Prince Castle 107-A, 99-A Service Manual

OPERATING

INSTRUCTIONS

Shortening Filter

Model No. 99-A, 102-A, &

107-A Series

TABLE OF CONTENTS PAGE

Installation..................................................................... 2

Operating ....................................................................... 3

Cleaning ........................................................................ 5

Parts List................................................................ 6 & 7

Troubleshooting ............................................................ 8

LIMITED WARRANTY

This product is warranted to be free from defects in

material and/or workmanship for a period of one (1)

years from date of original installation, not to exceed 18 months from date of shipment from our

factory.

Any component which proves to be faulty in material

and/or workmanship will be replaced or repaired (at

the option of Prince Castle, Inc.) without cost to the

customer for parts or labor.

The Prince Castle Shortening Filter was designed

and constructed to perform an important part in the

operation and maintenance of fryers. This filter was

designed to give excellent service and save hundreds of dollars by keeping oil as clean as possible.

Cleaner oil not only saves money it results in making a better product.

PRODUCT SPECIFICATION

Electrical

115 Volts, 1/3 Hp Motor, 60 Hz, 6.5 Amps, 780 Watts

This warranty is subject to the following exceptions/

conditions:

! Use of non-genuine Prince Castle spare parts

will void this warranty.

! This equipment is portable; charges for on-loca-

tion service (e.g., trip charges, mileage) are only

included in the provisions of this warranty for a

failure which occurs within the first 30 days of

installation.

! All labor should be performed during regular work

hours. Overtime is not covered under the provisions of this warranty.

! Damage caused by carelessness, neglect, and/

or abuse (e.g., dropping, tampering or altering

electrical parts), equipment damaged in shipment, by fire, flood or an act of God is not covered

under this warranty.

!Running water through the pump rusts internal

parts and will void this warranty.

Clogged pumps are not covered under the

warranty. Cleaning the pump is part of the

routine mainatenance for this equipment.

Printed in 2001

Prince Castle Inc.

355 East Kehoe Blvd. ! Carol Stream, IL 60188

Tel: (630) 462-8800 ! Fax: (630) 462-1460

Toll Free: 1-800-PCASTLE

99-502

INSTALLATION

1. After you have removed the Shortening Filter from

the carton, inspect the unit for signs of damage. If

there is damage to the unit:

! Notify carrier within 24 hours after delivery.

! Save carton and packing materials for inspection

purposes.

! Contact the Prince Castle Customer Sales

Department at 1-800-722-7853 to arrange for

a replacement to be sent.

