35,0(6

Operating Manual

Translation of the original instructions

MicroSpotMonitor MSM

LaserDiagnosticsSoftware LDS 2.98

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

IMPORTANT!

READ CAREFULLY BEFORE USE.

KEEP FOR FUTURE USE.

Revision 01/2019 EN

3

MicroSpotMonitor MSM

35,0(6

Table of Contents

1 Basic safety instructions 9

2 Symbol explanations 11

3 About this operating manual 12

4 Conditions at the installation site 12

5 Introduction 13

5.1 System description .................................................................................................................13

5.2 Measuring principle .................................................................................................................14

5.3 Short overview installation .......................................................................................................15

6 Transport 16

6.1 Disassemble the transport lock ...............................................................................................16

6.2 Assemble the transport lock .................................................................................................... 17

7 Installation 17

7.1 Preparation and mounting position ..........................................................................................17

7.2 Manually aligning the MicroSpotMonitor MSM .........................................................................18

7.2.1 Important conditions for the position of the focused laser beam ................................ 18

7.2.2 Positioning the focused laser beam above the measuring objective ..........................19

7.2.3 Positioning the focused laser beam above the optional cyclone ................................20

7.3 Install the MicroSpotMonitor MSM...........................................................................................21

8 Connect cooling circuit (500W version only) 22

8.1 Water quality ...........................................................................................................................22

8.2 Water pressure ........................................................................................................................ 22

8.3 Humidity .................................................................................................................................. 23

8.4 Water connections and water flow rate ....................................................................................24

9 Electrical connection 25

9.1 Connections ............................................................................................................................ 25

9.2 Pin assignment .......................................................................................................................26

9.2.1 Power supply ............................................................................................................ 26

9.2.2 Inlet external trigger ..................................................................................................26

9.2.3 Outlet internal trigger .................................................................................................26

9.2.4 Outlet internal data-transfer signal ............................................................................. 26

9.3 Connection to the PC and connect power supply ...................................................................27

10 Status LEDs 28

11 Installation and configuration of the LaserDiagnosticsSoftware LDS 29

11.1 System requirements ..............................................................................................................29

11.2 Installing the software ..............................................................................................................29

11.3 Ethernet configuration .............................................................................................................30

11.3.1 Enter IP address .......................................................................................................30

11.3.2 Establishing a connection to PC (menu Communication > Free Communication) .. 31

11.3.3 Changing the standard IP address of the device (menu Communication > Free

Communication) ...................................................................................................... 32

4

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

12 Description of the LaserDiagnosticsSoftware LDS 34

12.1 Graphical user interface ........................................................................................................... 34

12.1.1 The menu bar ...........................................................................................................36

12.1.2 The toolbar ...............................................................................................................37

12.1.3 Menu overview .......................................................................................................... 38

12.2 File .......................................................................................................................................... 41

12.2.1 New (menu File > New) ............................................................................................ 41

12.2.2 Open (menu File > Open) ......................................................................................... 41

12.2.3 Close/Close all (menu File > Close/Close all) ........................................................... 41

12.2.4 Save (menu File > Save) ........................................................................................... 41

12.2.5 Save as (menu File > Save As) ................................................................................. 41

12.2.6 Export (menu File > Export) .....................................................................................41

12.2.7 Load measurement preferences (menu File > Load measurement preferences) ....42

12.2.8 Save measurement preferences (menu File > Save measurement preferences) .....42

12.2.9 Protocol (menu File > Protocol) ...............................................................................42

12.2.10 Print (menu File > Print) ...........................................................................................42

12.2.11 Print preview (menu File > Print preview) .................................................................42

12.2.12 Recently opened files (menu File > Recently opened Files) ..................................... 42

12.2.13 Exit (menu File > Exit) ............................................................................................... 42

12.3 Edit .........................................................................................................................................43

12.3.1 Copy (menu Edit > Copy) ......................................................................................... 43

12.3.2 Clear plane (menu Edit > Clear plane) .....................................................................43

12.3.3 Clear all planes (menu Edit > Clear all planes) ......................................................... 43

12.3.4 Change user level (menu Edit > Change User Level) ............................................... 43

12.4 Measurement ..........................................................................................................................44

12.4.1 Measuring environment (menu Measurement > Environment) ................................44

12.4.2 Sensor parameters (menu Measurement > Sensor parameter) .............................. 45

12.4.3 Beam find settings (menu Measurement > BeamFind Settings: Beamfind ........... 46

12.4.4 CCD info (menu Measurement > CCD Info) ............................................................47

12.4.5 CCD settings (menu Measurement > CCD Settings) ..............................................48

12.4.6 LQM adjustment (menu Measurement > LQM Adjustment) .................................... 50

12.4.7 Power measurement (menu Measurement > Power Measurement) .......................50

12.4.8 Single (menu Measurement > Single) ...................................................................... 50

12.4.9 Caustic measurement (menu Measurement > Caustic) ...........................................54

12.4.10 Start adjust mode (menu Measurement > Start Adjust mode) ................................ 55

12.4.11 Option (advanced user only) (menu Measurement > Option) ................................... 56

12.5 Presentation ............................................................................................................................58

12.5.1 False colors (menu Presentation > False colors) ..................................................... 59

12.5.2 False colors (filtered) (menu Presentation > False colors (filtered)) .........................60

12.5.3 Isometry (menu Presentation > Isometry) ...............................................................60

12.5.4 Isometry 3D (menu Presentation > Isometry 3D) ...................................................61

12.5.5 Review 86% or 2. moment (menu Presentation > Review (86%)/(2. moment)) .... 62

12.5.6 Caustic (menu Presentation > Caustic) .................................................................. 63

12.5.7 Raw beam (menu Presentation > Raw-beam) .......................................................67

12.5.8 Symmetry check (menu Presentation > SymmetryCheck) ...................................... 68

12.5.9 Fixed contour lines (menu Presentation > Fixed Contour Lines) ............................. 69

12.5.10 Variable contour lines (menu Presentation > Variable Contour Lines) ..................... 70

12.5.11 Graphical review (menu Presentation > Graphical Review) .....................................72

12.5.12 Systemstate (menu Presentation > Systemstate) ...................................................72

12.5.13 Evalution parameter view (menu Presentation > Evalution Parameter View) .......... 73

12.5.14 Evaluate document (menu Presentation > Evaluate doc) ........................................ 74

12.5.15 Color tables (menu Presentation > Color Tables) .................................................... 76

12.5.16 Toolbar (Menu Presentation > Toolbar) ...................................................................76

12.5.17 Position (menu Presentation > Position) .................................................................77

12.5.18 Evaluation (option) (menu Presentation > Evaluation) .............................................. 77

Revision 01/2019 EN

5

MicroSpotMonitor MSM

35,0(6

12.6 Communication ....................................................................................................................... 79

12.6.1 Rescan bus (menu Communication > Rescan bus) ................................................79

12.6.2 Free communication (menu Communication > Free Communication) ...................79

12.6.3 Scan device list (menu Communication > Scan device list) ................................... 80

12.7 Script (menu Script) ...............................................................................................................81

12.7.1 Editor (menu Script > Editor) ..................................................................................81

12.7.2 List (menu Script > List) .......................................................................................... 81

12.7.3 Python (menu Script > Python) ............................................................................... 81

13 Measurement 82

13.1 Safety instructions ................................................................................................................... 82

13.2 Selection and change of measuring objectives ........................................................................83

13.2.1 Selection of the measuring objective .........................................................................83

13.2.2 Exchanging the measuring objective .........................................................................85

13.2.3 Damage thresholds ...................................................................................................86

13.3 Prepare measurement .............................................................................................................89

13.3.1 Check list measurement settings...............................................................................89

13.3.2 Check list measurement settings...............................................................................89

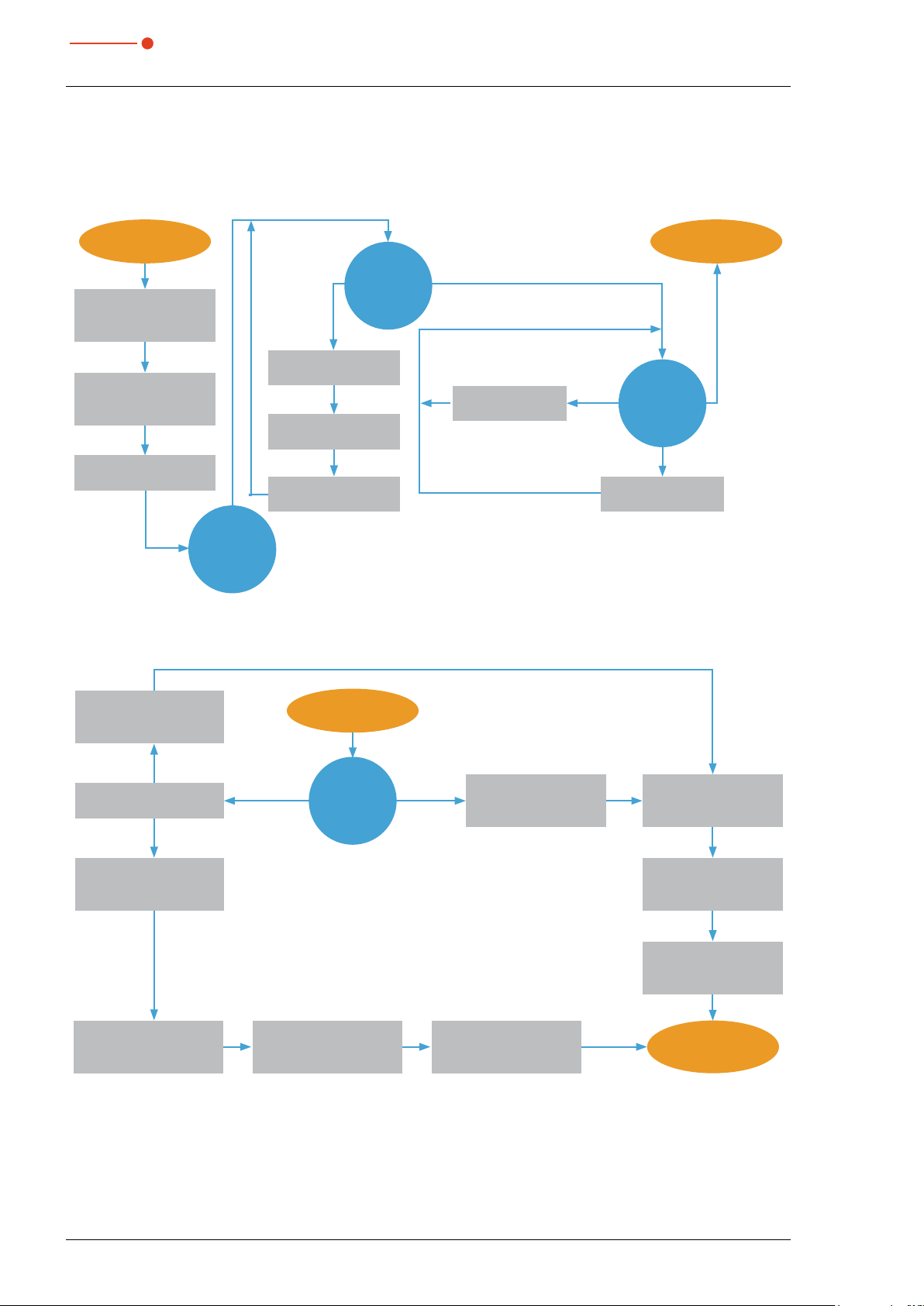

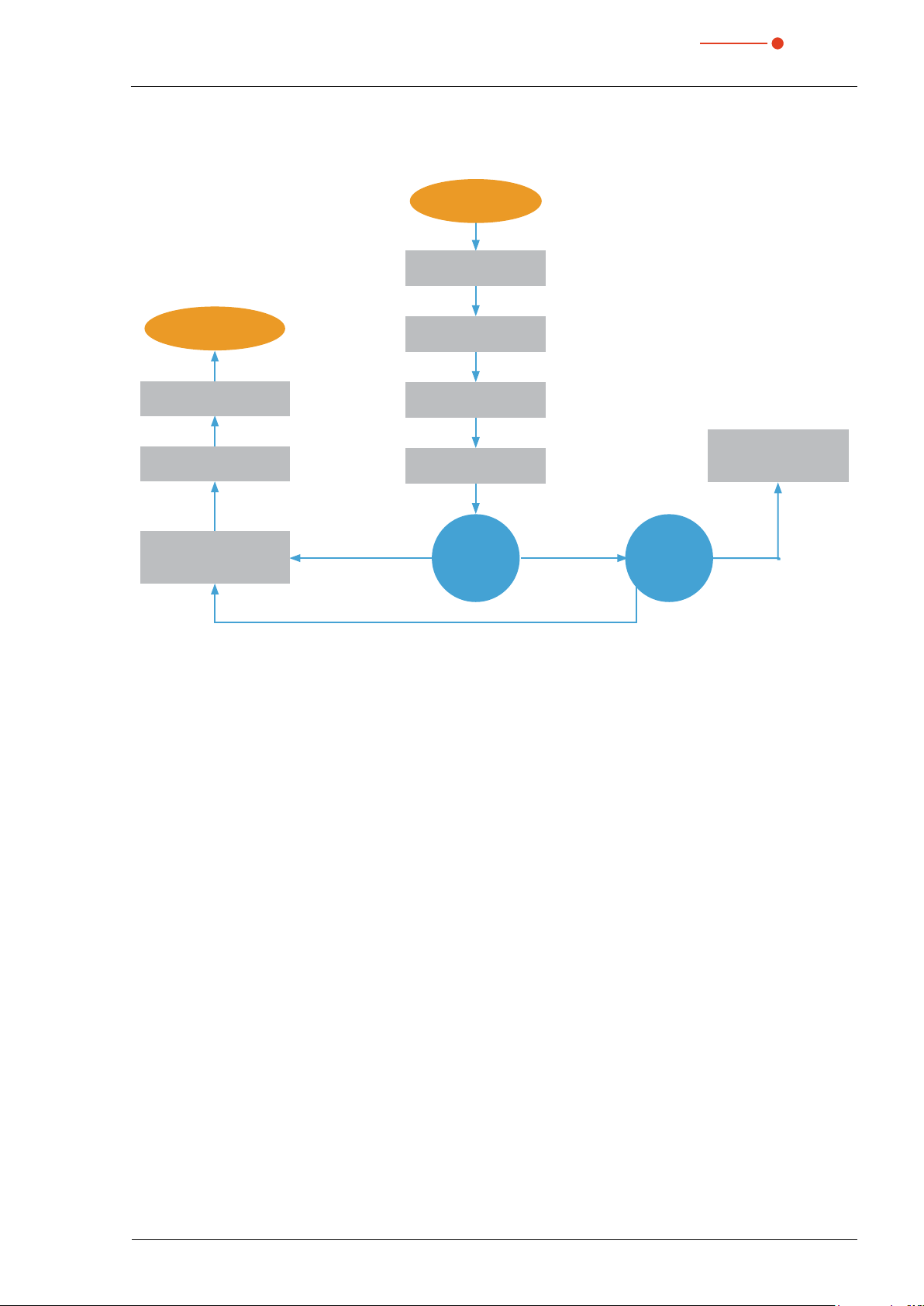

13.4 Flowchart of a measurement ...................................................................................................90

13.4.1 Prepare measurement ...............................................................................................90

13.4.2 Set caustic limits ....................................................................................................... 90

13.4.3 Perform caustic measurement ..................................................................................91

13.5 Perform measurement settings in the LaserDiagnosticsSoftware LDS .....................................92

13.5.1 Sensor parameters (menu Measurement > Sensor parameter) .............................. 93

13.5.2 Measuring environment (menu Measurement > Environment) ................................94

13.5.3 Measurement settings (menu Measurement > Single) .............................................95

13.5.4 Caustic settings (menu Measurement > Caustic) .................................................... 96

13.5.5 CCD settings (menu Measurement > CCD Settings) ..............................................98

13.5.6 Option (advanced user only) (menu Measurement > Option) ................................. 100

13.5.7 CCD info (menu Measurement > CCD Info) ..........................................................101

13.5.8 Single measurement (menu Measurement > Single) ..............................................102

13.5.9 Caustic measurement (menu Measurement > Caustic) .........................................104

14 Troubleshooting 108

14.1 Error during a measurement ..................................................................................................108

14.2 No measurement signal at the MicroSpotMonitor MSM .........................................................108

15 Maintenance and service 109

15.1 Exchanging the protective window ........................................................................................109

15.1.1 Safety instructions ..................................................................................................109

15.1.2 Replacing the protective window ............................................................................110

15.1.3 Replacing the protective window for cyclone ...........................................................111

16 Storage 112

17 Measures for the product disposal 112

18 Declaration of conformity 113

19 Technical data 114

6

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

20 Dimensions 116

21 Appendix 117

21.1 Insert fixed OD filter (option) in the inspection chamber .........................................................117

21.2 File “laserds.ini” – an Example ...............................................................................................118

21.3 Description of the MDF file format .........................................................................................119

21.4 Optical components .............................................................................................................. 120

21.4.1 Measuring objective ................................................................................................ 121

21.4.2 Fixed filter and filter wheel .......................................................................................126

21.4.3 Beam path extension (BPE) ....................................................................................127

21.4.4 Alignment objective (JO) .......................................................................................... 127

21.4.5 Absorber ................................................................................................................. 128

21.4.6 Trigger diode ........................................................................................................... 128

21.4.7 Charge-coupled device sensor (CCD sensor) .......................................................... 128

21.5 Measuring pulsed irradiation ................................................................................................. 132

21.5.1 Measuring configuration selection ...........................................................................134

21.5.2 Influence of the pulse parameters on the integration time control ............................134

21.5.3 Examples for triggered measuring mode .................................................................138

21.5.4 Summary ................................................................................................................ 139

22 Basis of laser beam diagnosis 140

22.1 Laser beam parameter .......................................................................................................... 140

22.1.1 Rotationally symmetric beams.................................................................................141

22.1.2 Non rotationally symmetric beams ..........................................................................142

22.2 Calculation of beam data ......................................................................................................143

22.2.1 Determination of the zero level ................................................................................143

22.2.2 Determination of the beam position ......................................................................... 144

22.2.3

22.2.4 Radius determination with the method of the 86% power inclusion ....................... 145

22.2.5 Further radius definitions (option).............................................................................146

22.3 Measurement errors ..............................................................................................................147

22.3.1 Error in determining zero level .................................................................................147

22.3.2 Saturating the signal ...............................................................................................147

22.3.3 Errors from incorrect measurement window size ..................................................... 148

Radius determination with the 2. moment method of the power density distribution ..

