35,0(6

Operating Manual

Translation of the original instructions

Cube L1

LaserDiagnosticsSoftware LDS

Cube App

Revision 01/2019 EN

35,0(6

Cube L1

IMPORTANT!

READ CAREFULLY BEFORE USE.

KEEP FOR FUTURE USE.

Revision 01/2019 EN

3

35,0(6

Cube L1

Table of contents

1 Basic safety instructions 8

2 Symbol explanation 10

3 About this operating manual 11

4 Conditions at the installation site 11

5 Important information for devices with rechargeable lithium-ion battery 12

5.1 Charging the battery ............................................................................ 12

5.2 Storing the battery ............................................................................... 12

5.3 If the battery is damaged ..................................................................... 12

5.4 Disposing of the battery ....................................................................... 12

6 System description 13

6.1 Measuring principles ............................................................................ 13

7 Transportation 13

8 Installation/Removal 14

8.1 Prepare installation ............................................................................... 14

8.2 Mounting position ................................................................................ 15

8.2.1 Align the Cube L1 with the alignment tool ............................... 16

8.3 Install the Cube L1 ............................................................................... 17

8.4 Remove the Cube L1 ........................................................................... 18

9 Connections 19

9.1 Safety interlock .................................................................................... 19

9.2 Micro-USB socket ............................................................................... 20

9.3 Bluetooth ............................................................................................. 20

10 Control elements 21

10.1 On/Off button ....................................................................................... 21

4

Revision 01/2019 EN

35,0(6

Cube L1

11 Display on the Cube L1 21

11.1 Status messages ................................................................................. 22

11.2 Warning message ................................................................................ 22

11.3 Capacity of the rechargeable lithium ion battery ................................... 22

12 Important information for measuring with the Cube L1 23

12.1 Safety instructions................................................................................ 23

12.2 Laser parameter setting ....................................................................... 24

12.2.1 Setting the laser rise time ....................................................... 24

12.2.2 Minimum energy per single measurement............................... 25

12.3 Series measurement ............................................................................ 26

12.4 Measurement with pulsed lasers .......................................................... 27

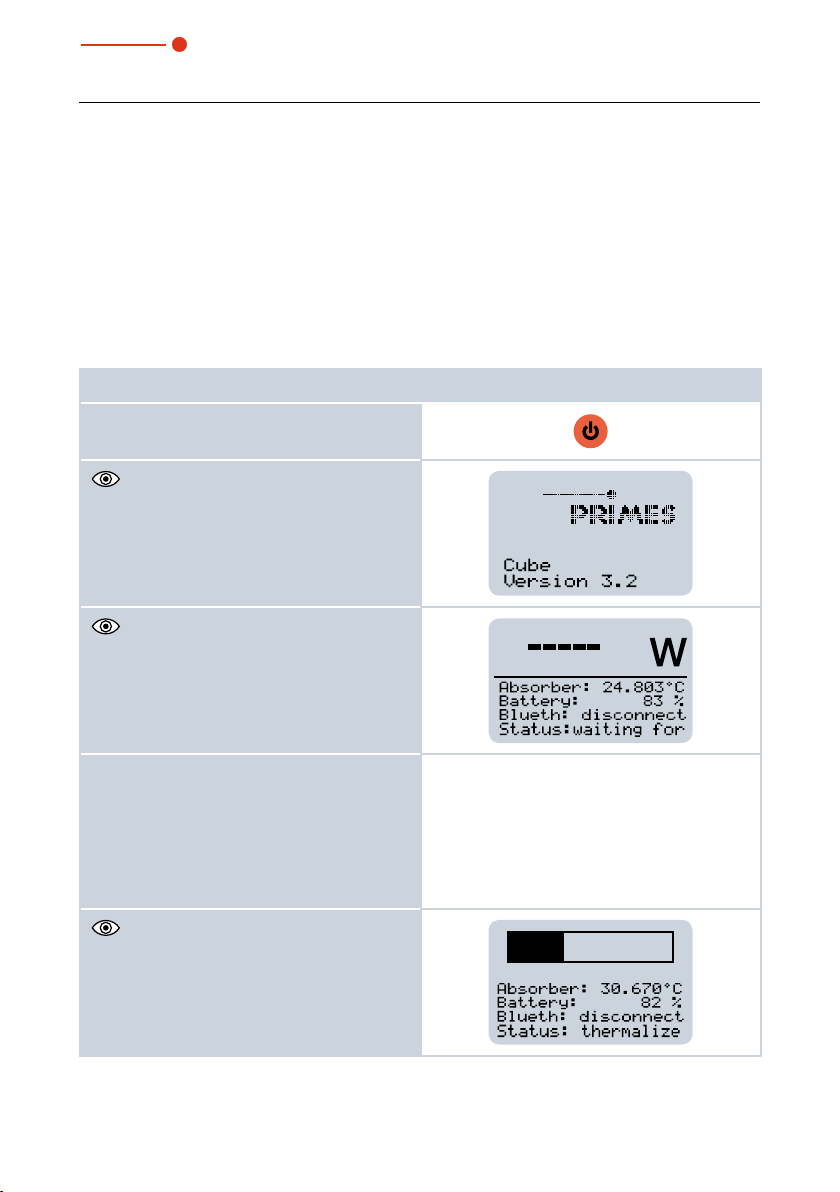

13 Measuring with the Cube L1 28

13.1 Start measurement .............................................................................. 28

13.2 Measuring results display ..................................................................... 30

14 Measuring with the optional LaserDiagnosticsSoftware LDS 31

14.1 Connect the Cube L1 with the LaserDiagnosticsSoftware LDS ............ 31

14.2 Select measurement mode CW Operation or Pulse Operation ............. 32

14.3 Make settings for power saving functions and automatic

measurement readiness ....................................................................... 33

14.4 Start measurement .............................................................................. 34

14.5 Measuring results display ..................................................................... 35

14.5.1 Displays in the toolbench CW Measurement or

Pulse Measurement ................................................................ 35

