocks set on R/Q.

Dual stop blocks allow you to switch back and forth

from Reg/Qtr. bun and Big Mac Bun toasting, or Rib

bun or Rye bun toasting.

1. Ensure the stop blocks are on the correct setting.

There are (6) combination Stop Block Settings:

1. R/Q / MAC 4. RIB / RYE

2. R/Q+ / MAC + 5. RIB+ / RYE +

3. R/Q- / MAC - 6. RIB- / RYE -

THE (+) SETTING IS FOR BUNS THAT ARE CUT

TOO THICK. THE (-) SETTING IS FOR BUNS CUT

TOO THIN. FOR NORMAL SIZE BUNS DO NOT

USE (+) or (-) SETTINGS.

[R/Q = REG/QTR]

2. Rotate stop blocks by hand to the desired

combination bun setting listed above.

3. View the stop block setting selected through the

index window bracket, which is located over the

3 5

STORING THE NEW TIME

figure 13

SIDE PANEL

STOP BLOCK

BUN SETTING

(REGULAR BUNS)

3 5

INDEX WINDOW BRACKET

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

7

Page 8

left stop block. See figure 13.

4. To switch between the two types of buns per

your stop block setting, locate the selector

lever on the front of the toaster frame. Move the

lever left or right to switch back and forth between

the combination setting. See figure 14.

figure 14

figure 15

FRONT OF

FRAME

SELECTOR

LEVER

BUN BOARD ADJUSTMENTS

1. Push or pull the bun board handle to desired

notched setting as indicated by graphics

stamped on top of bun board. See figure 15.

2. Bun board graphics are:

FRONT = REG, RYE, QTR HEELS

REAR = BIG MAC, (CROWNS) AND RIB

HEELS

CLEANING

1. Press the power switch to the off position.

2. Unplug toaster.

3. Allow toaster and platens to cool down.

4. Wipe entire platen with clean, damp grill cloth.

Full toaster cleaning must be done in the morning when toaster is cold. See your Planned

Maintenance Card for proper cleaning procedures.

IMPORTANT: Do not drape cord over hot toaster

bun board or platen. This will cause cord to burn.

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

Platen loose. Platen bolts loose. Tighten platen bolts.

Buns being crushed. Stop blocks not adjusted Adjust stop blocks.

properly.

Warped bun trays. Straighten or replace bun

trays.

Contact Bakery.

No Display. Fuse Defective. Check fuse with ohmmeter,

reading should be 1-2 ohms.

DIAGNOSTIC SIGNALS

This toaster comes with self-diagnostic signals. When the P.C. Board senses a component

failure, the display will change from showing the actual temperature to one of the signals

listed on the following two pages, an audio alarm will sound when an error cole message is

displayed. There are two different error code alarms. During a “LO” temp signal, the alarm

will alternately beep 5 times then pause for 5 seconds until the platen heats back up to the

toasting temperature. All other error code messages will be accompanied by an alarm that

alternately sounds for 6 seconds then goes silent for 2 minutes.

