Page 1

1

OPERATOR’S MANUAL

AND PARTS LIST

MODEL GR150 JOIST HANGER NAILER

MODEL GR250 JOIST HANGER NAILER

Distributed By

www.grip-rite.com

Tough as nails

Page 2

32

TABLE OF CONTENTS

TABLE OF CONTENTS -------------------------------- 2

SPECIFICATIONS --------------------------------------- 3

SAFETY ---------------------------------------------------- 4

TOOL PARTS --------------------------------------------- 8

PARTS DESCRIPTION--------------------------------- 9

LOADING FASTENERS ----------------------------- 10

OPERATION---------------------------------------------- 11

GR150 PARTS SCHEMATIC ----------------------- 12

GR150 PARTS LIST ---------------------------------- 13

GR250 PARTS SCHEMATIC ----------------------- 14

GR250 PARTS LIST ---------------------------------- 15

MAINTENANCE ---------------------------------------- 16

TROUBLESHOOTING ------------------------------- 17

WARRANTY --------------------------------------------- 18

SPECIFICATIONS

SPECIFICATIONS

MODEL GR150 GR250

FASTENER LENGTH 1 1/2” 1 1/2” - 2 1/2”

FASTENER DIA. .131 - .148” .131 - .162”

COLLATION ANGLE 33° 33°

COLLATION TYPE Paper/Plastic Paper/Plastic

MAGAZINE CAPACITY 30 Nails 30 Nails

MAX AIR PRESSURE 120 psi 120 psi

MIN AIR PRESSURE 100 psi 100 psi

TOOL WEIGHT 4.4 lbs. 4.8 lbs.

TOOL LENGTH 9.5” 11”

TOOL HEIGHT 12.25” 11.75”

TOOL WIDTH 3.75” 3.75”

TRIGGER TYPE AUTO AUTO

AIR CONNECTION QUICK CONNECT

LUBRICATION 10W Air Tool Oil (Provided)

IMPORTANT SAFETY INFORMATION

You must read this entire manual and familiarize yourself with all

safety, operating, and service instructions before loading, handling,

or using your tool. When used correctly, pneumatic fastening tools

provide a lightweight, powerful, and safe means of fastening. Used

improperly, these tools can cause serious injury to you and those

around you.

For best results, use only Grip-Rite™ collated fasteners.

FASTENER SELECTION CHART

SIZE BOX BRIGHT GALVANIZED FITS FITS

QTY. SKU SKU GR150 GR250

1-1/2 x .131” (38 x 3.4 mm) 4M GRJSN131 N/A X X

1-1/2 x .148” (38 x 3.8 mm) 4M GRJSN112 GRJSN112HG X X

2-1/2 x .148” (64 x 3.8 mm) 4M GRJSN212 GRJSN212HG X

2-1/2 x .162” (64 x 4.2 mm) 4M GRJSN162 GRJSN162HG X

Page 3

54

SAFETY

SAFETY

SAFETY INSTRUCTIONSSAFETY LABELS

This pneumatic fastening tool includes a warning label to help remind you of

important safety information when operating the tool. The safety label must be

legible at all times, and must be replaced if it becomes worn or damaged.

SAFETY SYMBOLS

The safety symbols on the safety label provide a visual reminder of

basic safety rules, and the personal injury hazard that may arise if

all safety and operating instructions are not followed. Make sure

you understand the meaning of each of these symbols, and protect

yourself and others by obeying all safety and operating instructions.

SYMBOL

DESCRIPTION

READ THE MANUAL - The manual contains

important safety and operating instructions

that must be followed. All tool users must

read the manual before using the tool.

WEAR SAFETY GLASSES - Tool operator

and bystanders must wear safety glasses

with side shield that meet ANSI Z87.1

requirements.

RISK OF PERSONAL INJURY - Failure to

follow all safety and operating instructions,

or misuse of the tool, can result in serious

injury to tool operator and bystanders.

WEAR SAFETY GLASSES

Always wear safety glasses with side shields that meet ANSI

Z87.1 requirements when operating the tool. Make sure all

others in work area wear safety glasses.

WEAR HEARING PROTECTION

Wear hearing protection to protect your hearing from noise.

Prolonged exposure to loud noise can result in hearing loss.

