Page 1

INSPECT CARTONINSPECT CARTON

INSPECT CARTON

INSPECT CARTONINSPECT CARTON

Remove product from carton ...........

If damaged :

Operating Instructions

SHORTENING FILTERSHORTENING FILTER

SHORTENING FILTER

SHORTENING FILTERSHORTENING FILTER

MODEL NO'S 102 & 107 CE SeriesMODEL NO'S 102 & 107 CE Series

MODEL NO'S 102 & 107 CE Series

MODEL NO'S 102 & 107 CE SeriesMODEL NO'S 102 & 107 CE Series

Notify carrier

Save carton and packing material

Contact your Dealer, Distributor or Prince

Castle.

If you find a part, or parts missing, contact our

Europeon Distribution Center,Catequip SA, located in Bouilly France at (33)-25-40-29-10 or

Fax to (33)-25-40-26-69

PARTSPARTS

PARTS

PARTSPARTS

1. Always refer to the Parts List in this manual

you will then have a part number for reference

when ordering.

2. All replacement parts should be purchased

from your local PRINCE CASTLE Distributor.

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

ELECTRICAL:ELECTRICAL:

ELECTRICAL:

ELECTRICAL:ELECTRICAL:

All Models 220-230v 1/3 HP 50-60Hz 3 AmpsAll Models 220-230v 1/3 HP 50-60Hz 3 Amps

All Models 220-230v 1/3 HP 50-60Hz 3 Amps

All Models 220-230v 1/3 HP 50-60Hz 3 AmpsAll Models 220-230v 1/3 HP 50-60Hz 3 Amps

Prince Castle Inc.Prince Castle Inc.

Prince Castle Inc.

Prince Castle Inc.Prince Castle Inc.

Printed 2001Printed 2001

Printed 2001

Printed 2001Printed 2001

102-516102-516

102-516

102-516102-516

Page 2

LIMITED WARRANTYLIMITED WARRANTY

LIMITED WARRANTY

LIMITED WARRANTYLIMITED WARRANTY

This product is warrantied to be free from defects in

material and/or workmanship for a period of 1 year

from date of original installation, not to exceed 18

months from date of shipment from our factory.

Any component which proves faulty in material and/or

workmanship within the warranty period will be replaced or repaired without cost to the customer for

parts or labor (at the option of Prince Castle Inc).

This warranty is subject to the following exceptions/

conditions:

This equipment is portable, charges for on location

service (e.g., trip charges, mileage) are not included in

the provisions of the warranty. All labor should be

performed during regular working hours. Overtime

premium will not be covered.

Damage caused by carelessness, neglect, and/or

abuse and misuse (e.g., using wrong electrical current, dropping,tampering with or improper maintenance) is not covered.