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

8

Page 9

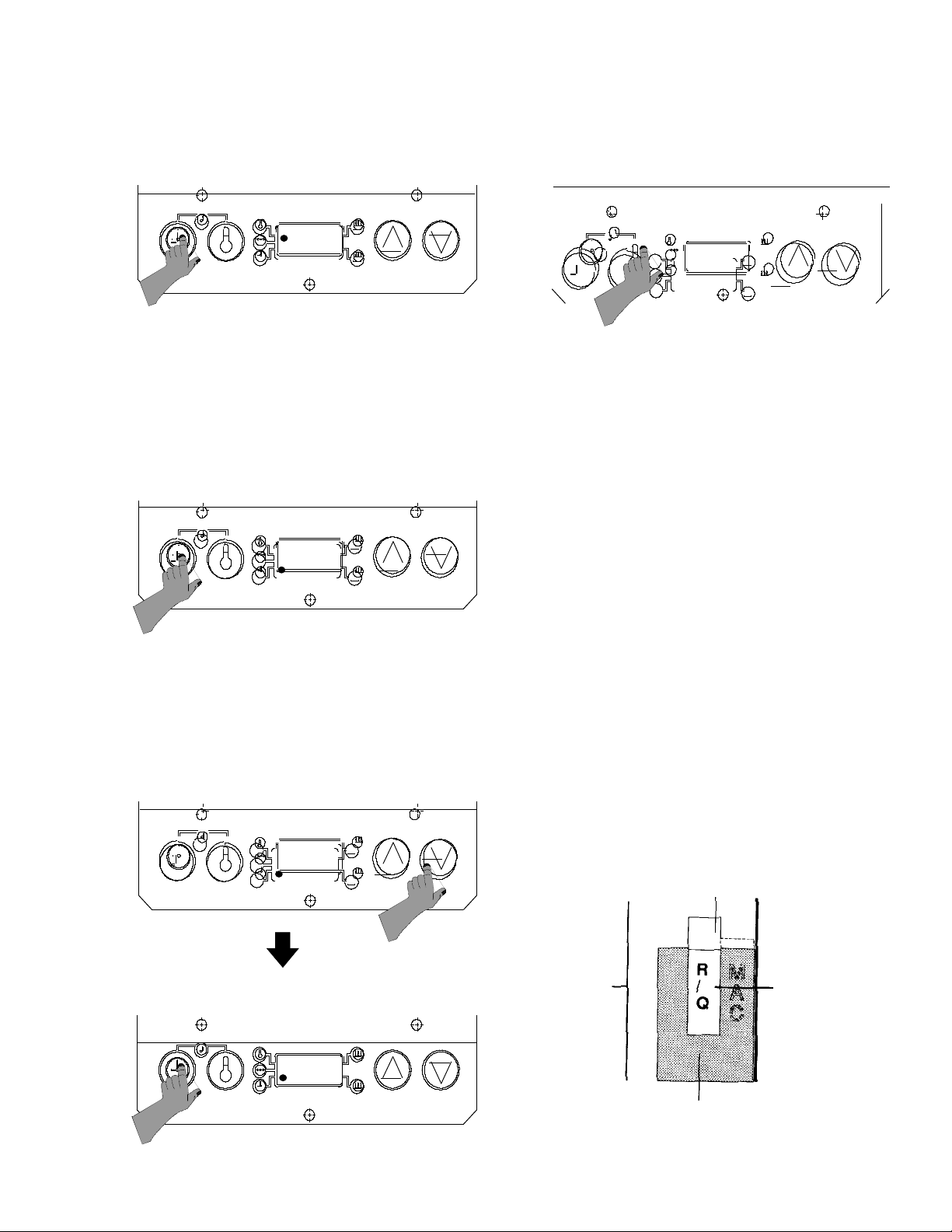

9

E01

Upper Heat

Indicator Light

Lower Heat

Indicator Light

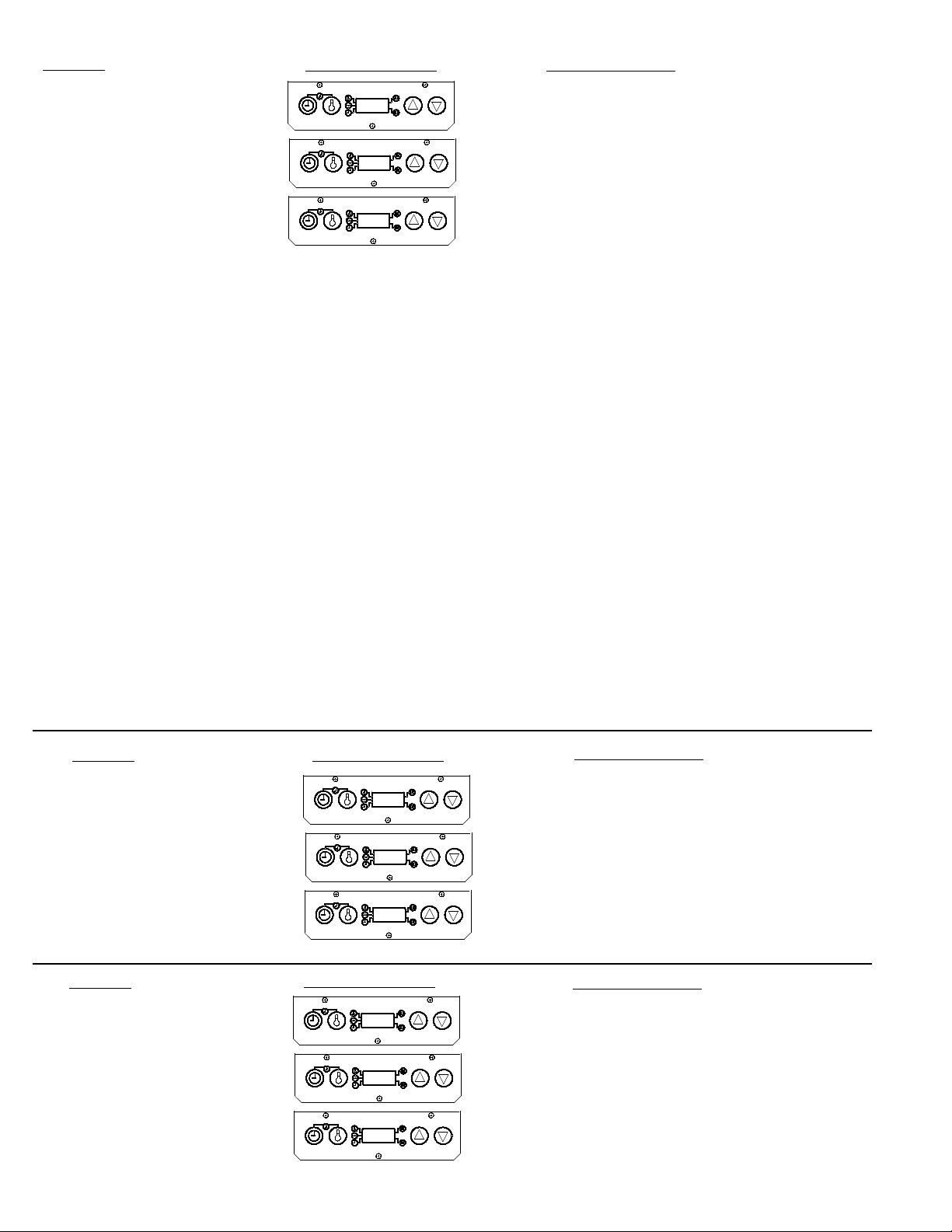

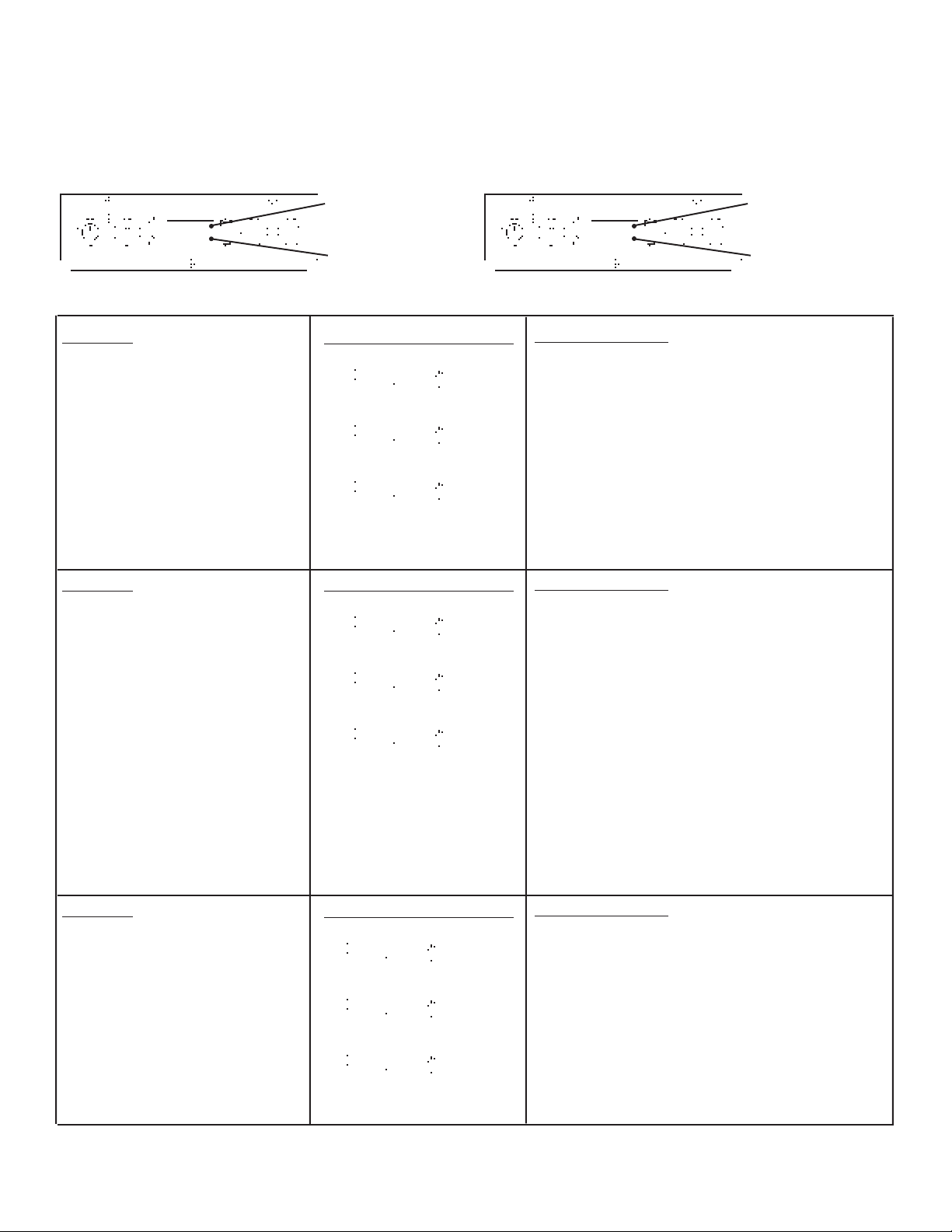

Solid State Toaster Diagnostic Chart

When a part or parts fail in the 213, 416 or 411 Solid State Toasters an ERROR CODE will flash in the display (see figures

below) and an audio alarm will sound. The troubleshooting chart below will explain each error code and what action to

take to determine which component has failed. A “0” on the left means there is a lower circuit failure, a “0” on the right

means there is a upper circuit failure.

UPPER CIRCUIT FAILURE LOWER CIRCUIT FAILURE

E10

Upper Heat

Indicator Light

Lower Heat

Indicator Light

EO1

E1O

E1 1

Diagnostic Codes

Lower platen over heating.

Upper platen over heating.

Both platens over heating.

Problem

Corrective Action

EO2

E2O

E2 2

Diagnostic Codes

Lower probe open.

Upper probe open.

Both probes open.

Problem

Disconnect the corresponding probe and

measure the probe resistance.

The corresponding probe is inoperable if:

The platen temperature is less than 25°C

and the resistance is greater than 1100 ohms.

The platen temperature is less than 100°C

and the resistance is greater than 1381 ohms.

The platen temperature is less than 200°C

and the resistance is greater than 1744 ohms.

IMPORTANT NOTE: If the probe resistance

is correct, check the corresponding probe

connection on the printed circuit board. If the

connection is secure, the printed circuit board

is inoperable.

Corrective Action

Lower platen over heating.

Lower probe open.

Upper platen over heating.

Upper probe open.

Both platens over heating.

Both probes open.

Problem

EO3

E3O

E33

Diagnostic Codes

Corrective Action

Go to failures 01 and 02 above for

corrective action steps to take for a

03 error code.

Go to failures 10 and 20 above for

corrective action steps to take for a

30 error code.

Go to failures 11 and 22 above for

corrective action steps to take for a

33 error code.

With platen heat indicator light off, if voltage

across terminals 3/A1 and 4/A4 of the

corresponding relay is greater than 2.5 volts,

the printed circuit board is inoperable.

Turn power off and disconnect line cord,

disconnect the wire lead from terminal 2/T1 of

the corresponding relay.Measure the resistance across 2/T1 and 1/L1, if resistance is

less than 50K ohms, the corresponding relay

is inoperable.

Page 10

10

With platen heat indicator light on, if voltage

across terminals 3/A1 and 4/A4 of the

corresponding relay is less than 4 volts, the

printed cicuit board is inoperable.

With platen on, measure the AC voltage across

terminals 2/T1 and 1/L1 of the corresponding

relay, if voltage is greater than 2 VAC, the

corresponding relay is inoperable.

IMPORTANT NOTE: E04, E40, and E44

error codes indicate the platen temperatures

have dropped 30°C below the set point

temperature and may be caused by the

following:

1. Cool air blowing on the platens.

2. Low voltage applied to the toaster.

3. Continued toasting during “LO” temp

periods.

4. Inoperable printed circuit board.

Turn the power off, disconnect one side of the

platen and check the platen resistance.

See below: Cold readings are below 50°C

Hot readings are above 200°C

Model 411 series toaster is:

27.8 ohms cold to 32.4 ohms hot.

Model 213 series toaster is:

23 ohms cold to 26.7 ohms hot.

Model 416 series toaster is:

41.8 ohms cold to 48.6 ohms hot

EO4

E4O

E44

Diagnostic Codes

Lower platen under heating.

Upper platen under heating.

Both platens under heating.

Problem

Corrective Action

EO5

E5O

E55

Lower platen under heating.

Upper platen under heating.

Both platens under heating.

EO6

E6O

E66

Lower platen under heating.

Lower probe open.

Upper platen under heating.

Upper probe open.

Both platens under heating.

Both probes open.

Diagnostic Codes

Problem

Corrective Action

Go to E02 and E04 corrective action.

Go to E20 and E40 corrective action.

Go to E22 and E44 corrective action.

Diagnostic CodesProblem

Corrective Action

Go to E01 and E04 corrective action.

Go to E10 and E40 corrective action.

Go to E11 and E44 corrective action.

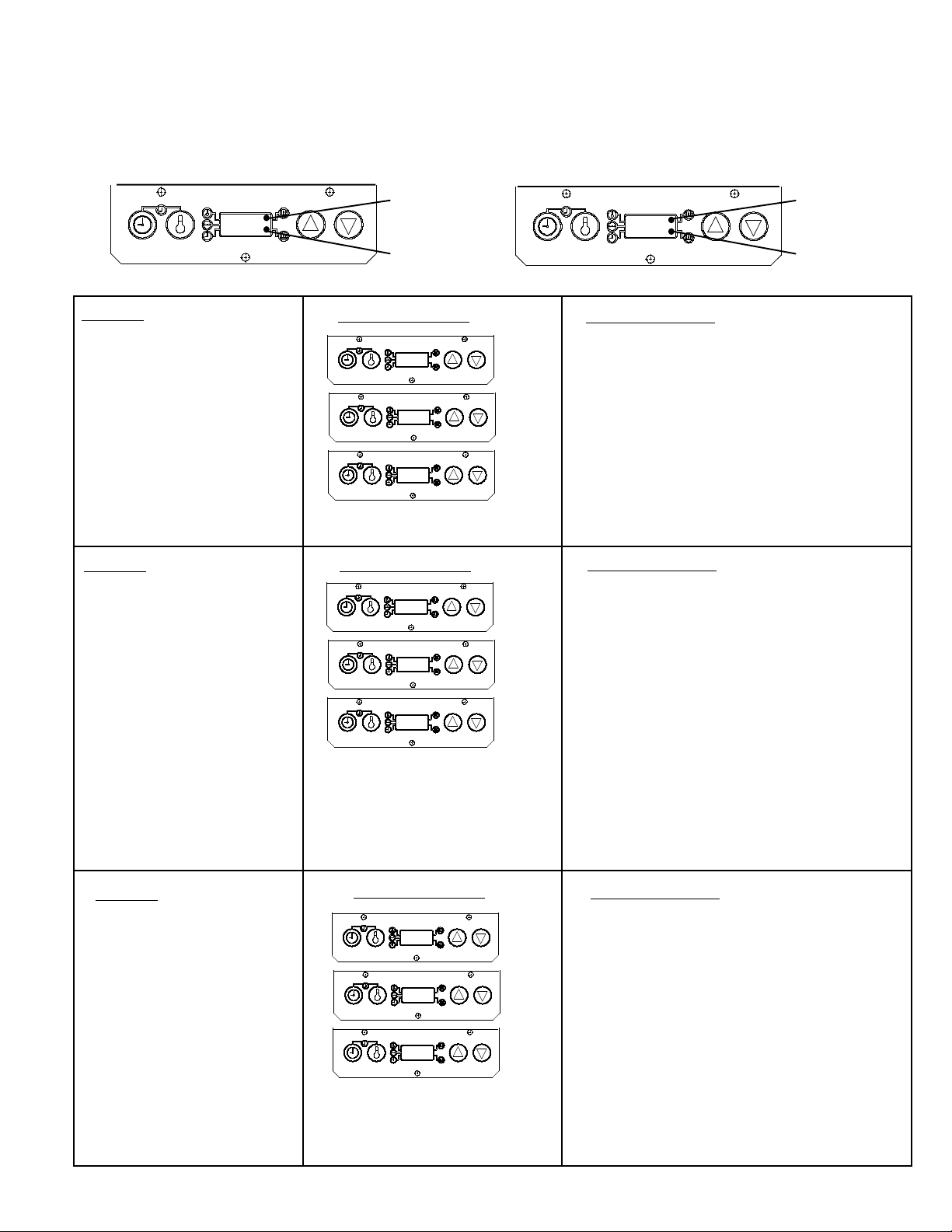

Page 11

11

EO7

E7O

E77

Lower platen under heating.

Lower platen over heating.

Lower probe open.

Upper platen under heating.

Upper platen over heating.

Upper probe open.

Both platens under heating.

Both platens over heating.

Both probes open.

Diagnostic CodesProblem Corrective Action

Go to E01, E02 and E04 corrective action.

Go to E01, E20 and E40 corrective action.

Go to E11, E22 and E44 corrective action.

EO8

E8O

E88

Lower probe circuit failure.

Upper probe circuit failure.

Both probe circuits failure.

Diagnostic Codes

Problem

Corrective Action

Go to E02 corrective action, replace the item

indicated by the test result.

Go to E20 corrective action, replace the item

indicated by the test result.

Go to E22 corrective action, replace the item

indicated by the test result.

EO9

E9O

E99

Lower platen over heating.

Lower probe open.

Upper platen over heating.

Upper probe open.

Both platens over heating.

Both probes open.

Diagnostic Codes

Problem

Corrective Action

Go to E01 and E08 corrective action.

Go to E01 and E80 corrective action.

Go to E11 and E88 corrective action.