NEVER OPERATE THE TOOL WITH OXYGEN OR OTHER

BOTTLED GASES

Oxygen and other reactive or high-pressure bottled gases

can cause the tool to explode. Use clean, dry regulated

compressed air from a properly operating air compressor.

DO NOT EXCEED MAXIMUM RECOMMENDED OPERATING AIR

PRESSURE OF 120 PSI /8.4 Bar.

Exceeding the maximum recommended air pressure can

cause the tool housing to burst, or cause premature failure of

components.

NEVER CONNECT THE TOOL TO AN AIR SUPPLY THAT HAS

THE POTENTIAL TO EXCEED 180 PSI/12.4 Bar.

Using a regulated air supply with a line or tank pressure

greater than 180 psi can cause the tool to burst if the air line

regulator fails suddenly.

USE AN AIR HOSE RATED FOR 180 PSI/12.4 Bar OR

GREATER

Always use air hose rated to handle 180 psi or the maximum

potential pressure of the air supply.

ONLY USE A RELIEVING-TYPE AIR COUPLING IN THE TOOL

AIR INLET OPENING.

Use of a non-relieving air coupling on the tool can trap air

inside the tool housing, and allow the tool to drive a fastener

even after the air hose has been disconnected.

120 psi

6.9 bar

100 psi

8.4 bar

Page 4

76

SAFETY

SAFETY

KEEP HANDS AND BODY PARTS AWAY FROM AREA BEING

FASTENED.

Fasteners can deflect and turn as they are being driven into

the workpiece, and penetrate fingers, hands, and other body

parts that may be in the fastening area.

DO NOT OVERREACH OR WORK WHILE ON UNSTABLE

FOOTING

If you lose your balance while fastening, you could drive a

fastener into yourself or a bystander.

DO NOT USE TOOL IF TOOL MALFUNCTIONS OR BEGINS

LEAKING AIR.

Operating a malfunctioning tool can result in an injury to

yourself or others.

DISCONNECT THE TOOL FROM THE AIR SUPPLY TO RELOAD, CLEAR JAMS, OR PERFORM MAINTENANCE.

Never attempt to reload a tool, clear a jam, or perform

maintenance without first disconnecting the air supply.

NEVER LEAVE A LOADED, PRESSURIZED TOOL

UNATTENDED

A loaded, pressurized tool could be picked up or handled by

someone who is unfamiliar with the tool or that has not read

the tool manual.

KEEP TOOLS OUT OF THE REACH OF CHILDREN

Place the tool back in the tool box after use, and store the tool

out of reach.

DO NOT MODIFY TOOL

Modifications can cause a tool to be unsafe and can cause

the tool to operate improperly.

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

DO NOT ATTEMPT TO OPERATE THE TOOL IF THE TOOL’S

OPERATING CONTROLS HAVE BEEN MODIFIED OR ARE NOT

WORKING PROPERLY.

Attempting to use a tool with modified or malfunctioning

trigger or workpiece contact can result in a fastener being

driven unintentionally.

USE CORRECT FASTENERS

Only use the correct fastener for the tool. Using fasteners

with incorrect specifications can jam the tool or cause

serious injuries.

USE THE CORRECT FASTENERS FOR THE APPLICATION.

Using the wrong fasteners can cause the workpiece to split

and allow the fastener to fly free.

KEEP TOOL POINTED IN A SAFE DIRECTION WHEN IN USE

Never point the tool at yourself or anyone else when in use.

DO NOT DEPRESS TOOL NOSE WHEN LOADING FASTENERS

Depressing the tool nose during loading can result in tool

actuation and an unintentional fastener drive

AVOID DRIVING FASTENERS INTO KNOTS, ON TOP OF

OTHER FASTENERS, AT WORKPIECE EDGES, OR INTO

BRITTLE MATERIALS.

Driving fasteners into extremely hard materials, or driving into

workpiece edges, can cause fasteners to deflect away from

the workpiece. Flying fasteners can cause serious injuries.

Page 5

98

DESCRIPTION

PART DESCRIPTIONS

1. Cylinder Cap - Covers valve and piston assembly.

2. Belt Hook - Convenient belt hook keeps tool within easy reach when

both hands are needed for placement and positioning of joist hangers.

3. Handle - Cushioned handgrip provides comfortable operation.

4. Safety Warning Label - Provides important safety reminders that

must be followed whenever handling, operating, or servicing the tool.

