Revision 01/2018 EN

FocusMonitor FMW+

Additional Documentation to the Operating Manual

FocusMonitor FM+

35,0(6

Short Start Guide

Translation of the Original Instructions

FocusMonitor FMW+

3

Revision 01/2018 EN

35,0(6

IMPORTANT!

READ CAREFULLY BEFORE USE.

KEEP FOR FUTURE USE.

FocusMonitor FMW+

4

Revision 01/2018 EN

35,0(6

Contents

1 About this documentation 5

2 Distinguishing features in comparison with the standard device 5

3 Connections 5

4 Status display 6

5 Adapt device 6

5.1 Inserting the measuring tip ........................................................................................................7

6 Hinweise zum Absorber 9

7 Mounting/Dismounting 9

7.1 Installation position ....................................................................................................................9

7.2 Alignment ..................................................................................................................................9

8 Electrical connection 10

8.1 Connection to the PC/LAN and establishing the power supply ................................................10

9 Measuring with the LaserDiagnosticsSoftware LDS 11

9.1 Single plane measurement ......................................................................................................11

9.2 Caustic measurement .............................................................................................................15

9.3 Measuring mode Monitor ......................................................................................................20

10 Declaration of conformity 24

11 Technical data 25

12 Dimensions 26

13 Appendix 27

13.1 Exchanging the measuring tip ................................................................................................27

13.2 Exchanging the detector .........................................................................................................29

FocusMonitor FMW+

5

Revision 01/2018 EN

35,0(6

1 About this documentation

This documentation describes the special version „FocusMonitor FMW+“ of the PRIMES measuring device

“FocusMonitor FM+” and presents the differences. It supplements the standard operating manual of the

FocusMonitor FM+.

IMPORTANT!

Please pay special attention to the safety instructions given in the standard operating manual of the

FocusMonitor FM+.

2 Distinguishing features in comparison with the standard device

• The FocusMonitor FMW+ does not have an integrated z-axis. For the measurement the focus is moved

along the axis by the system. Information regarding the z-position can either be entered manually via the

settings dialogue (measurement >> single measurement) in the LaserDiagnosticsSoftware.

• An absorber is integrated into the measuring device (maximum absorber power of 1000 watts).

• The maximum energy per measurement is 90kJ (max. irradiation time=90s at 1000Watt).

• The measuring device does not have a protective gas connection

• Direct connection to the PC via Ethernet.

3 Connections

LED display

On/off switch

Ethernet connection RJ-45

Power supply connection

Fig. 3.1: Connections of the FMW+

FocusMonitor FMW+

6

Revision 01/2018 EN

35,0(6

4 Status display

The different operating modes are indicated by three LEDs.

Designation Color Meaning

Measuring Red Measurement is running

Rotation Orange Motor is running

Power White Voltage is applied (24V)

5 Adapt device

Depending on the laser type the corresponding measuring tip and a suitable detector have to be used. The

DFIG-PS+ detector is included ex works; the measuring tip has to be mounted by the customer.