Page 12

12

Page 13

Page 14

Page 15

Page 16

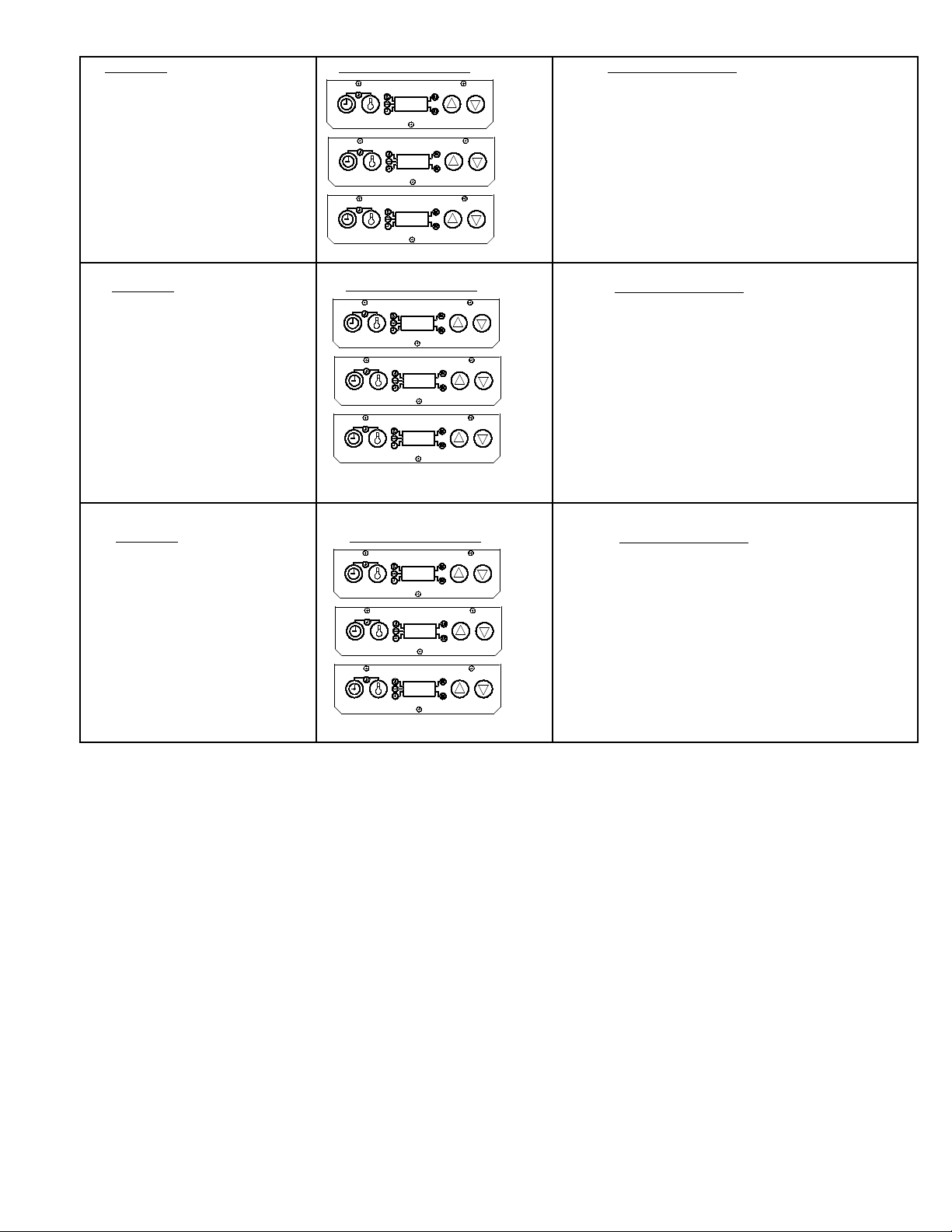

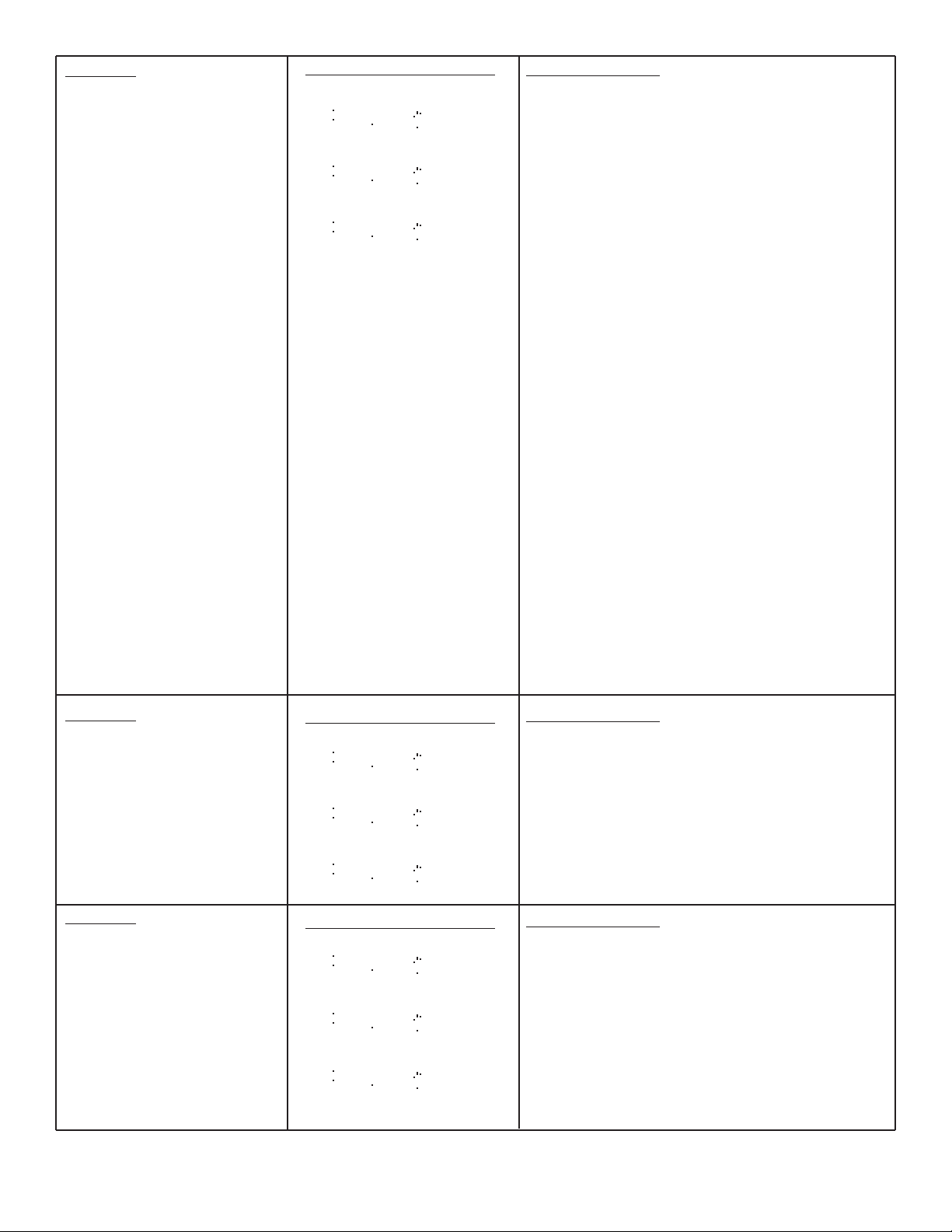

Fiche diagnostique pour grille-pain à semi-conducteurs

Quand une ou des pièces de grille-pain à semi-conducteur des séries 213, 416 ou 411 font défaut, un CODE

D’ERREUR clignotera sur l’indicateur (voir les figures ici-bas) et une alarme sonore se fera entendre. Le guide de

dépannage ci-dessous expliquera chaque code d’erreur et ce qui devra être fait afin de déterminer quel composant a fait

défaut. Un “O” à gauche veut dire qu’il y a une panne du circuit inférieur. Un “O” à droite veut dire qu’il y a une panne

du circuit supérieur.

Voyant indicateur pour

chaleur supérieure

E10 E01

Voyant indicateur pour

chaleur inférieure

Voyant indicateur pour

chaleur supérieure

Voyant indicateur pour

chaleur inférieure

PANNE DU CIRCUIT SUPÉRIEUR PANNE DU CIRCUIT INFERIEURE

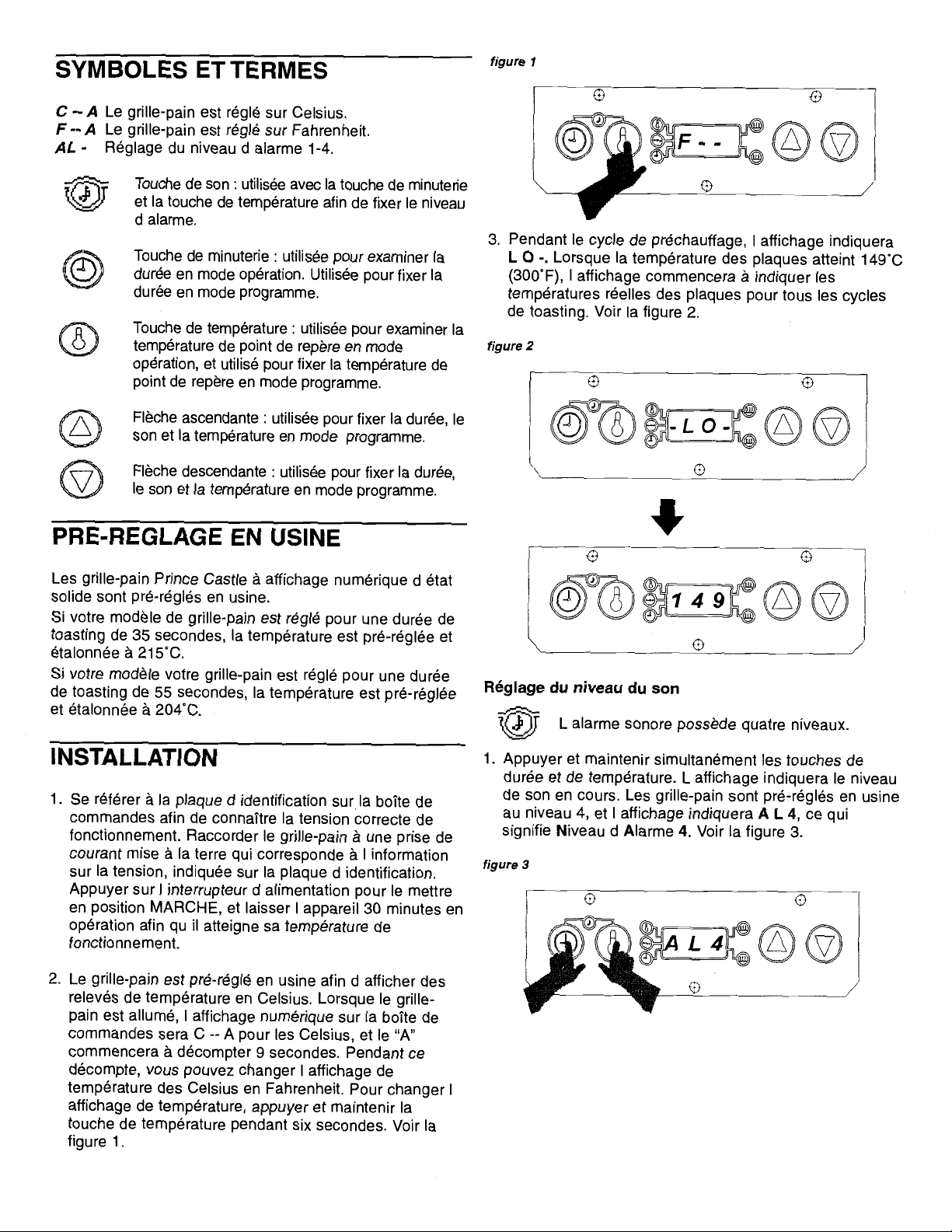

Problème

• La plaque inférieure surchauffe.

• La plaque supérieure surchauffe.

• Les deux plaques surchauffent.

Problème

• La sonde inférieure est ouverte.

• La sonde supérieure est ouverte.

• Les deux sondes sont ouvertes.

Codes des diagnostiques

E01

E10

E11

Codes des diagnostiques

E02

E20

E22

Mesure corrective

• Si le voyant de l’indicateur de chaleur est éteint

et le voltage des terminaux 3/A1 et 4/A4 des

relais correspondants est plus élevé que 2,5

Volts, la carte de circuits imprimés ne peut

fonctionner.

• Éteignez le circuit d’alimentation, déconnectez le

cordon électrique et déconnectez le fil conducteur du terminal 2/T1 du relais correspondant.

Mesurez la résistance du 2/T1 et du 1/L1. Si la

résistance est inférieure à 50K ohms, le relais

correspondant ne fonctionne pas.

Mesure corrective

• Déconnectez la sonde correspondante et

mesurez la résistance de la sonde.

La sonde correspondante ne fonctionne pas si:

• La température de la plaque est inférieure à

25°C et la résistance est supérieure à 1100 ohms.

• La température de la plaque est inférieure à

100°C et la résistance est supérieure à 1381 ohms.

• La température de la plaque est inférieure à

200°C et la résistance est supérieure à 1744 ohms.

NOTE IMPORTANTE:

Si la résistance de la

sonde est juste, vérifiez la connexion de la sonde

correspondante sur la carte de circuits imprimés.

Si la connexion est sûre, la carte de circuits

imprimés ne fonctionne pas.