144

Revision 01/2019 EN

7

MicroSpotMonitor MSM

35,0(6

PRIMES - The Company

PRIMES manufactures measuring devices used to analyze laser beams. These devices are employed for

the diagnostics of high-power lasers ranging from CO

length range from infrared through to near UV is covered, offering a wide variety of measuring devices to

determine the following beam parameters:

• Laser power

• Beam dimensions and position of an unfocused beam

• Beam dimensions and position of a focused beam

• Beam quality factor M²

PRIMES is responsible for both the development, production, and calibration of the measuring devices. This

guarantees optimum quality, excellent service, and a short reaction time, providing the basis for us to meet all

of our customers’ requirements quickly and reliably.

lasers and solid-state lasers to diode lasers. A wave-

2

PRIMES GmbH

Max-Planck-Str. 2

64319 Pfungstadt

Germany

Tel +49 6157 9878-0

info@primes.de

www.primes.de

8

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

1 Basic safety instructions

Intended Use

The MicrsoSpotMonitor MSM has been designed exclusively for measurements carried out in or near the

optical path of high-power lasers. Please observe and adhere to the specifications and limit values given

in chapter19, „Technical data“, on page114. Other uses are considered to be improper. The information

contained in this operating manual must be strictly observed to ensure proper use of the device.

Using the device for unspecified use is strictly prohibited by the manufacturer. By usage other than intended

the device can be damaged or destroyed. This poses an increased health hazard up to fatal injuries. When

operating the device, it must be ensured that there are no potential hazards to human health.

The device itself does not emit any laser radiation. During the measurement, however, the laser beam is

guided onto the device which causes reflected radiation (laser class 4). That is why the applying safety regulations are to be observed and necessary protective measures need to be taken.

Observing applicable safety regulations

Observing applicable safety regulations

Please observe valid national and international safety regulations as stipulated in ISO/CEN/TR standards as

well as in the IEC-60825-1 regulation, in ANSI Z 136 “Laser Safety Standards” and ANSI Z 136.1 “Safe Use

of Lasers”, published by the American National Standards Institute, and additional publications, such as the

“Laser Safety Basics”, the “LIA Laser Safety Guide”, the “Guide for the Selection of Laser Eye Protection”

and the “Laser Safety Bulletin”, published by the Laser Institute of America, as well as the “Guide of Control

of Laser Hazards” by ACGIH.

Necessary safety measures

DANGER

Serious eye or skin injury due to laser radiation

During the measurement the laser beam is guided on the device, which causes scattered or

directed reflection of the laser beam (laser class 4). The reflected beam is usually not visible.

Please take the following precautions.

X

If people are present within the danger zone of visible or invisible laser radiation, for example near laser

systems that are only partly covered, open beam guidance systems, or laser processing areas, the following

safety measures must be implemented:

• Please wear safety goggles adapted to the power, power density, laser wave length and operating

mode of the laser beam source in use.

• Depending on the laser source, it may be necessary to wear suitable protective clothing or protective

gloves.

• Protect yourself from direct laser radiation, scattered radiation, and beams generated from laser radiation

(by using appropriate shielding walls, for example, or by weakening the radiation to a harmless level).

• Use beam guidance or beam absorber elements that do not emit any hazardous substances when they

come in to contact with laser radiation and that can withstand the beam sufficiently.

• Install safety switches and/or emergency safety mechanisms that enable immediate closure of the laser

shutter.

• Ensure that the device is mounted securely to prevent any movement of the device relative to the beam

axis and thus reduce the risk of scattered radiation. This in the only way to ensure optimum performance

during the measurement.

Revision 01/2019 EN

9

MicroSpotMonitor MSM

35,0(6

Employing qualified personnel

The device may only be operated by qualified personnel. The qualified personnel must have been instructed

in the installation and operation of the device and must have a basic understanding of working with highpower lasers, beam guiding systems and focusing units.

Conversions and modifications

The device must not be modified, neither constructionally nor safety-related, without our explicit permission.

The device must not be opened e.g. to carry out unauthorized repairs. Modifications of any kind will result in

the exclusion of our liability for resulting damages.

Liability disclaimer

The manufacturer and the distributor of the measuring devices do not claim liability for damages or injuries

of any kind resulting from an improper use or handling of the devices or the associated software. Neither the

manufacturer nor the distributor can be held liable by the buyer or the user for damages to people, material

or financial losses due to a direct or indirect use of the measuring devices.

10

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

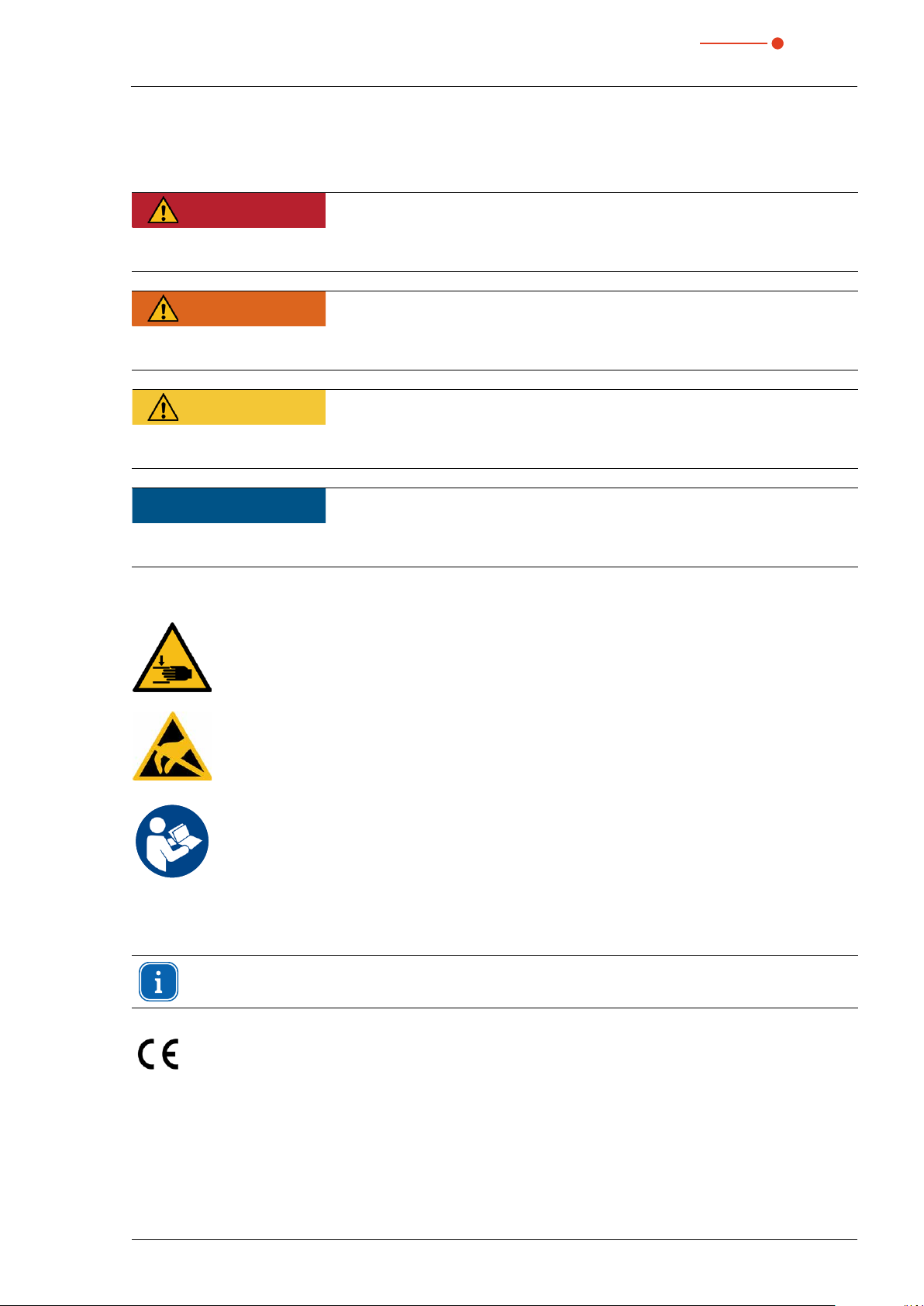

2 Symbol explanations

The following symbols and signal words indicate possible residual risks:

DANGER

Means that death or serious physical injuries will occur if necessary safety precautions are not

taken.

WARNING

Means that death or serious physical injuries may occur if necessary safety precautions are not

taken.

CAUTION

Means that minor physical injury may occur if necessary safety precautions are not taken.

NOTICE

Means that property damage may occur if necessary safety precautions are not taken.

The following symbols indicating requirements and possible dangers are used on the device:

Hand injuries warning

Components susceptible to ESD

Read and observe the operating instructions and safety guidelines before startup!

Further symbols that are not safety-related:

Here you can find useful information and helpful tips.

Revision 01/2019 EN

With the CE designation, the manufacturer guarantees that its product meets the requirements of

the relevant EC guidelines.

Call for action

X

11

MicroSpotMonitor MSM

35,0(6

3 About this operating manual

This documentation describes how to work with the MicroSpotMonitor MSM and operate it with the LaserDiagnosticsSoftware LDS 2.98.

The software description includes a brief introduction on using the device for measurements.

This operating manual describes the software version valid at the time of printing.

Since the user software is continuously being developed further, the supplied data medium may

have a different version number. Correct functioning of the device is, however, still guaranteed with

the software.

Should you have any questions, please specify the software version installed on your device. The software

version can be found under the following menu item: Help > About LaserDiagnosticsSoftware.

Fig. 3.1: Information regarding the current software version

4 Conditions at the installation site

• The device must not be operated in a condensing atmosphere.

• The ambient air must be free of organic gases.

• Protect the device from splashes of water and dust.

• Operate the device in closed rooms only.

12

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

5 Introduction

5.1 System description

The MicroSpotMonitor MSM determines beam parameters of focused laser beams with medium powers up

to 200W in a range between 20micro meters and one millimeter directly in the processing zone.

The air-cooled system depicts the laser beam, which is attenuated by different beam splitter and neutral

density filters, on a CCD sensor. On the basis of the determined beam distribution of a plane, the beam position as well as the beam radius can be derived. By means of the integrated z-axis and the measurement at

different positions of the laser beam the described beam parameters are determined and logged.

The measuring objectives of the MicroSpotMonitor MSM are selected individually, depending on the beam

source that is supposed to be measured. In this regard, the wavelength (248 up to 1 090 nm) as well as the

magnification (3.3:1, 5:1, 10:1), which is determined by the focus diameter, are the essential parameters.

The dynamic range of the integrated CCD sensor is amplified to more than 130dB via an irradiation time

control, which enables caustic measurements over more than four Rayleigh lengths, as demanded in the

standard ISO11146.

Optionally, the MicroSpotMonitor MSM can be equipped with a filter wheel with neutral density filters (OD1

to OD5). This filter wheel enables the measurement of power densities between several W/cm² up to several

MW/cm² without having to modify the system.

Cyclone (option)

Knurled screw

Absorber

Ventilator

Traversing motor

Transport lock

Beam entrance

to filter wheel (option) and fixed OD-filter (option)

Access (inspection chamber)

Lever to adjust the

magnification

(option)

Beam path extension (BPE)

Standard

Fig. 5.1: Components of the MicroSpotMonitor MSM

Revision 01/2019 EN

Alignment objective (AO)

13

MicroSpotMonitor MSM

35,0(6

5.2 Measuring principle

The MicroSpotMonitor MSM is a camera-based measuring system. Depending on the application, up to 7

different optical components can be in the beam path. The purpose and functioning of individual components is described in chapter21.4, „Optical components“, on page120.

Laser beam

Upper limit

Measuring plane

Lower limit

Measuring

objective

Absorber

Prisms

Fixed OD-filter (option)

Alignment objective (AO)

CCD sensor

Fig. 5.2: Optomechanical design

Mirrors

Absorber

Trigger

Filter wheel (option)

Beam path extension (BPE)

14

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

5.3 Short overview installation

1. Taking safety precautions Chapter 1 on page 9

2. Transport

• Disassemble the transport lock

3. Installation

• Make preparations

• Set the installation position

• Align the device manually

• Mount the device firmly

4. Connect the water-cooling (500 W version only)

• Connection diameter

• Observe flow rate

5. Electrical connection

• Establish voltage supply

Chapter 6 on page 16

Chapter 7 on page 17

Chapter 8 on page 22

Chapter 9 on page 25

6. Connect with the PC

• Via Ethernet or LAN

7. Installing the LaserDiagnosticsSoftware LDS on the PC

• Software is part of the scope of delivery

• Connect the MicroSpotMonitor MSM with the LaserDiagnosticsSoftware LDS

8. Measure

• Follow the safety instructions

• Select and insert the measuring objective

• Observe damage thresholds

• Perform measurement

Chapter 9.3 on page 27

Chapter 11 on page 29

Chapter 13 on page 82

Revision 01/2019 EN

15

35,0(6

6 Transport

WARNING

Risk of injury when lifting or dropping the device

Lifting and positioning heavy devices can, for example, stress intervertebral disks and cause

chronic changes to the lumbar or cervical spine. The device may fall.

Use a lifting device to lift and position the device.

X

NOTICE

Damaging/destroying the device

Optical components may be damaged if the device is subjected to hard shocks or is allowed

to fall.

Handle the measuring device carefully when transporting or installing it.

X

To avoid contamination, close the measuring objective with the cover provided.

X

Only transport the device in the original PRIMES transport box (option).

X

MicroSpotMonitor MSM

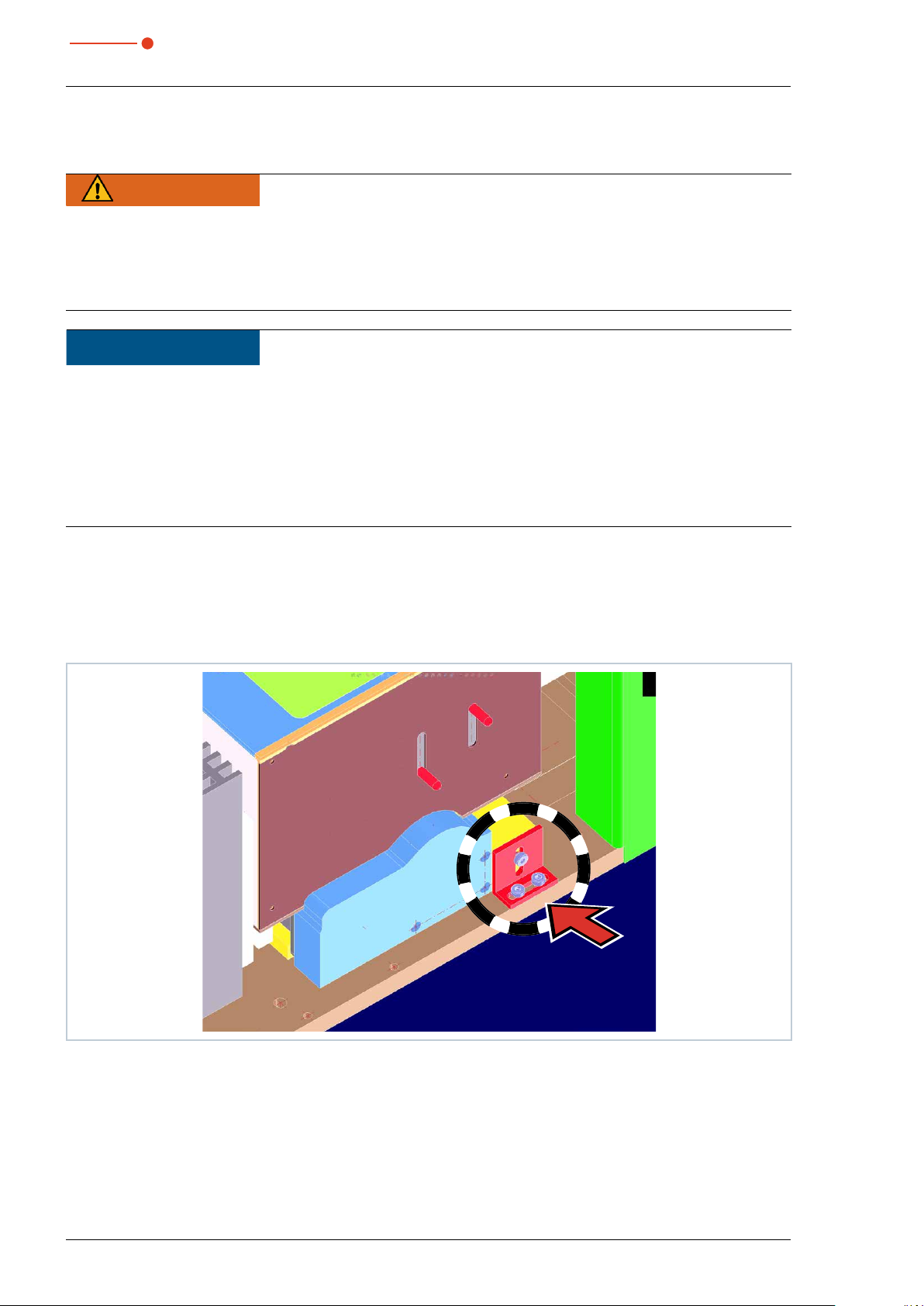

6.1 Disassemble the transport lock

After unpacking the device, the transport lock has to be removed first. The transport lock secures the linear

actuator of the z-axis. It is located on the bottom plate and is fastened by means of 3 screws (see Fig. 6.1 on

page 16).