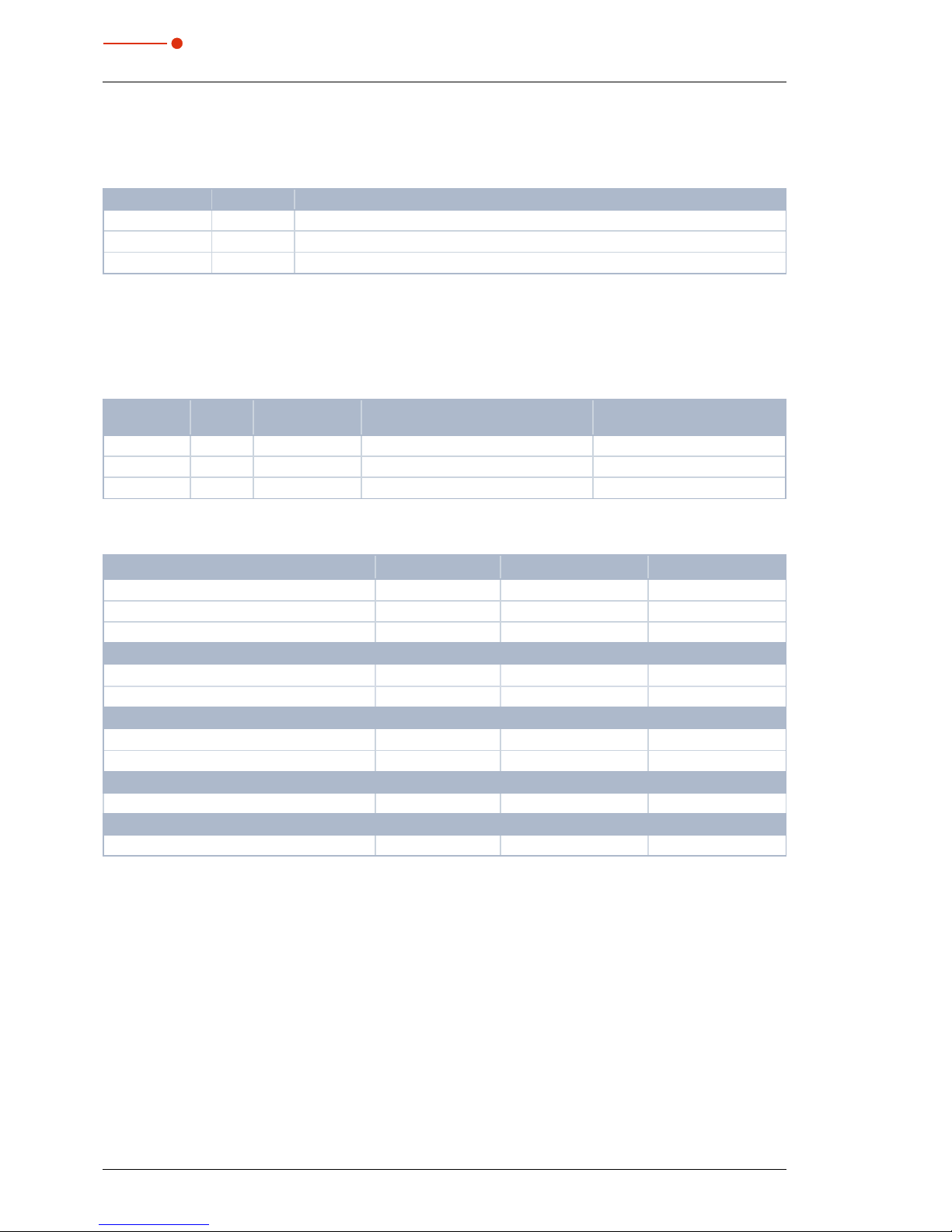

Detector

type

Laser Type of Sensor Amplification Wavelength range in μm

DFC+ CO

2 Pyro-detector 1 9 − 12

DFY-PS+ NIR/VIS Photodiode Automatic adaptation of the sensitivity 0.4 − 1.1

DFIG-PS+ NIR Photodiode Automatic adaptation of the sensitivity 1 − 2.1

Tab. 5.1: Variety of detectors

Measuring tip High Power CO

2

High Div YAG Diode Tip

Typical pin hole diameter in µm 20-25 20 50

Beam divergence/acceptance angle in mrad < 240 < 200 < 500

Typical wavelength in µm 9-12 0.4-1.1 0.4-1.0

CO

2

Laser

Max. power density

*

)

in MW/cm2

30 — —

Max. power in kW 1 — —

Nd:YAG Laser

Max. power density

*

)

in MW/cm

2

— 10 1

Max. power in kW — 1 1

Diode Laser

Max. power density in MW/cm

2

— 1 1

Suitable Detectors

Detector type DFC+ DFIG-PS+, DFY-PS+ DFIG-PS+, DFY-PS+

Tab. 5.2: Variety of measurement tips and detectors

*) Please note the damage threshold in the Operating Manual FocusMonitor FM+.

FocusMonitor FMW+

7

Revision 01/2018 EN

35,0(6

5.1 Inserting the measuring tip

To prevent transport damage, the measuring tip is disassembled when delivered. It is to be installed with the

curved part facing towards the beam source.

There are different measurement tips available for different wavelengths (see Tab. 5.2 on page6).

NOTICE

Danger of damaging the measuring tip

The small drill hole in the measuring tip can be blocked easily by dirt particles or by

touching it with bare hands.

When mounting/dismounting the tip, please wear powder-free latex gloves and ensure a

dirt- and dust-free environment.

1. Turn off the supply voltage.

2. Turn the drive wheel (see Fig. 5.4) clockwise until the disc extends approx. 15mm into the measuring

window in a positive y-direction.