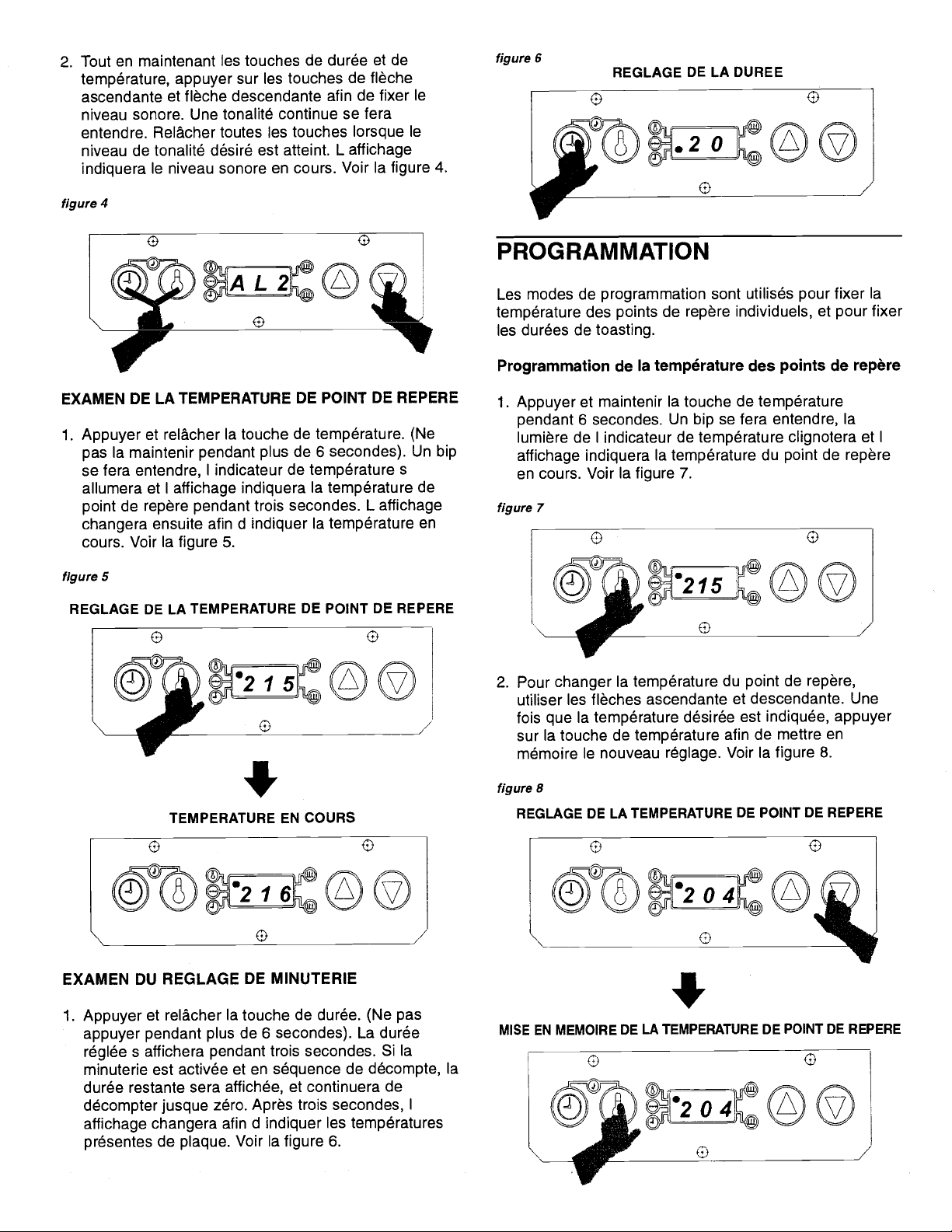

Problème

Codes des diagnostiques

Mesure corrective

• Revoir les pannes 01 et 02 décrites plus haut

• La plaque inférieure surchauffe.

La sonde inférieure est ouverte.

E03

afin de vérifier les mesures correctives à

prendre pour le code d’erreur 03.

• Revoir les pannes 10 et 20 décrites plus haut

• La plaque supérieure surchauffe.

La sonde supérieure est ouverte.

• Les deux plaques surchauffent.

Les deux sondes sont ouvertes.

2000 McDonald’s Corporation Part No. 411-543B Rev. B Printed in the

All Rights Reserved United States of America

E30

E33

afin de vérifier les mesures correctives à

prendre pour le code d’erreur 30.

• Revoir les pannes 11 et 22 décrites plus haut

afin de vérifier les mesures correctives à

prendre pour le code d’erreur 33.

16

Page 17

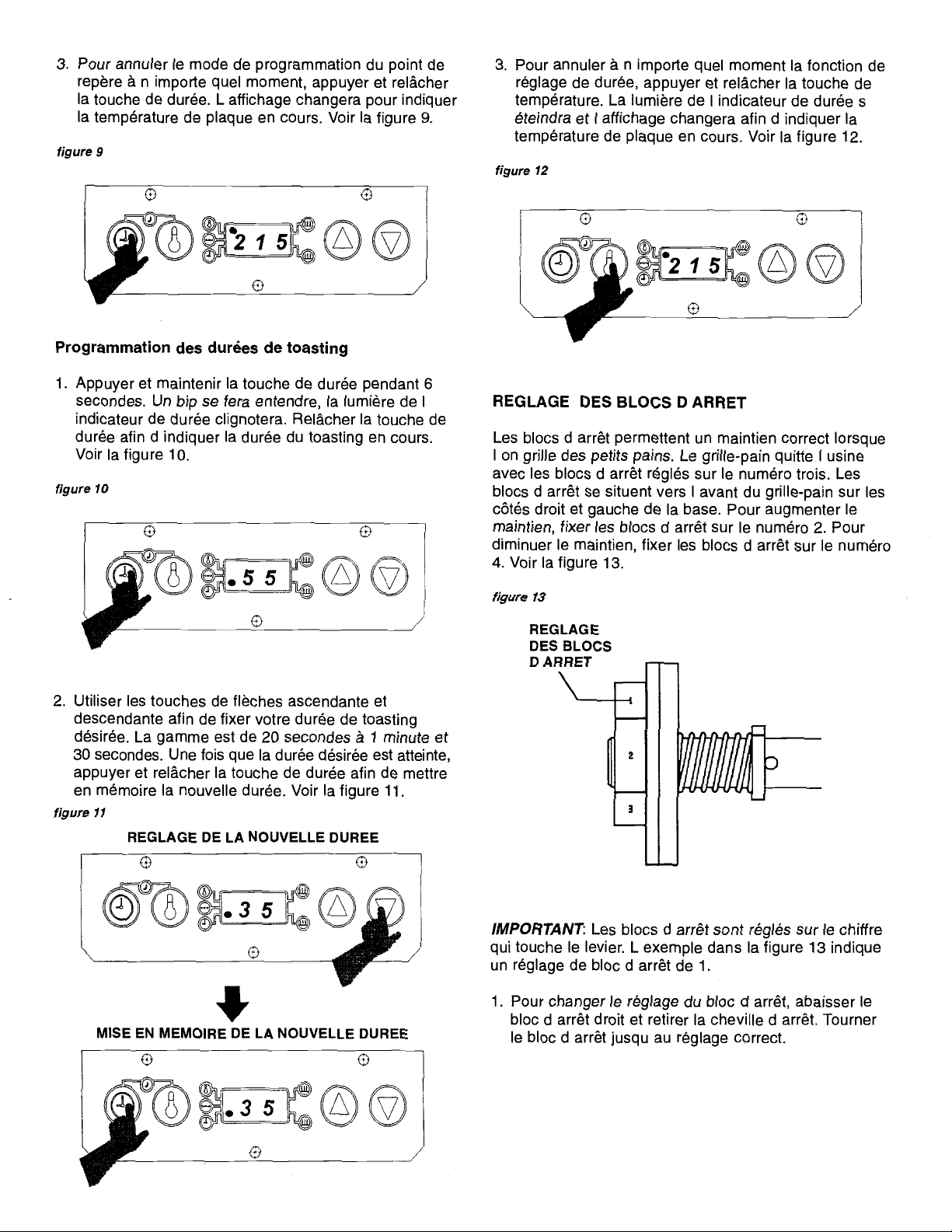

Problème

• Réchauffement insuffisant de

la plaque inférieure.

• Réchauffement insuffisant

de la plaque supérieure.

• Réchauffement insuffisant

des deux plaques.

Codes des diagnostiques

E04

E40

E44

Mesure corrective

• Si le voyant de l’indicateur de chaleur est allumé

et le voltage des terminaux 3/A1 et 4/A4 des

relais correspondants est plus élevé que 4 Volts,

la carte de circuits imprimés ne peut fonctionner.

• Avec la plaque allumée, mesurez le voltage CA

des terminaux 2/T1 et 1/L1 du relais correspondant. Si le voltage est supérieur à 2 VCA, le

relais correspondant ne peut fonctionner.

NOTE IMPORTANTE: Les codes d’erreur E04,

E40 ET E44 indiquent une baisse des températures des plaques de 30°C au-dessous du seuil

de température et peuvent être causés par les

problèmes suivants:

1. Air froid qui souffle sur les plaques.

2. Bas voltage appliqué sur le grille-pain.

3. Usage continu du grille-pain durant les

périodes de température “LO”.

4. Carte des circuits imprimés ne fonctionne pas.

• Éteignez le circuit d’alimentation électrique,

déconnectez un côté de la plaque et vérifiez la

résistance de la plaque chauffante. Voir

cidessous: Lecture des températures froides est

au-dessous de 50°C. Lecture des températures

chaudes est au-dessus de 200°C.

• Modèle de grille-pain de la série 411 est: 27,8

ohms froid à 32,4 ohms chaud.

• Modèle de grille-pain de la série 213 est: 23 ohms

froid à 26.7 ohms chaud.

• Modèle de grille-pain de la série 416 est: 41,8

ohms froid à 48,6 chaud.

Problème

• Réchauffement insuffisant

de la plaque inférieure.

• Réchauffement insuffisant

de la plaque supérieure.

Codes des diagnostiques

E05

E50

Mesure corrective

• Passez aux mesures correctives E01 et E04.

• Passez aux mesures correctives E10 et E40.

• Passez aux mesures correctives E11 et E44.

• Réchauffement insuffisant

des deux plaques.

Problème

• Réchauffement insuffisant

de la plaque inférieure. La

sonde inférieure est ouverte.

• Réchauffement insuffisant

de la plaque supérieure. La

Codes des diagnostiques

E55

E06

E60

Mesure corrective

• Passez aux mesures correctives E02 et E04.

• Passez aux mesures correctives E20 et E40.

• Passez aux mesures correctives E22 et E44.

sonde supérieure est ouverte.

• Réchauffement insuffisant

E66

des deux plaques. Les deux

sondes sont ouvertes.

2000 McDonald’s Corporation Part No. 411-543B Rev. B Printed in the

All Rights Reserved United States of America

17

Page 18

Problème

• Réchauffement insuffisant

de la plaque inférieure.

La plaque inférieure

surchauffe.

La sonde inférieure est

ouverte.

Codes de diagnostiques

E07

E70

Mesure corrective

• Passez aux mesures correctives E01, E02 et E04.

• Passez aux mesures correctives E01, E20 et E40.

• Réchauffement insuffisant

de la plaque supérieure.

La plaque supérieure

surchauffe.

La sonde supérieure est

ouverte.

• Réchauffement insuffisant

des deux plaques.

Les deux plaques

surchauffent.

Les deux sondes sont

ouvertes.

Problème

• Panne du circuit sonde

inférieure.

• Panne du circuit sonde

supérieure.

• Panne du circuit des deux

sondes.

E77

Codes de diagnostiques

E08

E80

E88

• Passez aux mesures correctives E11, E22 et E44.

Mesure corrective

• Passez à la mesure corrective E02 et remplacer

l’article indiqué par le résultat de l’essai.

• Passez à la mesure corrective E20 et remplacer

l’article indiqué par le résultat de l’essai.

• Passez à la mesure corrective E22 et remplacer

l’article indiqué par le résultat de l’essai.