5. Air Coupling - Quick-disconnect male coupling allows quick

connection to air hose. Dust cap keeps dirt out when tool is not in

use.

6. Rear Load Nail Magazine - Holds fasteners securely and protects

nail strips from damage. Dual loading slots on GR250 allow use of

1 1/2” or 2 1/2” nails

7. Spring-loaded Pusher - Provides positive fastener feeding in all

tool positions.

8. Nose - Narrow profile design permits visual nail positioning for

accurate placement.

9. Automatic Actuation - Tool actuates when nail in driving position is

pressed against work surface, stops when pressure is released.

10. 2-Position Nail Length Adjustment - (Model GR250 Only) -

Permits efficient driving of both 1 1/2” and 2 1/2” nails.

11. Tool Housing - Contains nail driver components.

Metric Hex Wrenches - Included with tool to allow tightening of

metric screws. Keep tools in tool case for periodic tightening of

screws.

Air Tool Oil - Lightweight oil formulated for use in air tools provides

proper lubrication to o-rings and internal parts.

Safety Goggles - Provide required eye protection

DESCRIPTION

GR150

GR250

1

2

4

3

5

8

6

7

11

1

2

4

3

5

8

6

7

10

9

11

9

Page 6

1110

OPERATIONOPERATION

LOADING FASTENERS

LOADING INSTRUCTIONS

The model GR150 and GR250 tools are automatically actuated when the

nail in driving position is pressed against the work surface. Tools

continue to deliver multiple hammer blows until the nail is fully driven or

tool is lifted off work surface. Never press tool nose down unless it has

been properly positioned to drive a nail into a safe work surface.

DANGER

OPERATION

1. Connect tool to air supply using quick-connect coupling.

2. Hold the tool securely using the handgrip. Do not depress tool nose

until tool is in driving position and you are ready to drive a fastener.

3. Position the nose of the tool on the workpiece, placing the nail in

driving position at the desired fastener driving location. If nail is being

driven to secure a joist hanger or other metal connector, make sure

nail is centered in punched hole in joist hangers.

4. Press the tool nose down firmly against the work surface, and

continue pushing until the nail is fully driven. Do not lift the tool from

the work surface during nail driving, or another nail may be fed into

the tool nose.

5. After the nail is fully driven, lift the tool off of the work surface, and

place the tool in position for the next nail to be driven.

6. Repeat steps 2 through 4 until all desired nails have been driven.

7. Reload tool as needed, using Grip-Rite™ nails for best results.

8. Increase air pressure to drive into harder materials. Reduce air

pressure to drive into softer materials. For longest tool and part life,

always use the lowest air pressure necessary to drive fasteners.

9. Disconnect tool from air supply when nailing is completed.

1a. Model GR250 Only:

Set nose position for driving

desired nail length:

Depress and hold nose. Push

spring-loaded adjustment pin

button (A) in, and slide pin into

correct position for nail length

being used. Release button,

and allow nose to extend.

Insert strip of 1 1/2” long nails

using lower slot (B), or 2 1/2”

nails using upper slot (C), and

allow nails (D) to slide toward

tool nose.

1b. Model GR150: Insert nail strip

(D) into rear of magazine, and

allow nails to slide toward tool

nose.

2. Depress pusher lever, and pull

pusher (E) back to rear of nail

strip. Release lever, and slide

pusher forward against nails.

3. Tool is now loaded and ready

to be connected to an air

supply for operation.