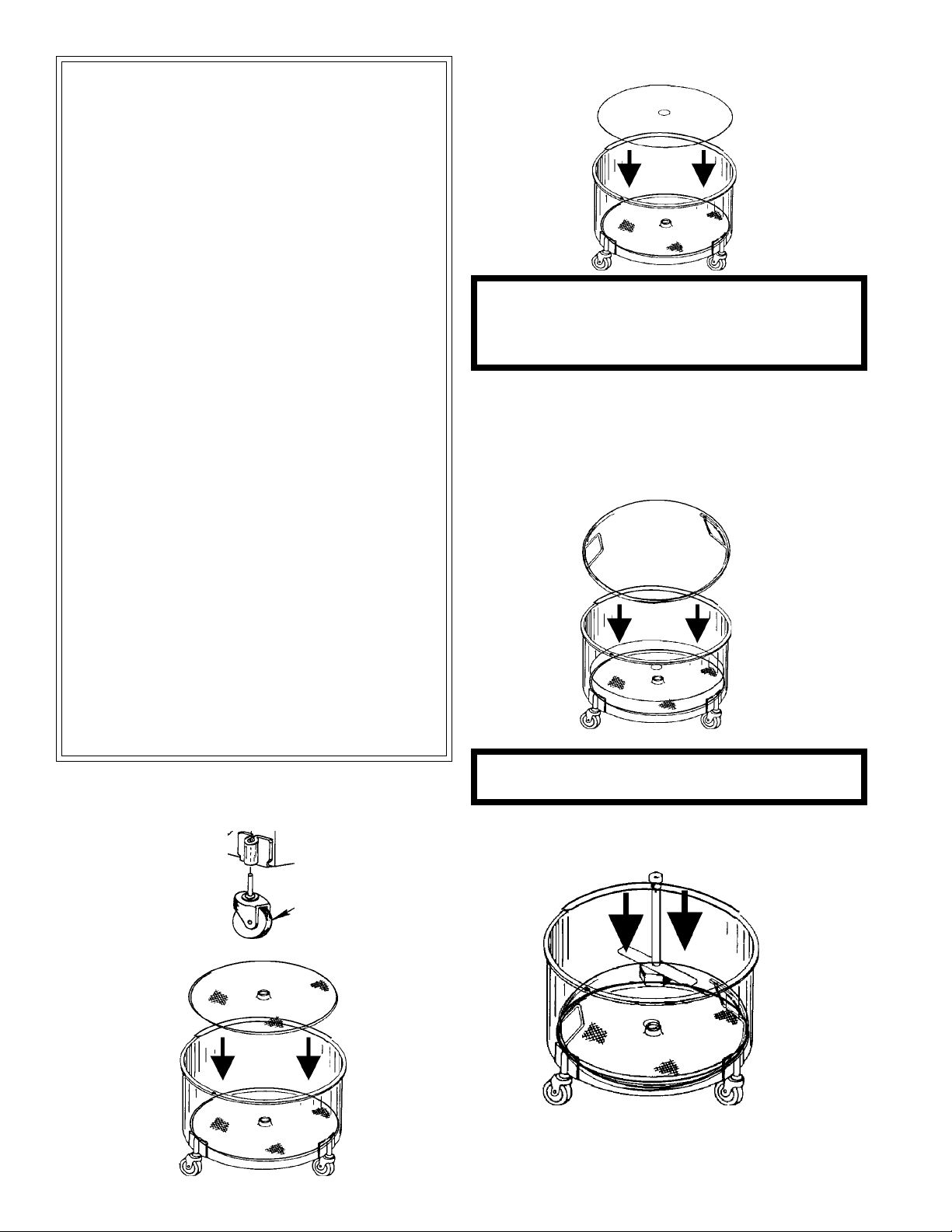

3. Place Filter Paper over thread on top of screen.

IMPORTANT : Center paper properly so it laysIMPORTANT : Center paper properly so it lays

IMPORTANT : Center paper properly so it lays

IMPORTANT : Center paper properly so it laysIMPORTANT : Center paper properly so it lays

flat on screen and overlaps on each end. Ifflat on screen and overlaps on each end. If

flat on screen and overlaps on each end. If

flat on screen and overlaps on each end. Ifflat on screen and overlaps on each end. If

incorrect,torn or no filter paper are used, theincorrect,torn or no filter paper are used, the

incorrect,torn or no filter paper are used, the

incorrect,torn or no filter paper are used, theincorrect,torn or no filter paper are used, the

unit will not filter properly.unit will not filter properly.

unit will not filter properly.

unit will not filter properly.unit will not filter properly.

4. Spread approximately 16oz, by volume, of filter

powder ( Prince Castle No. 712 ) over filter paper

before installing ring weight

5. Place the ring weight on the filter paper.

Running water through the pump rusts internal parts

and will void this warranty.

Equipment damaged in shipment, by fire,flood or an

act of God is not covered.

Any use of non-genuine Prince Castle Replacement

Spare Parts voids this warranty. All genuine Prince

Castle Replacement Spare Parts are warrantied for

ninety (90) days from date of purchase. All Service

shall be performed by a Prince Castle Authorized and

Qualified Service Technician.

HOW TO SET - UPHOW TO SET - UP

HOW TO SET - UP

HOW TO SET - UPHOW TO SET - UP

1. Insert ( 4 ) casters into caster bracket weldments.

2. Place Screen assembly, with thread facing up

inside filter tank.

IMPORTANT: Make sure paper is not folded orIMPORTANT: Make sure paper is not folded or

IMPORTANT: Make sure paper is not folded or

IMPORTANT: Make sure paper is not folded orIMPORTANT: Make sure paper is not folded or

creased under the ring.creased under the ring.

creased under the ring.

creased under the ring.creased under the ring.