14.5.2 Displays in the toolbench Cube series ................................... 36

14.6 Load and delete measuring values ....................................................... 37

15 Measuring with the optional Cube App 38

Revision 01/2019 EN

5

35,0(6

Cube L1

16 Maintenance and service 39

16.1 Exchanging the protective window on the device ................................. 39

16.1.1 Safety instructions .................................................................. 39

16.1.2 Exchanging the protective window ......................................... 41

17 Measures for the product disposal 42

18 Declaration of conformity 43

19 Technical data 44

20 Dimensions 46

21 Appendix 47

21.1 System control (option) ........................................................................ 47

6

Revision 01/2019 EN

35,0(6

Cube L1

PRIMES - The Company

PRIMES manufactures measuring devices used to analyze laser beams. These devices

are employed for the diagnostics of high-power lasers ranging from CO

solid-state lasers to diode lasers. A wavelength range from infrared through to near UV

is covered, offering a wide variety of measuring devices to determine the following beam

parameters:

• Laser power

• Beam dimensions and position of an unfocused beam

• Beam dimensions and position of a focused beam

• Beam quality factor M²

PRIMES is responsible for both the development, production, and calibration of the

measuring devices. This guarantees optimum quality, excellent service, and a short reaction time, providing the basis for us to meet all of our customers’ requirements quickly

and reliably.

lasers and

2

PRIMES GmbH

Max-Planck-Str. 2

64319 Pfungstadt

Germany

Tel +49 6157 9878-0

info@primes.de

www.primes.de

Revision 01/2019 EN

7

35,0(6

Cube L1

1 Basic safety instructions

Intended use

The Cube L1 is used to measure power in the beam path of lasers. Please observe and

adhere to the specifications and limit values given in chapter19, „Technical data“, on

page44. Other forms of usage are improper. The information contained in this operating manual must be strictly observed to ensure proper use of the device.

Measurements with the CubeL1 should be performed exclusively with a static (unmoving) laser beam. While crossing over the absorber structure, moving beams can

produce faulty measurements during the exposure time, thus also producing the associated faulty power measurements.

Using the device for unspecified use is strictly prohibited by the manufacturer. By usage

other than intended the device can be damaged or destroyed. This poses an increased

health hazard up to fatal injuries. When operating the device, it must be ensured that

there are no potential hazards to human health.

The device itself does not emit any laser radiation. During the measurement, however, the laser beam is guided onto the device which causes reflected radiation (laser

class4). That is why the applying safety regulations are to be observed and necessary

protective measures need to be taken.

In measuring mode, the laser control’s safety interlock must be connected with the

device.

Observing applicable safety regulations

Please observe valid national and international safety regulations as stipulated in ISO/

CEN/TR standards as well as in the IEC-60825-1 regulation, in ANSIZ136 “Laser

Safety Standards” and ANSIZ136.1 “Safe Use of Lasers”, published by the American

National Standards Institute, and additional publications, such as the “Laser Safety

Basics”, the “LIA Laser Safety Guide”, the “Guide for the Selection of Laser Eye Protection” and the “Laser Safety Bulletin”, published by the Laser Institute of America, as well

as the “Guide of Control of Laser Hazards” by ACGIH.

Taking necessary safety measures

If there are people present within the danger zone of visible or invisible laser radiation,

for example near laser systems that are only partly covered, open beam guidance systems or laser processing areas, the following safety measures need to be taken:

8

Revision 01/2019 EN

35,0(6

Cube L1

• Connect the laser control’s safety interlock to the device. Check that the safety

interlock will switch off the laser properly in case of error.

• Please wear safety goggles adapted to the power, power density, laser wave

length and operating mode of the laser beam source in use.

• Depending on the laser source, it may be necessary to wear suitable protective

clothing or protective gloves.

• Please protect yourself from direct laser radiation, scattered radiation as well as

from beams generated from laser radiation (e.g. by using appropriate shielding

walls or by weakening the radiation to a harmless level).

• Please use beam guidance- or beam absorber elements which do not emit any

hazardous particles as soon as they get in contact with laser radiation and which

resist the beam sufficiently.

• Please install safety switches and/or emergency safety mechanisms which enable

an immediate closure of the laser shutter.

• Please ensure a stable mounting of the device in order to prevent a relative motion

of the device to the beam axis of the laser and thus to reduce the risk of stray

radiation. This in the only way to ensure optimum performance during the measurement.

Employing qualified personnel

The device may only be operated by qualified personnel. The qualified personnel must

have been instructed in the installation and operation of the device and must have a

basic understanding of working with high-power lasers, beam guiding systems and

focusing units.

Conversions, modifications and repairs

The device must not be modified, neither constructionally nor safety-related, without

our explicit permission. The device must not be opened e.g. to carry out unauthorized

repairs. Modifications of any kind will result in the exclusion of our liability for resulting

damages.

Liability disclaimer

The manufacturer and the distributor of the measuring devices do not claim liability

for damages or injuries of any kind resulting from an improper use or handling of the

devices or the associated software. Neither the manufacturer nor the distributor can be

held liable by the buyer or the user for damages to people, material or financial losses

due to a direct or indirect use of the measuring devices.

Revision 01/2019 EN

9

35,0(6

2 Symbol explanation

The following symbols and signal words indicate possible residual risks:

DANGER

means that death or serious physical injuries will occur if necessary safety

precautions are not taken.

WARNING

means that death or serious physical injuries can occur if necessary safety

precautions are not taken.

CAUTION

means that a slight physical injury can occur if necessary safety precautions

are not taken.

NOTICE

means that property damages can occur if necessary safety precautions are

not taken.

Cube L1

The device itself or the packing bears the following symbols to indicate requirements and possible dangers:

Read and observe the operating instructions and safety guidelines before

startup!

The device contains a non-removable lithium ion battery. In order to prevent

health hazards and damage to the environment, the battery must be disposed of as required by the applicable national and international laws.