Problème

• La plaque inférieure

surchauffe. La sonde

inférieure est ouverte.

• La plaque supérieure

surchauffe. La sonde

supérieure est ouverte.

Codes de diagnostiques

E09

E90

Mesure corrective

• Passez aux mesures correctives E01, et E08.

• Passez aux mesures correctives E01 et E80.

• Passez aux mesures correctives E11 et E88.

• Les deux plaques surchauffent. Les deux sondes sont

E99

ouvertes.

2000 McDonald’s Corporation Part No. 411-543 Rev C. Printed in the

All Rights Reserved United States of America

18

Page 19

Page 20

Page 21

Page 22

Page 23

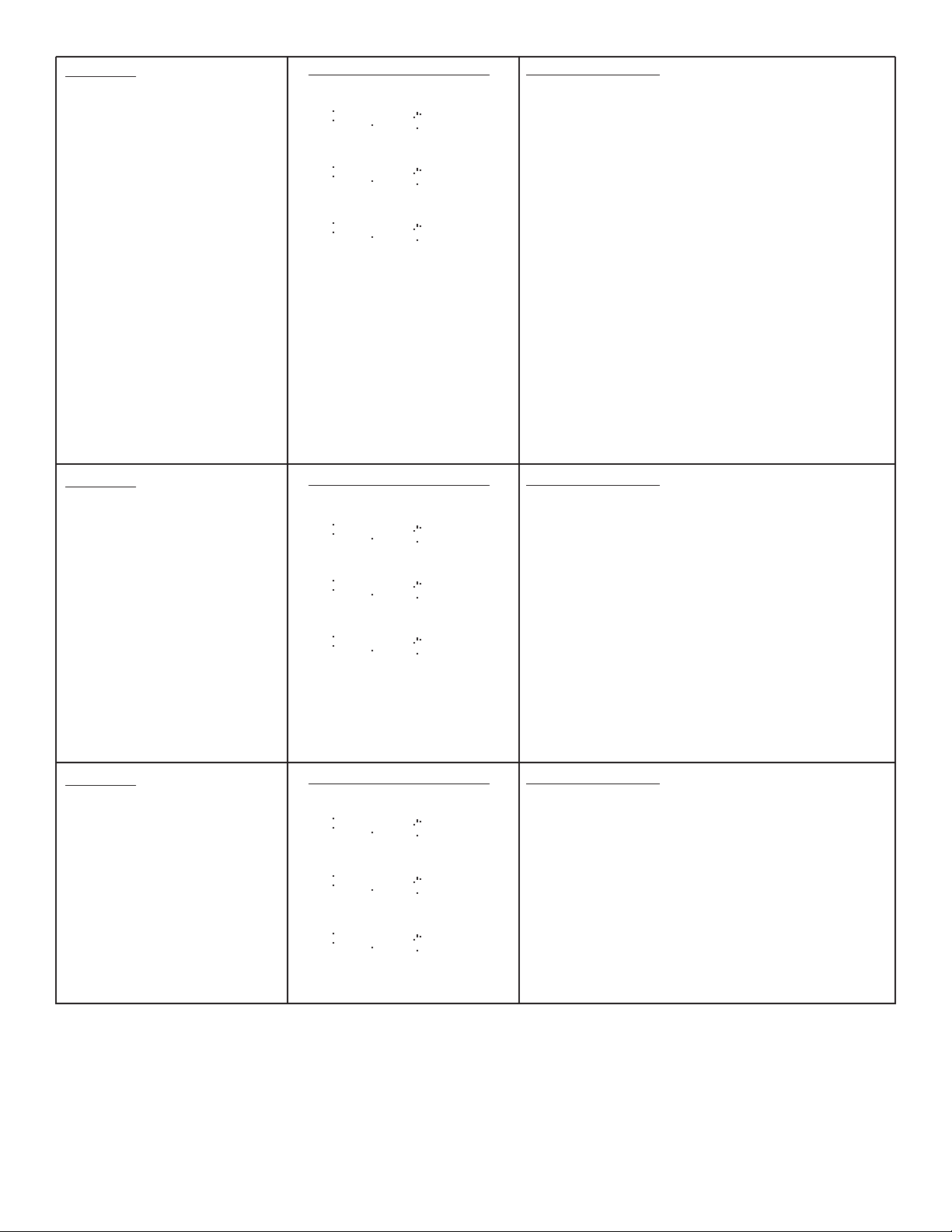

Diagnose Karte für monolithischer Toaster

Als ein Teil oder Teile nicht werken in den monolithischen Toasters 213, 416, oder 411, eine Fehlercode erscheint (siehe

die nachfolgende Abbildung) und ein Audioalarm ertönt. Die nachfolgende Karte zur Fehlerbeseitigung erklärt jede

Fehlercode und wie man entscheidet welche Komponente nicht funktioniert. Ein “O” am links bedeutet ein Fehler des

unteren Temperaturfühler; ein “O” am rechts bedeutet ein Fehler des oberen Temperaturfühler.

Obere Heizanzeige

Obere Heizanzeige

E10 E01

Untere Heizanzeige

FEHLER DES OBEREN TEMPERATURFÜHLER FEHLER DES UNTEREN TEMPERATURFÜHLER

Problem

Diagnose-Code

Verbessernde Handlung

• Mit der Heizanzeige der Platte ausleuchtet,

• Untere Heizplatte überhitzt.

• Obere Heizplatte überhitzt.

• Beide Heizplatten überhitzen.

E01

E10

wenn die Spannung von 3/A1 bis 4/A4 des

entsprchender Relais ist mehr als 2.5 volts,

dann ist die Hauptschaltkarte unterbrochen.

• Den Strom ausschalten und die Kabel ziehe,

der Haupdraht von den 2/T1 des entsprchender

Relais ziehen. Machen einen Messer der

E11

Festigheit von 2/T1 bis 1/L1. Wenn die

Festigheit ist weniger als 50K ohms, dann ist

das entsprchende Relais unterbrochen.

Problem

• Unterbrechung des unteren

Temperaturfühlers.

Diagnose-Code

E02

erbessernde Handlung

V

• Ziehen den entsprchenden Sensor ab und

machen einen Messer der Festigheit des

Sensors. Der entsprchender Sensor ist

• Unterbrechung des oberen

Temperaturfühlers.

E20

unterbrochen wenn:

• Die temperatur der Platte ist weniger als 25°C

und die Festigheit ist mehr als 1100 ohms.

• Unterbrechung den beiden

Temperaturfühlers.

E22

• Die temperatur der Platte ist weniger als 100°C

und die Festigheit ist mehr als 1381 ohms.

• Die temperatur der Platte ist weniger als 200°C

und die Festigheit ist mehr als 1744 ohms.

WICHTIG:

Als die Festigheit des Sensors hat

Rechts, prüfen Sie die Verbindung des

entsprechender Sensor auf der

Hauptschaltkarte. Als die Verbindung eng ist, ist

die Hauptschaltkarte verbrochen.

Untere Heizanzeige

Problem

Diagnose-Code

V

erbessernde Handlung

• Siehe Fehler 01 und 02 oben für Verbessernde

• Untere Heizplatte überhitzt.

E03

Handlung für eine Fehlercode 03.

Unterbrechung des unteren

Temperaturfühlers.

• Obere Heizplatte überhitzt.

Unterbrechung des oberen

Temperaturfühlers.

E30

E33

• Siehe Fehler 10 und 20 oben für Verbessernde

Handlung für eine Fehlercode 30.

• Siehe Fehler 11 und 22 oben für Verbessernde

Handlung für eine Fehlercode 33.

• Beide Heizplatten überhitzen.

Unterbrechung den beiden

Temperaturfühlers.

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

23

Page 24

Problem

Diagnose-Code

Verbessernde Handlung

• Untere Heizplatte erreicht

nicht die gewünschte

Temperatur.

• Obere Heizplatte erreicht

nicht die gewünschte

Temperatur.

• Beide Heizplatten erreichen

nicht die gewünschte

Temperatur.

E04

E40

E44

• Mit der Heizanzeige der Platte aufleuchtet, wenn

die Spannung von 3/A1 bis 4/A4 des entsprchender Relais ist mehr als 4 volts, dann ist die

Hauptschaltkarte unterbrochen.

• Mit der Platte ausleuchtet, machen einen Messer

der Spannung AC von 2/T1 bis 1/L1 des entsprchender

Relais. Wenn die Spannung mehr als 2 VAC ist,

dann ist das entsprchender Relais unterbrochen.

WICHTIG: Wenn die E04, E40, und E44

Fehlercode leuchtet ist die Plattetemperaturen

30°C weniger als die programmierte

Temperaturen und die Gründe folgenden:

1. Auf kalte Zugluft um den Platten.

2. Nicht genug Spannung zum Toaster.

3. Wann der Toaster hat “LO” Temperaturen,

erforsetzt.

4. Hauptschaltkarte unterbrochen.

• Den Strom ausschalten, ziehen eine Seite der

Platte und prüfen die Festigheit de Platte.

Vergleichen Sie dazu.

Kalte Temperaturen sind weniger als 50°C

Heize Temperaturen sind mehr als 200°C

• Toaster Modell der Serie 411 ist: 27.8 ohms kalt

bis 32.4 ohms heiz.

• Toaster Modell der Serie 213 ist: 23 ohms kalt bis

26.7 ohms heiz.

• Toaster Modell der Serie 416 ist: 41.8 ohms kalt

bis 48.6 ohms heiz.

Problem

• Untere Heizplatte erreicht

Diagnose-Code

E05

Verbessernde Handlung

• Siehe E01 und E04 Verbessernde Handlung.

nicht die gewünschte

Temperatur.

• Obere Heizplatte erreicht

nicht die gewünschte

E50

• Siehe E10 und E40 Verbessernde Handlung.

• Siehe E11 und E44 Verbessernde Handlung.

Temperatur.

• Beide Heizplatten erreichen

E55

nicht die gewünschte

Temperatur.

V

Problem

Diagnose-Code

erbessernde Handlung

• Untere Heizplatte erreicht

nicht die gewünschte

Temperatur. Unterbrechung

des unteren

Temperaturfühlers.

• Obere Heizplatte erreicht nicht

E06

E60

• Siehe E02 und E04 Verbessernde Handlung.

• Siehe E20 und E40 Verbessernde Handlung.

• Siehe E22 und E44 Verbessernde Handlung.

die gewünschte Temperatur.

Unterbrechung des oberen

Temperaturfühlers.

E66

• Beide Heizplatten erreichen

nicht die gewünschte

Temperatur. Unterbrechung

den beiden Temperaturfühlers.

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

24

Page 25

Problem

• Untere Heizplatte erreicht

nicht die gewünschte

Temperatur.

Untere Heizplatte überhitzt.

Unterbrechung des unteren

Temperaturfühlers.

Diagnose-Code

E07

E70

Verbessernde Handlung

• Siehe E01, E02 and E04 Verbessernde

Handlung.

• Siehe E01, E20 and E40 Verbessernde

Handlung.

• Obere Heizplatte erreicht

nicht die gewünschte

Temperatur.

Obere Heizplatte überhitzt.

Unterbrechung des oberen

Temperaturfühlers.

• Beide Heizplatten erreicht

nicht die gewünschte

Temperatur.

Beide Heizplatten überhitzen.

Unterbrechung den beiden

Temperaturfühlers.

Problem

• Fehler des unteren

TemperaturfühlerStromkreises.

• Fehler des unteren

TemperaturfühlerStromkreises.

• Fehler des unteren

TemperaturfühlerStromkreises.

E77

Diagnose-Code

E08

E80

E88

• Siehe E11, E22 and E44 Verbessernde

Handlung.

Verbessernde Handlung

• Siehe E02 Verbessernde Handlung, auswechseln den Artikel den mit dem Test angezeigt ist.

• Siehe E20 Verbessernde Handlung, auswechseln den Artikel den mit dem Test angezeigt ist.

• Siehe E22 Verbessernde Handlung, auswechseln den Artikel den mit dem Test angezeigt ist.

Problem

• Untere Heizplatte überhitzt.

Unterbrechung des unteren

Temperaturfühlers.

• Obere Heizplatte überhitzt.