6. Hand tighten standpipe to screen.

22

2

22

Page 3

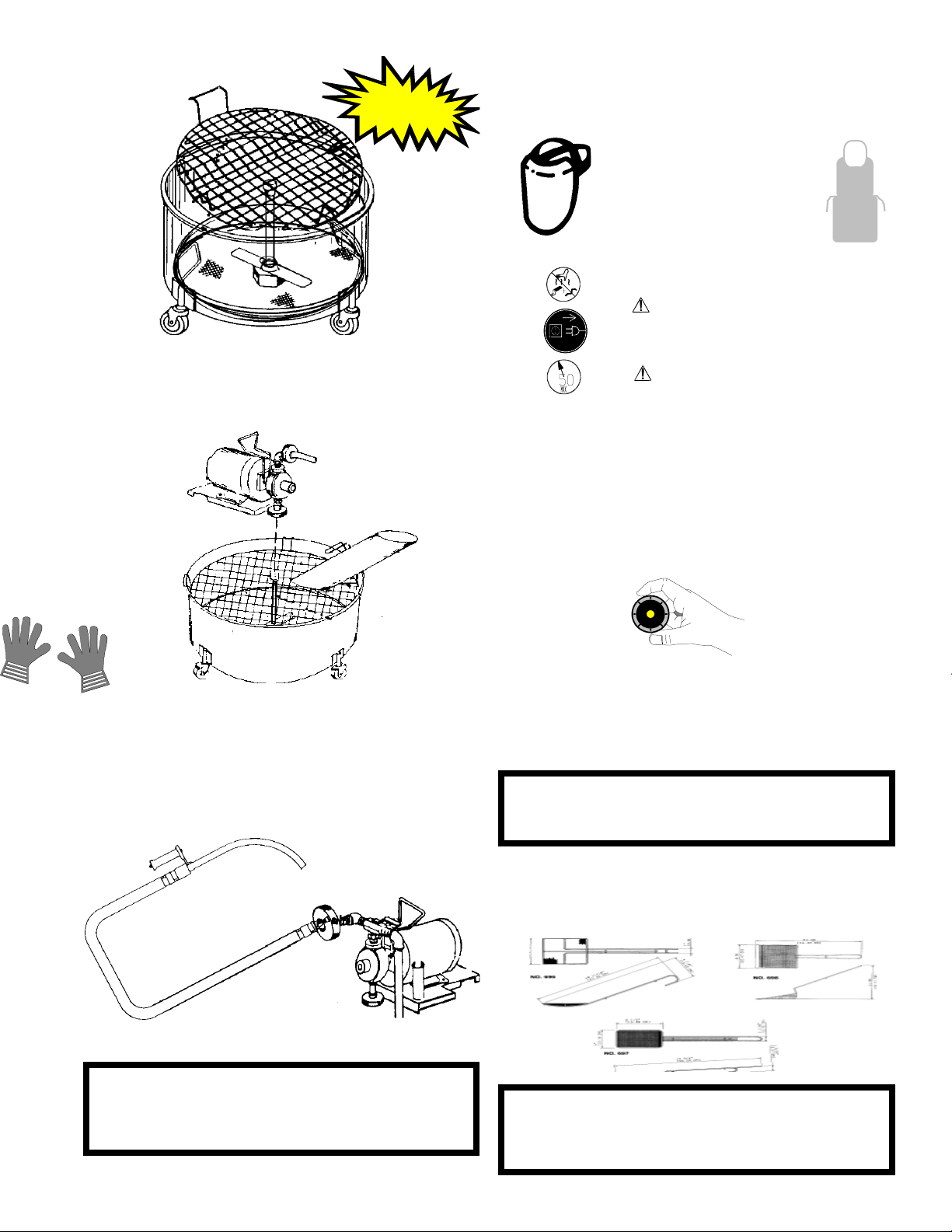

7. Place safety guard on tank.

IMPORTANTIMPORTANT

IMPORTANT

IMPORTANTIMPORTANT

8. Grasp motor assembly by handle on motor and set

it on edge of tank so that the pump lines up with the

standpipe. Hand tighten the union nut to the standpipe

making sure the connection is tight.

HOW TO USEHOW TO USE

HOW TO USE

HOW TO USEHOW TO USE

REQUIRED PROTECTIVE EQUIPMENT :REQUIRED PROTECTIVE EQUIPMENT :

REQUIRED PROTECTIVE EQUIPMENT :

REQUIRED PROTECTIVE EQUIPMENT :REQUIRED PROTECTIVE EQUIPMENT :