Drive wheel

Disc with measuring tip retaner

Fig. 5.1: Moving the disc into the measuring window

3. Turn the disc until the measuring tip retainer becomes visible in the opening of the housing.

4. Remove the fastening screws (Torx T8) as well as the retaining plate.

5. Carefully insert the new measuring tip in the disc (caution, the entrance aperture is located on the arched

side of the tip, see Fig. 5.2).

FocusMonitor FMW+

8

Revision 01/2018 EN

35,0(6

Entrance aperture

Fig. 5.2: Entrance aperture (pinhole) in the measuring tip

Fig. 5.3: Inserting the measuring tip

6. Insert the retaining plate in the disc with the guidance groove pointing upwards and an angle of 45 degrees and press it downwards into the opening (see Fig. 5.4).

Fig. 5.4: Inserting the retaining plate

7. Insert the screws and fasten them hand-tight.

8. Move the measuring tip out of the measuring window to ensure it is protected.

When turning the supply voltage back on, the measuring head automatically moves back into its

resting position.

FocusMonitor FMW+

9

Revision 01/2018 EN

35,0(6

6 Notes on the absorber

The high-power absorber can absorb an energy application of 90 kJ (1000 W · 90 s).

NOTICE

Risk of damage caused by overheating

The absorber is equipped with an alarm siren that warns of overheating. It activates when

the absorber casing reaches a temperature of 60 °C.

In case of alarm, immediately turn off the laser and allow the absorber to cool!

NOTICE

Risk of burns

The laser beam can make the surface of the absorber very hot.

Do not touch the absorber during or immediately after a measurement!

7 Mounting/Dismounting

7.1 Installation position

The FMW+ was designed for a vertical beam incidence from above.

7.2 Alignment

1. When positioning the device in x- and y- direction,

please make sure that the laser beam hits the

center of the semi-circle in the inlet aperture.

Air in

Air out

Power

Position of the laser beam

FocusMonitor FMW+

10

Revision 01/2018 EN

35,0(6

8 Electrical connection

The FMW+ requires a voltage supply of 24VDC for the operation. A suitable power supply is included in the

scope of delivery. Use only the included cable to connect the power supply with the local power supply.

Data is transmitted between the FocusMonitor FMW+ and PC/LAN via the Ethernet connection.

8.1 Connection to the PC/LAN and establishing the power supply

Offset: 10.6 mm

Measuring

Rotation

Power

x

+

-

+

y

FMW

+

FocusMonitor

Ethernet

Power In

Ethernet crossover cable

Ethernet

PC

FMW+

PRIMES power supply

Fig. 8.1: Connection of FMW+

Connect the FMW+ to the PC via a crossover cable or to the network via a patch cable.

FocusMonitor FMW+

11

Revision 01/2018 EN

35,0(6

9 Measuring with the LaserDiagnosticsSoftware LDS

With the FocusMonitor FMW+, you can measure one or more planes. Since the FocusMonitor FMW+ does

not have its own mobile z-axis, the system must move the focusing lens or the device in this direction when

measuring multiple planes.

You will find detailed explanations concerning the settings and measuring mode in the operating manuals of

the FM+ and LaserDiagnosticsSoftware LDS.

9.1 Single plane measurement

9.1.1 Connect the device with the LaserDiagnosticsSoftware LDS

1. Switch on the FocusMonitor FMW+.

The operating mode is shown in

the status display (see chapter 4 on

page6).

2. Start the LaserDiagnosticsSoftware

LDS.

3. Click on the Devices tab.

4. Click on the + Connect to device

button under the tab.

The Connections window appears.

5. Click on the desired device.

6. Click on the Connect to device button.

The FocusMonitor FMW+ is estab-

lished as a connected device.

7. Click on the Scanner function.

The Device control menu opens.

Function Scanner

Device control

FocusMonitor FMW+

12

Revision 01/2018 EN

35,0(6

9.1.2 Selecting the measuring mode Single planes

1. In the Device control click on the

Measuring mode drop-down list.

2. Click on the entry Single planes.

Dropdown list Measuring mode

Measuring mode Single planes

The corresponding Device control

opens.

The Single planes toolbench opens

wit the tools Caustic analysis and

Plane analysis.

