Page 1

Operating

Instructions

Vertical Contact Toaster

296 & 297 Series

Electrical Specifications

Volts Hz Watts Amps

230 60 1700 7.5

110/120 60 1700 15.5

220 50/60 1700 7.5

Table of Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 – 8

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Limited Warranty

This product is warranted to be free from defects in

material and/or workmanship for a period of 1 year from

date of original installation, not to exceed 18 months

from the date of manufacture.

Any component which proves to be faulty in material

and/or workmanship will be replaced or repaired (at the

option of Prince Castle, Inc.) without cost to the

customer for parts and labor. This warranty covers on

location service (i.e. trip charges an d/or mile age). Tr a vel

mileage is limited to 100 miles (200 Kilometers) round

trip (one trip warranty) from an authorized service

agency or its sub-service agency.

This warranty is subject to the following exceptions/

conditions:

• Use of any non-genuine Prince Castle parts voids

this warranty.

• All labor to be performed during regular work hours.

Overtime premium (the incremental amount) will be

charged to the customer.

• Damage caused by carelessness, neglect and/or

abuse (e.g., dropping, tampering or altering parts,

equipment damaged in shipment, by fire, flood or an

act of God) is not covered under this warranty.

• All problems due to operation at voltages other than

that specified on equipment nameplates are not

covered by this warranty. Conversion to correct

voltage is the customer’s responsibility.

• This equipment must be serviced by Prince Castle

Authorized Service Agency or a Prince Castle

Service Technician during the warranty period.

• Normal adjustments as outlined in this manual are

not covered under warranty.

• Motors that fail due to the lack of monthly lubrication

will not be covered under warranty.