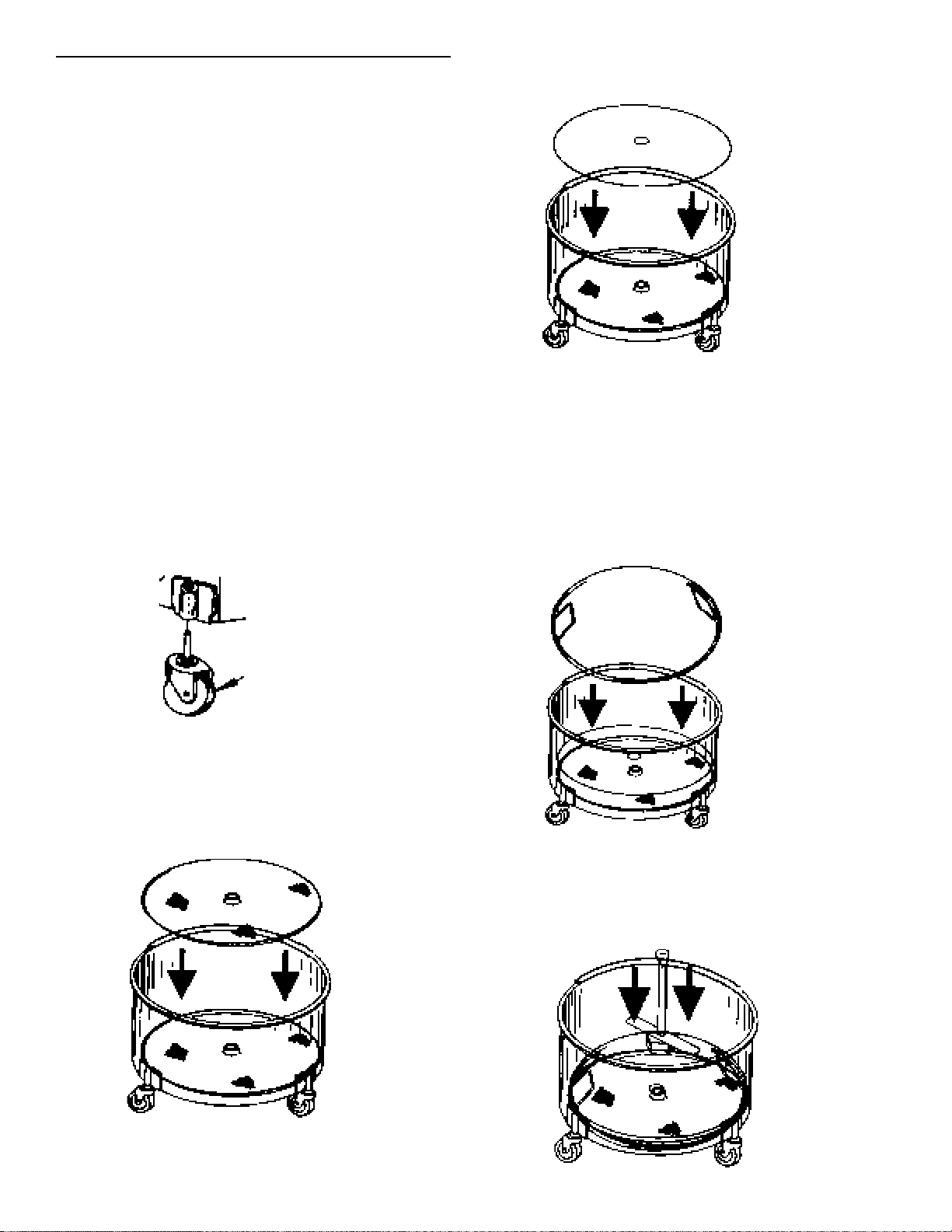

2. Verify that all parts have been received.

! Motor, Pump and Hardware Assembly

! Ring Weight

! Standpipe/Casters

! Hose Assembly

! Screen Assembly

3. Insert (4) casters into caster bracket weldments.

5. Place filter paper over thread on top of screen.

IMPORTANT: Center paper properly so it lays flat on

the screen and overlaps on each end. If incorrect, torn,

or no filter paper is used the unit will not filter properly.

6. Spread approximately 16oz, by volume, of filter

powder (Prince Castle No. 712) over filter paper.

7. Place the ring weight on the filter paper.

4. Place screen assembly, with thread facing up,

inside filter tank.

IMPORTANT: Make sure paper is not folded or creased

under the ring weight.

8. Hand-tighten standpipe to screen.

2

9. Place safety guard on tank.

OPERATION

Required Protective Equipment:

! Face Shield

! Rubber Gloves

! Apron

CAUTION: Handle and Hose are Hot

CAUTION: Maximum normal operating

pressure 50PSI (35, 155 KGS/SQ Meter)

1. Remove cooking probes from fryer, if present.

10. Grasp motor assembly by handle and set it on

the edge of the tank so the union nut lines up

with standpipe. Hand tighten the union nut to the

standpipe, making sure the connection is tight.

11. Attach anti-splash tube on the filter tank by hook-

ing the tube over the rim of the tank so that the

diffuser end of the tube is closest to the safety

guard.

2. Turn on fryer and set thermostat to cooking temperature.

IMPORTANT: Do not turn off fryer until you are

ready to filter, this will allow shortening to remain

hot for filtering.

3. Slowly agitate the shortening in all the fryers with

the wood paddle provided. This will blend hot and

cold shortening, boil off excess moisture and bring

any debris to the surface.

CAUTION: Excessive moisture could cause

fryer to boil over. Continue agitation to all

boiling ceases.

4. Skim off any debris from the shortening surface (use

a Prince Castle Fry Vat Skimmer).

12. Hand tighten hose to the pump union nut, making

sure the connection is tight.

IMPORTANT: This hose is flexible, however, excessive

bending can crease or crack the hose causing hot oil

to leak. Do not use a cracked hose.

IMPORTANT: Failure to skim the fryer thoroughly could

cause excess food particles to clog the drain valve or

the filter machine pump.

5. Roll assembled filter machine to fryer and plug

power cord into wall outlet. Turn off fryer and

engage locking casters.

IMPORTANT: Do not pull filter machine by hose

assembly or power cord.

3

Loading...

Loading...