Caustic analysis Plane analysis

9.1.3 Configuring the settings (Device control > Settings)

1. Click on the Settings tab.

2. Enter the desired manual z-Position

in mm.

3. Activate the check box autom. Mea-

surement window.

4. Activate the check box autom. Gain.

• Please keep in mind that automatic

amplification is not available with the

CO

2

detector.

Only when measuring a time series

5. Enter the number of measurements.

6. Enter the measuring break between

automatic caustic measurements in s.

FocusMonitor FMW+

13

Revision 01/2018 EN

35,0(6

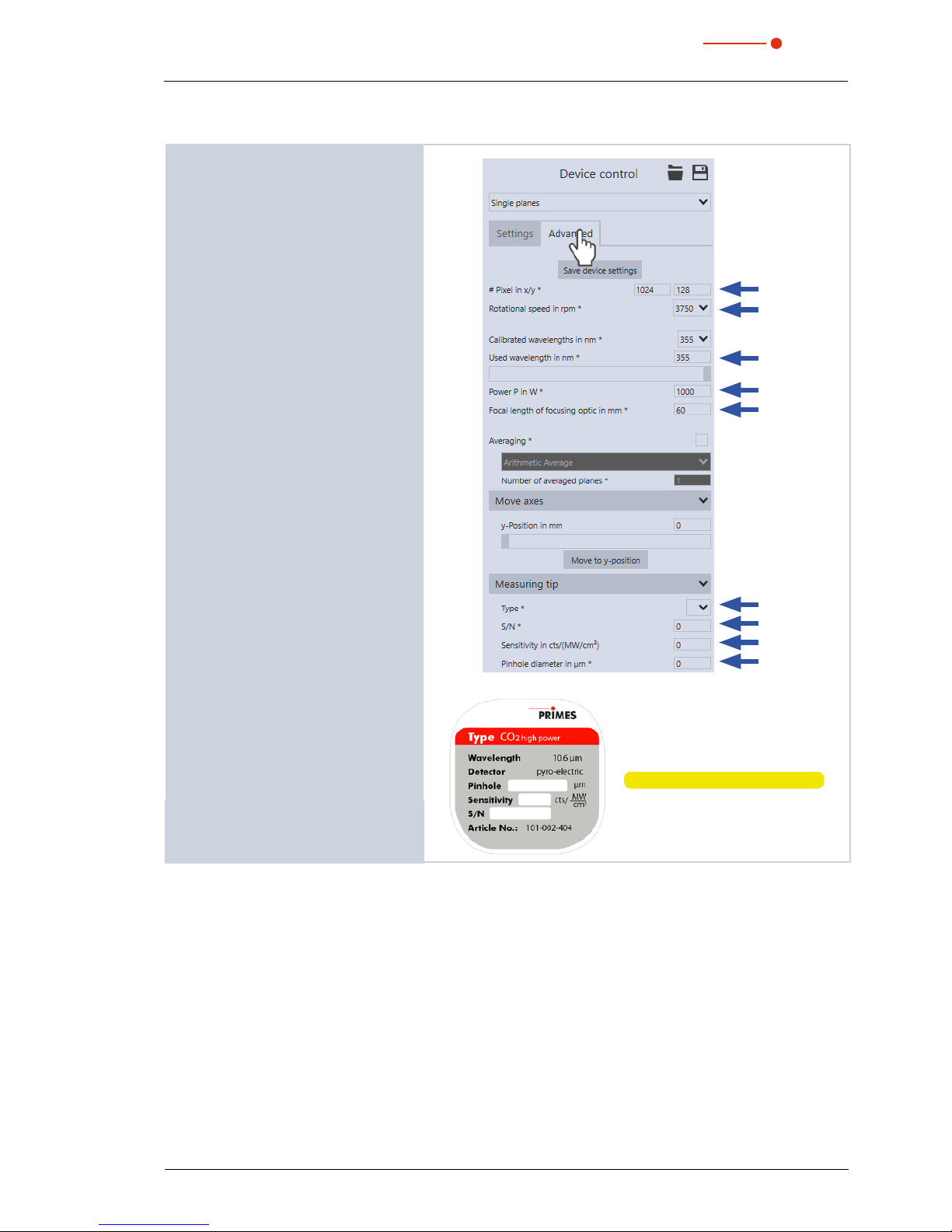

9.1.4 Configuring advanced settings (Device control > Advanced)

1. Click on the Advanced tab.

2. Enter the number of pixels in the

x/y-direction in order to configure the

resolution.

