Page 1

PRINCE CASTLE NO. 107-AMC

Place this chapter in the Small Equipment/

Miscellaneous Section of your Equipment

Manual.

MANUFACTURED

EXCLUSIVELY FOR

McDONALD’S

BY

PRINCE CASTLE INC.

CAROL STREAM, IL 60188 USA

PHONE 1-800-323-2930

TOLL FREE NUMBER

1-800-323-2930

FAX: 1-630-462-1460

SHORTENING FILTER

110 VOLT SERIES

TABLE OF CONTENTS

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

PARTS IDENTIFICATION/FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

EQUIPMENT SET-UP AND CLOSE PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

ORDERING/SERVICE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

NON-SCHEDULED MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

HAZARD COMMUNICATION STANDARD (HCS) – THE PROCEDURES IN THIS CHAPTER INCLUDE THE

USE OF CHEMICAL PRODUCTS. THESE CHEMICAL PRODUCTS WILL BE HIGHLIGHTED WITH BOLD

FACE LETTERS FOLLOWED BY THE ABBREVIATION (HCS). SEE THE HAZARD COMMUNICATION

STANDARD (HCS) MANUAL FOR THE APPROPRIATE MATERIAL SAFETY DATA SHEET(S) (MSDS).

WARRANTY

This product is warranted to be free from defects in material and/or workmanship for a period of one year

from the date of original installation. Any component which proves to be faulty during the warranty period

will be replaced without cost to the customer.

This warranty is subject to the following exceptions/conditions:

(1) This equipment is portable; charges for on-location service (e. g., trip charges, mileage) are only

included in the provisions of this warranty for a failure which occurs within the first 30 days of installation.

(2) Damage caused by carelessness, neglect, and/or abuse (e.g., using wrong current, dropping, tamper-

ing with or altering electrical components) voids this warranty.

(3) Running water through pump rusts internal parts and will void the warranty.

This manual is for the exclusive use of licensees and employees of McDonald’s Systems, Inc.

2001 McDonald’s Corporation

All Rights Reserved

Part No. 107-515

Printed in September

EM MISC 5

The United States of America

Printed in

Page 2

INTRODUCTION

This filter is used for cleaning the shortening used in

frying. The Filter Aid (HCS) is sprinkled evenly onto the

filter paper (refer to your Operations and Training Manual).

The shortening is drained from the fry vats to the filter.

The shortening is recirculated thru the filter paper and

Filter Aid (HCS) to remove impurities.

