Prince T8870 Owner's Manual

TABLE TENNIS TABLE

MODEL NO.

T8870

O W N E R ’ S M A N U A L

1. Read this manual carefully before starting assembly. Read each step completely before beginning

each step.

2. Some smaller parts may be shipped inside larger parts. Check inside all parts and cartons

before assembling or ordering parts.

3. Do not tighten hardware until instructed to do so. If hardware is tighten too soon, mounting holes

may not align and parts may not easily fit togeth er. Leave locknuts slightly loose until you are instructed to

tighten them.

4. Tools required for assembly: Phillips Screwdriver, Adjustable Wrenches, Rubber Hammer, 8mm Wrench,

and 10mm wrench.

5. To make assembly as easy as possible, place all parts of the table in a cleared area and remove the packaging

material. Do not remove parts from bags until you are ready to assemble that part. Do not dispose of the

packing material until assembly is completed. For he lp in identifying parts, use the the Parts List, Hardware

Identification and the Exploded Drawings.

An electric screwdriver is helpful in assembly. However, please set at low torque and use caution because you

6.

could overtighten the hardware and strip the screws.

Please Do Not Return This Product To The Store!

Contact Escalade Sports customer service department at:

Phone: 1-866-873-3528 Toll-Free!

Fax: 1-866-873-3533 Toll-Free!

E-mail: tabletennis@escaladesports.com

Mailing Address(correspondence only):

Escalade Sports

PO box 889

Evansville, IN 47706

Please visit our World Wide Web site at: www.escaladesports.com

ON-LINE TROUBLE SHOOTING TECHNICAL ASSISTANCE

ON-LINE PARTS REQUESTS FREQUENTLY ASKED QUESTIONS

ADDITIONAL ESCALADE SPORTS PRODUCT INFORMANTION

R

2L-4241-00

Escalade Sport products may be manufactured and/or

6120397, 5816957, 5769744, 5119741, 4911085, 4717157, D460140, D420563

Additional patents may be pending. One or more of the listed patents and/or pending patents may cover specific product.

R

licensed under the following patents.

C

2015 Escalade Sports

R

14

17

28

26

19

11

1/2 OD X .281 ID X 3/4 Long

Plastic Spacer (4 pieces)

13

3/4 OD X1/4 ID X 1/16 Thick Flat

Plastic Washer (4 pieces)

#10-24 Locknut (4 pieces)

#10 Washer (8 pieces)

HARDWARE IDENTIFICATION

12

1/4-20 Locknut (8 pieces)

1/4-20 X 2 1/4 Phillips Rd. Hd. Bolt (4 pieces)

#10-24 X 2" Phillips Rd. Hd. Bolt (4 pieces)

1/4-20 X 2 Carriage Bolt (4 pieces)

10

#8-32 X 1 1/4 Phillips Rd. Hd. Sms (8 pieces)

16

#8 X 1/2 Phillips Rd. Hd. Sms (100 pieces)

15

2

33

#10-24 X 3/4 Thumb

Screw (4 pieces)

3/4 OD X1/4 ID X 1/8 Thick Flat

Plastic Washer (4 pieces)