10

Revision 01/2019 EN

35,0(6

Cube L1

Further symbols that are not safety-related:

Here you can find useful information and helpful hints.

With the CE marking the manufacturer guarantees that his product is in conformity with the EC guidelines.

Call for observing (visual feedback from the device or the software).

Call for action

X

3 About this operating manual

This documentation describes the installation and operation of the Cube L1 and performing measurements with the Cube L1, the Cube App or the optional LaserDiagnosticsSoftware LDS.

With the Cube App for mobile devices with Android™ you can operate and evaluate the

device via a smartphone/tablet. The Cube App is available for free in Google Play-Store/

Apps.

For measurement operation with a PC, the LaserDiagnosticsSoftware LDS (option)

must be installed on the PC. For a detailed description of the software installation, file

management and evaluation of the measured data, please refer to the separate operating manual LaserDiagnosticsSoftware LDS.

4 Conditions at the installation site

• The device must not be operated in a condensing atmosphere.

• The ambient air must be free of organic gases.

• Protect the device from splashes of water and dust.

• Operate the device in closed rooms only.

In industrial environments erroneous measurements may be triggered by strong electromagnetic fields. In this case we recommend EMC compliant shielding of the safety

interlock cable.

Revision 01/2019 EN

11

35,0(6

Cube L1

5 Important information for devices with rechargeable lithium-

ion battery

The device is equipped with a non-removable lithium ion battery. Please note that this

battery can catch fire at temperatures exceeding 60°C. While operating the device, it is

therefore essential to observe and adhere to the requirements of chapter19, „Technical

data“, on page44 in regards to environmental conditions.

5.1 Charging the battery

Charge the battery fully before first use. The optimal charging temperature is 20°C.

Make sure that the battery never loses its charge completely. Directly following a measurement, charge the battery to at least 80% of battery capacity. Do not leave the battery to charge unattended - overnight for example. Do not expose the device to direct

sunlight.

5.2 Storing the battery

Store the device in a cool, dry place. The optimal charge level is 80%. The optimal storage temperature is 15°C. Maintain a minimum distance of 3 m from flammable materials. Do not expose the device to direct sunlight. Please charge the battery to 80%

charging capacity every three months when the device is not in use.

5.3 If the battery is damaged

Do not open the device to replace or remove the battery. When the battery is damaged,

fluids (electrolytes) may leak out. These are flammable, contact with the eyes or skin

may cause irritation. Vapors may irritate the eyes, respiratory organs, and skin. Fire or

high temperatures can cause a serious explosion. Heating or fire can release poisonous

gases. Hazardous smoke may be released when ignited.

5.4 Disposing of the battery

In order to prevent hazards to health and damage to the environment, the device must

be disposed of as required by the applicable national and international laws. Please

send the device to PRIMES as described in chapter17, „Measures for the product

disposal“, on page42.

If you are located outside of the EU, please contact your PRIMES distribution partner for

matters concerning device disposal.

12

Revision 01/2019 EN

35,0(6

Cube L1

6 System description

Display

Safety interlock

connection

Laser beam

Protective

window

Protective win-

dow holder

On/Off button

Fig. 6.1: System description of the Cube L1

Micro-USB socket

6.1 Measuring principles

The absorber of the calorimetric measurement system is irradiated by a laser for a short

period of time. The temperature difference of the absorber between start and finish

of the laser pulse is measured. From the increase in temperature, the microprocessor

based electronics is able to calculate laser power to a high degree of accuracy.

7 Transportation

NOTICE

Damaging/Destruction of the device

Hard impacts or dropping the device can damage the optical and electrical components.

X

Handle the device carefully when transporting or installing it.

X

To avoid contamination, cover the inlet aperture with the alignment tool

provided.

X

Only transport the device in its original packaging.

Revision 01/2019 EN

13

35,0(6

Cube L1

8 Installation/Removal

8.1 Prepare installation

1. Turn off the laser source.

2. Ensure that moving parts, e.g. robot arms, etc. are at a standstill and that they

cannot be set in motion unintentionally.

DANGER

Serious eye or skin injury due to laser radiation

If the stability of the device is not guaranteed or the inlet aperture is not

centered and mounted perpendicular to the laser beam, increased scattered or directed reflection of the laser beam will occur.

X

Align the device as described in chapter 8.2 on page15.

X

Install the device according to chapter 8.3 on page17 in a way that

ensures, that the device can not shift or fall.

NOTICE

Damaging/Destruction of the device

Contamination and fingerprints on the protective window can lead to

damage or shattering or splintering of the protective window during measuring operation.

X

Do not touch the protective window.

X

Only operate the device with a clean protective window.

14

Revision 01/2019 EN

35,0(6

Cube L1

8.2 Mounting position

The Cube L1 can be mounted vertically or horizontally. The Cube L1 must be aligned to

the laser beam. The laser beam must hit the inlet aperture in the middle. Please mind

and adhere to the specifications and limit values given in chapter19, „Technical data“,

on page44.

The Cube L1 is positioned above the focus (see Fig. 8.1 on page15). Make sure that

the laser beam is convergent and the permissible power density at beam entrance is

not exceeded. The focal position of the laser beam must be located on the lower edge

of the device.

To align the Cube L1 under the laser, a alignment tool is included (see chapter 8.2.1 on

page16).

5°

Laser beam

Presentation with perpen-

dicular beam incidence

Fig. 8.1: Alignment to the laser beam

Revision 01/2019 EN

Cube L1

Focusing

plane

max. 7mmmax. 7mm

Presentation with max. angle

of incidence of 5°

15

35,0(6

Cube L1

8.2.1 Align the Cube L1 with the alignment tool

Using the alignment tool and a pilot laser beam, you can position the device with the

necessary accuracy (see Fig. 8.2 on page16):

1. Put the alignment tool on the inlet aperture.

2. Turn on the pilot laser and align the device:

• If the laser beam hits the little marking in the alignment tool, the device is aligned.