Unterbrechung des oberen

Diagnose-Code

E09

E90

Verbessernde Handlung

• Siehe E01 and E08 Verbessernde Handlung.

• Siehe E01 and E80 Verbessernde Handlung.

• Siehe E11 and E88 Verbessernde Handlung.

Temperaturfühlers.

• Beide Heizplatten überhitzen.

E99

Unterbrechung den beiden

Temperaturfühlers.

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

25

Page 26

Page 27

Page 28

Page 29

Page 30

Scheda diagnostica per Tostapane elettronico

Quando un componente o dei componenti si guastano nei Tostapane a stato solido 213, 416 o 411 viene visualizzato un

CODICE ERRORE lampeggiante (vedere figure sotto) ed entra in funzione un allarme sonoro. La seguente scheda per

la localizzazione dei guasti contiene la spiegazione di ciascun codice errore e le indicazioni degli interventi necessari per

determinare quale componente si è guastato. Una “O” sulla sinistra indica che c’è un guasto del circuito inferiore; una

“O” sulla destra indica che c’è un guasto nel circuito superiore.

Spia calore della

piastra superiore

Spia calore della

piastra superiore

E10 E01

Spia calore della

piastra inferiore

GUASTO CIRCUITO SUPERIORE GUASTO CIRCUITO INFERIORE

Spia calore della

piastra inferiore

Problema

• Surriscaldamento piastra

inferiore.

• Surriscaldamento piastra

superiore.

• Surriscaldamento delle due

piastre.

Problema

• Sonda inferiore aperta.

• Sonda superiore aperta.

• Le due sonde sono aperte.

Codici diagnostici

E01

E10

E11

Diagnose-Code

E02

E20

E22

Intervento correttivo

• Con la spia calore della piastra spenta, se il

voltaggio tra i terminali 3/A1 e 4/A4 dei relè

corrispondenti è maggiore di 2,5 volt, la scheda

del circuito stampato è fuori uso.

• Spegnere l’interruttore e scollegare il cavo d’alimentazione, scollegare i fili dal terminale 2/T1

dal relè corrispondente. Misurare la resistenza

tra 2/T1 e 1/L1. Se la resistenza è inferiore ai

50K ohm, il relè corrispondente è fuori uso.

Intervento correttivo

• Scollegare la sonda corrispondente e misurare la

resistenza della sonda. La sonda corrispon-

dente è fuori uso se:

• La temperatura della piastra è inferiore ai 25°C e

la resistenza è maggiore di 1100 ohm.

• La temperatura della piastra è inferiore ai 100°C

e la resistenza è maggiore di 1381 ohm.

• La temperatura della piastra è inferiore ai 200°C

e la resistenza è maggiore di 1744 ohm.

NOTA IMPORTANTE:

Se la resistenza della sonda

è corretta, controllare la connessione della sonda

corrispondente sulla scheda del circuito stampato.

Se la connessione è a ben salda, la scheda del

circuito stampato è fuori uso.

Problema

Diagnose-Code

Intervento correttivo

• Vedere sopra i guasti 01 e 02 per i passi degli

• Surriscaldamento piastra

inferiore. Sonda inferiore aperta.

• Surriscaldamento piastra

superiore. Sonda superiore

aperta.

• Surriscaldamento delle due

piastre. Le due sonde sono

aperte.

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

E03

E30

E33

interventi correttivi da intraprendere per un

codice errore 03.

• Vedere sopra i guasti 10 e 20 per i passi degli

interventi correttivi da intraprendere per un

codice errore 30.

• Vedere sopra i guasti 11 e 22 per i passi degli

interventi correttivi da intraprendere per un

codice errore 33.

30

Page 31

Problema

• Scarso riscaldamento piastra

inferiore.

• Scarso riscaldamento piastra

superiore.

• Scarso riscaldamento delle

due piastre.

Codici diagnostici

E04

E40

E44

Intervento correttivo

• Con la spia calore della piastra accesa, se il

voltaggio tra i terminali 3/A1 e 4/A4 dei relè

corrispondenti è inferiore a 4 volt, la scheda del

circuito stampato è fuori uso.

• Con la piastra accesa, misurare il voltaggio AC

tra i terminali 2/T1 e 1/L1 dei relè corrispondenti:

se il voltaggio è maggiore di 2 VAC, il relè

corrispondente è fuori uso.

NOTA IMPORTANTE: i codici errore E04, E40, e

E44 indicano che le temperature delle piastre

sono scese di 30°C al di sotto della temperatura

di funzionamento impostata; ciò può essere

dovuto a quanto segue:

1. Flusso di aria fredda sulle piastre.

2. Voltaggio insufficiente applicato al tostapane.

3. Uso continuato del tostapane durante i periodi

di temperatura “LO”.

4. Scheda del circuito stampato fuori uso.

• Spegnere l’interruttore, scollegare un lato della

piastra e controllare la resistenza della piastra.

Vedere sotto: le letture fredde sono al di sotto dei

50°C Le letture calde sono al di sporta dei 200°C

Problema

• Scarso riscaldamento piastra

inferiore.

• Scarso riscaldamento piastra

superiore.

• Scarso riscaldamento delle

due piastre.

Problema

• Scarso riscaldamento piastra

inferiore. Sonda inferiore aperta.

• Scarso riscaldamento piastra

superiore. Sonda superiore

aperta.

Codici diagnostici

E05

E50

E55

Codici diagnostici

E06

E60

• Per il modello della serie tostapane 411: da 27,8

ohm freddo a 32,4 ohm caldo.

• Per il modello della serie tostapane 213: da 23

ohm freddo a 26,7 ohm caldo.

• Per il modello della serie tostapane 416: da 41,8

ohm freddo a 48,6 ohm caldo.

Intervento correttivo

• Passare agli interventi correttivi E01 e E04.

• Passare agli interventi correttivi E10 e E40.

• Passare agli interventi correttivi E11 e E44.

Intervento correttivo

• Passare agli interventi correttivi E02 e E04.

• Passare agli interventi correttivi E20 e E40.

• Passare agli interventi correttivi E22 e E44.

• Scarso riscaldamento delle

due piastre. Le due sonde

E66

sono aperte.

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

31

Page 32

Problema

Codici diagnostici

Intervento correttivo

• Scarso riscaldamento piastra

inferiore.

Surriscaldamento piastra

inferiore.

Sonda inferiore aperta.

• Scarso riscaldamento piastra

superiore.

Surriscaldamento piastra

superiore.

Sonda superiore aperta.

• Scarso riscaldamento delle

due piastre.

Surriscaldamento delle due

piastre.

Le due sonde sono aperte.

Problema

• Guasto del circuito della

sonda inferiore.

• Guasto del circuito della

sonda superiore.

• Guasto del circuito delle due

sonde.

E07

E70

E77

Codici diagnostici

E08

E80

E88

• Passare agli interventi correttivi E01, E02 e E04.

• Passare agli interventi correttivi E01, E20 e E40.

• Passare agli interventi correttivi E11, E22 e E44.

Intervento correttivo

• Passare all’intervento correttivo E02 e sostituire

l’elemento indicato dal risultato della prova.

• Passare all’intervento correttivo E20 e sostituire

l’elemento indicato dal risultato della prova.

• Passare all’intervento correttivo E22 e sostituire

l’elemento indicato dal risultato della prova.

Problema

• Surriscaldamento piastra

inferiore. Sonda inferiore

Diagnose-Code

E09

Intervento correttivo

• Passare agli interventi correttivi E01 e E08.

aperta.

• Surriscaldamento piastra

E90

• Passare agli interventi correttivi E01 e E80.

superiore. Sonda superiore

aperta.

• Surriscaldamento delle due

E99

• Passare agli interventi correttivi E11 e E88.

piastre. Le due sonde sono

aperte.

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

32

Page 33

Page 34

Page 35

Page 36

Page 37

Carta diagnóstica para Tostadoras de Estado Sólido

Cuando un piezo o piezos no funciona en los tostadoras de estado sólido un código de error [ERROR CODE] muestra

en la pantalla (ver las figuras abajo) y se escuchará una alarma audible. La guía para la resolución de problemas explicará cada código de error y como determinar cual componente no funciona. Cuando aparece un “O” a la izquierda el

circuito inferior falta.

Luz del indicador del

calentador superior

E10 E01

Luz del indicador del

calentador inferior

FALTA DE CIRCUITO SUPERIOR FALTA DE CIRCUITO INFERIOR

Problema

• Plato inferior calenta

demasiado.

• Plato superior calenta

demasiado.

• Los dos platos calentan

demasiado.

Problema

• Sonda inferior abierta.

• Sonda superior abierta.

• Los dos sondas abiertas.

Códigos diagnósticos

E01

E10

E11

Códigos diagnósticos

E02

E20

E22

Acción Correctiva

• Cuando el luz del indicador del calentador del

plato no está iluminada, si el voltaje de terminales 3/Al a 4/A4 del relevador correspondiente

está más de 2,5 voltios, el tablero impreso del

circuito está inoperable.

• Desactive la potencia y desconecte la cuerda de

línea, desconecte el guía del cable de terminal

2/T1 de relevador correspondiente. Mida la

resistencia de 2/Tl y 1/L1. Si la resistencia está

menos de 5OK ohmios, el relevador correspondiente está inoperable.

Acción Correctiva

• Desconecte la sonda correspondiente y mida la

resistencia de la sonda. La sonda correspondi-

ente está inoperable si:

• La temperatura del plato está menos de 25°C y

la resistencia está más de 1100 ohmios.

• La temperatura del plato está menos de 100°C y

la resistencia está más de 1381 ohmios.

• La temperatura del plato está menos de 200°C y

la resistencia está más de 1744 ohmios.

Luz del indicador del

calentador superior

Luz del indicador del

calentador inferior

NOTA IMPORTANTE:

Si la resistencia de la

sonda está correcta, verifique la conexión de la

sonda correspondiente en el tablero impreso del

circuito. Si la conexión está segura, el tablero

impreso del circuito está inoperable.

Problema

• Plato inferior calenta demasiado.

Códigos diagnósticos

E03

Sonda inferior abierta.

• Plato superior calenta demasiado.

E30

Sonda superior abierta.

• Los dos platos calenta demasiado.

E33

Los dos sondas abiertas.

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

Acción Correctiva

• Ir a las faltas 01 y 02 arriba para etapas de

acción correctiva para el código de error 03.

• Ir a las faltas 10 y 20 arriba para etapas de

acción correctiva para el código de error 30.

• Ir a las faltas 11 y 22 arriba para etapas de

acción correctiva para el código de error 33.

37

Page 38

Problema

• Plato inferior calenta

insuficiente.

• Plato superior calenta

insuficiente.

• Los dos platos calentan

insuficiente.

Códigos diagnósticos

E04

E40

E44

Acción Correctiva

• Cuando el luz del indicador del calentador del

plato está iluminada, si el voltaje de terminales

3/Al a 4/A4 del relevador correspondiente está

menos de 4 voltios, el tablero impreso del

circuito está inoperable.

• Cuando el plato está activado, mida el voltaje

CA desde los terminals 2/T1 a 1/Ll del relevador

correspondiente, si el voltaje está más de 2

VCA, el relevador está inoperable.

NOTA IMPORTANTE: Códigos de error E04,

E40, y E44 indica que las temperaturas del plato

disminuen 30°C debajo de la temperatura

programada “set point” y los siguientes puede

causarlo:

1. Aire fría en los platos.

2. Voltaje insuficiente en la tostadora.

3. La tostadora continua durante de los periodos

de temp “‘LO”.

4. Tablero impreso del circuito inoperable.

• Desactive la potencia, desconecte un lado del

plato y verifique la resistencia del plato. Ver

abajo: Medidas frías están menos de 50°C.

Medidas calientes están más de 200°C.

Problema

• Plato inferior calenta

insuficiente.

• Plato superior calenta

insuficiente.

• Los dos platos calentan

insuficiente.

Problema

• Plato inferior calenta insufuciente. Sonda inferior abierta.

• Plato superior calenta insufuciente. Sonda superior abierta.

Códigos diagnósticos

E05

E50

E55

Códigos diagnósticos

E06

E60

• La tostadora modelo serie 411 está: 27,8 ohmios

fría a 32,4 ohmios caliente.