197-538revC-EN

355 East Kehoe Blvd. • Carol Stream, IL 60188 USA

Telephone: 630-462-8800 • Fax : 630-462-1460

Toll Free: 1-800-PCASTLE

www.princecastle.com

Printed in USA 6/06 © 2006

Page 2

Installation

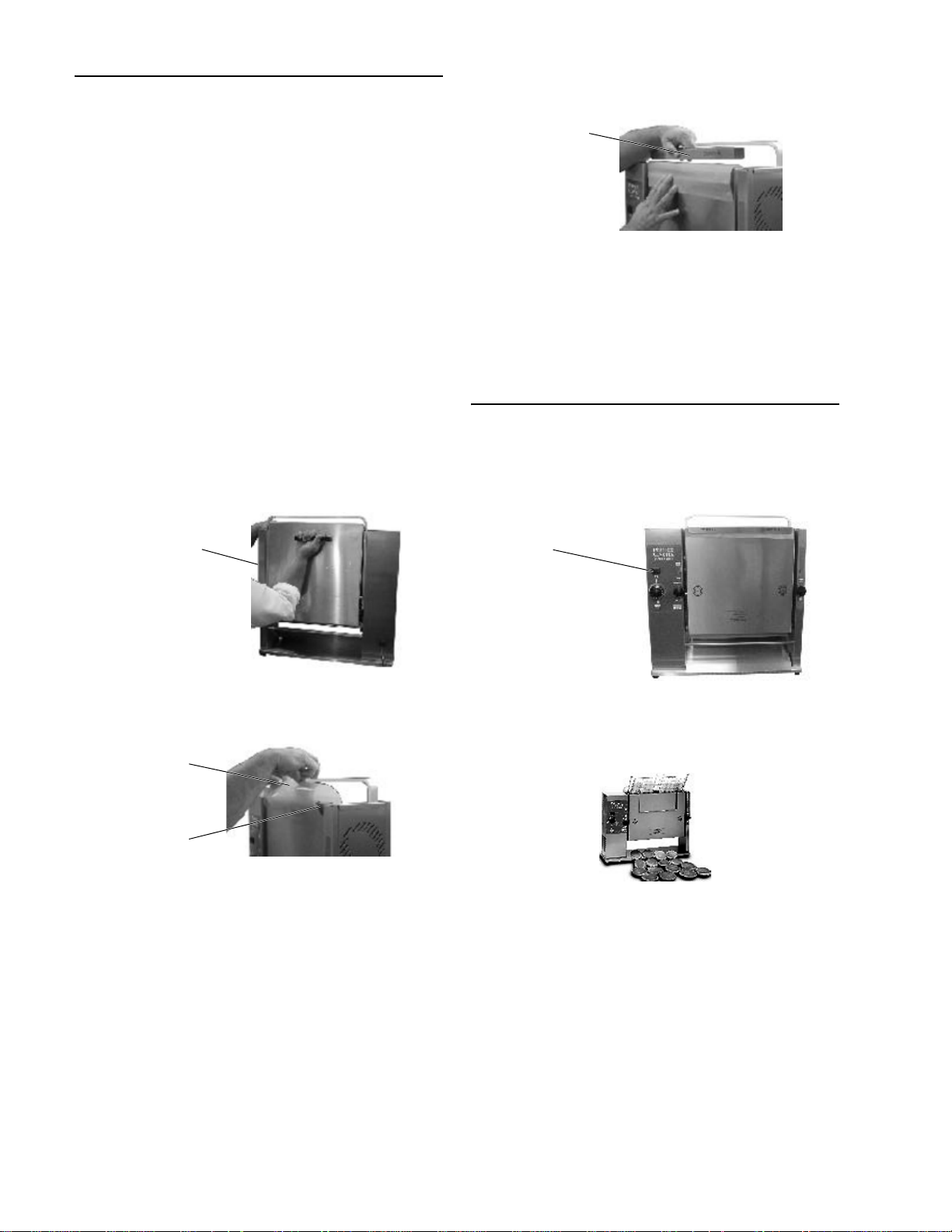

6. Slide the release sheet holding bracket onto the top of

the platen housing.

1. After you have removed the toaster from the carton,

inspect the unit fo r signs of damage . If the re is dama ge

to the unit:

• Notify carrier within 24 hours after delivery.

• Save carton and packing material for inspection

purposes.

• Contact your Prince Castle dealer or the

Prince Castle Customer Sales Department at

1-630-462-8800 if purchased directly.

2. Verify that all parts have been received.

• Slim-Line Bun Toaster and conveyor assembly.

• Release Sheet Kit — located in a 14" box.

• Crumb Tray — taped to the front of the conveyor.

3. Place toaster on flat surface. Remove protective

covering.

4. Lift conveyor off conveyor guide rails and set aside.

Remove all packing materials (nylon tape, foam block,

plastic coating on sheet metal, and black rubber

packaging space r s) from conveyor and convey or

guides.

Conveyor Guides

Holding Bracket

Figure 3

7. Attach conveyor to the toaster by sliding the four pins

(conveyor slides) on the conveyor housing into the four

conveyor guides. Lower the conveyor housing until it is

securely in place.

8. Hook the back end of the crumb tray onto the bar

located below the conveyor ass em bly.

9. Plug unit into a grounded receptacle.

Operation

1. Turn the Power switch to the “On” po si tion . The or ange

indicator light will illuminate . Allow 30 minutes f or plate n

to reach operating temperature.

Power Switch

Figure 1

5. Place the Teflon sheet over the top of the platen

housing, making sure to ha v e three inche s of o v erhan g.

3-inch Overhang

Release Sheet

Figure 2

Figure 4

2. Place a sample run of the product being toasted into

the top of the conveyor housi ng. The si de to be to asted

should face the pla ten .

Figure 5

3. The toasted product will be dispensed automatically

from the bottom of the conv eyor assembly.

4. Verify that product meets acceptable standards. If not,

see adjustment section.