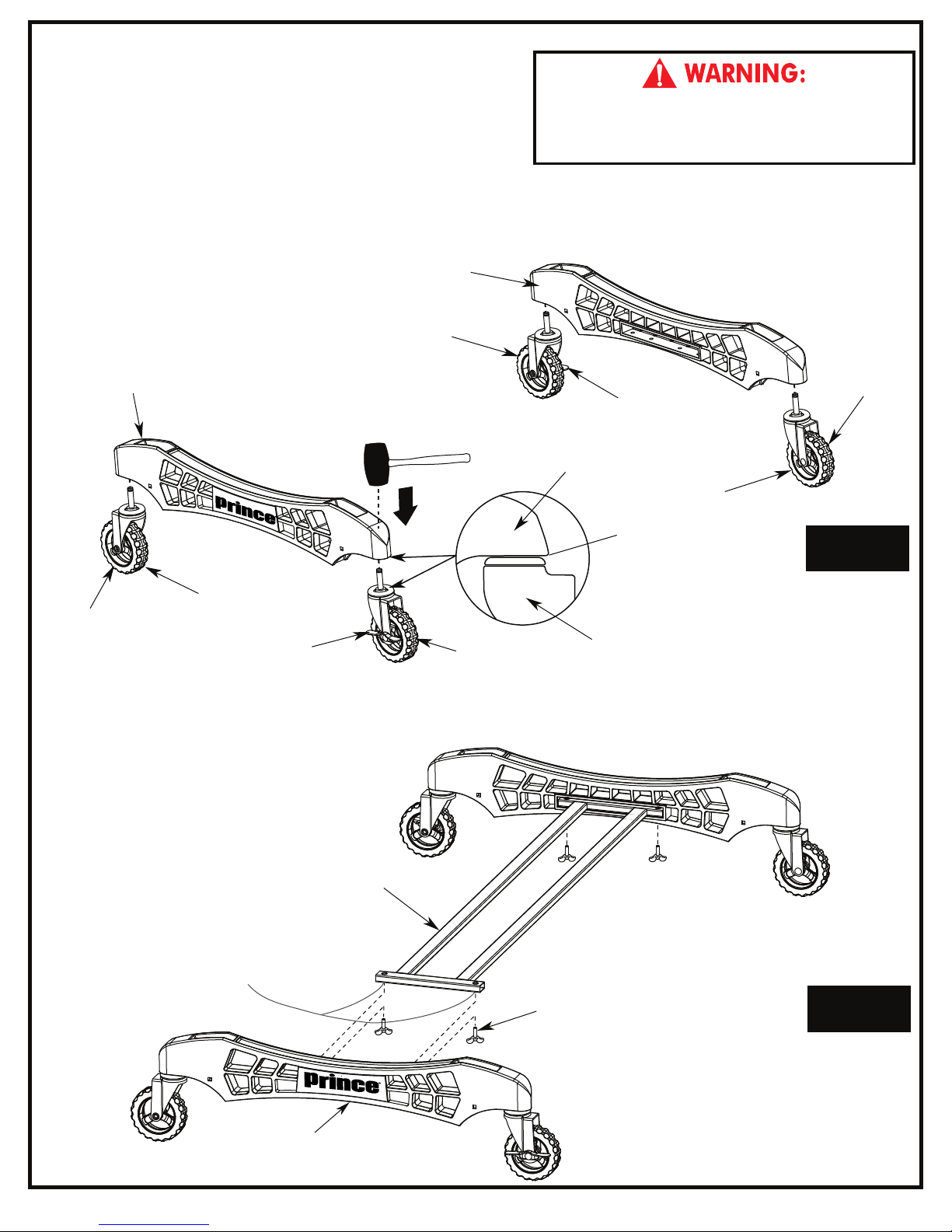

NOTE: If casters came pre-assembled

on Caster Beam (#8), skip to Step 2.

1. Slide a Caster Wheel with Lock (#30) into Caster Beam

as shown in FIGURE 1. On the other end of the Caster

Beam attach a Caster Wheel without Lock (#9).

Make sure you have one Caster Wheel with lock and a

Caster Wheel without lock for each Caster Beam.

Repeat this step to attach the Casters to the second

Caster Beam.

Parts Needed:

8

2 pcs - #8 Caster Beam

2 pcs - #9 Caster without lock

2 pcs - #30 Caster with lock

8

30

Rubber Hammer

without lock

9

with lock

9

30

READ AND FOLLOW ALL ASSEMBLY, OPERATING,

fAND SAFETY INSTRUCTIONS CAREFULLY. AT LEAST

TWO (2) ADULTS ARE NEEDED TO PUT THIS TABLE

TOGETHER!

without

with lock

8

9

NOTE:

Make sure the Caster

Stem is completely installed

into Caster Beam as shown.

30

lock

Figure 1

2. Attach Cross Tube (#7) to Caster Beam Assemblies (#8) using four Thumb Screws (#28) as shown

in FIGURE 2. Tighten bolts snug but DO NOT over tighten.

