PrimeVOLT PV-5000W-V Installation & Operation Manual

SINGLE PHASE GRID-TIE PV INVERTERS

PV-5000W-V

Installation & Operation Ma nual

〇Safety Precautions

Qualified Personnel ONLY!

Only Qualified technicians shall install o r service unit(s) in

accordance with local wiring regulatio ns.

PV Modules ONLY!

Designed for PV and solar power conve rsion only; do not use

for other DC sources or conversion pur poses.

Hot Surface

Metallic parts of enclosure may be ho t during operation.

Recycle

Do not throw this electronic device in a trash dumpster

when being disposed of. To mi nimize pollution of

environment, please consult your local service provider.

Danger!

High voltage inside inverter can cause e lectric

shock, even when inverter is not operati ng. Wait

for at least 41 minutes before openin g the

enclosure.

41 minutes

1/2

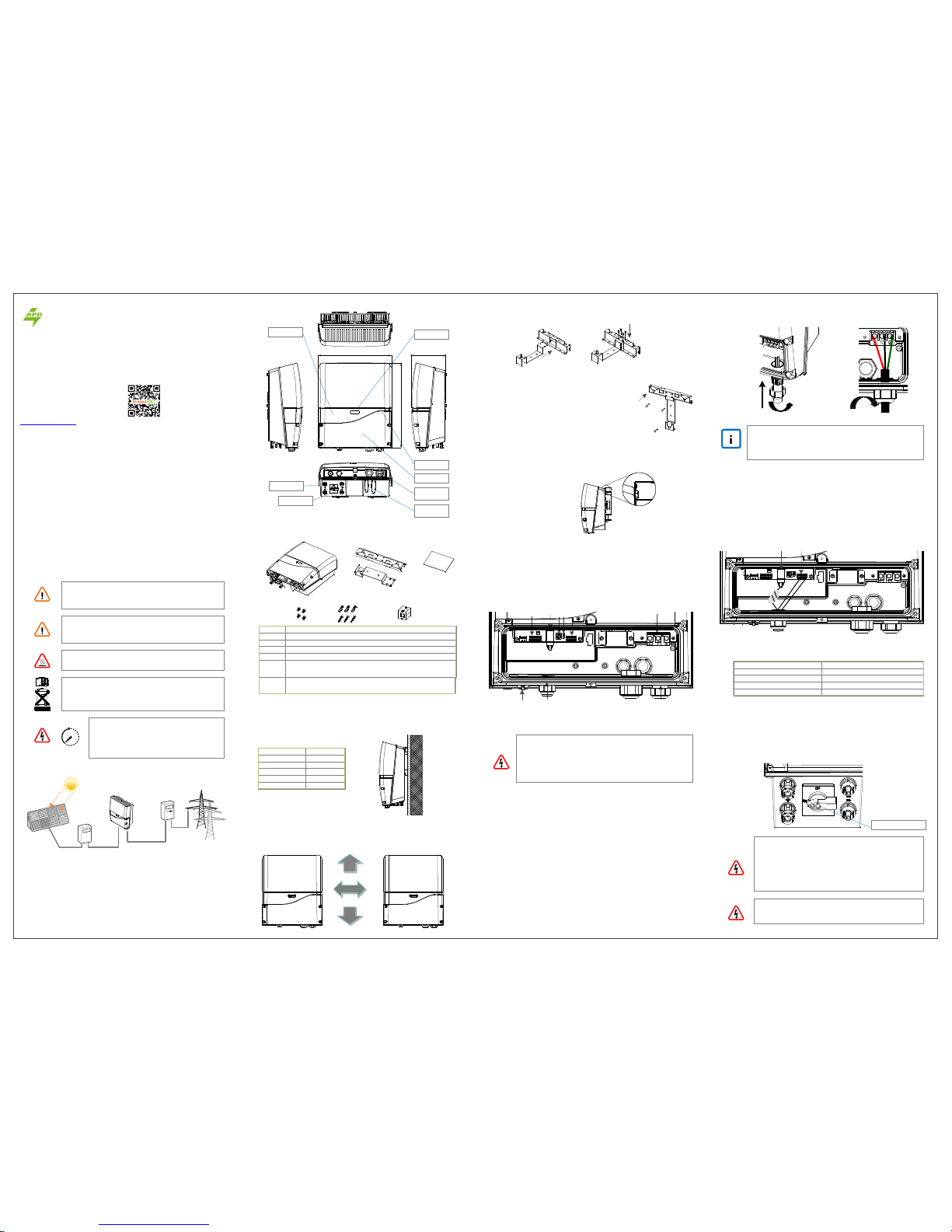

〇Outline & Dimensions

Before beginning your journey, please rea d the following safety instructions

carefully.