Fig. 6.1: Position of the transport lock

16

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

6.2 Assemble the transport lock

NOTICE

Damaging/destroying the device

The device must only be transported with a mounted transport lock.

Keep the transport lock for future use.

X

Before transportation, move the MicroSpotMonitor MSM into the parking position (see chapter12.5.17, „Position (menu Presentation > Position)“, on page77) and mount the transport lock.

7 Installation

7.1 Preparation and mounting position

Check the space available before mounting the device, especially the required space for the connection

cables and the movement range of the z-axis (see chapter20, „Dimensions“, on page116). The device

must be set up so that it is stable and fastened with screw (see chapter 7.3 on page 21).

The MicroSpotMonitor MSM is designed to operate in a horizontal position with a beam incidence from

above. With an optional side plate (order no. 801-004-060), operation with horizontal beam incidence is also

possible.

NOTICE

Damaging/destroying the device

Obstacles in the movement range of the MicroSpotMonitor MSM can lead to collisions and

damage the device.

Keep the movement range free of obstacles (cutting nozzle, pressure rolls, etc.).

X

Revision 01/2019 EN

17

MicroSpotMonitor MSM

35,0(6

7.2 Manually aligning the MicroSpotMonitor MSM

7.2.1 Important conditions for the position of the focused laser beam

Due to the imaging characteristics of the measuring objective (see chapter21.4.1, „Measuring objective“, on

page121) it is necessary for the laser beam focus to be positioned in a certain range above the measuring

objective.

NOTICE

Damaging/destroying the device

The focus has to be in a defined range with reference to the measuring objective. In case it

is too close or too distant, the optics might be damage in case of high beam intensities.

Use the enclosed alignment tool for the alignment.

X

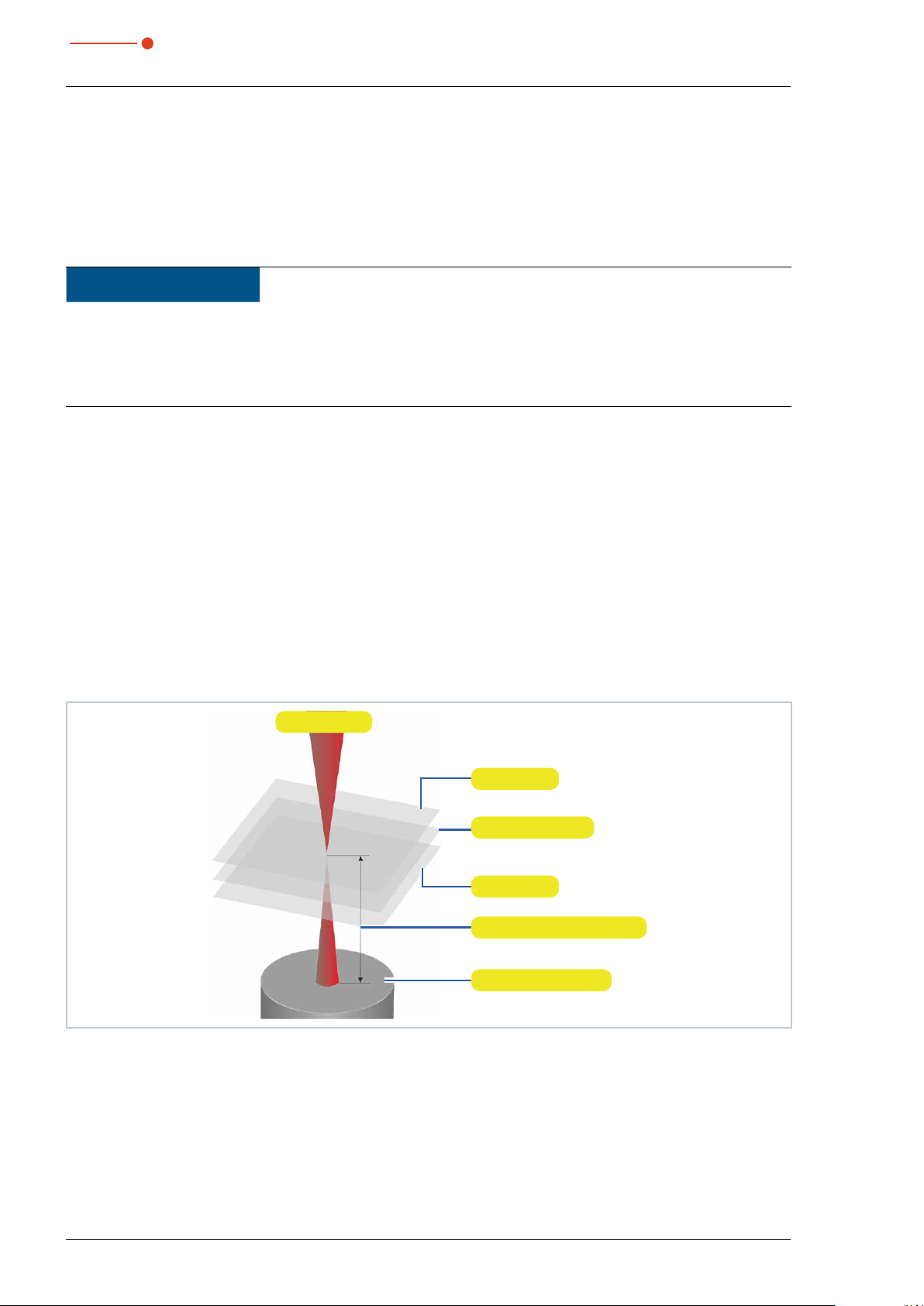

The size of the range in which the focus is to be positioned before the first measurement depends on the

chosen measuring objective, the used wavelength and the type of focusing. The measurement range lies

within an upper and a lower limit.

Upper limit

If the focus is located too high above the measuring objective, a focus on the image-sided beam path can

develop. Together with too high beam intensities, the optics might be damaged.

Measuring plane

The beam distribution of the measuring plane is displayed on the CCD sensor.

Lower limit

If the focus is too close to the measuring objective, it can – depending on the type of focusing and the power

used – damage the entrance lens.

Laser beam

Upper limit

Measuring plane

Lower limit

Measuring plane distance

Measuring objective

Fig. 7.1: Measuring range of the MicroSpotMonitor MSM

18

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

7.2.2 Positioning the focused laser beam above the measuring objective

The measuring plane distance equals the distance of the measuring plane from the upper corner of the measuring objective or the protective glass.

In order to be able to align the MicroSpotMonitor MSM beneath the laser, an associated alignment tool is

provided with each measuring objective. By means of this alignment tool and a pilot laser beam, you can

position the device with the necessary accuracy.

1. Place the alignment tool directly on the measuring objective (see Fig. 7.2 on page 19) or on the protective window holder on the measuring objective (see Fig. 7.3 on page 19).

• The upper edge of the measuring objective corresponds to the z position of the measuring plane.

• When using a protective window with a thickness of 1.5mm, the measuring plane moves upwards by

approx. 500µm.

2. Turn on the pilot laser. If the laser hits the marking in the alignment tool vertically, it is displayed centrally

on the CCD sensor.

Marking in the alignment tool

10x

Fig. 7.2: Alignment tools for direct placement on the measuring objective

Marking in the alignment tool

10x 5x 3.3x

Fig. 7.3: Alignment tools for placement on the protective window holder on the measuring objective

5x

3.3x

Revision 01/2019 EN

19

MicroSpotMonitor MSM

35,0(6

The measuring plane distance equals the distance of the imaging plane from the upper corner of the measuring objective. It does not only depend on the beam path (standard, beam path extension BPE, alignment

objective AO) but also on the wavelength (see Tab. 7.1 on page 20).

When using a protective window with a thickness of 1.5mm, the measuring plane moves upwards

by approx. 500µm.

Measuring ob-

jective MOB

3.3x

1 064nm

532nm

355nm

5x

1 064nm

532nm

355nm

10x

1 064nm

532nm

355nm

Tab. 7.1: Measuring plane distances

NA limit

values

1

0.1

0.09

0.19

0.18

0.14

0.24

0.24

0.17

Typ. magnification Measuring plane distance in mm

Standard BPE AO Standard BPE AO

3.12

3.23

3.36

4.96

5.15

5.35

8.84

9.17

9.62

5.65

5.81

6.02

8.31

8.6

8.92

14.39

14.91

15.6

1.12

1.11

*)

1.63

1.59

*)

2.77

2.72

*)

73

70.5

67.3

51.1

49.3

47.2

29.9

-

-

64.6

62.6

60.1

47.1

45.7

43.8

27.9

-

-

63.7

61.5

57.7

46.7

45.1

42.7

27.6

-

-

*) Only suitable for adjustment

Due to the production tolerances, the values of the measuring plane distance contain a deviation of

±800µm. However, it is possible to have the measuring distance of the measuring objective calibrated to

±50µm (TCP calibration).

7.2.3 Positioning the focused laser beam above the optional cyclone

For measuring objectives with a cyclone or a protective window special alignment aids are provided.

Marking in the alignment tool

Alignment tool

Cyclone with disassembled protective window

holder and attached alignment tool

Fig. 7.4: Alignment tool for an optional cyclone using the example of a measuring objective with 3.3x magnification

Cyclone with mounted protective window

holder and removed alignment tool

20

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

7.3 Install the MicroSpotMonitor MSM

DANGER

Serious eye or skin injury due to laser radiation

If the device is moved from its calibrated position, increased reflected radiation

(laser class 4) may result during measuring operation.

When mounting the device, please ensure that it cannot be moved, neither due to an unin-

X

tended push or a pull on the cables and hoses.

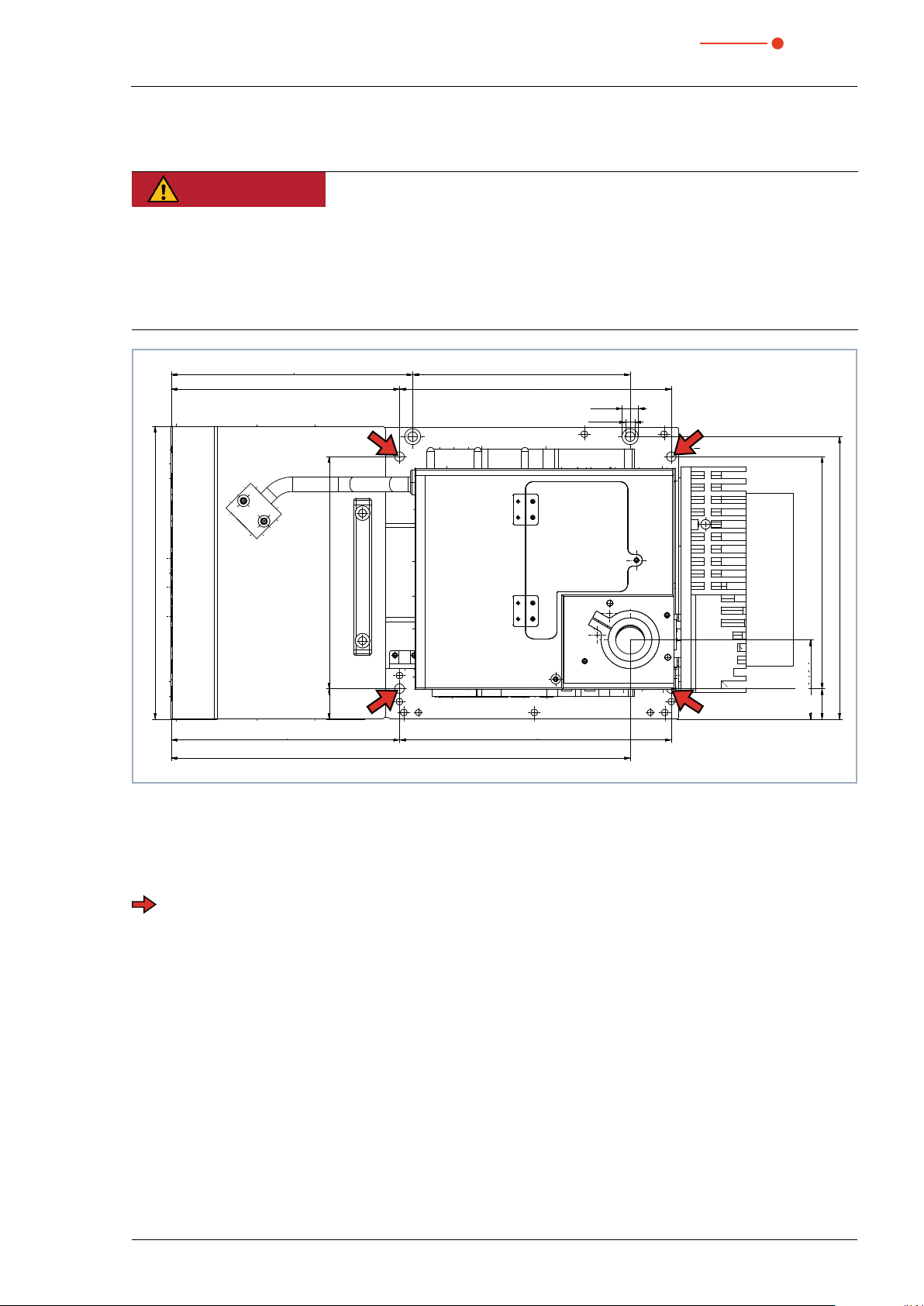

150166.6

187.5157.5

2x Ø11

2x Ø6.6

4x Ø 6.6 Ø11

202

157.5 187.5

Fig. 7.5: Fastening bores, view from above

For the installation onto a holder provided by the customer, there are four mounting holes Ø6,6mm in the

bottom plate. We recommend screws M6 of the strength class 8.8 and a tightening torque of 20N∙m.

4 Mounting holes Ø6,6mm

160

21

316.6 +12

160

54.8 ±0.5

21

194.8

Revision 01/2019 EN

21

35,0(6

8 Connect cooling circuit (500W version only)

DANGER

Fire hazard; Damage/Destruction of the device due to overheating

If there is no water cooling or a water flow rate which is insufficient, there is a danger of

overheating, which can damage the device or set it on fire.

Operate the device with a connected water cooling and a sufficient water flow rate only.

X

8.1 Water quality

NOTICE

Damage/Destruction of the device due to different chemical potentials

The parts of the device which get in contact with cooling water consist of copper, brass or

stainless steel. Connecting the unit to a colling curcuit containing aluminum components

may cause corrosion of the aluminum due to the different chemical potentials.

Do not connect the device on a cooling circuit in which aluminum components are installed.

X

MicroSpotMonitor MSM

• The device can be operated with tap water as well as demineralized water.

• Do not operate the device on a cooling circuit containing additives such as anti-freeze.

• Do not operate the device on a cooling circuit in which aluminum components are installed. Especially

when it comes to the operation with high powers and power densities, it may otherwise lead to corrosion

in the cooling circuit. In the long term, this reduces the efficiency of the cooling circuit.

• Should the cooling fail, the device can withstand the laser radiation for a few seconds. In this case,

please check the device as well as the water connections for damages.

• Large dirt particles or teflon tape may block internal cooling circuits. Therefore, please thoroughly rinse

the system before connecting it.

8.2 Water pressure

Normally, 2 bar primary pressure at the entrance of the absorber are sufficient in case of an unpressurized

outflow.