Parts Needed:

1 pc - #7 Cross Tube

Hardware Needed:

4 pcs - #28 #10-24 Thumb Screw

7

NOTE: Assemble with

threaded insert facing down.

28

8

Figure 2

3

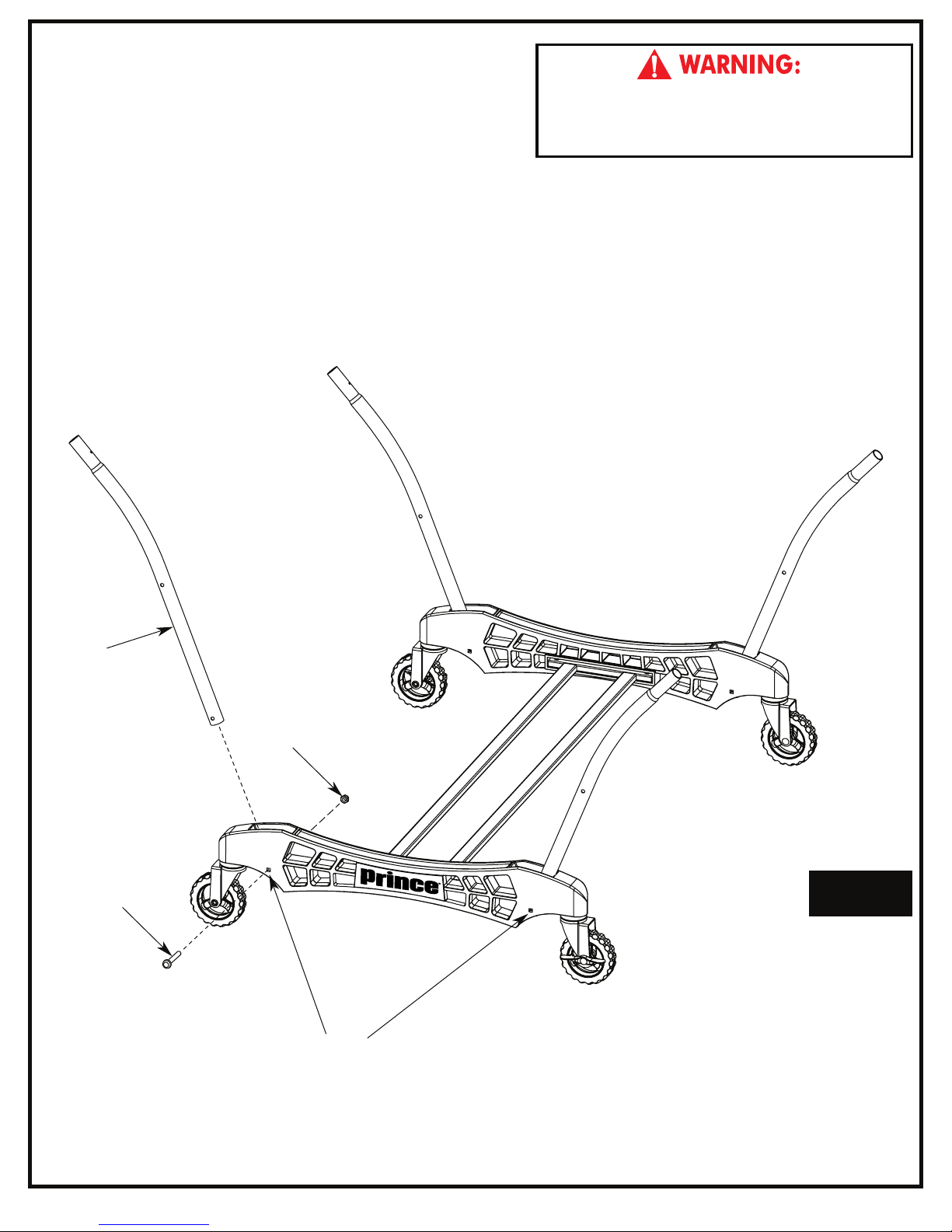

3. Attach four Strut Tubes (#4) to Caster Beam Assembly

with four Carriage Bolts (#10) and four Locknuts (#14)

as shown in FIGURE 3. Tighten nuts snug but DO NOT

over tighten.