〇Installation

■ Unpacking

Recommended Max. DC Power (W)

Max. DC (V)

Max. Current (A)

String

5500

580

9A/String, 18A in Total

2

■Wire Connections

■ AC(Grid) Wiring

Caution!

For safety purposes, place an indepe ndent circuit breaker

between inverter and grid BEFORE all connections. Make sure

inverter will be safely disconnected from the grid in all

circumstances.

It is recommended to use certified 250V /30A circuit breakers.

Note on Cable Selection

It is recommended to use solid cables to ensure steadfastness of

cables on terminal block. If stranded wir es are used, apply coreend materials enclosed in accessory kit fo r all sakes.

■ RS485 & RJ45 Connections

■ DC (PV) Wiring

Be Sure to SWITCH OFF PV

Direct pull-off of DC plugs can lead to sparks. Be sure to switch

off PV before hand.

2. Use either connector

a. Wieland PST40i1C (Preferred)

b. Multi-Contact MC4

3. Connect to PV, After all the associated cables and connectors have been

prepared

4. Remove sealing plugs as depicted on r ight

5. Plug in PV cables gently as depicted belo w

1. DC Input Ratings

614-37089-02

■ Choosing Proper Installation Site

Remind!

1. Using the 600Vdc/20A x 2(tracke rs) circuit breaker between

PV Module with PV Inverter.

2. Only non-grounding PV module is applicable, user is

suggested to consult with system instal ler for PV module

type selection.

3. Require PV modules that have IEC 61 730 class A rating.

SpecificationItem

>30

cm

>30

cm

>20cm

1. Remove sealing plug and twist off th e cable gland (M25)

2. Insert wires from rear of guidance and holes of rubber sealing (M25)

3. Connect RJ45 and RS485 wires as show n below

4. Make sure that RJ45 cable is wound two turns the gray EMI core

5. Tighten cable gland to secure cables firm ly in position

■ Keeping Clearance

Avoid exposing the inverter in direct su nlight or to rain.

Mount the inverter in vertical direction ; tilt or horizontal mounting should be

avoided.

Mounting Surface

Concrete

OK/NO

OK

Metal

Stone

OK

OK

PLastics / Acrylic NO

Wood NO

To retain the good cooling condition , keep each of unit over 20cm left and right,

30cm upper and down and ensure no any object is put around the units to affect

the cooling.

■ Assembling Bracket

Before fixing on wall, assemble the bracket as below.(Use M4 flat screws × 4 item

Ⓓ of accessory kit)

■ Mounting Bracket

■ Checking

1. Place the assembled bracket on where the inverter

will be installed. Make prope r drill holes and mount

the assembled bracket with screws from accessory kit.

2. For safe and firm mounting, make a t least 3 drill holes

in a triangular manner as demonstr ated on right.

3. Use Ⓔ item to install mounting bra cket on wall.

1. All supporting points are firm

2. Lock caps are tightened with screws

3. Inverter is well installed and secured on wall

Warranty Information

Warranty or liability will be void if dama ge caused by, but not limited to the

following:

1. Unauthorized opening of unit

2. Installation faults such as improp er environment, wiring and applications

3. Working conditions beyond spe cified

4. Improper operation of unit

5. Violation of safety instructions in this manual

6. Damage during transportation

7. Any internal modifications

8. Replacing or installation of unautho rized software

9. Unforeseen calamity or force majeu re

Contact Information

〇PV System

DC Switchboard

PV Generator

AC Switchboard

Public Grid

PV Inverter

A typical PV system contains:

1. PV Generator : Receive sunli ght and generate DC power.

2. DC Switchboard : Links between PV panels and PV inverter, include of DC switch

and surge protection.