NOTICE

Damaging/Destruction of the device

The exposure with laser radiation will destroy the alignment tool and the

underlying protective window.

X

Remove the alignment tool before measurement.

Marking

Alignment tool

Fig. 8.2: Alignment of the Cube L1 using the alignment tool

16

Revision 01/2019 EN

35,0(6

Cube L1

8.3 Install the Cube L1

1. Align the device with the laser beam as described in chapter 8.2 on page15

and Fig. 8.1 on page15.

2. Install the device with the mounting threads as shown in Fig. 8.3 on page17.

3. Ensure a stable installation of the device:

• The device must not be able to move.

4. Connect the safety interlock connection cable.

5. Remove the alignment tool from the protective window of the device.

92

110

21 50 21

55

Fig. 8.3: Mounting threads in the Cube L1 housing

97

X

M6 x 10

View X

M4 x 6

Revision 01/2019 EN

17

35,0(6

Cube L1

8.4 Remove the Cube L1

1. Turn off the laser source.

2. Ensure that moving parts, e.g. robot arms, etc. are at a standstill and that they

cannot be set in motion unintentionally.

3. Unscrew the mounting screws from the mounting threads (see Fig. 8.3 on

page17).

4. Remove the safety interlock connection cable and remove the device from the

laser system.

5. Apply the alignment tool to prevent contamination of the protective window.

18

Revision 01/2019 EN

35,0(6

Cube L1

9 Connections

Safety interlock

connection

Micro-USB socket

Fig. 9.1: Connections

9.1 Safety interlock

At temperatures over 200°C, the safety interlock is triggered in order to protect the

absorber from overheating. If the absorber is hotter than 200°C, Pin3 and Pin4 will

connect.

Due to the concentration of heat in the area of the incident laser beam, the temperature

of the absorber may exceed 100°C for a short time. This brief temperature peak of the

absorber poses no danger to the absorber and the current measurement can be completed. However, if the temperature of the absorber exceeds 100°C after the measurement has been completed, the safety interlock is triggered to protect the absorber.

Once the absorber cools off, Pin1 and Pin4 of the safety interlock are connected. A

suitable 2m long connection cable is included.

Revision 01/2019 EN

19

35,0(6

NOTICE

Damaging/Destruction of the device

If the safety interlock is not connected, the device can be damaged or

destroyed due to overheating.

X

When connecting the laser control, please ensure that the laser is turned

off in case of an interruption of the connection.

Cube L1

Pin diagram safety interlock

plug (view connector side)

4

1

Tab. 9.1: Pin assignment of the safety interlock plug

3

Pin Wire color Function

4 Black Mutual pin

1 Brown Connected with pin4, when ready for

operation

3 Blue Connected with pin4, when in safety

interlock mode (absorber too hot)

9.2 Micro-USB socket

You can charge the rechargeable lithium ion battery of the device by plugging it into

the micro-USB socket on the PC. A suitable cable is included in the scope of delivery.

When using the optional LaserDiagnosticsSoftware LDS (not included in delivery), the

device communicates with the LDS via the micro-USB socket or bluetooth.

You will find the PRIMES USB-driver for all USB-capable devices on the PRIMES website at: https://www.primes.de/en/support/downloads/software.html.

9.3 Bluetooth

A class1 Bluetooth interface is integrated in the device. This enables a wireless connection with the PC, tablet or the smartphone. When connected to a PC with a class1

Bluetooth stick, the range under free space conditions is approx. 100m. After switching on the device, the Bluetooth connection is permanently active. When the Bluetooth

connection is activated, the USB interface is deactivated.

When using the optional Cube App for mobile devices with Android™ (not included in

delivery), the device communicates with the app via Bluetooth. The Cube App is available for free in Google Play-Store/Apps.

20

Revision 01/2019 EN

35,0(6

Cube L1

10 Control elements

10.1 On/Off button

The on/off button have several functions:

Keystroke Function

Short press Turn on

5seconds Turn off

2seconds Show measuring values

Press again for 2 seconds Turn over measuring value display

Tab. 10.1: On/Off button

11 Display on the Cube L1

Laser power in Watt

Battery capacity

Status message

Fig. 11.1: Display on the Cube L1

Revision 01/2019 EN

Absorber temperature

Bluetooth connection

active/inactive

21

35,0(6

Cube L1

11.1 Status messages

Status message Meaning

Waiting for laser beam The device is ready for operation, the laser can be turned on.

Check temp. The temperature gradient (change in the absorber temperature/time)

is checked. Please wait until the message disappears. Thereafter, the

device is ready to measure again.

Thermalize The thermalization time allows for a uniform temperature distribution

in the absorber. Afterwards, the temperature is measured.

Finished The measurement is completed.

Tab. 11.1: Status messages

11.2 Warning message

Warning message Reason

Safety interlock open The absorber temperature has exceeded 100°C. In order to protect

the device, the safety interlock is open.

Tab. 11.2: Warning message

This warning message does not imply an error. The message is automatically

reset as soon as the absorber temperature is below 100°C again. Likewise,

the safety interlock is then closed again.

11.3 Capacity of the rechargeable lithium ion battery

The capacity of the rechargeable lithium-ion battery is displayed in percentage. The

accuracy of this display is subject to various factors (such as, for example, the temperature, the battery condition, etc.). We therefore recommend charging the battery when

20% are displayed. If the battery is fully discharged, the charging can take between 12

and 14hours.

Please note that the charging process can only be carried out in the temperature range

from 0°C to +45°C to protect the battery. With a battery capacity of 100%, the device

has an operating time of approx. 6hours (equivalent to approx. 100measurements).

When using all power saving functions (see chapter 14.3 on page33) approx.

15hours.

22

Revision 01/2019 EN

35,0(6

Cube L1

12 Important information for measuring with the Cube L1

12.1 Safety instructions

DANGER

Severe eye or skin injury due to laser radiation

During the measurement the laser beam is guided on the device, which

causes scattered or directed reflection of the laser beam (laser class 4).