Hardware Needed:

4 pcs - #10 Carriage Bolt

4 pcs - #14 Locknut

Parts Needed:

4 pcs - #4 Strut Tube

READ AND FOLLOW ALL ASSEMBLY, OPERATING,

AND SAFETY INSTRUCTIONS CAREFULLY. AT LEAST

TWO (2) ADULTS ARE NEEDED TO PUT THIS TABLE

TOGETHER!

4

14

10

Figure 3

NOTE:

Snug, but DO NOT over-tighten these four pivot points.

4

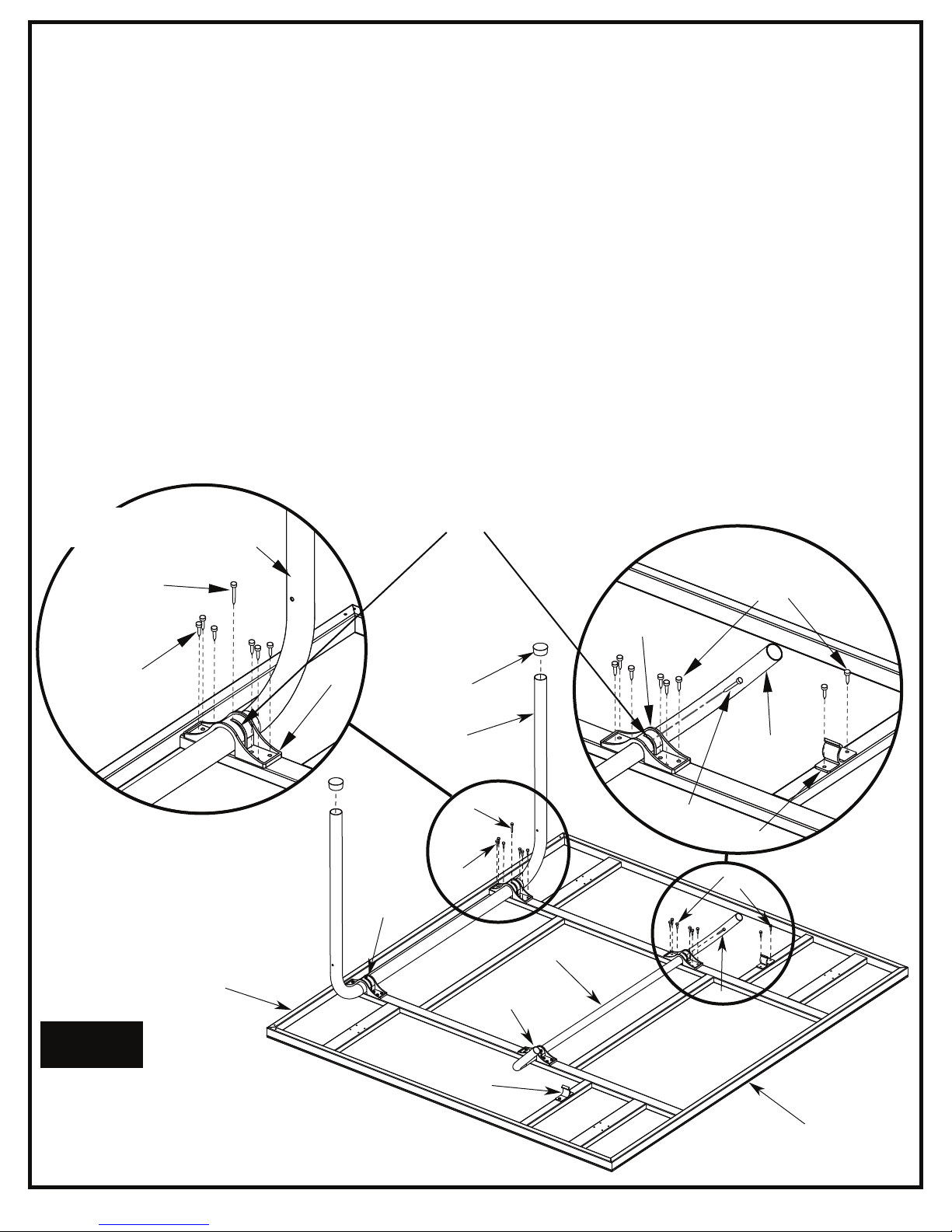

4. A) Attach two 1" Plastic Clips (#23) to bottom of aluminum top assembly using four Screws (#15) as

shown in FIGURE 4 and DETAIL B.

B) Attach U-Leg (#1) with two 1-1/2" Plastic Tube Brackets (#27) as shown in FIGURE 4 and

DETAIL A. Attach with twelve Screws (#15). CAUTION: Slots in Plastic Tube Brackets (#27)

must face toward middle of table exactly as shown or the table will not operate properly.

C) Attach U-Support (#3) with two 1" Plastic Tube Brackets (#24) as shown in DETAIL B. Attach with

twelve Screws (#15). CAUTION: slots in Plastic Tube Brackets (#24) must face toward middle

of table exactly as shown or the table will not operate properly.