PARTS IDENTIFICATION/FUNCTION

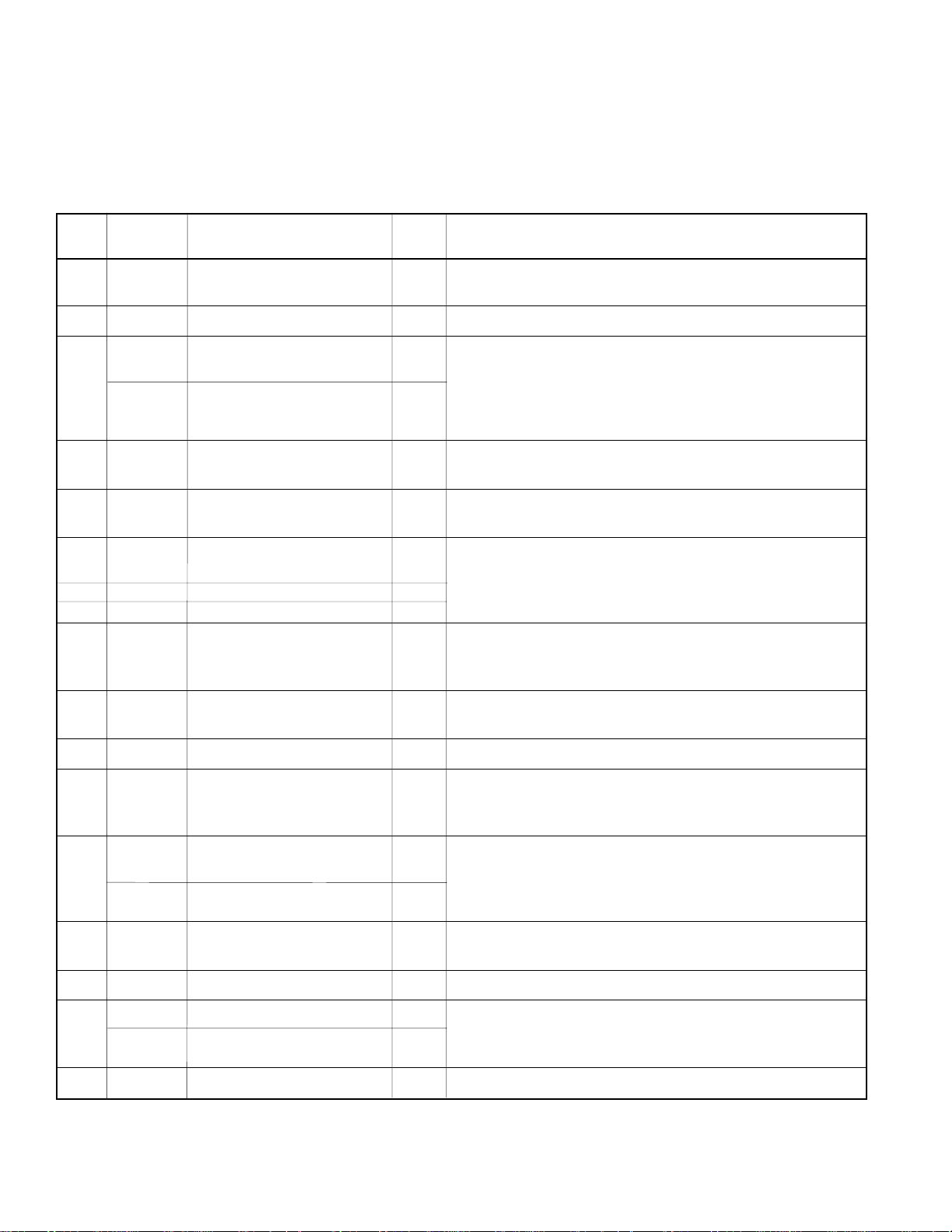

PART

ITEM DESCRIPTION

NO.

QTY.

1 102-32 Union Nut, Knurled 2 Used to attach hose assembly and standpipe to

pump.

2 102-33 Female Union 2 When used with male union, forms a seal.

3 100-59

3

/8 ” NPT x 1” (10 X 25 2 Used to attach female union to the standpipe

mm) coupling.

102-1103/8 ” NPT x 11/4 ” (10 X 32 1

mm) Long Close Nipple

(For 102-117)

4 100-57

c

” (10 mm)– 18 NPT 1 Used to attach female union to the hose coupling.

Street Elbow

5 102-171 Three way Valve 1 Directs the flow of the shortening to the ose or the

& Bushing recirculating nipple.

FUNCTION

6 93-027 Nipple 1/2” NPT X 11/2” 1 Parts used for recirculating the hot shortening into

Long the filter bowl.

7 93-026 Elbow (1/2 ” NPT 90°) 1

8 93-023 Nipple (1/2” NPT) 1

9 107-087 Motor Base Assembly 1 Attaches to the motor and holds up the motor and

pump when it is placed on top of the filter bowl. Also

holds the hose nozzle when not in use.

10 93-003 Close Nipple 1/2 ” NPT 1 Attaches 3-way valve to the pump.

11 105-152 Handle 1 Used for carrying the motor and pump assembly.

12 100-58 Reducing Bushing 1/2 ” to 1 Used to attach the motor and pump to the standpipe

3

/8 NPT assembly.

X 3/4” Long

13 102-117 Standpipe Coupling 1 Used to attach the motor and pump to the standpipe

assembly.

14 72-296S Power Cord 1 Transfers electrical power from the wall outlet to the

motor.

15 100-22 Rubber Strip 2 Absorbs vibrations from the motor when it is running.

16 105-77 Pump Assembly (Blue) 1 Creates a vacuum and pulls the hot shortening thru

the paper and filter powder up the standpipe, thru the

pump and out the filter hose.