A

C

B

D

E

E

Page 7

1312

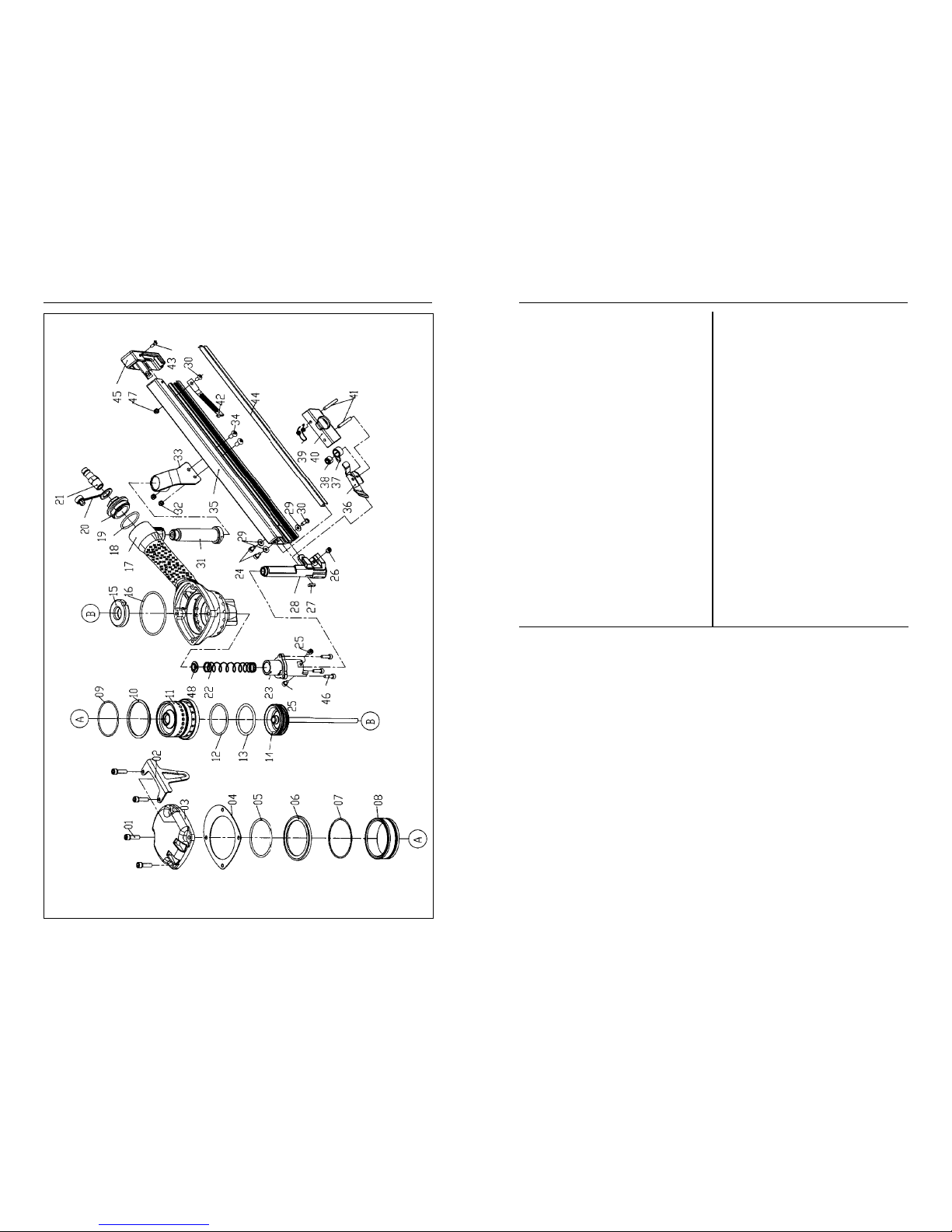

GR150 PARTS LISTGR150 PARTS SCHEMATIC

ITEM P/N DESCRIPTION

1 GRBN17 BOLT

2 GRBN18 HANGER

3 GRBN19 C AP

4 GRBN270 GASKET

5 GRBN271 O-RING

6 GRBN20 COLLAR

7 GRBN272 RING

8 GRBN21 SPACER

9 GRBN273 O-RING

10 GRBN22 SEAL

11 GRBN23 CYLINDER

12 GRBN275 O-RING

13 GRBN276 O-RING

14 GRBN24 DRIVER

15 GRBN25 BUMPER

16 GRBN277 O-RING

17 GRBN26 BODY

18 GRBN278 O-RING

19 GRBN27 END CAP

20 GRBN279 DUST COVER

21 GRBN28 AIR PLUG

22 GRBN29 SPRING

23 GRBN30 GUIDE

24 GRBN5 BOLT

ITEM P/N DESCRIPTION

25 GRBN267 BOLT

26 GRBN31 BOLT

27 GRBN268 MAGNET

28 GRBN269 NOSE PIECE

29 GRBN33 WASHER

30 GRBN34 BOLT

31 GRBN50 SHAFT

32 GRBN7 LOCK NUT

33 GRBN51 BRACKET

34 GRBN35 BOLT

35 GRBN36 MAGAZINE

36 GRBN37 PUSHER

37 GRBN38 SPRING

38 GRBN39 DRUM

39 GRBN40 SPRING

40 GRBN41 END COVER

41 GRBN42 ROLL PIN

42 GRBN43 NAIL STOP

43 GRBN44 BOLT

44 GRBN45 CHANNEL

45 GRBN46 COVER

46 GRBN52 BOLT

47 GRBN47 LOCK NUT

48 GRBN48 DRIVER GUIDE

A GRDAK700 Driver Maintenance Kit

B GRRBK700 O-Ring Maintenance Kit

C GRT150250MAN Operator’s Manual

D GRT150250CASE Tool Case

Page 8

1514

GR250 PARTS LISTGR250 PARTS SCHEMATIC

ITEM P/N DESCRIPTION

1 GRBN17 BOLT

2 GRBN18 HANGER

3 GRBN19 C AP

4 GRBN270 GASKET

5 GRBN271 O-RING

6 GRBN20 COLLAR

7 GRBN272 O-RING

8 GRBN21 CYLINDER SPACER

9 GRBN273 O-RING

10 GRBN274 SEAL

11 GRBN23 CYLINDER

12 GRBN275 O-RING

13 GRBN276 O-RING

14 GRBN53 DRIVER UNIT

15 GRBN25 BUMPER

16 GRBN277 O-RING

17 GRBN26 GUN BODY UNIT

18 GRBN278 O-RING

19 GRBN27 END CAP

20 GRBN279 DUST COVER

21 GRBN28 AIR PLUG

22 GRBN48 DRIVER GUIDE

23 GRBN54 SPRING

24 GRBN55 GUIDE BOX

25 GRBN56 LATCH SPRING BUSHING

26 GRBN57 PIN

27 GRBN58 HEX SOC. HD. BOLT

ITEM P/N DESCRIPTION

28 GRBN59 SHAFT

29 GRBN60 FLAT WASHER