NOTICE

Damage/Destruction of the device due to overpressure

The maximum permissible water inlet pressure must not exceed 4bar.

X

22

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

8.3 Humidity

• The device must not be operated in a condensing atmosphere. The humidity has to be considered in

order to prevent condensates within and outside the device.

• The temperature of the cooling water must not be lower than the dew point (see Tab. 8.1 on page 23).

NOTICE

Damage/Destruction of the device due to condensing water

Condensation water inside of the objective will lead to damage.

Mind the dew-point in Tab. 8.1 on page 23.

X

Do only cool the device during the measuring operation. We recommend starting the cooling approx. 2minutes before the measurement and terminating it approx. 1minute after the measurement.

40

35

30

25

20

15

10

Cooling water temperature in °C

5

0

Tab. 8.1: Dew point diagram

Example

Air temperature: 22°C

Relative humidity: 60%

0 5 10 15 20 25 30 35 40

Air temperature in °C

100

80

70

60

50

40

30

20

Relative humidity in %

10

The cooling water temperature cannot fall below 14°C.

Revision 01/2019 EN

23

MicroSpotMonitor MSM

35,0(6

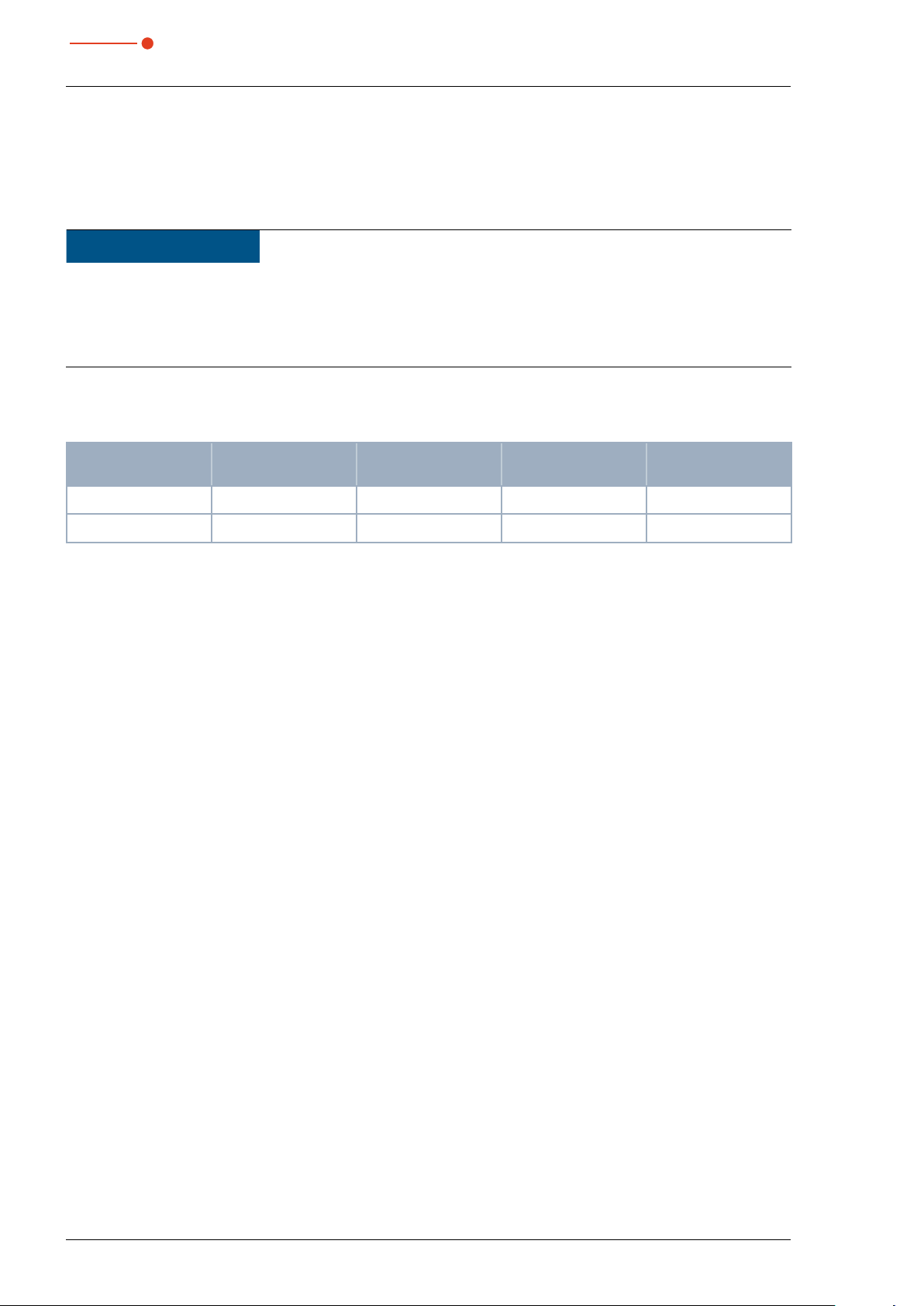

8.4 Water connections and water flow rate

Connection diameter Recommended flow rate Minimum flow rate

PE hoses 12mm 1.5l/min (1l/(min · kW) Not lower than 1.0l/min

Tab. 8.2: Water connections and water flow rate

Remove the sealing plugs of the water connections

Release ring

1. Push

2. Pull

Fig. 8.1: Remove the sealing plugs of the water connections

1. Please push down the release ring of the connection

and pull out the plug with your free hand.

2. Remove the sealing plugs of the water connections and

keep it in a save place.

3. Close the flow line (Water In) and the return flow (Water

Out) of the device, by inserting the hose as far as possible (approx. 2cm deep).

24

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

9 Electrical connection

The MicroSpotMonitor MSM requires a supply voltage of 24V±5% (DC) for the operation. A suitable power

supply with an adapter is included in the scope of delivery. Please use only the provided connection lines.

Please ensure that all electrical connections have been established and switch the device on before

starting the LaserDiagnosticsSoftware LDS.

The MicroSpotMonitor MSM serves as a dongle for the software on the PC in order to enable certain software functions.

9.1 Connections

On/off switch

RS485 PRIMES bus

D-Sub socket9 pole

(Power supply connection)

Fig. 9.1: Connections

Revision 01/2019 EN

Input

external trigger

BNC

Output

internal trigger

BNC

Ethernet

Outlet data transfer signal

25

35,0(6

9.2 Pin assignment

9.2.1 Power supply

D-Sub socket, 9-pin (view: connector side)

MicroSpotMonitor MSM

Pin Function

1 GND

15

69

Tab. 9.1: D-Sub socket RS485

2 RS485 (+)

3 +24 V

4 Trigger RS485 (+)

5 Not assigned

6 GND

7 RS485 (–)

8 +24 V

9 Trigger RS485 (–)

9.2.2 Inlet external trigger

BNC connector (view: connector side)

Pin Function

1 +5 V (Trigger signal)

1

2

Fig. 9.2: Connection socket inlet for an external trigger in the connection panel

2 GND

9.2.3 Outlet internal trigger

BNC connector (view: connector side)

Pin Function

1 +5 V (Trigger signal)

1

2

Fig. 9.3: Connection socket outlet for the internal trigger in the connection panel

2 GND

9.2.4 Outlet internal data-transfer signal

BNC connector (view: connector side)

Pin Function

1 +5 V (Trigger signal)

1

2

Fig. 9.4: Connection socket outlet for the internal data-transfer signal in the connection panel

2 GND

26

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

9.3 Connection to the PC and connect power supply

NOTICE

Damage/Destruction of the device

When the electrical cables are disconnected during operation (when the power supply is applied), voltage peaks occur which can destroy the communication components of the measuring device.

Please turn off the PRIMES power supply before disconnecting the cables.

X

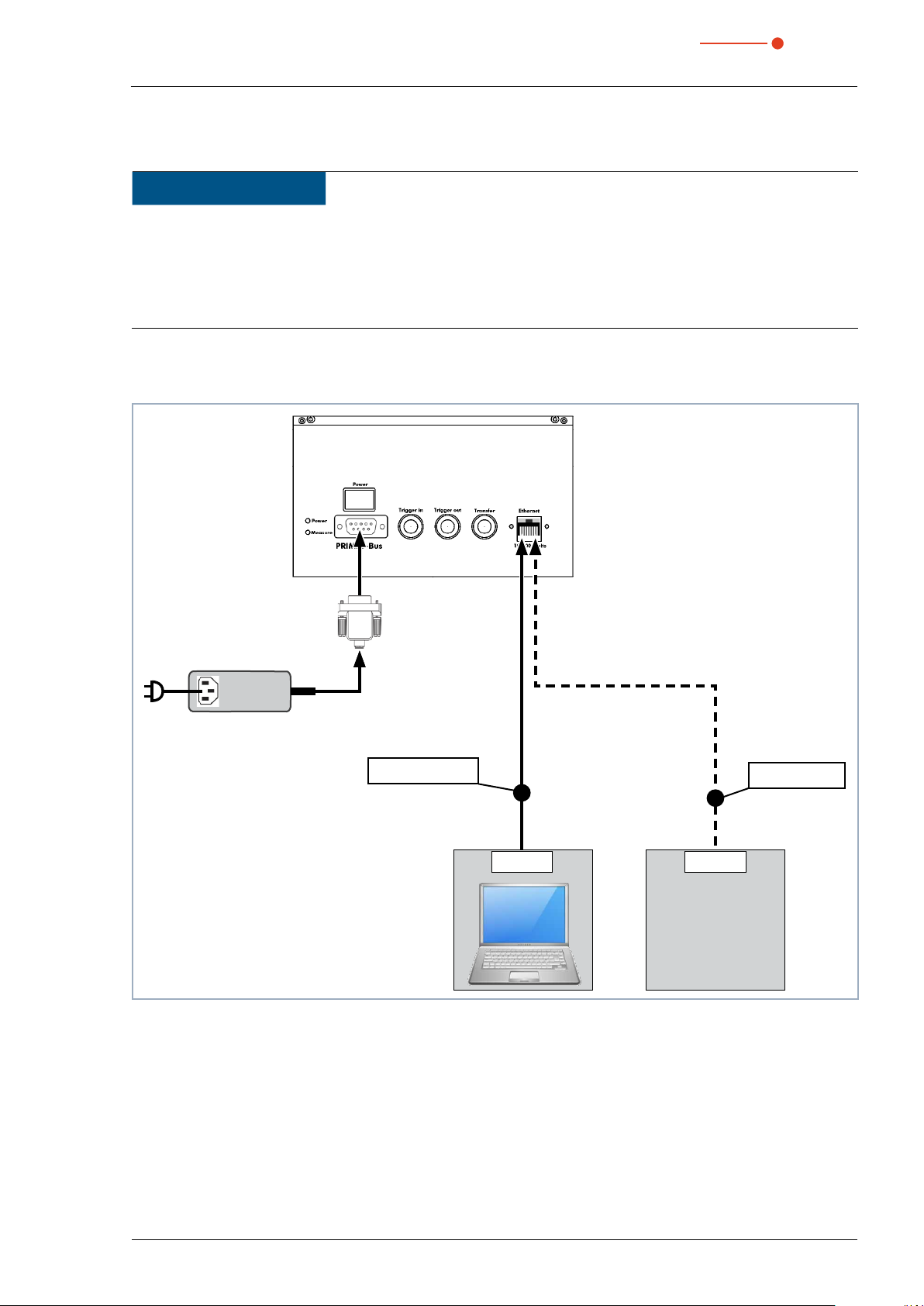

1. Connect the device with the PC via a crossover cable or with the network via a patch cable.

2. Use the adapter to connect the power supply to the 9-pin D-sub socket (RS485) of the device.

MSM

Adapter

PRIMES Power Supply

Crossover cable

Ethernet

PC

Fig. 9.5: Connection via Ethernet with a PC or a local network

or

Patch cable

Ethernet

LAN

Revision 01/2019 EN

27

35,0(6

10 Status LEDs

The device has two status LEDs.

Bezeichnung Farbe Bedeutung

Power Green The power supply is switched on

Measuring Yellow A measurement is running

Tab. 10.1: Description of the status LEDs on the MicroSpotMonitor MSM

Power supply

MicroSpotMonitor MSM

Measuring mode

Fig. 10.1: Status LEDs on the MicroSpotMonitor MSM

28

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

11 Installation and configuration of the LaserDiagnosticsSoftware LDS

In order to operate the measuring device, the PRIMES LaserDiagnosticsSoftware LDS has to be installed on

the computer. The program can be found on the enclosed medium.

You will find the latest version on the PRIMES website at: https://www.primes.de/en/support/downloads/

software.html.

11.1 System requirements

Operating system: Windows® 7/10

Processor: Intel® Pentium® 1GHz (or comparable processor)

Free disc space: 15 MB

Monitor: 19“ screen diagonal is recommended, resolution at least 1024x768

LDS-Version: 2.98 or higher

11.2 Installing the software

The installation of the software is menu driven and is effected by means of the enclosed medium. Please

start the installation by double-clicking the file “Setup LDS v.X.X.exe” (X = placeholder for version number)

and follow the instructions.

Fig. 11.1: Setup of the PRIMES LaserDiagnosticsSoftware LDS

If not stipulated differently, the installation software stores the main program “LaserDiagnosticsSoftware.

exe” in the directory “Programs/PRIMES/LDS”. Moreover, the settings file “laserds.ini” is also copied into this

directory. In the file “laserds.ini” the setting parameters for the PRIMES measuring devices are stored.

Revision 01/2019 EN

29

35,0(6

11.3 Ethernet configuration

11.3.1 Enter IP address

The MicroSpotMonitor MSM has a fixed IP address that is specified on the type plate:

• If the MicroSpotMonitor MSM is connected directly to the PC, enter the fixed IP address in the

menu Communication > Free Communication (see chapter 11.3.2 on page 31).

• If the MicroSpotMonitor MSM is connected over a network, the MicroSpotMonitor MSM will

spend about one minute pulling up a variable IP address in the network.

You can read off this variable IP address with the provided software, “PrimesFindlp” and enter it

into the Communication > Free Communication (see chapter 11.3.2 on page 31)

• If you want to connect the MicroSpotMonitor MSM to the network using the fixed IP address,

first turn on the MicroSpotMonitor MSM and then connect the network cable to the MicroSpotMonitor MSM. Then enter the fixed IP address in the menu Communication > Free Commu-

nication (see chapter 11.3.2 on page 31).

The standard IP address of the MicroSpotMonitor MSM is:

IP Address: 192.168.116.84

Subnet mask: 255.255.255.0

MicroSpotMonitor MSM

The PC must also have an IP address in the same subnet, for example:

IP Address: 192.168.116.XXX

Subnet mask: 255.255.255.0

The first three blocks of the IP address must match the IP of the MicroSpotMonitor MSM.

Type plate MSM

192

168

255

255

116

255800

Fig. 11.2: Ethernet configuration in the dialogue window Ethernet

30

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

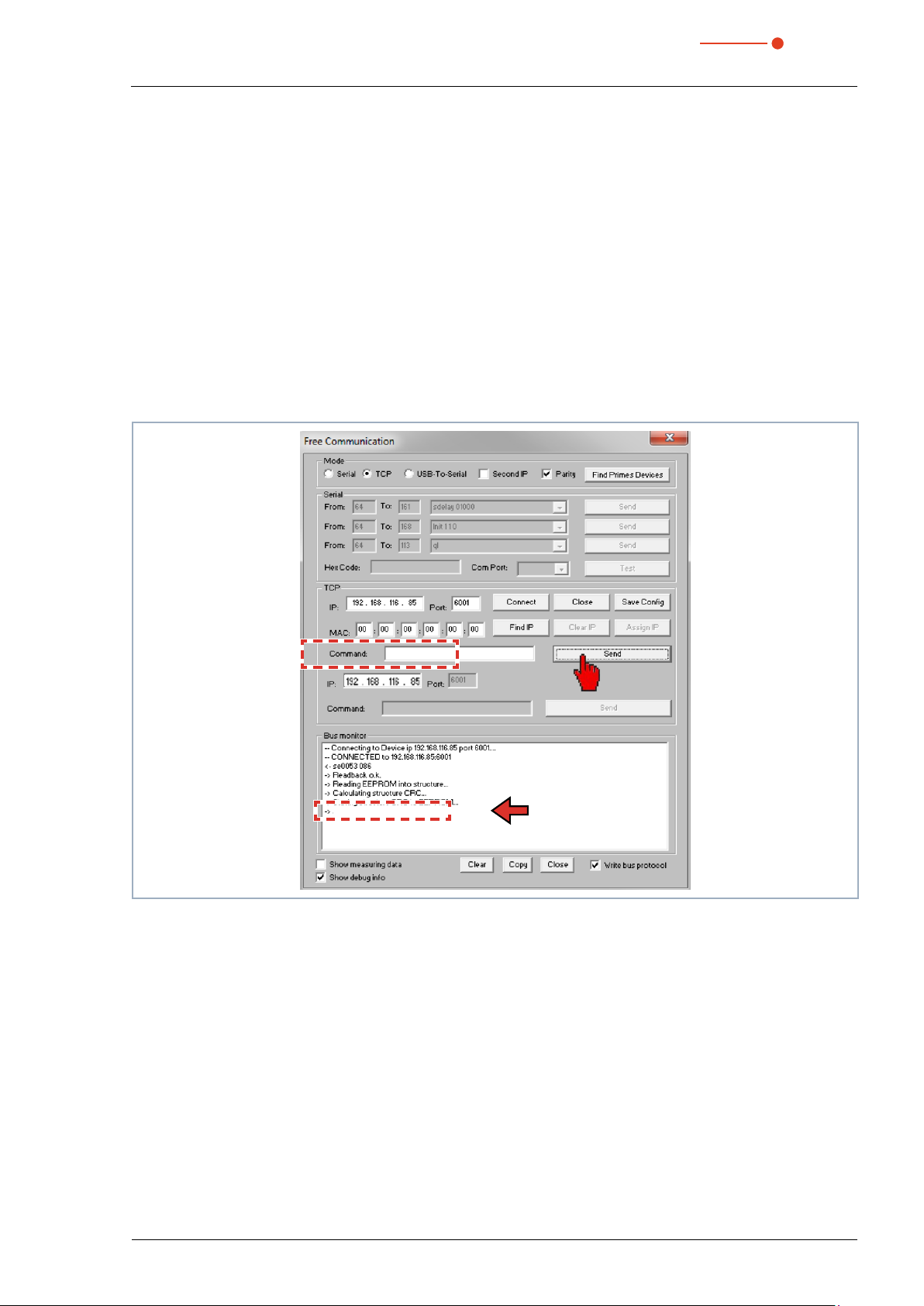

11.3.2 Establishing a connection to PC (menu Communication > Free Communication)

1. Please start the LaserDiagnosticsSoftware LDS (see chapter 12 on page 34).

2. Open the dialogue window Communication > Free Communication.

3. Choose in the field “Mode” TCP (the option “Second IP” must not be activated!).

4. Enter in the field “TCP” the IP Address.

5. Click on the Connect button (“connected” appears in the bus monitor).

6. Click on the Find Primes Devices button.

7. Click on the Safe Config button (the configuration is saved and does not need to be re-entered when

starting the LaserDiagnosticsSoftware LDS again).