*16A 102-219 Set Screws (Pkg. of 3) 1 Mounts blue pump to blue motor.

* Not Shown

2

Page 3

PART

ITEM DESCRIPTION

17 108-385S Motor Assembly (Blue) 1 Turns the gears in the blue pump (or turns the

* 88-409 Strain Relief (Not shown) 1 Securely holds power cord to motor.

* 100-19 Strain Relief (Wire Mesh) 1

A 76-061 1/4” #20 X 3/4” Hardware used to attach motor and pump

B 76-049 5/16” – 18 X 5/8”

C 76-061 1/4” – 20 X 3/4”

NO.

(not shown)

Hex Head Screw assembly to base.

79-028 1/4” I.D. Split Lockwasher

79-030 1/4” I.D. Flatwasher

73-022 1/4” – #20 Hex Nut

Hex Head Screw

79-046 5/16” I.D. Split

Lockwasher

Hex Head Screw

79-028 1/4” Split

Lockwasher

79-030 1/4” I.D. Flatwasher

73-022 1/4” –20 Hex Nut

QTY.

impeller in the gray pump) creating a vacuum, which

then moves the shortening from the filter bowl the

through standpipe, and pump assembly to the hose

and into the fry vat.

FUNCTION

D 100-5 Hose Coupling Assembly 1 Used to attach hose assembly to pump.

18 102-286 Hose Assembly 1 Transfers the hot shortening from the pump to

the fry vats.

19 110 Anti-Splash Tube 1 Prevents the hot shortening from splashing onto

the floor when draining the shortening from the fry

vat into the filter bowl.

20 102-125 Safety Screen 1 Prevents hands and feet from accidentally going

into the bowl.

21 105-22 Ring Weight 1 Seals the filter paper to the filter bowl.

22 102-10 Standpipe 1 Connects the filter pump with the screen assembly

and transfers the shortening from the bowl to the

pump.

23 – Filter Paper (available 1 Removes unwanted solids. When used with filter-aid

from your purveyor) also removes moisture and frees fatty acids,

extending the life of the shortening.

24 100-13 Screen 1 Support for the filter paper and powder. Provides

attachment for standpipe.

25 105-21 Bowl with Casters 1 Holds the filter paper, screen, ring weight and

shortening for filtering.

* Not Shown

3

Page 4

PART

ITEM DESCRIPTION

26 89-112 Caster 2 Used to easily move the shortening filter from one

27 126 Maple Wood Paddle 1 Used to stir the shortening after the filter powder has

*28 Transfers the shortening through the filter paper

* Not Shown

NO.

89-410 Caster (Locking) 2 one fry vat to another.

107-088 Complete Motor and Pump 1

Assembly 110V

QTY.

been added.

into the fry vat.