30 GRBN61 POSITIONING SPRING

31 GRBN62 NOSE PIECE

32 GRBN32 MAGNET

33 GRBN63 HEX. SOC. HD. BOLT

34 GRBN64 FLAT WASHER

35 GRBN4 E-RING

36 GRBN65 BRACKET

37 GRBN66 MAGAZINE A

38 GRBN7 LOCK NUT

39 GRBN67 BRACKET

40 GRBN35 HALF ROUND HD. HEX. BOLT

41 GRBN3 LOCK NUT

42 GRBN68 STOP NAIL PLATE

43 GRBN69 SPRING PIN

44 GRBN34 HALF ROUND HD. HEX. BOLT

45 GRBN70 PROT ECTING H OOD COVE R

46 GRBN71 STEEL CHANNEL

47 GRBN72 STEEL CHANNEL

48 GRBN73 STEEL CHANNEL

49 GRBN74 PROT ECTING H OOD COVE R

50 GRBN75 PUSHER

51 GRBN76 SPRING

52 GRBN2 FIXED PIN

53 GRBN77 SPRING

54 GRBN1 URETHANE RETAINER

A GRDAK800 Driver Maintennce Kit

B GRRBK800 O-Ring Maintenance Kit

C GRT150250MAN Operator’s Manual

D GRT150250CASE Tool Case

Page 9

1716

TROUBLESHOOTINGMAINTENANCE

MAINTENANCE

Your tool will last longer and perform better if periodic maintenance is

performed. Please use the information below to keep your tool operating in

top condition.

Lubrication

Disconnect tool from the air supply and remove all fasteners. Apply three

drops of air tool oil (provided) in the air inlet before each use, and after

every 1000 fasteners driven. If the tool will be used outside in the winter,

use a winter grade air tool oil to help keep frost from forming inside the

tool. Do not use other types of lubricants on this tool, as other lubricants

may contain chemicals harmful to o-rings and other tool components.

Cleaning

Disconnect tool from the air supply and remove all fasteners. Brush tool

off using a parts cleaning brush or clean rag. Brush out dirt and debris

from magazine and tool nose.

Daily Inspection

• Check for broken, damaged, or excessively worn parts, and repair

or replace as needed.

• Check for air leaks at cap, and nose. Disconnect tool from air

supply immediately if leaks are present, and see dealer for service.