Face ShieldFace Shield

Face Shield

Face ShieldFace Shield

HANDLE AND HOSE ARE HOTHANDLE AND HOSE ARE HOT

HANDLE AND HOSE ARE HOT

HANDLE AND HOSE ARE HOTHANDLE AND HOSE ARE HOT

BEFORE PERFORMING SERVICEBEFORE PERFORMING SERVICE

BEFORE PERFORMING SERVICE

BEFORE PERFORMING SERVICEBEFORE PERFORMING SERVICE

MAXIMUM NORMAL OPERATINGMAXIMUM NORMAL OPERATING

MAXIMUM NORMAL OPERATING

MAXIMUM NORMAL OPERATINGMAXIMUM NORMAL OPERATING

PRESSURE 50PSI (35, 155 KGS/SQ METERPRESSURE 50PSI (35, 155 KGS/SQ METER

PRESSURE 50PSI (35, 155 KGS/SQ METER

PRESSURE 50PSI (35, 155 KGS/SQ METERPRESSURE 50PSI (35, 155 KGS/SQ METER

1. Remove cooking computer probes from fryer, if

present.

2. Turn on fryer and set thermostat to cooking temperature.

ARE READY TO FILTER,THIS WILL ALLOWARE READY TO FILTER,THIS WILL ALLOW

ARE READY TO FILTER,THIS WILL ALLOW

ARE READY TO FILTER,THIS WILL ALLOWARE READY TO FILTER,THIS WILL ALLOW

SHORTENING TO REMAIN HOT FOR FILTERING.SHORTENING TO REMAIN HOT FOR FILTERING.

SHORTENING TO REMAIN HOT FOR FILTERING.

SHORTENING TO REMAIN HOT FOR FILTERING.SHORTENING TO REMAIN HOT FOR FILTERING.

DO NOT TURN OFF FRYER UNTIL YOUDO NOT TURN OFF FRYER UNTIL YOU

DO NOT TURN OFF FRYER UNTIL YOU

DO NOT TURN OFF FRYER UNTIL YOUDO NOT TURN OFF FRYER UNTIL YOU

Rubber GlovesRubber Gloves

Rubber Gloves

Rubber GlovesRubber Gloves

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

IMPORTANTIMPORTANT

IMPORTANT

IMPORTANTIMPORTANT

DISCONNECT POWER PLUGDISCONNECT POWER PLUG

DISCONNECT POWER PLUG

DISCONNECT POWER PLUGDISCONNECT POWER PLUG

ON MOTOR OR PUMPON MOTOR OR PUMP

ON MOTOR OR PUMP

ON MOTOR OR PUMPON MOTOR OR PUMP

NOTENOTE

NOTE

NOTENOTE

ApronApron

Apron

ApronApron

9.Attach anti-splash tube on the filter tank by hooking

the tube over the rim of the tank so the diffuser end of

the tube is closest to the safety guard.

(See drawing above)

10. Hand tighten hose to pump union nut, making

sure the connection is tight.

IMPORTANT: This hose is flexible. However,IMPORTANT: This hose is flexible. However,

IMPORTANT: This hose is flexible. However,

IMPORTANT: This hose is flexible. However,IMPORTANT: This hose is flexible. However,

excessive bending can crease or crack theexcessive bending can crease or crack the

excessive bending can crease or crack the

excessive bending can crease or crack theexcessive bending can crease or crack the

hose causing hot oil to leak. Do not use ahose causing hot oil to leak. Do not use a

hose causing hot oil to leak. Do not use a

hose causing hot oil to leak. Do not use ahose causing hot oil to leak. Do not use a

creased or cracked hose.creased or cracked hose.

creased or cracked hose.

creased or cracked hose.creased or cracked hose.

3. Slowly agitate shortening in all fryers with wood

paddle provided. This will blend hot and cold shortening, boil off excess moisture, and bring any debris to

the surface.

CAUTION,EXCESSIVE MOISTURE COULDCAUTION,EXCESSIVE MOISTURE COULD

CAUTION,EXCESSIVE MOISTURE COULD

CAUTION,EXCESSIVE MOISTURE COULDCAUTION,EXCESSIVE MOISTURE COULD

CAUSE FRYER TO BOIL OVER. CONTINUECAUSE FRYER TO BOIL OVER. CONTINUE

CAUSE FRYER TO BOIL OVER. CONTINUE

CAUSE FRYER TO BOIL OVER. CONTINUECAUSE FRYER TO BOIL OVER. CONTINUE

AGITATION UNTIL ALL BOILING CEASES.AGITATION UNTIL ALL BOILING CEASES.

AGITATION UNTIL ALL BOILING CEASES.

AGITATION UNTIL ALL BOILING CEASES.AGITATION UNTIL ALL BOILING CEASES.