X

Please wear safety goggles adapted to the power, power density, laser

wave length and operating mode of the laser beam source in use.

X

Wear suitable protective clothing and protective gloves.

X

Protect yourself from laser radiation by separating protective devices

(e.g. by using appropriate shielding).

NOTICE

Damaging/Destruction of the device

The maximum permissible energy per laser pulse depends on various

variables, including the absorber temperature.

X

Please observe the limit values and dependencies specified in chapter19, „Technical data“, on page44 and chapter21, „Appendix“, on

page47 before the measurement.

NOTICE

Damaging/Destruction of the device

Contamination and fingerprints on the protective window can lead to

damage or shattering or splintering of the protective window during measuring operation.

X

Do not touch the protective window.

X

Regularly check the condition of the protective window and exchange it

in case of pollution (see chapter16.1, „Exchanging the protective window

on the device“, on page39).

X

Only operate the device with a clean protective window.

Revision 01/2019 EN

23

35,0(6

Cube L1

12.2 Laser parameter setting

12.2.1 Setting the laser rise time

The applicable measurement time is between 0.1s and 2.0s, which has to be transferred to the laser controller as pulse length. The maximum laser rise time for measuring

the power cannot exceed 100µs. This limit has to be adhered to in order to avoid incorrect results of the power measurement.

Some laser beam sources are factory set with power ramps of up to a few 100ms to

switch on the laser beam. To achieve the correct power values the shortest possible rise

time (<100μs) has to be set.

P

P

Max

P

Meas

t

0

Fig. 12.1: Laser rise time >100µs

P

t

0

Fig. 12.2: Laser rise time <100µs

24

100µs

100µs

t

t

p

P

≙ P

Max

Meas

t

t

p

Revision 01/2019 EN

35,0(6

Cube L1

12.2.2 Minimum energy per single measurement

The energy used for the measurement must achieve a sufficiently high temperature in

the absorber to be recorded with high precision. Typically, an energy of approx. 500J is

recommended, as long as the measuring duration is <2s.

Example: With a laser power of 1kW and an irradiation time of 500ms, 500 J are

absorbed.

E = P·t = 1000W · 0.5s = 500J

Fig. 12.3 on page25 shows information for selecting the energy permissible for a

measurement in conjunction with the absorber temperature.

10000

5000

Max. energy input

25°C Ambient temperature

1000

The measuring range varies in accordance with the ambient

temperature. To achieve the greatest possible accuracy, the

absorber temperature should be close to the ambient tempe-

Permissible measuring energy in J

100

25 30 35 40 45 50 55 60 65 70

Fig. 12.3: Measuring range as a function of the absorber temperature

rature, particularly when it comes to the measurement of small

amounts of energy (<200J).

Absorber temperature in °C

Min. energy input

The minimum energy application shows the limit above which a measurement can be

performed with high precision. The maximum energy application value specifies the limit

at which the absorber reaches its reliable limit temperature. The energy, e.g. for multiple

measurements (series measurements) can be distributed across the range shown in

green.

If the absorber temperature is greater than 70°C, it won’t be possible to take any further measurements. In this case, please wait until the temperature falls to below 50°C

(depending on the energy application selected). Please take the limit values from Fig.

12.3 on page25.

Revision 01/2019 EN

25

35,0(6

Cube L1

12.3 Series measurement

Always start a measurement series with the smallest power and increase it gradually.

Small amounts of energy should be measured with absorber temperatures that are

close to the ambient temperature.

In general:

The minimum amount of irradiated energy should amount to approximately twenty times

the difference of the absorber temperature minus room temperature, so at least 200J.

In case of subsequent measurements, the residual capacity of the absorber for another

laser pulse has to be considered. Fig. 12.4 on page26 shows information for selecting the energy permissible for a series measurement in conjunction with the absorber

temperature.

10000

5000

Max. energy input

5th measurement 2000J

1000

3rd measurement 800J

2nd measurement 400J

Permissible measuring energy in J

Fig. 12.4: Example of a series measurement in conjunction with the absorber temperature

1st measurement 200J

100

2520 30 35 40 45 50 55 60 65 70

Absorber temperature in°C

4th measurement 1600J

Min. energy input

If the absorber temperature is greater than 70°C, it won’t be possible to take any further measurements. In this case, please wait until the temperature falls to below 50

(depending on the energy application selected). Please take the limit values from Fig.

12.4 on page26.

26

Revision 01/2019 EN

°C

35,0(6

Cube L1

12.4 Measurement with pulsed lasers

When it comes to pulsed laser radiation a correct exposure time measurement up to a

pulse frequency of 10kHz and a duty cycle of 50% is possible. In case of on/off times

shorter than 50μs a correct exposure time measurement is not possible.

With pulsed lasers, the device recognizes the number of pulses n and the number of

pulse pauses n-1. Since the last pulse pause t

and this would lead to an increased display of the average power with a low number of

pulses, the average power is corrected on the basis of the corrected burst duration (see

Fig. 12.5 on page27).

For cw lasers respectively one pulse, the average power corresponds to the maximum

power of one pulse.

Laser power P in W

Pulse 1 Pulse 2 Pulse 3

t

t

on

off

Uncorrected burst duration

is not measured for technical reasons

off

Pulse 4

Pulse 5

t

off

Corrected burst duration for the calculation of the average laser power

Fig. 12.5: Uncorrected and corrected burst duration with pulsed lasers

Revision 01/2019 EN

Time t

27

35,0(6

Cube L1

13 Measuring with the Cube L1

Please read chapter12, „Important information for measuring with the Cube L1“, on

page23 first.

13.1 Start measurement

Measurements with the Cube L1 should be performed exclusively with a static (unmoving) laser beam.

1. Observe the safety instructions in chapter 12.1 on page23.

2. Press the on/off button.

The start menu appears.

After approx. 5seconds, the device is

ready for operation.