192 168 116 84

Fig. 11.3: Establishing a connection in the dialogue window Free Communication

Revision 01/2019 EN

31

MicroSpotMonitor MSM

35,0(6

11.3.3 Changing the standard IP address of the device (menu Communication > Free Communication)

If the fixed IP address of the MicroSpotMonitor MSM conflicts with another device bearing the same IP address on the network, the fixed IP address of the MicroSpotMonitor MSM can be changed.

NOTICE

Device malfunction due to erroneous entries

While changing the IP address, it is possible that another EE cell might be overwritten by a

mistype, for example, and the MicroSpotMonitor MSM could thus be rendered unusable.

Only very skilled users should attempt to change the IP address.

X

You can change the preset IP address in the menu Communication > Free communication by means of

the following commands:

IP-address

(Sample address)

Commands

Tab. 11.1: Changing the IP address

In this case xyz are place holders of the four IP-address bytes (values 1 - 254) which always have to be

entered with three digits!

For example, the number 84 has to be entered like this: 084.

For reasons of clarity the symbol marks a space.

192. 168. 116. 85

se0328wxyz se0329xyz se0330xyz se0331xyz

32

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

Example: You will change the IP address from 192.168.116.85 to 192.168.116.86.

1. Please start the LaserDiagnosticsSoftware LDS (see chapter 12 on page 34).

2. Open the dialogue window Communication > Free Communication.

3. Choose in the field “Mode” TCP (the option “Second IP” must not be activated!).

4. Enter the current IP address in the “TCP” field.

5. Click on the Connect button (“connected” appears in the bus monitor).

6. Activate the check box Write bus protocol (the protocol can be helpful in case of problems):

• The protocol is stored in the installation index of the LaserDiagnosticsSoftware LDS.

• The file name is buspro.log.YYYY/MM/DD (YYYY/MM/DD = date file was created).

7. Enter the following in the field “Command”: se0331086

(please make sure that the blank character is entered correctly).

8. Click on the Send button and wait for the confirmation in the bus monitor

(see Fig. 11.4 on page 33 „-> Adr:0331 Wert: 086“)

9. Please turn off the device and turn it on again. After the restart the IP-address is updated.

se0331 086

Adr: 0331 Wert:086

Confirmation

Fig. 11.4: Changing the IP address in the dialogue window Free Communication

Revision 01/2019 EN

33

MicroSpotMonitor MSM

35,0(6

12 Description of the LaserDiagnosticsSoftware LDS

The LaserDiagnosticsSoftware LDS is the control centre for all PRIMES measuring devices which measures

the beam distribution as well as focus geometries by means of which the beam propagation characteristics

can be determined.

The LaserDiagnosticsSoftware LDS includes all functions necessary for the control of measurements and

displays the measuring results graphically.

Moreover, the systems uses the measured data to carry out an evaluation in order to give the operator of the

beam diagnosis an information regarding the reliability of the measuring results.

Please do not start the LaserDiagnosticsSoftware LDS before all devices are connected and turned

on.

Please start the program by double-clicking the LDS symbol

link.

in the new start menu group or the desktop

12.1 Graphical user interface

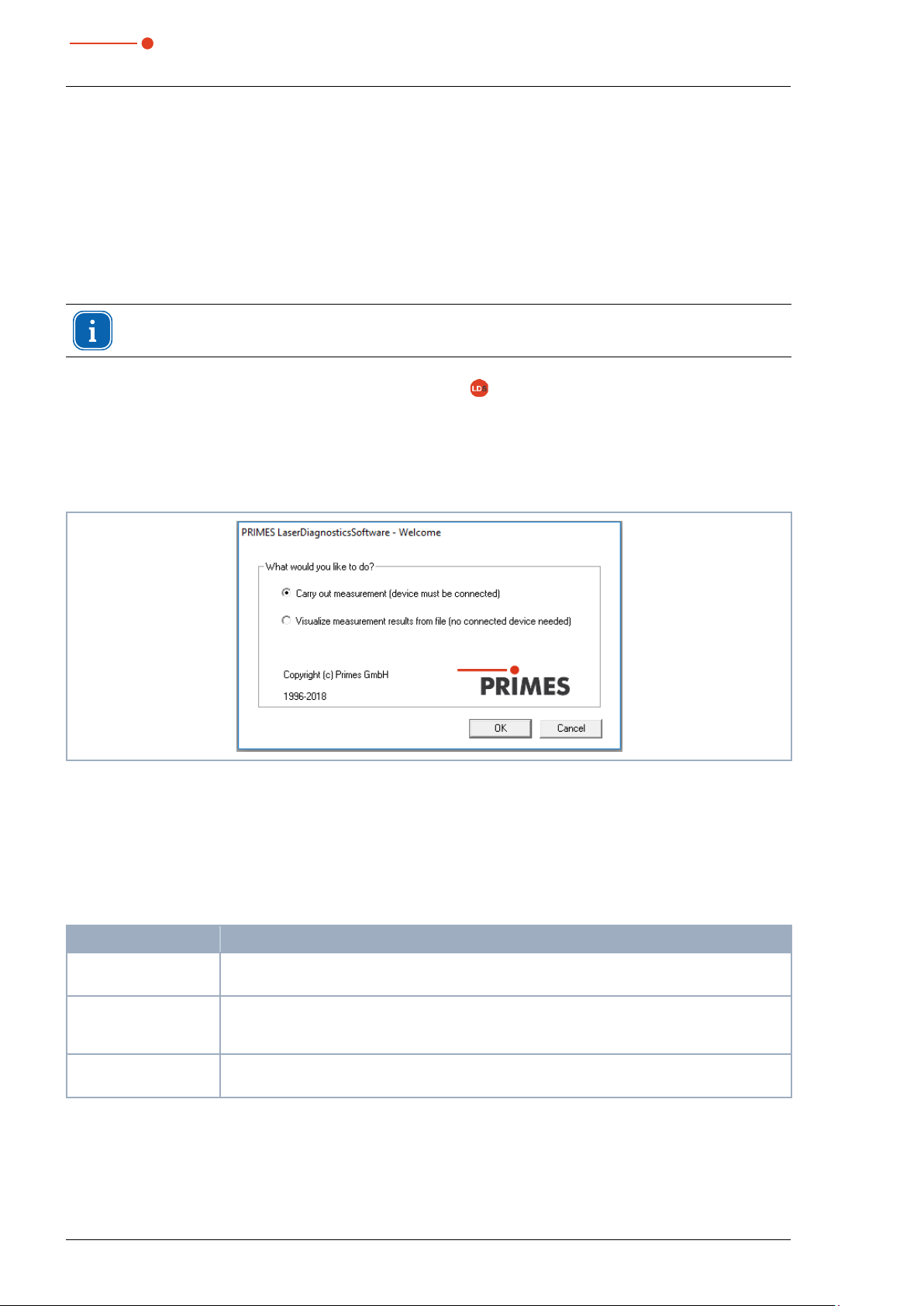

Firstly, a start window is opened in which you can choose, whether you would like to measure or whether

you would just like to depict an existing measurement (factory setting “measurement”).

Fig. 12.1: Start window of the LaserDiagnosticsSoftware LDS

After the detection of the connected device, the graphical user interface and several important dialogue

windows are opened.

In order to ensure that corresponding information can be assigned quickly, special markups for menu items,

menu paths and texts of the user interface will be used in the following chapters.

Markup Description

Text Marks menu items.

Text1 > Text2 Marks the navigation to certain menu items.

Text Marks buttons, options and fields.

Fig. 12.2: Special markups for menu items, menu paths and texts

34

Example: Dialogue window Sensor parameters

The Order of the menus is depicted by means of the Sign “>”

Example: Presentation > Caustic

Example: With the button Start

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

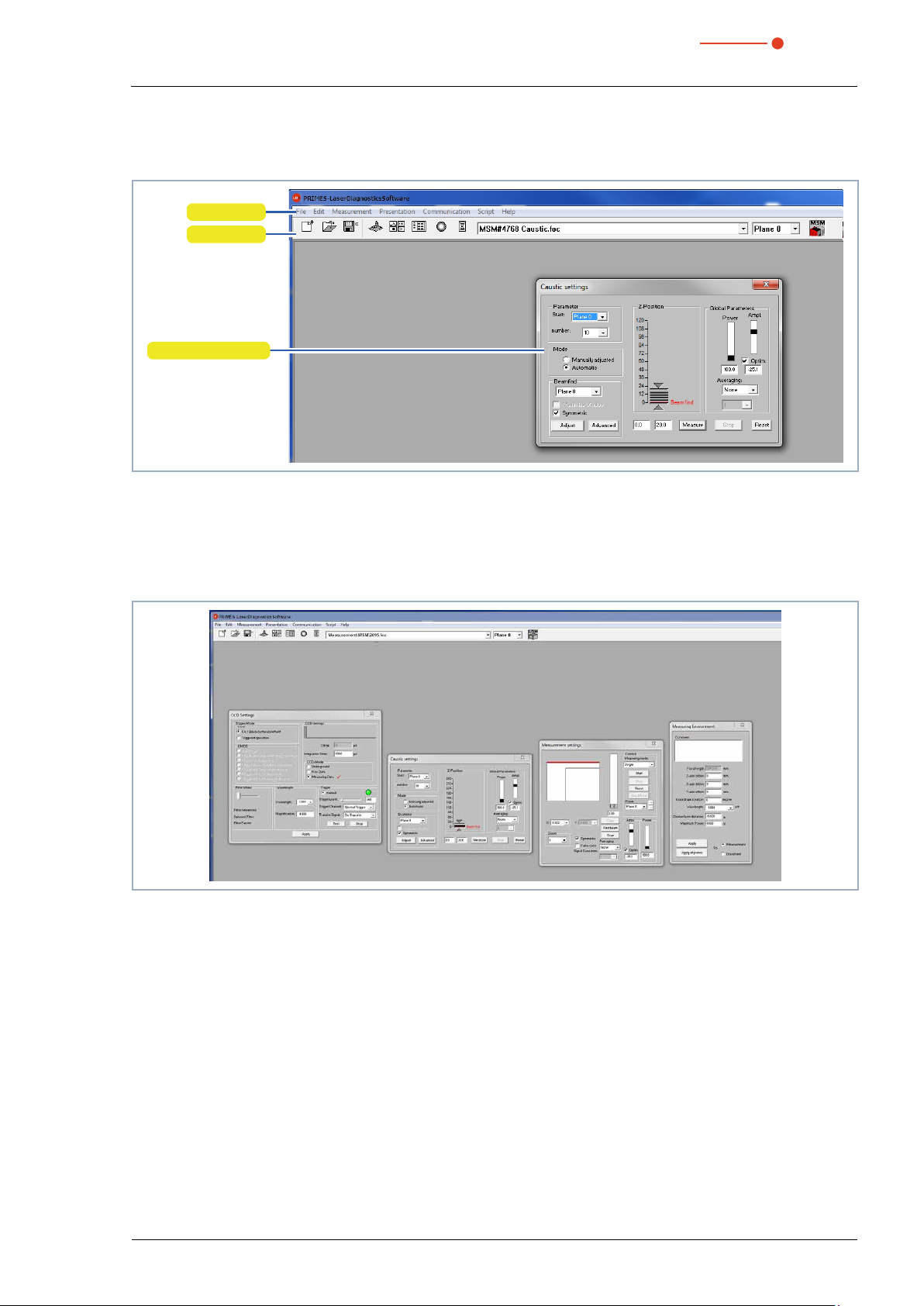

The graphical user interface mainly consists of the menu as well as the toolbar by means of which different

dialogue or display windows can be called up.

Menu bar

Tool bar

Dialogue window

Fig. 12.3: The main elements of the user interface

It is possible to open several measuring and dialogue windows simultaneously. In this case, windows that are

basically important (for the measurement or the communication) remain in the foreground. All other dialog

windows fade into the background as soon as a new window opens.

Fig. 12.4: The main dialogue windows

Revision 01/2019 EN

35

35,0(6

12.1.1 The menu bar

In the menu bar, all main and sub menus offered by the program can be opened.

MicroSpotMonitor MSM

Fig. 12.5: Menu bar

36

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

12.1.2 The toolbar

By clicking the symbols in the toolbar, the following program menus can be opened.

File administration Notation File selection Plane selection

1 2 3 4 5 6 7 8 9 10 11

Fig. 12.6: Symbols in the toolbar

1 - Create a new data record

2 - Open an existing data record

3 - Save the current data record

4 - Open the isometric view of the selected data record

5 - Open the variable contours line view

6 - Open review (86%)

7 - Open false color depiction

8 - Caustic presentation 2D

9 - List with all data records opened

10 - Display of the selected measuring plane

11 - Display of the measuring devices available for the bus by means of graphical symbols

All measuring results are always written into the document selected in the toolbar.

It is only possible to display documents chosen here. After opening, the data set has to be explicitly selected.

Revision 01/2019 EN

37

35,0(6

12.1.3 Menu overview

File

New Opens a new file for the measuring data

Open Opens a measuring file with the extensions “.foc” or “.mdf”

Close Closes the file selected in the toolbar

Close all Closes all files opened

Save Saves the current file in foc- or mdf format

MicroSpotMonitor MSM

Save as Opens the menu for the storage of the files selected in the toolbar. Only files with the

Export Exports all current data in protocol format “.xls” and “.pkl”

Load measurement preferences

Save measurement preferences

Protocol Starts a protocol of the numeric results. They can either be written into a file or a data

Print Opens the standard print menu

Print preview Shows the content of the printing order

Recently opened files Shows the file opened before

Exit Terminates the program

Edit

Copy Copies the current window to the clipboard

Clear plane Deletes the data of the plane selected in the toolbar

Clear all planes Deletes all data of the file selected in the toolbar

Change user level By entering a password a different user level can be activated.