FUNCTION

4

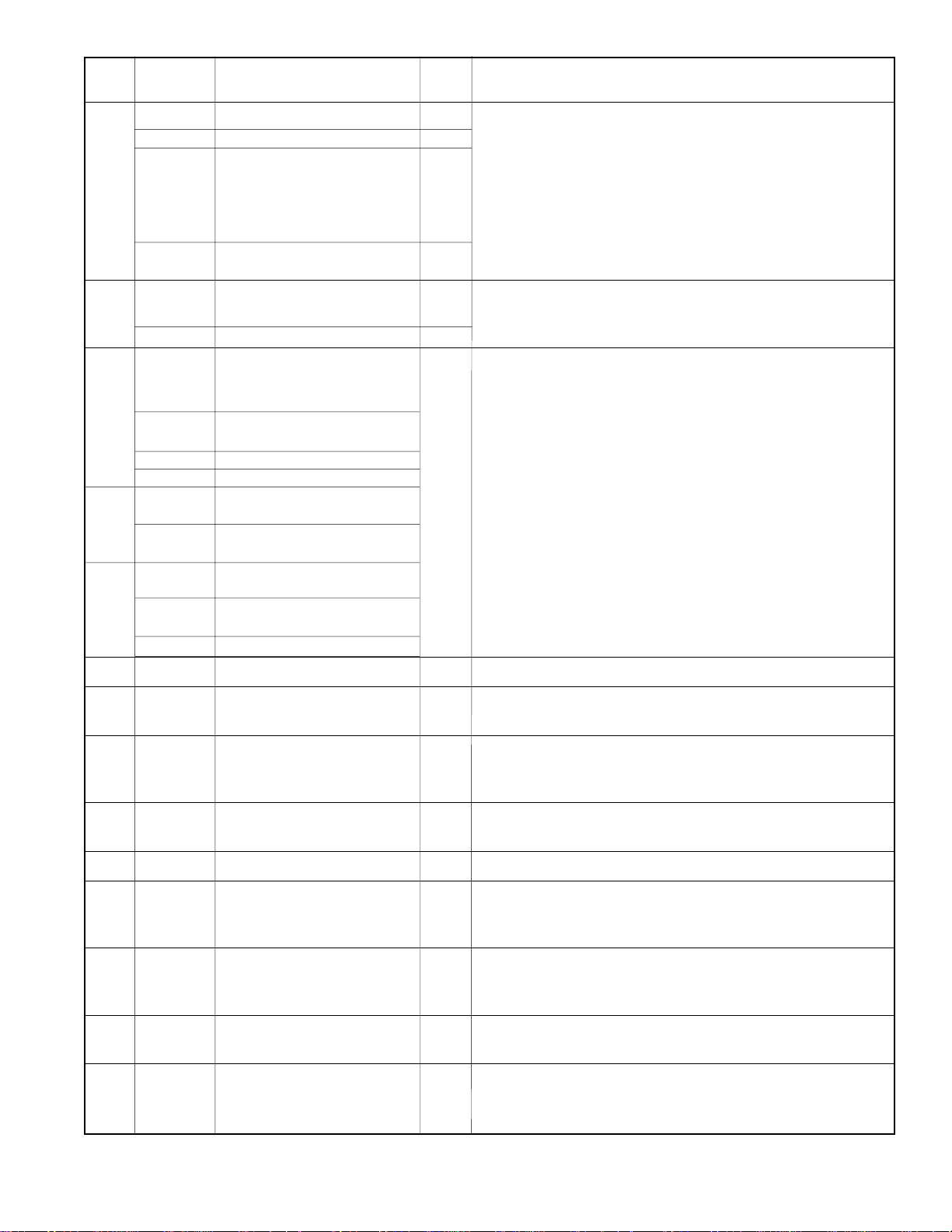

Page 5

PART

ITEM DESCRIPTION

*37 578-61 Switch Guard 1 Provides protection for switch against accidental

38 78-120 Overload Protector Switch 1 Protects motor from overheating. Must be reset

39 63-077 Starting Capacitor 1 Provides extra power to start motor.

40 78-129 ON/OFF Toggle Switch 1 Turns unit ON when switch is up and OFF when

41 102-202 Starting Switch 1 When ON/OFF Switch is activated, turns ON

42 102-211 Insulator 1 Protects switches from shorting.

43 102-210 Spring Wave Washer 1 Keeps bearing and shaft from binding on end

44 102-209 Bearing 1 Allows armature and shaft to rotate freely.

45 102-93 Rotor Switch (115V) 1 Provides power to field when first starting, at

NO.

QTY.

activation or breakage.

manually.

switch is down.

capacitor.

cap.

higher R.P.M. moves out of circuit.

FUNCTION

46 88-409 Strain Relief 1 Protects power cord from misuse.

*47 578-61 Switch Guard 1 Provides protection for switch against accidental

activation or breakage.

48 100-62 Male Union Fitting 1 Provides connection for hose assembly to pump

union nut.

49 102-240S Handle w/Hardware 1 Allows a safe method to hold the nozzle

when returning the shortening to the fry vat.