3. Inverter's DC Switch : PV Inverte r with DC Switch(Optional).

4. PV Inverter : Converts DC power by P V panels to AC output power for public grid.

5. AC Switchboard : Links betwe en PV inverter and public grid.

6. Public Grid : Provides utility for h omes.

1. AC cord configured with M25 ca ble gland, containing waterproof rubber plug

three holes for cable diameter of 4.8 ~ 6.2mm, diameter is recommended to

3.5/5.5/8mm2 of wire. The following factors should be taken into account when

it comes to actual wiring: Ambient te mperature, Wiring nearby, Cooling

2. Recommend to use right M25 cab le gland for Line(L), neutral(N)/ground(PE)

wires

3. Twist off the cable gland and remov e rubber waterproof plug. Remove the

required number of sealing plu g for AC wires

4. Use the cable with appropriated wi re diameter through the rubber waterproof

plug. Then insert the rubber wate rproof plug into the cable gland

5. Remove an appropriated length of the jacket and insulation layer from

cable and crimp the wires wit h terminal

6. Use a screwdriver to fix L(Line), N( Neutral) and ground(PE) wires on the AC

terminal block from left to right si de

7. Tighten cable gland firmly to fix wir es and achieve waterproof effect

Note:Be sure to use the water-proof plugs that you put in order to achieve the waterproof function.

ES-Series

◎

ES-Series

◎

Your PV Inverter Professional

PrimeVOLT

Asian Power Devices Inc.

(Trade mark: PrimeVOLT )

www.primevolt.com

1. AC Cable Gland M25 (AC cabl e)

2. Signal Cable Gland M25 (Ethernet/RS48 5)

3. AC terminal block

4. RS485 terminal

5. RS485 terminal resistor switch

6. RS485 address selector

7. RJ45 port for Internet access

8. Ripple Control Receiver (RCR) termi nal

9. USB connector

190mm418mm

485mm

Status LED

Front Cover

AC Cable

Guidance

Signal Cable

Guidance

Button & LED

Display LCD

DC (PV) Input

DC Switch

Ⓐ Ⓑ Ⓒ

Ⓓ Ⓔ

Ⓕ

*

Black EMI core x 1(Ethernet cable RJ45)

DescriptionItem

Ⓐ Inverter

Ⓑ

Ⓒ

Ⓓ

Ⓔ

Ⓕ

Mounting bracket kit

User manual

M4(8mm) flat screws × 4, used for mounting bracket

Plastic anchors & screws(Φ6.5*32mm) × 3. Used to install mounting

bracket on wall

RS485 Port

RJ45 Port (Internet)

L

N

②

①

③

⑨

④ ⑤ ⑥

⑦ ⑧

L

N

L

N

⑥

③

④

PV1(+) PV1(-)

PV2(-)PV2(+)

DC Switch

Internal fault detected

Please keep DC breaker of solar panels off

Grid voltage below range

Measured voltage displayed

AC VOLT LOW

VacXXX/XXX/XXX V

AC FREQ HIGH

fac XXX.X Hz

Grid frequency over range

Measured frequency displayed

AC FREQ LOW

fac XXX.X Hz

Grid frequency below range

Measured frequency displayed

PV VOLT HIGH

Vdc XXX/XXXV

Solar panel voltage over range

Measured voltage displayed

PV ISUL LOW Check for insulation of solar panels failed

GFC HIGH

Ig XXX mA

Leakage current high

Measured current displayed

C1

C2

High DC current detected

Relay failed

C3

C4

DC current sensor failed

Internal temperature high

C5

C7

GFCI detection failed

Anti-islanding detection failed

FAN FAILS

F1

Fan not working properly

Bus voltage low

F2

F3

Bus voltage high

CPU communication abnormal

F4

F5

Mismatch of firmware version between CPUs

EEPROM memory faulty

F6

F7

Error on system consistency

Over-current in inverter detected

F8 Slow start-up on Bus

Grid voltage over range

Measured voltage displayed

AC VOLT HIGH

VacXXX/XXX/XXX V

ES-Serial Description

■ Error Message

Input (DC)

Recommended Maximum Power W 5500

MPPT Working Range V 180 ~ 580

MPPT Range(full load) V 290 ~ 500

Maximum DC Voltage V 580

Maximum DC Current A 10x2

No. of MPP Trackers 2

Max. backfeed current to array mA 1.6

Output (AC)

Nominal Power W 5000

Maximum Power W 5000

Nominal Voltage V 220/230/240

Nominal Frequency Hz 50/60

Power Factor -0.8 ~ +0.8

Maximum Current A 23.8

Max. O/P Over-Current Protection A 45

Efficiencies

Max. Efficiency % 97.2

Euro- Eta % 96.1

General

Temp. Range °C -25 ~ 55

Temp. (Full Power) °C -20 ~ 45

Topology Transformerless

Protection IP65

Humidity % 0 ~ 100

Cooling Force-Air Cooling

Protection Class I

Overvoltage Cat.