4. Skim off any debris from shortening surface (use

a Prince Castle Fry Vat Skimmer).

IMPORTANT: Failure to skim the fryer thor-IMPORTANT: Failure to skim the fryer thor-

IMPORTANT: Failure to skim the fryer thor-

IMPORTANT: Failure to skim the fryer thor-IMPORTANT: Failure to skim the fryer thoroughly could cause excess food particles tooughly could cause excess food particles to

oughly could cause excess food particles to

oughly could cause excess food particles tooughly could cause excess food particles to

clog the drain valve or the filter machineclog the drain valve or the filter machine

clog the drain valve or the filter machine

clog the drain valve or the filter machineclog the drain valve or the filter machine

pump.pump.

pump.

pump.pump.

33

3

33

Page 4

5. Roll assembled filter machine to fryer and plug

power cord into wall outlet. Turn off fryer and engage

locking casters.

IMPORTANT: Do not pull filter machine byIMPORTANT: Do not pull filter machine by

IMPORTANT: Do not pull filter machine by

IMPORTANT: Do not pull filter machine byIMPORTANT: Do not pull filter machine by

hose assembly or power cord. Use the handlehose assembly or power cord. Use the handle

hose assembly or power cord. Use the handle

hose assembly or power cord. Use the handlehose assembly or power cord. Use the handle

on the tank assembly to transport the unit.on the tank assembly to transport the unit.

on the tank assembly to transport the unit.

on the tank assembly to transport the unit.on the tank assembly to transport the unit.

6. Connect drain extension to drain of fryer if available, and place a strainer under the drain to catch

large particles. Open drain slowly and let hot shortening enter tank. If drain valve is clogged use a drain line

clean-out rod to free the drain.

7. When shortening covers ring weight insert nozzle

of hose into fryer and turn motor on.

9. Let shortening drain from fryer and proceed to

clean fryer according to your accepted method.

9A. For

On the Pump To the Recirculating Position and turn

the motor on allowing the shortening to recirculate for

a minimum of 4 to 5 minutes.

IMPORTANT: Do not leave filter machine un-IMPORTANT: Do not leave filter machine un-

IMPORTANT: Do not leave filter machine un-

IMPORTANT: Do not leave filter machine un-IMPORTANT: Do not leave filter machine unattended whilefilteringattended whilefiltering

attended whilefiltering

attended whilefilteringattended whilefiltering

10. After cleaning, insert nozzle into fryer and turn

motor on leaving fryer drain open. Rinse fryer clean.

Direct flow of shortening against sides of fryer to

minimize splashing.

10A. For

HOSE(Back to the center) HOSE(Back to the center)

to

HOSE(Back to the center) before turning motor

HOSE(Back to the center) HOSE(Back to the center)

on.

Recirculating Motor Recirculating Motor

Recirculating Motor move the 3 Way Valve

Recirculating Motor Recirculating Motor

Recirculating Motor Recirculating Motor

Recirculating Motor turn the 3 Way Valve

Recirculating Motor Recirculating Motor

7A. For

valve to hosevalve to hose

valve to hose

valve to hosevalve to hose

8. When fryer is clean of particles, turn motor off and

put nozzle of hose in hole on motor mount.

8A.

ing Valve in The Center.ing Valve in The Center.

ing Valve in The Center.

ing Valve in The Center.ing Valve in The Center.

Recirculating Motor Recirculating Motor

Recirculating Motor move the

Recirculating Motor Recirculating Motor

flushing particles from the fryer.

HOSEHOSE

HOSE

HOSEHOSE

For Recirculating Motor leave the Recirculat-For Recirculating Motor leave the Recirculat-

For Recirculating Motor leave the Recirculat-

For Recirculating Motor leave the Recirculat-For Recirculating Motor leave the Recirculat-

recirculatingrecirculating

recirculating

recirculatingrecirculating

HOSEHOSE

HOSE

HOSEHOSE

12. Close drain valve and fill fryer with filtered shortening until filter machine tank is empty.

13. Turn fryer on and make sure thermostat is set to

your cooking temperature. Using fresh shortening

carefully refill fryer to proper level. A small amount of

shortening will be left in the filter tank, which is

normal.