Printed in USA 6/06 © 2006 2 197-538revC-EN

Page 3

Adjustments

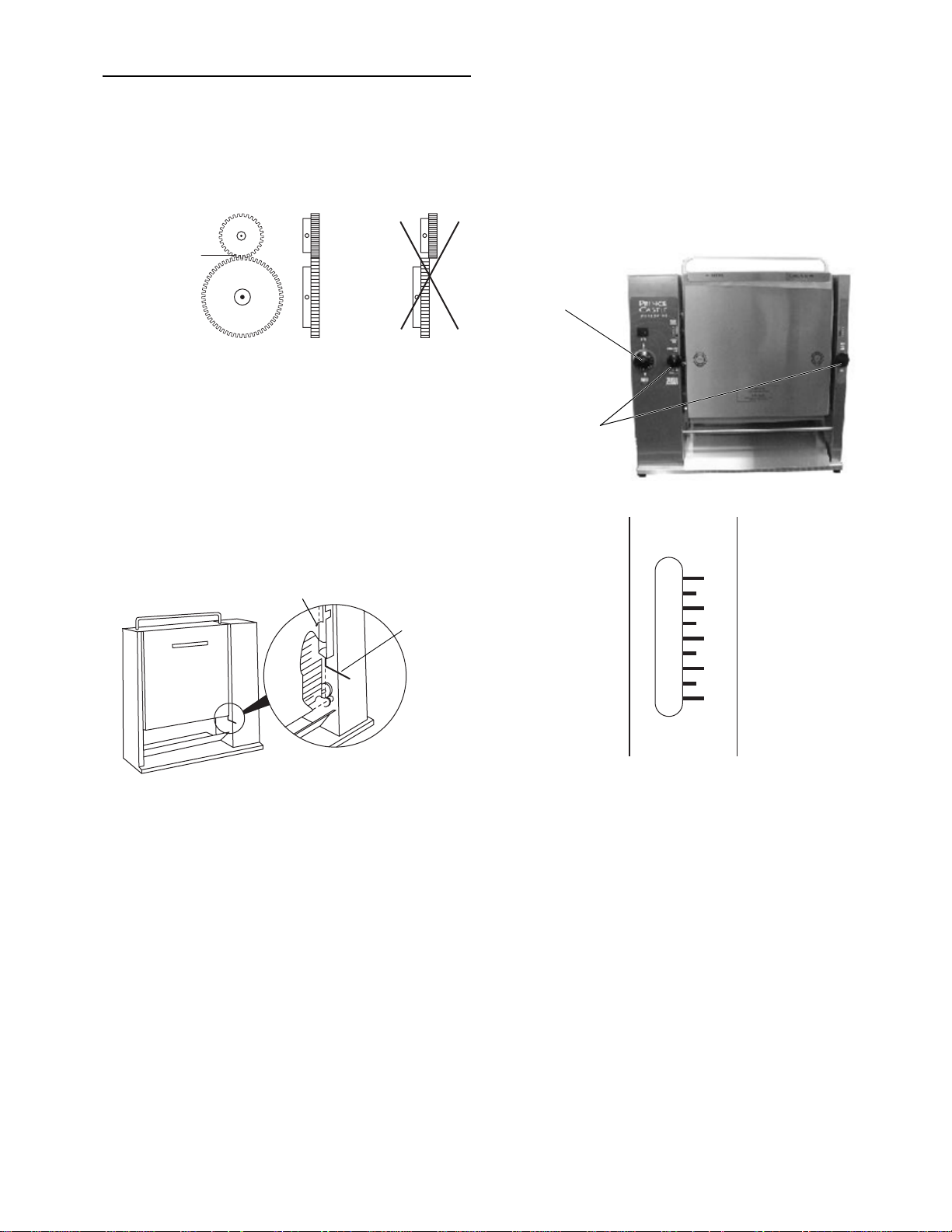

Conveyor an d Motor Gears:

There will be a 1/64" clearance between the conveyor gear

and motor gear when properly aligned. Improper alignment

will cause the conveyor to periodically bind.

1/64" Clearance

Figure 6

Tools Needed: 3/32" Allen wrench

Wicking grade thread locking fluid

Gears

Properly

Mesh

Bun Compression:

The toaster platen can be ad justed to provid e the necessary

compression needed on various products.

• Turn the two platen adjustment knobs clockwise to

compensate for use on thicker bread products. Tu rn

the two platen adjustment knobs counterclockwise

for thinner produc ts. Th e numbers o n the front of th e

end and motor housi ng will indicate the se ttings, 1 f or

thinnest product, 5 for thickest.

Thermostat Knob

1. Working from the “back side” of the toaster, loosen the

2 setscrews at the bottom of the conveyor guide until

they are even with the conveyor stop. Note: the

conveyor assembly may need to be removed for easier

access.