D) Rotate U-Leg (#1) and U-Support (#3) until you see the screw hole in the slot of Tube Bracket (#27)

and (#24). Slide U-Leg and U-Support side to side if necessary to see hole. See DETAIL A & B.

E) Thread two Screws (#16) through slot in Plastic Tube brackets (#24) & into U-Support (#3) and two

Screws (#16) through slot in Plastic Tube Brackets (#27) & into U-Leg (#1) as shown in DETAIL A & B.

F) Slide two Plastic Leg Caps (#20) onto ends of U-Leg (#1).

Hardware Needed:

28 pcs - #15 Phillips Rd. Hd. Screw

4 pcs - #16 Phillips Rd. Hd. Screw

DET

AIL A

Tube Bracket Slots

Parts Needed:

1 pc - #1 U-Leg-White

1 pc - #2 Aluminum Top Assembly

1 pc - #3 U-Support-White

2 pcs - #20 Plastic Leg Cap

2 pcs - #23 1” Plastic Clip

2 pcs - #24 1’’ Plastic Tube Bracket

2 pcs - #27 1-1/2” Plastic Tube Bracket

1

DET

16

AIL B

15

15

NOTE: Tighten screws snug,

but do not overtighten, causing

screws to strip in metal tube.

2

Figure 4

27

27

15

20

1

16

24

24

3

16

23

15

3

16

NOTE: All Tube Bracket Slots face toward

middle of the table. As shown in Figure 4.

23

Middle of table is

end without stripe.