44

4

44

Page 5

14. Replace the cooking computer probes.

IMPORTANT: Make sure floor around filteringIMPORTANT: Make sure floor around filtering

IMPORTANT: Make sure floor around filtering

IMPORTANT: Make sure floor around filteringIMPORTANT: Make sure floor around filtering

area is free from any splattering. Floor shouldarea is free from any splattering. Floor should

area is free from any splattering. Floor should

area is free from any splattering. Floor shouldarea is free from any splattering. Floor should

be kept clean and dry.be kept clean and dry.

be kept clean and dry.

be kept clean and dry.be kept clean and dry.

15. Repeat procedures for remaining fryers.

16. The number of fryers that can be filtered with one

dose of powder will depend on the product being

cooked and the amount of debris in each fryer.

HOW TO CLEANHOW TO CLEAN

HOW TO CLEAN

HOW TO CLEANHOW TO CLEAN

THIS APPLIANCE IS NOT OF WATER TIGHT

!

CONSTRUCTION. DO NOT CLEAN WITH A

WATER JET / JET SPRAY.

DO NOT IMMERSE APPLIANCE IN WATER

CAUTION: PARTS ARE EXTREMELY HOT !!CAUTION: PARTS ARE EXTREMELY HOT !!

CAUTION: PARTS ARE EXTREMELY HOT !!

CAUTION: PARTS ARE EXTREMELY HOT !!CAUTION: PARTS ARE EXTREMELY HOT !!

USEUSE

USE

USEUSE

PROTECTIVEPROTECTIVE

PROTECTIVE

PROTECTIVEPROTECTIVE

GLOVES THATGLOVES THAT

GLOVES THAT

GLOVES THATGLOVES THAT

ARE TEMPERATUREARE TEMPERATURE

ARE TEMPERATURE

ARE TEMPERATUREARE TEMPERATURE

AND OIL RESISTANTAND OIL RESISTANT

AND OIL RESISTANT

AND OIL RESISTANTAND OIL RESISTANT

1. Unplug the power cord.

GRASP PLUG, DO NOTGRASP PLUG, DO NOT

GRASP PLUG, DO NOT

GRASP PLUG, DO NOTGRASP PLUG, DO NOT

PULL CORD.PULL CORD.

PULL CORD.

PULL CORD.PULL CORD.

5. Disassemble standpipe from screen and place in

sink.

6. Remove filter paper from screen and discard.

CAUTION: FILTER PAPER MAY BE HOT !!!CAUTION: FILTER PAPER MAY BE HOT !!!

CAUTION: FILTER PAPER MAY BE HOT !!!

CAUTION: FILTER PAPER MAY BE HOT !!!CAUTION: FILTER PAPER MAY BE HOT !!!

7. Remove screen from tank and place in sink.

2. Immediately disconnect hose from pump union nut

and drain excess shortening from hose into tank.

3. Disconnect pump from standpipe and remove

motor assembly from tank.

4. Remove anti-splash tube(A) , safety guard(B), and

ring weight (C) from tank and place in sink.

9. Wash anti-splash tube ( if applicable ), ring weight,

standpipe, screen and tank with very hot water.

10. Wipe all parts dry with a clean towel.

IMPORTANT:DO NOT RUN WATER THROUGHIMPORTANT:DO NOT RUN WATER THROUGH

IMPORTANT:DO NOT RUN WATER THROUGH

IMPORTANT:DO NOT RUN WATER THROUGHIMPORTANT:DO NOT RUN WATER THROUGH

MOTOR AND PUMP ASSEMBLY AT ANY TIMEMOTOR AND PUMP ASSEMBLY AT ANY TIME

MOTOR AND PUMP ASSEMBLY AT ANY TIME

MOTOR AND PUMP ASSEMBLY AT ANY TIMEMOTOR AND PUMP ASSEMBLY AT ANY TIME

!! THIS WILL CAUSE PUMP TO RUST INTER-!! THIS WILL CAUSE PUMP TO RUST INTER-

!! THIS WILL CAUSE PUMP TO RUST INTER-

!! THIS WILL CAUSE PUMP TO RUST INTER-!! THIS WILL CAUSE PUMP TO RUST INTERNALLY AND VOID THE WARRANTY.NALLY AND VOID THE WARRANTY.

NALLY AND VOID THE WARRANTY.

NALLY AND VOID THE WARRANTY.NALLY AND VOID THE WARRANTY.

11. Place screen, ring weight, standpipe, anti-splash

tube ( if applicable ), safety guard and hose assembly

inside tank and roll into storage area.