• Make sure all screws are tightened securely.

Always disconnect tool from air supply before performing any service on

tool. Correcting a problem while the tool is pressurized may result in

injury from nail drive or tool operation.

DANGER

Your pneumatic fastening tool has been designed for long life and troublefree operation. However, if operating problems arise, please use the

troubleshooting information below to determine how to remedy the problem.

FASTENER DRIVING PROBLEMS

Fasteners do not drive

completely.

Increase air pressure. Do not exceed 120

psi. Add 2 - 3 drops of air tool oil to inlet.

Fastener or debris

jammed in tool nose,

preventing tool from

operating.

Pull pusher back, and remove nails from

magazine. Remove debris or fastener from

nose. Check nose for obstructions, and

clean as needed. Reload tool.

PROBLEM CORRECTIVE ACTION

Fasteners do not drive

completely after air

pressure is increased.

Driver blade worn or broken. See dealer for

replacement.

Tool leaks air. Check for source of leak, and tighten fittings

and screws as required. Discontinue using

tool if air leaks after tightening. Contact your

dealer.

TOOL TROUBLESHOOTING

Always disconnect tool from air supply before performing any service on

tool. Correcting a problem while the tool is pressurized may result in

injury from nail drive or tool operation.

DANGER

Page 10

1918

WARRANTYWARRANTY

PNEUMATIC TOOL/COMPRESSOR WARRANTY

Pneumatic nailers, staplers & compressors marketed under the

GRIP RITETM brand are warranted to be free from defects in work-

manship & materials (except rubber o-rings, bumpers, seals, driver

blades, dipsticks, & air filters) for a period of one year from the date

of original purchase.

This warranty will not apply when:

• The original receipt (or copy of the original receipt), showing the

original purchase date, is not provided with tools/compressors sent

in for warranty repair

• The tool/compressor has been misused, abused or improperly

maintained

• Alterations have been made to the original tool/compressor

• Repairs have been attempted/made to the original tool/compressor

by any entity other than a proprietary PRIMESOURCE® service/

warranty center or authorized service/warranty center

• Non- GRIP-RITE TOOLS

TM

/ GRIP-RITE COMPRESSORS

TM /

parts

have been used

• The tool has suffered any physical damage due to the use of nonPRIMESOURCE® approved fasteners*

• Repairs are required due to normal wear & tear

• The tool/compressor has been inadequately packaged leading to

damage in-transit to the service/warranty center.

*Approved fasteners include the following brands GRIP-RITE

FAS’NERSTM, FAS’NERS UNLIMITED

TM

IN NO EVENT SHALL PRIMESOURCE® BE LIABLE FOR ANY INDIRECT,

ACCIDENTAL OR CONSEQUENTIAL DAMAGE FROM THE SALE OR

USE OF THESE PRODUCTS. THIS DISCLAIMER APPLIES BOTH

DURING & AFTER THE TERM OF WARRANTY.

THIS IS OUR WARRANTY & IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(EXCEPT AS MAY BE OTHERWISE PROVIDED BY LAW).

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND

YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY, FROM STATE TO

STATE.

PNEUMATIC TOOL/COMPRESSOR SERVICE INFORMATION

Should any mechanical problems develop during the life of your

equipment the following options are available for service and parts:

• Call (800)676-7777 where you will be routed to the nearest

PRIMESOURCE® distribution center and directed to the nearest

authorized service/warranty center.

• Logging on to our website at www.primesourcebp.com where

you will find a list of our authorized service centers.

• Contact the PRIMESOURCE® Factory Warranty Center directly

at Phone: (800)207-9259 or Fax: (800)207-9614

STEPS TO TAKE WHEN SHIPPING TOOLS

• Adequately package the product to avoid damage in-transit (in

the case of pneumatic tools, the original blow mold plastic

carrying case is considered adequate packaging).

• Provide the original/copy of receipt showing the original purchase

date.

• Insure your shipment with the shipping company.

PRIMESOURCE® will not be responsible for any tool/compressor

that is lost or damaged by the shipper on route to the

PRIMESOURCE® service/warranty center.

Page 11

20

USE GENUINE GRIP-RITE®

FASTENERS FOR BEST

PERFORMANCE

www.grip-rite.com

GR150250MAN

Loading...

Loading...