3. Turn on the laser. For a high measurement accuracy, we recommend an energy input of 300J per measurement (see chapter 12.2.2 on page25).

Observe the information on series measurements according to chapter 12.3 on

page26.

The thermalization is displayed by means

of a progress bar (duration approx.

15seconds).

28

Revision 01/2019 EN

35,0(6

Cube L1

4. To access the following windows, press

the on/off button for approx. 2seconds.

The window displays the following mea-

surement values:

• Laser power in W

• Absorber temperature in °C

• Corrected burst duration in ms (Time)

1)

With a cw laser, the max. power of the laser is

displayed in W (Pk Pow).

With a pulsed laser, the average power of a

pulse is displayed in W (Av Pow).

For a pulsed laser the measured values

of the pulse parameters are displayed:

• Total pulse duration in ms (Ontime)

• Total pulse pause in ms (Offtime)

• Uncorrected burst duration in ms

(uBurst)

• Number of pulses (Pulses)

• Max. Power of a pulse in W (Pk Pow)

• Average power in W (Av Pow)

• Energy in J

Further information on measuring with pulsed

lasers can be found in chapter 12.4 on

page27.

1)

The device turns off automatically after approx. 10minutes. You can also turn off the

device manually by keeping the on/off button pressed for approx. 5seconds.

Revision 01/2019 EN

29

35,0(6

Cube L1

13.2 Measuring results display

The last 14measuring values can be read off from the display of The Cube L1. You can

read off the last 30measuring values with the optional Android™ PRIMES Cube App for

mobile devices or optional LaserDiagnosticsSoftware LDS.

1. Press the on/off button for approx.

2seconds.

The measured values and the time

displayed.

2. Press the on/off button again for 2se-

conds to have the remaining measuring

values (no.8-14) displayed.

1)

With a cw laser, the maximum power of the

laser is displayed in W (Power) and the pulse

duration in ms (Time).

With a pulsed laser, the average power of a

pulse is displayed in W (Power) and the corrected burst duration in ms (Time).

1)

are

30

Revision 01/2019 EN

35,0(6

Cube L1

14 Measuring with the optional LaserDiagnosticsSoftware LDS

This chapter aims to provide some basic information as you get to know the Cube L1,

discussing the example of a measurement with the LaserDiagnosticsSoftware LDS. For a

detailed description of the software installation, file management and evaluation of the mea

sured data, please refer to the separate operating manual LaserDiagnosticsSoftware LDS.

Please read chapter12, „Important information for measuring with the Cube L1“, on

page23 first.

14.1 Connect the Cube L1 with the LaserDiagnosticsSoftware LDS

1. Connect the USB cable to the Micro-USB socket on the device and with the PC (see

Fig. 9.1 on page19) or activate the Bluetooth function on the PC. When the Bluetooth

connection is activated, the USB interface is deactivated.

2. Press the on/off button on the

device.

3. Start the LaserDiagnosticsSoft-

ware LDS.

4. Click on the Devices tab.

5. Click on the + Connect to de-

vice button under the tab.

-

The Connections window ap-

pears.

6. Click on the desired device.

7. Click on the Connect to device

button.

Revision 01/2019 EN

31

35,0(6

Cube L1

14.2 Select measurement mode CW Operation or Pulse Operation

The Cube L1 is established as a

connected device.

1. Click on the connected device.

2. Click on the CW Operation/Pul-

se Operation button

or on the drop-down list

CW Operation/Pulse Operation.

The corresponding Device

control opens.

The following toolbenches are

opened:

• CW Measurement/Pulse

Measurement to display the

measurement results.

• Cube series for displaying and

evaluating an entire CW measurement series.

Drop-down list

If the toolbenches have previously

been closed, click the Open measu-

rement toolbench button to open it

again.

32

Revision 01/2019 EN

35,0(6

Cube L1

14.3 Make settings for power saving functions and automatic measurement readiness

In the LaserDiagnosticsSoftware LDS

you can make additional settings for

power saving functions and the automatic measurement readiness.

1. Enter the desired settings in the

Device control.

2. Click on the Save settings

button.

Autom. ready for measurement By default, the device automatically returns to

measurement readiness after each measurement. If

you uncheck the box, you will need to reset the unit

after each measurement by briefly pressing the on/of

button.

Power Saving Function Continuous background on/off

Turn off lighting after (ins). The set time only applies if

the permanent backlight is switched off.

Switch the safety interlock on/off. For safety reasons

switching off the safety interlock is not recommended.

Switch off the device after an entered time

Revision 01/2019 EN

33

35,0(6

Cube L1

14.4 Start measurement

Measurements with the Cube L1 should be performed exclusively with a static (unmoving) laser beam.

The measurement in the Cube L1

starts when the laser is switched on.

The display field Start is therefore not

active.

If you have previously displayed a

measurement in the workbench,

press the New measurement button.

If the setting Autom. ready for

measurement (see chapter 14.3

on page33) is deactivated, briefly

press the on/off button on the device.

1. Observe the safety instructions

in chapter 12.1 on page23.

2. Turn on the laser.

The progress of the mea-

surement is indicated in the

Measurement is running and

then Measurement is finished

displays.