* Not Shown

5

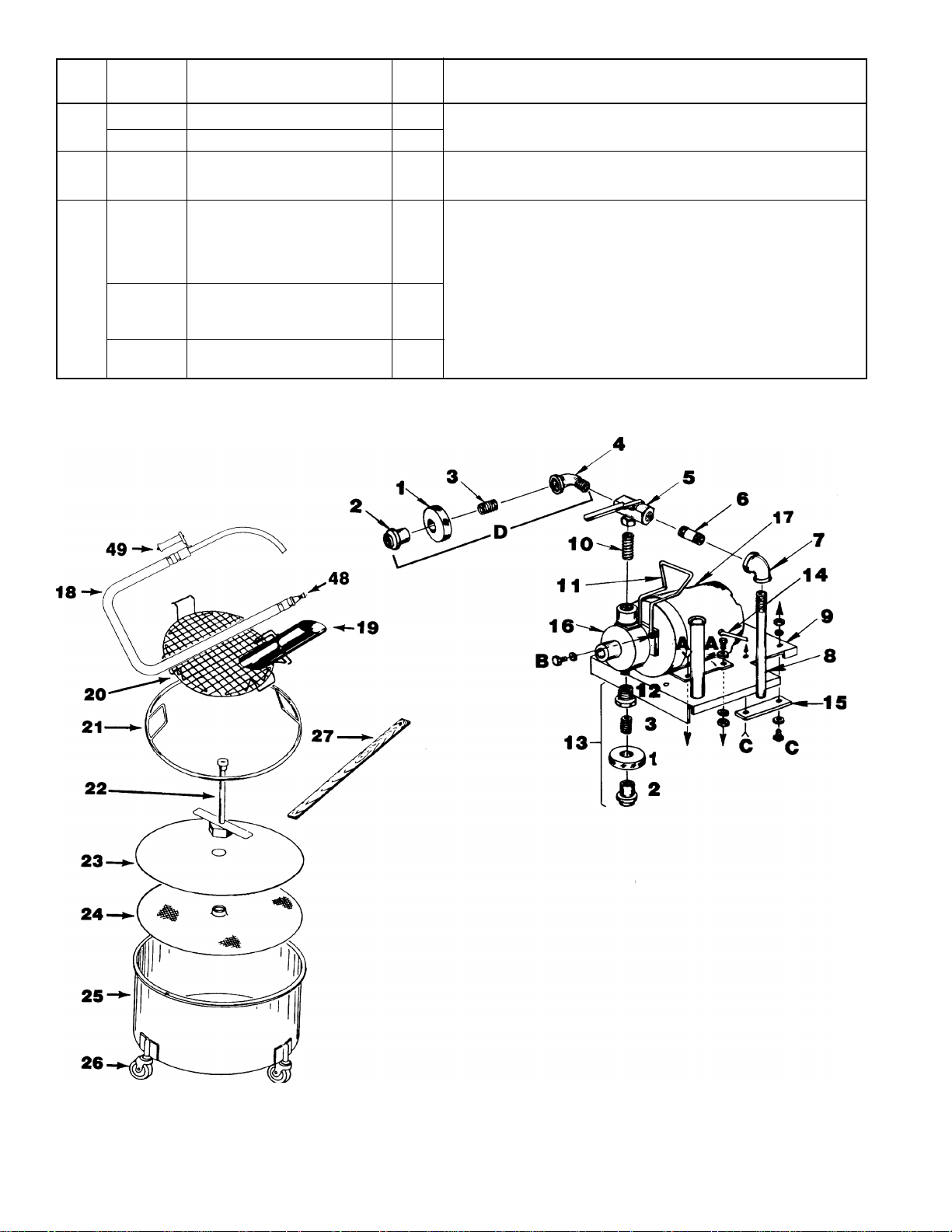

Page 6

16

11

14

15

12

13

PART

ITEM

NO.

DESCRIPTION

QTY.

FUNCTION

11 105-140 Casting 1 Holds the gears.

12 105-144 Cover 1 Holds the gears in the casting.

13 105-145S Screw (Pkg. of 4) 1 Hold the cover in place.

14 102-128S Drive Gear 1 Provides movement to idler gear

which moves shortening.

15 105-73S Idler Gear 1 When turning creates a vacuum which moves the

shortening

16 93-021S Package of one Oil Seal 1 Seals the pump to the motor.

and 2 O-Rings

6

Page 7

EQUIPMENT SET-UP, CALIBRATION,

CLEANING AND CLOSE PROCEDURES

Set-up

IMPORTANT: Clean out any remaining water from filter

machine bowl.