CAUTION: DO NOT STORE MOTOR AND PUMPCAUTION: DO NOT STORE MOTOR AND PUMP

CAUTION: DO NOT STORE MOTOR AND PUMP

CAUTION: DO NOT STORE MOTOR AND PUMPCAUTION: DO NOT STORE MOTOR AND PUMP

ASSEMBLY ON THE SCREEN. THIS COULDASSEMBLY ON THE SCREEN. THIS COULD

ASSEMBLY ON THE SCREEN. THIS COULD

ASSEMBLY ON THE SCREEN. THIS COULDASSEMBLY ON THE SCREEN. THIS COULD

CAUSE THE SCREEN TO WARP OR CAUSECAUSE THE SCREEN TO WARP OR CAUSE

CAUSE THE SCREEN TO WARP OR CAUSE

CAUSE THE SCREEN TO WARP OR CAUSECAUSE THE SCREEN TO WARP OR CAUSE

GREASE TO DAMAGE THE POWER CORD ANDGREASE TO DAMAGE THE POWER CORD AND

GREASE TO DAMAGE THE POWER CORD AND

GREASE TO DAMAGE THE POWER CORD ANDGREASE TO DAMAGE THE POWER CORD AND

MOTOR.MOTOR.

MOTOR.

MOTOR.MOTOR.

AA

A

AA

BB

B

BB

CC

C

CC

12. Slide handle down and forward so it lays on the side

of the tank when storing filter machine.

55

5

55

Page 6

2929

29

2929

EXPLODED VIEWEXPLODED VIEW

EXPLODED VIEW

EXPLODED VIEWEXPLODED VIEW

4A4A

4A

4A4A

66

6

66

Page 7

PARTS LISTPARTS LIST

PARTS LIST

PARTS LISTPARTS LIST

ITEMITEM

ITEM

ITEMITEM

1

2

3

4

4A

5

6

7

8

9

10

12

13

16

17

18

19

20

21

23

24

25

26

27

28

29

A & C

B

PART NUMBERPART NUMBER

PART NUMBER

PART NUMBERPART NUMBER

102-32

102-33

100-57

102-110

100-59

100-58

102-117S

100-5S

102-7

107-6

102-338SCE

102-338SGB

105-77

72-232S

72-233S

100-22S

102-8

107-4

78-199S

66-039

102-286

110

102-125

105-22

102-10

713

712

100-13

105-21

89-112S

89-410S

126

100-62

102-240S

102-171

76-061

79-028

79-030

73-022

76-049

79-046

102-272

107-82

Not Shown

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

Union Nut

Female Union

Street Elbow

Long Close Nipple (Standpipe Coupling)

Long Close Nipple (Hose Coupling)

Reducing Bushing

Standpipe Coupling Assy

Hose Coupling, Coupling and Nipple Assy

Handle(102 Series)

Handle (107 Series)

Motor Only (102-FCE, 107-FCE & 107-FMCCE)

Motor Only (102-FGB, 107-FGB & 107-FMCGB)

Pump

Line Cord (102-FCE, 107-FCE & 107-FMCCE)

Line Cord (102-FGB, 107-FGB & 107-FMCGB)

Rubber Strip

Motor Base (102-FCE & 102-FGB)

Motor Base W/Holster (107-FCE, 107-FGB, 107-FMCCE

& 107-FMCGB)

Rocker Switch

Strain Relief

Hose Assembly

Anti-Splash Tube

Safety Guard

Ring Weight

Standpipe

Filter Paper (100 Sheets)

Filter Powder (50lbs)

Screen

Bowl With Casters

Casters (Pkg of 2)

Locking Casters (Pkg of 2)

Wood Paddle

Male Union Fitting

Handle With Hardware

3 Way Recirculating Valve (107-FCE,107-FGB, 107-FMCE,

& 107-FMGB)

Hex Head Screw

Split Lockwasher

Flat Washer

Hex Nut

Hex Head Screw

Split Lockwasher

Motor Pump And Hardware (102-FCE & 102-FGB)

Motor Pump And Hardware (107-FCE, 107-FGB, 107-FMCCE

& 107-FMCGB)

77

7

77

Page 8

MOTOR WIRING DIAGRAMMOTOR WIRING DIAGRAM

MOTOR WIRING DIAGRAM

MOTOR WIRING DIAGRAMMOTOR WIRING DIAGRAM

NO. 102-338SCE 230 Volt Motor (Continental Europe)NO. 102-338SCE 230 Volt Motor (Continental Europe)

NO. 102-338SCE 230 Volt Motor (Continental Europe)

NO. 102-338SCE 230 Volt Motor (Continental Europe)NO. 102-338SCE 230 Volt Motor (Continental Europe)