DC input:II、AC input:III

Features(ES-Series)

LCD 1602 character display

RS485 Standard, half-duplex

Network

Cable Network (RJ45)、Wi-Fi(Optional)

Data Logging Yes, 3 years

Web Server Yes

Clock Synchronization Automatically sync with time server

Mechanical

W x H x D mm 418 x 485 x 190

Weight kg 22

Input Pairs 2

DC Switch Built-in

Compliances

Grid Monitoring

VDE-AR-N 4105

VDE0126-1-1/A1、PEA/MEA、G83-2

Safety

IEC 62109-1、62109-2

EMC

EN 61000-6-2、EN 61000-6-4

EN 61000-3-11、EN 61000-3-12

Note: Specifications are subject to change without prior notice.

〇Specifications

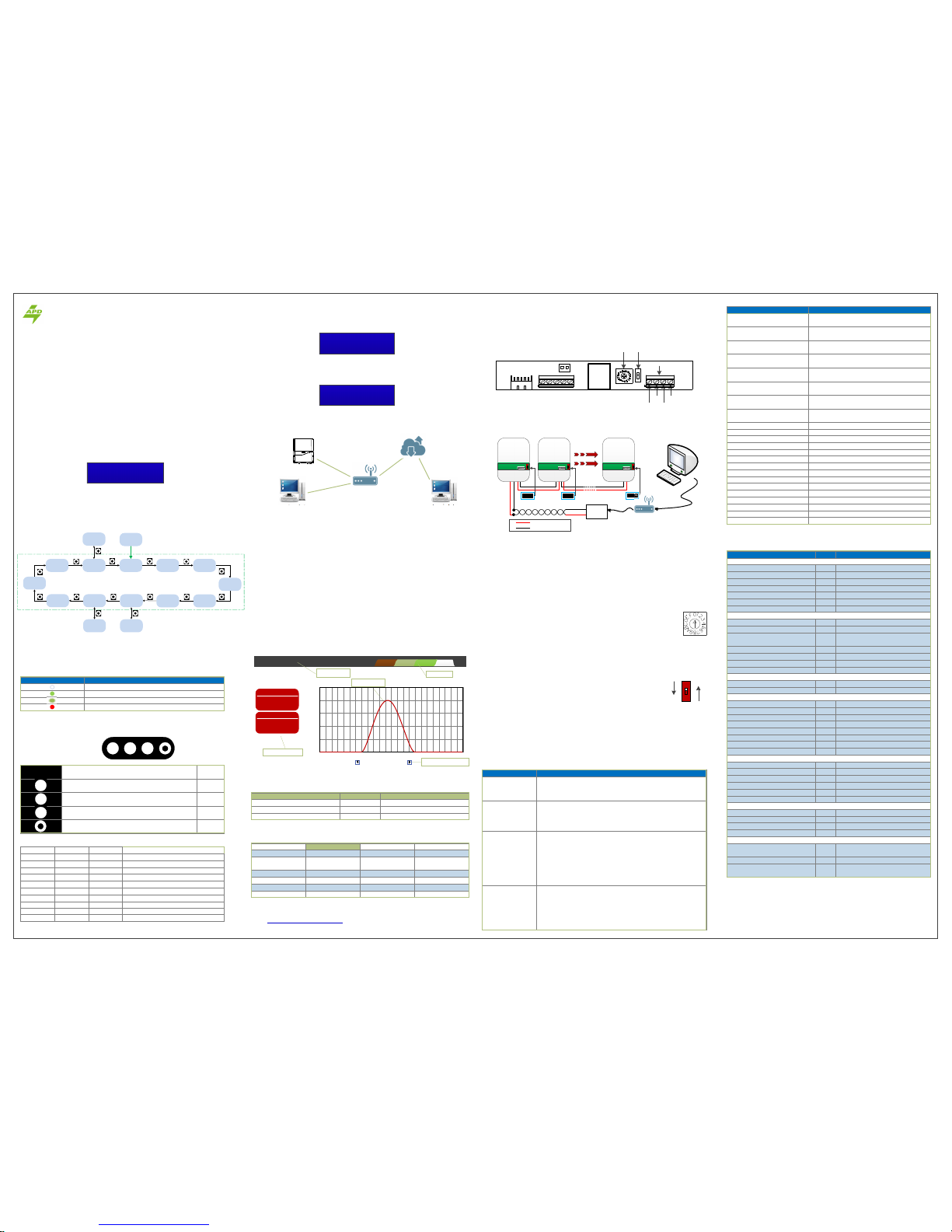

■ Wiring Diagram

Inverter Info. PV-5000W-HV Date & Time Jan/1/2016 2:04:33

Voltage Range 184.0 ~ 264.5 V Frequency Range 50 Hz

Grid Regulation VDE-AR-N 4105

IP Address 192.168.60.43 Wi-Fi (Edit)

Auto FW Update ON Language English

Feed-in Rate $0.32 Administration admin

UPLOAD (Edit)

When in Settings sheet, you will see the table below.

■ Settings

〇Browsing Inverter Web Page(ES-Series)

■ Basics

Inverter has a built-in and multi-functio nal web page that user can access via LAN/

WLAN. The recommended web browsers ar e Internet Explorer, Firefox and Safari.

Follow the steps below to explore the i nverter web page.

1. Make sure you have successfully conne cted inverter to a LAN by either Ethernet

or Wi-Fi.

2. Tap button to switch to “Operation Fram e” to read off the inverter’s IP address.

3. Open a web browser on your desktop/ laptop, key in the IP address you have

read previously at the address bar

4. Daily graphs will load soon after.

〇Network and Internet(ES-Series)

■ Accessing Inverter via LAN (Local Area Network)

The illustration above demonstrates ho w to access the inverter via Internet. Similar

to LAN, the inverter can be accessed by we b browser. However, there is usually a

firewall that would block direct access of the LAN from the Internet. In order to

overcome this, you will need to set up NA T (Network Address Translation) or Port

Forwarding of the router. For detailed information, please refer to the manual

provided by your router supplier.

Information Board

Inverter Status

Daily Graphs

Forward/Backward Tabs

Display Tabs

■ Error Message Display

KEEP PV OFF

614-37089-02

Function Unit Specification

〇RS485 Communication Interface

■RS485 hardware interface

Address

Switch

Terminal