3. Select the rotation speed of the measuring tip 1875, 3750 or 7500rpm.

4. Enter the used wave length in nm.

5. Enter the laser power in Watt.

6. Enter the focal length of the focusing

optic in mm.

Move axis

With FocusMonitor FMW+, it is only possible to move along the y-axis.

• More detailed information

can be found in the manual

„LaserDiagnosticsSoftware LDS“.

Measuring tip

You will find the entry values on the label

attached to the packaging of the measuring tip used.

7. Select the type of measuring tip used.

8. Enter the serial number S/N of the

measuring tip.

9. Enter the sensitivity of the measuring

tip used in cts/(MW/cm²).

10. Enter the pinhole diameter of the

measuring tip used.

Label with measuring tip data

FocusMonitor FMW+

14

Revision 01/2018 EN

35,0(6

9.1.5 Starting measurement

1. Follow the safety instructions in the

Operating Manual „FocusMonitor

FM+“.

2. Turn on the laser.

3. Click on the Start button.

The progress of the measurement is

indicated in the status window below

the start/stop control panel.

9.1.6 Terminating measurement

In the status window below the Start/

Stop operating panel, Measuring

completed is displayed.

1. Press the Stop Rotation button.

2. Turn off the laser.

9.1.7 Measuring results display

The measuring results are displayed in the opened tools once the measurement has been completed.

Fig. 9.1: Measuring results in the opened tools

FocusMonitor FMW+

15

Revision 01/2018 EN

35,0(6

9.2 Caustic measurement

Since the FocusMonitor FMW+ does not have its own z-axis to move along, the system must move either

the device or focusing lens in this direction in order to measure the caustic.

You can enter each new z-position manually and start it manually or specify a z-increment with equidistant

offsets.

9.2.1 Checking the Alignment with the LaserDiagnosticsSoftware LDS

1. Switch on the FocusMonitor FMW+.

The operating mode is shown in

the status display (see chapter on

page4).

2. Start the LaserDiagnosticsSoftware

LDS.

3. Click on the Devices tab.

4. Click on the + Connect to device

button under the tab.

The Connections window appears.

5. Click on the desired device.

6. Click on the Connect to device button.

The FocusMonitor FMW+ is estab-

lished as a connected device.

7. Click on the Scanner function.

The Device control menu opens.

Function Scanner

Device control

FocusMonitor FMW+

16

Revision 01/2018 EN

35,0(6

9.2.2 Selecting the measuring mode Single planes

1. In the Device control click on the

Measuring mode drop-down list.

2. Click on the entry Single planes.

Dropdown list Measuring mode

Measuring mode Single planes

The corresponding Device control

opens.

The Single planes toolbench opens

wit the tools Caustic analysis and

Plane analysis.

9.2.3 Configuring the settings (Device control > Settings)

1. Click on the Settings tab.

2. Enter the desired z-increment in mm.

3. Enter the desired manual z-Position

in mm.

4. Activate the check box autom. Mea-

surement window.

5. Activate the check box autom. Gain.

• Please keep in mind that automatic

amplification is not available with the

CO

2

detector.

Only when measuring a time series

6. Enter the number of measurements.

7. Enter the measuring break between

automatic caustic measurements in s.

FocusMonitor FMW+

17

Revision 01/2018 EN

35,0(6

9.2.4 Configuring advanced settings (Device control > Advanced)

1. Click on the Advanced tab.

2. Enter the number of pixels in the

x/y-direction in order to configure the

resolution.

3. Select the rotation speed of the measuring tip 1875, 3750 or 7500rpm.

4. Enter the used wave length in nm.

5. Enter the laser power in Watt.

6. Enter the focal length of the focusing

optic in mm.

Move axis

With FocusMonitor FMW+, it is only possible to move along the y-axis.

• More detailed information

can be found in the manual

„LaserDiagnosticsSoftware LDS“.

Measuring tip

You will find the entry values on the label

attached to the packaging of the measuring tip used.

7. Select the type of measuring tip used.

8. Enter the serial number S/N of the

measuring tip.

9. Enter the sensitivity of the measuring

tip used in cts/(MW/cm²).

10. Enter the pinhole diameter of the

measuring tip used.