5

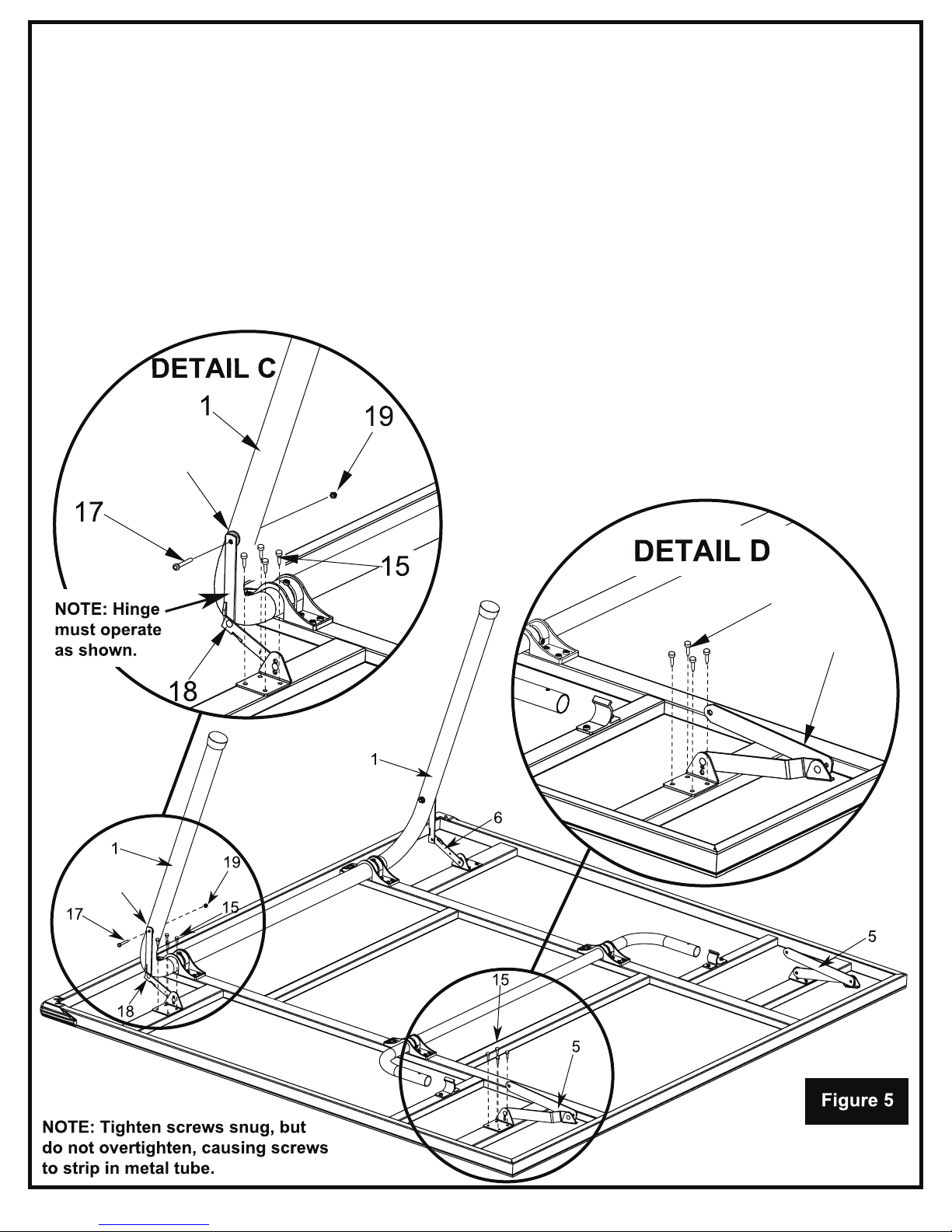

5. A) Attach one LH short Hinge & Mounting Bracket Assembly (#18) using four Screws (#15) as shown in

DETAIL C. Attach one RH short Hinge & Mounting Bracket Assembly (#6) using four Screws (#15) as

shown in FIGURE 5. Attach two Long Hinge & Mounting Bracket Assemblies (#5) using eight Screws

(#15) as shown in DETAIL D & FIGURE 5.

B) Attach LH short Hinge & Mounting Bracket Assembly (#18) and RH short Hinge & Mounting Bracket

Assembly (#6) to U-Leg (#1) using two Bolts (#17) with two Thick Flat Plastic Washers (#33) and two

Locknuts (#19) as shown in FIGURE 5 and DETAIL C. DO NOT OVERTIGHTEN hinge must pivot.

Note: 1/8” Thick Plastic Washer (#33) goes between Hinge and Leg.

REPEAT STEPS 4-5 ON THE OTHER ALUMINUM TOP ASSEMBLY.

CAUTION: Hinges must be positioned

exactly as shown or table will not operate

correctly and could be damaged.

Do not overtighten nuts, hinge must pivot.

33

(Thick Washer)

Parts Needed:

1 pc - #6 RH short Hinge & Mounting Bracket Assembly

1 pc - #18 LH short Hinge & Mounting Bracket Assembly

2 pcs - #5 Long Hinge & Mounting Bracket Assembly

Hardware Needed:

16 pcs - #15 Phillips Rd. Hd. Screw

2 pcs - #17 Phillips Rd. Hd. Bolt

2 pcs - #19 Locknut

2 pcs - #33 Flat Plastic Washer (1/8” Thick)

33

15

5

6

6. Attach table top to base assembly. Pivot Strut Tubes (#4)

up and then with at least one adult on each side of table

top, lift top and align ends of U-support Tube (#3) with

tops of strut tubes on caster beams as shown in

FIGURE 6.