Measurement

extensions “.foc” or “.mdf” can be imported safely

Opens a file with measurement settings with the extension “.ptx”

Opens the menu to save the settings of the last program run. Only files with the extension “.ptx” can be opened

base

Environment Different system parameters can be entered, e.g.:

- Reference value for the laser power

- Focal length

- Wavelength

- Comment

- Device offset (Not relevant for MicrosSpotMonitor MSM)

Sensor parameters The following device parameters can be e.g. set here:

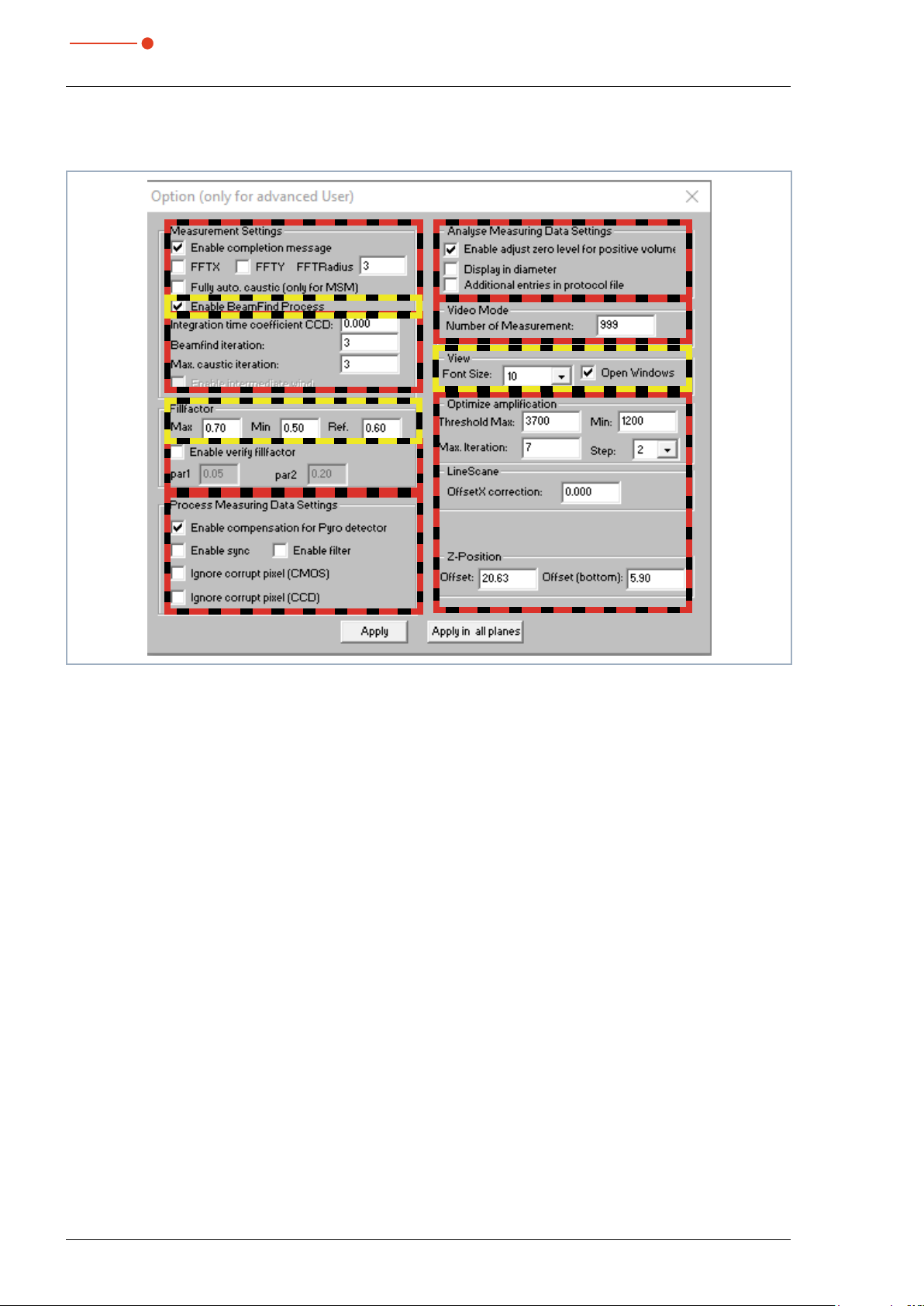

- The mechanical locked area of the z-axis

- The spatial resolution (32, 64, 128 or 256 Pixel)

- The manual settings of the z-axis

- Choosing the measuring devices connected to the bus

- Deactivating the z-axis

Beamfind settings Not relevant for MicrosSpotMonitor MSM

CCD info Provides information on device parameters

CCD settings Special settings can be made, e.g.:

- Trigger mode

- Trigger level

- Exposure time

- Wave length

38

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

LQM-Adjustment Not relevant for MicrosSpotMonitor MSM

Power measurement Not relevant for MicrosSpotMonitor MSM

Single This menu item enables the start of single measurements, of the monitor mode and the

Caustic Enables the start of a caustic measurement. Not only automatic measurements but also

Start adjustment mode Not relevant for MicrosSpotMonitor MSM

Options Enables the setting of device parameters

Presentation

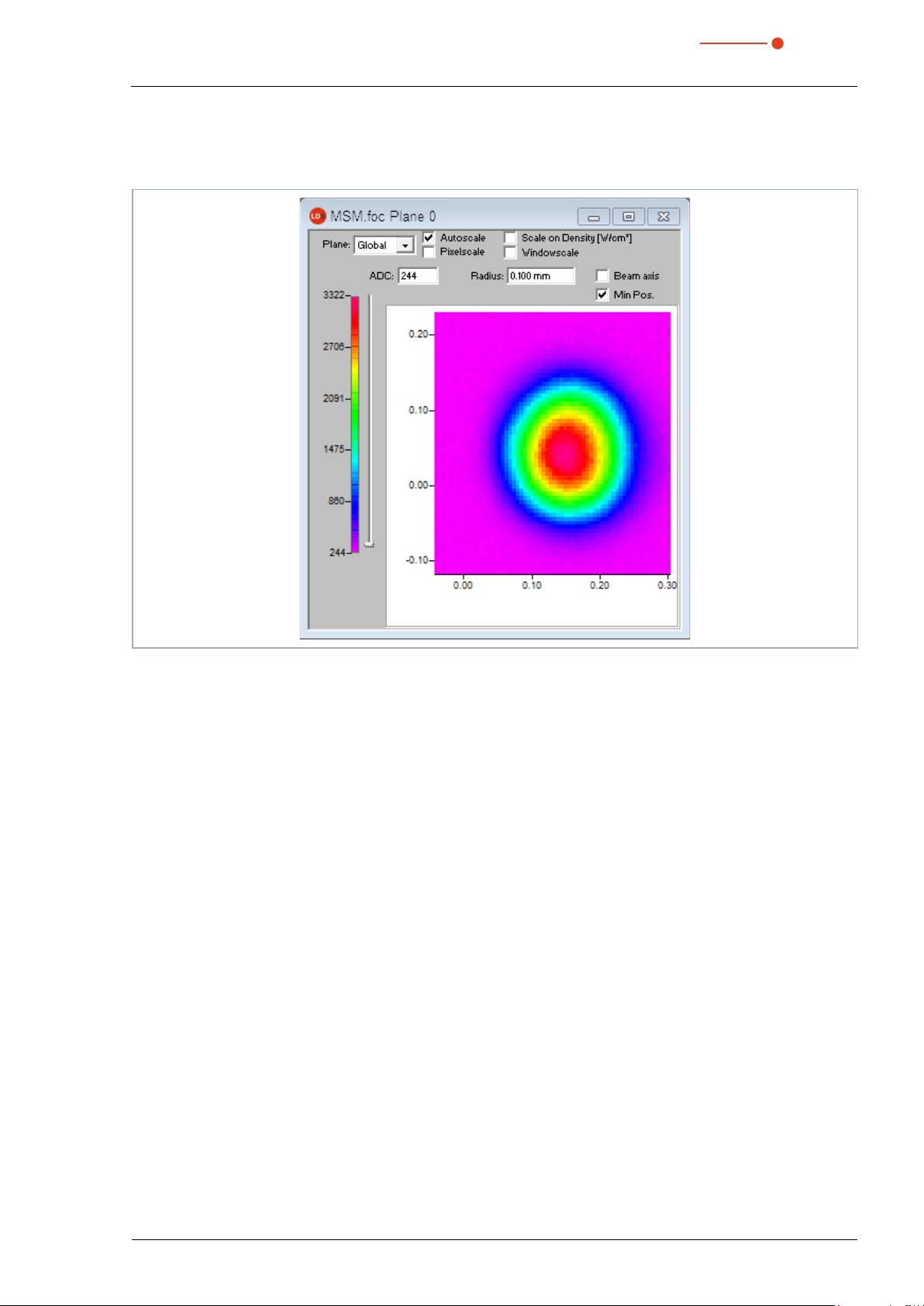

False colors False color display of the spatial power density distribution

False colors (filtered) Usage of a spatial filtration (spline function) on the false color display of the power den-

Isometry 3-dimensional display of the spatial power density distribution

Isometry 3D Allows a 3D display of caustic and power density distribution with spatial rotation as well

Review (86%) Numerical overview of measuring results in the different layers basing on the 86% beam

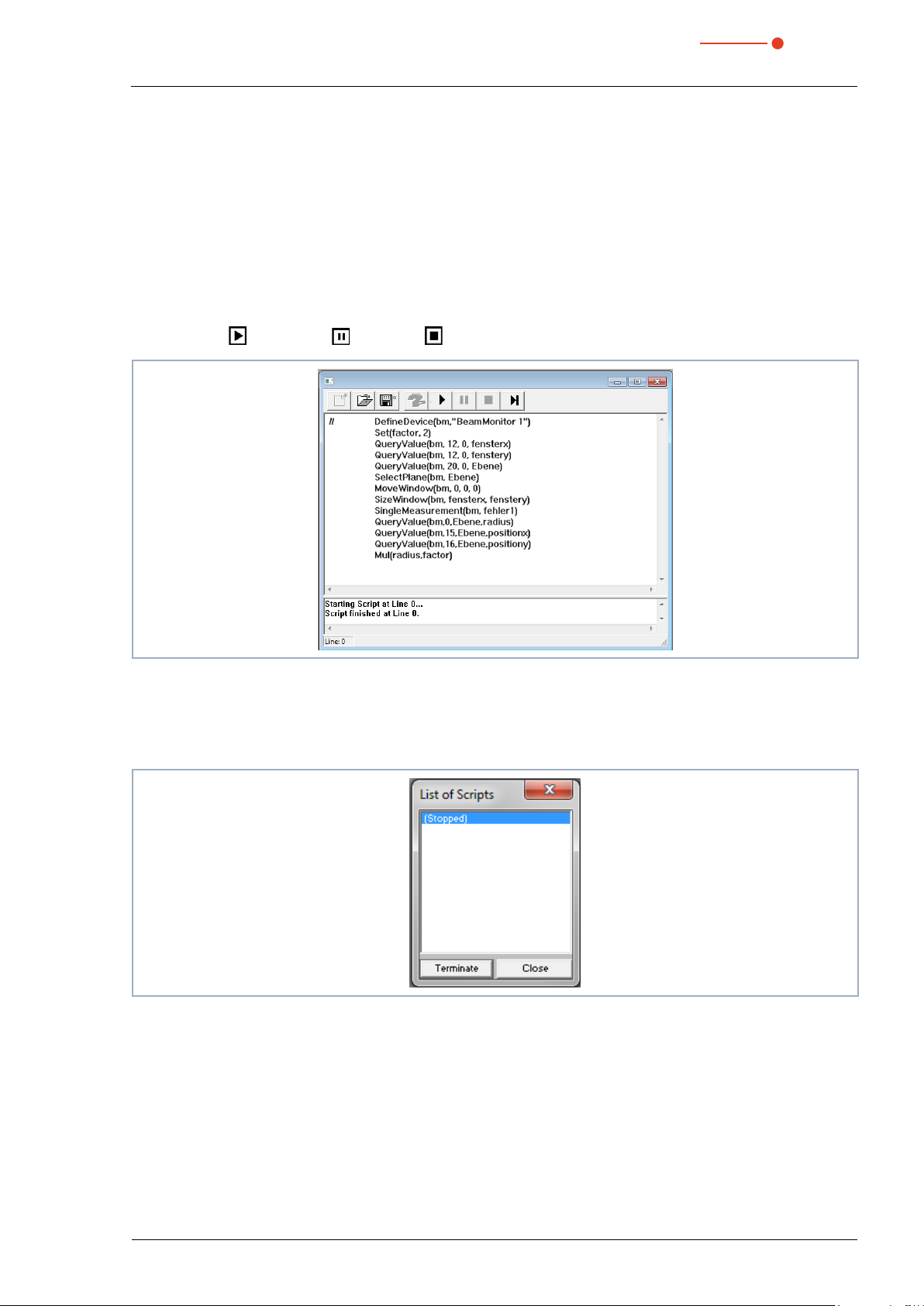

Review (2. moment) Numerical overview of the measuring results in the different layers basing on the 2. mo-

Caustic Results of the caustic measurement and the results of the caustic fit – such as beam

video mode

serial measurements of manually set parameters are possible. The automatic measurement starts with a beam search and then caries out the entire measuring procedure

independently. Only the z-range that is to be examined as well as the desired measuring

plane have to entered

sity distribution

as an optional isophote display

radius definition

ment beam radius definition

quality factor M², focus position and focus radius

Raw beam Not relevant for MicrosSpotMonitor MSM

Symmetry check Analysis tool to check the beam symmetry especially for the alignment of laser resona-

Fixed contour lines Display of the spatial laser density distribution with fixed intersection lines for 6 different

Variable contour lines Display of the spatial power density distribution with freely selectable intersection lines

Graphical review Enables a selection of graphical displays – among them the radius, the x- and y- position

System state Not relevant for MicrosSpotMonitor MSM

Evaluation parameter Loading stored evaluation parameters

Color tables Different color charts are available in order to analyse e.g. diffraction phenomena in detail

Toolbar In order to display or to hide the toolbar

Position Moving the device into a defined position

Evaluation Comparison of the measured values with defined limit values and evaluation (optionally)

Communication

Rescan bus The system searches the bus for the different device addresses. This is necessary

Free Communication Display of the communication on the PRIMES bus

tors. No standard feature of the device

power levels

above the z-position and the time

whenever the device configuration at the PRIMES bus was changed after starting the

software.

Scan device list Lists the device addresses of the single PRIMES devices

Revision 01/2019 EN

39

35,0(6

Script

MicroSpotMonitor MSM

Editor Opens the script generator, a tool, by means of which complex measuring procedures

List Shows a list of the opened windows

Python Opens the script generator in order to control complex measuring procedures automati-

Help

Activation Enables the activation of special functions

About LaserDiagnosticsSoftware LDS

Tab. 12.1: Menü overview

are controlled automatically (with a script language developed by PRIMES).

cally (scripting language Python)

Provides information regarding the software version

40

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

12.2 File

This menu includes – among others – the administration of measurement and setting data.

12.2.1 New (menu File > New)

By means of New a new file is created.

12.2.2 Open (menu File > Open)

By means of Open a selected file is opened.

12.2.3 Close/Close all (menu File > Close/Close all)

Close will close the file that is currently open. Close all will close all files currently open.

12.2.4 Save (menu File > Save)

The file currently opened is stored. The standard type of file is a binary file format with a minimal memory

requirements. The file ending for a measuring file of this type is “.foc”. As an alternative, it is possible to store

the data in a ASCII format with the extension “.mdf”. Information regarding the file format “.mdf” can be

found enclosed. Only files with this formats can be opened by the program (see also chapter 21.3 on page

119).

12.2.5 Save as (menu File > Save As)

You have to assign a file name, choose the storage location and the file format.

Only save the measurement data with the extensions “.foc” or “.mdf”. You can only view measurement data if the respective file was explicitly selected in the toolbar.

12.2.6 Export (menu File > Export)

Exports the pixel information of the power density distribution to a Excel table (*.xls). As an alternative, the

numeric results from a “.foc” file can be stored in a tab-separated text file (*.pkl) which can be imported into

Microsoft Excel. The pkl export function has a coordinate origin in the middle of the measuring area (yellow

dot).