• La tostadora modelo serie 213 está: 23 ohmios

fría a 26,7 ohmios caliente.

• La tostadora modelo serie 416 está: 41,8

ohmios fría a 48,6 ohmios caliente.

Acción Correctiva

• Ir a E01 y E04 acción correctiva.

• Ir a E10 y E40 acción correctiva.

• Ir a E11 y E44 acción correctiva.

Acción Correctiva

• Ir a E02 y E04 acción correctiva.

• Ir a E20 y E40 acción correctiva.

• Los dos platos calentan insufuciente. Los dos sondas

E66

• Ir a E22 y E44 acción correctiva.

abiertas.

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

38

Page 39

Problema

• Plato inferior calenta

insufuciente.

Plato inferior calenta

demasiado.

Sonda inferior abierta.

• Plato superior calenta

insufuciente.

Plato superior calenta

demasiado.

Sonda superior abierta.

• Los dos platos calentan

insufuciente.

Los dos platos calentan

demasiado.

Los dos sondas abiertas.

Códigos diagnósticos

E07

E70

E77

Acción Correctiva

• Ir a E01, E02 y E04 acción correctiva .

• Ir a E01, E20 y E40 acción correctiva .

• Ir a E11, E22 y E44 acción correctiva .

Problema

• Falta del circuito de sonda

inferior.

• Falta del circuito de sonda

superior.

• Falta del circuito de falta de

los dos sondas.

Problema

• Plato inferior calenta

demasiado. Sonda inferior

abierta.

• Plato superior calenta

demasiado. Sonda superior

abierta.

• Los dos platos calentan

demasiado. Los dos sondas

abiertas.

Códigos diagnósticos

E08

E80

E88

Códigos diagnósticos

E09

E90

E99

Acción Correctiva

• Ir a E02 acción correctiva , reemplazar el artículo

indicado del resultado de la prueba.

• Ir a E20 acción correctiva , reemplazar el artículo

indicado del resultado de la prueba.

• Ir a E22 acción correctiva , reemplazar el artículo

indicado del resultado de la prueba.

Acción Correctiva

• Ir a E01 y E08 acción correctiva.

• Ir a E01 y E80 acción correctiva.

• Ir a E11 y E88 acción correctiva.

2000 McDonald’s Corporation Part No. 411-543 Rev C Printed in the

All Rights Reserved United States of America

39

Page 40

Page 41

TS 016-i

Toasters

Precaution

During some checks, live electrical circuits will be exposed, and hot toasting

surfaces will be uncovered.

Hazard Communication Standard (HCS) – The procedures on this card

include the use of chemical products. These chemical products will be

highlighted with bold face letters followed by the abbreviation (HCS) in the

tools portion of the procedure. See the Hazard Communication Standard

(HCS) Manual for the appropriate Material Safety Data Sheet(s) (MSDS)

Applying Bun Toaster Release Agent

IMPORTANT: Use only McD Toaster Release Agent on bun toasters.

Other products may damage bun toasters.

1. Dust all loose crumbs from toaster surfaces.

2. Toaster platens must be well rinsed and dry. McD Bun Toaster Release Agent

may be applied to hot toaster platens. Before applying to hot platens, put on

protective gloves.

3. To coat top platen surface, thoroughly wet a clean, folded customer napkin or

paper towel, with Release Agent.

4. Rub a generous amount of Release Agent over entire surface of a platen until well

coated. Use protective gloves and No. 257 cleaning tool.

5. Repeat steps 2 and 3 for other platens, including undersides.

IMPORTANT: Platen undersides and difficult to reach areas can be coated

by placing a folded customer napkin or paper towel with Release Agent on

No. 257 cleaning tool to apply Release Agent to platen surface.

IMPORTANT: Do not wipe toaster with a damp cloth after Release Agent is

applied. This removes Release Agent and causes sticking.

6. If sticking occurs between weekly applications, reapply Release Agent using steps

1-4.

IMPORTANT: Toaster does not need to be recleaned or cooled down before

applying Release Agent.

IMPORTANT: Reapply Release Agent weekly, while toaster is cold between

monthly cleaning, to all platen surfaces.

Toasters

Prince Castle: Bun Toasters

Planned Maintenance

System: Maintenance

Requirement Card

(MRC)

Pictures and additional

information:

Corresponding Chapter of

Equipment Manual

When

Weekly

Tools

McD Bun Toaster Release

Agent (HCS), customer

paper napkins or paper

towels, protective gloves,

257 cleaning tool.

©2000 McDonald’s Corporation

Printed in DEC 00

Revised in SEP 00

Page 1 of 5

Page 42

Check Calibration of Temperature

IMPORTANT: Do not perform this procedure until the toaster has been on

for at least 45 minutes and temperature has stabilized. Do not use the toaster

during this 45-minute period.

1. Place the rear of the bun board on top of the control box and place the rest of the

bun board on top of the platen.

NOTE: On dual platen toasters (411 & 416), the bun board is only required

for use on the top platen.

2. On dual platen toasters, use to select the platen to be calibrated.

3. Center the digital thermometer on the front edge of the platen. When the

corresponding LED on the control panel turns on, immediately record the digital

thermometer temperature reading.

NOTE: On dual platen toasters (411 & 416), perform step 2 on the lower

platen first, then the upper platen.

IMPORTANT: If the temperature reading on the platen is greater than +/3°C (+/-5°F) compared to the toaster temperature display, proceed with step

3 to perform calibration. If temperature reading is within range, toaster is

functioning properly and does not require calibration.

4. Enter the calibration mode by pressing and holding for 6 seconds. A

beep will sound and the LED next to the calibration symbol will turn on. Release

all buttons.

5. Press and release to select upper platen for calibration or to select lower

platen. Allow 10 seconds for the display to stabililize. The display will show the

measured platen temperature value with no offset.

NOTE: On dual platen toasters (411 & 416), calibrate each platen separately.

6. When the corresponding platen LED turns on, use to adjust the display

temperature to match the reading recorded in step 3.

NOTE: Temperature can only be adjusted +/-5°C (+/-9°F).

7. Press to store the new calibrated temperature and to exit calibration mode.

IMPORTANT: After calibration is complete, allow one full heater on/off

cycle to allow the new calibrated temperature to stabilize.

TS 016-i

Toasters

When

Monthly

Tools

Digital thermometer with

surface probe.

©2000 McDonald’s Corporation

Printed in DEC 00

Revised in SEP 00

Page 2 of 5

Page 43

Clean Nickel Platen

PREPARING BUN TOASTER

1. If toaster is cool, heat to operating temperature.

IMPORTANT: Bun toaster must be at operating temperature for cleaning.

2. Turn toaster power switch to OFF position and unplug power cord.

CAUTION: Failure to unplug power cord before cleaning may cause

electrical shock.

3. Remove all buns, bun trays, and bun tray liners from the bun toaster stand.

4. Turn on the grill exhaust fan.

5. Move toaster stand in front of grill.

HOW TO CLEAN

1. Firmly attach McD No-Scratch Pad to cleaning tool. Use only nonabrasive blue

No-Scratch pads designed for grill cleaning. Do not use a green pad. It will

damage platen surface.

2. Pour one packet of McD Hi-Temp Grill Cleaner into a breakfast container base.

3. Put on protective gloves.

4. Turn bun board upside-down and lay on upper platen or plate.

5. Dip No-Scratch Pad into Hi-Temp Grill Cleaner.

6. Spread cleaner over bun board and lightly scrub until clean. Apply additional

cleaner as needed. Place bun board in the back sink area for cooling and rinsing.

7. If toaster is equipped with an aluminum plate, repeat step 6 so both sides of plate

are clean.

8. Dip No-Scratch Pad into cleaner and lightly spread a coasting of cleaner onto top

surface of platen.

IMPORTANT: Do not pour cleaner on surface. Apply only with No-Scratch

Pad and Cleaning Tool. Do not scrub while applying cleaner.

9. Repeat Step 8 for all platen surfaces, including undersides.

10. After repeating cleaner, lightly scrub all platen surfaces (including undersides)

with No-Scratch Pad until all soil liquifies. Apply additional cleaner to cleaning

as needed.

11. Remove No-Scratch Pad from cleaning tool. Fold a clean, damp grill cloth

lengthwise and lay it over the end of the cleaning tool. Thoroughly rinse platens,

including undersides, by wiping with a damp grill cloth. Before wiping platens,

always rinse grill cloth in clear water and wring it out until no soil is seen.

IMPORTANT: Thorough rinsing of the platen is required to ensure proper

release agent performance. Rinse platens with clean grill cloths until no soil

is seen on the cloth.

CAUTION: Do not pour water on platens or use dripping wet grill cloths.

TS 016-i Toasters

When

Monthly

Tools

McD Hi Temp Grill Cleaner

(HCS), McD Bun Toaster

Release Agent (HCS), McD

No Scratch Pad, base of

Big Breakfast container,

No. 257 cleaning tool,

clean grill cloths (qty. 6-8),

customer paper napkins or

paper towels, protective

gloves.

©2000 McDonald’s Corporation

Printed in DEC 00

Revised in SEP 00

Page 3 of 5

Page 44

©2000 McDonald’s Corporation

Printed in DEC 00

Revised in SEP 00

Page 4 of 5

TS 016-i

Toasters

12. Repeat the rinsing procedure in Step 11 with a fresh, clean, damp grill cloth to

ensure all cleaner and soil are removed from platens.

13. Wipe remaining parts of the toaster with a clean damp cloth.

14. Take bun tray platform, bun board, and aluminum plate to back sink. Scrub with

a pot brush or No-Scratch Pad in a solution of McD All Purpose Concentrate.

Do not use abrasive pads. Rinse parts under running water and let air dry.

Tighten Platen and Leg Bolts

TIGHTEN PLATEN BOLTS

1. Turn the power switch to the OFF Position.

2. Unplug the power cord.

3. Allow toaster to cool before proceeding.

4. Using an adjustable wrench, tighten the platen bolts which hold handle in upright

position.

TIGHTEN LEG BOLTS

1. Carefully turn the toaster upside down for access to legs.

2. Adjust and tighten leg bolts to obtain a level setting for toasting.

3. Set toaster right side up and check for level setting.

4. Adjust leg bolts as necessary until toaster sits level.

5. Plug the power cord into the appropriate electrical receptacle.

6. If the toaster is about to be used, turn the power switch to ON position.

When

Monthly

Tools

Adjustable wrench,

flatblade screwdriver

Page 45

©2000 McDonald’s Corporation

Printed in DEC 00

Revised in SEP 00

Page 5 of 5

TS 016-i

Toasters

When

Monthly

Tools

Pliers, hammer, file

Check Bun Tray Platforms, Bun Board, Bun Trays and Spatulas

IMPORTANT: This check procedure should be conducted while the

platforms, trays and spatulas are cold. It should be done for all spatulas,

trays and platforms.

BUN SPATULA

1. Lay the spatula on a flat work table top.

2. Make sure the entire surface is flat, including the front edge. The front end of

bun spatula must be free from necks and burrs.

3. Sharpen front edge of spatula so all nicks and burrs are removed.

IMPORTANT: Straightening curled corners with pliers and hammer middle

part of the tray flat.

BUN TRAY

1. Lay the track on a flat work tabletop and inspect for flatness.

2. Inspect the try for uniform height.

3. Straightened curled corners with pliers and hammer middle part of the tray flat.

BUN TRAY PLATFORM

1. Remove the platform from the lower part of the toaster.

2. Lay the platform on a flat work tabletop and inspect the entire surface to make

sure it is flat.

3. Using pliers or a hammer, straighten as needed.

4. Reinstall the platform into toaster.

BUN BOARD

1. Remove the bun board from toaster.

2. Lay the bun board on a flat work tabletop and inspect for flatness.

3. Measure the distance between the tabletop and the bottom side of the bun board in

the front, center, and rear. It should be approximately 1/2" (13mm) for all

toasters except Big Mac 412 and 416 series, and approximately 1/2" (19cm) for

Big Mac Toasters.