Slide tubes together. Repeat for other Table Top.

3

AT LEAST TWO (2) ADULTS ARE NEEDED T O

COMPLETE THE REST OF THIS ASSEMBLY! WHEN

ASSEMBLING TOPS TO BASE, HANDLE TOP

ASSEMBLIES BY GRASPING ONLY THE T OPS

THEMSELVES. DO NOT GRASP METAL LEGS, USUPPORT, LINKAGE, OR HINGES. THESE PARTS

CAN MOVE AND COULD PINCH FINGERS OR

HANDS CAUSING SERIOUS INJURY! ASSEMBLE

AS SHOWN WITH LEGS FULLY CLOSED AND

TOPS IN A VERTICAL POSITION. DO NOT OPEN

LEGS AND TRY TO ASSEMBLE. TABLE TOPS ARE

HEAVY - DO NO T ATT EMPT TO ASSEM BLE

ALONE!

DO NOT OPEN THE TABLE TO PLAYING POSITION

UNTIL BOTH TOPS ARE INSTALLED! DO NOT LEAVE

TABLE STANDING UNATTENDED. IT C OULD BE

KNOCKED OVER CAUSING SERIOUS BODILY INJURY

OR PROPERTY DAMAGE.

Figure 6

4

NOTE: PIVOT STRUT TUBES UP AS SHOWN.

7

7. Attach U-Support (#3) and Strut Tubes (#4) using two Screws (#15) as shown in FIGURE 7.

Note: If hinge (#5) is positioned as shown in DETAIL E, you will have to rotate the hinge to the position shown in

Detail F. DO NOT unscrew the hinge, you can rotate the hinge without unscrewing it from the table. If you want to

see a video on how to position Hinge (#5) go to: http://www.escaladesports.com/customer-service/videos.html

8. Attach Long Hinge & Mounting Bracket Assemblies (#5) to Strut Tubes (#4) using two Bolts (#12), two Spacers (#11),

two Flat Plastic Washers (#13) and two LockNuts (#14) as shown in FIGURE 7 and DETAIL F.

Tighten Nuts snug, but DO NOT OVERTIGHTEN, hinges must pivot.

9. Attach two Corner Protectors (#25) to Top Assembly using four Screws (#15) with four Washers (#26) as shown in FIGURE 7.

Repeat for other Table Top.

Hardware Needed:

2 pcs 2 pcs - #12 Phillips Rd. Hd. Bolt

2 pcs - #13 Flat Plastic Washer

2 pcs - #14 LockNut

6 pcs - #15 Phillips Rd. Hd. Screw

4 pcs - #26 Washer

#11 Spacer

ATTENTION: If hinge is positioned as shown

below (DETAIL E), rotate the hinge as shown in

DETAIL F. Do not take hinge off.

5

4

DET

AIL E

INCORRECT POSITION OF HINGE

Part Needed:

2

#25 Corner Protector

pcs -

DO NOT OPEN THE TABLE TO PLAYING POSITION

UNTIL BOTH TOPS ARE INSTALLED! DO NOT LEAVE

TABLE STANDING UN ATTEN DED. IT COUL D BE

KNOCKED OVER CAUSING SERIOUS BODILY INJURY

OR PROPERTY DAMAGE.

25

26

15

3

CAUTION: Position hinges exactly as

shown in DETAIL F or table will not

operate correctly and could be damaged.

14

4

12

DET

13

AIL F

1

1

5

CORRECT POSITION OF HINGE

In the correct position Hinge (

like a “V” when attached to Strut Tube (#4).

#5) will look

12

5

15

4

14

13

11

Figure 7

NOTE: Tighten screws snug,

but do not overtighten, causing

screws to strip in metal tube.

8

Loading...

Loading...