Label with measuring tip data

FocusMonitor FMW+

18

Revision 01/2018 EN

35,0(6

9.2.5 Starting caustic measurement

1. Follow the safety instructions in the

Operating Manual „FocusMonitor

FM+“.

2. Turn on the laser.

3. Click on the Start button.

The progress of the measurement is

indicated in the status window below

the start/stop control panel.

9.2.6 Measuring next plane

1. As soon as the Measurement completed status notification appears,

you can measure the next plane.

1. Click on the Settings tab.

2. Enter the desired offset in mm in the

z-Increment field.

3. Enter the desired start position in mm

in the z-position field.

4. As soon as the Measurement com-

pleted status notification appears,

click on Start again.

5. Repeat this process until the desired

number of planes has been achieved.

FocusMonitor FMW+

19

Revision 01/2018 EN

35,0(6

9.2.7 Terminating caustic measurement

X Click on the Stop button.

X Turn off the laser.

In the status window below the Start/

Stop operating panel, Measuring

completed is displayed.

9.2.8 Measuring results display

The measuring results are displayed in the opened tools once the measurement has been completed.

Fig. 9.2: Measuring results in the tools

FocusMonitor FMW+

20

Revision 01/2018 EN

35,0(6

9.3 Measuring mode Monitor

Monitor measuring mode was meant to be used to make adjustments. Data is not determined in this measuring mode, but rather only the desired plane is shown in false-colors.

9.3.1 Checking the Alignment with the LaserDiagnosticsSoftware LDS

1. Switch on the FocusMonitor FMW+.

The operating mode is shown in

the status display (see chapter 4 on

page6).

2. Start the LaserDiagnosticsSoftware

LDS.

3. Click on the Devices tab.

4. Click on the + Connect to device

button under the tab.

The Connections window appears.

5. Click on the desired device.

6. Click on the Connect to device button.

The FocusMonitor FMW+ is estab-

lished as a connected device.

7. Click on the Scanner function.

The Device control menu opens.

Function Scanner

Device control

FocusMonitor FMW+

21

Revision 01/2018 EN

35,0(6

9.3.2 Selecting the measuring mode Monitor

1. In the Device control click on the

Measuring mode drop-down list.

2. Click on the entry Monitor.

Drop down list Measuring mode

Measuring mode Monitor

The corresponding Device control

opens.

The Monitor toolbench opens wit the

tool False color image.

9.3.3 Configuring the settings (Device control > Settings))

1. Click on the Settings tab.

2. Enter the desired z-Position in mm.

3. Enter the desired gain in dB.

FocusMonitor FMW+

22

Revision 01/2018 EN

35,0(6

9.3.4 Configuring advanced settings (Device control > Advanced)

1. Click on the Advanced tab.

2. Select the rotation speed of the measuring tip 1875, 3750 or 7500rpm.

3. Enter the number of pixels in the

x/y-direction in order to configure the

resolution.

4. Enter the used wave length in nm.

5. Enter the laser power in Watt.

6. Enter the focal length of the focusing

optic in mm.

Move axis

These settings are not relevant to the

Monitor measuring mode.

Measuring tip

You will find the entry values on the label

attached to the packaging of the measuring tip used.

7. Select the type of measuring tip used.

8. Enter the serial number S/N of the

measuring tip.

9. Enter the sensitivity of the measuring

tip used in cts/(MW/cm²).

10. Enter the pinhole diameter of the

measuring tip used.

Label with measuring tip data

FocusMonitor FMW+

23

Revision 01/2018 EN

35,0(6

9.3.5 Starting measuring mode Monitor

1. Follow the safety instructions in the

Operating Manual „FocusMonitor

FM+“.

2. Turn on the laser.

3. Click on the Start button.

The selected planes are continu-

ally scanned in the x-y direction and

shown in the False color view tool.

9.3.6 Terminating measuring mode Monitor

1. Click on the Stop button.

2. Turn off the laser.

In the status window below the Start/

Stop operating panel, Measurement

completed is displayed.