3. To stop recording a measurement, press the Stop button.

4. Turn off the laser.

34

Revision 01/2019 EN

35,0(6

Cube L1

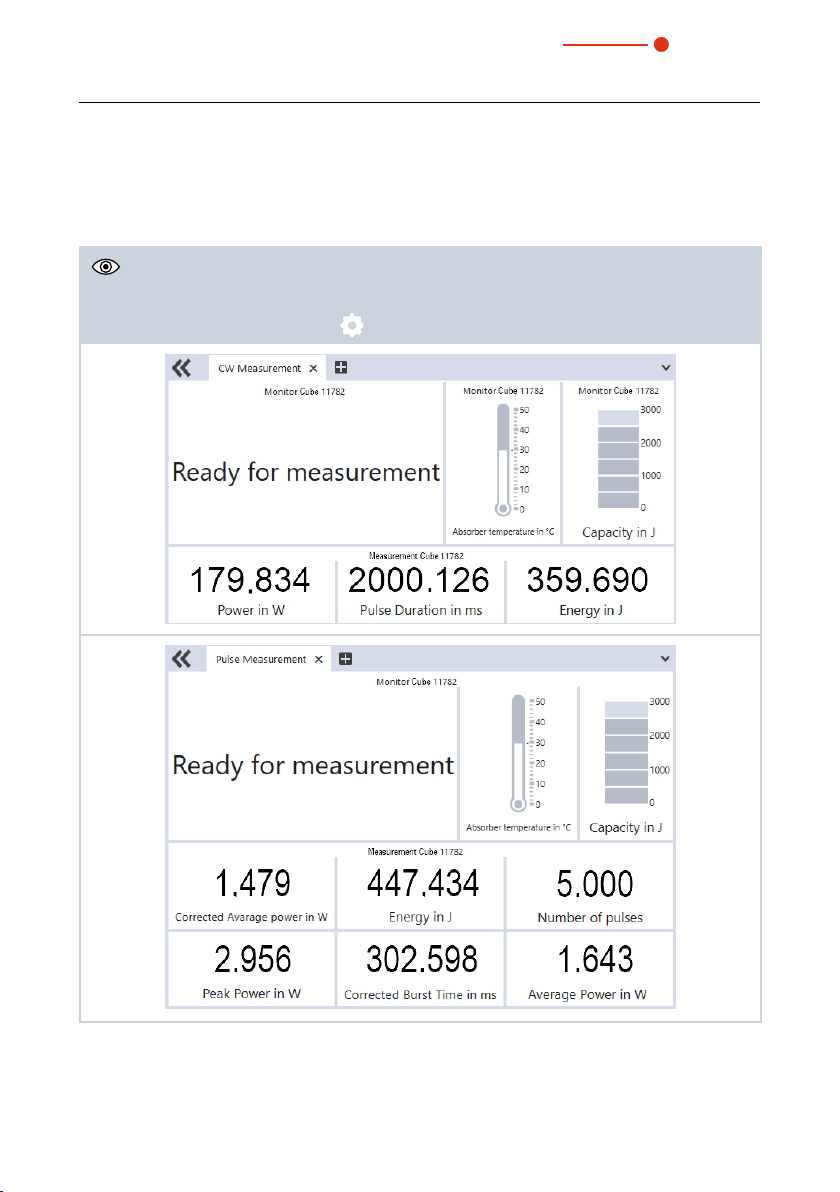

14.5 Measuring results display

14.5.1 Displays in the toolbench CW Measurement or Pulse Measurement

The measuring results are displayed in the opened toolbenchs once the measurement has

been completed (see below).

By clicking on the gear symbol

you can adjust the displayed parameters.

Revision 01/2019 EN

35

35,0(6

Cube L1

14.5.2 Displays in the toolbench Cube series

Press the Load measurements button in the device control. The last 30 measurements

are readout from the Cube L1 and the measuring values are displayed in the left table.

Click on the arrow in the column Use to transfer the measuring values to the analysis

table. If required, you can assign target values to the measuring values in the analysis

table. By clicking on the gear symbol

Analysis tableMeasuring values

you can save and load these.

The two graphs below the table show the measurements marked in the analysis table

with a check.

By clicking on the gear symbol you can adjust the displayed parameters in both

graphs.

The left graph is the standard graph with the Cube L1 adapted parameter selection:

Index (number of measurement) and power in W.

In the right graph, select both parameters shown on the axes from the parameter list.

Press the CTRL key and highlight the first parameter for the x-axis (gray background)

and then the second parameter for the y-axis.

36

Revision 01/2019 EN

35,0(6

Cube L1

14.6 Load and delete measuring values

The Cube L1 stores the measured

values in an internal memory. The

measuring values can be displayed

and deleted in the LaserDiagnosticsSoftware LDS.

1. Click on the Load measure-

ments button.

• In the toolbench CW Measure-

ment/Pulse Measurement the

last measured measurement is

displayed.

• In the toolbench Cube series

the last 30 measurements are

loaded.

2. To delete all measured values, click on the Clear history

button.

• The measuring values in the

Cube L1 are deleted.

Revision 01/2019 EN

37

35,0(6

Cube L1

15 Measuring with the optional Cube App

With the Cube App for mobile devices with Android™ you can operate and evaluate the

device via a smartphone/tablet.

The Cube App is available for free in Google Play-Store/Apps. You need therefor a valid

Google Account. In the Google Play Store search box, type “Primes cube app”.

A bluetooth connection with the device makes it possible to read out and graphically

display the measured values (laser power, pulse length, and energy per pulse) with the

mobile end device. The Cube App also shows an overview of the device status (temperature, capacity, status notifications).

In the Cupe App you can make additional settings for power saving functions and the

automatic measurement readiness (see Tab. 15.1 on page38).

Function Possible settings

Autom. ready for measurement

Power Saving Function Continuous background on/off

Tab. 15.1: Functions and settings

By default, the device automatically returns to measurement readiness after each measurement. If you uncheck the box, you will need

to reset the unit after each measurement by briefly pressing the on/

of button.

Turn off backlight after (ins). The set time only applies if the permanent backlight is switched off.

Switch the safety interlock on/off. For safety reasons switching off the

safety interlock is not recommended.

Switch off the device after an entered time

Please find detailed information on the operation of the Cube App in the separate operating instructions Cube App. These can be found on the PRIMES website at: https://

www.primes.de/en/support/downloads/operating-manuals.html.

38

Revision 01/2019 EN

35,0(6

Cube L1

16 Maintenance and service

The operator is responsible for determining the maintenance intervals for the measuring

device.

PRIMES recommends a maintenance interval of 12months for inspection and validation

or calibration.

If the device is used only sporadically, the maintenance interval can also be extended up

to 24months.