1. Place the screen, with its thread facing up, inside the

filtering bowl. See figure 1.

figure 1

2. Place filter paper (manufactured to McDonalds

specifications) over the threads and on top of the

screen. Be sure the hole in the paper is centered to

fit over the shoulder so the paper will lay flat. See

figure 2.

figure 4

5. Center safety grid over standpipe. This will allow the

grid to suspend over the rim of the filtering bowl. See

figure 5.

figure 5

figure 2

3. Screw on the standpipe. Tighten by hand. See figure

3.

figure 3

6. Set the motor on the edge of bowl and screw the union

to the standpipe by hand. Make sure the connection

is hand tight. See figure 6.

figure 6

4. Place the ring weight on the filter paper. Make sure

paper is not folded or creased under the ring. See

figure 4.

7

Page 8

7. Place the anti-splash tube on filter bowl by doing the

following:

A. Grasp tube by handle.

B. Hook prongs under lip of bowl.

C. Rotate downward until tube rest is against the

shortening filter bowl.

The anti-splash tube has 2 ends. One end has a

diffuser plate attached inside the tube, and the

opposite end is open. Hook the tube over the filtering

bowl rim so that the end with the diffuser is closest to

the safety grid.

8. Attach hose to pump. Make sure the connection is

hand tight. Put the nozzle in its holder.

CAUTION: This hose is made to bend up to a

radius of six inches (15.2 cm). If the hose is

bent under six inches (15.2 cm) or if the hose

is crimped, it could crack, causing it to leak

hot oil which may cause burns. If the hose is

cracked and/or leaking, do not use until it

has been replaced or repaired.

Close

After the filtering, the filter must be cleaned and stored

so that it will be ready for next use. Follow these

cleaning procedures:

CAUTION: Parts are hot. Handle with care,

and use filter shortening gloves.

1. Unplug the power cord. Return the filtering machine

to the back sink to disassemble.

2. IMMEDIATELY disconnect the hose from the pump

and drain the shortening from the hose into the bowl.

3. Unscrew the pump from the standpipe and lift the

motor assembly from the bowl.

4. Remove the safety grid, ring weight, anti-splash tube,

and place them in the back sink. Unscrew the

standpipe assembly from the screen assembly and

place in the back sink.

5. Remove and discard filter paper.

When finished filtering each vat, roll the unit to the next

vat by using the handle attached to the motor and pump

assembly.

CAUTION: Do not pull the unit by the power

cord or the hose.

OPERATING INSTRUCTIONS

Refer to your McDonald’s Operations and

Training Manual for the proper procedures to

filter your Fry Vats. If your manual does not

contain this procedure, contact your Regional

Training Department.

7. Discard any shortening left in the bowl into the

shortening disposal cart/shortening drum.

8. Wash the ring weight, standpipe, screen and bowl

with the hottest water possible and fryer cleanser to

prevent carbon buildup. (Do not use APC.)

9. Wipe dry with a clean towel.

10. Wipe the motor assembly and filter hose using a

clean towel.

11. Reassemble bowl, filter screen and ring weight.

Place the standpipe assembly, and filter hose inside

the bowl.

12. Roll filtering equipment into storage location.

CAUTION: Do not store motor and pump

assembly on the screen assembly. This

could cause the screen to warp, tear away

from the welds or cause grease to damage

the power cord and motor.

CAUTION: Do not pump water through the

motor and pump assembly. This will cause

the pump gears to rust and void the warranty.

8

Page 9

TROUBLESHOOTING CHART

PROBABLE CAUSEPROBLEM

Filter will not pump Filter paper too thick. Use new sheet of paper.

shortening. Dirt or nick on standpipe pump Clean off dirt.

fittings which results in leaking Replace standpipe assembly.

air into the pump intake. Replace standpipe coupling.

Leaking gaskets. Return for service.

Oil seal leaking. Return for service.

Motor not running. Check power supply.

Return for service.

Cold shortening. Ensure vat is at operating temperature.

Hose clogged. Hose not drained at Soak in hot water until loose.

finish of previous operation. CAUTION: Make sure there is not water

CAUTION: HOSE MAY BURST IF in hose before reconnecting to pump.

USED IN THIS CONDITION

Pump not operating. Consult operating procedures.