4. Bend as needed to maintain flatness.

Page 46

©2000 McDonald’s Corporation

Printed in DEC 00

Revised in SEP 00

Page 1 of 5

TS 016-i

Grille-pains

Images et informations

additionnelles:

Chapitre correspondant du

manuel d’équipement

Quand

Hebdomadairement

Outils

Agent de démoulage de

grille-petits pains McD

(HSC), serviettes de table

en papier ou essuie-tout

du client, gants

protecteurs, outil de

nettoyage no 257.

Grille-pains

Prince Castle: Grille-petits pains

Précaution

Durant certaines vérifications, les circuits électriques sous tension seront

exposés et les surfaces de grillage chaudes seront découvertes.

Hazard Communication Standard (HCS)- Les procédures sur cette carte

incluent l’utilisation de produits chimiques. Ces produits chimiques seront mis

en surbrillance avec des lettres en gras suivies de l’abréviation (HSC) dans la

partie outils de la procédure. Voir le manuel Hazard Communication Standard

(HSC) pour voir la ou les feuille(s) des Données de sécurité du matériel (FDSM).

Application de l’agent de démoulage de grille-petits pains

IMPORTANT: Utilisez seulement l’agent de démoulage grille-petits pains

McD sur les grilles-petits pains. D’autres produits pourraient endommager

le grille-petits pains.

1. Enlevez toutes les miettes des surfaces du grille-pain.

2. Les plaques du grille-pain doivent être bien rincées et séchées. L’agent de

démoulage de grille-petits pains McD peut être appliqué sur les plaques chaudes

du grille-pain. Mettez les gants protecteurs avant d’appliquer sur les plaques chaudes.

3. Pour couvrir la surface supérieure de la plaque, mouillez à fond une serviette de

table pliée ou un essuie-tout de client avec l’agent de démoulage.

4. Frottez une quantité généreuse de l’agent de démoulage sur toute la surface de la

plaque jusqu’à ce qu’elle soit bien recouverte. Utilisez les gants protecteurs et

l’outil de nettoyage no 257.

5. Répétez les étapes 2 et 3 pour d’autres plaques y compris les dessous.

IMPORTANT: Les dessous des plaques et les endroits difficiles à atteindre

peuvent être couverts en plaçant une serviette de table en papier du client ou

un essuie-tout avec l’agent de démoulage sur l’outil de nettoyage no 257 pour

appliquer l’agent de démoulage à la surface de la plaque.

IMPORTANT: Ne pas essuyer le grille-pain avec un linge humide après avoir

appliqué l’agent de démoulage. Cela enlève l’agent de démoulage et colle.

6. Si la surface colle entre les applications hebdomadaires, réappliquer l’agent de

démoulage en vous basant sur les étapes 1 à 4.

IMPORTANT: Le grille-pain n’a pas besoin d’être relavé ou refroidi avant

d’appliquer l’agent de démoulage.

IMPORTANT: Réappliquer l’agent de démoulage à toutes les surfaces de la

plaque à chaque semaine quand le grille-pain est froid entre les nettoyages

mensuels.

Système d’entretien

planifié: carte de

spécifications de

maintenance (CSM)

Page 47

©2000 McDonald’s Corporation

Printed in DEC 00

Revised in SEP 00

Page 2 of 5

TS 016-i

Grille-pains

Vérifiez l’étalonnage de la température

IMPORTANT: Ne pas exécuter cette procédure avant que le grille-pain n’ait

été en marche pendant 45 minutes et que la température se soit stabilisée. Ne

pas utiliser le grille-pain pendant cette période de 4 minutes.

1. Placez l’arrière de la planche à petits pains par-dessus la boîte de commande et

placez le reste de la planche à petits pains par-dessus la plaque.

NOTE: Sur les grille-pain à plaque double (411 et 416), la plaque de petits

pains est seulement nécessaire pour être utilisée sur la plaque supérieure.

2. Sur les grille-pain à plaque double, utilisez pour sélectionner la plaque à

étalonner.

3. Centrez le thermomètre digital en face de la plaque. Lorsque le voyant

correspondant s’allume sur le panneau de commande, enregistrez immédiatement

la lecture de la température du thermomètre digital.

NOTE: Sur les grille-pain à plaque double (411 et 416), exécutez d’abord

l’étape 2 sur la plaque la plus basse puis ensuite sur la plaque du haut.

IMPORTANT: Si la lecture de la température sur la plaque est plus élevée

que +/- 3°C (+/-5°F) comparativement à l’affichage de la température du

grille-pain, exécutez l’étape 3 pour faire l’étalonnage. Si la lecture de la

température est en dedans de l’intervalle, le grille-pain fonctionne

adéquatement et n’a pas besoin d’étalonnage.

4. Introduisez le mode d’étalonnage en appuyant et en maintenant pour 6

secondes. Un bip retentira et le voyant situé à côté du symbole d’étalonnage

s’allumera. Relâchez tous les boutons.

5. Appuyez sur pour sélectionner la plaque supérieure pour l’étalonnage ou

sur t pour sélectionner la plaque inférieure. Laissez 10 secondes pour que

l’affichage se stabilise. L’affichage va montrer la valeur mesurée de la

température de la plaque sans décalage.

NOTE: Sur les grille-pain à plaque double (411 et 416), étalonnez chaque

plaque séparément.

6. Lorsque le voyant correspondant de la plaque s’allume, utilisez pour

ajuster l’affichage de la température pour qu’elle corresponde à la lecture

enregistrée à l’étape 3.

NOTE: La température peut seulement être ajustée +/-5°C (+/-9°F).

7. Appuyez sur pour mémoriser la nouvelle température étalonnée et quitter le

mode d’étalonnage.

IMPORTANT: Lorsque l’étalonnage est terminé, laissez un cycle complet

marche/arrêt de la plaque chauffante pour permettre à la nouvelle

température étalonnée de se stabiliser.

Quand

Tous les mois

Outils

Thermomètre digital

avec sonde en

surface.

Page 48

©2000 McDonald’s Corporation

Printed in DEC 00

Revised in SEP 00

Page 3 of 5

TS 016-i

Grille-pains

Nettoyage de la plaque en nickel

PRÉPARATION DU GRILLE-PETITS PAINS

1. Si le grille-pain est froid, réchauffez-le jusqu’à la température de fonctionnement.

IMPORTANT: le grille-petits pain doit être à la température de

fonctionnement pour le nettoyage.

2. Mettez l’interrupteur d’alimentation du grille-pain en position OFF (ARRÊT) et

débranchez le cordon d’alimentation.

MISE EN GARDE: En omettant de débrancher le cordon d’alimentation

avant le nettoyage, on peut causer un choc électrique.

3. Retirez tous les petits pains, plateaux à petits pains et les garnitures de plateau à

petits pains du support de grille-petits pains.

4. Mettez en marche le ventilateur aspirant du gril.

5. Déplacez le support de grille-pain pour le mettre en face du gril.

COMMENT NETTOYER

1. Attachez fermement le tampon No-Scratch (ne grattant pas) McD à l’outil de nettoyage.

N’utilisez que des tampons bleus non abrasifs No-Scratch conçus pour le nettoyage

de gril. N’utilisez pas un tampon vert. Il endommagerait la surface de la plaque.

2. Versez un paquet de produit de nettoyage de gril température élevée McD dans

une base de récipient de petit déjeuner.

3. Mettez les gants protecteurs.

4. Retournez la planche à petits pains et posez-la sur la plaque supérieure.

5. Trempez le tampon No-Scratch dans un produit de nettoyage de gril température élevée.

6. Étalez le produit de nettoyage sur la planche à petits pains et brossez-la un peu

jusqu’à ce qu’elle soit propre. Appliquez un supplément de produit de nettoyage si

nécessaire. Placez la planche à petits pains dans la zone arrière de l’évier pour

refroidissement et rinçage.

7. Si le grille-pain est muni d’une plaque en aluminium, répétez l’étape 6 de sorte

que les deux côtés de la plaque soient propres.

8. Trempez le tampon No-Scratch dans un produit de nettoyage et étalez légèrement

une couche de produit de nettoyage sur la surface supérieure de la plaque.

IMPORTANT: Ne versez pas le produit de nettoyage sur la surface. Ne

l’appliquez qu’avec le tampon No-Scratch et l’outil de nettoyage. Ne brossez

pas tout en appliquant le produit de nettoyage.

9. Répétez l’étape 8 pour toutes les surfaces de plaque y compris les dessous.

10. Après avoir répété l’application du produit de nettoyage, brossez un peu toutes les

surfaces de plaque (y compris les dessous) avec le tampon No-Scratch jusqu’à ce

que toute la salissure soit liquéfiée. Appliquez un supplément de produit de

nettoyage si nécessaire.

11. Retirez le tampon No-Scratch de l’outil de nettoyage. Pliez un chiffon propre et

humide pour gril dans le sens de la longueur et posez-le sur l’extrémité de l’outil

de nettoyage. Rincez complètement les plaques, y compris leurs dessous en les

essuyant avec un chiffon humide pour gril. Avant d’essuyer les plaques, rincez

toujours le chiffon pour gril dans l’eau claire et faites sortir l’eau jusqu’à ce

qu’aucune trace de salissure ne soit vue.

IMPORTANT: Un rinçage complet de la plaque est requis pour assurer un fonctionnement correct de l’agent de démoulage. Rincez les plaques avec des chiffons

propres pour gril jusqu’à ce qu’aucune trace de salissure ne soit vue sur le chiffon.

MISE EN GARDE: Ne versez pas d’eau sur les plaques et n’utilisez pas de

chiffons pour gril humides et dégouttant.

Quand

À tous les mois

Outils

Produit de nettoyage de

gril température élevée

McD (HCS), agent de

démoulage de grille-petits

pains McD (HCS),

tampon No-Scratch (ne

grattant pas) McD, base

de récipient Big Breakfast

(gros déjeuner), outil de

nettoyage no 257,

chiffons de nettoyage de

gril (quantité 6-8),

serviettes de table en

papier ou essuie-tout du

client, gants protecteurs.

Page 49

©2000 McDonald’s Corporation

Printed in DEC 00

Revised in SEP 00

Page 4 of 5

TS 016-i

Grille-pains

12. Répétez la procédure de rinçage de l’étape 11 avec un nouveau chiffon pour gril,

propre et humide, pour assurer que tout le produit de nettoyage et toute la

salissure soient enlevés des plaques.

13. Essuyez les pièces restantes du grille-pain avec un chiffon humide et propre.

14. Mettez la plate-forme de plateau à petits pains, la planche à petits pains et la

plaque d’aluminium dans l’évier arrière. Brossez-les avec une brosse de pot ou

un tampon No-Scratch dans une solution de concentré McD à tout faire.

N’utilisez pas des tampons abrasifs. Rincez les pièces dans de l’eau courante et

laissez-les sécher à l’air.

Resserrer les boulons de la plaque et des pattes

RESERRER LES BOULONS DE LA PLAQUE

1. Mettez l’interrupteur d’alimentation à la position ARRÊT (OFF).

2. Débranchez le cordon d’alimentation.

3. Laissez le temps au grille-pain de refroidir avant de procéder.

4. En utilisant une clé à vis ajustable, resserrez les boulons de la plaque qui tiennent

la poignée en position verticale.

RESSERRER LES BOULONS DES PATTES

1. Tournez le grille-pain à l’envers avec soin pour accéder aux pattes.

2. Ajustez et resserrez les boulons des pattes pour obtenir un niveau de réglage pour

le brunissement.

3. Réglez le grille-pain, le côté droit en haut, et vérifiez le niveau de réglage.

4. Ajustez les boulons de pattes comme nécessaire jusqu’à ce que le grille-pain soit à

niveau.

5. Branchez le cordon d’alimentation dans la prise de courant appropriée.

6. Si le grille-pain est sur le point d’être utilisé, mettez l’interrupteur d’alimentation

à la position MARCHE (ON).

Quand

À tous les mois

Outils

Clé à vis ajustable,

tournevis à lame plate

Page 50

©2000 McDonald’s Corporation

Printed in DEC 00

Revised in SEP 00

Page 5 of 5

TS 016-i

Grille-pains

Vérifiez les plates-formes pour plateaux à petits pains, les

planches à petits pains, les plateaux à petits pains et les spatules