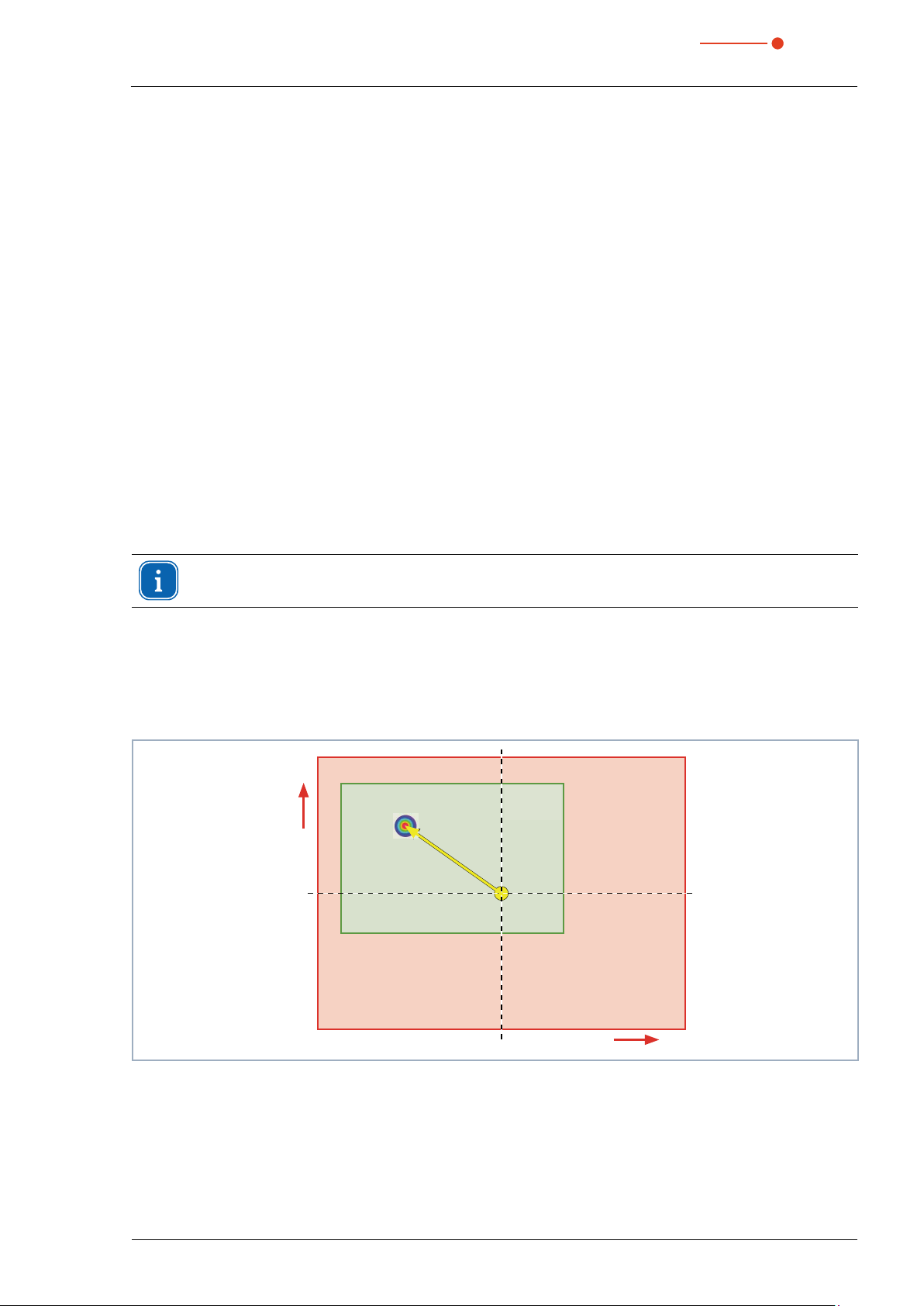

y

Laser Beam

Measurement Range

Measring

Window

Zero Point pkl-coordinates

Fig. 12.7: Coordinates of the pkl-export function (the illustration is not to scale)

Revision 01/2019 EN

x

41

MicroSpotMonitor MSM

35,0(6

12.2.7 Load measurement preferences (menu File > Load measurement preferences)

Stored settings can be resorted to with Load measurement preferences. The standardized extension for a

setting file of the MicroSpotMonitor MSM is “.ptx”.

12.2.8 Save measurement preferences (menu File > Save measurement preferences)

The current measurement settings are stored (.ptx-file).

12.2.9 Protocol (menu File > Protocol)

The calculated measurement results from a single plane can directly be written into a text file.

The following is stored:

• Date and time of the measurement

• Beam position and beam radius (according to 86%- and 2. moment method definition)

Therefore please activate the check box Write. Then you can directly enter the name in the field Filename or

you can use the standard selection menu with the button Browse.

Fig. 12.8: Window Protocol

12.2.10 Print (menu File > Print)

You can print directly from the program. The current window can be printed with the menu point Print in the

menu File. With the menu point Settings it is also possible to change the settings as far as the formats etc.

are concerned.

12.2.11 Print preview (menu File > Print preview)

Shows a preview of your printing order.

12.2.12 Recently opened files (menu File > Recently opened Files)

Selection of the files processed before.

12.2.13 Exit (menu File > Exit)

Terminates the program.

42

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

12.3 Edit

12.3.1 Copy (menu Edit > Copy)

By means of the copy function a direct export of graphics to other programs is possible. In this case the

content of the current window is transmitted to the Windows clipboard.

12.3.2 Clear plane (menu Edit > Clear plane)

The content of the actual displayed measurement plane of the measurement data set selected in the toolbar

is deleted.

12.3.3 Clear all planes (menu Edit > Clear all planes)

The content of all measurement planes of the measurement data set selected in the toolbar is deleted.

12.3.4 Change user level (menu Edit > Change User Level)

By entering a password a different user level can be activated.

Revision 01/2019 EN

43

35,0(6

12.4 Measurement

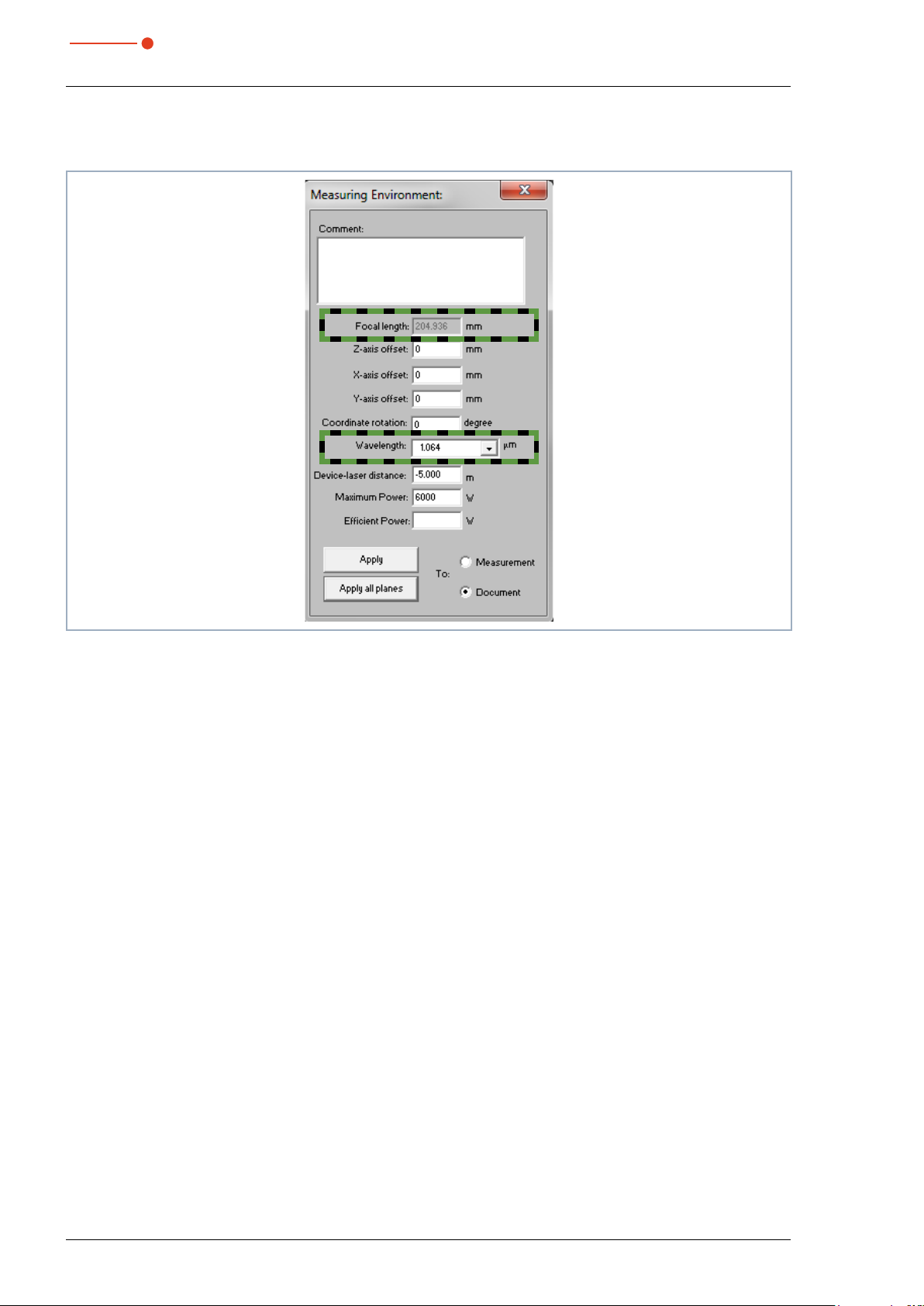

12.4.1 Measuring environment (menu Measurement > Environment)

MicroSpotMonitor MSM

Fig. 12.9: Dialogue window Measuring Environment

In the dialogue window Measuring Environment data such as the laser type, focal length etc. can be

stored. These data can be read via Presentation > Review.

Focal length

Stating the focal length is relevant for the evaluation of the caustic measurements. From the caustic process

and the entered focal length the raw beam diameter on the focussing optic can be calculated.

Wave length

The wave-length is the basis for a correct determination of the beam quality factor M². There are the following options:

• 1.064 μm for Nd:YAG laser

• 0.532 μm for Green laser

• 0.355 μm for UV laser

A wavelength can also be typed in numerically.

While only the calibration points of the measuring objective can be configured in the CCD Settingdialog window, the exact value of the laser’s wavelength can be entered in this window. This value is used in all numeric

evaluations, such as the calculation of the beam quality factor M².

Caution: If the wavelength is newly selected in the CCD Setting dialog window, the value in this

window will be overwritten with the selected calibration point.

44

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

Application

By means of the button Apply the entries can also be changed after a measurement. With the button

Apply all planes the entered values are inserted and settled, while the button Apply only refers to the value

in the current plane.

Laser power

Entering the laser power is a reference value for the relative power position in the menu point Single measurement or Caustic measurement. Furthermore, a z-axes offset as well as a coordinate rotation angle can

be entered.

Comment

Please do not use the character # in the comment field “Comment”. This character is used as a separator

in the software. If it is entered in the field “Comment”, problems could occur when it comes to storing or

activating measuring data.

A line break can be enforced by means of the key combination: <Ctrl> + <Enter>.

12.4.2 Sensor parameters (menu Measurement > Sensor parameter)

Adaptable squares

Z

Y

Fig. 12.10: Dialogue window Sensor parameters

Mechanical limits

By pulling the turquoise square with the mouse pointer you can restrict the movement range of the y- and zaxis. Therewith you can prevent damages in case other components reach into the movement range of your

device. The maximum value corresponds to the value Y3 and Z3.

Device

By means of this option, you can select the device which is supposed to be operated. Depending on the

number of devices connected, additional device numbers are assigned.

RPM

Not relevant for MicrosSpotMonitor MSM.

Revision 01/2019 EN

45

MicroSpotMonitor MSM

35,0(6

Resolution

Here you can enter the number of pixels in the measuring window, ranging from 32 x 32 to 256 x 256 pixels.

Generally, 64 pixels per line and a total of 64 lines is sufficient. Please keep in mind that the more pixels there

are, the longer the measurement will take.

Detector

Not relevant for MicrosSpotMonitor MSM.

Manual z-axis

With this function you can deactivate the z-axes of the measuring system. This is useful if you want to use

external movement axes. In this case you can manually assign a z-value to every measurement plane in the

dialogue window Single measurement.

12.4.3 Beam find settings (menu Measurement > BeamFind Settings: Beamfind

Not relevant for MicrosSpotMonitor MSM.

46

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

12.4.4 CCD info (menu Measurement > CCD Info)

The most important device data is shown in the menu Measurement > CCD Device Info. Here you can see

the magnification information for the measuring objective and also check which beam path is turned on.

If obvious default values (1:1) are shown instead of the actual magnification, then please check the mounting

of the measurement objective.

Fig. 12.11: Window CCD Info

Revision 01/2019 EN

47

35,0(6

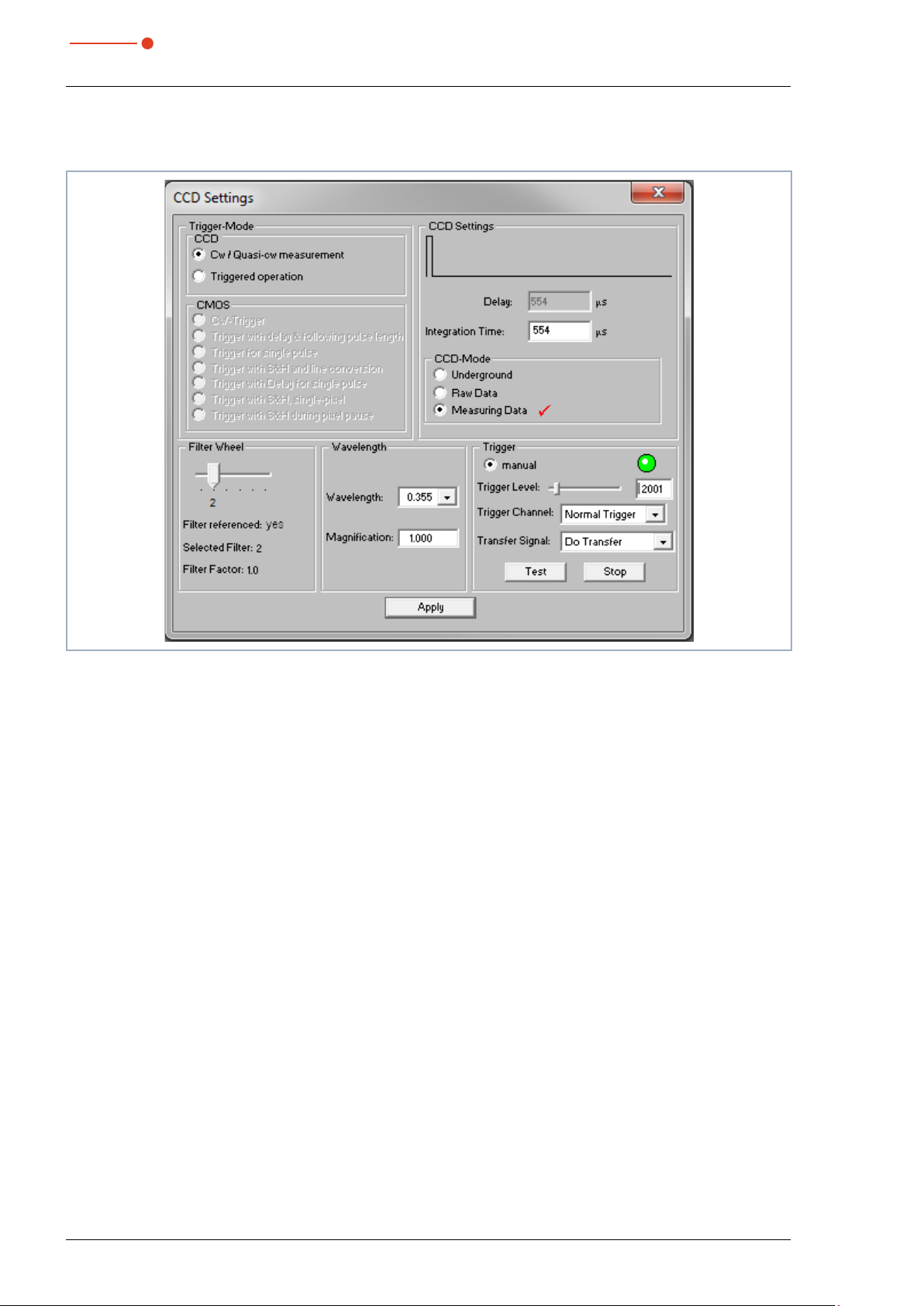

12.4.5 CCD settings (menu Measurement > CCD Settings)

MicroSpotMonitor MSM

Fig. 12.12: Dialogue window CCD Settings

The wavelength, attenuation, and operating mode are all set in the CCD Settings dialog window.

Trigger modes

The appropriate settings must be configured here in keeping with the operating mode of the laser to be measured. Here it is important to consider that pulsed lasers with a pulse frequency of more than 500 Hz can be

measured in cw mode. If, however, the operating mode is set to pulsed and a cw laser system is involved,

the measuring device will always display the error message “Error Black Pixel Measurement” or “Time Out

During Measurement” in reaction to a measurement request.

Delay

This function can only be used with a “triggered operation” trigger mode. The time the measuring system

should wait between when it detects the trigger pulse and the start of the measurement is set here. Together

with the function “Integration Duration”, defined “Windows” from the plus cycles can be measured (e.g. exactly one pulse or parts of an ms pulse. The minimum delay is 12µs.

CCD operating modes

Three different modes can be set here. If the Raw Data setting is activated, the measuring system will return

the uncompensated data of the CCD when a measurement is requested. Especially with NIR irradiation,

these can be riddled with measuring errors such as “smear effect” readout noise. Even the numeric beam

data generated generated from this data will be affected by this.

If a Background is selected as the operating mode, only correction data will be returned while measuring.

Measuring Data mode should always be the default setting here though. Only when this mode is turned on

can the measuring system deliver reliable measuring values.

48

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

Integration duration

This function sets a defined integration duration. The optimizer must be deactivated before this can be accomplished, since otherwise the measuring device itself will optimize and thus change the integration duration. This function is also used mainly in measuring pulsed laser systems.

Filter wheel

Which filter is needed for measuring depends on the wavelength and the intensity of the laser beam being

measured and the appropriate one must be chosen specifically for each measuring task.

A filter can be considered suitable when all measuring planes of a caustic measurement can be measured

using an exposure time between 18ms (-20dB) and 0.18ms (-60dB). Outside of these limits, the S/N ratio

of the CCD declines, thus reducing the accuracy.

Wavelength

Due to the wavelength-dependent overall magnification of the camera-based measuring system, it is important to check that the right selections have been made before each measurement. The wavelengths shown

here represent the calibration points of the measuring objective. As a result of the achromatic properties of

the measuring objective, a wavelength range between 1030 and 1100 can be achieved, for example, with a

calibration point at 1064 nm without causing generating measuring errors.