16.1 Exchanging the protective window on the device

The protective window in the beam entrance is a wearing part and can be replaced

if necessary. Low levels of contamination of the protective window can be carefully

removed when cooled with Isopropanol (observe the manufacturer‘s safety instructions).

In case of heavy, non-removable contamination or damage, the protective window must

be replaced with a new one.

The protective window is coated with an antireflex coating and has low reflection values of less than 1%. To avoid increased reflection values, use only

original PRIMES protective windows.

Protective window diameter 55mm

Glass thickness 1.5mm

Order number 410-070-021 (1Stück); 410-011-018 (10Stück)

16.1.1 Safety instructions

DANGER

Severe eye or skin injury due to laser radiation

If the protective window is not correctly positioned, reflections can cause

directional laser radiation.

X

Ensure that the new protective window is positioned evenly in the indentation on the O-ring.

Revision 01/2019 EN

39

35,0(6

CAUTION

Burns due to hot components

After a measurement the optics below the protective window is hot!

Unintentional contact during the protective window exchange could lead

to burns.

X

Do not replace the protective window directly after a measurement.

X

Let the device cool down for an adequate period of time. The cooling

time varies depending on the laser power and the irradiation time.

NOTICE

Damaging/Destruction of the device

Contamination and fingerprints on the protective window can lead to

damage or shattering or splintering of the protective window during measuring operation.

X

Only replace the protective window in a dust-free environment.

X

Do not touch the protective window.

X

When exchanging the protective window wear powder-free latex gloves.

Cube L1

NOTICE

Damage to the optics

Pollution on the optics surface causes measurement deviation during laser beam irradiation by means of absorption and can damage the optics.

X

Ensure during exchanging the protective window that the subjacent optics will not be polluted.

40

Revision 01/2019 EN

35,0(6

Cube L1

16.1.2 Exchanging the protective window

1. Observe the safety instructions in chapter16.1.1, „Safety instructions“, on

page39.

2. Unscrew the 3Torx screws M3 x 6mm on the protective window holder.

3. Place the device as shown in Fig. 16.1 on page41 and carefully remove the

protective window holder upwards.

• Make sure that the inserted O-ring does not fall out of the device.

4. Remove old protective window from the device and dispose of it.

5. Wear powder-free latex gloves and insert the new protective window into the

device.

• Ensure that the inserted O-ring is not out of place.

6. Place the protective window holder according to Fig. 16.1 on page41.

7. Tighten the protective window holder with 3Torx screws M3 x 6mm.

8. Check for secure fit of the protective window holder:

• The protective window holder must lie flat against the device.

Torx screws

M3 x 6mm

O-ring

Fig. 16.1: Exchanging the protective window on the Cube L1

Revision 01/2019 EN

Protective win-

dow holder

Protective

window

Optics

41

35,0(6

Cube L1

17 Measures for the product disposal

Due to the Electrical and Electronic Equipment Act (“Elektro-G“) PRIMES is obliged to

dispose PRIMES measuring devices manufactured after August, 2005, free of charge.

PRIMES is a registered manufacturer in the German “Used Appliances Register“

(Elektro-Altgeräte-Register “EAR“) with the number WEEE-reg.-no. DE65549202.

Provided that you are located in the EU, you are welcome to send your PRIMES devices

to the following address, where they will be disposed free of charge (this service does

not include shipping costs):

PRIMES GmbH

Max-Planck-Str. 2

64319Pfungstadt

Germany

42

Revision 01/2019 EN

35,0(6

Cube L1

18 Declaration of conformity

Revision 01/2019 EN

43

35,0(6

19 Technical data

Measurement parameters

Power range 200 – 16000W

Wavelength range 1030 – 1090nm

Beam diameter on the protective window 1–7mm

Max. power density on the protective window 250kW/cm²

Irradiation time 0,1 – 2,0s

1)

Cube L1

1)

(depending on laser power)

Min. on/off times (duty cycle)

for pulsed lasers

Max. laser rise time 100µs

Energy per measurement 200 – 5000J

Recommended energy per measurement 500 – 2000J

Total duration until measurement value output <15s

Nominal measurement frequency 700J: 1cycle/min

Device parameters

Max. absorber temperature 120°C

Max. angle of incidence perpendicular to inlet

aperture

Max. centered tolerance ±2.0mm

Accuracy at an angle of incidence up to5° ±3%

Reproducibility ±1%

1)

The stated limit values are to be understood in correlation with the permitted maximum energy

(E = P ∙ t).

50 µs

(e.g. max. 10kHz at 50% duty cycle)

5000J: 1cycle/15min

±5°

44

Revision 01/2019 EN

35,0(6

Cube L1

Supply Data

Power supply Integrated lithium-ion battery, which can be

charged via a micro-USB port

Temperature range for charging the lithiumIon battery

Communication

Interfaces USB/Bluetooth

Dimensions and Weight

Dimensions (L x W x H) 92x97x110mm

Weight (approx.) 1700g

Environmental Conditions

Operating temperature range 15 – 40°C

Storage temperature range 5 – 50°C

Reference temperature 22°C

Permissible relative humidity

(non-condensing)

0 – 45°C

10 – 80%

Revision 01/2019 EN

45

35,0(6

20 Dimensions

Cube L1

110

92

Ø 50

35,5

33,5

21 50 21

97

X

M6 x 10

48,5

46

View X

55

All dimensions in mm (general tolerance ISO 2768-v)

46

M4 x 6

Revision 01/2019 EN

35,0(6

Cube L1

21 Appendix

21.1 System control (option)

An optional connection to the system control is available. Please contact your PRIMES

sales partner with any questions.

An overview of the PRIMES sales contacts can be found under

www.primes.de/en/contact.html or www.primes.de/en/worldwide.html.

Revision 01/2019 EN

47

PRIMES GmbH

Max-Planck-Str. 2

64319 Pfungstadt

Germany

Tel +49 6157 9878-0

info@primes.de

www.primes.de

Loading...

Loading...