Resistor Switch

RS485 terminal

T/R 1+ T/R 2+

T/R 1- T/R 2-

ES-Series

◎

■ Address Setup(ES-Series)

To do this setting, use the address rot ary switch shown on right. For a

single inverter, set the position to “1”; for multiple inverters, please assign

them different positions with no dupl ications. Since only 15 positions (1~F)

are available, the maximum number of inverters that can be grouped at a

time in a RS485 bus is 15.

■ Setting the Terminal Resistor

As shown on right, “ON” indicates a resisto r is added. ONLY the

terminal-end inverter (last inverte r of the row) should have this switch

set to “ON”. Switches of the other inve rters should be set as “OFF.”

ON

OFF

5.0kW

4.0kW

3.0kW

2.0kW

1.0kW

0.0kW

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

2016 / 01 / 01

Production

System

Now

Today

Total

Vac

Vdc

Fac

50000W

22.2kWh

23.8kWh

230V

650.1 V

50.1 Hz

Grid-Connected

PV-5000W-HV

DAYSETTINGS LOGS MONTH

ON

1

■ LCD display

Buttons are used to change frame display on LCD screen.

DescriptionIcon Note

LED A,Reference LED fault table A

LED B,Reference LED fault table B

LED C,Reference LED fault table C

Button

2/2

CBA

A

B

C

Pac 5000W

Etoday 50.5kWh

Computer via LAN

Router/Modem

Computer via Internet

Inverter

■ Logs

Event records of inverter. Events inclu de activities and errors of inverter. See

picture below for demonstration

When inverter encounters an error, LC M screen enter error mode and an error

message will be displayed on LCM screen continuously. The maximum is 5 in ESserial For more detail content, please refer to the“error message”chapter.

2016/01/20 10:26:12 System StartedInformation

2016/02/27 15:25:24 AC FREQ HIGHError

2016/01/22 11:23:15 Frequency range changedInformation

Time EventType

■ Cloud Monitoring

Trouble Suggestions

No display or

incorrect display

No generation

(No Error)

1. Check PV wiring.

2. Check PV polarities.

3. Check PV voltages.

4. Wait for stronger sunlight.

Error on display

1. Check PV module installation.

2. Check the PV module is damage d or sheltered.

3. Ensure inverter is not in direc t sun light.

4. Remove all objects on inverter .

5. Check the setting space of each in verter.

6. Check inverter’s ambient temper ature and coiling condition.

Generated power

less than expected

Refer to error table in Error Frame section .