NO. 102-338SGB 230 Volt Motor (Great Britain)NO. 102-338SGB 230 Volt Motor (Great Britain)

NO. 102-338SGB 230 Volt Motor (Great Britain)

NO. 102-338SGB 230 Volt Motor (Great Britain)NO. 102-338SGB 230 Volt Motor (Great Britain)

NO. 105-77 PUMP ASSEMBLYNO. 105-77 PUMP ASSEMBLY

NO. 105-77 PUMP ASSEMBLY

NO. 105-77 PUMP ASSEMBLYNO. 105-77 PUMP ASSEMBLY

ITEM PART NO. DESCRIPTIONITEM PART NO. DESCRIPTION

ITEM PART NO. DESCRIPTION

88

8

88

66

6

66

11

1

11

44

4

44

55

5

55

77

7

77

22

2

22

33

3

33

ITEM PART NO. DESCRIPTIONITEM PART NO. DESCRIPTION

1

2

3

4

5

6

7

8

105-140

105-144

105-145S

102-128S

105-73S

93-021S

105-146

105-139

Casting

Cover

Screws (Pkg of 4)

Drive Shaft

Idler Gear

Oil Seal (Includes Items 7 & 8)

O' Ring

O' Ring

88

8

88

Page 9

PROBLEMPROBLEM

PROBLEM

PROBLEMPROBLEM

Filter will not pump shortening

Or pumping shortening slowly

TROUBLESHOOTING GUIDETROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDETROUBLESHOOTING GUIDE

PROBABLE CAUSEPROBABLE CAUSE

PROBABLE CAUSE

PROBABLE CAUSEPROBABLE CAUSE

Filter paper too thick

Dirt or nick on standpipe pump

fittings which results in leaking

air into the pump intake

Oil seal & Orings Replace Oil seal & Orings

Motor not running

Cold shortening

Hose clogged. Hose not drained

at finish of previous operation.

(Caution: Hose may burst if used

in this condition.)

Pump clogged with debris Clean pump of debris and

Using too much Gycor or filter

aid

Loose connections

Shortening too cool ( will cause

paper to clog and machine to

pump slowly)

Using too much Gycor or filter

aid causing pump to clog

Power cord attached improperly

or not in good repair

CORRECTIVE ACTIONCORRECTIVE ACTION

CORRECTIVE ACTION

CORRECTIVE ACTIONCORRECTIVE ACTION

Try a sheet from another part of

the package

Clean off dirt

Replace standpipe assy.

Replace standpipe coupling

Check motor reset

Check circuit breaker

Replace ON/OFF Switch

Clean shortening debris in

pump

Ensure vat is at cooking temperature

Soak in hot water until loose (Caution: make sure there is no water

in hose before reconnecting to

pump.)

reattach to motor

Use recommended amount

16oz by volume

Check all fittings for tightness

Keep vat at cooking temperature

until emptied into filter machine

Use recommended amount 16oz

by volume (clean pump of debris)

Repair or replace cord

Shortening cannot be completely

pumped out

Filter powder pumped back into

fryer

Motor not operating correctly Repair or replace motor

O rings or Oil seal defective Replace Orings & Oil seal

Filter paper not centered or

creased under ring

Ring weight is bent or warped Warped or bent ring should be

Tank rim is bent or not clean

Tank not level ( can cause seal

to break )

Filter paper clogged

Too much filter aid or Gycor Use 16oz by volume

Excessive food particles Skim vats before filtering

Shortening too cool

Ring weight bent Straighten or replace

Nick or debris on seal surface

on Tank

Screen assembly bent Straighten or replace

Filter paper torn Replace filter paper

Ensure paper is centered and

placed flat on screen

replaced

Clean bowl thoroughly. Remove

dents or replace bowl

Repair or replace wheels on

filter machine

Machine must be broken down,

cleaned, and set up again

Shortening must be at cooking

temperature prior to filtering

Replace bowl

99

9

99

Page 10

105-139

O'Ring

93-021S

Oil Seal

105-140

Casting

102-128S

Drive

Shaft

105-73S

Idler Gear

105-77PUMP EXPLODED VIEW105-77PUMP EXPLODED VIEW

105-77PUMP EXPLODED VIEW

105-77PUMP EXPLODED VIEW105-77PUMP EXPLODED VIEW

105-146

O'Ring

105-144

Cover

105-145S

Screw (Pkg of 4)

Loading...

Loading...