Return for service.

Filter paper clogged. 2” (5 cm) of Spread filter powder around ring weight.

shortening in bowl. See sealing procedure on page 11.

Examine ring weight and bowl for defects

(ie, warps, dents). If defective, replace.

Lost seal. See sealing procedure on page 11.

Using too much Gycor (HCS) or Use recommended amount 1 McD portion

filter aid. pak (HCS) 10.5 oz. (300 grams).

CORRECTIVE ACTION

Machine pumping Shortening too cool (will cause Keep vat at cooking temperature until

shortening slowly. paper to clog and machine to pump emptied into filter machine.

slowly). CAUTION: Vat must be turned OFF just

before vat is drained.

Using too much Gycor (HCS) or Use recommended amount of McD portion

filter aid. pak (HCS) 10.5 oz. (300 grams).

Power cord attached improperly or Return for service.

not in good repair (Motor will not

run at full power).

Motor not operating correctly. Return for service.

Shortening cannot be Filter paper not centered or creased See sealing procedure on page 11.

completely pumped under ring. Ensure paper is centered and placed flat.

out (Shortening Ring weight is bent or warped See sealing procedure on page 11.

covering surface (should be flat). Badly warped or bent rings should be

of filter paper.) replaced.

Bowl rim is bent or not clean (buildup See sealing procedure on page 11.

of hardened shortening). Clean bowl thoroughly.

Remove dents or replace bowl.

9

Page 10

TROUBLESHOOTING CHART

PROBLEM

Shortening cannot be Bowl not level (Can cause See sealing procedures on page 11.

completely pumped out “seal” to break). Repair or replace wheels on filter machine.

(shortening covering Filter paper clogged. Machine must be broken down, cleaned,

surface of filter paper). and set up again.

(cont.) Too much Gycor or Filter Aid Must use recommended amounts to prevent

Filter powder Ring weight bent. Replace ring weight.

pumped back into fryer. Nick or debris on seal surface Replace bowl.

SEALING PROCEDURE:

Sprinkle 5 oz. (142 g) of Gycor (HCS) around the edge of

the ring weight. Drain the vat and re-circulate the shortening. This process should “seal” air leaks around the

ring.

CAUTION: Use this procedure only when a leak

occurs and all shortening cannot be drained. Using

excess Gycor (HCS) can cause the machine to clog

during filtering of last vats. THIS SHOULD ONLY BE

AN INTERIM PROCEDURE UNTIL EQUIPMENT CAN

BE REPAIRED OR REPLACED.

PROBABLE CAUSE

(HCS). clogging.

Excessive food particles. Skim vats more often and before filtering.

Shortening too cool. Shortening must be at cooking temperature

prior to filtering.

on bowl.

Screen assembly bent. Replace screen assembly.

Filter paper torn. Replace filter paper.

3. PRICES:

A. All prices are F.O.B. Prince Castle Service

Center or F.O.B. factory, Carol Stream, Illinois.

B. All prices are subject to change without notice.

These prices are exclusive of all sales taxes or any

special taxes which may be levied by federal, state,

or city governments.

Contact your kitchen equipment supplier or designated

repair facility for parts and service.

ORDERING/SERVICE INFORMATION

IMPORTANT: No user-serviceable parts are inside this

1. WHERE AND HOW TO ORDER

REPLACEMENT PARTS

To order replacement parts, look on the back of your

Prince Castle Price List for the name and phone

number of your local Prince Castle Service Center.

You may also call Prince Castle at 1-800-323-2930

(or fax us at 630-462-1460) for the name of your local

Service Center.

motor and pump assembly. This motor and pump

assembly must be serviced by a Prince Castle Authorized Service Center. Failure to do so can void the

warranty.

CORRECTIVE ACTION

OUTSIDE THE U.S.

NON-SCHEDULED MAINTENANCE

2. PARTS RETURNS

To return parts to your Service Center for credit, you

must obtain authorization from your Service Center.

iMPORTANT: All warranty situations should be handled

by your center.

10

Page 11

PRINTED ON RECYCLED PAPER

10%Post-Consumer Content

40% Pre-Consumer Content

12

Loading...

Loading...