1. Error other than “C#”: Check the er ror message and take

suitable action.

2. “C#” Error: Switch off the AC br eaker then the DC breaker.

Switch on the DC breaker then th e AC breaker again.

3. If “C#” error persists, call your local service provider for

assistance.

1. Check AC connection segments such as fuses, breakers and

wires. Be sure AC is connected t o inverter properly.

2. Switch AC off and on again.

■ Troubleshooting

In cases where an inverter detects a pro blem, an error message may be conveyed

by the system. Use the table below t o resolve accordingly. If the problem persists,

contact your local service provider for further assistance.

〇Maintenance

Go to http://mypowermanager.net to down load the user manual of cloud and

register your user account to set up you r inverters for cloud monitoring.

1. Connect T/R+ and T/R- of RS485 converter to the T/R1+ and T/R1- of the data logger

respectively.

2. Between two data loggers, match T/R2+ and T/R2- of this inverter to T/R1+ and T/R1 of the next inverter.

3. Set terminal resistor switch “ON” of the terminal-end inverter (last data logg er of the row)

only. The others’ should be set as “OFF.”

4. Connect data logger and router of RJ45 Cable.

T/R -

T/R +

T/R - T/R1 -

T/R + T/R1 +

RJ45 Cable

RJ45 Cable

Data

Logger

Router

Pin:Off Pin:Off Pin:On

Inverter

RS485 Connector

ON

1

Inverter

RS485 Connector

ON

1

Inverter

RS485 Connector

ON

1

〇Operation

ES-Series

◎

■ Status LED

The LED on the inverter right side wil l show the inverter operation status by

different colors. In normal operatio n, the LED appears in green color; in error

circumstance, it appears in red color.

IndicationStatus

Solid Green: Inverter is standing by/operating (day).

Flashing Green: Inverter is standing by (evening/night).

Solid Red: Inverter is having a fault.

Inverter is not connected to AC.

■ LED Fault and LED Indication

Error Message

LED A LED CLED B

Off Off Off All Normal

ON

Off Off High DC Current Detected

Off

ON

Off Relay(s) Failed

ON

Off Off DC Current Sensor(s) Fail ed

ON ON

Off Internal Temperature High

Bus Failed

GFCI Detection Failed

ON

Off

ON

Off

ON ON

Check for insulation of solar panels failed

Leakage Current High

Fan not Working Properly

Blink

Off

Off Off

Blink

Off Off

Blink

Note:Blinking means LEDs on for 0.5 seconds and off for 0.5 seconds.

LED fault table

AC VOLT HIGH

Vac 271/ 262/ 261V

■ Operation Chart

The inverter error that has occurred most recently is generally recorded by the

history error.

■ Error Message Display

History Error

Message Record

Output Power

Daily Energy

LAN IPWi-Fi IP

AC Voltage

AC Current

Safety Mode

Model

F/W Version

Modbus

Adress

5 Seconds

WELCOME

DC Voltage

DC Current

E-Total

H-Total

Date/Time

VAC/FAC

Range

Error Record

Clock

Setting

F/W Version

History Error

Record

Press

Press5 Seconds

Press5 Seconds

5 Seconds

When inverter has connected to electrica l grid and started generating power, the

LCM screen enters regular mode. The LC D display flow chart sequence of on-screen

information is as the frames as below .

Off

Your PV Inverter Professional

PrimeVOLT

Your PV Inverter Profess ional

PrimeVOLT

E S-Se ries offer s basic logger functionalit ies with simple and necessary onscreen information form.

The pro duction using for RS485 or R J 45 t o monitor the inverter working

status, and provide the LED and LCD d isplay, the LCD is 16*2 character type.

The LED panel has three LED lights and one button. When a fault occurs, one

or two or three LED lights will be blink ing in response.

The display content s include outp ut power、grid voltage & current、PV

module voltage & cu rrent、energy of today ( E-Today)、 accumul ated ener gy

(E -To ta l) 、totally op er at ion time (H -T ota l) 、regulation setting ( Saf et y

Mode)、model name and firmware v ersion.

Loading...

Loading...