2. Use the Allen Wrench to tighten the left setscrew (end

housing side) until the setscrew just touches the

conveyor slide.

Top of the #10-32 Setscrew

Both Sides

3/32 Hex

Head Key

Figure 7

3. Tighten the right setscrew (motor housing side) until

the bottom of the con v ey or housing is par allel to the top

of the base.

4. Carefully tighten each setscrew another 1/2 turn.

5. Remove the conveyor assembly .

6. Apply a drop of wicking grade thread locking fluid to

each setscrew.

7. Replace conveyor assembly.

Platen Adjustment

Knobs

Figure 8

THICKER

5

4

3

2

1

THINNER

Figure 9

Platen Temperature:

The temperature of the platen can be adjusted to

compensate for darker or lighter toasting requirements.

• Turn the thermostat adjustment knob clockwise for

darker toasting. T u rn the thermostat adjustment knob

counterclockwise for lighter toasting.

IMPORTANT:

adjusting the thermostat.

Allow 15 minutes for toaster to stabilize after

197-538revC-EN 3 Printed in USA 6/06 © 2006

Page 4

Cleaning

Preventive Maintenance (Motor)

CAUTION: This is not jet-water approved, and

should not be cleaned with a water hose or jet

spray.

CAUTION: Do not immerse in water.

1. Turn off the Power switch and unplug the toaster.

2. Allow platen to cool for 60 minutes before cleaning.

3. Remove the conveyor assembly .

4. Wipe the conv e y or with a dam p cloth. F or the chain us e

a soft bristle brush.

5. Remove the release sheet and lay it on a flat surface.

Thoroughly clean both sides with a damp cloth making

sure all carbon buildup is removed. Allow to air dry.

IMPORTANT:

last 4 – 6 months based on care and volume of product

toasted.

6. Use a damp cloth to rem o ve any carbon b u ild up o n th e

platen surface.

IMPORTANT:

scouring pads, or abrasive cleaners on the platen or Teflon

release sheets as it will cause irreparable damage.

Rotate two sheets daily for longer life. Sheets

Do not use sharp objects, Scotch Brite pads,

To extend the life of your replacement motor, have an

authorized factory servi ce tec hnici an or sto re m anage r wick

the shaft of the motor with 2-3 drops of oil every 3,000 ho urs

of run time.

IMPORTANT:

preventive maintenance.

Shaft

Figure 10

Unplug toaster before performing any

Printed in USA 6/06 © 2006 4 197-538revC-EN

Page 5

Troubleshooting

5

PROBLEM PROBABLE CAUSE SOLUTION

Unit will not heat up. No power to unit. Ensure power cord is connected to proper

Power rocker switch light off. Inoperable power cord. Replace power cord.

Loose connection on power switch. Tighten power switch connections.

Inoperable power switch. Replace power switch.

Unit will not heat up. Inoperable thermostat. Replace thermostat.

Power rocker switch light on. Inoperable platen. Replace platen.

Unit heats up, but the conveyor

does not run.

Loose motor switch connection. Tighten motor switch connection.

Inoperable motor. Replace motor.

Stripped drive gear. Replace drive gear.

Loose chain sprockets. Adjust and tighten sprockets.

Gears not meshing. Adjust conveyor setscrews (s ee Conveyor and

Inoperable motor switch. Replace switch.

Unit under- and over-heats

Inoperable thermostat. Replace thermostat.

(does not respond to the rmostat

adjustments).

Buns under or over done. Check platen adjustment. (See Bun

Compression on page 3.)

Check platen temperature.

Temperature on page

(See Plat en

3.)

receptacle and the power inlet.

Motor Gears on page 3).

Adjust platen for proper compression.

Adjust thermostat for proper temperature.

Front View Parts List

Item

1 78-184S Power Lighted Rocke r Switch

1

3

2

2 197-185S Platen Adjustment Knob (Pkg of 2)

3 70-012 Thermostat Knob

4 197-232S Foot (Pkg of 4)

5 197-124 Conveyor Guide with Handle

* 197-475 Overlay (Motor Housing)

* 197-259 Release Sheet Convers i on Ki t ,

* 197-402 Release Sheet (Pkg of 2)

* 297-151 Release Sheet (Pkg of 4)

* 297-149 Clamp Bar

* 197-260 Release Sheets (Pkg of 2),

* Not shown.