FocusMonitor FMW+

24

Revision 01/2018 EN

35,0(6

10 Declaration of conformity

FocusMonitor FMW+

25

Revision 01/2018 EN

35,0(6

11 Technical data

Measurement parameters

Power range up to 1000W

Max. energy per measurement 90 kJ

Wavelength range 0.4 – 12 µm

Beam dimensions, typ. 150 – 3000 µm (optionally up to 5000 µm)

Function of the measuring system

Measurement window sizes 0.08 x 0.08 up to 8 x 8 mm

Optionally 0.08 x 0.08 up to 12 x 24 mm (at 64 pixel resolution)

Resolution 32 x 32 – 256 x 256 pixel

Rotation speed 1875, 3750 rpm

Supply data

Power supply 24 V DC ± 5 %, max. 1.8 A

Communication

Interfaces Ethernet

Dimensions and weight

Dimensions (L x W x H)

Height with the carrying handle folded down

185.5 x 153 x 237.5 mm

208.5mm

Weight, approx. 8 kg

Environmental conditions

Operating temperature range +10°C up to +40°C

Permissible relative humidity (non-condensing)

10 – 80%

FocusMonitor FMW+

26

Revision 01/2018 EN

35,0(6

12 Dimensions

All dimensions in mm (general tolerance ISO 2768-v)

FocusMonitor FMW+

27

Revision 01/2018 EN

35,0(6

13 Appendix

13.1 Exchanging the measuring tip

There are different measurement tips available for different wavelengths (see „Tab. 5.2: Variety of measurement tips and detectors“ on page6).

NOTICE

Danger of damaging the measuring tip

The small drill hole in the measuring tip can be blocked easily by dirt particles or by touching it with bare hands.

When mounting/dismounting the tip, please wear powder-free latex gloves and ensure a

dirt- and dust-free environment.

1. Turn off the supply voltage.

2. Turn the drive wheel (see Fig. 13.1) clockwise until the disc extends approx. 15mm into the measuring

window in a positive y-direction.

Drive wheel

Measuring tip retaner

Fig. 13.1: Moving the disc into the measuring window

3. Turn the disc until the measuring tip retainer becomes visible in the opening of the housing.

4. Remove the fastening screws (Torx T8) as well as the retaining plate.

5. Carefully insert the new measuring tip in the disc (caution, the entrance aperture is located on the arched

side of the tip, see Fig. 13.2).

FocusMonitor FMW+

28

Revision 01/2018 EN

35,0(6

Entrance aperture

Fig. 13.2: Entrance aperture (pinhole) in the measuring tip.

Fig. 13.3: Inserting the measuring tip

6. Insert the retaining plate in the disc with the guidance groove pointing upwards and an angle of 45 degrees and press it downwards into the opening (see Fig. 13.4).

Fig. 13.4: Inserting the retaining plate

7. Insert the screws and fasten them hand-tight.

8. Move the measuring tip out of the measuring window to ensure it is protected.

When turning the supply voltage back on, the measuring head automatically moves back into its

standby position.

FocusMonitor FMW+

29

Revision 01/2018 EN

35,0(6

13.2 Exchanging the detector

The NIR detector is the standard detector of the FMW+. For measurements with a CO2 laser the detector

has to be replaced by a CO2 detector.

NOTICE

Danger of damage for the detector sensor

The detector sensor must not be damaged and has to be protected from pollution.

Do not touch the detector sensor with your fingers and do not put it down on the sensor

surface.

Only use insulating plastic screws to fasten the detector to prevent noise signals. Do not forget the

foam rubber plate, otherwise the disc may be mechanically blocked by the screws.

Mounting sequence:

1. Turn off the supply voltage

2. Turn the drive wheel anti-clockwise as long as

possible. Now the detector is in its dismounting

position.

3. Carefully remove the two plugs from the detector,

for example by means of long nose pliers.

FocusMonitor FMW+

30

Revision 01/2018 EN

35,0(6

4. Remove the fastening screws on both sides of the

bottom plate (please mind that the screws have

different lengths).

5. Tilt the housing backwards.

FocusMonitor FMW+

31

Revision 01/2018 EN

35,0(6

6. Opened FMW+.

Detektor

7. Remove the plastic retaining screws of the detector with the short screw driver (included in the

scope of delivery) and carefully take the detector

out of the housing.

FocusMonitor FMW+

32

Revision 01/2018 EN

35,0(6

8. Build in the new detector in reversed order. Make

sure you do not forget the foam rubber spacer!

Attention!

If the screws are tightened too firmly, they might

block the rotary disc! Only tighten the screws

hand-tight. The foam rubber spacer may not be

compressed by more than 50% of its original

thickness!

Foam rubber spacer

Detector

x

x

2

Max.

Before

After

Foam Rubber Spacer

Loading...

Loading...