Trigger

The trigger menu is only pertinent when measuring pulsed laser systems. A fixed value (2001) is generally

specified for the trigger diode by default. This value describes the threshold value at which a trigger signal

is emitted. If you switch the trigger to automatic, the trigger level will first be set to the maximum value. The

Test button is renamed in Optimize. In the optimize routine (laser must be turned on), the trigger threshold

is lowered gradually until the MicroSpotMonitor starts receiving trigger signals (lower trigger level). The trigger

level is then increased until the MicroSpotMonitor stops receiving trigger signals (top trigger level). The final

trigger level is determined by calculating the arithmetic mean of the two limit values. External trigger entry

can be activated via the menu point Trigger Channel. Transfer signal pertains to the transfer output of the

MicroSpotMonitor. Here it is possible to define the CCD sensor state at which there should be a trigger signal

(e.g. for turning on the laser).

Fig. 12.13: Trigger connections

Revision 01/2019 EN

Input

external trigger

BNC

Ausgang

Interer Trigger

BNC

49

35,0(6

12.4.6 LQM adjustment (menu Measurement > LQM Adjustment)

Not relevant for MicrosSpotMonitor MSM.

12.4.7 Power measurement (menu Measurement > Power Measurement)

Not relevant for MicrosSpotMonitor MSM.

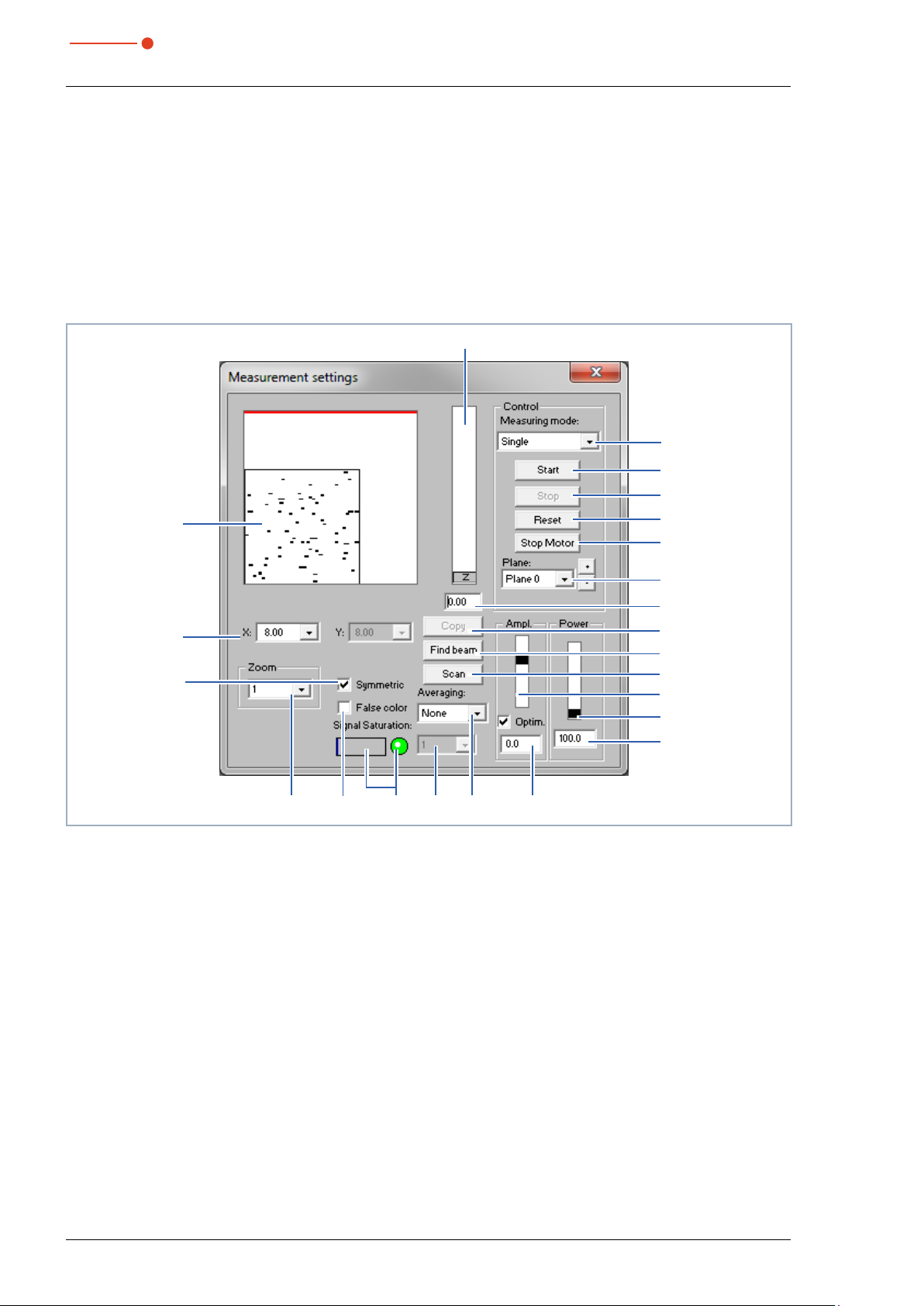

12.4.8 Single (menu Measurement > Single)

23

22

MicroSpotMonitor MSM

1

2

3

4

5

21

20

Fig. 12.14: Dialogue window Measurement settings

6

7

8

9

10

11

12

13

141516171819

50

Revision 01/2019 EN

MicroSpotMonitor MSM

35,0(6

1 Single

Monitor

Video Mode

2 Start Starts a measurement in the currently chosen plane

3 Stop Finishes the measurement in the currently chosen plane

4 Reset The measuring device is reset

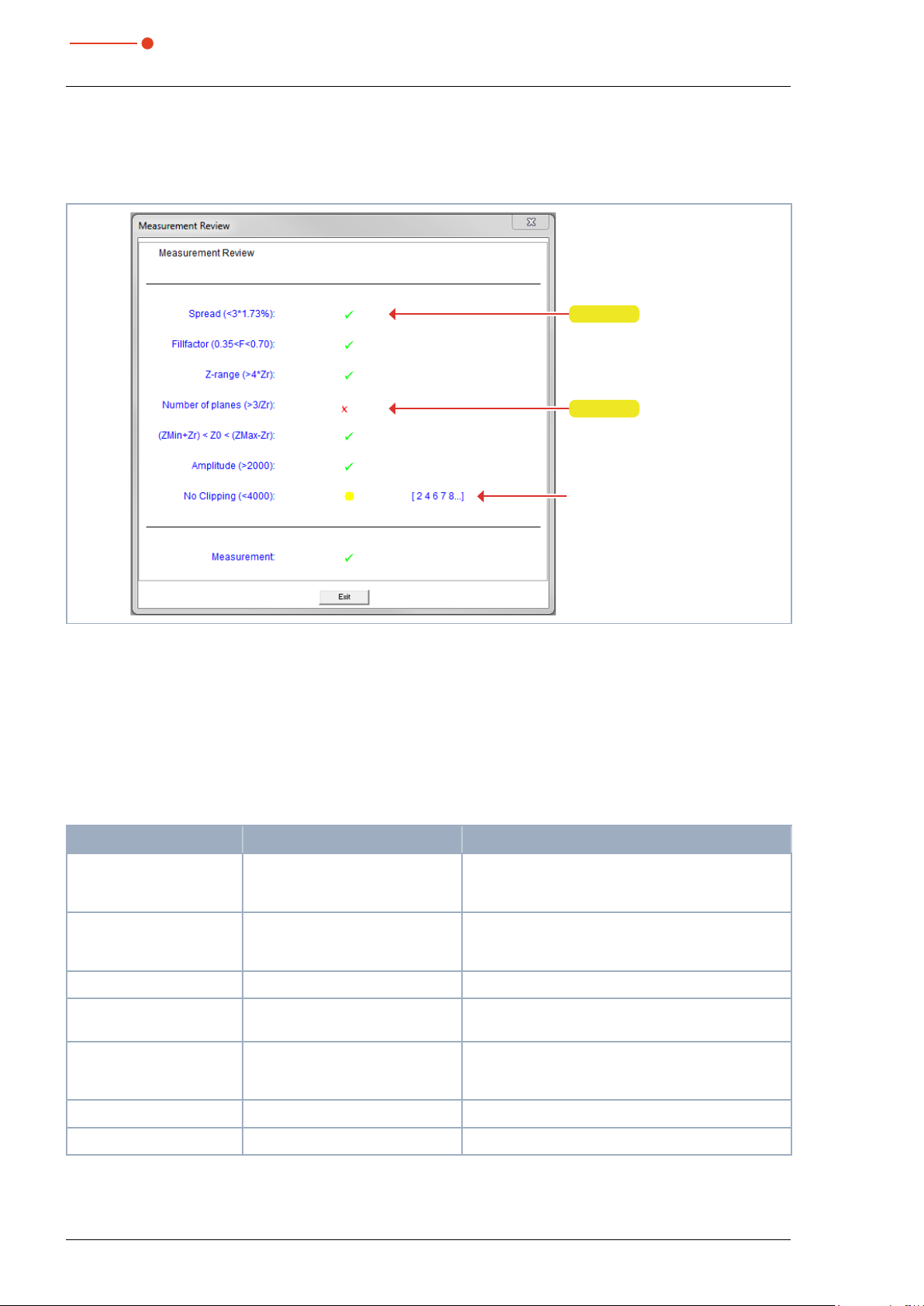

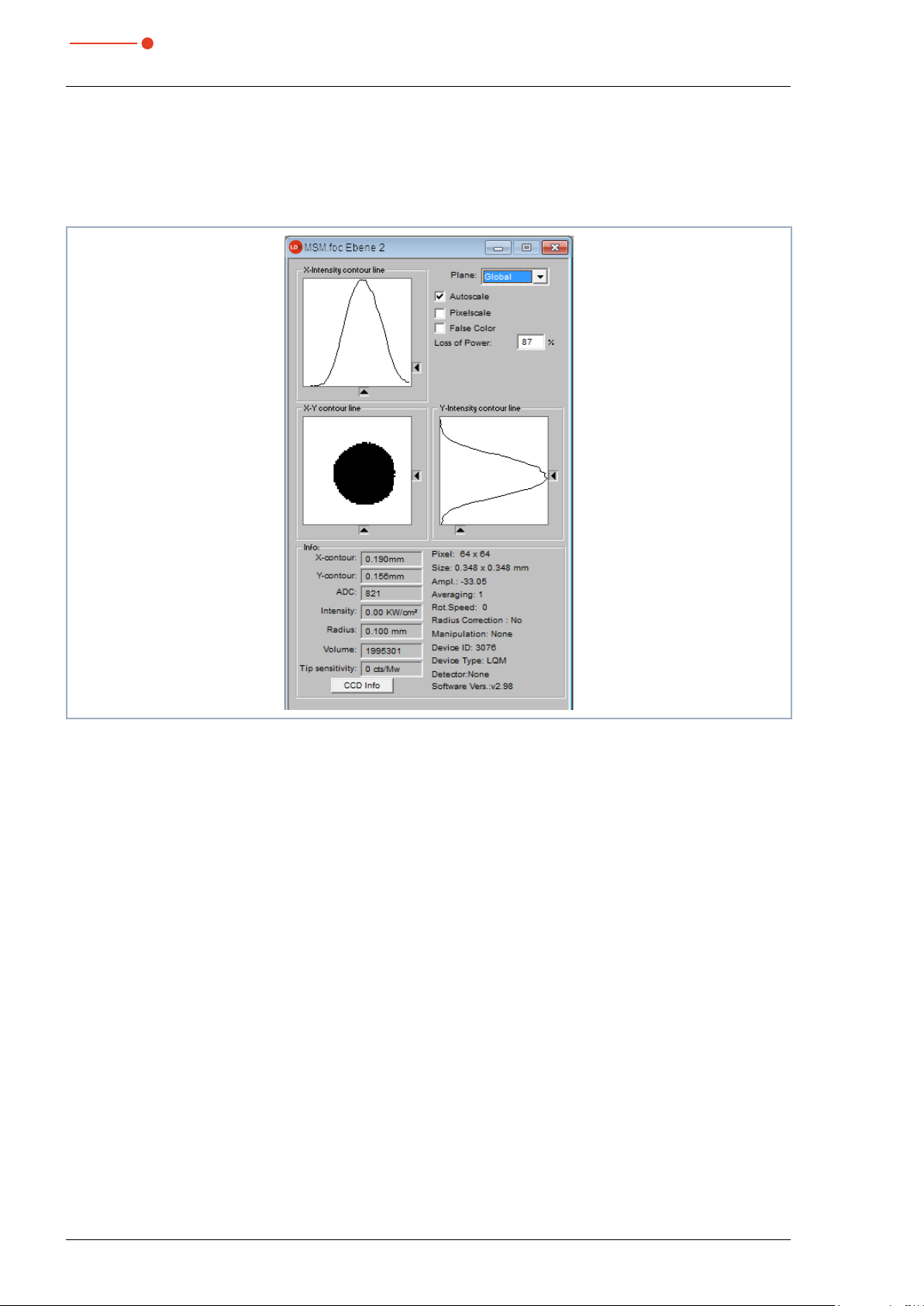

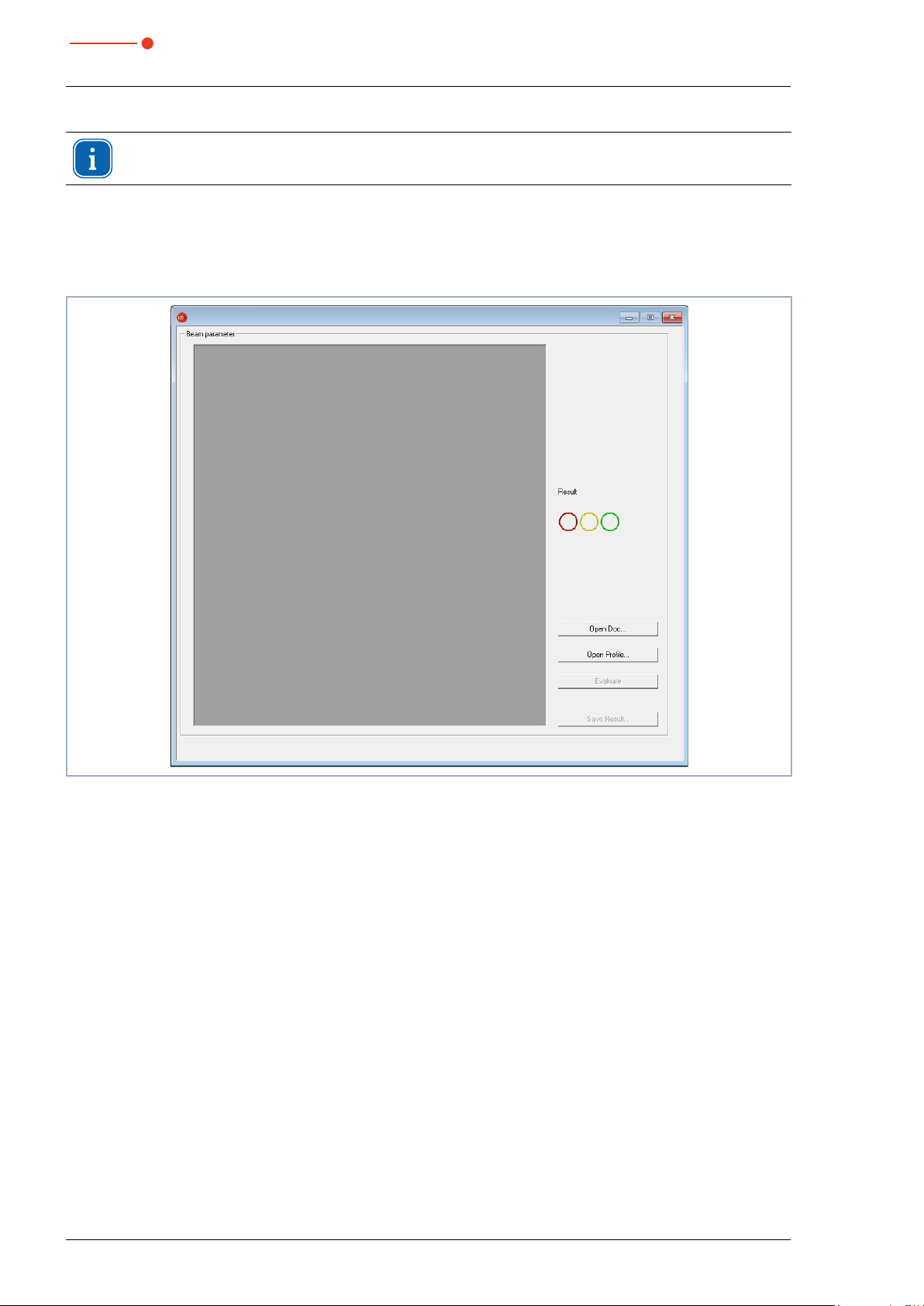

5 Stop Motor Not relevant for MicrosSpotMonitor MSM