4

Number Description

Part

197/297

Conversion Kit 296 Series

297-T12PHH only

297-T12PHH only

297 Series

197-538revC-EN 5 Printed in USA 6/06 © 2006

Page 6

Conveyor Assembly

10

11

454

2

8

3

1

4

9

Parts List

Item

1 197-463S Left and Right Side Shaft Carrier

2 197-459S Left and Right Side Shaft Carrier

3 81-015 Compression Spring

4 197- 467 Conveyor Sl ide

5 197-280 Shaft Assy.

Part

Number Description

Assy

Adjustment Assy

2

3

1

4

776

Part

Item

6 197-465 Driven Shaft

7 197-302 Sprocket Kit (Pkg of 2)

8 89-684 Complete Chain Assy

9 89-590 Single C onveyor Chain Link

10 197-7S Black Han dle w i th S cr ew

11 197-466S Complete C onveyor Assy (Passive)

Number Description

Printed in USA 6/06 © 2006 6 197-538revC-EN

Page 7

Rear View

12 13

3

14

15

16

1

5

4

6

2

11

10

9

8

4 Places

17

Parts List

Item

1 197-436S Gear Kit (20/40 Second)

2 197-114 Motor Cover

3 197-473 End Housing

4 76-225 Slotted Pan Head Screw

5 197-131 Guard

6 197-33 Crumb Tray

8 73-007 Hex Nut

9 76-640 Screw

10 197-96 Left Side Bun Fence

Part

Number Description

197-476S Gear Kit (12 Second)

197-477S Gear Kit (14 Second)

197-437S Gear Kit (30 Second)

196-026S Gear Kit (55 Second) (196-Jack)

197-497 Crumb Tray (297-T12PHH on ly )

197-16 Conveyor Stop

76-165 Setscrew

Item

11 73-008 Self Locking Hex Nut

12 76-640 Screw

13 197-13 Lead Pan Weldment

14 197-97 Right Bun Fence

15 197-431S Platen (220 Volt ) (297)

16 197-95 Tray Support

17 72-232S Line Cord (CE)

* Instruction Card for 297-T12PHH

* Part not shown.

Number Description

73-030 Hex Nut

79-016 Flat Washer

76-033 Slotted Flat Head Scr ew

197-430S Platen (110 Volt) (297 )

196-023S Platen (110 Volt) (296 )

72-233S Line Cord (GB)

72-280S Line Cord (120 Volt)

Part

197-538revC-EN 7 Printed in USA 6/06 © 2006

Page 8

Internal Components Parts List

12

Part

11

Item

1 76-300 Slotted Pan Head Screw

Number Description

2 87-028AS Motor (208-240 Volt )

87-029S Motor (120 Volt)

10

3 73-031 Hex Nut

4 79-033 Washer

1

9

5 76-051 Slotted Binder Head Screw

6 79-055 Flat Washer

7 76-040 Slotted Binder Head Screw

79-017 Split Lock Washer

73-030 Hex Nut

6

13

8 76-150 Slotted Pan Head Screw

79-094 Flat Washer

9 79-016 Flat Washer

2

1

10 197-90 LH Side Plat e Weldment with

76-095 Slotted Binder Head Screw

Adjustment Screw

8

197-89 RH Slide Plate Brac ket with

Adjustment Screw

11 197-428 Baffle (Motor Housing)

3

197-429 Baffle (End Housing)

12 196-19 Housing

4

5

7

13 197-140 Thermostat with Knob

297-010S Thermostat with Knob and Thermo

Compound

Printed in USA 6/06 © 2006 8 197-538revC-EN

Page 9

Wiring Diagram

Voltage Connection

High Voltage Connection (220-240 Volts) Low Vo ltage Con nection (200-208 Volts)

197-538revC-EN

355 East Kehoe Blvd. • Carol Stream, IL 60188 USA

Telephone: 630-462-8800 • Fax : 630-462-1460

Toll Free: 1-800-PCASTLE

www.princecastle.com

Printed in USA 6/06 © 2006

Loading...

Loading...